Coppiced Biochars as Partial Replacement of Carbon Black Filler in Polybutadiene/Natural Rubber Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used

2.2. Chemical and Physical Material Properties

2.3. Formation of Rubber Composites and Tensile Testing

3. Results

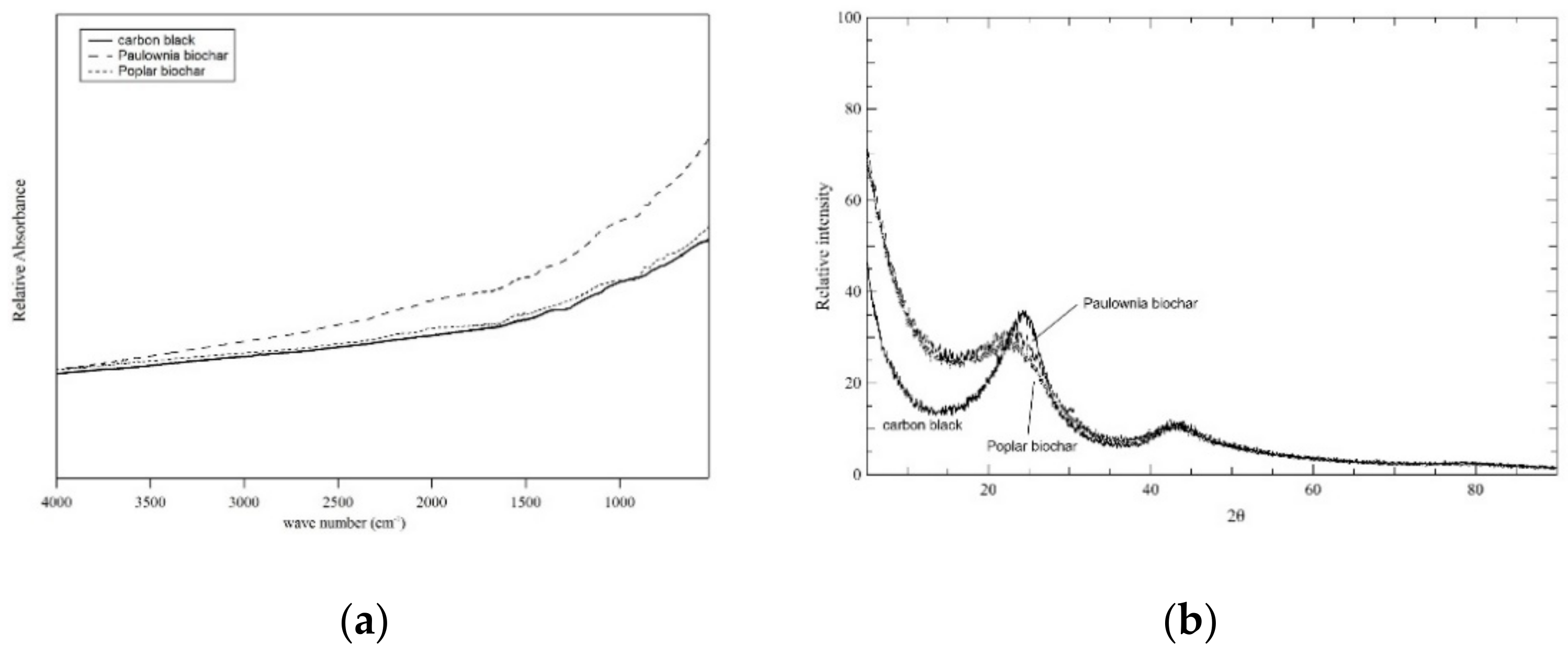

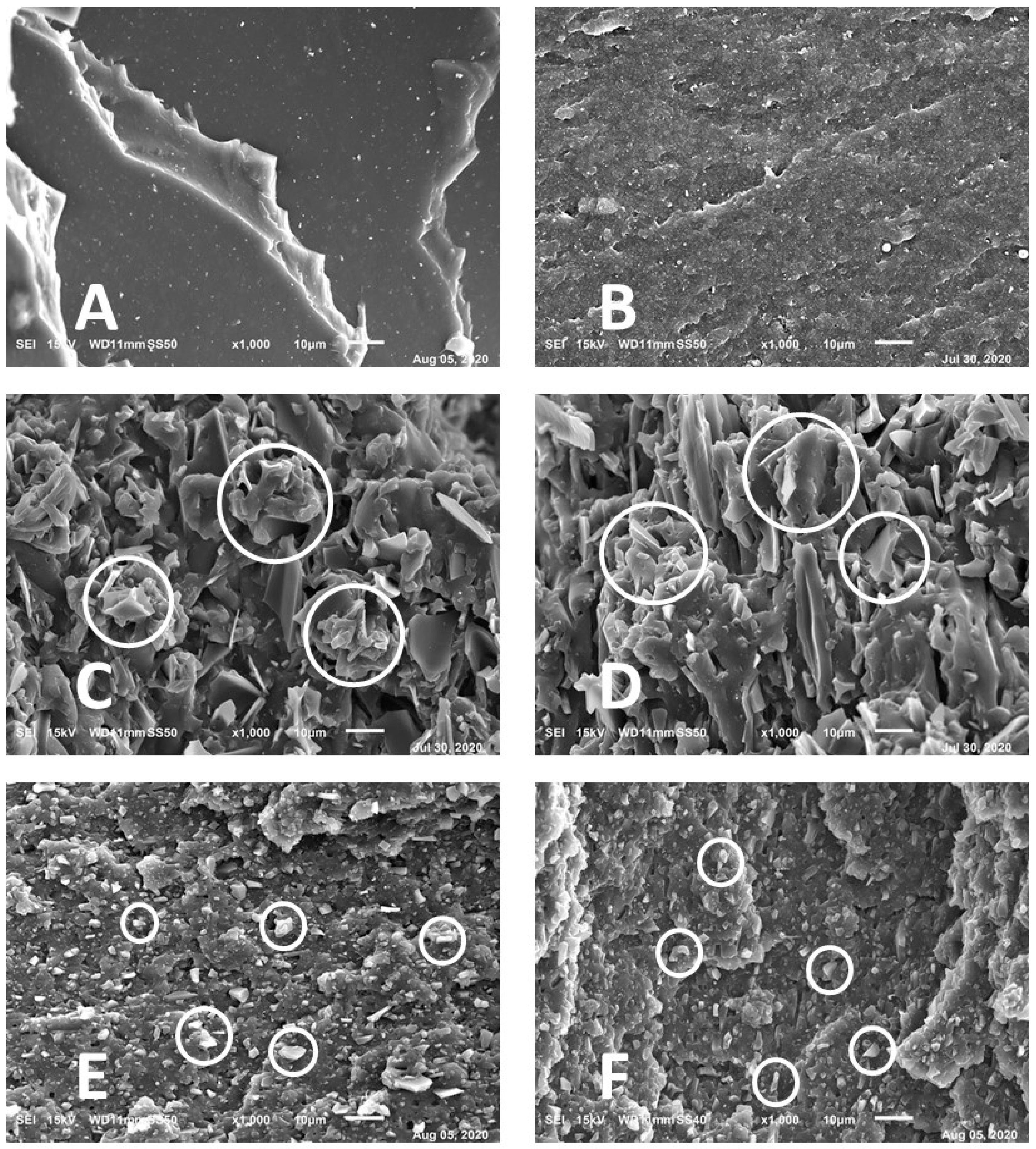

3.1. Biochar Characterization

3.2. Composite Properties

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Osswald, T.A.; Menges, G. Materials Science of Polymers for Engineers; Hanser/Gardner Publications: Cincinnati, OH, USA, 1996; p. 10. [Google Scholar]

- Hofmann, W. Rubber Technology Handbook; Hanser/Gardner Publications: Cincinnati, OH, USA, 1989. [Google Scholar]

- Morrow, N.L. The industrial production and use of 1,3-butadiene. Environ. Health Perspect. 1990, 86, 7–8. [Google Scholar] [CrossRef]

- Sanders, I.J.; Peeten, T.L. Carbon Black: Production, Properties and Uses; Nova Science Publishers: Hauppage, NY, USA, 2011. [Google Scholar]

- Spahr, M.E.; Rothon, R. Carbon black as a polymer filler. In Polymers and Polymeric Composites: A Reference Series; Palsule, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–31. [Google Scholar]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: Science and Technology, 2nd ed.; Routledge: New York, NY, USA, 2015. [Google Scholar]

- Mukome, F.N.D.; Zhang, X.; Silva, L.C.R.; Six, J.; Parikh, S.J. Use of chemical and physical characteristics to investigate trends in biochar feedstocks. J. Agric. Food Chem. 2013, 61, 2196–2204. [Google Scholar] [CrossRef]

- Demirbas, A. Effects of temperature and particle size on bio-char yield from pyrolysis of agricultural residues. J. Anal. Appl. Pyrol. 2004, 72, 243–248. [Google Scholar] [CrossRef]

- Yadav, N.K.; Vaidya, B.N.; Henderson, K.; Lee, J.F.; Stewart, W.M.; Dhekney, S.A.; Joshee, N. A review of paulownia biotechnology: A short rotation, fast growing multipurpose bioenergy tree. Am. J. Plant Sci. 2014, 4, 2070–2082. [Google Scholar] [CrossRef]

- Basu, C.; Joshee, N.; Gezalian, T.; Vaidya, B.N.; Satidkit, A.; Hemmati, H.; Perry, Z.D. Cross-species pcr and field studies on paulownia elongata: A potential bioenergy crop. Bioethanol. 2016, 2, 12–23. [Google Scholar] [CrossRef]

- Jiménez, L.; Rodríguez, A.; Ferrer, J.L.; Ṕerez, A.; Angulo, V. Paulownia, a fast-growing plant, as a raw material for paper manufacturing. Afinidad 2005, 62, 100–105. [Google Scholar]

- Paulownia Growing Zones. Available online: http://worldpaulownia.com/growing-zones (accessed on 6 September 2019).

- Dominguez, E.; Romani, A.; Domingues, L.; Garrote, G. Evaluation of strategies for second generation bioethanol production from fast growing biomass paulownia within a biorefinery scheme. Appl. Energy. 2017, 187, 777–789. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kaymakci, A. Fast growing biomass as reinforcing filler in thermoplastic composites: Paulownia elongata wood. Ind. Crops Prod. 2013, 43, 457–464. [Google Scholar] [CrossRef]

- Vaughn, S.F.; Kenar, J.A.; Tisserat, B.; Jackson, M.A.; Joshee, N.; Vaidya, B.N.; Peterson, S.C. Chemical and physical properties of paulownia elongata biochar modified with oxidants for horticultural applications. Ind. Crops Prod. 2017, 97, 260–267. [Google Scholar] [CrossRef]

- Sannigrahi, P.; Ragauskas, A.J.; Tuskan, G.A. Poplar as a feedstock for biofuels: A review of compositional characteristics. Biofuels Bioprod. Biorefin. 2010, 4, 209–226. [Google Scholar] [CrossRef]

- Tuskan, G.A.; Di Fazio, S.; Jansson, S.; Bohlmann, J.; Grigoriev, I.; Hellsten, U.; Putnam, N.; Ralph, S.; Rombauts, S.; Salamov, A.; et al. The genome of black cottonwood, populus trichocarpa (Torr. & Gray). Science (Washington, DC, USA) 2006, 313, 1596–1604. [Google Scholar] [CrossRef]

- Tharakan, P.J.; Volk, T.A.; Abrahamson, L.P.; White, E.H. Energy feedstock characteristics of willow and hybrid poplar clones at harvest age. Biomass Bioenerg. 2003, 25, 571–580. [Google Scholar] [CrossRef]

- Zalesny, R.S.; Hall, R.B.; Zalesny, J.A.; McMahon, B.G.; Berguson, W.E.; Stanosz, G.R. Biomass and genotype × environment interactions of populus energy crops in the midwestern united states. Bioenergy Res. 2009, 2, 106–122. [Google Scholar] [CrossRef]

- Zamora, D.S.; Wyatt, G.J.; Apostol, K.G.; Tschirner, U. Biomass yield, energy values, and chemical composition of hybrid poplars in short rotation woody crop production and native perennial grasses in minnesota, USA. Biomass Bioenergy 2013, 49, 222–230. [Google Scholar] [CrossRef]

- Stanton, B.J.; Haiby, K.; Gantz, C.; Espinoza, J.; Shuren, R.A. The economics of rapid multiplication of hybrid poplar biomass varieties. Forests 2019, 10, 446. [Google Scholar] [CrossRef]

- Peterson, S.C. Utilization of low-ash biochar to partially replace carbon black in sbr composites. J. Elastom. Plast. 2013, 45, 487–497. [Google Scholar] [CrossRef]

- Peterson, S.C.; Chandrasekaran, S.R.; Sharma, B.K. Birchwood biochar as partial carbon black replacement in styrene-butadiene rubber composites. J. Elastom. Plast. 2016, 48, 305–316. [Google Scholar] [CrossRef]

- Gent, A.N.; Pulford, C.T.R. Micromechanics of fracture in elastomers. J. Mater. Sci. 1984, 19, 3612–3619. [Google Scholar] [CrossRef][Green Version]

- Peterson, S.C.; Kim, S. Reducing biochar particle size with nanosilica and its effect on rubber composite reinforcement. J. Polym. Environ. 2020, 28, 317–322. [Google Scholar] [CrossRef]

- Peterson, S.C.; Joshee, N. Co-milled silica and coppiced wood biochars improve elongation and toughness in styrene-butadiene elastomeric composites while replacing carbon black. J. Elastom. Plast. 2018. [Google Scholar] [CrossRef]

- Modulus of Toughness. Available online: https://www.instron.us/en-us/our-company/library/glossary/m/modulus-of-toughness#:~:text=Modulus%20of%20toughness%20is%20measured,fracture%20point%20of%20the%20specimen. (accessed on 16 September 2020).

- Peterson, S.C. Silica-milled paulownia biochar as partial replacement of carbon black filler in natural rubber. J. Compos. Sci. 2019, 3, 107. [Google Scholar] [CrossRef]

- Darmstadt, H.; Roy, C.; Kaliaguine, S.; Xu, G.; Auger, M.; Tuel, A.; Ramaswamy, V. Solid state 13C-NMR spectroscopy and XRD studies of commercial and pyrolytic carbon blacks. Carbon 2000, 38, 1279–1287. [Google Scholar] [CrossRef]

- Tisserat, B.; Joshee, N.; Mahapatra, A.K.; Selling, G.W.; Finkenstadt, V.L. Physical and mechanical properties of extruded poly(lactic acid)-based paulownia elongata biocomposites. Ind. Crops Prod. 2013, 44, 88–96. [Google Scholar] [CrossRef]

- Tisserat, B.; Reifschneider, L.; Joshee, N.; Finkenstadt, V.L. Evaluation of paulownia elongata wood polyethylene composites. J. Thermoplast. Compos. 2013, 28, 1301–1320. [Google Scholar] [CrossRef]

- Kaygin, B.; Kaplan, D.; Aydemir, D. Paulownia tree as an alternative raw material for pencil manufacturing. BioResources 2015, 10, 3426–3433. [Google Scholar] [CrossRef]

- He, T.; Vaidya, B.N.; Perry, Z.D.; Parajuli, P.; Joshee, N. Paulownia as a medicinal tree: Traditional uses and current advances. Eur. J. Med. Plants 2016, 14, 1–15. [Google Scholar] [CrossRef]

- Kalaycioglu, H.; Deniz, I.; Hiziroglu, S. Some of the properties of particleboard made from paulownia. J. Wood Sci. 2005, 51, 410–414. [Google Scholar] [CrossRef]

- Devappa, R.K.; Rakshit, S.K.; Dekker, R.F.H. Forest biorefinery: Potential of poplar phytochemicals as value-added co-products. Biotechnol. Adv. 2015, 33, 681–716. [Google Scholar] [CrossRef]

- Kramer, A.; Barbosa, A.R.; Sinha, A. Viability of hybrid poplar in ANSI approved cross-laminated timber applications. J. Mater. Civ. Eng. 2014, 26, 06014009. [Google Scholar] [CrossRef]

- Da Ros, L.M.; Soolanayakanahally, R.Y.; Guy, R.D.; Mansfield, S.D. Phosphorus storage and resorption in riparian tree species: Environmental applications of poplar and willow. Environ. Exp. Bot. 2018, 149, 1–8. [Google Scholar] [CrossRef]

| Filler Composition | NR | BR | TMQ | 6PPD | CB | Biochar | Stearic Acid | ZnO | Sulfur | CBTS |

|---|---|---|---|---|---|---|---|---|---|---|

| unfilled BR-NR | 50 | 50 | 1 | 0.5 | 0 | 0 | 2 | 5 | 2.5 | 1 |

| 100% CB | 50 | 50 | 1 | 0.5 | 50 | 0 | 2 | 5 | 2.5 | 1 |

| 100% PAUL | 50 | 50 | 1 | 0.5 | 0 | 50 | 2 | 5 | 2.5 | 1 |

| 100% POP | 50 | 50 | 1 | 0.5 | 0 | 50 | 2 | 5 | 2.5 | 1 |

| 100% PAUL Si milled | 50 | 50 | 1 | 0.5 | 0 | 50 | 2 | 5 | 2.5 | 1 |

| 100% POP Si milled | 50 | 50 | 1 | 0.5 | 0 | 50 | 2 | 5 | 2.5 | 1 |

| 50/50 CB/PAUL silica milled | 50 | 50 | 1 | 0.5 | 25 | 25 | 2 | 5 | 2.5 | 1 |

| 50/50 CB/POP silica milled | 50 | 50 | 1 | 0.5 | 25 | 25 | 2 | 5 | 2.5 | 1 |

| 60/40 CB/PAUL silica milled | 50 | 50 | 1 | 0.5 | 30 | 20 | 2 | 5 | 2.5 | 1 |

| 60/40 CB/POP silica milled | 50 | 50 | 1 | 0.5 | 30 | 20 | 2 | 5 | 2.5 | 1 |

| 70/30 CB/PAUL silica milled | 50 | 50 | 1 | 0.5 | 35 | 15 | 2 | 5 | 2.5 | 1 |

| 70/30 CB/POP silica milled | 50 | 50 | 1 | 0.5 | 35 | 15 | 2 | 5 | 2.5 | 1 |

| Sample | C (%) | H (%) | N (%) | O (%) a | Ash (%) | Density (g/cm3) |

|---|---|---|---|---|---|---|

| CB control b | >99 | <1 | <1 | <1 | <1 | 1.7–1.9 |

| Paulownia biochar | 95.15 ± 0.67 | 1.39 ± 0.27 | 0.03 ± 0.03 | 0.91 | 2.52 | 1.76 ± 0.01 |

| Poplar biochar | 89.07 ± 4.39 | 1.52 ± 0.18 | 0.02 ± 0.01 | 7.42 | 1.97 | 1.66 ± 0.01 |

| Sample | Resistivity (Ohms) | Material Classification |

|---|---|---|

| 100% CB control | 104 | conductive |

| 100% PAUL | 106 | dissipative |

| 70/30 CB/PAUL Si milled | 106 | dissipative |

| 70/30 CB/POP Si milled | 106 | dissipative |

| 50/50 CB/PAUL Si milled | 108 | dissipative |

| 60/40 CB/PAUL Si milled | 108 | dissipative |

| 60/40 CB/POP Si milled | 108 | dissipative |

| 100% POP | 109 | dissipative |

| 50/50 CB/POP Si milled | 109 | dissipative |

| 100% PAUL Si milled | 1012 | insulative |

| 100% POP Si milled | 1012 | insulative |

| unfilled BR-NR | 1012 | insulative |

| Filler | n | CB Replaced (%) | Tensile Strength (MPa) | Elongation (%) | Toughness (MPa) | Young’s Modulus (MPa) |

|---|---|---|---|---|---|---|

| unfilled BR-NR | 5 | n/a | 4.2 ± 0.4 | 457 ± 47 | 9.2 ± 1.4 | 1.4 ± 0.2 |

| 100% CB | 5 | 0 | 21.0 ± 0.3 | 388 ± 8 | 34.6 ± 1.2 | 6.0 ± 0.3 |

| 100% PAUL | 5 | 100 | 7.4 ± 0.4 | 275 ± 39 | 13.8 ± 2.9 | 7.6 ± 0.4 |

| 100% POP | 6 | 100 | 7.0 ± 0.4 | 307 ± 33 | 14.0 ± 2.4 | 6.6 ± 0.7 |

| 100% PAUL Si | 5 | 100 | 14.4 ± 0.2 | 397 ± 20 | 25.5 ± 1.4 | 3.2 ± 0.3 |

| 100% POP Si | 5 | 100 | 14.6 ± 0.4 | 397 ± 9 | 26.4 ± 1.3 | 3.8 ± 0.5 |

| 50/50% CB/PAUL Si | 5 | 50 | 18.3 ± 0.9 | 434 ± 22 | 35.7 ± 3.5 | 4.4 ± 0.5 |

| 50/50% CB/POP Si | 8 | 50 | 17.6 ± 1.1 | 391 ± 14 | 31.1 ± 2.8 | 4.4 ± 0.5 |

| 60/40% CB PAUL Si | 4 | 40 | 18.1 ± 1.5 | 393 ± 29 | 32.1 ± 4.4 | 4.5 ± 0.5 |

| 60/40% CB POP Si | 6 | 40 | 19.2 ± 0.5 | 423 ± 10 | 35.9 ± 2.0 | 4.0 ± 0.5 |

| 70/30% CB PAUL Si | 5 | 30 | 20.1 ± 1.1 | 443 ± 6 | 38.9 ± 3.0 | 4.3 ± 0.5 |

| 70/30% CB POP Si | 6 | 30 | 20.9 ± 1.2 | 432 ± 21 | 39.8 ± 4.1 | 4.2 ± 0.2 |

| Sample | Average G′ (MPa) |

|---|---|

| unfilled BR-NR | 0.45 ± 0.01 |

| 100% CB | 2.87 ± 0.03 |

| 100% PAUL | 1.72 ± 0.01 |

| 100% POP | 1.44 ± 0.01 |

| 100% PAUL Si | 0.80 ± 0.01 |

| 100% POP Si | 0.86 ± 0.01 |

| 50/50% CB/PAUL Si | 1.27 ± 0.01 |

| 50/50% CB/POP Si | 1.25 ± 0.01 |

| 60/40% CB/PAUL Si | 1.60 ± 0.01 |

| 60/40% CB/POP Si | 1.62 ± 0.01 |

| 70/30% CB/PAUL Si | 1.90 ± 0.01 |

| 70/30% CB/POP Si | 1.76 ± 0.01 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peterson, S.C. Coppiced Biochars as Partial Replacement of Carbon Black Filler in Polybutadiene/Natural Rubber Composites. J. Compos. Sci. 2020, 4, 147. https://doi.org/10.3390/jcs4040147

Peterson SC. Coppiced Biochars as Partial Replacement of Carbon Black Filler in Polybutadiene/Natural Rubber Composites. Journal of Composites Science. 2020; 4(4):147. https://doi.org/10.3390/jcs4040147

Chicago/Turabian StylePeterson, Steven C. 2020. "Coppiced Biochars as Partial Replacement of Carbon Black Filler in Polybutadiene/Natural Rubber Composites" Journal of Composites Science 4, no. 4: 147. https://doi.org/10.3390/jcs4040147

APA StylePeterson, S. C. (2020). Coppiced Biochars as Partial Replacement of Carbon Black Filler in Polybutadiene/Natural Rubber Composites. Journal of Composites Science, 4(4), 147. https://doi.org/10.3390/jcs4040147