Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry

Abstract

1. Introduction

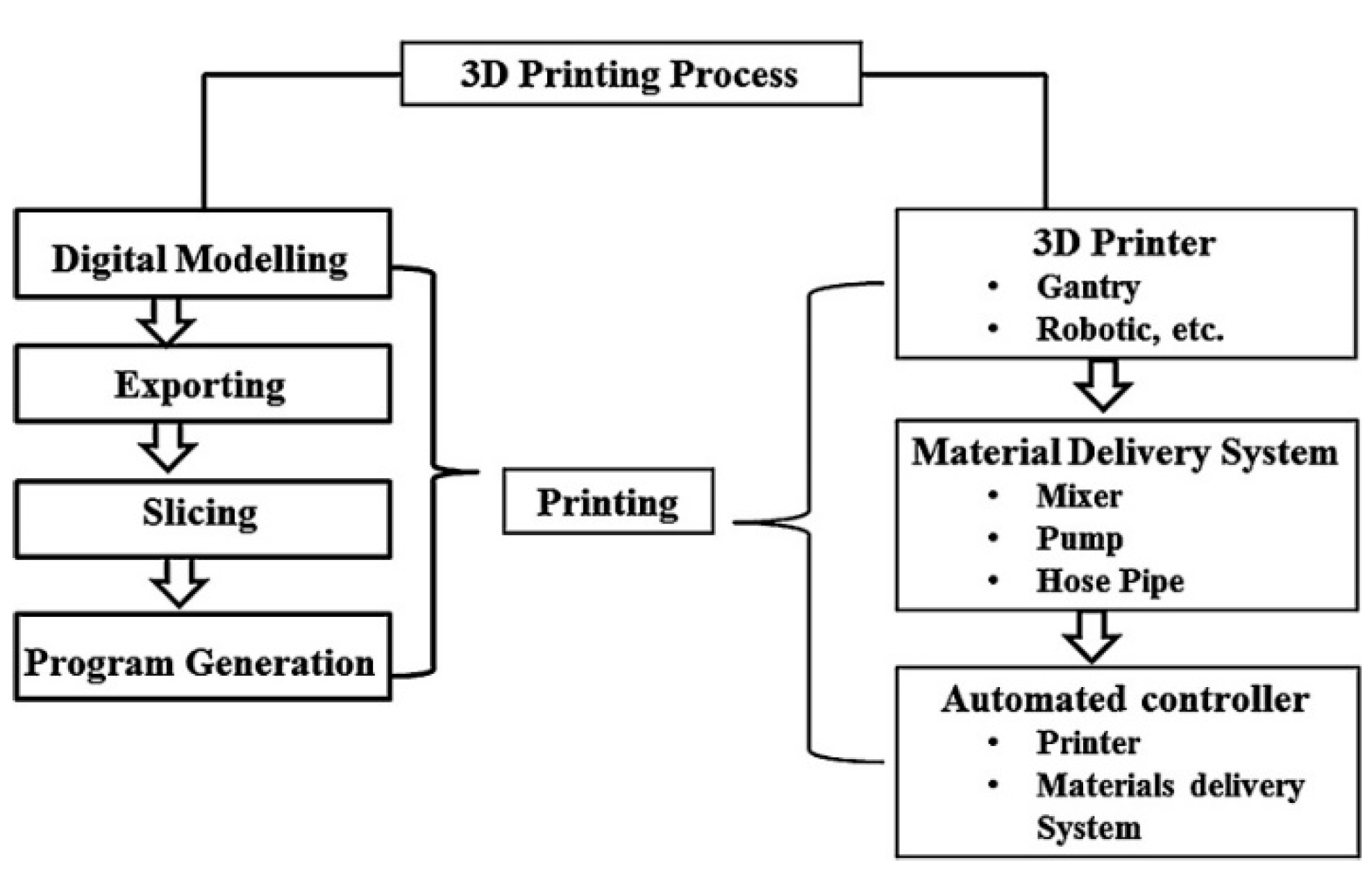

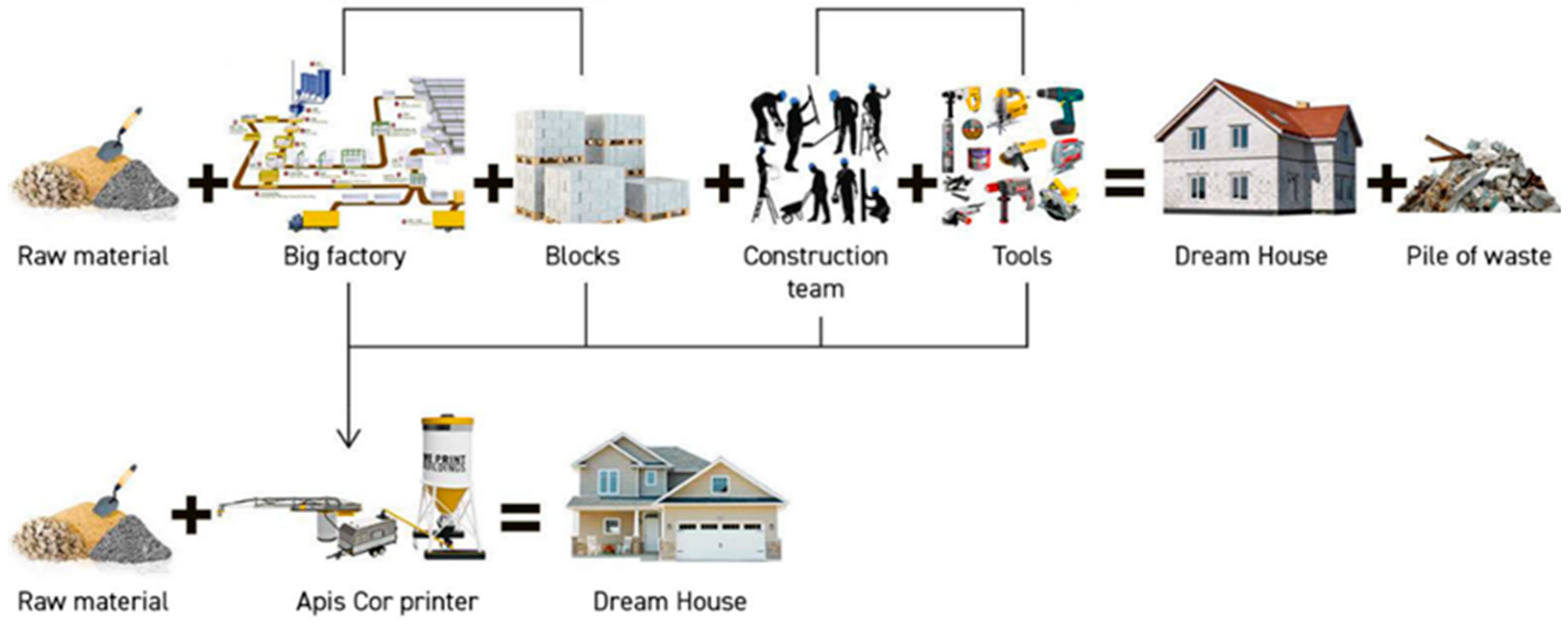

1.1. Design of the Printing Apparatus

1.2. Composition of the Printable Mixture

2. Properties of Printable Mixture

2.1. Fresh Material Properties

- Extrudability refers to the material’s ability to be pumped out smoothly through an extruder without any disruption/clogging in the pipe flow. This parameter is not an intrinsic chemical or physical property of the mixture but rather a specific property of a complex printing process. It depends on the mixture composition, the nozzle geometry, the extruder design, the pumping system, and some process parameters [37]. A deposition without discontinuity or deformation (due to the drainage phenomena of the fresh mixture or obstructions of the nozzle by the concrete solid fraction) implies a good extrudability [33]. The literature highlights that the main methods used to determine the extrusion of printable mixtures allow a qualitative evaluation of this parameter. Generally, three tests can be identified: the ram-extruder method [38], penetration resistance method [39], and vane rheometry [26]. In the ram-extruder approach, the force required to extrude material through a nozzle is a measure of its extrudability. Experimental analysis is supported by mathematical models that take into account different variables related to the deposition process: friction between cement material and the extruder’s inner surface and mixture rheology and mechanical properties of the aggregated [38]. In the Vane test, extrudability is evaluated concerning Bingham parameters and other flow properties. According to these measurements, materials possessing very high (static) yield stress are difficult to extrude and may result in discontinuities during the extrusion process [26];

- Flowability refers to the easy-flowing paste passing through the printing nozzles without discontinuity [29]. The slump test is the experimental procedure mainly used to evaluate the flowability of the mixture, as it provides immediate results and is easy to run. A metallic cone, with well-defined geometric characteristics, is filled with the fresh cement mixture. The magnitude of the height decrease of the paste, after the removal of the cone, allows quantifying the fluidity of the material. A larger slump value corresponds to a greater flowability [33];

- Buildability refers to the ability of the printed concrete layer to hold the layers above other layers without crumbling. This property can be evaluated either by quantifying the number of layers stacked up to the collapse of the structure [33] and by considering the degree of deformation of the stacked layers of cement material as a result of the mass of the new layers of extrudate [40]. One of the variables, related to the printing process, which significantly affects this material parameter is the paste age (or rest time). Paste age is defined as the time that elapses from the mixing phase of the printing material at the beginning of the deposition. This parameter affects the viscous properties of the fresh material and then the adhesion between one layer and the other. Longer paste age promotes an easier transition of material from the fluid state to the plastic state and therefore greater stiffness of each layer. In the condition of optimal buildability, the resulting layered structure will be characterized by a greater number of layers poorly deformed compared to the dimensions of the nozzle. However, by extending the paste age, a worsening of the mechanical integrity of the printed structure occurs. The higher stiffness of extruded filaments reduces the interfacial adhesion among two layers, resulting in the formation of unwanted voids [41];

- Open time refers to studying the change of concrete flowability with time. The aim is to guarantee that each printed layer can to hold itself and stay harden when poured, but then remain fluid enough to bond with the layer above it and not to be turned into a different structure. This parameter can be evaluated by rheological measurements on the mix (by monitoring variations in material viscosity) [27] or by extruding the filament and measuring the time at which it breaks [29]. Open time needs to be set according to two factors: the total printing time and the capabilities of the printing device. Rheological tests allow to monitor how the shear strength of the fresh material varies with the time (using a vane shear apparatus). This property is established when the shear strength reaches values that make the workability of the material worse (related to a difficulty in the printing process) [27].

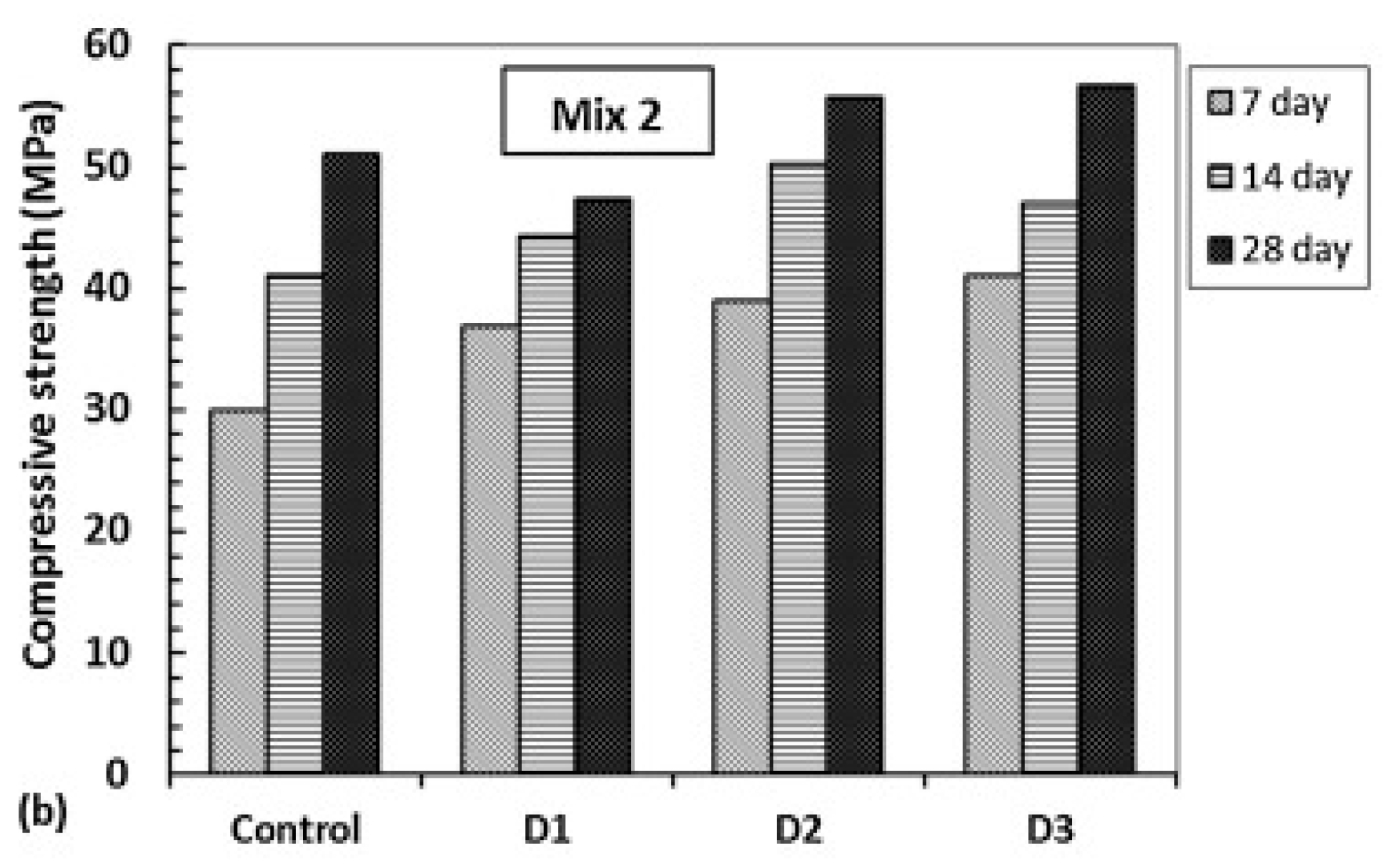

2.2. Hardened Material Properties

2.3. Fundamental Requirements of Printed Applications

3. Pros, Cons, and Future Perspectives of 3D Concrete Printing in Comparison with Traditional Construction

3.1. Pros of Additive Manufacturing in the Construction Sector

- Cost reduction: Additive manufacturing is a construction technology that does not use a conventional formwork. In traditional construction, formwork represents 35–60% of the overall cost of the concrete structure;

- Reduction of environmental pollution: In the course of development, there is no waste or debris which would require expulsion from construction sites and recycling;

- Reducing the quantity of the workforce associated with development and, therefore, reducing the cost of servicing staff (e.g., transportation, cooking, costs for garments), protection, charges, emergency clinics, etc. Moreover, innovation can essentially diminish the expense of the development of structures with one of a kind engineering. Three-dimensional printers are not restricted to rectilinear shapes;

- Reduction in manufacturing time: 3D printer does not require a break for lunch and weekend, it can work without interruption and faster than human labor;

- Improving the quality and unwavering quality of a structure by taking out the human factor: staff insufficiency and development errors. This aspect is also related to the decrease in injuries and fatalities in the workplace;

- Reduction of time and work for the establishment of utilities because printed structures incorporate a space for laying building correspondences, engineering communication, and other equipment;

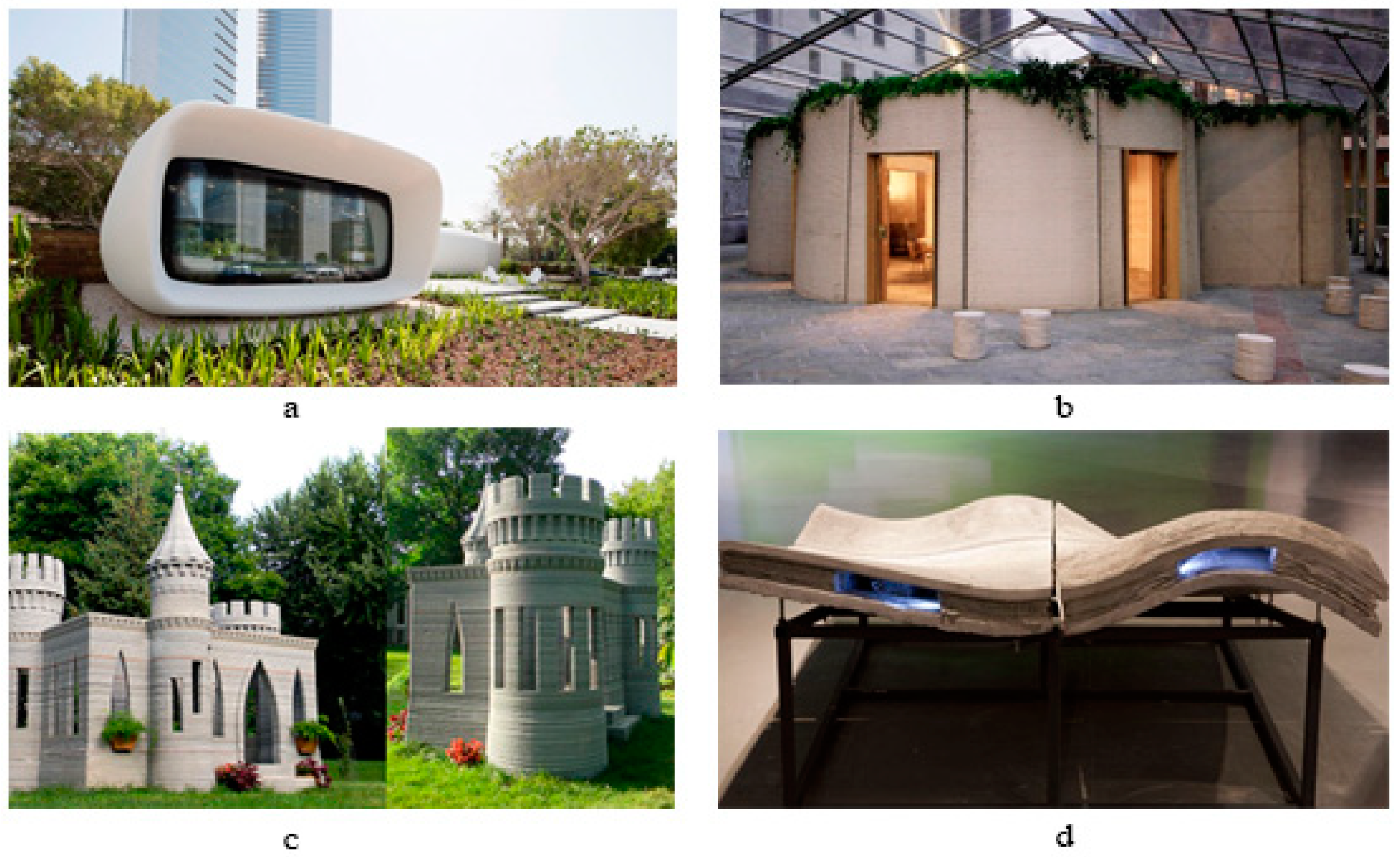

- Architectural freedom: a 3D printer based on 3 degrees of freedom (x, y, z) manufacturing. This feature allows the development of highly complex shapes and geometry (Figure 7). Thanks to this feature, additive manufacturing allows the possibility to realize unconventional building elements (e.g., holes, porous structure, curved structure) with improved engineering and aesthetic properties. While traditional manufacturing is based on the use of formwork or molds as shown in Figure 8. Moreover, this aspect allows the realization of buildings with “standard” shapes with no possibility to work on the morphology of the element.

Case Study: Structural Wall Elements with Functional Properties

3.2. Cons of Additive Manufacturing in the Construction Sector

- Architectural freedom and dimensional tolerance are limited by the size of the printing frame;

- In the most sophisticated dual extruder systems (i.e., using a support material to create overhangs and other freeform features [49]), there is less efficiency, cost-effectiveness, and flexibility in the process. The additional deposition system requires more maintenance, cleaning, and control instructions.

Case Study: Certification of the Structural Integrity of a Bridge Made by Additive Manufacturing

- (1)

- Printable material testing;

- (2)

- Structural tests on a scale model (1:2) of the bridge;

- (3)

- Structural tests at the site on the actual bridge.

3.3. Future Perspectives of Additive Manufacturing in the Construction Sector

3.3.1. Topological Optimization

3.3.2. Technology Improvement

3.3.3. Development of New Printable Materials

4. Architectural Projects Done by 3D Concrete Printing

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nematollahi, B.; Xia, M.; Sanjayan, J. Current Progress of 3D Concrete Printing Technologies. In Proceedings of the 34th International Symposium on Automation and Robotics in Construction (ISARC), Taipei, Taiwan, 28 June–1 July 2017. [Google Scholar] [CrossRef]

- Kreiger, M.A.; MacAllister, B.A.; Wilhoit, J.M.; Case, M.P. The Current State of 3D Printing for Use in Construction. In Proceedings of the Conference on Autonomous and Robotic Construction of Infrastructure, Ames, IA, USA, 2–3 June 2015. [Google Scholar]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Gibson, I.; Rosen, D.; Stucker, B. Binder Jetting. In Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Flatt, R. Digital concrete: Opportunities and challenges. RILEM Tech. Lett. 2016, 1, 67–75. [Google Scholar] [CrossRef]

- All3dp. Available online: https://all3dp.com/2/concrete-3d-printing-how-to-do-it-and-application (accessed on 1 May 2019).

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Construction-3d. Available online: https://www.constructions-3d.com/ (accessed on 1 June 2019).

- Iconbuild. Available online: https://www.iconbuild.com/updates/introducing-the-vulcan-ii-printer (accessed on 1 June 2019).

- Designboom. Available online: https://www.designboom.com/architecture/dus-architects-kamermaker-3d-printer-pavilion/ (accessed on 1 June 2019).

- 3dWasp. Available online: https://www.3dwasp.com/ (accessed on 1 June 2019).

- Qz. Available online: https://qz.com/924909/apis-cor-can-3d-print-and-entire-house-in-just-one-day/ (accessed on 1 May 2019).

- Xia, M.; Sanjayan, J. Method of formulating geopolymer for 3D printing for construction applications. Mater. Des. 2016, 110, 382–390. [Google Scholar] [CrossRef]

- Hwang, D.; Khoshnevis, B. Concrete Wall Fabrication by Contour Crafting. In Proceedings of the 21st International Symposium on Automation and Robotics in Construction, Jeju, Korea, 21–25 September 2004. [Google Scholar] [CrossRef]

- Apis Cor Robotics in Construction. Available online: http://apis-cor.com/en/faq/texnicheskie-xarakteristiki-3d-printer (accessed on 1 May 2019).

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Hwang, D.; Yao, K.T.; Yeh, Z. Mega-scale fabrication by Contour Crafting. Int. J. Ind. Syst. Eng. 2006, 1, 301. [Google Scholar] [CrossRef]

- Shakor, P.; Nejadi, S.; Paul, G.; Malek, S. Review of emerging additive manufacturing technologies in 3d printing of cementitious materials in the construction industry. Front. Built Environ. 2019, 4, 85. [Google Scholar] [CrossRef]

- Lojanica, V.; Colic-Damjanovic, V.M.; Jankovic, N. Housing of the future: Housing design of the fourth industrial revolution. In Proceedings of the 2018 5th International Symposium on Environment-Friendly Energies and Applications (EFEA), Rome, Italy, 24–26 September 2018. [Google Scholar] [CrossRef]

- 3dWasp. Available online: https://www.3dwasp.com/en/giant-3d-printer-bigdelta-wasp-12mt/ (accessed on 1 July 2019).

- 3dWasp. Available online: https://www.3dwasp.com/en/3d-printer-house-crane-wasp/ (accessed on 1 July 2019).

- Dezeen. Available online: https://www.dezeen.com/2019/02/27/gaia-wasp-3d-printed-house-biodegradable-video/ (accessed on 1 June 2019).

- Blog.fazedores. Available online: https://blog.fazedores.com/vulcon-ii-a-nova-impressora-3d-da-icon-que-promete-revolucionar-o-mercado-da-construcao-civil (accessed on 1 June 2019).

- Lessbydesign. Available online: https://lessbydesign.org/2014/11/07/is-technology-getting-in-the-way-of-good-design (accessed on 1 June 2019).

- Book: Materials Science, Wikipedia Website. Available online: https://en.wikibooks.org/wiki/Materials_Science/Materials/Concrete (accessed on 1 May 2019).

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Malaeb, Z.; Hachem, H.; Tourbah, A.; Maalouf, T.; El Zarwi, N.; Hamzeh, F. 3D concrete printing: Machine and mix design. Int. J. Civ. Eng. Technol. 2015, 6, 14–22. [Google Scholar]

- Hambach, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. Cem. Concr. Compos. 2017, 79, 62–70. [Google Scholar] [CrossRef]

- Pellegrino, C.; Faleschini, F. Experimental behavior of reinforced concrete beams with electric arc furnace slag as recycled aggregate. ACI Mater. J. 2013, 110, 197–206. [Google Scholar]

- Rael, R.; San Fratello, V. Developing Concrete Polymer Building Components for 3D Printing. In Integration Through Computation, Proceedings of the 31st Annual Conference of the Association for Computer Aided Design in Architecture, ACADIA 2011, San Francisco, CA, USA, 13–16 October 2011; ACADIA: Fargo, ND, USA, 2011. [Google Scholar]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Valente, M.; Sibai, A. Rubber/crete: Mechanical properties of scrap to reuse tire-derived rubber in concrete; A review. J. Appl. Biomater. Funct. Mater. 2019, 17, 1–8. [Google Scholar] [CrossRef]

- Franchin, G.; Scanferla, P.; Zeffiro, L.; Elsayed, H.; Baliello, A.; Giacomello, G.; Colombo, P. Direct ink writing of geopolymeric inks. J. Eur. Ceram. Soc. 2017, 37, 2481–2489. [Google Scholar] [CrossRef]

- ApisCor. Available online: http://apis-cor.com available 15.04.2018 (accessed on 1 May 2019).

- Nerella, V.N.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos. 2019, 95, 260–270. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques. Mater. Struct. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Chen, Y.; Struble, L.J.; Paulino, G.H. Extrudability of cement-based materials. Am. Ceram. Soc. Bull. 2006, 85, X1–X5. [Google Scholar]

- Valkenaers, H.; Jansen, D.; Voet, A.; Van Gysel, A.; Ferraris, E. Additive manufacturing for concrete: A 3D printing principle. In Proceedings of the 14th International Conference of the European Society for Precision Engineering and Nanotechnology, EUSPEN 2014, Dubrovnik, Croatia, 2–6 June 2014. [Google Scholar]

- Li, Z.; Wang, L.; Ma, G. Method for the Enhancement of Buildability and Bending Resistance of 3D Printable Tailing Mortar. Int. J. Concr. Struct. Mater. 2018, 12, 37–48. [Google Scholar] [CrossRef]

- Edilportale. Available online: https://www.edilportale.com/prodotti/faresin-formwork/cassaforma-e-sistema-di-casseratura-per- cls/modulo-2700-s120_49911.html (accessed on 1 May 2019).

- Flickr. Available online: https://www.flickr.com/photos/eastlothian/540650616 (accessed on 1 June 2019).

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—a new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef]

- García de Soto, B.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Yossef, M.; Chen, A. Applicability and Limitations of 3D Printing for Civil Structures. In Proceedings of the Conference on Autonomous and Robotic Construction of Infrastructure, Ames, IA, USA, 2–3 June 2015. [Google Scholar]

- Lim, S.; Buswell, R.; Le, T.; Wackrow, R.; Austin, S.; Gibb, A.; Thorpe, T. Development of a Viable Concrete Printing Process. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction (ISARC 2011), Seoul, Korea, 29 June–2 July 2011. [Google Scholar] [CrossRef]

- Nerella, V.N.; Krause, M.; Näther, M.; Mechtcherine, V. Studying printability of fresh concrete for formwork free Concrete on-site 3D Printing technology technology (CONPrint3D). In Proceedings of the 25th Conference on Rheology of Building Materials, Regensburg, Germany, 2–3 March 2016. [Google Scholar]

- Salet, T.A.M.; Ahmed, Z.Y.; Bos, F.P.; Laagland, H.L.M. Design of a 3D printed concrete bridge by testing*. Virtual Phys. Prototyp. 2018, 13, 222–236. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- 3DToday. Available online: https://3d-today.blogspot.com/2017/10/3d-printed-bicycle-bridge.html (accessed on 1 July 2019).

- Ma, G.W.; Wang, L.; Ju, Y. State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Sci. China Technol. Sci. 2018, 61, 475–495. [Google Scholar] [CrossRef]

- Panda, B.; Chandra Paul, S.; Jen Tan, M. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Hameed, M.S.; Sekar, A.S.S. Properties of green concrete containing quarry rock dust and marble sludge powder as fine aggregate. J. Eng. Appl. Sci. 2009, 4, 83–89. [Google Scholar]

- Briga-Sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Raut, S.P.; Ralegaonkar, R.V.; Mandavgane, S.A. Development of sustainable construction material using industrial and agricultural solid waste: A review of waste-create bricks. Constr. Build. Mater. 2011, 25, 4037–4042. [Google Scholar] [CrossRef]

- Aaltodoc. Available online: https://aaltodoc.aalto.fi/bitstream/handle/123456789/34224/master_Nadarajah_Nithesh_2018.pdf?sequence=1&isAllowed=y (accessed on 1 July 2019).

- Eraallstar Properties, Apis Cor Is the First Company to Develop a Specialized Equipment for 3D Printing in Construction Which Is Capable of Printing Whole Buildings Completely. Available online: https://www.apis-cor.com/en/3d-printer, 3d-printing perspectives and challenges (accessed on 1 May 2019).

- Officeofthefuture. Available online: http://www.officeofthefuture.ae/#&gid=1&pid=1 (accessed on 1 May 2019).

- Arup. Available online: https://www.arup.com/news-and-events/new-3d-printed-house-points-the-way-to-a-more-sustainable-construction-industry (accessed on 1 May 2019).

- Totalkustom. Available online: http://www.totalkustom.com/3d-castle-completed.html (accessed on 1 May 2019).

- NewAtlas. Available online: https://newatlas.com/foster-partners-skanska-3d-concrete-printing/34944 (accessed on 1 May 2019).

| 3D printer | Type | Material | Country | Informational Reference |

|---|---|---|---|---|

| Constructions 3D | Robotic arm | Concrete/Earth materials | France | [8] |

| ICON Vulcan II | Gantry system | Concrete | USA | [9] |

| Kamer Maker | Robotic arm | Recycled/Bio-based | Netherlands | [10] |

| WASP Crane | Delta system | Concrete/Earth materials | Italy | [11] |

| Apis Cor | Robotic arm | Concrete | Russia | [12] |

| SC3DP Mobile robot | Robotic arm | Mortar/Geopolymer cement | Singapore | [13] |

| Contour Crafting | Gantry system | Concrete | USA | [14] |

| Construction Method | Labor | Material | Equipment | Total Cost |

|---|---|---|---|---|

| Curved Wall/Traditional | 1,071,466 € | 3,697,863 € | 136,210 € | 4,905,539 € |

| Curved Wall/Additive Manufacturing | 1,077,926 € | 721,698 € | 287,764 € | 2,087,388 € |

| Construction Method | Labor | Material | Equipment | Total Cost |

|---|---|---|---|---|

| Straight Wall/Traditional | 355,657 € | 149,815 € | 135,047 € | 640,518 € |

| Straight Wall/Additive Manufacturing | 9859 € | 694,631 € | 284,951 € | 1,965,482 € |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valente, M.; Sibai, A.; Sambucci, M. Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry. J. Compos. Sci. 2019, 3, 88. https://doi.org/10.3390/jcs3030088

Valente M, Sibai A, Sambucci M. Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry. Journal of Composites Science. 2019; 3(3):88. https://doi.org/10.3390/jcs3030088

Chicago/Turabian StyleValente, Marco, Abbas Sibai, and Matteo Sambucci. 2019. "Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry" Journal of Composites Science 3, no. 3: 88. https://doi.org/10.3390/jcs3030088

APA StyleValente, M., Sibai, A., & Sambucci, M. (2019). Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry. Journal of Composites Science, 3(3), 88. https://doi.org/10.3390/jcs3030088