Modification of Ground Tire Rubber—Promising Approach for Development of Green Composites

Abstract

1. Introduction

2. Materials and Methods

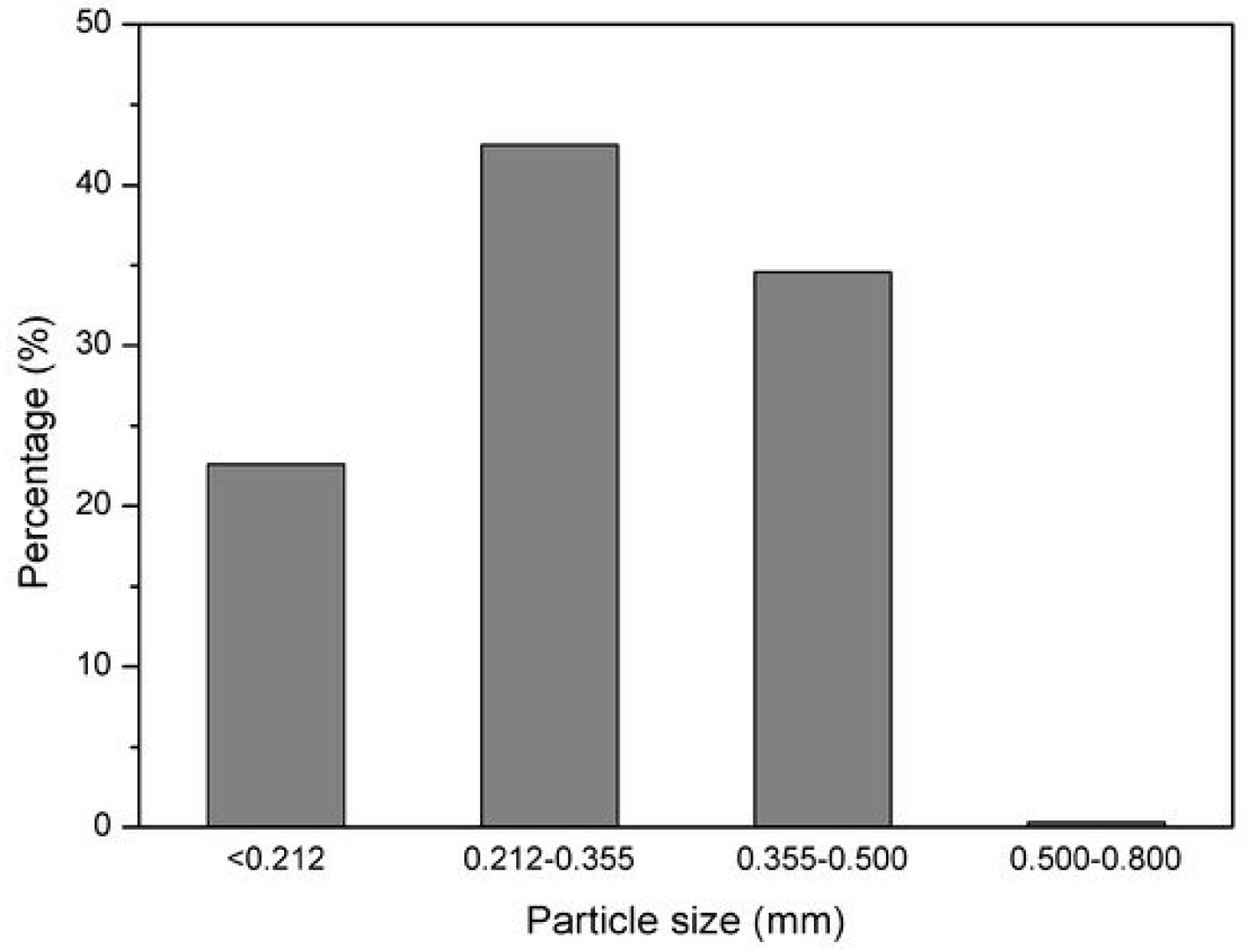

2.1. Materials

2.2. Sample Preparation

2.3. Measurements

3. Result and Discussion

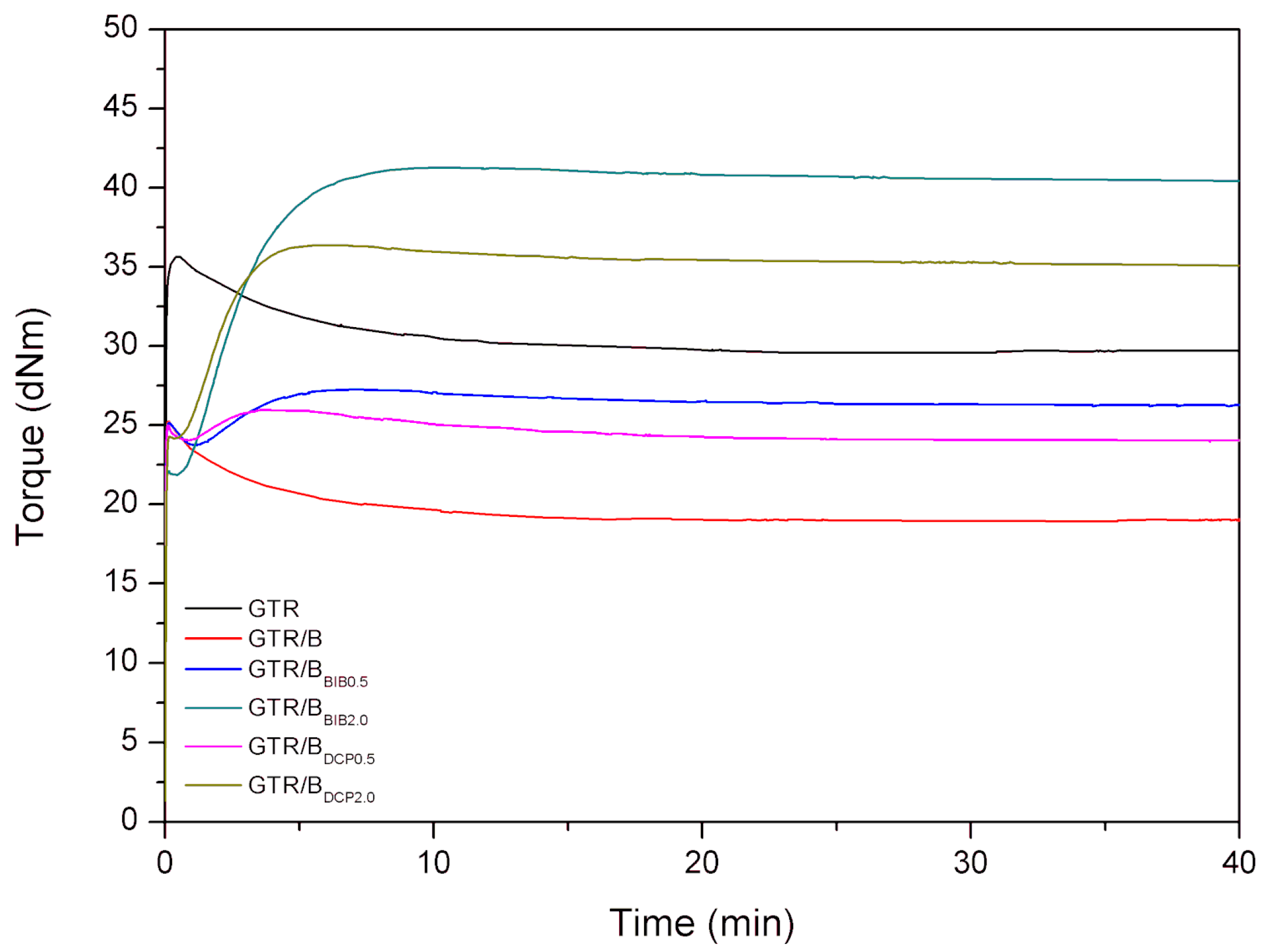

3.1. Curing Characteristics

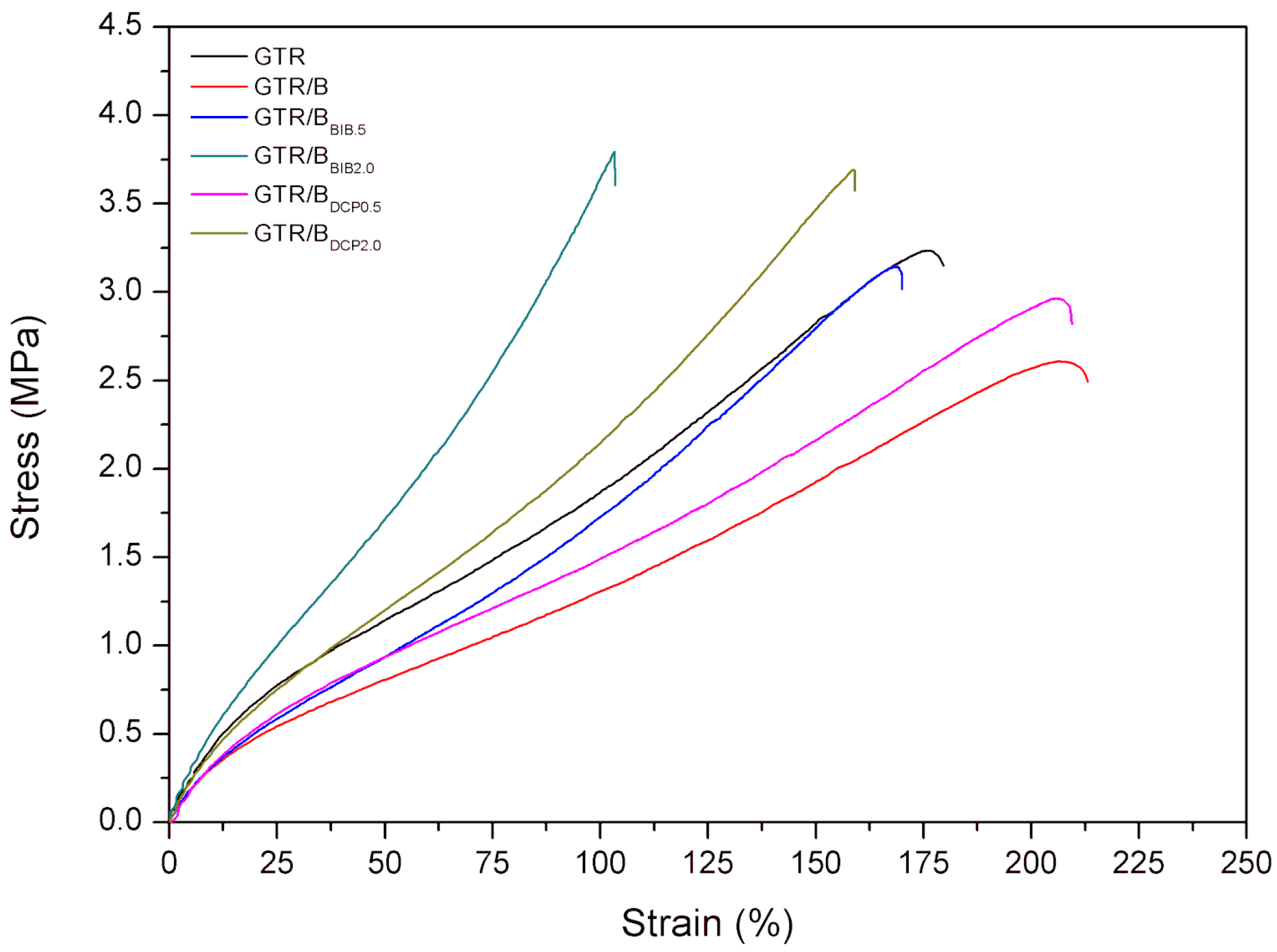

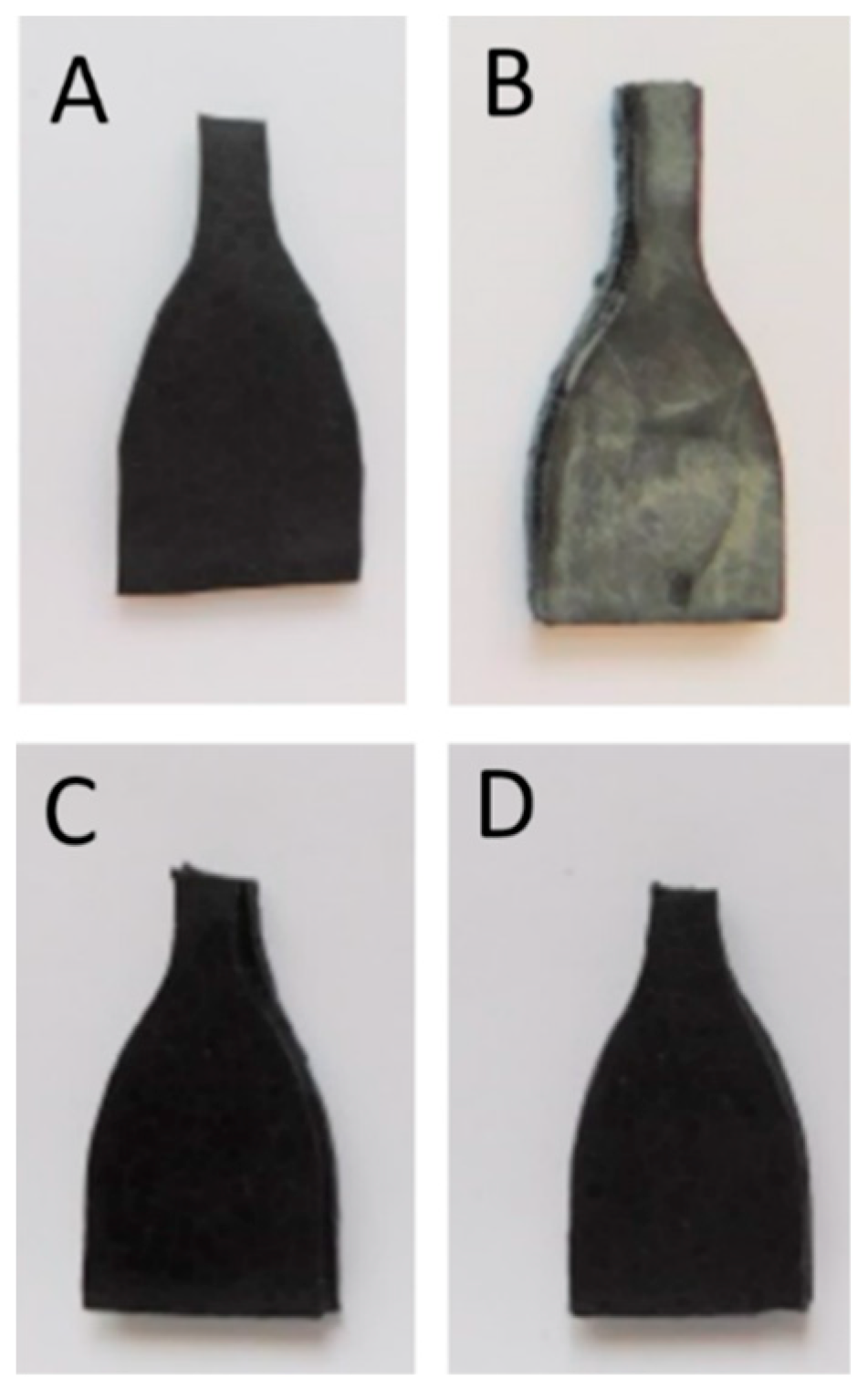

3.2. Physico-Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mitchell, N.C. Process of Reclaiming Rubber from Waste-Rubber Goods. U.S. Patent US419697, 21 January 1890. [Google Scholar]

- Garlick, F.W.; Bear, C.I.; Vail, W.A.; Wheeler, O.A. Art or Process of Reclaiming Scrap or Waste Vulcanized Rubber. U.S. Patent US866759, 24 September 1907. [Google Scholar]

- Lovette, N.G. Process for Reclaiming Rubber, Metal and Fabric from Whole Tires. U.S. Patent US4025990, 28 April 1976. [Google Scholar]

- Kim, J.K.; Lee, S.H. New technology of crumb rubber compounding for recycling of waste tires. J. Appl. Polym. Sci. 2000, 78, 1573–1577. [Google Scholar] [CrossRef]

- De, D.; Das, A.; De, D.; Dey, B.; Debnath, S.C.; Roy, B.C. Reclaiming of ground rubber tire (GRT) by a novel reclaiming agent. Eur. Polym. J. 2006, 42, 917–927. [Google Scholar] [CrossRef]

- Asaro, L.; Gratton, M.; Seghar, S.; Aït Hocine, N. Recycling of rubber wastes by devulcanization. Resour. Conserv. Recycl. 2018, 133, 250–262. [Google Scholar] [CrossRef]

- Formela, K.; Hejna, A.; Zedler, Ł.; Colom, X.; Cañavate, J. Microwave treatment in waste rubber recycling–Recent advances and limitations. Express Polym. Lett. 2019, 13, 565–588. [Google Scholar] [CrossRef]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Nadal, M.; Rovira, J.; Díaz-Ferrero, J.; Schuhmacher, M.; Domingo, J.L. Human exposure to environmental pollutants after a tire landfill fire in Spain: Health risks. Environ. Int. 2016, 97, 37–44. [Google Scholar] [CrossRef]

- Jang, J.-W.; Yoo, T.-S.; Oh, J.-H.; Iwasaki, I. Discarded tire recycling practices in the United States, Japan and Korea. Resour. Conserv. Recycl. 1998, 22, 1–14. [Google Scholar] [CrossRef]

- Ogilvie, G.; Macdonald, K.; Karlik-Neale, M. Product Stewardship Case Study for End-of-Life Tyres; Raport of URS: Wellington, New Zealand, 2006. [Google Scholar]

- Torretta, V.; Rada, E.C.; Ragazzi, M.; Trulli, E.; Istrate, I.A.; Cioca, L.I. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mészáros, L.; Bárány, T. Ground tyre rubber (GTR) in thermoplastics, thermosets, and rubbers. J. Mater. Sci. 2013, 48, 1–38. [Google Scholar] [CrossRef]

- Ramarad, S.; Khalid, M.; Ratnam, C.T.; Chuah, A.L.; Rashmi, W. Waste tire rubber in polymer blends: A review on the evolution, properties and future. Prog. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- Arastoopour, H.; Schocke, D.A.; Bernstein, B.; Bilgili, E. Process for Recycling of Rubber Materials. U.S. Patent US5904885, 18 May 1999. [Google Scholar]

- Saiwari, S.; Dierkes, W.K.; Noordermeer, J.W.M. Comparative investigation of the devulcanization parameters of tire rubbers. Rubber Chem. Technol. 2014, 87, 31–42. [Google Scholar] [CrossRef]

- Sabzekar, M.; Chenar, M.P.; Mortazavi, S.M.; Kariminejad, M.; Asadi, S.; Zohuri, G. Influence of process variables on chemical devulcanization of sulfur-cured natural rubber. Polym. Degrad. Stab. 2015, 118, 88–95. [Google Scholar] [CrossRef]

- De, D.; De, D.; Singharoy, G.M. Reclaiming of ground rubber tire by a novel reclaiming agent. I. Virgin natural rubber/reclaimed GRT vulcanizates. Polym. Eng. Sci. 2007, 47, 1091–1100. [Google Scholar] [CrossRef]

- Thaicharoen, P.; Thamyongkit, P.; Poompradub, S. Thiosalicylic acid as a devulcanizing agent for mechano-chemical devulcanization. Korean J. Chem. Eng. 2010, 27, 1177–1183. [Google Scholar] [CrossRef]

- Ostad, M.S.; Ansarifar, A.; Karbalaee, S.; Athary Far, S. Devulcanization and recycling of waste automotive EPDM rubber powder by using shearing action and chemical additive. Prog. Rubber Plast. Recycl. Technol. 2015, 31, 87–116. [Google Scholar]

- Neto, J.R.A.; Visconte, L.L.Y.; Tavares, M.I.B.; Pacheco, E.B.A.V.; Furtado, C.R.G. Regeneration of vulcanized compounds based on butadiene-styrene copolymer. Int. J. Polym. Mater. Polym. Biomater. 2007, 56, 565–578. [Google Scholar] [CrossRef]

- Formela, K.; Cysewska, M.; Januszewicz, K. Effect of addition of reclaimed rubber on curing characteristics and mechanical properties of styrene-butadiene rubber. Przem. Chem. 2014, 93, 666–671. [Google Scholar]

- Sabzekar, M.; Zohuri, G.; Chenar, M.P.; Mortazavi, S.M.; Kariminejad, M.; Asadi, S. A new approach for reclaiming of waste automotive EPDM rubber using waste oil. Polym. Degrad. Stab. 2016, 129, 56–62. [Google Scholar] [CrossRef]

- Formela, K.; Klein, M.; Colom, X.; Saeb, M.R. Investigating the combined impact of plasticizer and shear force on the efficiency of low temperature reclaiming of ground tire rubber (GTR). Polym. Degrad. Stab. 2016, 125, 1–11. [Google Scholar] [CrossRef]

- Khang, T.H.; Ariff, Z.M. Vulcanization kinetics study of natural rubber compounds having different formulation variables. J. Therm. Anal. Calorim. 2012, 109, 1545–1553. [Google Scholar] [CrossRef]

- Yazdani, H.; Karrabi, M.; Ghasmi, I.; Azizi, H.; Bakhshandeh, G.R. Devulcanization of waste tires using a twin-screw extruder: The effects of processing conditions. J. Vinyl Addit. Technol. 2011, 17, 64–69. [Google Scholar] [CrossRef]

- Kim, S.W.; Park, H.Y.; Lim, J.C.; Jeon, I.R.; Seo, K.H. Cure characteristics and physical properties of ground-rubber-filled natural rubber vulcanizates: Effects of the curing systems of the ground rubber and rubber matrix. J. Appl. Polym. Sci. 2007, 105, 2396–2406. [Google Scholar] [CrossRef]

- Ray, S.; Cooney, R.P. Chapter 7: Thermal degradation of polymer and polymer composites. In Handbook of Environmental Degradation of Materials; Kutz, M., Ed.; William Andrew Publishing (Elsevier): Norwich, NY, USA, 2013. [Google Scholar]

- Zedler, Ł.; Colom, X.; Saeb, M.R.; Formela, K. Preparation and characterization of natural rubber composites highly filled with brewers’ spent grain/ground tire rubber hybrid reinforcement. Compos. Part B Eng. 2018, 145, 182–188. [Google Scholar] [CrossRef]

- Morin, J.E.; Williams, D.E.; Farris, R.J. A novel method to recycle scrap tires: High-pressure high-temperature sintering. Rubber Chem. Technol. 2002, 75, 955–968. [Google Scholar] [CrossRef]

- Zhao, F.; Bi, W.; Zhao, S. Influence of crosslink density on mechanical properties of natural rubber vulcanizates. J. Macromol. Sci. Part B Phys. 2011, 50, 1460–1469. [Google Scholar] [CrossRef]

- Nandi, S.; Winter, H.H. Swelling behavior of partially cross-linked polymers: A ternary system. Macromolecules 2005, 38, 4447–4455. [Google Scholar] [CrossRef]

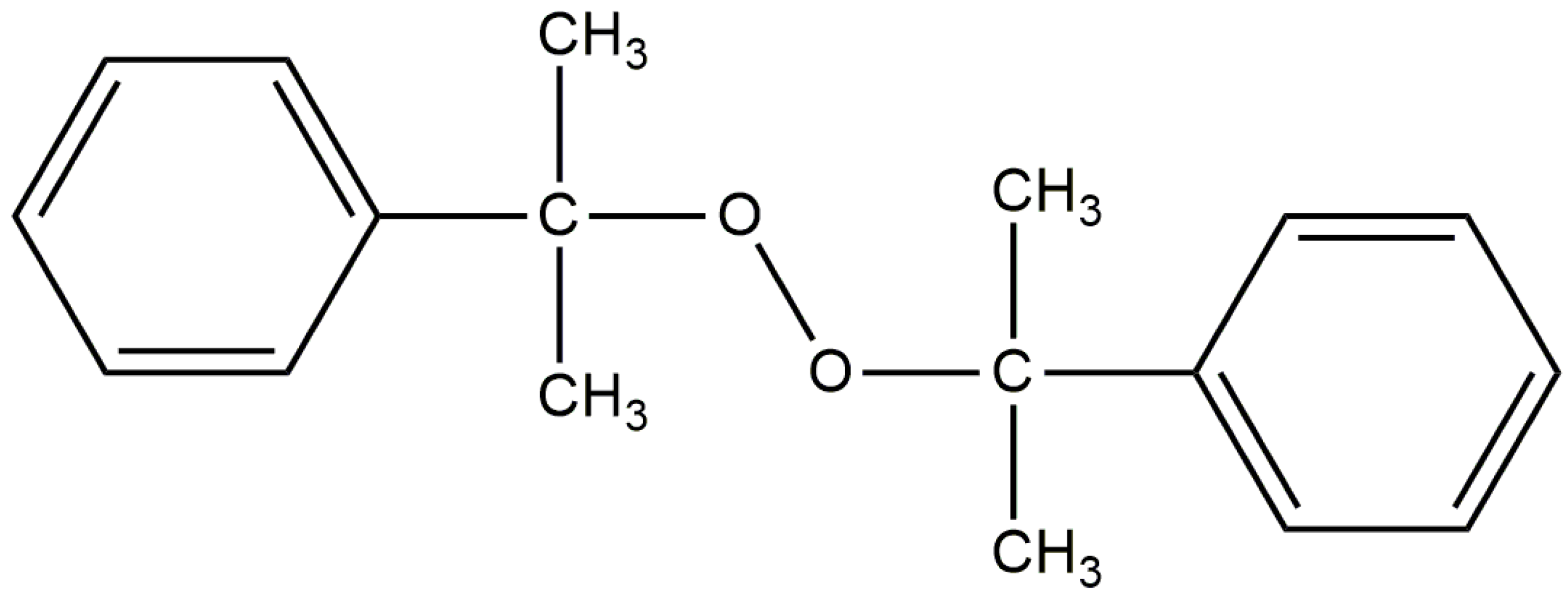

| Name | Abbreviation | Active Oxygen (%) * | The Half-Life Temperature (°C) * |

|---|---|---|---|

| Di-(2-tert-butyl-peroxyisopropyl)-benzene | BIB | 8.98 | 169 |

| Dicumyl peroxide | DCP | 5.80 | 162 |

| Components (phr) | Sample Code | |||||

|---|---|---|---|---|---|---|

| GTR | GTR/B a | GTR/BBIB0.5 b | GTR/BBIB2.0 b | GTR/BDCP0.5 c | GTR/BDCP2.0 c | |

| GTR | 100 | 100 | 100 | 100 | 100 | 100 |

| Bitumen 100/150 | - | 10 | 10 | 10 | 10 | 10 |

| BIB | - | - | 0.5 | 2.0 | - | - |

| DCP | - | - | - | - | 0.5 | 2.0 |

| Properties | Sample Code | |||||

|---|---|---|---|---|---|---|

| GTR | GTR/B | GTR/BBIB0.5 | GTR/BBIB2.0 | GTR/BDCP0.5 | GTR/BDCP2.0 | |

| Minimal torque (dNm) | - | - | 23.7 | 21.9 | - | 24.3 |

| Maximal torque (dNm) | - | - | 27.3 | 41.3 | - | 36.4 |

| ΔM (dNm) | - | - | 3.6 | 19.4 | - | 12.1 |

| Scorch time (t1, min) | - | - | 3.0 | 1.2 | - | 1.2 |

| Optimum cure time (t90, min) | 5 | 5 | 4.9 | 5.3 | 5 | 3.5 |

| Cure rate index (CRI, min−1) | - | - | 52.9 | 24.0 | - | 42.2 |

| Thermal aging resistance (R300, %) | - | - | 1.5 | 0.6 | - | 1.6 |

| Properties | Sample Code | |||||

|---|---|---|---|---|---|---|

| GTR | GTR/B | GTR/BBIB0.5 | GTR/BBIB2.0 | GTR/BDCP0.5 | GTR/BDCP2.0 | |

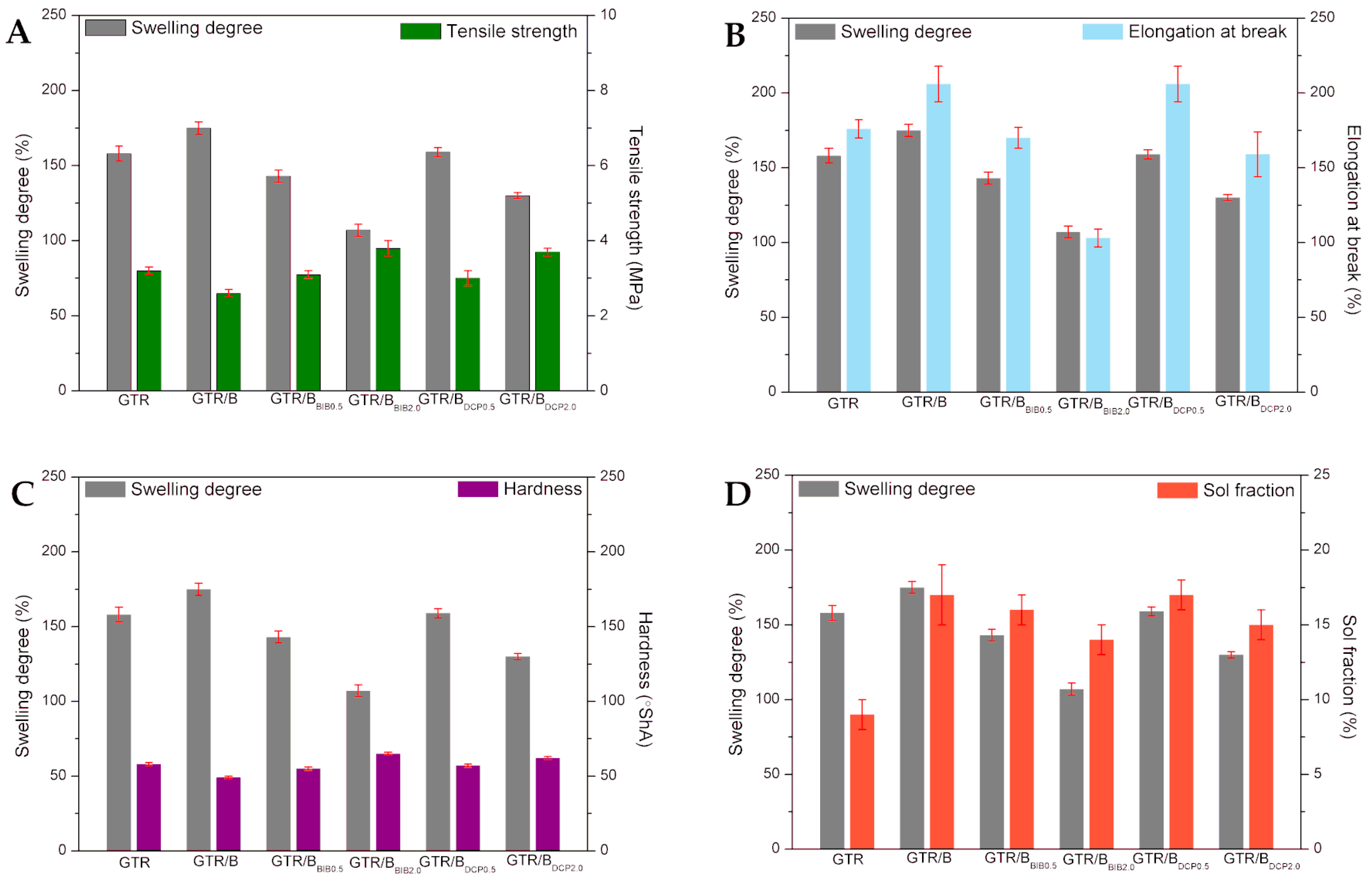

| Tensile strength (MPa) | 3.2 ± 0.1 | 2.6 ± 0.1 | 3.1 ± 0.1 | 3.8 ± 0.2 | 3.0 ± 0.2 | 3.7 ± 0.1 |

| Elongation at break (%) | 176 ± 6 | 206 ± 12 | 170 ± 7 | 103 ± 6 | 206 ± 12 | 159 ± 15 |

| M100 (MPa) | 1.8 | 1.3 | 1.5 | 3.6 | 1.4 | 2.4 |

| Hardness (Sh A) | 58 ± 1 | 49 ± 1 | 55 ± 1 | 65 ± 1 | 57 ± 1 | 62 ± 1 |

| Density at 25 °C (g/cm3) | 1.162 ± 0.010 | 1.142 ± 0.011 | 1.149 ± 0.012 | 1.18 ± 0.011 | 1.144 ± 0.010 | 1.149 ± 0.013 |

| Swelling degree (%) | 158 ± 5 | 175 ± 4 | 143 ± 4 | 107 ± 4 | 159 ± 3 | 130 ± 2 |

| Sol fraction (%) | 9 ± 1 | 17 ± 2 | 16 ± 1 | 14 ± 1 | 17 ± 1 | 15 ± 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zedler, Ł.; Przybysz-Romatowska, M.; Haponiuk, J.; Wang, S.; Formela, K. Modification of Ground Tire Rubber—Promising Approach for Development of Green Composites. J. Compos. Sci. 2020, 4, 2. https://doi.org/10.3390/jcs4010002

Zedler Ł, Przybysz-Romatowska M, Haponiuk J, Wang S, Formela K. Modification of Ground Tire Rubber—Promising Approach for Development of Green Composites. Journal of Composites Science. 2020; 4(1):2. https://doi.org/10.3390/jcs4010002

Chicago/Turabian StyleZedler, Łukasz, Marta Przybysz-Romatowska, Józef Haponiuk, Shifeng Wang, and Krzysztof Formela. 2020. "Modification of Ground Tire Rubber—Promising Approach for Development of Green Composites" Journal of Composites Science 4, no. 1: 2. https://doi.org/10.3390/jcs4010002

APA StyleZedler, Ł., Przybysz-Romatowska, M., Haponiuk, J., Wang, S., & Formela, K. (2020). Modification of Ground Tire Rubber—Promising Approach for Development of Green Composites. Journal of Composites Science, 4(1), 2. https://doi.org/10.3390/jcs4010002