Milling of Nanoparticles Reinforced Al-Based Metal Matrix Composites

Abstract

:1. Introduction

2. Experiments

3. Results and Discussions

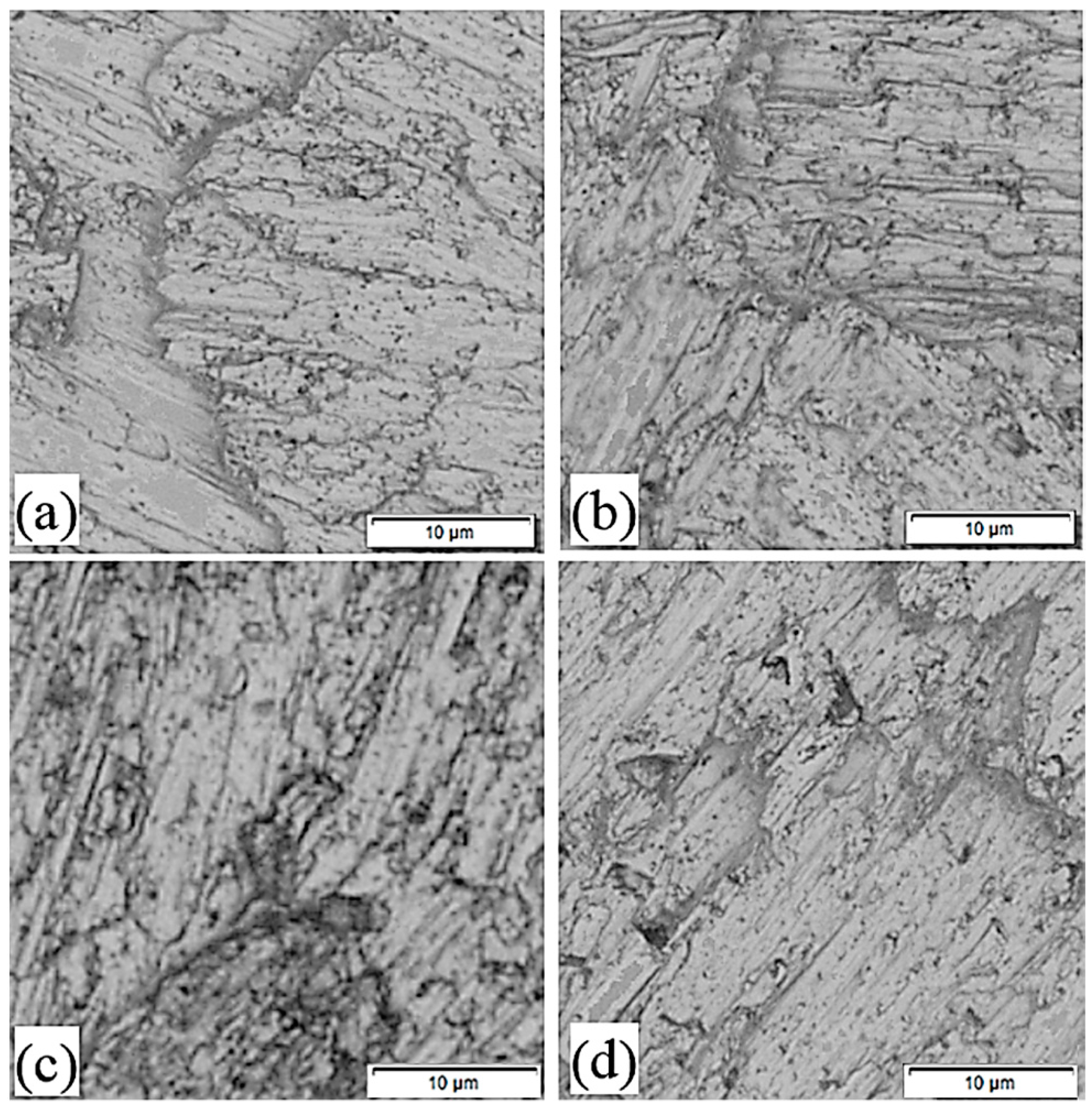

3.1. Machined Surfaces

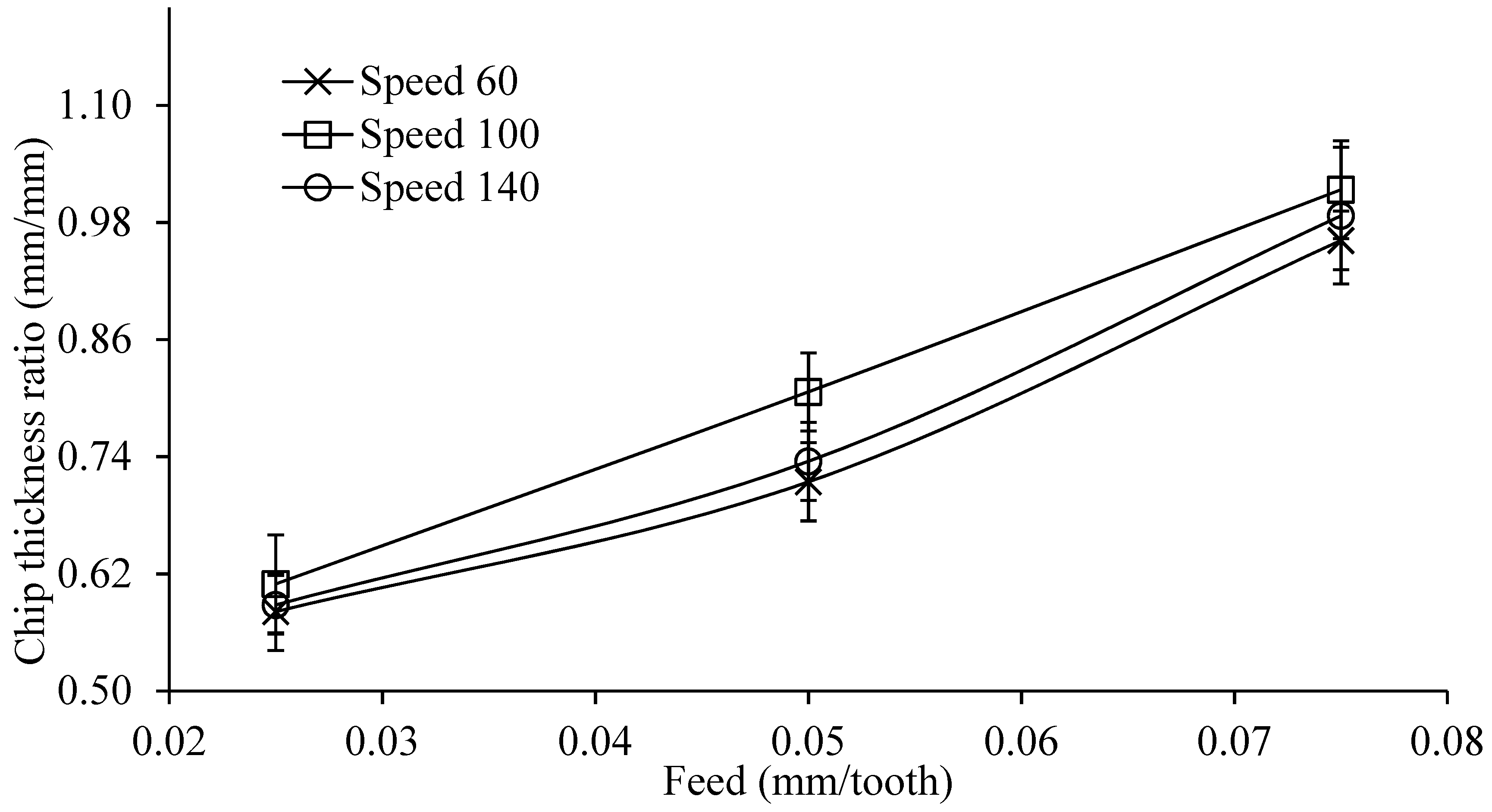

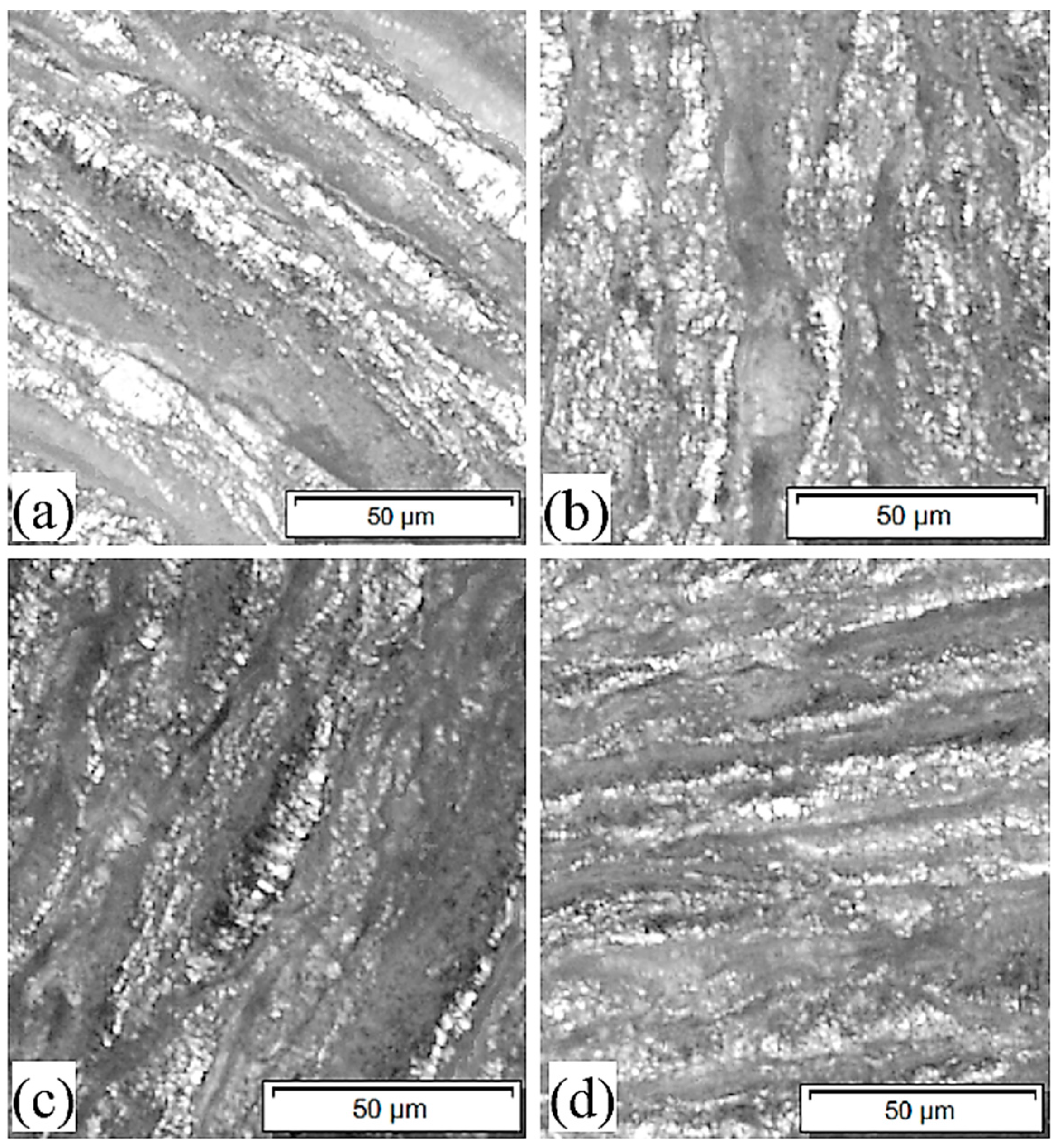

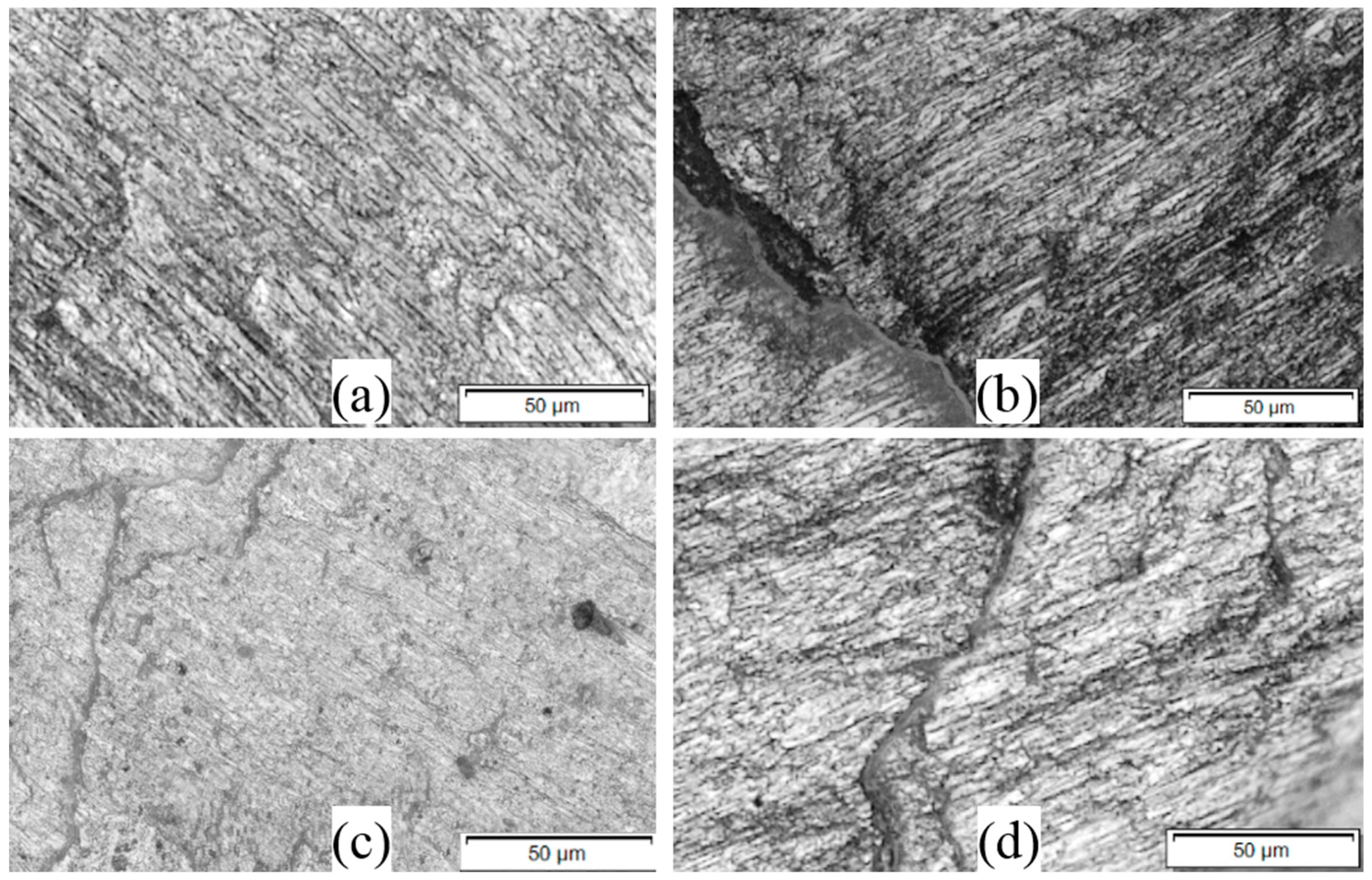

3.2. Machined Chips Morphology

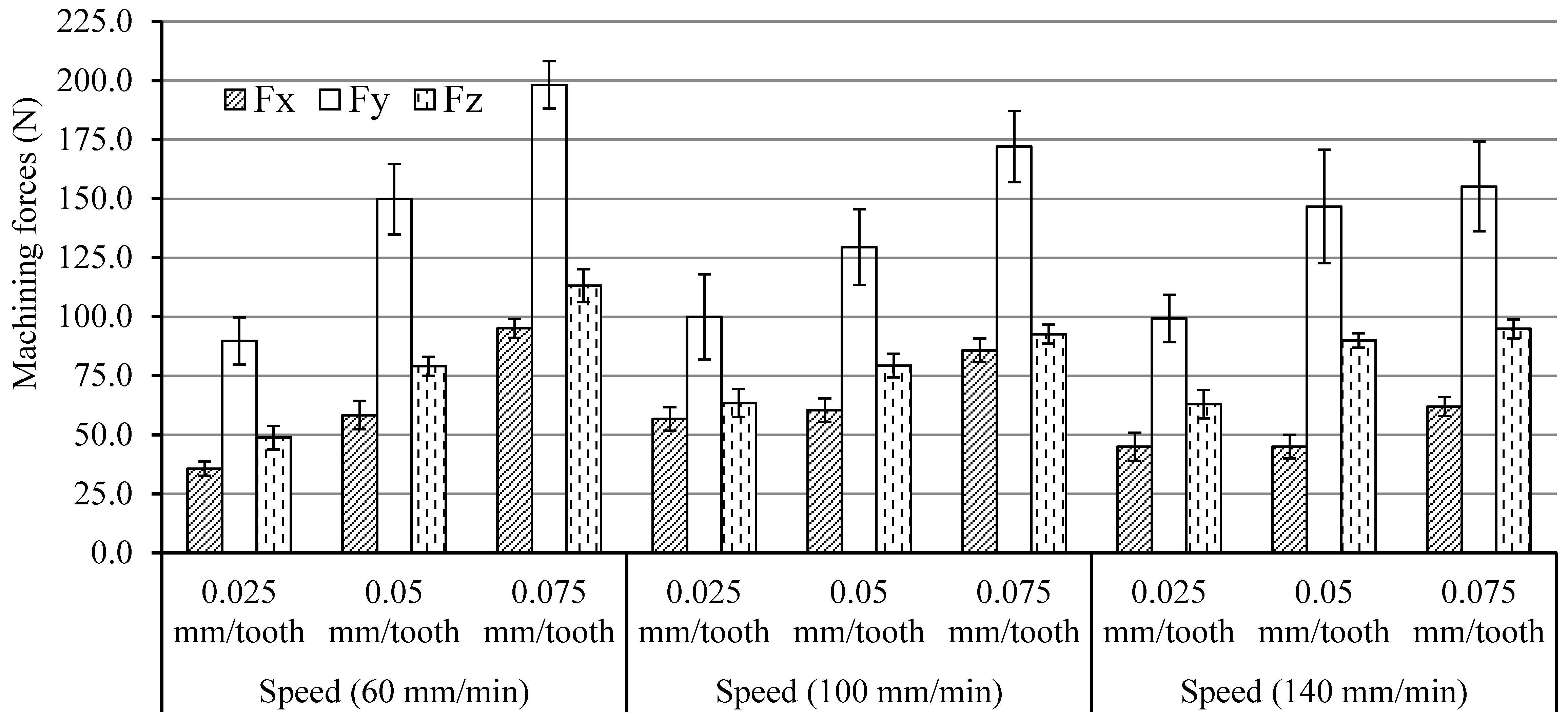

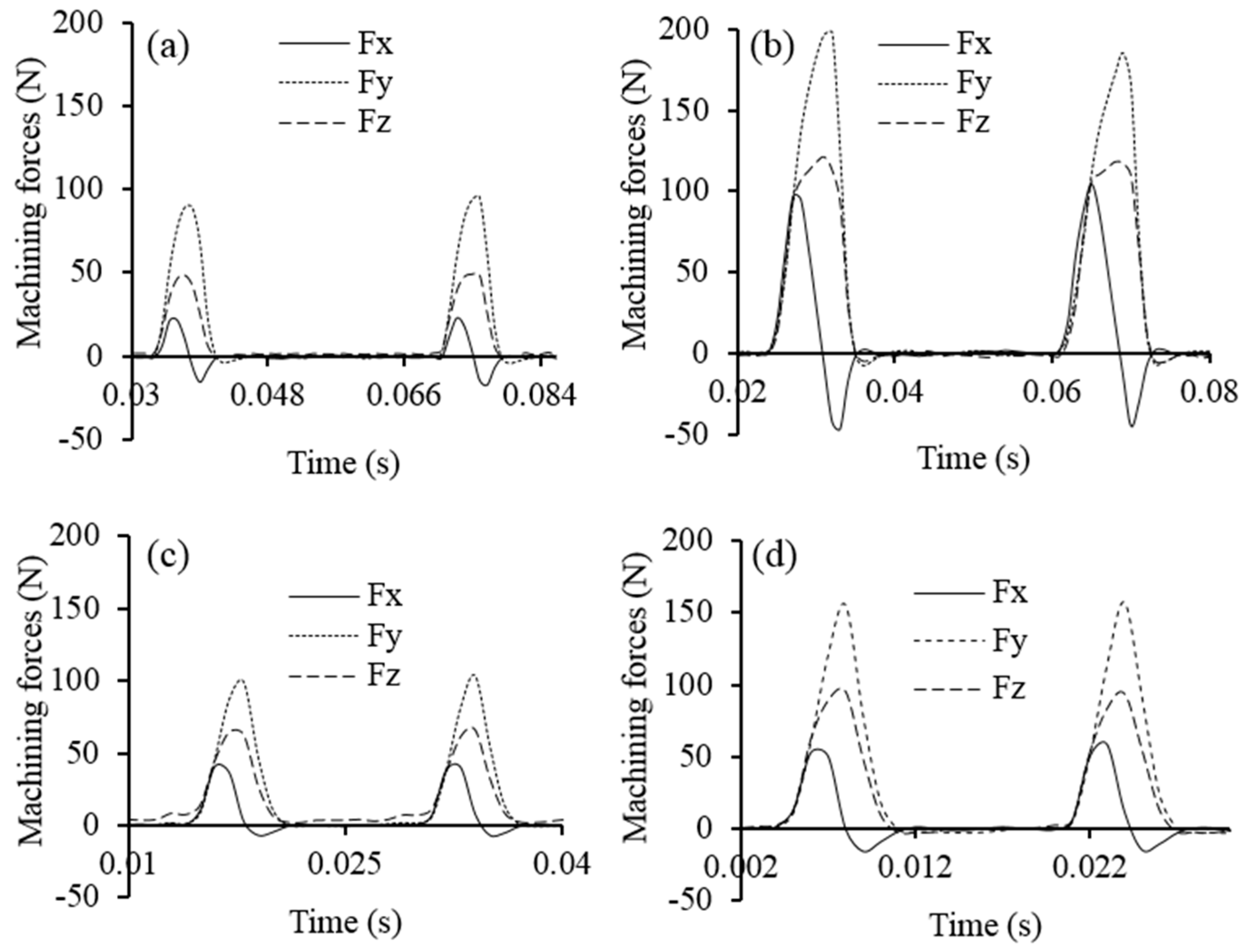

3.3. Machining Forces

4. Conclusions

- Under different milling conditions, the surface generated on nano-MMCs is similar to that of monolithic materials due to the absence of particle fracture and pull-out related damage. Surface defects, such as lobes and layers, were minimum and the average surface roughness increased with the increase of feed at the lower speed. The effect of feed was negligible at higher speeds.

- The chip ratio was higher at the higher feed for all cutting speeds. Wrinkles were noted on the top surface of the chips due to curly shape. At lower feed, the friction is more dominant in contrast to higher feed scenario where both adhesion and materials flow contribute to the chip formation.

- Machining forces increase with the increase of feed at all speeds with the increase of material removal rate. The influence of machining speed on the forces was insignificant without following any trend. These behaviors could be attributed to the combined effects of thermal softening and strain hardening of machined materials in different machining conditions.

Author Contributions

Conflicts of Interest

References

- Basak, A.; Pramanik, A.; Islam, M.N. Failure mechanisms of nanoparticle reinforced metal matrix composite. Adv. Mater. Res. 2013, 774–776, 548–551. [Google Scholar] [CrossRef]

- Basak, A.; Pramanik, A.; Islam, M.N.; Anandakrishnan, V. Challenges and recent developments on nanoparticle-reinforced metal matrix composites. Fill. Reinf. Adv. Nanocompos. 2015, 14, 349–367. [Google Scholar] [CrossRef]

- Basumallick, A.; Sarkar, J.; Das, G.; Mukherjee, S. On the Synthesis of In Situ Ni–SiO2 Nanocomposites by Isothermal and Non Isothermal Reduction Technique. Mater. Manuf. Process. 2006, 21, 648–651. [Google Scholar] [CrossRef]

- Ferkel, H.; Mordike, B. Magnesium strengthened by SiC nanoparticles. Mater. Sci. Eng. A 2001, 298, 193–199. [Google Scholar] [CrossRef]

- Hassan, S.; Gupta, M. Development of high performance magnesium nano-composites using nano-Al2O3 as reinforcement. Mater. Sci. Eng. A 2005, 392, 163–168. [Google Scholar] [CrossRef]

- Huda, D.; El Baradie, M.A.; Hashmi, M.S.J. Analytical study for the stress analysis of Metal Matrix Composites. J. Mater. Process. Technol. 1994, 45, 429–434. [Google Scholar] [CrossRef]

- Kang, Y.-C.; Chan, S.L.-I. Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites. Mater. Chem. Phys. 2004, 85, 438–443. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Liu, J.; Ji, Y.; Xu, C. Experimental investigation on the machinability of SiC nano-particles reinforced magnesium nanocomposites during micro-milling processes. Int. J. Manuf. Res. 2013, 8, 64–84. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Ji, Y.; Xu, C. Investigation on the effect of SiC nanoparticles on cutting forces for micro-milling magnesium matrix composites. In Proceedings of the ASME 2011 International Manufacturing Science and Engineering Conference, Corvallis, OR, USA, 13–17 June 2011. [Google Scholar]

- Lü, L.; Lai, M.; Liang, W. Magnesium nanocomposite via mechanochemical milling. Compos. Sci. Technol. 2004, 64, 2009–2014. [Google Scholar] [CrossRef]

- Ma, Z.; Li, Y.; Liang, Y.; Zheng, F.; Bi, J.; Tjong, S. Nanometric Si3N4 particulate-reinforced aluminum composite. Mater. Sci. Eng. A 1996, 219, 229–231. [Google Scholar] [CrossRef]

- Miracle, D. Metal matrix composites–from science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Paramsothy, M.; Chan, J.; Kwok, R.; Gupta, M. Al2O3 nanoparticle addition to commercial magnesium alloys: Multiple beneficial effects. Nanomaterials 2012, 2, 147–162. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, A.; Arsecularatne, J.; Zhang, L. Machining of particulate-reinforced metal matrix composites. In Machining; Springer: New York, NY, USA, 2008; pp. 127–166. [Google Scholar]

- Pramanik, A.; Basak, A.K. Fracture and fatigue life of Al-based MMCs machined at different conditions. Eng. Fract. Mech. 2018, 191, 33–45. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.K. Effect of machining parameters on deformation behaviour of Al-based metal matrix composites under tension. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2018, 232, 217–225. [Google Scholar] [CrossRef]

- Pramanik, A.; Littlefair, G. Fabrication of nano-particle reinforced metal matrix composites. Adv. Mater. Res. 2013, 651, 289–294. [Google Scholar] [CrossRef]

- Pramanik, A.; Zhang, L.; Arsecularatne, J. Micro-indentation of metal matrix composites—An FEM analysis. Key Eng. Mater. 2007, 340–341, 563–570. [Google Scholar] [CrossRef]

- Pramanik, A.; Zhang, L.; Arsecularatne, J. Machining of metal matrix composites: Effect of ceramic particles on residual stress, surface roughness and chip formation. Int. J. Mach. Tools Manuf. 2008, 48, 1613–1625. [Google Scholar] [CrossRef]

- Pramanik, A.; Zhang, L.C.; Arsecularatne, J.A. Deformation mechanisms of MMCs under indentation. Compos. Sci. Technol. 2008, 68, 1304–1312. [Google Scholar] [CrossRef]

- Teng, X.; Huo, D.; Wong, E.; Meenashisundaram, G.; Gupta, M. Micro-machinability of nanoparticle-reinforced Mg-based MMCs: An experimental investigation. Int. J. Adv. Manuf. Technol. 2016, 87, 2165–2178. [Google Scholar] [CrossRef]

- Teng, X.; Huo, D.; Wong, W.L.E.; Sankaranarayanan, S.; Gupta, M. Machinability Investigation in Micro-milling of Mg Based MMCs with Nano-Sized Particles. In Magnesium Technology; Springer: New York, NY, USA, 2017; pp. 61–69. [Google Scholar]

- Tjong, S.C.; Ma, Z. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, T.K.; Lloyd, D.J. Stress distribution in particulate-reinforced metal-matrix composites subjected to external load. Metall. Trans. A 1993, 24, 197–207. [Google Scholar] [CrossRef]

- Xiaochun, L.; Yang, Y.; Weiss, D. Theoretical and experimental study on ultrasonic dispersion of nanoparticles for strengthening cast Aluminum Alloy A356. Metall. Sci. Technol. 2013, 26, 12–20. [Google Scholar]

- Zhang, Z.; Zhang, L.; Mai, Y.W. Modeling steady wear of steel/Al2O3-Al particle reinforced composite system. Wear 1997, 211, 147–150. [Google Scholar] [CrossRef]

| Particle Size (nm) | 700 | ||

|---|---|---|---|

| Speed (m/min) | 60 | 100 | 140 |

| Feed (mm/tooth) | 0.025 | 0.0 | 0.075 |

| Experiment No. | Cutting Speed (mm/min) | Feed Rate (mm/tooth) |

|---|---|---|

| 1 | 60 | 0.025 |

| 2 | 60 | 0.05 |

| 3 | 60 | 0.075 |

| 4 | 100 | 0.025 |

| 5 | 100 | 0.05 |

| 6 | 100 | 0.075 |

| 7 | 140 | 0.025 |

| 8 | 140 | 0.05 |

| 9 | 140 | 0.075 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pramanik, A.; Basak, A.K.; Dong, Y.; Shankar, S.; Littlefair, G. Milling of Nanoparticles Reinforced Al-Based Metal Matrix Composites. J. Compos. Sci. 2018, 2, 13. https://doi.org/10.3390/jcs2010013

Pramanik A, Basak AK, Dong Y, Shankar S, Littlefair G. Milling of Nanoparticles Reinforced Al-Based Metal Matrix Composites. Journal of Composites Science. 2018; 2(1):13. https://doi.org/10.3390/jcs2010013

Chicago/Turabian StylePramanik, Alokesh, Animesh Kumar Basak, Yu Dong, Subramaniam Shankar, and Guy Littlefair. 2018. "Milling of Nanoparticles Reinforced Al-Based Metal Matrix Composites" Journal of Composites Science 2, no. 1: 13. https://doi.org/10.3390/jcs2010013

APA StylePramanik, A., Basak, A. K., Dong, Y., Shankar, S., & Littlefair, G. (2018). Milling of Nanoparticles Reinforced Al-Based Metal Matrix Composites. Journal of Composites Science, 2(1), 13. https://doi.org/10.3390/jcs2010013