1. Introduction

In a global perspective, the growth verified in the usage of composite materials may be attributed mainly to the transportation and construction industries, although in other areas such as medical and health technologies they are becoming more relevant. Within the manufacturing processes, some are witnessing a higher development; namely, resin transfer moulding (RTM) and glass-mat-reinforced thermoplastics (GMT), as well as the long-fibre-reinforced thermoplastics (LFRT) [

1]. According to the composites industry report for 2017 [

2], since 1960 the composites industry has grown 25 times, whereas the aluminium and steel industries grew less than 5 times. These numbers denote an important reality landscape on the increasing use of composite materials, confirming a continuous need for deeper holistic research to enhance the understanding of these kinds of materials [

3].

The need for materials with better mechanical properties has already led to the development of glass fibres—most often used as reinforcement—with a tensile strength 2–3 times higher than the traditional ones for fulfilling specific operation requirements, such as those posed by the blades of wind turbines, bicycle frames, and the diverse automotive and aerospace parts. Simultaneously, lightweight materials have become very attractive as they simultaneously meet regulatory requirements for emission reduction, fuel economy and safety. For instance, in the automotive and aerospace industries, carbon-fibre-reinforced polymers (CFRP) have been the primary beneficiary. However, the cost of carbon fibres still constitutes a disadvantage and these materials are not fully recyclable at the end of their life cycle.

The use of composite materials in the most diverse areas poses different questions depending on the nature of the specific application. Moreover, the great heterogeneity intrinsic in the constitution of these kinds of materials in conjunction with the usual manufacturing processes is deemed to be responsible for the significant variability in the structural responses when compared to those of a structure made of homogeneous traditional materials, such as metals, for instance.

Attempting to consider this uncertainty and to assess its effects using different approaches, several published works can be found. Mesogitis et al. [

4] presented a review about the multiple sources of uncertainty associated with material properties and boundary conditions. In this work, the authors presented numerical and experimental results concerning the statistical characterization and influence of uncertain inputs on the main steps of the manufacturing process of composites, including defects induced by the process itself.

In the context of more focused work, we refer to Noor et al. [

5] who proposed a two-phase approach and a computational procedure for predicting variability in the nonlinear responses of composite structures associated with variations in the geometric and material parameters of the structure. To this aim, the authors considered a hierarchical sensitivity analysis to identify the parameters with greater influence on the responses. After this screening stage, the selected parameters were fuzzified and a fuzzy set analysis was performed to determine the variability of the responses.

The problem of uncertainty propagation in composite laminate structures was studied by António and Hoffbauer [

6]. They considered an approach based on the optimal design of composite structures to achieve a target reliability level. In this work, the uniform design method (UDM) was used to study the space variability using a set of design points generated over a design domain centred on the mean values of the random variables. An artificial neural network (ANN) was developed based on supervised evolutionary learning with the input/output patterns of each UDM design point. This ANN was used to implement a Monte Carlo simulation (MCS) procedure to obtain the variability of the structural responses. The use of ANN was also considered by Teimouri et al. [

7] to investigate the impact of manufacturing uncertainty on the robustness of commonly used ANN in the field of structural health monitoring (SHM) of composite structures, namely concerning the thickness variation in laminate plies. The ANN SHM system was assessed through an aerofoil case study based on the sensitivity of location and size predictions for delamination with noisy data. Mukherjee et al. [

8] studied the influence of material uncertainties in failure strength and reliability analysis for single- and cross-ply laminated composites subjected to only axial loading. These authors have categorized the uncertainty at different scales, although in [

8] they only considered ply level uncertainties. Note that these uncertainties are included as random variables and the strength parameters of the composite are derived through uncertainty propagation considering both Tsai-Wu and maximum stress criteria. MCS was performed to quantify the effect of those uncertain parameters. In [

9], the authors were concerned with the prediction of the uncertainty induced by the manufacturing process on the effective elastic properties of long fibre-reinforced composites with a thermoplastic matrix. Carvalho et al. [

10] studied the uncertainty propagation in functionally graded material (FGM) plates with an approach that can be viewed as the precursor of the present work.

In the present work, the goal was to study the uncertainty propagation of laminate material properties as well as geometric parameters related to the thickness and fibre orientation or stacking angle of each ply. These modelling parameters have specific contributions to the simulated linear static response and, therefore, on the characterization of its variability. To enable the simulation of uncertainty on the modelling or input parameters, a random multivariate normal distribution was used to generate the set of input parameters, ensuring independence. The obtained results intend to enable a more comprehensive understanding of the influence of uncertain modelling parameters on the variability of structural responses.

3. Results and Discussion

The results presented in the present Section are focused on the assessment of the influence of the parameter uncertainty on the maximum transverse displacement

and on the fundamental frequency

of a carbon fibre-reinforced composite plate. Based on the methodology presented in

Section 2.3, the material and geometrical properties were simulated using a sample of 30 observations, as referred. With the sampled modelling parameters, we carried out a set of finite element analysis to build a sample of the maximum transverse displacement and natural frequencies for each of the cases identified in

Section 2.4. The finite element analysis was carried out using nine-node quadrilateral plate finite elements based on the FSDT as described in

Section 2.2. In the linear static analysis, a unitary uniform transverse pressure loading was applied. In all the presented case studies, the plate is simply supported. Note that the reference to a ply number is related to the stacking sequence order illustrated in

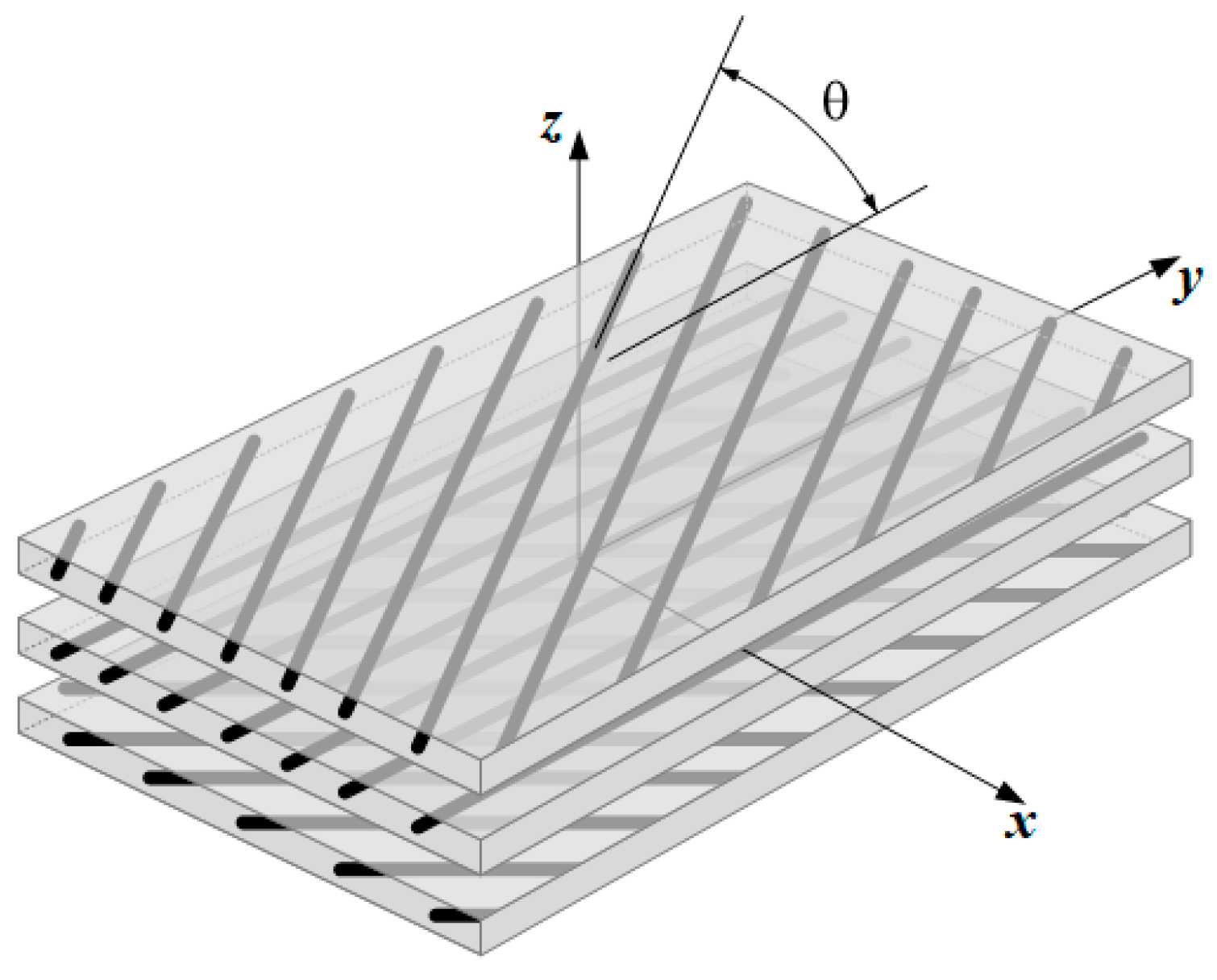

Figure 1, where the first ply is the lower one considering an ascending stacking order. Unless stated otherwise, the aspect ratio (

) of the plates was set to 20.

The results for the different case studies are discussed based on the analysis of the correlation coefficients obtained for different plates and uncertain parameter sets. In the following matrix plots, significance codes were used to ease the results interpretation. Thus, absolute values of correlation coefficients above 0.30 are marked with “*”, above 0.50 with “**” and above 0.75 with “***”.

3.1. Uncertainty in the Material Properties

The first case was focused on characterizing the influence that uncertain material properties may have in the maximum transverse displacement and natural frequencies of the plate. To this purpose, we assumed that the plates were built from a unique unidirectional composite layer with the material properties’ mean values presented in

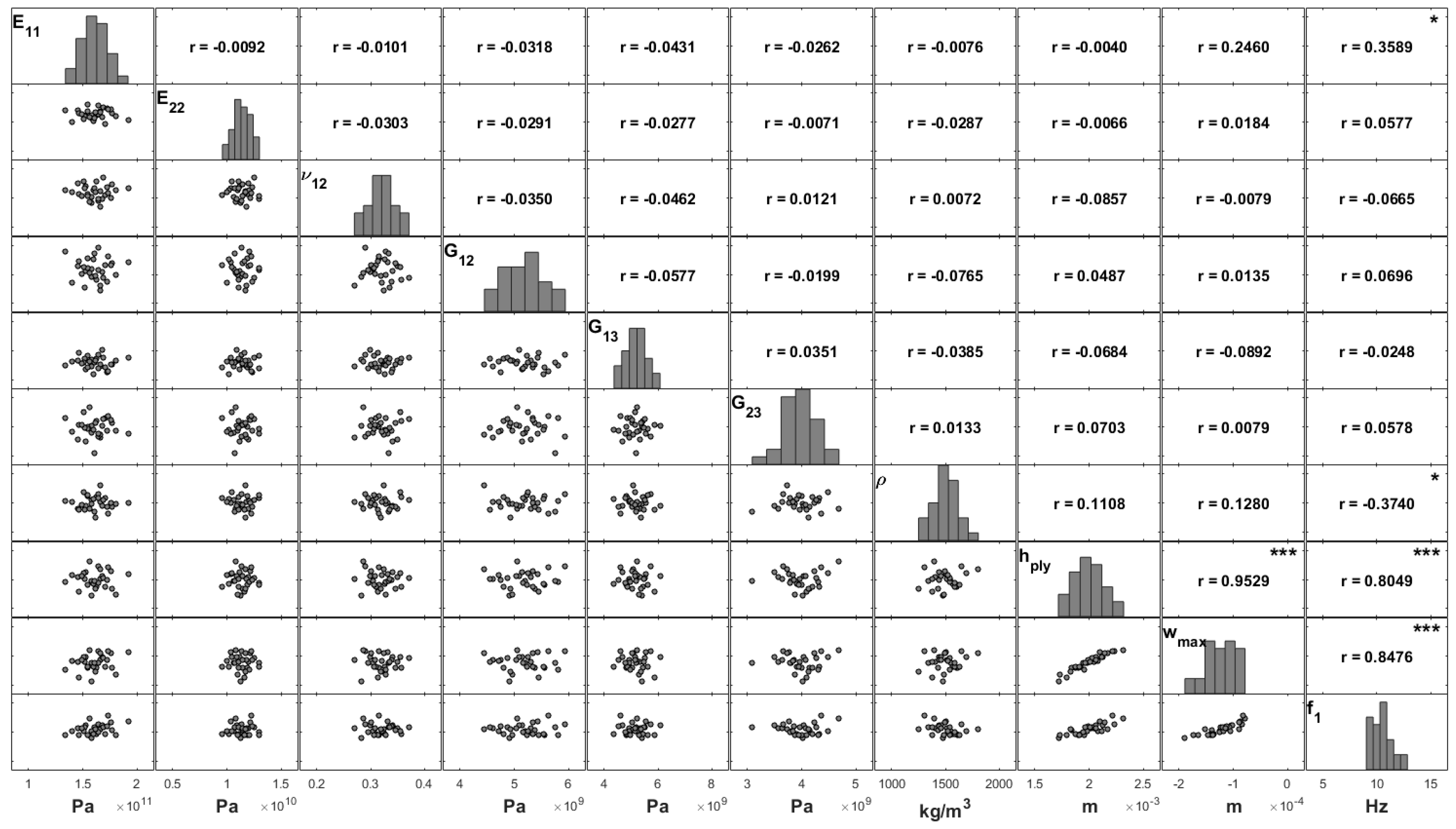

Table 1. In this case study, the stacking angle was assumed to be unaffected by uncertainty, whereas the material properties and the total thickness of the plate, considered as a single layer, were deemed to be uncertain. Hence, if the referred modelling parameters vary, it is possible to compute the scatter plots of both parameters and responses and the respective correlation coefficients, as well as their histograms. These results are organized in the matrix plot of

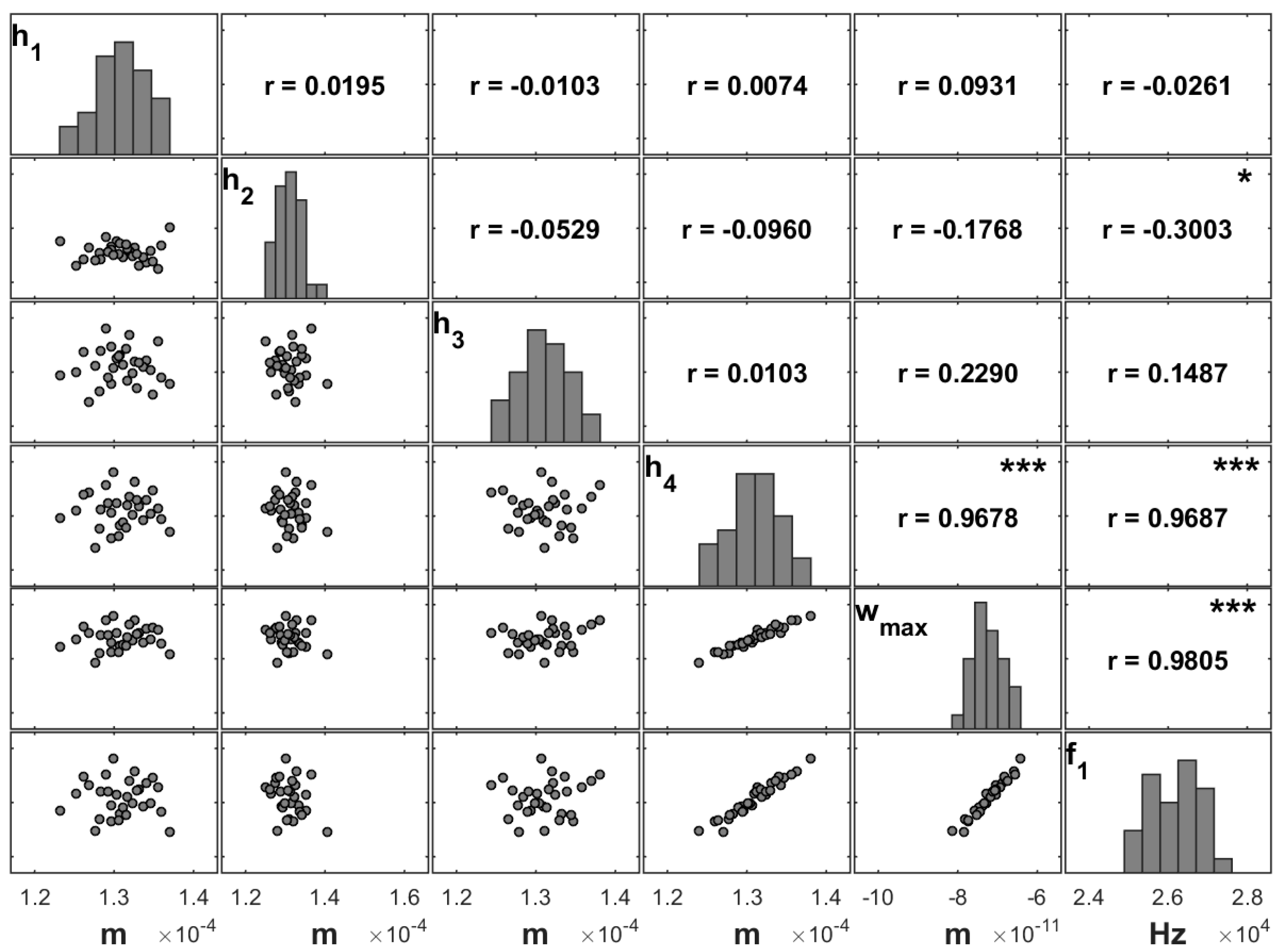

Figure 2.

As a first observation, it is important to conclude on the independence among the modelling parameters, which present a Gaussian pattern with nearly null linear correlation coefficients among each other and consistent scatterplots. This was expected according to the uncertainty simulation described in

Section 2.3.

From the matrix plot of

Figure 2, it is possible to conclude that the responses are highly correlated (0.85), which was an expected result. It is also important to note the influence of the plate thickness, which plays a very significant role here for both responses: the maximum deflection (0.95) and the fundamental frequency (0.80). Although with a lower significance, the fundamental frequency is correlated with the density (−0.37) and with the longitudinal elasticity modulus

(0.36). Besides the plate thickness, only the elasticity modulus is slightly correlated with the maximum deflection with a correlation coefficient of 0.25.

Considering now the static analysis of the unidirectional composite plate where all modelling parameters are uncertain, a set of correlation coefficients between each of the material and geometrical parameters and the maximum transverse displacement, along with the corresponding scatter plots, are presented in

Figure 3. Note that in

Figure 3 the different cases for different sets of uncertain parameters are considered;

all means that all of the modelling parameters are uncertain, as in

Figure 2; all

hply (fix) means that all modelling parameters are uncertain except the ply thickness, which is kept at its nominal value; the cases where a single property is identified means that only that parameter is uncertain and all the others are kept at their nominal values.

Considering the first row of the matrix plot in

Figure 3 where all of the modelling parameters are uncertain, we conclude that all the parameters except the density (1.00) are responsible for explaining, to some extent, the whole variability in the transverse displacement. This was an expected conclusion as in a static analysis situation the self-weight of the plate is discarded; the density parameter does not influence the maximum deflection of the plate.

It is important to note the high influence of the plate thickness, which presents a high correlation value (0.96) to the maximum deflection. As seen in

Figure 2, the longitudinal elasticity modulus

is the second most significant parameter, although with a correlation coefficient much lower than the one corresponding to the ply thickness. As the ply thickness has the highest influence on the mechanical response of the plate, we proceeded to another study where this modelling parameter was fixed to its nominal value and only the remaining ones could vary. This study aimed to improve the understanding of the relative importance of the other parameters. The results are presented in

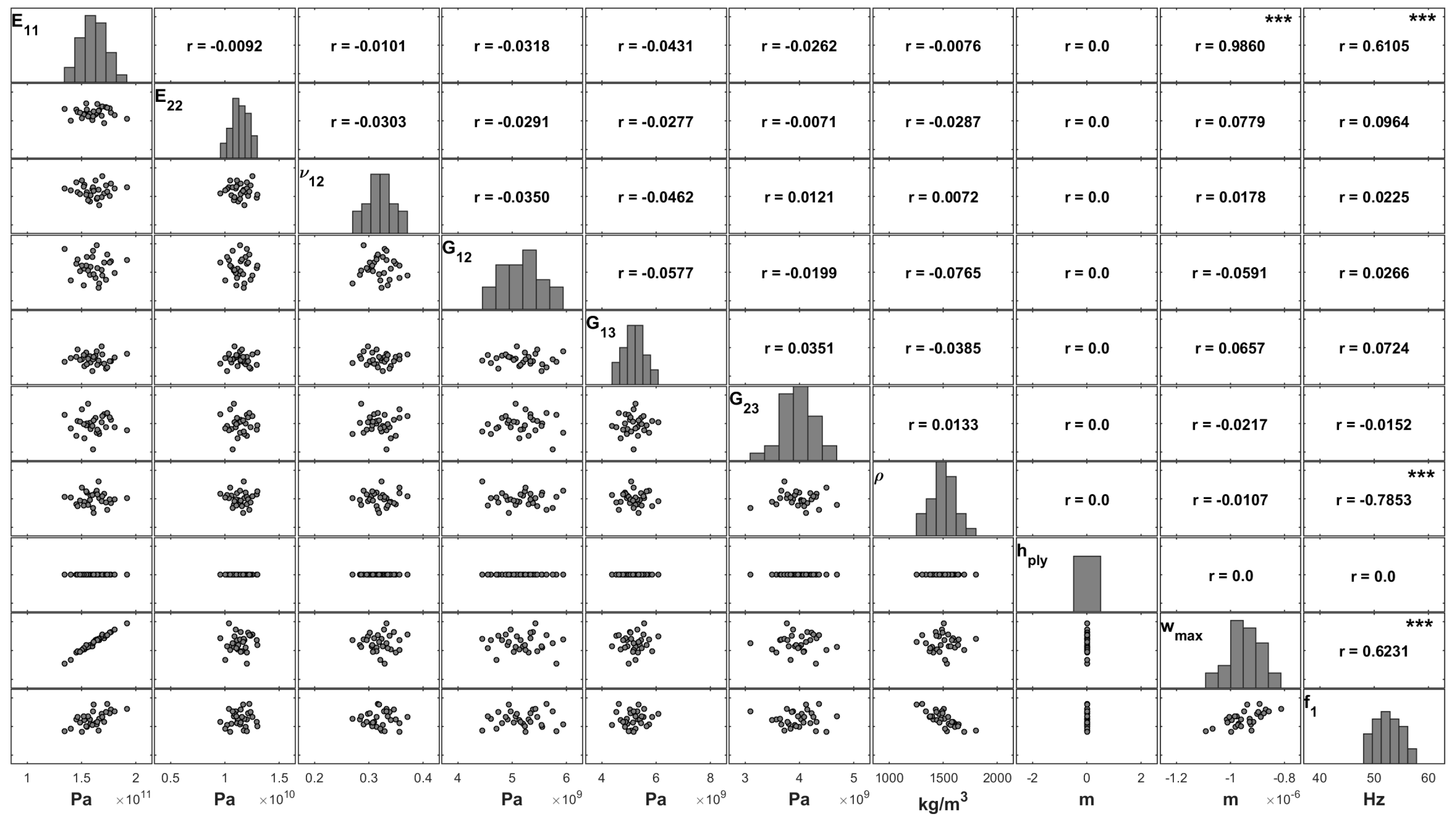

Figure 4.

If the ply thickness is not affected by uncertainty, it is possible to observe in

Figure 4 that in these conditions the longitudinal elasticity modulus

presents a very high correlation (0.99) with a maximum deflection of the plate. It is also a significant parameter concerning the fundamental frequency, although in this case the correlation coefficient between the fundamental frequency and the material density is higher, −0.79 against 0.61. An inverse correlation (minus sign) is observed between the density and the fundamental frequency, as expected.

Another interesting result concerns the correlation between responses. Although they present a significant correlation, this value is not as high as when the thickness was deemed to be uncertain.

3.2. Uncertainty in the Layer Orientation

In this section, we considered that the plate was built from a laminate with four layers, as already mentioned in

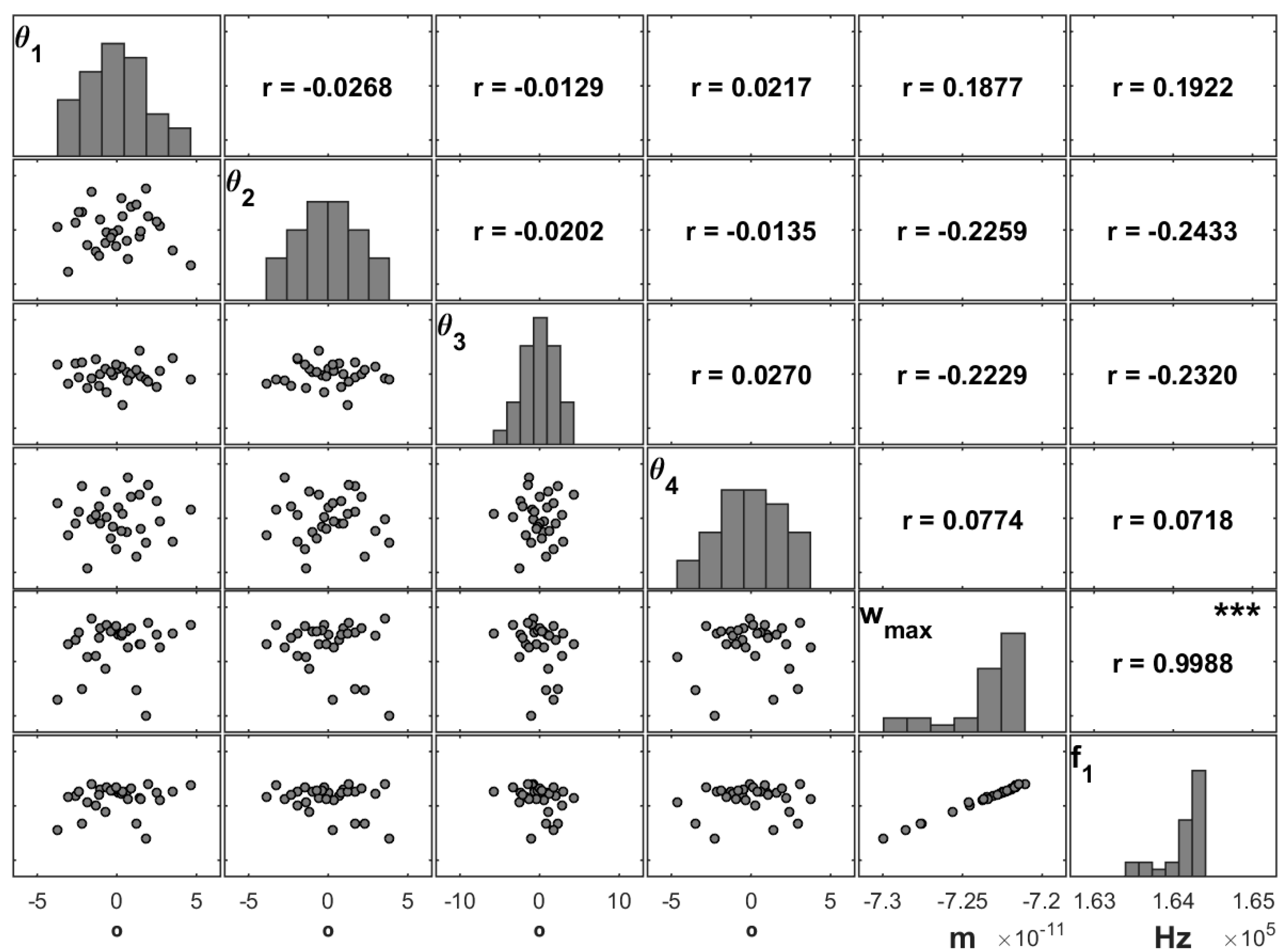

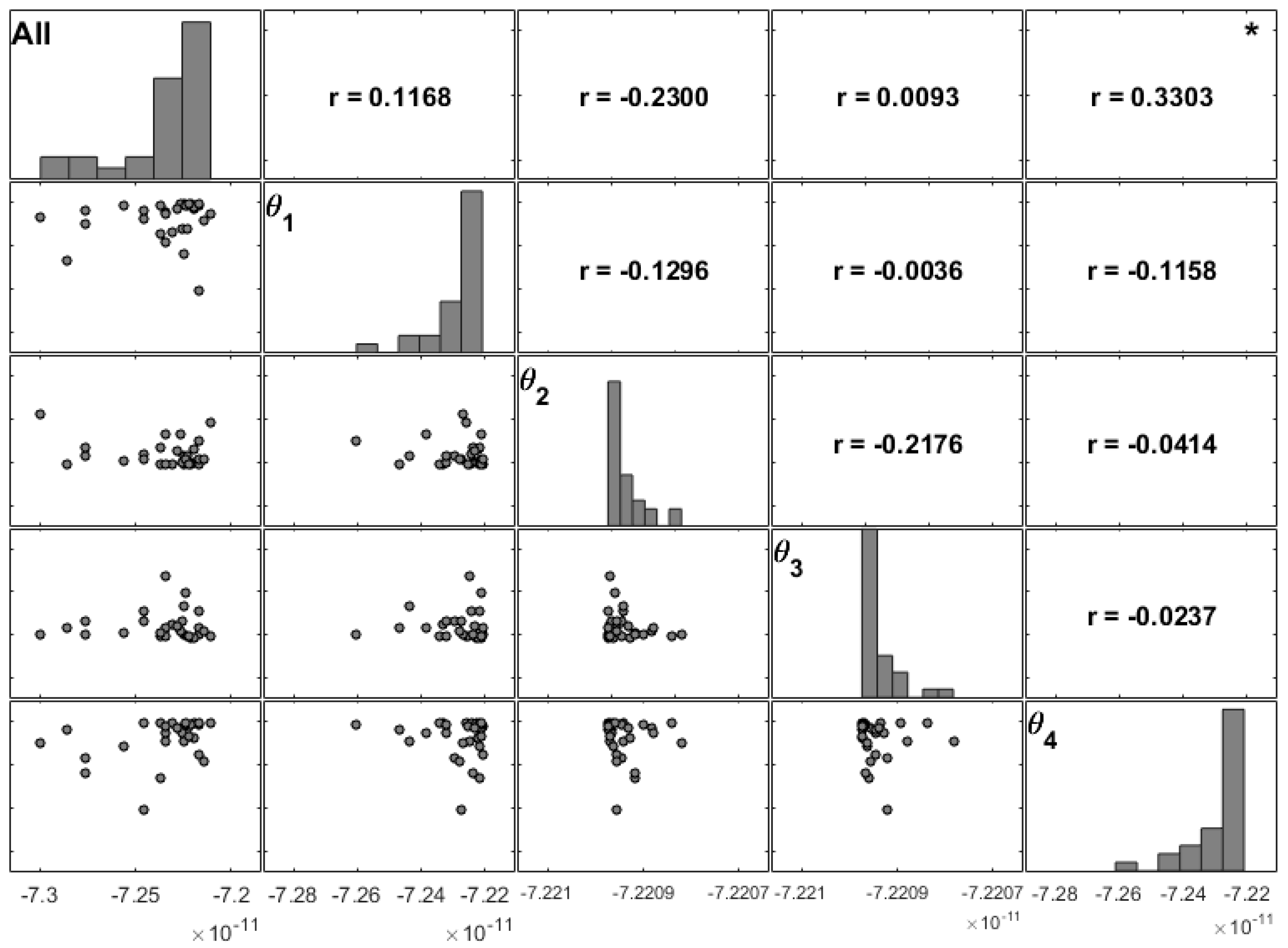

Section 2.4. In the first stage of analysis, we assumed that the stacking angles of each layer are affected by uncertainty. The computed results are presented in

Figure 5, which presents the sampled values for a set of laminated plates modelled according to Case 1.a (

Table 2).

As already mentioned in the previous case study, the individual histograms show a Gaussian behaviour for the stacking angles, which are uncorrelated between themselves as shown by the scatterplots and the corresponding correlation coefficients. It is again relevant that the correlation coefficients related to the modelling parameters are close to zero (

Figure 5), which means that their independence is verified. This is consistent with the uncertainty simulation described in

Section 2.3.

From

Figure 5, we conclude that the stacking angles with higher correlations to the maximum transverse deflection are the first three in the stacking, although there is not a significant predominance from a statistical point of view. It is also visible that the angles of the inner layers provide an inverse effect when compared to those of the outer layers.

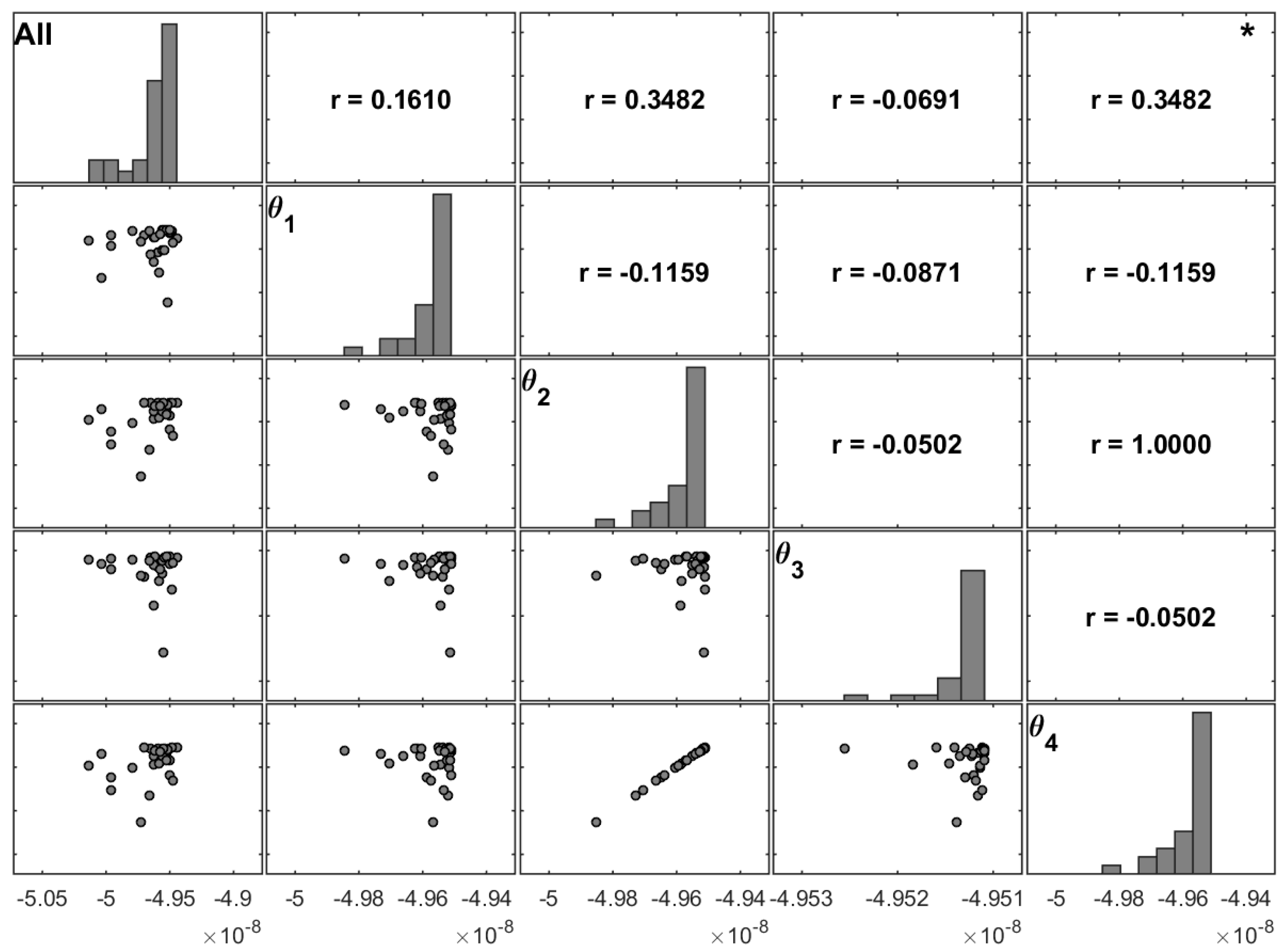

To assess in a more detailed way the influence of each ply, we computed several combinations and considered different sets of uncertain parameters. These sets assumed that all the stacking angles are uncertain (

All) and that only one ply at a time would have an uncertain orientation (θ

1–θ

4), as shown in

Figure 6. Note that the sample with the maximum transverse displacement given in

Figure 5 is the one in

Figure 6 with the combination of all stacking angles being uncertain (

All).

Figure 6 and

Figure 7 present the same study for moderately thin and thin unidirectional plates, respectively. The presented matrix plots show different varying patterns for the maximum transverse displacement. Both figures show that the fourth fibre angle has the highest correlation.

For a better understanding,

Table 4 presents the correlation coefficients for Cases 1.a and 2.a. We observe that the correlation coefficients related to the second ply angle

are higher than those for the first (

) and third (

) ply angles.

It is also worthy to note the inversion of the correlation sign between Cases 1.a and 2.a (a/h = [20; 100]). This happens only for

and

, which correspond to the inner layers for the unidirectional stacking sequence [0]

4 and must be further evaluated. To evaluate the results for other stacking sequences, the case studies presented in

Table 2 are considered.

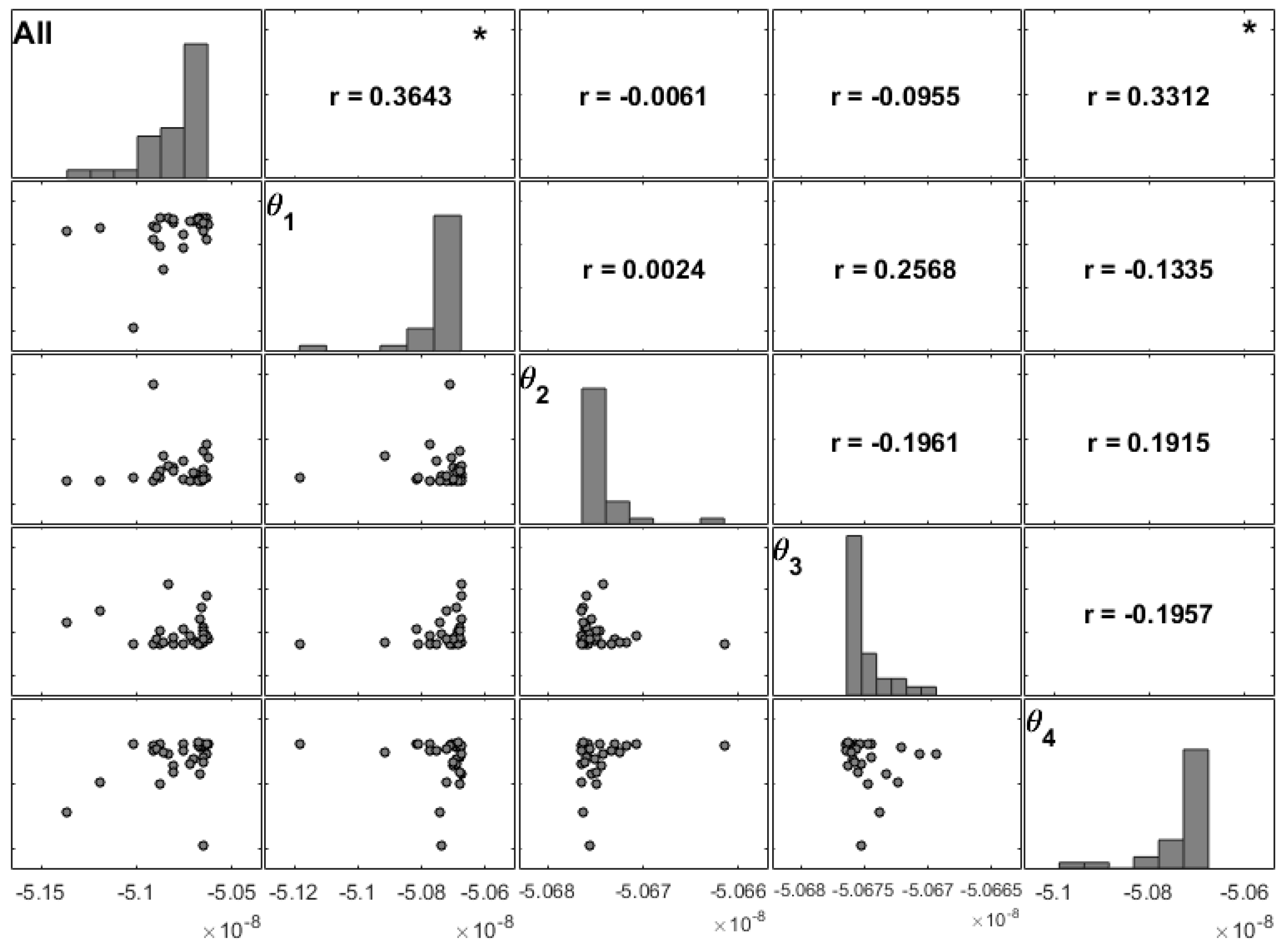

From

Figure 7 and

Figure 8, both associated with thin plates, it is concluded that the fourth ply remains significant in the [0/90]

S laminate, although its significance is now shared with the first layer. Note that both are external layers.

However, for moderately thin plates (comparing

Figure 6 and

Figure 9), we conclude that on the non-symmetric cross-ply laminate there is a more spread significance between stacking angles. Nevertheless, the correlation coefficient of the fourth layer maintains a higher value. The correlation coefficients between angles

and

change with the stacking sequence from around zero for [0]

4 (

Table 4) to almost 0.30 for [0/90]

S (

Table 5), and to an inverse correlation in the [0/90]

2 laminate (

Table 6).

The results in

Table 5 and

Table 6 are similar, despite the difference between stacking sequences. Note that the correlation coefficient for

is higher in these cases, reaching values similar to those for

(

Table 6). On the other hand,

Table 5 shows that the correlation for [0/90]

S presents higher values for all stacking angles, with the value for

remaining the highest.

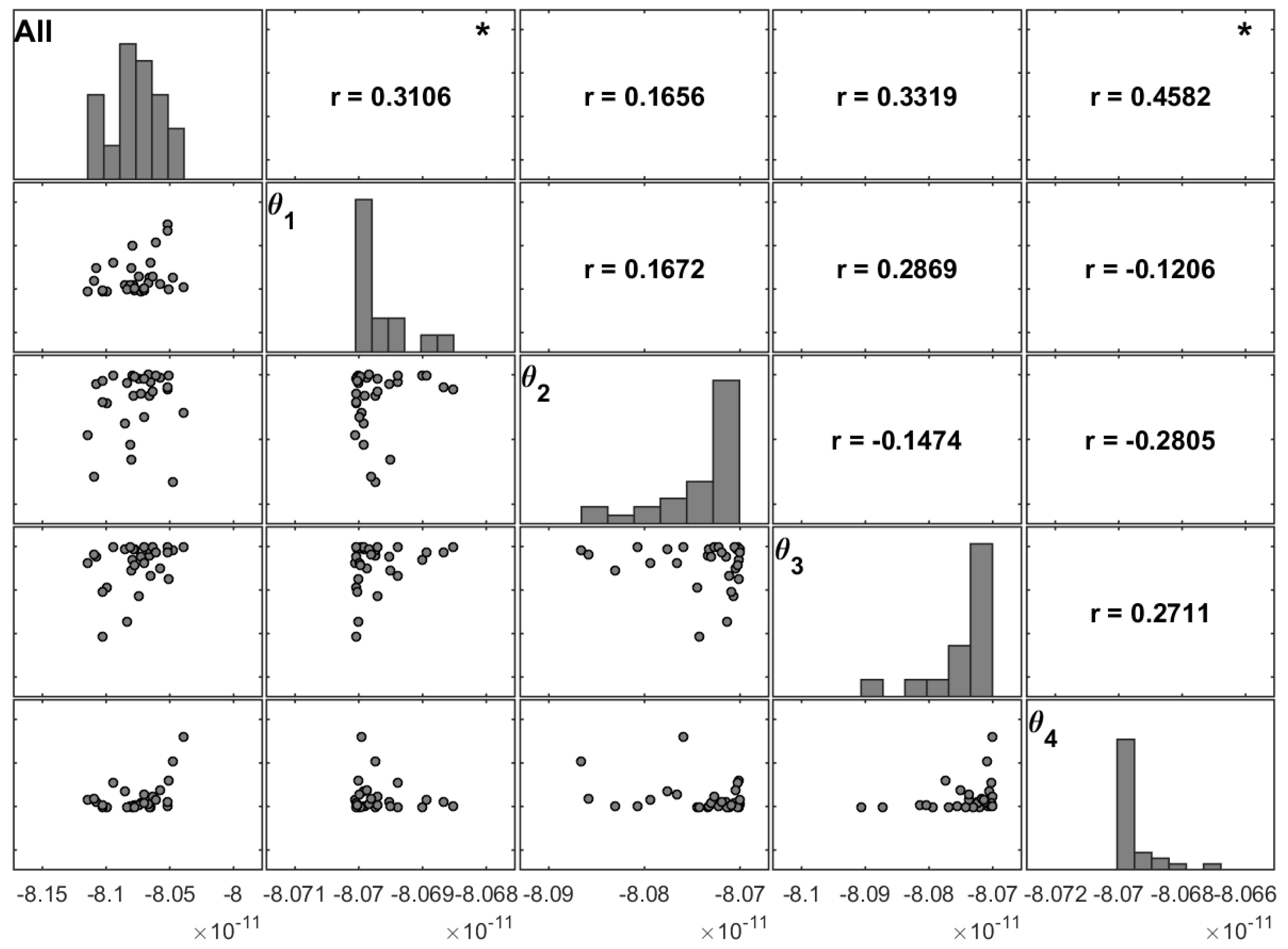

3.3. Uncertainty in the Layer Thickness

In the present work, the variability on the maximum deflection due to uncertain ply thicknesses was also analysed.

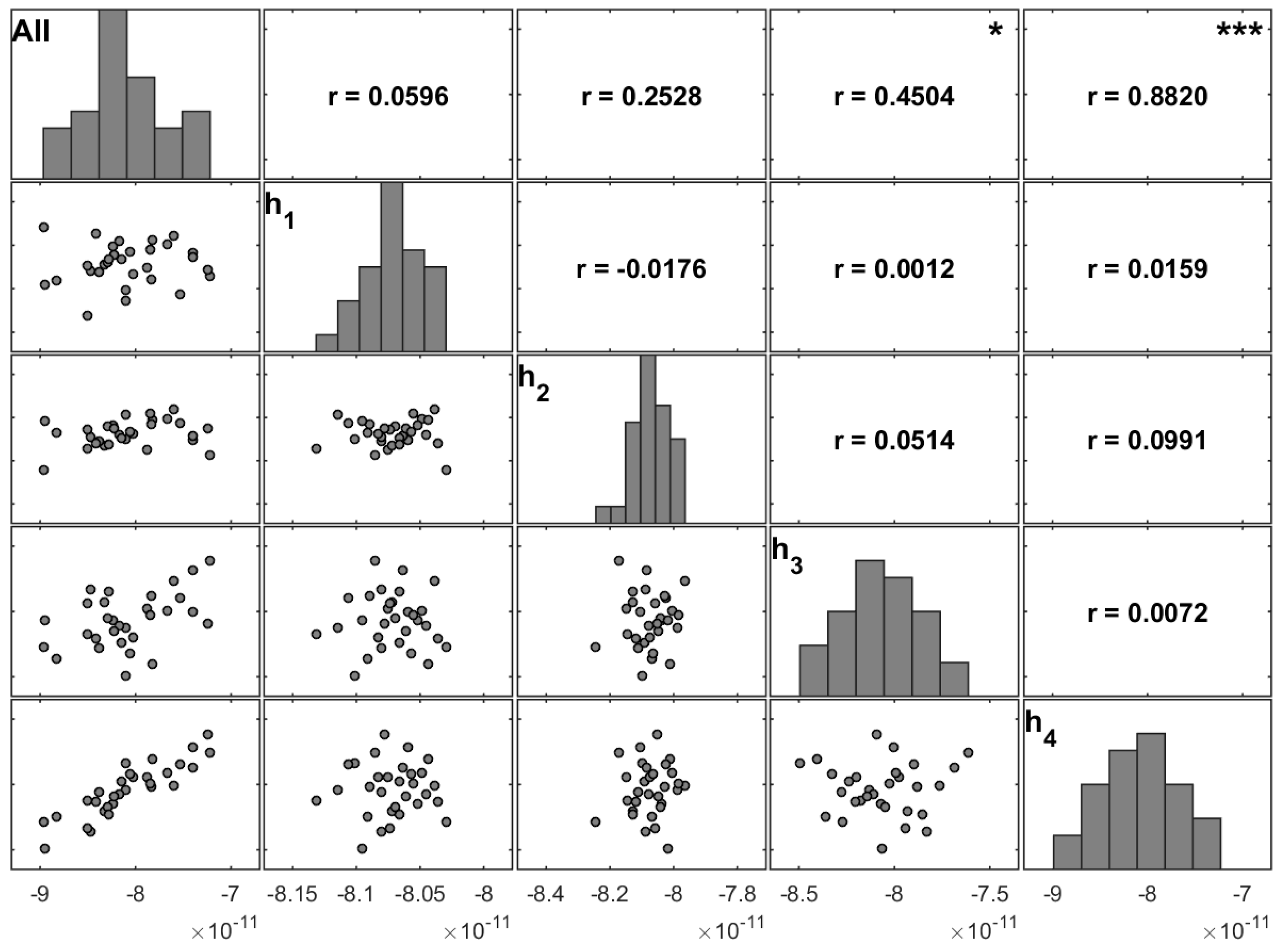

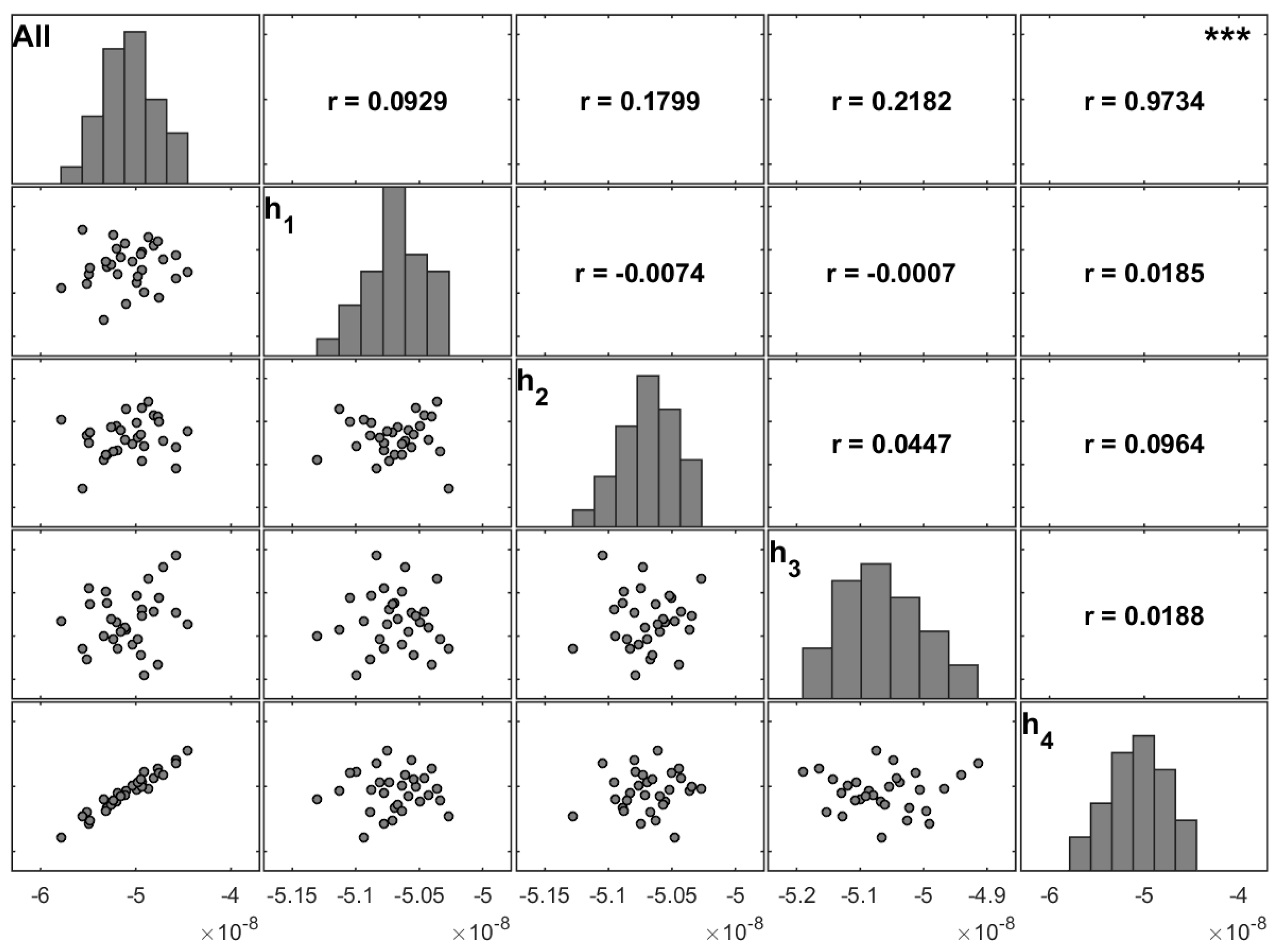

Figure 10 shows the same type of matrix plot but for Case 3.a.

Matrix plots were constructed and analysed for all of the studied cases. However, for the sake of simplicity,

Table 7,

Table 8 and

Table 9 summarise the results obtained.

The correlation coefficients between samples for maximum transverse displacement for almost all case studies are dominated by the uncertain properties of the fourth ply (

Table 7,

Table 8 and

Table 9). A correspondence can be observed with the results presented in the previous sections, although for the ply thickness higher values are obtained for the correlation coefficients.

Comparing the cases with uncertain stacking angles (Cases 1 and 2) and those with uncertain ply thicknesses (Cases 3 and 4) for different aspect ratios, there is greater consistency in the distributions of the maximum transverse displacement for Cases 3 and 4 (

Figure 10,

Figure 11 and

Figure 12), which are almost symmetric. On the other hand, for Cases 1 and 2, there are significant changes in the aspect ratios and stacking sequences (

Figure 6,

Figure 7,

Figure 8 and

Figure 9).

In the cases with uncertain ply thicknesses, the correlation coefficients for the thickness of the fourth ply (h4) overcome all the others with values near 1.0 (

Figure 11 and

Figure 12), with the exception of Cases 3.b and 4.b.

From

Table 7,

Table 8 and

Table 9, it is possible to conclude that the fourth ply is by far the most significant parameter.

3.4. Regression Models

In the previous case studies, we assessed the correlation of the material and geometrical parameters, assuming different uncertain sets. From those studies, it is already possible to conclude that some parameters are more significant for the plate responses.

The present study intended to build probabilistic models to represent the unidirectional composite plate response, both in the case of its maximum transverse deflection (

) and in the case of its fundamental frequency (

). To this purpose, a multivariable linear regression approach (

Section 2.5) has been considered. According to this methodology, the models predicting those two responses were initially written as:

The results obtained for the different regression coefficients

are summarized in

Table 10. It is important to mention that a set of significance codes were used to classify the significance of each regression coefficient based on the

p-value of the

t-test.

From

Table 10, it is possible to conclude on the very high values of the adjusted

. However, concerning the maximum transverse deflection regression model, the hypothesis of independence and normality of the residuals has been rejected, which does not happen in the case of the model for the fundamental frequency where all of the model assumptions have been verified.

Concerning the regression model for the maximum deflection, we conclude that the most significant parameters are the longitudinal elasticity modulus and the plate thickness . Poisson’s ratio and the shear modulus are the next two in terms of significance.

For the fundamental frequency, all of the parameters are significant except the shear moduli and . However, we consider the regression model for the fundamental frequency validated, even with some nonsignificant variables.

Therefore, in a second stage of this study we considered alternative models considering only the previous most significant parameters in both cases. After a forward selection process, the following simplified models were obtained:

The results for these final models are presented in

Table 11.

It is worth mentioning that there was no need for an alternative model in the case of the fundamental frequency, although this was considered.

From the results in

Table 11, it is possible to say that the simplified models (Equation (7)) present high values of adjusted

, and in both cases the residuals assumptions are verified. Therefore, these simplified models are validated. Moreover, it can be observed that in the case of the maximum deflection model, by considering only the thickness, we attain a model that explains 90.46% of the plate deflection variability. For the simplified fundamental frequency model, a very high explanation (99.317%) is obtained, continuing to observe the residuals assumptions.

It is relevant to note that an intermediate simplified model for the maximum deflection can be given by:

where

is included. However, in this case, the residuals problems persisted, although the value of the adjusted

is 97.58 %. The normality of the residuals was improved when compared to the model in Equation (7), but the residuals independency was not guaranteed as observed in

Figure 13. Considering this, it is not possible to accept the corresponding multivariable linear regression model.

4. Conclusions

This work presents a study on the uncertainty propagation of the geometrical and material parameters on the mechanical response of carbon fibre-reinforced composite laminate. The simulation of the uncertain modelling parameters was carried out by considering a random multivariate normal distribution.

The significance of each material and geometrical parameters on the simulated linear static and free vibration response of a certain composite structure was assessed and, therefore, the characterization of the response variability was analysed and conclusions were drawn.

From the obtained results, it is possible to conclude that the variability of the maximum transverse deflection and fundamental frequency is more sensitive to laminate thickness than to other parameters. The longitudinal elasticity modulus appears as the second most significant parameter and the density is the next, when considering the laminate fundamental frequency.

It is also important to summarize the greater sensitivity of the simulated static response to changes on the geometrical parameters of external layers, namely the upper one. Additional simulations were carried out for a larger sample size, confirming the presented conclusions, although this topic should be addressed in more detail in future studies.

The multivariable linear regression analysis confirms the conclusions of the presented correlation analysis in what concerns the influence of the material properties and the global thickness of the laminate. Valid multivariable linear regression models were obtained for the response variables, allowing for the identification of the most important parameters regarding the description of the response variability.

As a final global conclusion, it is considered that under the present assumptions, this methodological study provides an effective tool to characterize the relative influence of each modelling parameter on the explanation of the variability of the mechanical response predictions.