Effect of Heat Treatment on High-Temperature Tribological Behavior of WE54 Alloy: An Experimental Study

Abstract

1. Introduction

2. Experimental Methods

3. Results and Discussions:

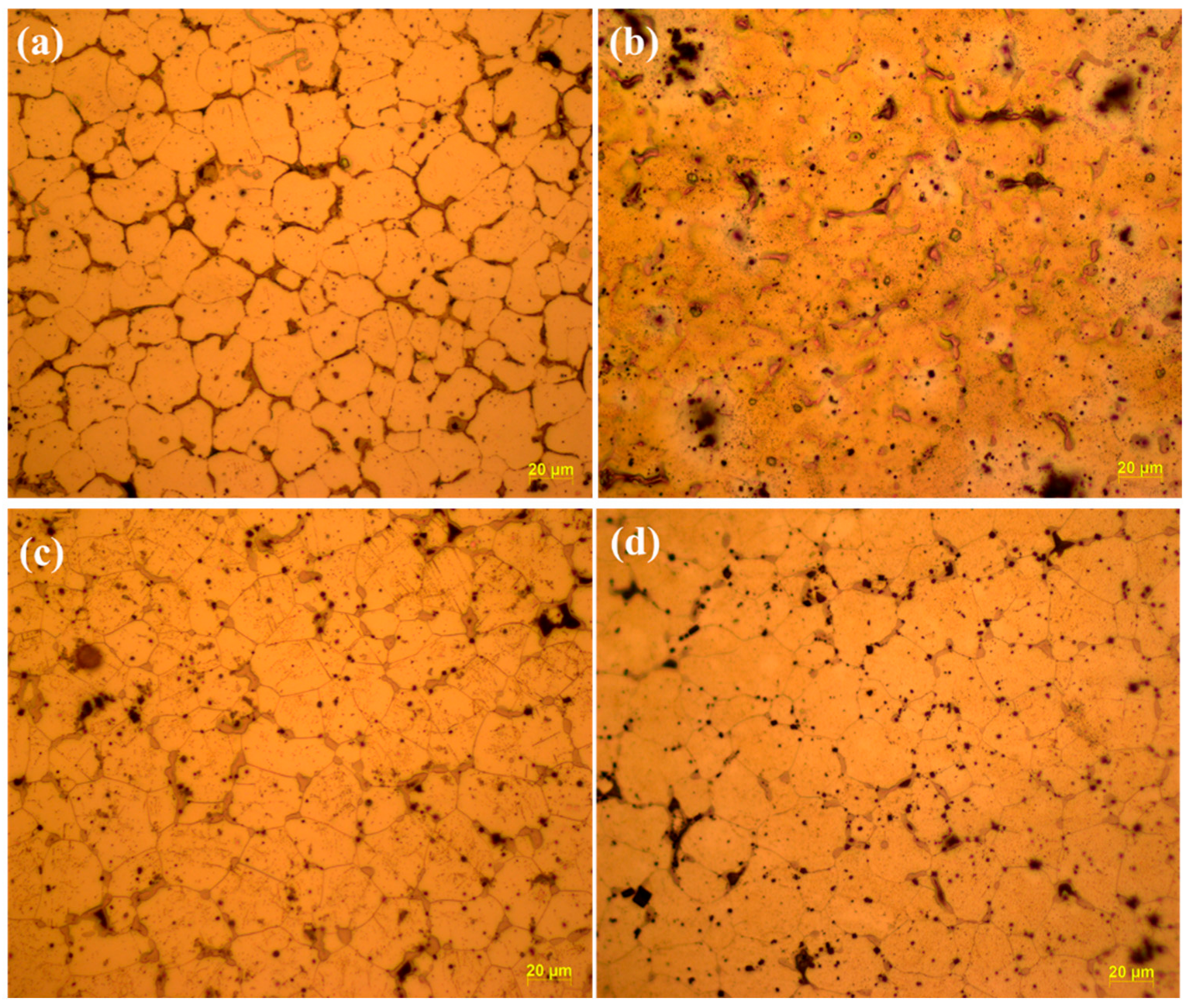

3.1. Microstructure Analysis (WE54 Mg Alloy)

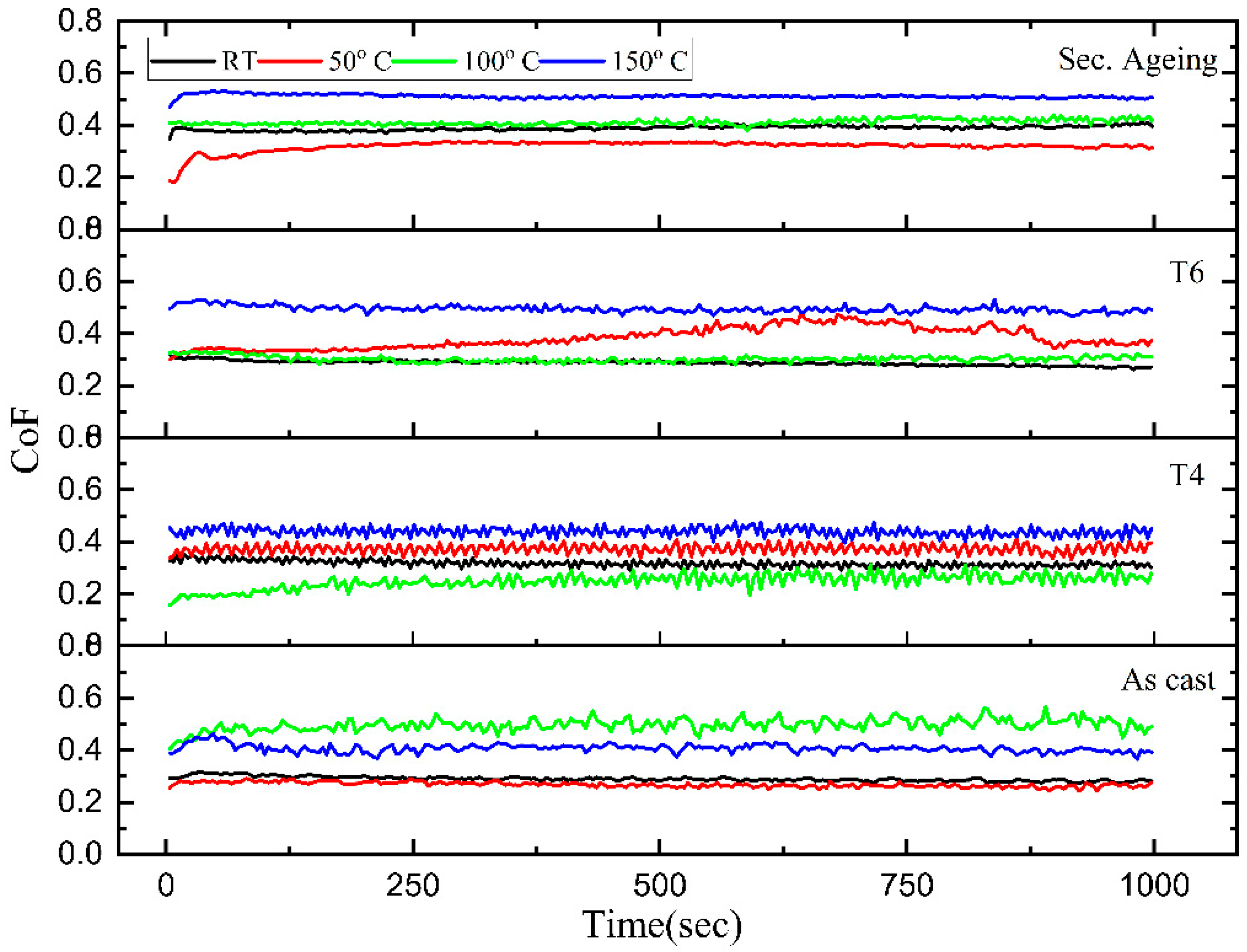

3.2. Volumetric Wear Rate and Coefficient of Friction (CoF):

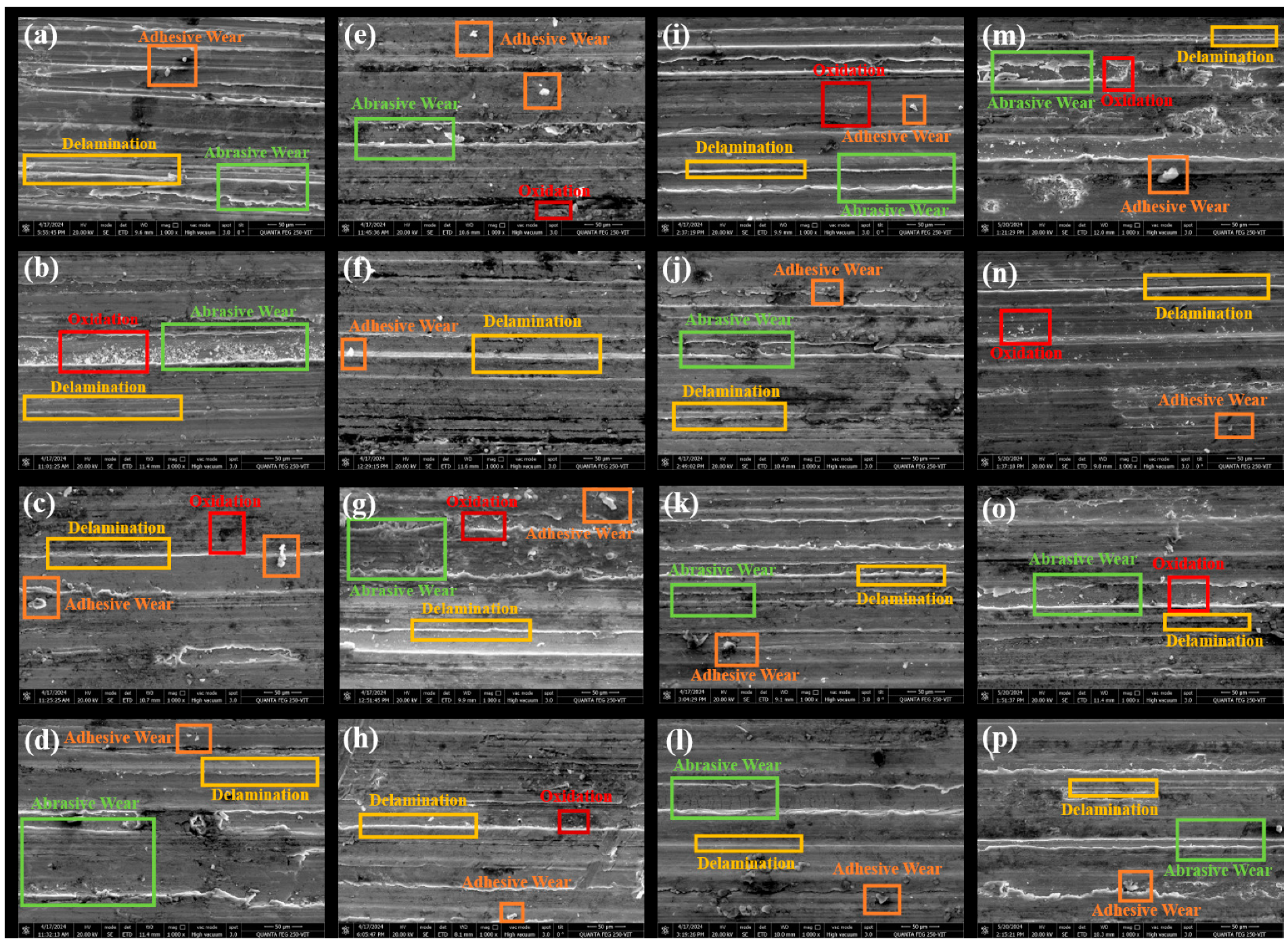

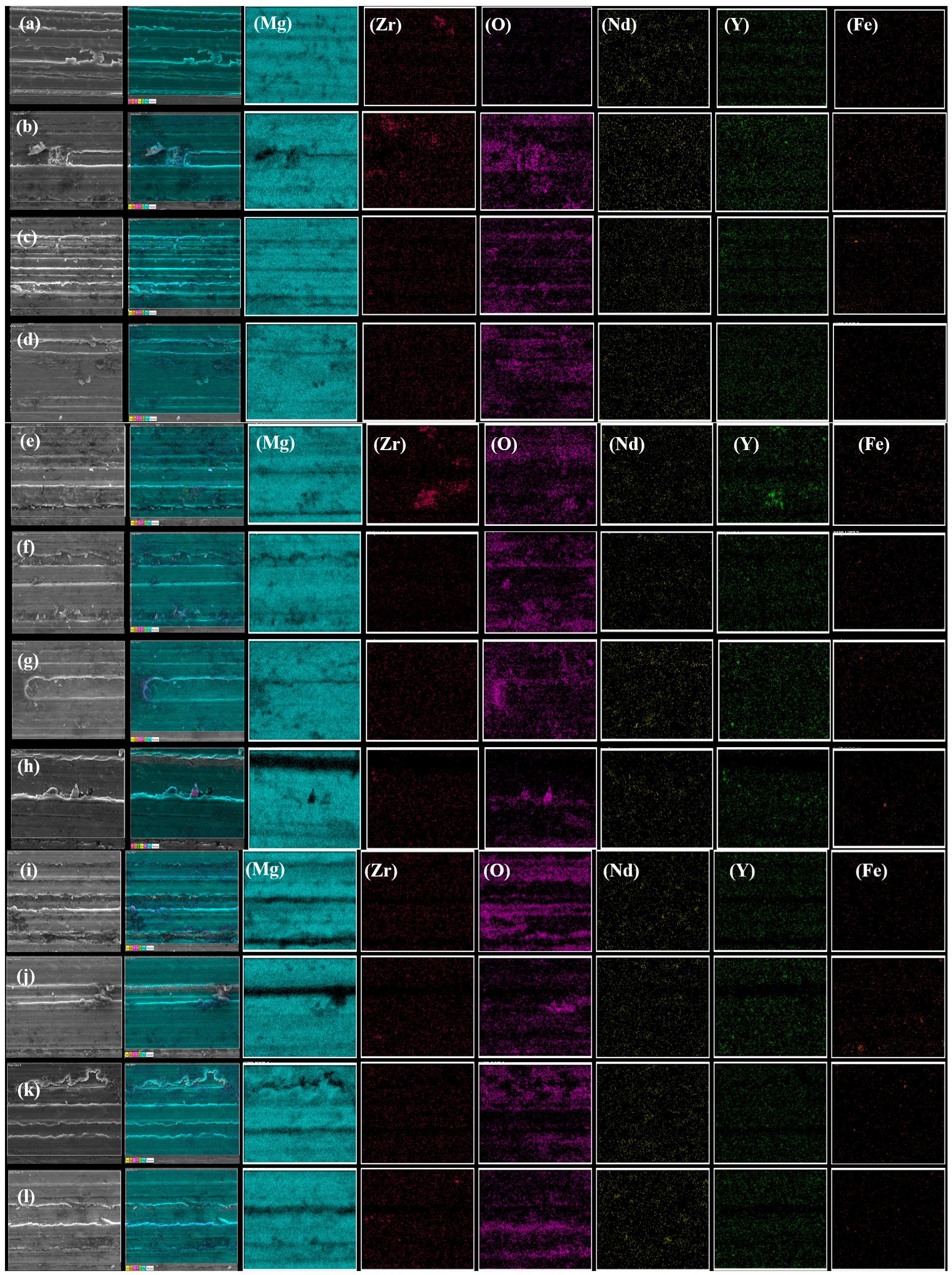

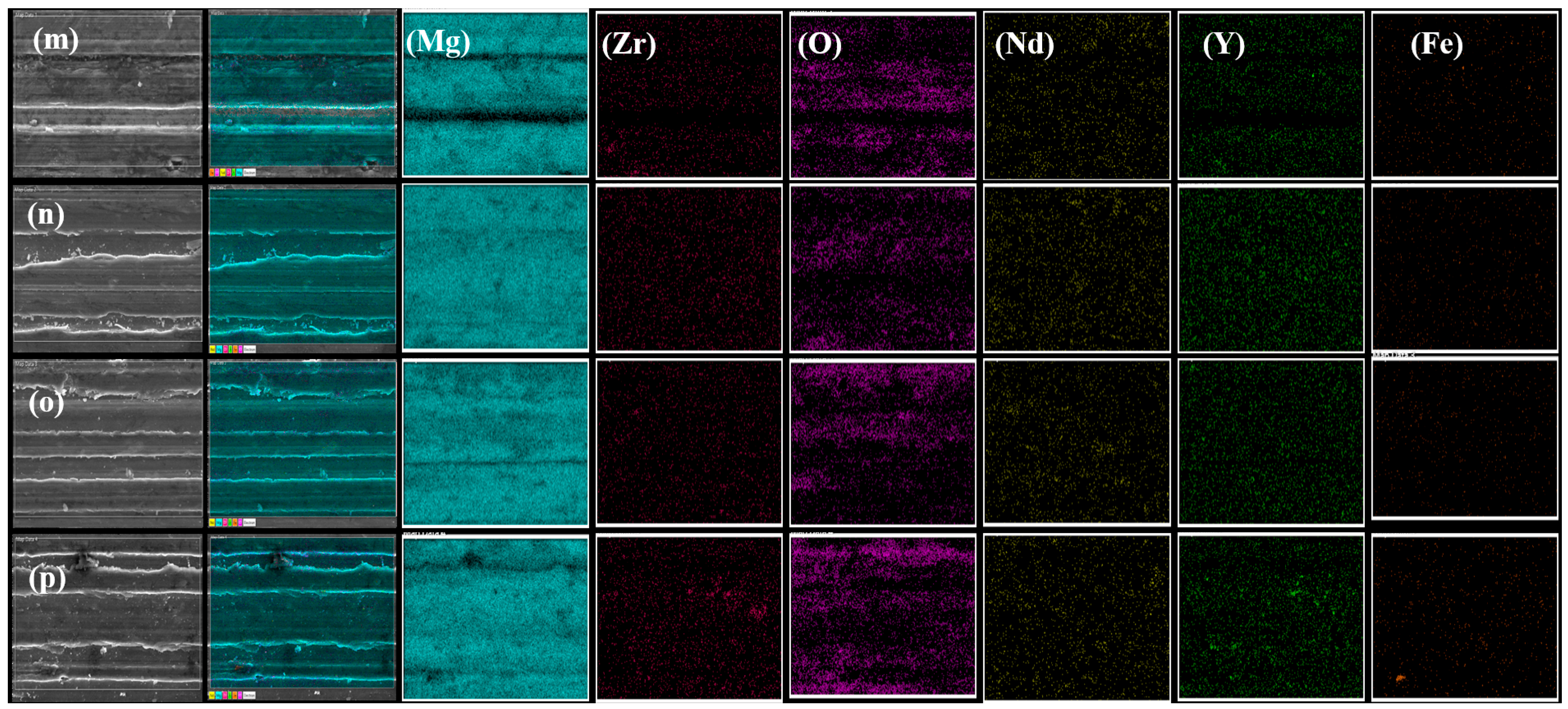

3.3. Characterization of Worn-Out Surface

4. Conclusions

- All the sample conditions show similar volumetric wear rates at room temperature and when tested at 50 °C. The as-cast sample has the lowest volumetric wear rates of 8.16 ± 1.47 mm3 and 10.44 ± 0.63 mm3 at 100 °C and 150 °C, respectively. In contrast, the highest volumetric wear rate was observed in the S.A. condition (14.68 ± 1.59 mm3) at 150 °C.

- Among the tested conditions, the T6 (age-hardened) samples showed the most consistent wear resistance across all tested specimens. Additionally, the T6-treated sample has a lower volumetric wear rate (11.4 ± 0.59 mm3) at 50 °C.

- The coefficient of friction (CoF) decreased from room temperature to 50 °C, possibly due to the formation of oxide layers that reduced friction. However, the CoF increased at higher temperatures as these oxide layers began to break down.

- Similarly to volumetric wear rate, wear mechanisms also changed with test temperatures, with abrasive and delamination wear dominating at lower temperatures, while oxidative and adhesive wear took over above 100 °C.

- The findings confirm that the T6 treatment significantly enhances the high-temperature wear resistance of WE54 alloy, making it suitable for demanding applications in the automotive and aerospace industries.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumaravelu, P.; Kandasamy, J. Effect of load and sliding velocity on wear behaviour of magnesium AZ91D composites reinforced with Ca2SiO4 at ambient temperature. Tribol. Int. 2024, 192, 109314. [Google Scholar] [CrossRef]

- Ajay, C.V.; Manisekar, K. Metallurgical, Mechanical and Tribological Properties of AZ31-Sn/Nano-Al2O3 Composites Fabricated by Stir Casting Technique. Trans. Indian Inst. Met. 2023, 76, 1819–1830. [Google Scholar] [CrossRef]

- Thanabal, N.; Silambarasan, R.; Seenuvasaperumal, P.; Basha, D.A.; Elayaperumal, A. Microstructure and mechanical behavior of AXM Mg alloy systems—A review. J. Magnes. Alloys 2024, 12, 2624–2646. [Google Scholar] [CrossRef]

- Patel, M.S.; Rahaman, A.; Immanuel, R.J. Tribological profiling of Mg-Gd-Y Alloy: Investigating sliding wear dynamics under varied temperature conditions. Mater. Lett. 2024, 370, 136808. [Google Scholar] [CrossRef]

- Sharma, S.K.; Gajević, S.; Sharma, L.K.; Pradhan, R.; Miladinović, S.; Ašonja, A.; Stojanović, B. Magnesium-Titanium Alloys: A Promising Solution for Biodegradable Biomedical Implants. Materials 2024, 17, 5157. [Google Scholar] [CrossRef]

- An, J.; Li, R.; Lu, Y.; Chen, C.; Xu, Y.; Chen, X.; Wang, L. Dry sliding wear behavior of magnesium alloys. Wear 2008, 265, 97–104. [Google Scholar] [CrossRef]

- Kumar, K.C.K.; Kumar, B.R.; Rao, N.M. Artificial Neural Network Modeling of Tribological Parameters Optimization of AZ31-SIC Metal Matrix Composite. Appl. Eng. Lett. 2023, 8, 111–120. [Google Scholar] [CrossRef]

- Arora, H.S.; Singh, H.; Dhindaw, B.K. Wear behaviour of a Mg alloy subjected to friction stir processing. Wear 2013, 303, 65–77. [Google Scholar] [CrossRef]

- Selvan, S.A.; Ramanathan, S. Dry sliding wear behavior of as-cast ZE41A magnesium alloy. Mater. Des. 2010, 31, 1930–1936. [Google Scholar] [CrossRef]

- El-Morsy, A.W. Dry sliding wear behavior of hot deformed magnesium AZ61 alloy as influenced by the sliding conditions. Mater. Sci. Eng. A 2008, 473, 330–335. [Google Scholar] [CrossRef]

- Buch, V.; Mordike, B.L. High-Temperature Properties of Magnesium Alloys. In Magnesium—Alloys and Technology; Wiley: Hoboken, NJ, USA, 2003; pp. 106–129. [Google Scholar] [CrossRef]

- An, J.; Zhao, W.; Feng, C.Q. Elevated-temperature wear characteristics and mild-severe wear transition in the mg-10.1gd-1.4y-0.4zr alloy. J. Tribol. 2019, 141, 121601. [Google Scholar] [CrossRef]

- Liu, L.; Chen, X.; Pan, F.; Wang, Z.; Liu, W.; Cao, P.; Yan, T.; Xu, X. Effect of Y and Ce additions on microstructure and mechanical properties of Mg–Zn–Zr alloys. Mater. Sci. Eng. A 2015, 644, 247–253. [Google Scholar] [CrossRef]

- Ma, C.; Liu, M.; Wu, G.; Ding, W.; Zhu, Y. Tensile properties of extruded ZK60–RE alloys. Mater. Sci. Eng. A 2003, 349, 207–212. [Google Scholar] [CrossRef]

- Chia, T.L.; Easton, M.A.; Zhu, S.M.; Gibson, M.A.; Birbilis, N.; Nie, J.F. The effect of alloy composition on the microstructure and tensile properties of binary Mg-rare earth alloys. Intermetallics 2009, 17, 481–490. [Google Scholar] [CrossRef]

- Wu, A.R.; Xia, C.Q. Study of the microstructure and mechanical properties of Mg-rare earth alloys. Mater. Des. 2007, 28, 1963–1967. [Google Scholar] [CrossRef]

- Chen, B.; Lu, C.; Lin, D.; Zeng, X. Microstructural evolution and mechanical properties of Mg 95.5Y3Zn1.5 alloy processed by extrusion and ECAP. Met. Mater. Int. 2014, 20, 285–290. [Google Scholar] [CrossRef]

- Cai, H.; Guo, F.; Su, J. Combined effects of cerium and cooling rate on microstructure and mechanical properties of AZ91 magnesium alloy. Mater. Res. Express 2018, 5, 016503. [Google Scholar] [CrossRef]

- Nouri, M.; Sun, X.; Li, D.Y. Beneficial effects of yttrium on the performance of Mg–3%Al alloy during wear, corrosion and corrosive wear. Tribol. Int. 2013, 67, 154–163. [Google Scholar] [CrossRef]

- Nodooshan, H.R.J.; Liu, W.; Wu, G.; Ding, W.; Mahmudi, R. Effect of Gd addition on the wear behavior of Mg–xGd–3Y–0.5 Zr alloys. J. Mater. Res. 2016, 31, 1133–1144. [Google Scholar] [CrossRef]

- Mansouri, A.; Ghasemi, H.M.; Yazdi, R.; Mahmudi, R.; Sohi, M.H. Dry tribological behavior of a cast Mg-Gd-Zr-Ag alloy at room and elevated temperatures. J. Mater. Res. Technol. 2022, 18, 5126–5143. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, L.; An, J. Dry wear behavior and mild-to-severe wear transition in an Mg-Gd-Y-Zr alloy. Surf. Topogr. 2021, 9, 025032. [Google Scholar] [CrossRef]

- An, J.; Tian, Y.X.; Feng, C.Q. Correlation between test temperature, applied load and wear transition of Mg97Zn1Y2 alloy. J. Magnes. Alloys 2021, 9, 592–603. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Liu, Q.; Yang, S.; Wang, Z. Effects of Load on Dry Sliding Wear Behavior of Mg–Gd–Zn–Zr Alloys. J. Mater. Sci. Technol. 2017, 33, 645–651. [Google Scholar] [CrossRef]

- Xu, W.; Yu, J.; Jia, L.; Gao, C.; Miao, Z.; Wu, G.; Li, G.; Zhang, Z. Grain refinement impact on the mechanical properties and wear behavior of Mg-9Gd-3Y-2Zn-0.5Zr alloy after decreasing temperature reciprocating upsetting-extrusion. J. Magnes. Alloys 2022, 10, 3506–3519. [Google Scholar] [CrossRef]

- Hu, M.L.; Wang, Q.D.; Li, C.; Ding, W.J. Dry sliding wear behavior of cast Mg–11Y–5Gd–2Zn magnesium alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 1918–1923. [Google Scholar] [CrossRef]

- Hu, M.; Wang, Q.; Chen, C.; Yin, D.; Ding, W.; Ji, Z. Dry sliding wear behaviour of Mg–10Gd–3Y–0.4Zr alloy. Mater. Des. 2012, 42, 223–229. [Google Scholar] [CrossRef]

- Li, J.; Chen, R.; Ma, Y.; Ke, W. Effect of Zr modification on solidification behavior and mechanical properties of Mg–Y–RE (WE54) alloy. J. Magnes. Alloys 2013, 1, 346–351. [Google Scholar] [CrossRef]

- Barylski, A.; Kupka, M.; Aniołek, K.; Rak, J. The effect of precipitation hardening on the structure and mechanical and tribological properties of magnesium alloy WE54. Vacuum 2017, 139, 77–86. [Google Scholar] [CrossRef]

- Somekawa, H.; Maeda, S.; Hirayama, T.; Matsuoka, T.; Inoue, T.; Mukai, T. Microstructural evolution during dry wear test in magnesium and Mg–Y alloy. Mater. Sci. Eng. A 2013, 561, 371–377. [Google Scholar] [CrossRef]

- Barylski, A.; Aniołek, K.; Dercz, G.; Matuła, I.; Kaptacz, S.; Rak, J.; Paszkowski, R. Improving the Tribological Properties of WE43 and WE54 Magnesium Alloys by Deep Cryogenic Treatment with Precipitation Hardening in Linear Reciprocating Motion. Materials 2024, 17, 2011. [Google Scholar] [CrossRef]

- Lv, X.X.; Liu, H.Y.; Wang, Y.B.; Lu, Y.; Li, G.Y.; An, J. Microstructure and dry sliding wear behavior of Mg-Y-Zn alloy modified by laser surface melting. J. Mater. Eng. Perform. 2011, 20, 1015–1022. [Google Scholar] [CrossRef]

- ASTM G99-23; Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, W.; Wu, G.; Ding, W. Effect of chemical composition on the microstructure, tensile properties and fatigue behavior of sand-cast Mg–Gd–Y–Zr alloy. Mater. Sci. Eng. A 2014, 612, 293–301. [Google Scholar] [CrossRef]

- Ramesh, S.; Anne, G.; Nayaka, H.S.; Sahu, S.; Ramesh, M.R. Investigation of dry sliding wear properties of multi-directional forged Mg–Zn alloys. J. Magnes. Alloys 2019, 7, 444–455. [Google Scholar] [CrossRef]

- Somasundaram, M.; NarendraKumar, U.; Annamalai, A.R.; Muthuchamy, A. High-temperature tribological performance of stir-cast and heat-treated EV31A magnesium alloy: Experiments and predictions. Heliyon 2023, 9, e19055. [Google Scholar] [CrossRef]

- Li, L.; Feng, J.; Liang, C.; An, J. Dry sliding wear behavior and mild-severe wear transition of Mg97Zn1Y2 alloy at elevated temperatures. Materials 2018, 11, 1735. [Google Scholar] [CrossRef]

- Venkataiah, M.; Kumar, T.A.; Rao, K.V.; Kumar, S.A.; Dumpala, R.; Sunil, B.R. Investigation on the role of microstructure and temperature on tribological characteristics of fine-grained ZE41 Mg alloy. Tribol.-Mater. Surf. Interfaces 2022, 16, 68–75. [Google Scholar] [CrossRef]

- Birks, N.; Meier, G.H.; Pettit, F.S. Oxidation of alloys. In Introduction to the High Temperature Oxidation of Metals; Cambridge University Press: Cambridge, UK, 2006; pp. 101–162. [Google Scholar] [CrossRef]

| Element | Mg | Y | Nd | Zr | Cu | Mn | Si |

|---|---|---|---|---|---|---|---|

| wt% | Bal | 5.5 | 2 | 0.45 | 0.03 | 0.01 | 0.01 |

| Condition | Before Wear | After Wear | |||

|---|---|---|---|---|---|

| RT | 50 °C | 100 °C | 150 °C | ||

| as-cast | 95.6 ± 1.8 | 117.1 ± 7 | 122.8 ± 8 | 136.1 ± 6 | 129.2 ± 5 |

| T4 | 94.9 ± 2.8 | 100.5 ± 8 | 106 ± 6 | 113.3 ± 10 | 110.8 ± 8 |

| T6 | 114.7 ± 1.9 | 102.3 ± 8 | 103.5 ± 7 | 112.2 ± 6 | 102.5 ± 6 |

| S.A | 115.9 ± 1.8 | 122.4 ± 2 | 126.7 ± 10 | 129.5 ± 2 | 116.5 ± 2 |

| Temp (°C) | CoF | Volumetric Wear Rate (mm3) | Wear Coefficient | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| as- Cast | T4 | T6 | S.A | as- Cast | T4 | T6 | S.A | as- Cast | T4 | T6 | S.A | |

| RT | 0.290 | 0.317 | 0.289 | 0.390 | 12.34 ± 1.04 | 12.39 ± 1.03 | 13.89 ± 0.89 | 11.9 ± 0.3 | 0.145 ± 0.01 | 0.125 ± 0.01 | 0.142 ± 0.01 | 0.146 ± 0.004 |

| 50 | 0.269 | 0.379 | 0.390 | 0.320 | 12.07 ± 0.9 | 12.98 ± 1.29 | 11.4 ± 0.59 | 13.4 ± 1.26 | 0.148 ± 0.01 | 0.138 ± 0.01 | 0.118 ± 0.01 | 0.17 ± 0.02 |

| 100 | 0.497 | 0.248 | 0.303 | 0.412 | 8.16 ± 1.47 | 9.14 ± 1.42 | 12.95 ± 1.65 | 11.97 ± 0.68 | 0.112 ± 0.02 | 0.104 ± 0.02 | 0.145 ± 0.02 | 0.155 ± 0.01 |

| 150 | 0.407 | 0.440 | 0.495 | 0.512 | 10.44 ± 0.63 | 10.7 ± 1.39 | 12.05 ± 1.45 | 14.68 ± 1.59 | 0.135 ± 0.01 | 0.119 ± 0.02 | 0.124 ± 0.02 | 0.171 ± 0.02 |

| Conditions | Temp (°C) | Content of Elements (wt.%) | |||||

|---|---|---|---|---|---|---|---|

| Mg | Y | Nd | O | Zr | Fe | ||

| as Cast | RT | 92.2 | 3.9 | 2.5 | 11.0 | 0.6 | 0.1 |

| 50 | 83.2 | 3.7 | 1.9 | 9.8 | 1.2 | 0.2 | |

| 100 | 83.4 | 4.4 | 2.4 | 9.0 | 0.3 | 0.5 | |

| 150 | 82.9 | 4.0 | 2.1 | 10.3 | 0.7 | 0 | |

| T4 | RT | 80.9 | 4.5 | 2.0 | 10.1 | 2.0 | 0.2 |

| 50 | 81.9 | 3.8 | 2.6 | 9.7 | 0.5 | 0.3 | |

| 100 | 82.9 | 3.9 | 2.6 | 9.7 | 0.5 | 0.3 | |

| 150 | 85.6 | 4.3 | 3.0 | 6.1 | 0.7 | 0.2 | |

| T6 | RT | 79.1 | 3.8 | 2.1 | 14.3 | 0.6 | 0.1 |

| 50 | 84.8 | 4.1 | 2.7 | 7.1 | 0.3 | 1.0 | |

| 100 | 82.4 | 3.6 | 2.4 | 10.9 | 0.6 | 0.1 | |

| 150 | 84.6 | 3.8 | 2.2 | 8.8 | 0.6 | 0 | |

| Secondary Aging | RT | 80.3 | 3.5 | 2.3 | 13.2 | 0.5 | 0.1 |

| 50 | 87.3 | 3.7 | 2.0 | 6.3 | 0.6 | 0 | |

| 100 | 82.9 | 3.5 | 2.1 | 10.9 | 0.5 | 0.1 | |

| 150 | 80.0 | 3.5 | 1.7 | 14.0 | 0.7 | 0.1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saravanan, S.; Hattimare, A.R.; Mahadik, A.B.; Singh, A.; Kumar, U.N.; Annamalai, A.R. Effect of Heat Treatment on High-Temperature Tribological Behavior of WE54 Alloy: An Experimental Study. J. Manuf. Mater. Process. 2025, 9, 304. https://doi.org/10.3390/jmmp9090304

Saravanan S, Hattimare AR, Mahadik AB, Singh A, Kumar UN, Annamalai AR. Effect of Heat Treatment on High-Temperature Tribological Behavior of WE54 Alloy: An Experimental Study. Journal of Manufacturing and Materials Processing. 2025; 9(9):304. https://doi.org/10.3390/jmmp9090304

Chicago/Turabian StyleSaravanan, Sudharsan, Aditya Raman Hattimare, Atharva Bharat Mahadik, Arnav Singh, Uttamchand Narendra Kumar, and A. Raja Annamalai. 2025. "Effect of Heat Treatment on High-Temperature Tribological Behavior of WE54 Alloy: An Experimental Study" Journal of Manufacturing and Materials Processing 9, no. 9: 304. https://doi.org/10.3390/jmmp9090304

APA StyleSaravanan, S., Hattimare, A. R., Mahadik, A. B., Singh, A., Kumar, U. N., & Annamalai, A. R. (2025). Effect of Heat Treatment on High-Temperature Tribological Behavior of WE54 Alloy: An Experimental Study. Journal of Manufacturing and Materials Processing, 9(9), 304. https://doi.org/10.3390/jmmp9090304