Sandwich Panels Bond with Advanced Adhesive Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Adhesive Film and Bonding Technique

- The film must be placed on the honeycomb without any restraint, just simply place on it.

- The film must be biaxially stretched in order to get a well distribution by the polymer molecules.

- The film must have a suitable slit pattern considering the honeycomb structure in order to adapt to it.

- Adhesive unwinder;

- Tabletop laminator with temperature control;

- Automatic adjustable pressure system after passing the heating zone;

- Cooling zone in order to obtain smooth surfaces;

- Separated heating and cooling zones in the same machine;

- Seamless polyamide conveyor belts for bidirectional transport; and

- Industrial computer to control the entire production line.

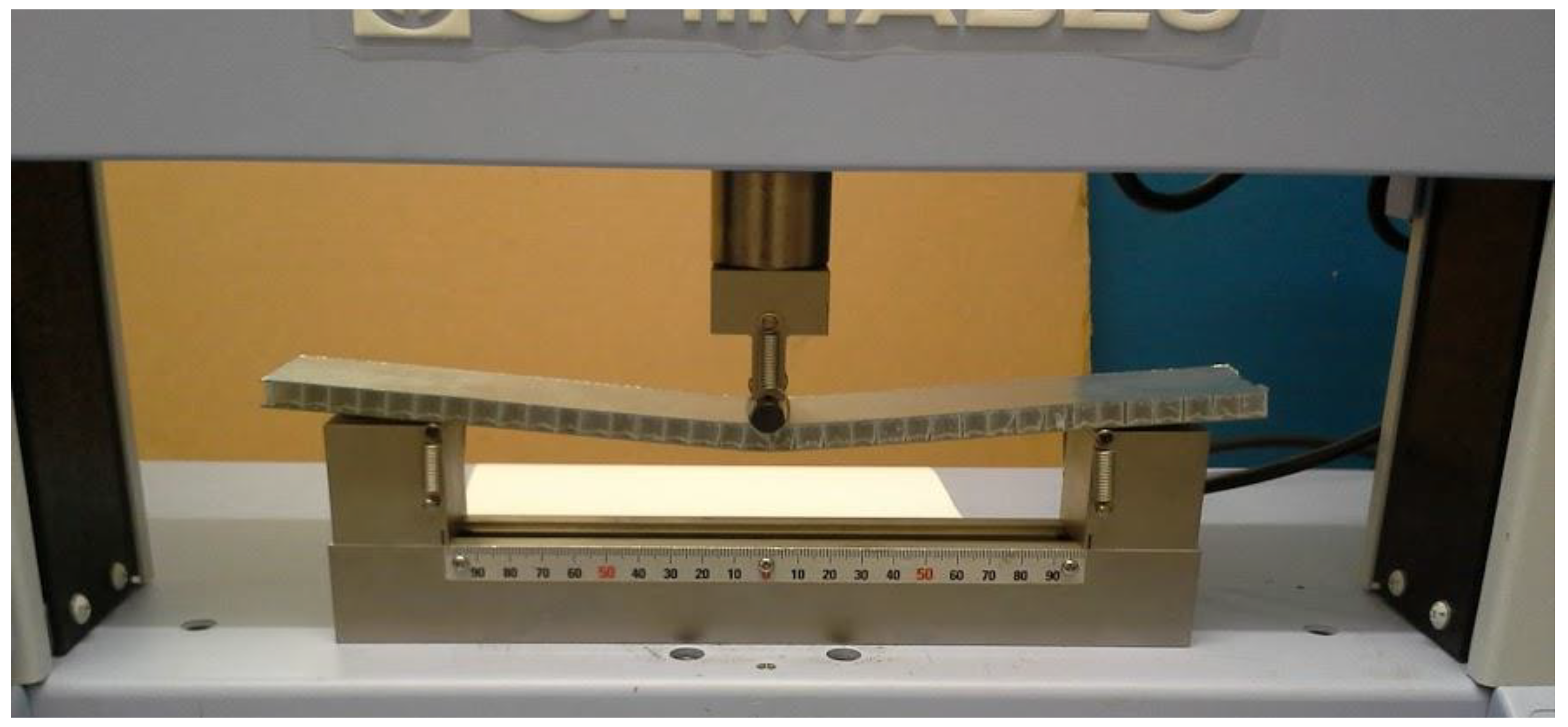

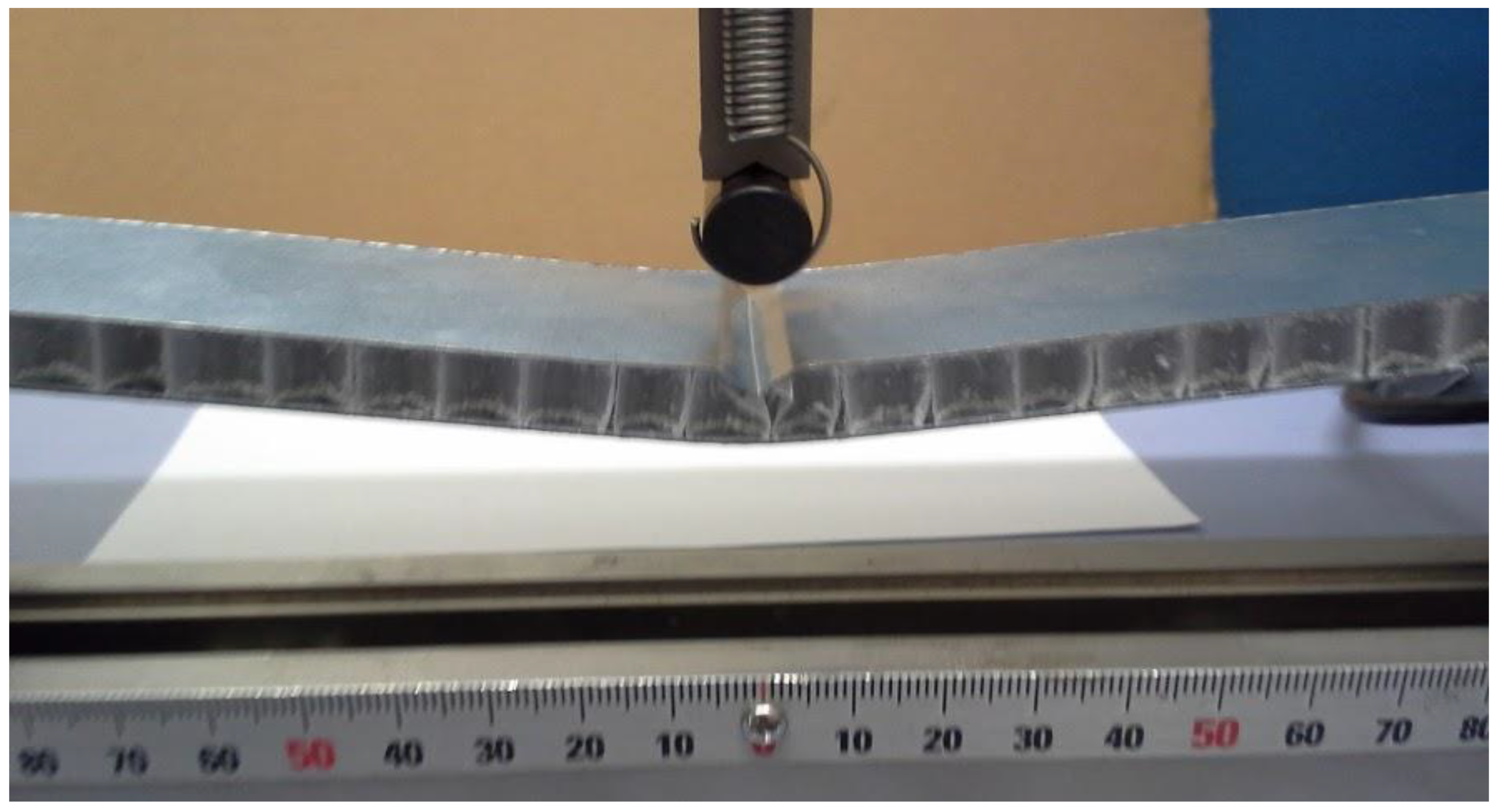

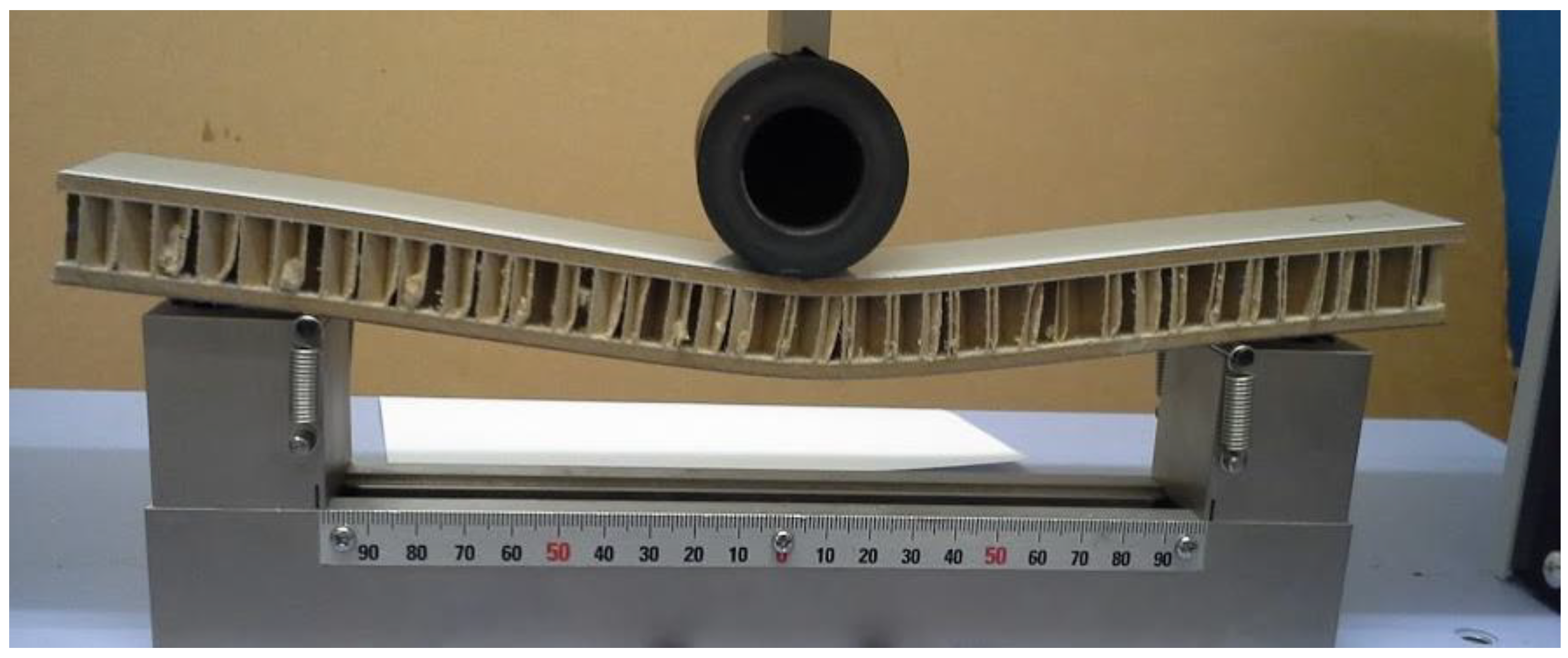

2.2. Bending Tests

3. Results

3.1. Sandwich 1—PP Honeycomb Core Panels with Advanced Adhesive Film

3.2. Sandwich 2—Cardboard Honeycomb Core Panels Reinforced with MDF

3.3. Summary

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lindström, A.; Hallström, S. In-plane Compression of Sandwich Panels with Debonds. Compos. Struct. 2010, 92, 532–540. [Google Scholar] [CrossRef]

- Hami, B.; Irekti, A.; Aribi, C.; Bezzazi, B.; Mir, A. Experimental Study of Sandwich Multilayer Reinforced by Glass Fibre and Agglomerated Cork. Adv. Compos. Lett. 2014, 23, 121–125. [Google Scholar] [CrossRef]

- Mohareb, A.S.O.; Hassanin, A.H.; Badr, A.A.; Hassan, K.T.S.; Farag, R. Novel Composite Sandwich Structure from Green Materials: Mechanical, Physical, and Biological Evaluation. J. Appl. Polym. Sci. 2015, 132, 42253. [Google Scholar] [CrossRef]

- Bader, S. Composites Handbook; Scott Bader Company Limited: Wollaston, England, 2002; pp. 1–90. [Google Scholar]

- Kandola, B.K.; Ebdon, J.R.; Zhou, C. Development of Vinyl Ester Resins with Improved Flame Retardant Properties for Structural Marine Applications. React. Funct. Polym. 2018, 129, 111–122. [Google Scholar] [CrossRef]

- Fernandes, F.A.O.; Tavares, J.P.; Alves de Sousa, R.J.; Pereira, A.B.; Esteves, J.L. Manufacturing and Testing Composites Based on Natural Materials. Procedia Manuf. 2017, 13, 227–234. [Google Scholar] [CrossRef]

- Kandola, B.K.; Krishnan, L.; Deli, D.; Luangtriratana, P.; Ebdon, J.R. Fire and Mechanical Properties of a Novel Free-Radically Cured Phenolic Resin Based on a Methacrylate—Functional Novolac and of its Blends with an Unsaturated Polyester Resin. RSC Adv. 2015, 5, 33772–33785. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Ferrante, L.; Sergi, C.; Russo, P.; Simeoli, G.; Cimino, F.; Ricciardi, M.R.; Antonucci, V. Quasi-Static and Low-Velocity Impact Behavior of Intraply Hybrid Flax/Basalt Composites. Fibers 2019, 7, 26. [Google Scholar] [CrossRef]

- Herráez, M.; Fernández, A.; Lopes, C.S.; González, C. Strength and Toughness of Structural Fibres for Composite Material Reinforcement. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150274. [Google Scholar] [CrossRef]

- Li, H.; Wang, Z.; Yu, Z.; Sun, M.; Liu, Y. The Low Velocity Impact Response of Foam Core Sandwich Panels with a Shape Memory Alloy Hybrid Face-Sheet. Materials 2018, 11, 2076. [Google Scholar] [CrossRef]

- Kaczyński, P.; Ptak, M.; Fernandes, F.A.O.; Chybowski, L.; Wilhelm, J.; Alves de Sousa, R.J. Development and Testing of Advanced Cork Composite Sandwiches for Energy-Absorbing Structures. Materials 2019, 12, 697. [Google Scholar] [CrossRef]

- Kazemahvazi, S.; Kiele, J.; Russel, B.; Deshpande, V.; Zenkert, D. Impact Properties of Corrugated Composite Sandwich Cores. In Proceedings of the 9th International Conference on Sandwich Structures. Caltech University, Pasadena, CA, USA, 14–16 June 2010. [Google Scholar]

- Zhang, Y.C.; Zhang, S.L.; Wang, Z.L. Crush Behavior of Corrugated Cores Sandwich Panels. Adv. Mater. Res. 2011, 217–218, 1584–1589. [Google Scholar] [CrossRef]

- Russell, B.P.; Malcom, A.; Wadley, H.N.G.; Deshpande, V.S. Dynamic Compressive Response of Composite Corrugated Cores. J. Mech. Mater. Struct. 2010, 5, 477–493. [Google Scholar] [CrossRef]

- Ptak, M.; Kaczyński, P.; Fernandes, F.; De Sousa, R.A. Computer Simulations for Head Injuries Verification after Impact. In Lecture Notes in Mechanical Engineering; Springer: Berlin, Germany, 2017; pp. 431–440. [Google Scholar]

- Ptak, M.; Wilhelm, J.; Sawicki, M. Safety Analysis of Children Transported on Bicycle-Mounted Seat During Traffic Accidents. Int. J. Crashworthiness. 2019, in press. [Google Scholar] [CrossRef]

- Fernandes, F.A.O.; Alves de Sousa, R.; Ptak, M.; Migueis, G. Helmet Design Based on the Optimization of Biocomposite Energy-Absorbing Liners under Multi-Impact Loading. Appl. Sci. 2019, 9, 735. [Google Scholar] [CrossRef]

- Saseendran, V.; Berggreen, C. Mixed-Mode Fracture Evaluation of Aerospace Grade Honeycomb Core Sandwich Specimens using the Double Cantilever Beam–Uneven Bending Moment Test Method. J. Sandwich Struct. Mater. 2018, in press. [Google Scholar] [CrossRef]

- Shi, S.; Chen, B.; Sun, Z. Equivalent Properties of Composite Sandwich Panels with Honeycomb–Grid Hybrid Core. J. Sandwich Struct. Mater. 2018, in press. [Google Scholar] [CrossRef]

- Jayaram, R.; Nagarajan, V.; Kumar, K.V. Compression and Low Velocity Impact Response of Sandwich Panels with Polyester Pin-Reinforced Foam Filled Honeycomb Core. J. Sandwich Struct. Mater. 2018, in press. [Google Scholar] [CrossRef]

- Odessa, I.; Frostig, Y.; Rabinovitch, O. Modeling of Interfacial Debonding Propagation in Sandwich Panels. Int. J. Solids Struct. 2018, 148–149, 67–78. [Google Scholar] [CrossRef]

- Li, H.; Zhou, Z. Detection and Characterization of Debonding Defects in Aeronautical Honeycomb Sandwich Composites Using Noncontact Air-Coupled Ultrasonic Testing Technique. Appl. Sci. 2019, 9, 283. [Google Scholar] [CrossRef]

- Funari, M.F.; Greco, F.; Lonetti, P. Sandwich Panels under Interfacial Debonding Mechanisms. Compos. Struct. 2018, 203, 310–320. [Google Scholar] [CrossRef]

- Lee, L.H. Adhesive Bonding. In Handbook of Plastics Joining, 2nd ed.; William Andrew: Norwich, UK, 2009; pp. 145–173. [Google Scholar]

- Davis, M.; Bond, D. Principles and Practices of Adhesive Bonded Structural Joints and Repairs. Int. J. Adhes. Adhes. 1999, 19, 91–105. [Google Scholar] [CrossRef]

- Ebnesajjad, S. Adhesive Applications and Bonding Processes. In Adhesives Technology Handbook, 2nd ed.; William Andrew: Norwich, UK, 2009; pp. 183–208. [Google Scholar]

- Gomes, G.M.F. Characterization and Optimization of the Production Process of Sandwich Composite Structures; Universidade de Lisboa: Lisbon, Portugal, 2016. [Google Scholar]

- Hussain, M.I.; Zain, Z.M.; Ying, C.J.; Sin, T.C. Effect of Humidity on Physical Properties of Prepreg and Adhesive Film of Composite Material Manufacturing. In Proceedings of the Sixth International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 8–10 March 2016. [Google Scholar]

- Bishopp, J. Adhesives for Aerospace Structures. In Handbook of Adhesives and Surface Preparation; William Andrew: Norwich, UK, 2011; pp. 301–344. [Google Scholar]

- Rider, A.N.; Arnott, D.R.; Mazza, J.J. Surface Treatment and Repair Bonding. In Aircraft Sustainment and Repair; Butterworth-Heinemann: Oxford, UK, 2018; pp. 253–323. [Google Scholar]

- Funari, M.; Greco, F.; Lonetti, P.; Spadea, S. A Numerical Model Based on ALE Formulation to Predict Crack Propagation in Sandwich Structures. Frat. ed Integrità Strutt. 2019, 47, 277–293. [Google Scholar] [CrossRef]

- Funari, M.F.; Greco, F.; Lonetti, P.; Luciano, R.; Penna, R. An Interface Approach Based on Moving Mesh and Cohesive Modeling in Z-Pinned Composite Laminates. Compos. Part B Eng. 2018, 135, 207–217. [Google Scholar] [CrossRef]

- Jud, K. Adhesive Films for the Production of Aluminium Honeycomb Panels; Collano Adhesives AG: Sempach Station, Switzerland, 2012. [Google Scholar]

- ASTM C393/C393M-16. Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

| Layer | Sandwich 1 | Sandwich 2 |

|---|---|---|

| 1 | Ceramic sheet | Ceramic sheet |

| 2 | Adhesive film | Paper glue |

| 3 | PP honeycomb | MDF reinforcement |

| 4 | Adhesive film | Paper glue |

| 5 | Galvanized sheet | Cardboard honeycomb |

| 6 | Paper glue | |

| 7 | MDF reinforcement | |

| 8 | Paper glue | |

| 9 | Galvanized sheet |

| Density (g/mL) | Shear Modulus (MPa) | Modulus of Elasticity (MPa) | Yield Stress (MPa) | Tensile Strength (MPa) | Ultimate Strain (%) |

|---|---|---|---|---|---|

| 0.9 | 60 | 115 | 3.8 | 14.1 | 1430 |

| Pressing Time (min) | Pressure (kPa) | Temperature (°C) |

|---|---|---|

| 3 | < 100 | 155 |

| Sandwich | Flexibility (mm/N) | Stiffness (N/mm) |

|---|---|---|

| 1 | 0.02 | 50 |

| 2 | 0.007 | 150 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, A.B.; Fernandes, F.A.O. Sandwich Panels Bond with Advanced Adhesive Films. J. Compos. Sci. 2019, 3, 79. https://doi.org/10.3390/jcs3030079

Pereira AB, Fernandes FAO. Sandwich Panels Bond with Advanced Adhesive Films. Journal of Composites Science. 2019; 3(3):79. https://doi.org/10.3390/jcs3030079

Chicago/Turabian StylePereira, António Bastos, and Fábio A.O. Fernandes. 2019. "Sandwich Panels Bond with Advanced Adhesive Films" Journal of Composites Science 3, no. 3: 79. https://doi.org/10.3390/jcs3030079

APA StylePereira, A. B., & Fernandes, F. A. O. (2019). Sandwich Panels Bond with Advanced Adhesive Films. Journal of Composites Science, 3(3), 79. https://doi.org/10.3390/jcs3030079