A Dimensionless Characteristic Number for Process Selection and Mold Design in Composites Manufacturing: Part I—Theory

Abstract

1. Introduction

- Process selection. Because of the absence of general guidelines, process selection represents the first difficulty. Among RTM, C-RTM, VARI, FI, or other processes, what is the best LCM technique to fabricate a given part by liquid injection through a porous medium? More specifically, should one inject in a closed and rigid mold (RTM), infuse under vacuum (VARI), or use a deformable cavity (FI)? Depending on the size and the number of parts to be produced, a preliminary assessment is possible by computer simulation. Nevertheless, apart from expert knowledge, no commonly accepted rules exist to choose the most suitable manufacturing process.

- Mold design. Once the fabrication technique has been selected, no systematic information is provided on process feasibility and robustness to assist in defining the best mold configuration in terms of inlet gates/lines and vents. In addition, specific features can be considered in the mold to enhance resin injection. For instance, flow channels and flow enhancement layers on top and/or bottom of the preform can speed up mold filling. Moreover, the resin can be heated to decrease viscosity and create a faster flow. These solutions aim at controlling the two main physical parameters that govern composite manufacturing, namely pressure and temperature in the mold. Although computer models represent a useful tool to simulate the injection process and improve mold design, expert knowledge is again necessary to use it effectively. Given the high number of design variables, the analysis of the different solutions is often arduous and computationally demanding. Therefore, the final processing decisions remain today mostly based on experience and experimental trials.

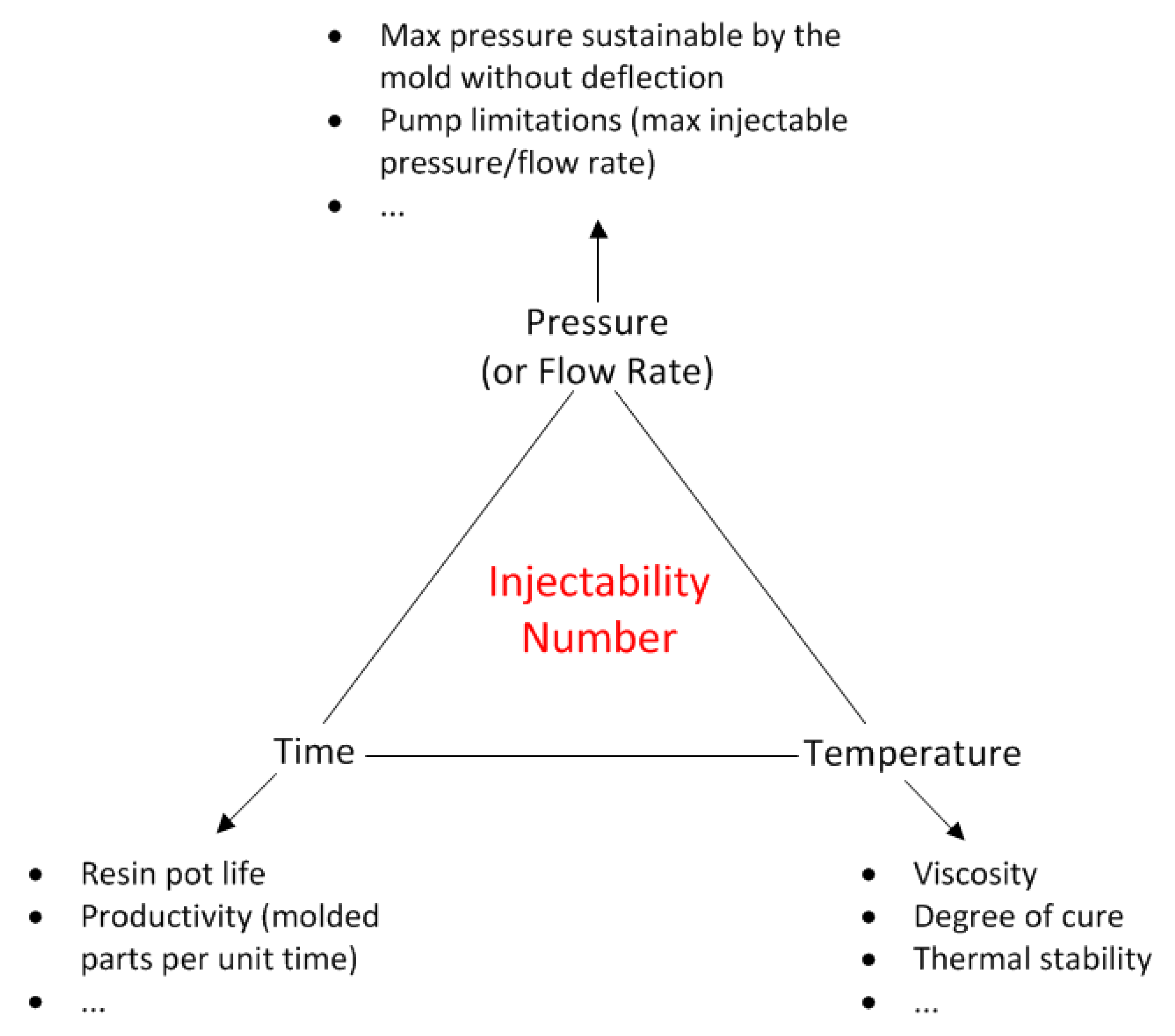

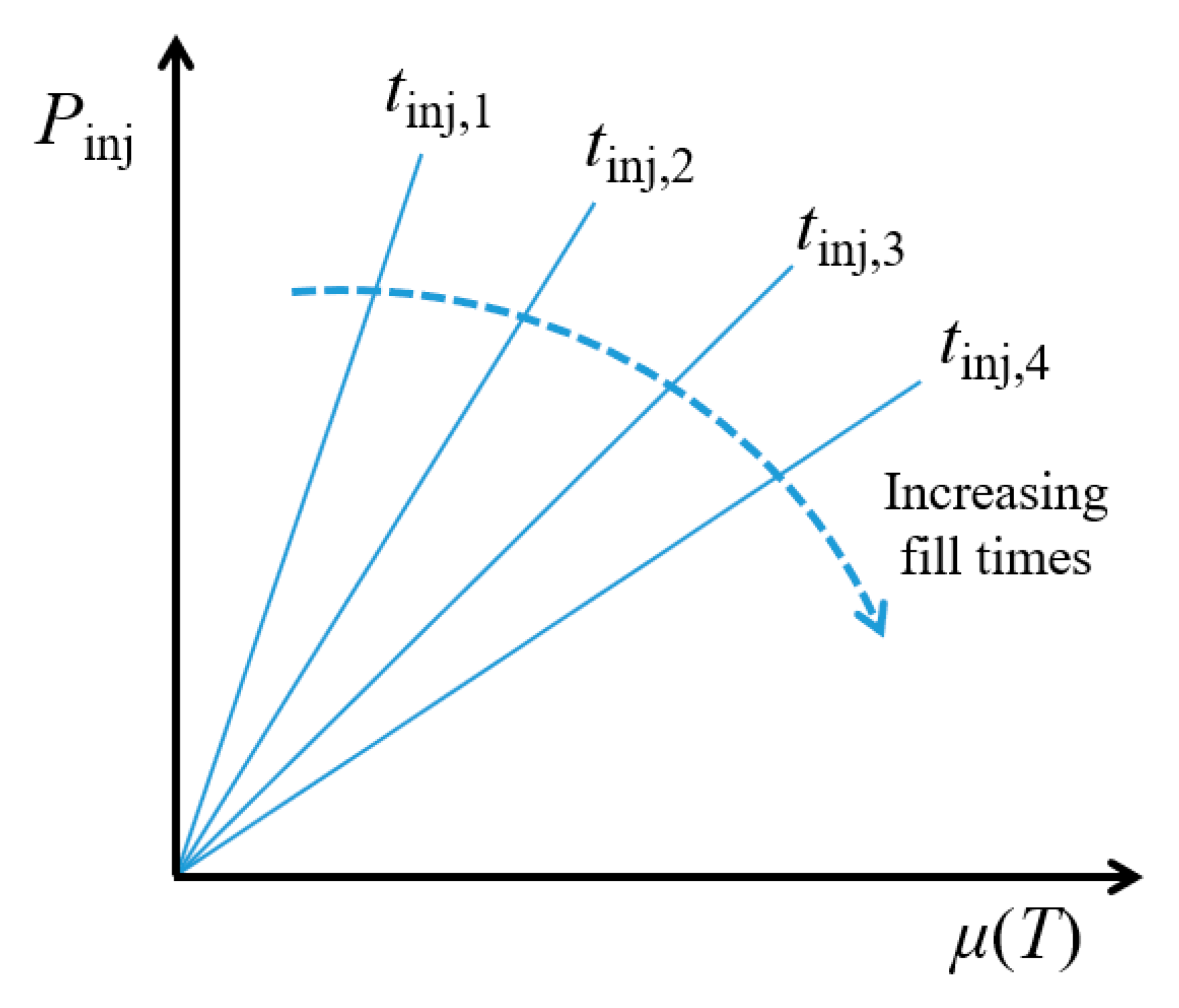

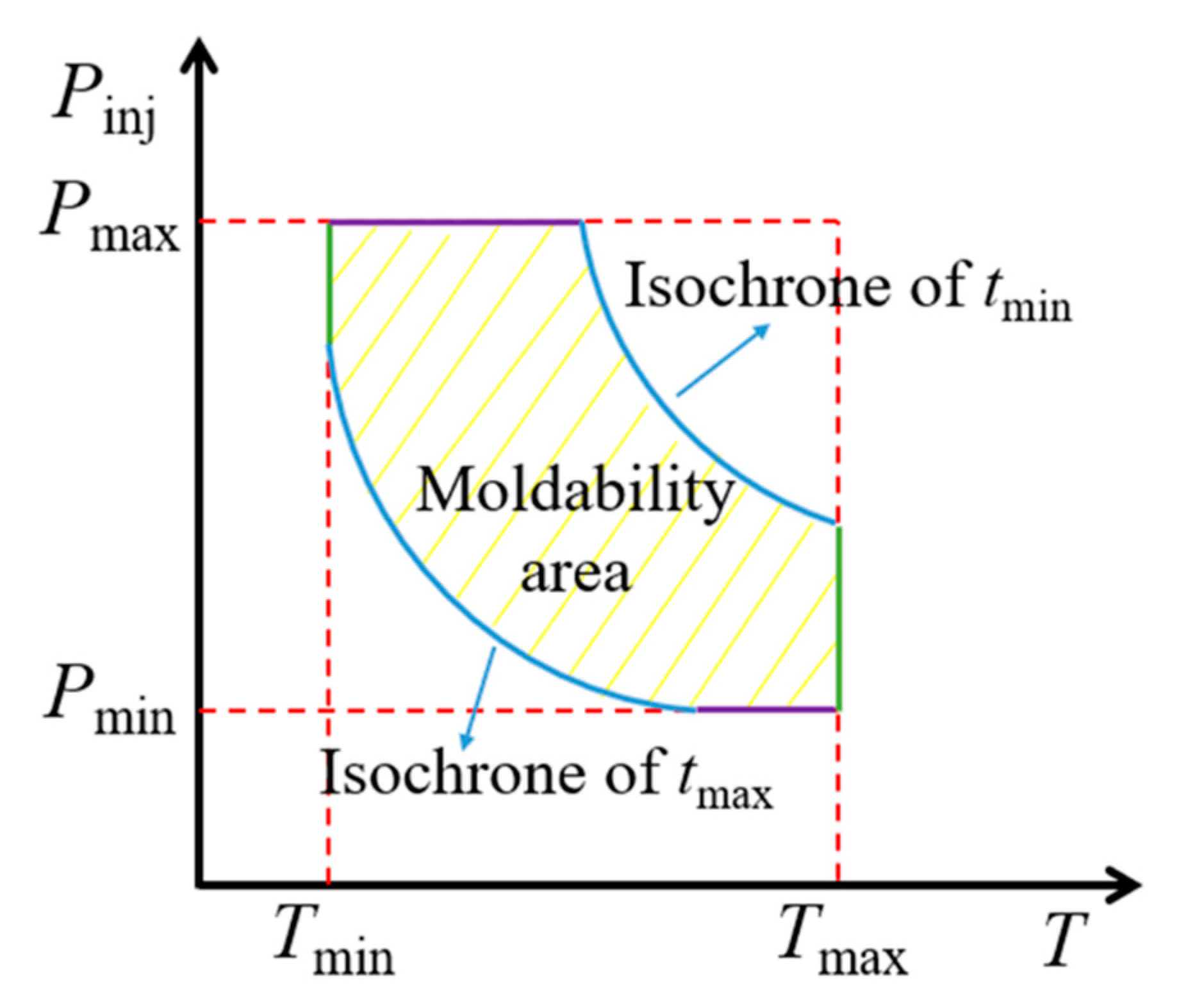

- Optimization of process parameters. The performance of LCM processes depends on the injection pressure and/or the liquid flow rate. Another critical factor is the viscosity of the resin, which depends on temperature. What is the optimal inlet pressure for a fast injection with minimum void content and limited fabric deformation? What is the best temperature to minimize resin viscosity and achieve a proper impregnation of the fiber bed? How do pressure and temperature changes affect the fill time in a complex mold? All of these questions can be partially answered by computer simulations, once the process has been defined. However, simple guidelines are still missing to both select a manufacturing technique and optimize process parameters. This latter task requires evaluating the interconnections between the fill time and the two key physical parameters of pressure and temperature (Figure 1).

2. State of the Art

3. Injectability Number

3.1. Definition

3.2. Invariance Property

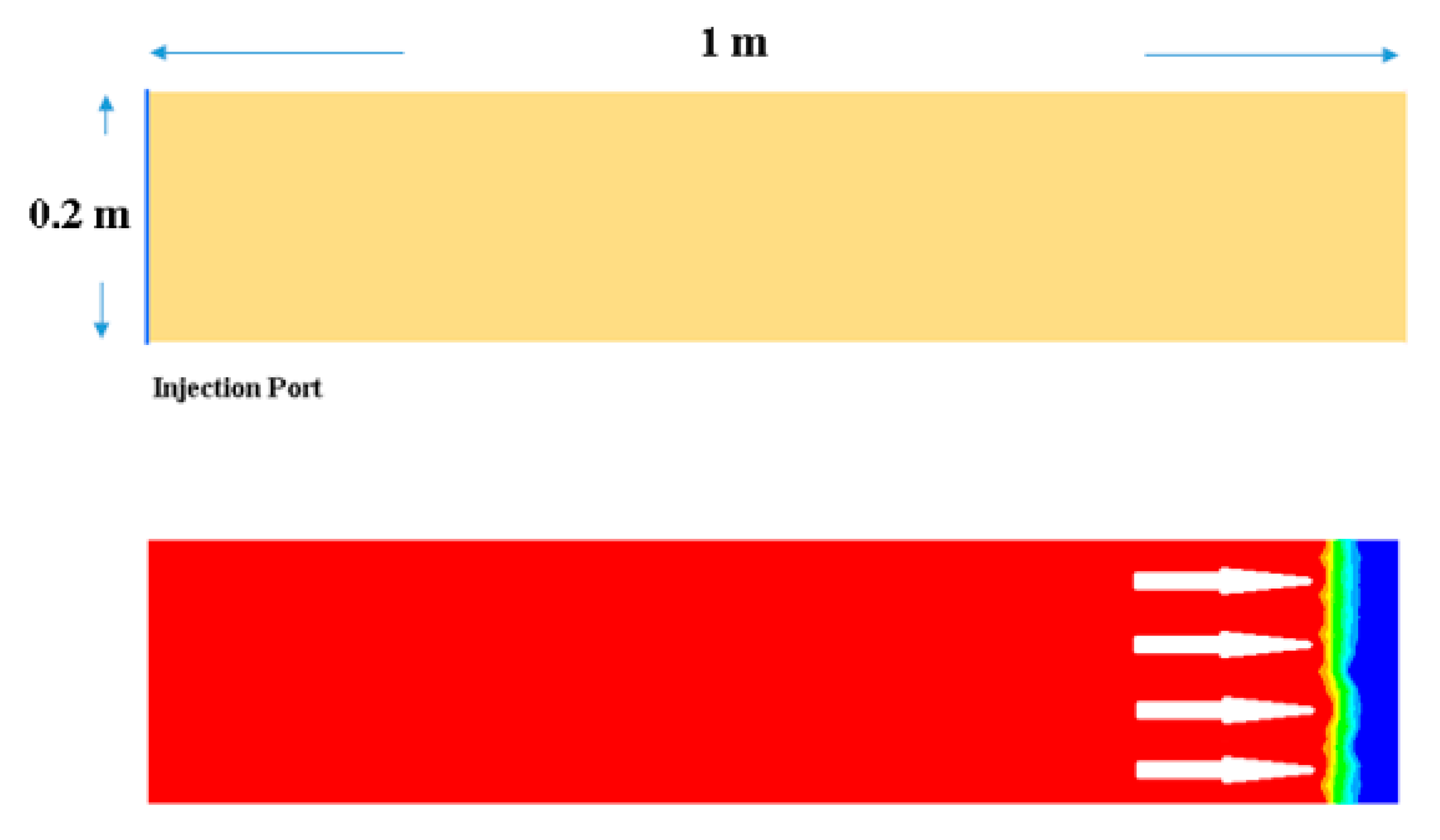

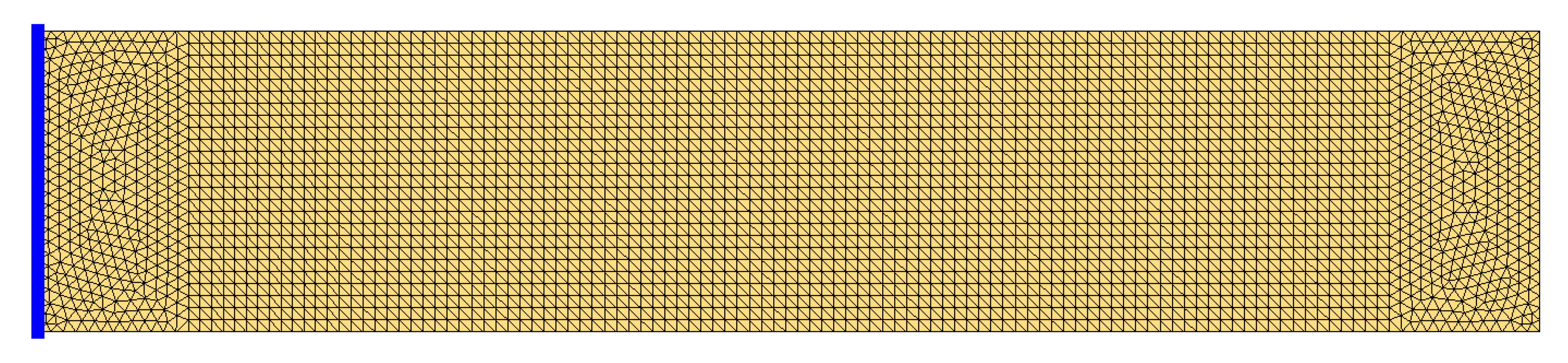

4. Analysis of Unidirectional Injection Cases

4.1. Analytical Solution at Constant Injection Pressure

4.2. Analytical Solution at Constant Injection Flow Rate

4.3. Computer Simulations for Constant and Time-Varying Pressure and Flow Rate

- Constant injection pressure Pinj = 2 bar.

- Constant flow rate Qinj = 2 cm3/s.

- Time-dependent injection pressure Pinj(t) = A·f(t), with A = 2 bar and f defined by Equation (7).

- Time-dependent flow rate Qinj(t) = B·f(t), with B = 2 cm3/s and f defined by Equation (7).

5. Usability of the Injectability Number

5.1. Process Selection

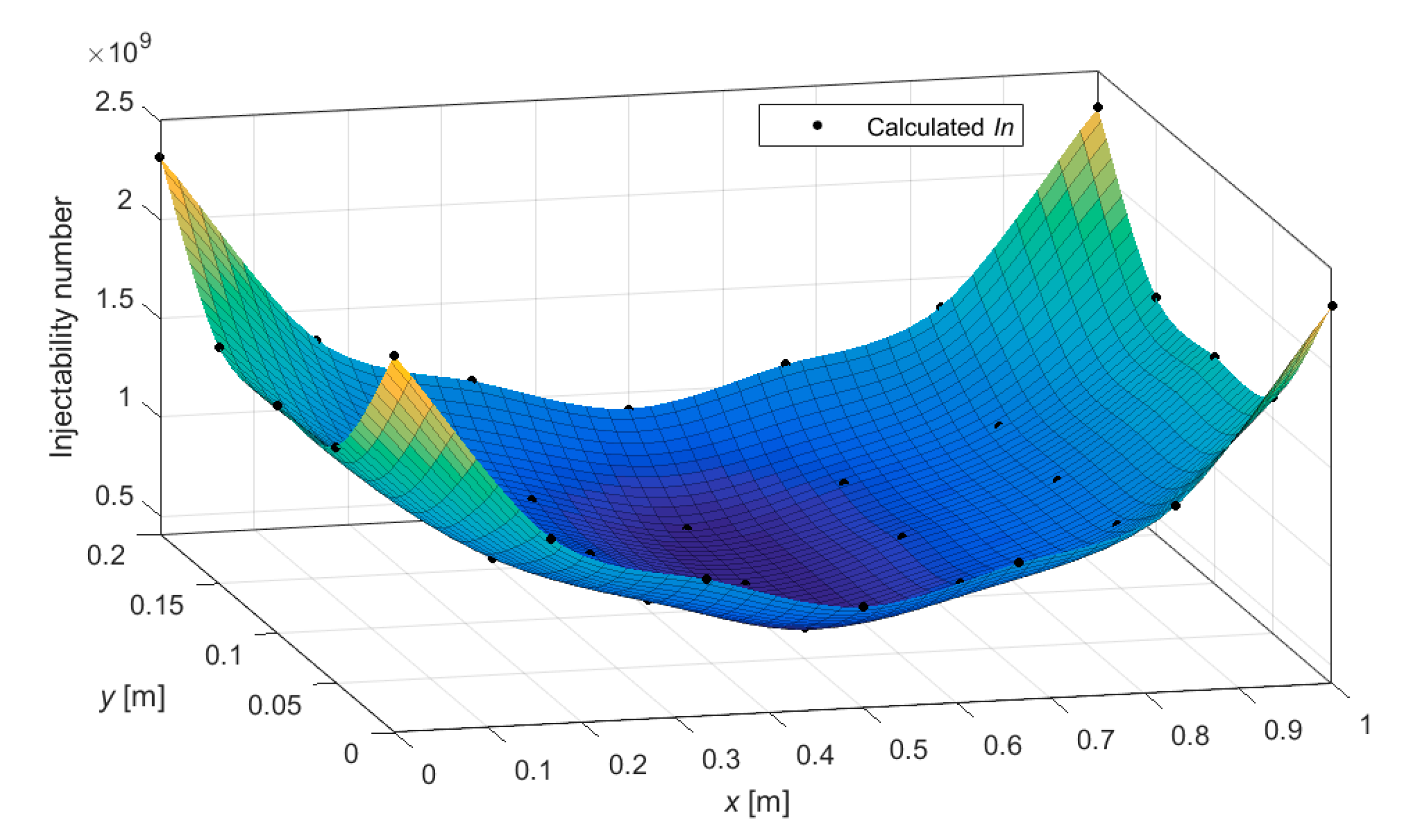

5.2. Mold Design

5.3. Optimization of Process Parameters

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

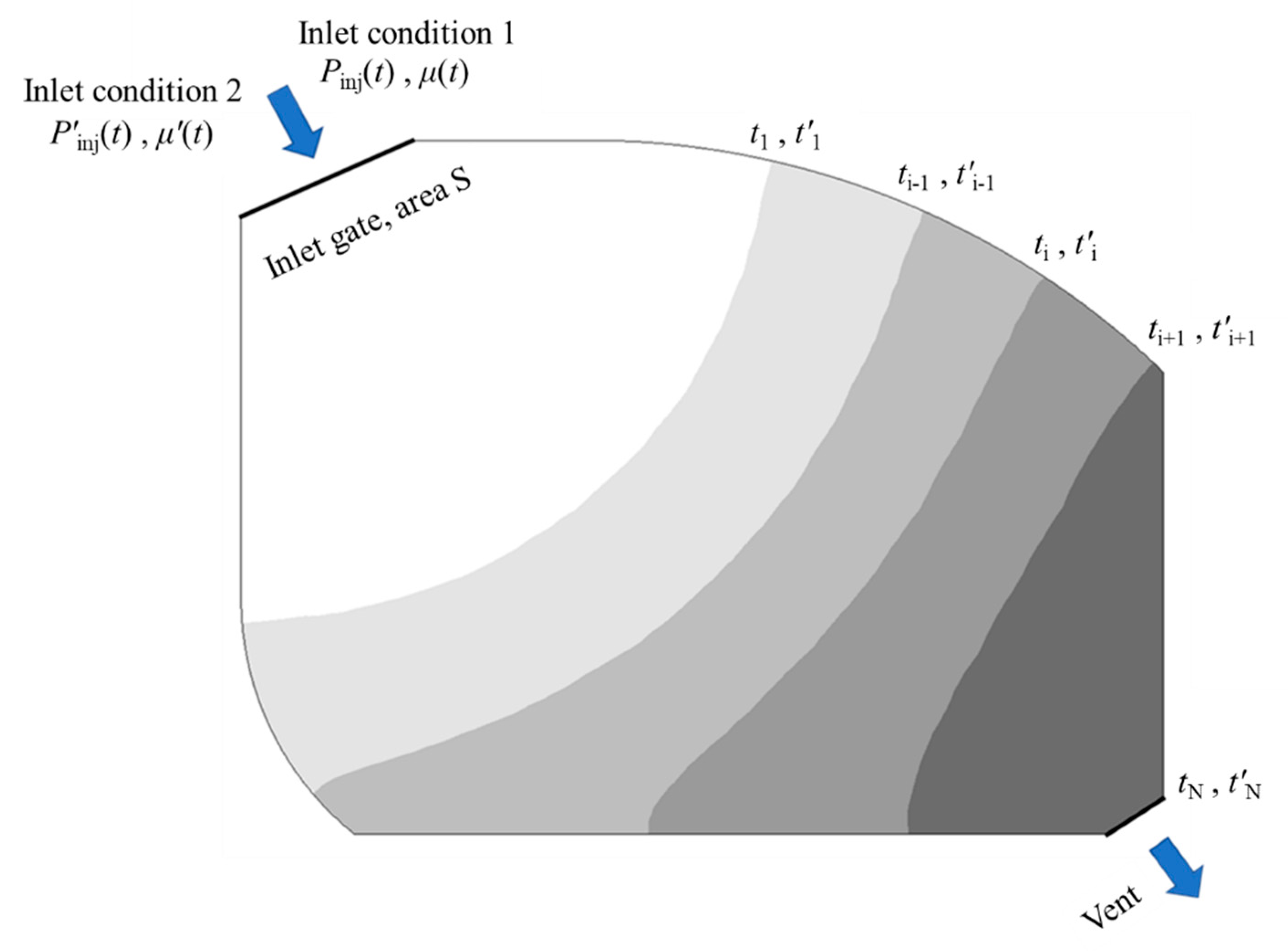

- Inlet condition 1, Pinj(t) and μ(t): 0 ≤ t1 ≤ … ≤ ti ≤ … ≤ tN = tinj,

- Inlet condition 2, P’inj(t) and μ’(t): 0 ≤ t’1 ≤ … ≤ t’i ≤ … ≤ t’N = t’inj

References

- Ermanni, P.; Di Fratta, C.; Trochu, F. Molding: Liquid Composite Molding (LCM). In Wiley Encyclopedia of Composites; Nicolais, L., Borzacchiello, A., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 1884–1894. [Google Scholar]

- Parnas, R.S. Liquid Composite Molding; Carl Hanser Verlag GmbH: Munich, Germany, 2000. [Google Scholar]

- Causse, P.; Ruiz, E.; Trochu, F. Experimental study of flexible injection to manufacture parts of strong curvature. Polym. Compos. 2011, 32, 882–895. [Google Scholar] [CrossRef]

- Alms, J.; Advani, S.G. Simulation and experimental validation of flow flooding chamber method of resin delivery in liquid composite molding. Compos. Part A 2007, 38, 2131–2141. [Google Scholar] [CrossRef]

- Yalcinkaya, M.A.; Guloglu, G.E.; Pishvar, M.; Amirkhosravi, M.; Sozer, E.M.; Altan, M.C. Pressurized Infusion: A New and Improved Liquid Composite Molding Process. J. Manuf. Sci. Eng. 2019, 141, 011007. [Google Scholar] [CrossRef]

- Pham, X.T.; Trochu, F. Simulation of compression resin transfer molding to manufacture thin composite shells. Polym. Compos. 1999, 20, 436–459. [Google Scholar] [CrossRef]

- Simacek, P.; Advani, S.G.; Iobst, S.A. Modeling Flow in Compression Resin Transfer Molding for Manufacturing of Complex Lightweight High-Performance Automotive Parts. J. Compos. Mater. 2008, 42, 2523–2545. [Google Scholar] [CrossRef]

- Bodaghi, M.; Cristóvão, C.; Gomes, R.; Correia, N. Experimental characterization of voids in high fibre volume fraction composites processed by high injection pressure RTM. Compos. Part A 2016, 82, 88–99. [Google Scholar] [CrossRef]

- Achim, V.; Ruiz, E. Guiding selection for reduced process development time in RTM. Int. J. Mater. Form. 2010, 3, 1277–1286. [Google Scholar] [CrossRef]

- Pierce, R.S.; Falzon, B.G. Simulating Resin Infusion through Textile Reinforcement Materials for the Manufacture of Complex Composite Structures. Engineering 2017, 3, 596–607. [Google Scholar] [CrossRef]

- Schubel, P.J. Cost modelling in polymer composite applications: Case study—Analysis of existing and automated manufacturing processes for a large wind turbine blade. Compos. Part B 2012, 43, 953–960. [Google Scholar] [CrossRef]

- Bear, J. Dynamics of Fluids in Porous Media; American Elsevier Publishing Company: New York, NY, USA, 1972. [Google Scholar]

- Strong, A.B. Fundamentals of Composites Manufacturing: Materials, Methods and Applications; Society of Manufacturing Engineers: Southfield, MI, USA, 2008. [Google Scholar]

- Advani, S.G.; Hsiao, K.-T. Manufacturing Techniques for Polymer Matrix Composites (PMCs); Woodhead Publishing Limited: Cambridge, UK, 2012. [Google Scholar]

- Controlled Vacuum Infusion (CVI)—Product and Services—Polyworx. Available online: http://www.polyworx.com/pwx/cvi/ (accessed on 28 August 2019).

- PAM-RTM—Composites Molding Simulation Software. Available online: https://www.esi-group.com/software-solutions/virtual-manufacturing/composites/pam-composites/pam-rtm-composites-molding-simulation-software (accessed on 28 August 2019).

- Simacek, P.; Advani, S.G. Desirable features in mold filling simulations for liquid composite molding processes. Polym. Compos. 2004, 25, 355–367. [Google Scholar] [CrossRef]

- Okabe, T.; Oya, Y.; Yamamoto, G.; Sato, J.; Matsumiya, T.; Matsuzaki, R.; Yashiro, S.; Obayashi, S. Multi-objective optimization for resin transfer molding process. Compos. Part A 2017, 92, 1–9. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, C.; Wang, B. Optimum arrangement of gate and vent locations for RTM process design using a mesh distance-based approach. Compos. Part A 2002, 33, 471–481. [Google Scholar] [CrossRef]

- Henz, B.J.; Mohan, R.V.; Shires, D.R. A hybrid global–local approach for optimization of injection gate locations in liquid composite molding process simulations. Compos. Part A 2007, 38, 1932–1946. [Google Scholar] [CrossRef]

- Trochu, F.; Ruiz, E.; Achim, V.; Soukane, S. Advanced numerical simulation of liquid composite molding for process analysis and optimization. Compos. Part A 2006, 37, 890–902. [Google Scholar] [CrossRef]

- Ruiz, E.; Achim, V.; Soukane, S.; Trochu, F.; Bréard, J. Optimization of injection flow rate to minimize micro/macro-voids formation in resin transfer molded composites. Compos. Sci. Technol. 2006, 66, 475–486. [Google Scholar] [CrossRef]

- Saad, A.; Echchelh, A.; Hattabi, M.; Ganaouli, M.E. Review of modeling and simulation of void formation in liquid composite molding. Compos. Mech. Comput. Appl. Int. J. 2018, 9, 51–93. [Google Scholar] [CrossRef]

- Ruiz, E.; Trochu, F. Multi-criteria thermal optimization in liquid composite molding to reduce processing stresses and cycle time. Compos. Part A 2006, 37, 913–924. [Google Scholar] [CrossRef]

- Di Fratta, C.; Klunker, F.; Ermanni, P. A methodology for flow-front estimation in LCM processes based on pressure sensors. Compos. Part A 2013, 47, 1–11. [Google Scholar] [CrossRef]

- Möller, J.; Kuncho, C.N.; Schmidt, D.F.; Reynaud, E. Rheological Studies of High-Performance Bioepoxies for Use in Fiber-Reinforced Composite Resin Infusion. Ind. Eng. Chem. Res. 2017, 56, 2673–2679. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Kobayashi, S.; Todoroki, A.; Mizutani, Y. Full-field monitoring of resin flow using and area-sensor array in a VaRTM process. Compos. Part A 2011, 42, 550–559. [Google Scholar] [CrossRef]

- Di Fratta, C.; Koutsoukis, G.; Klunker, F.; Ermanni, P. Fast method to monitor the flow front and control injection parameters in resin transfer molding using pressure sensors. J. Compos. Mater. 2016, 50, 2941–2957. [Google Scholar] [CrossRef]

- Voller, V.R.; Chen, Y.F. Prediction of filling times of porous cavities. Int. J. Numer. Methods Fluids 1996, 23, 661–672. [Google Scholar] [CrossRef]

- Di Fratta, C.; Klunker, F.; Trochu, F.; Ermanni, P. Characterization of textile permeability as a function of fiber volume content with a single unidirectional injection experiment. Compos. Part A 2015, 77, 238–247. [Google Scholar] [CrossRef]

- Di Fratta, C. Combined Experimental–Numerical Methods to Monitor Liquid Composite Molding and Characterize Textile Permeability. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, July 2015. [Google Scholar]

- Hergan, P.; Beter, J.; Stelzer, S.; Fauster, E.; Schledjewski, R. Influence of processing parameters on quality factors of one-shot hybrid structures made by RTM. Prod. Eng. 2018, 12, 185–194. [Google Scholar] [CrossRef]

- Di Fratta, C.; Koutsoukis, G.; Klunker, F.; Trochu, F.; Ermanni, P. Characterization of Anisotropic Permeability from Flow Front Angle Measurements. Polym. Compos. 2016, 37, 2037–2052. [Google Scholar] [CrossRef]

| Symbol. | Description |

|---|---|

| α | Degree of cure |

| µ | Viscosity |

| τ | Integration variable related to time |

| φ | Porosity |

| ζ, ω, b | Parameters for time-dependent function f |

| A, B | Target values of time-dependent injection pressure and flow rate |

| f | Time-dependent function of injection pressure and flow rate |

| H, W | Cavity height and width |

| In | Injectability number |

| K | Permeability |

| L | Cavity length |

| Leq | Equivalent length |

| p | Pressure field resulting from prescribed unit injection pressure |

| P | Pressure |

| Pinj | Injection pressure, relative to the outlet pressure |

| Qinj | Injection flow rate |

| S | Cavity cross-section or inlet area |

| t | Time during injection process |

| tinj | Fill time |

| T | Temperature |

| vf | Fiber volume content |

| V | Volume |

| Vinj | Total volume of liquid injected |

| xf | Flow front position |

| x, y | Spatial coordinates |

| Case | Type of Injection | Fill Time [s] | Injectability Number |

|---|---|---|---|

| 1 | Constant injection pressure | 500 | 1.00 × 109 |

| 2 | Constant flow rate | 150 | 1.00 × 109 |

| 3 | Time-dependent injection pressure | 540 | 1.00 × 109 |

| 4 | Time-dependent flow rate | 190 | 1.00 × 109 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Fratta, C.; Sun, Y.; Causse, P.; Trochu, F. A Dimensionless Characteristic Number for Process Selection and Mold Design in Composites Manufacturing: Part I—Theory. J. Compos. Sci. 2020, 4, 11. https://doi.org/10.3390/jcs4010011

Di Fratta C, Sun Y, Causse P, Trochu F. A Dimensionless Characteristic Number for Process Selection and Mold Design in Composites Manufacturing: Part I—Theory. Journal of Composites Science. 2020; 4(1):11. https://doi.org/10.3390/jcs4010011

Chicago/Turabian StyleDi Fratta, Claudio, Yixun Sun, Philippe Causse, and François Trochu. 2020. "A Dimensionless Characteristic Number for Process Selection and Mold Design in Composites Manufacturing: Part I—Theory" Journal of Composites Science 4, no. 1: 11. https://doi.org/10.3390/jcs4010011

APA StyleDi Fratta, C., Sun, Y., Causse, P., & Trochu, F. (2020). A Dimensionless Characteristic Number for Process Selection and Mold Design in Composites Manufacturing: Part I—Theory. Journal of Composites Science, 4(1), 11. https://doi.org/10.3390/jcs4010011