Spot Melting Strategy for Contour Melting in Electron Beam Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

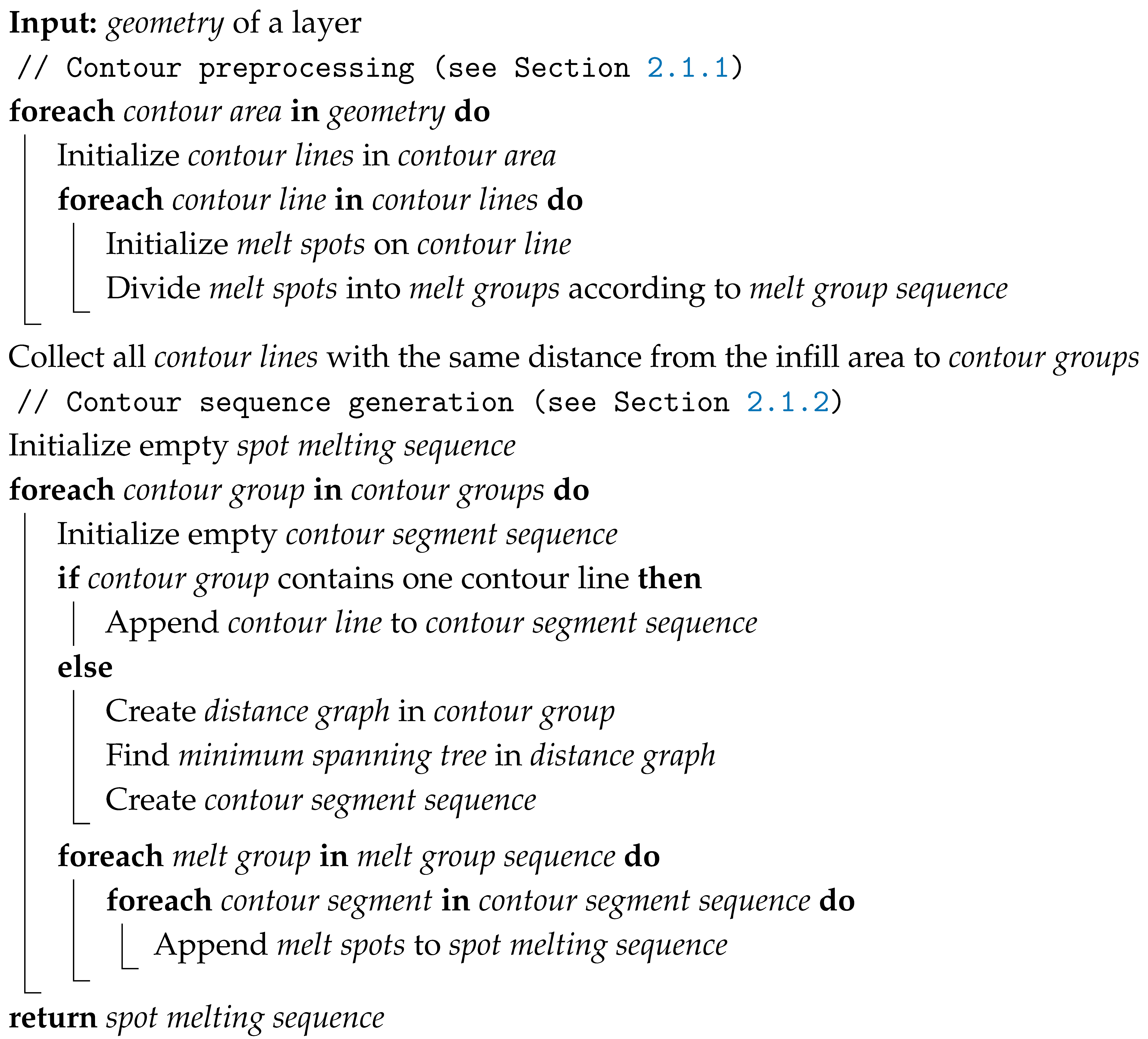

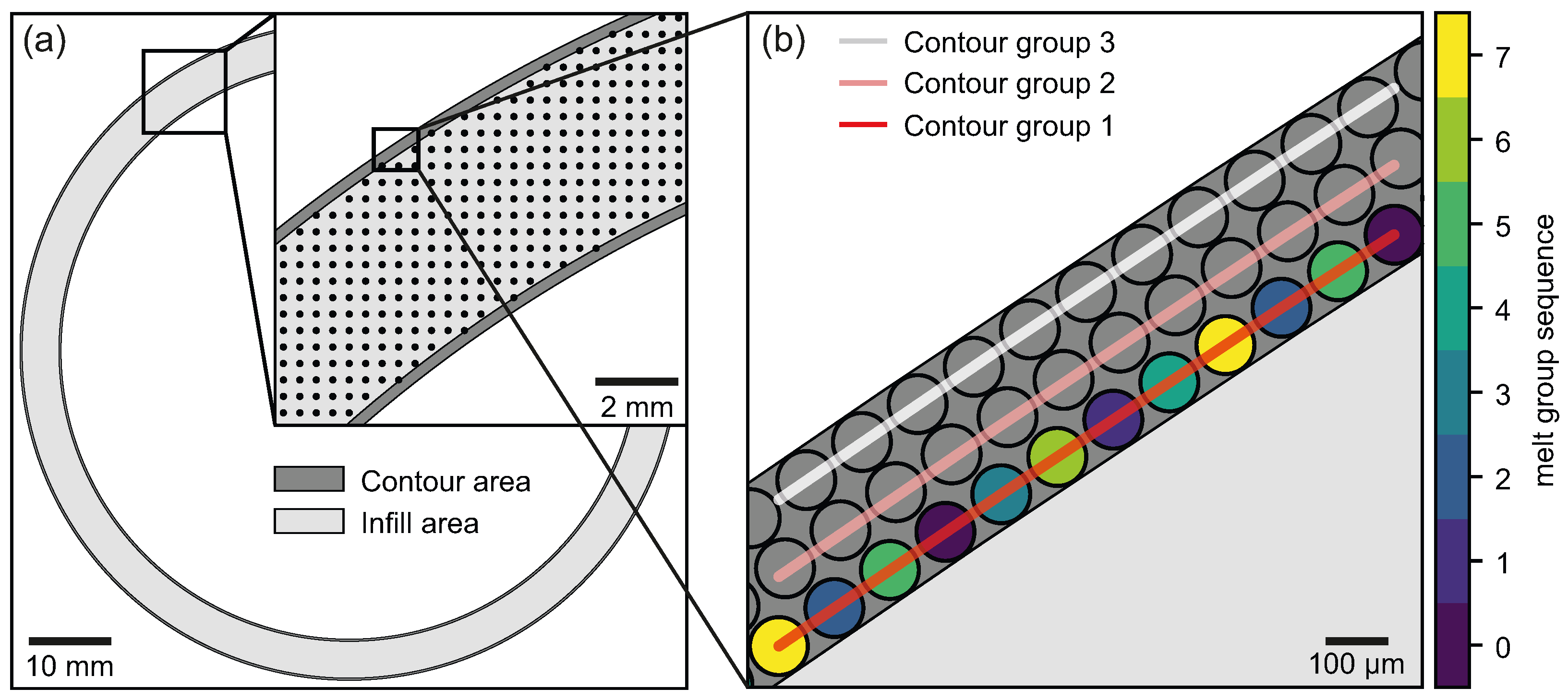

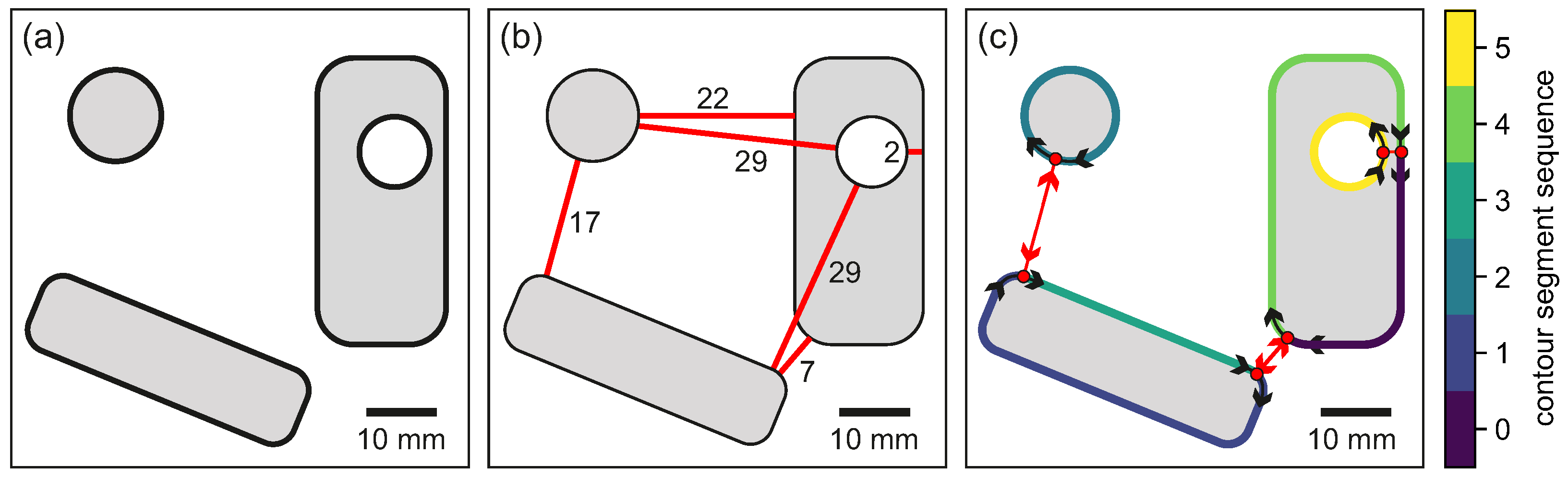

2.1. Contour Sequence Planning Algorithm

2.1.1. Contour Preprocessing

| Algorithm 1: Contour sequence planning algorithm. |

|

2.1.2. Contour Melting Sequence

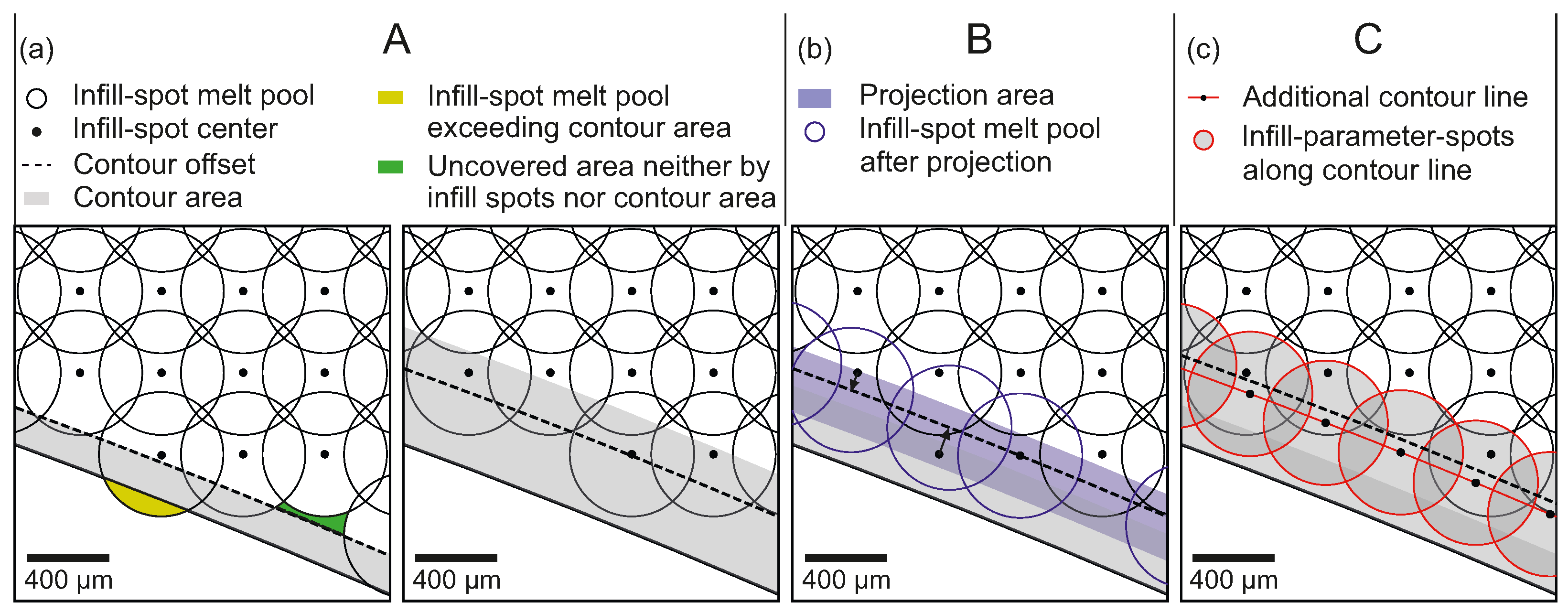

2.2. Spot Arrangement

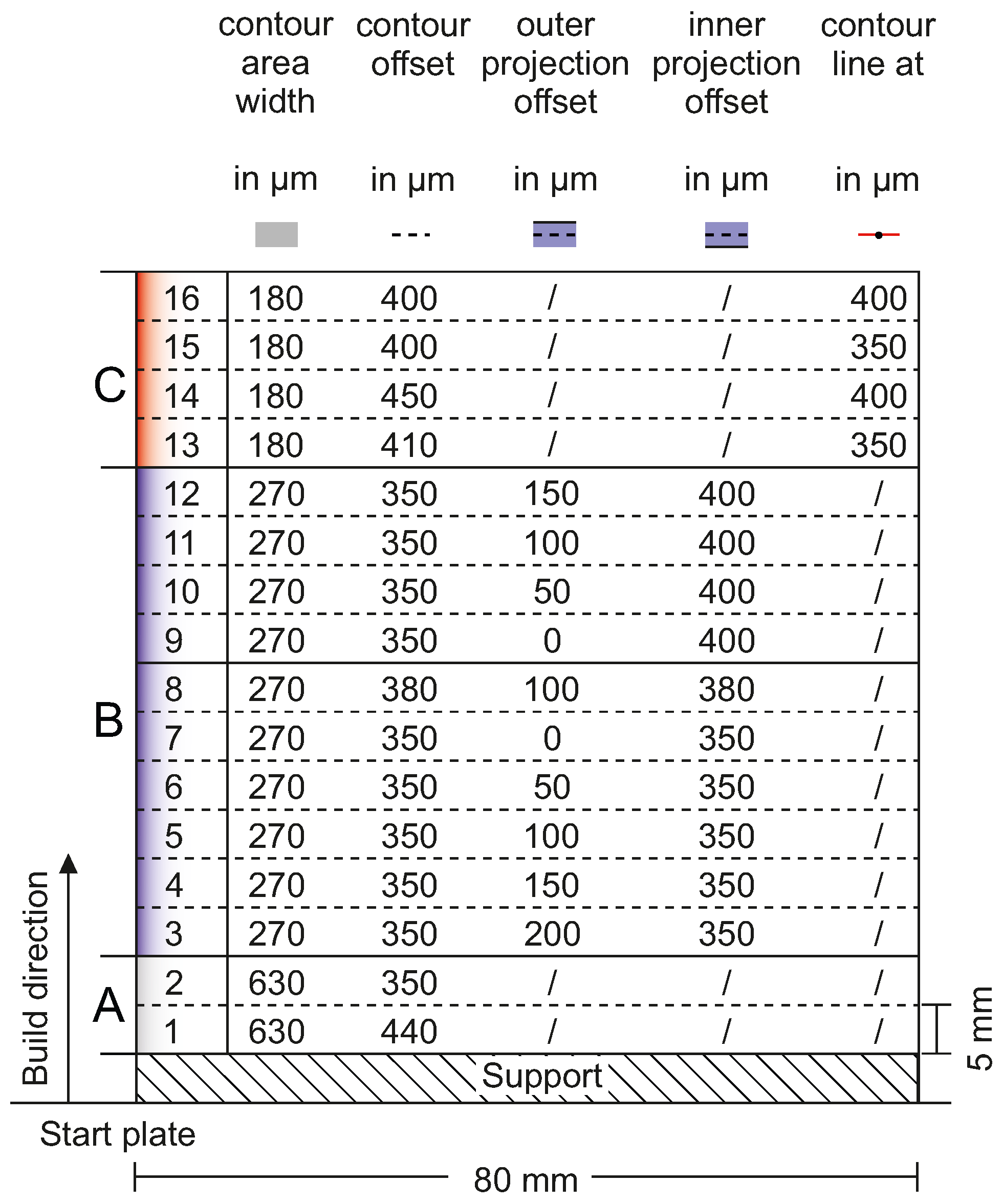

2.3. Experimental Setups

2.3.1. Process Setup

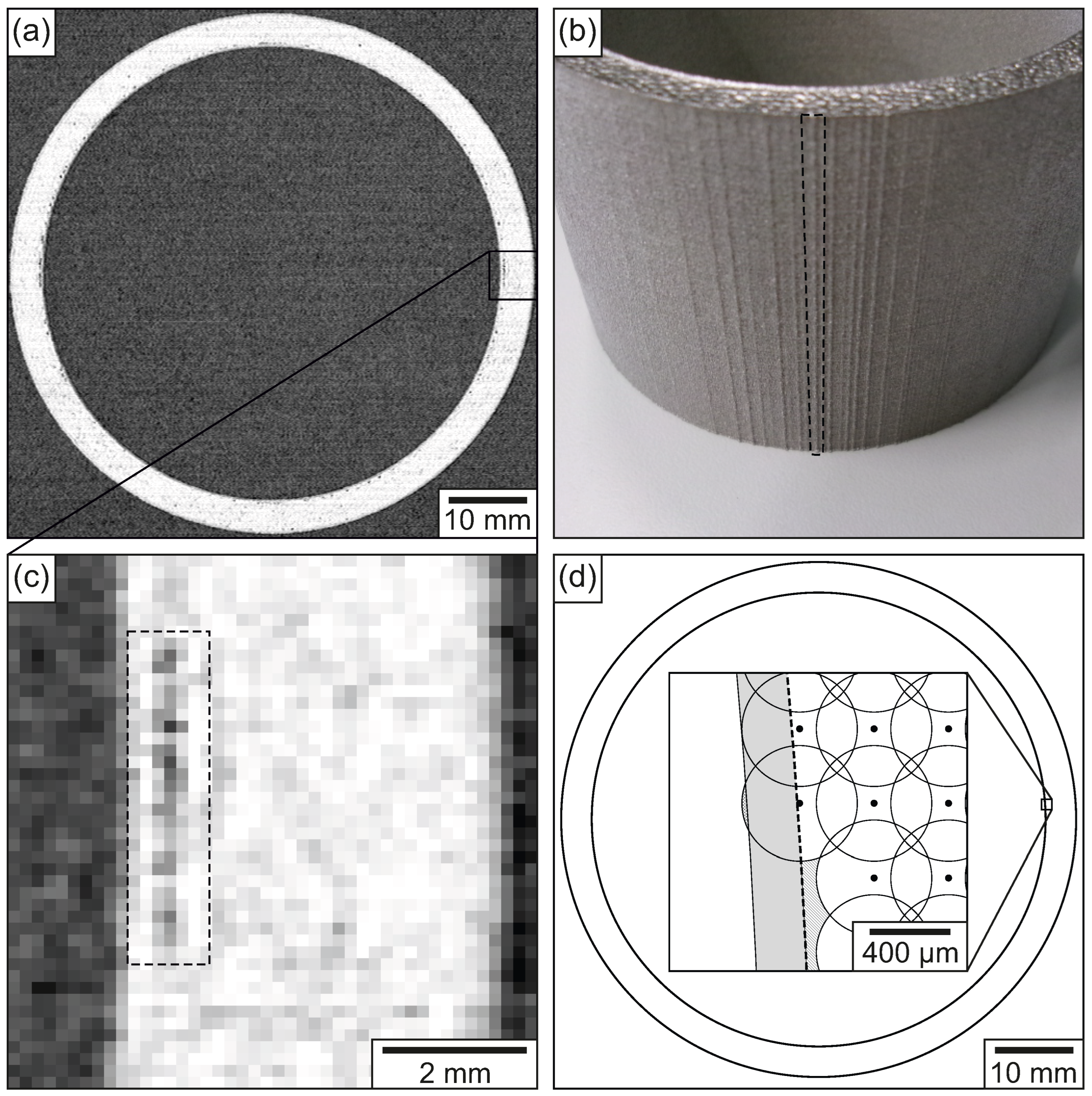

2.3.2. Hollow Cylinder

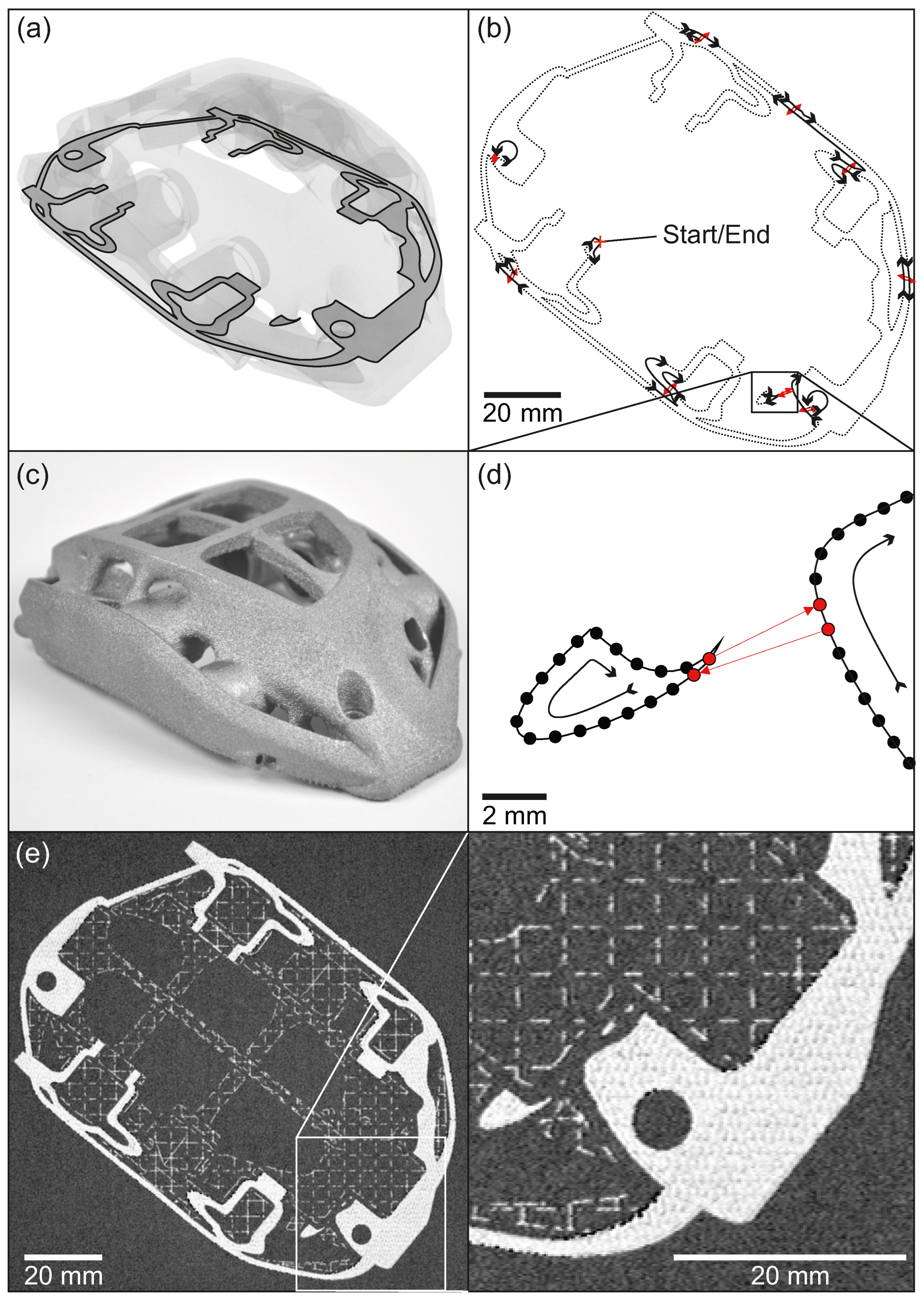

2.3.3. Brake Caliper

3. Results

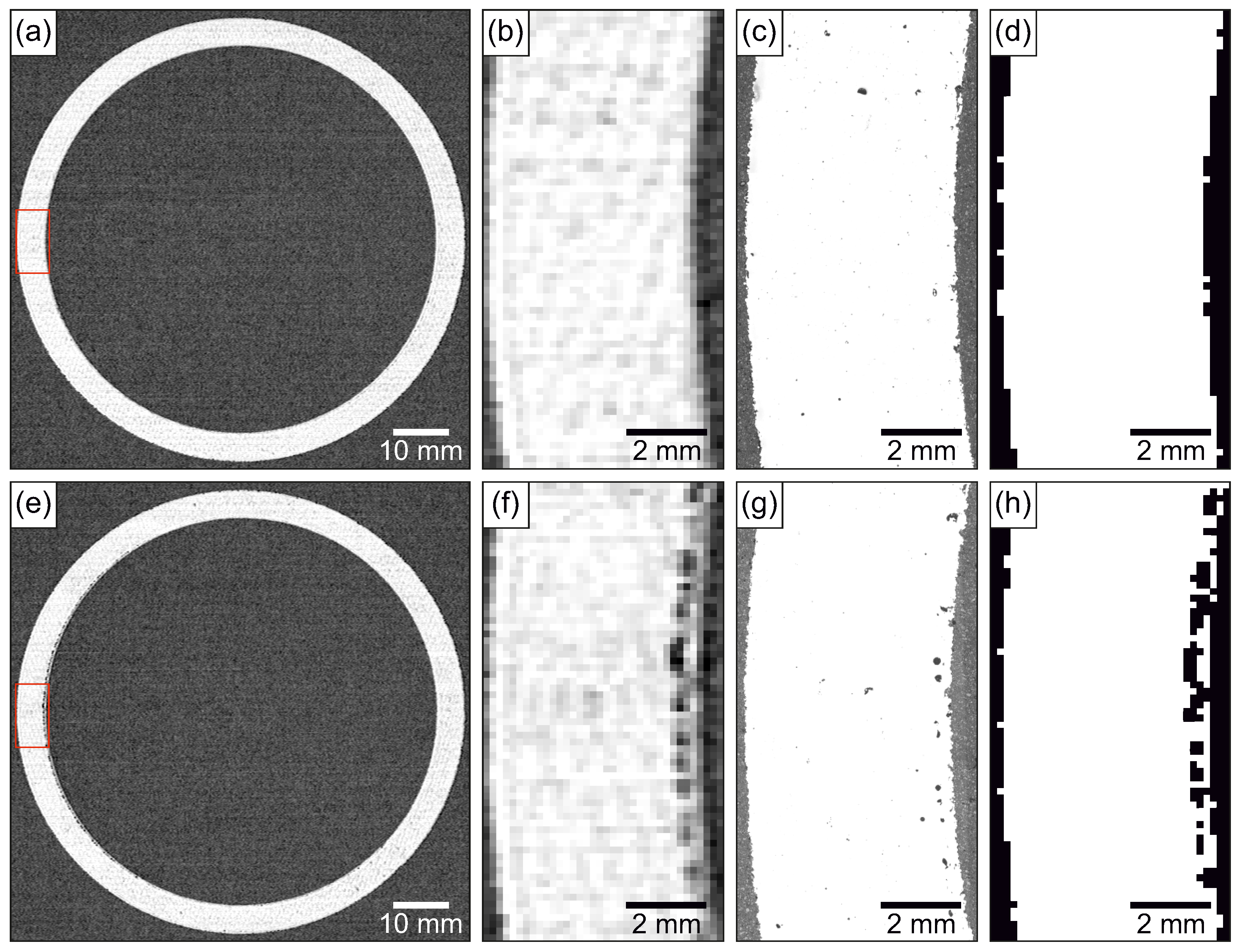

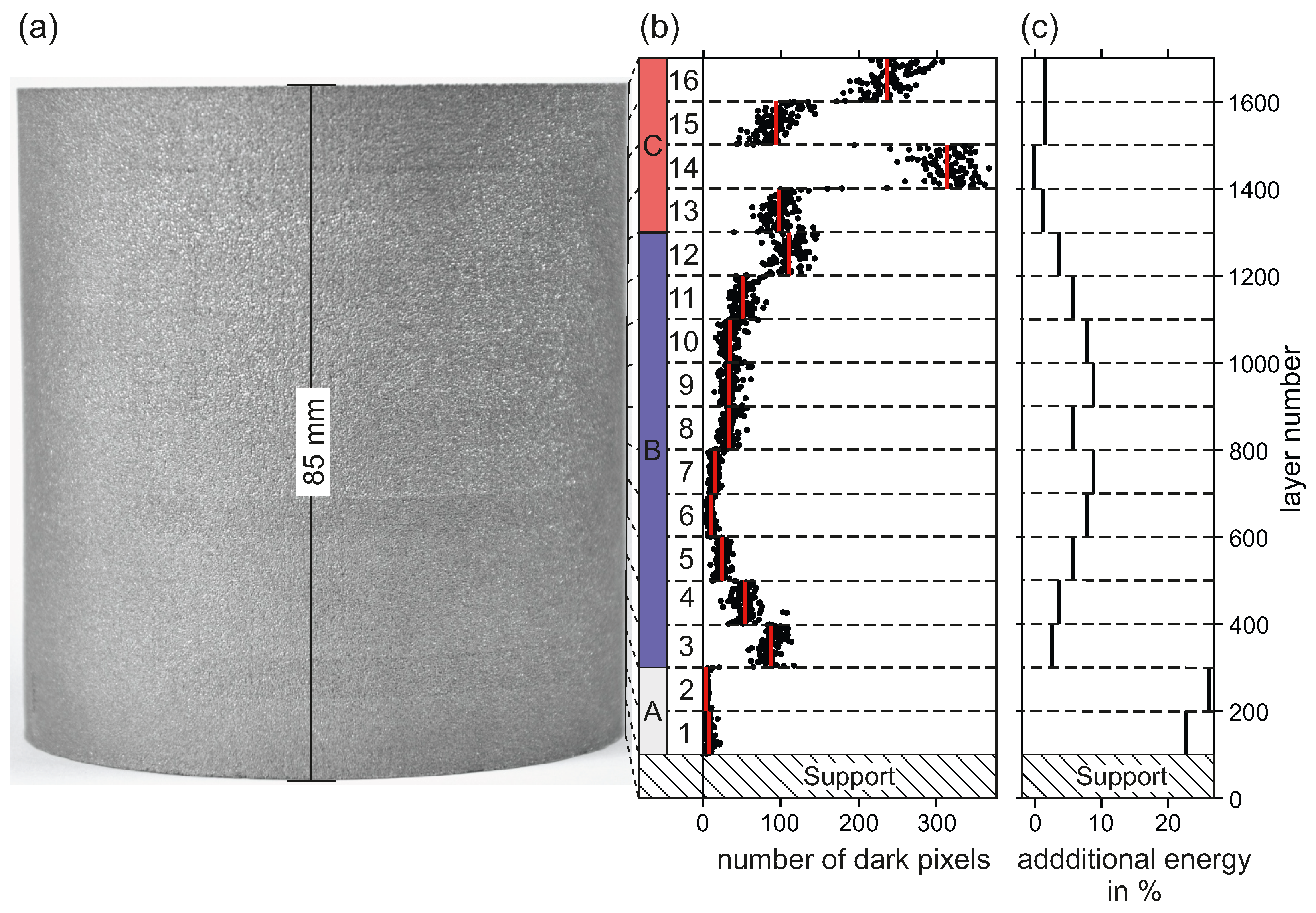

3.1. Hollow Cylinders

3.1.1. Main Challenges

3.1.2. Micrograph Analysis

3.1.3. Segmented Hollow Cylinder

3.2. Brake Caliper

4. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dehoff, R.R.; Kirka, M.M.; Sames, W.J.; Bilheux, H.; Tremsin, A.S.; Lowe, L.E.; Babu, S.S. Site specific control of crystallographic grain orientation through electron beam additive manufacturing. Mater. Sci. Technol. 2015, 31, 931–938. [Google Scholar] [CrossRef]

- Sabourin, E.; Houser, S.A.; Helge Bøhn, J. Adaptive slicing using stepwise uniform refinement. Rapid Prototyp. J. 1996, 2, 20–26. [Google Scholar] [CrossRef]

- Di Angelo, L.; Di Stefano, P.; Marzola, A. Surface quality prediction in FDM additive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 93, 3655–3662. [Google Scholar] [CrossRef]

- Carolo, L.C.B.; Cooper O, R.E. A review on the influence of process variables on the surface roughness of Ti-6Al-4V by electron beam powder bed fusion. Addit. Manuf. 2022, 59, 103103. [Google Scholar] [CrossRef]

- Mallipeddi, D.; Hajali, T.; Rännar, L.E.; Bergström, A.; Hernandez, S.; Strandh, E.; Nyborg, L.; Krajnik, P. Surface Integrity of Machined Electron Beam Melted Ti6Al4V Alloy Manufactured with Different Contour Settings and Heat Treatment. Procedia CIRP 2020, 87, 327–332. [Google Scholar] [CrossRef]

- Sullivan, E.M.; Sharif Hedås, S.; Jerhamre Engström, M.; Lindwall, G. Effect of powder particle size distribution and contouring on build quality in electron beam powder bed fusion of a medium-C hot-work tool steel. Int. J. Adv. Manuf. Technol. 2023, 128, 2953–2967. [Google Scholar] [CrossRef]

- Wang, F.; Wu, C.; Liang, Y.; Liang, X.; Wu, H.; Liu, L.; Lin, F.; Kan, W.; Lin, J. A surface quality optimization strategy based on a dedicated melt-pool control via the dashed-scan contouring technique in electron beam powder bed fusion. J. Mater. Process. Technol. 2024, 330, 118445. [Google Scholar] [CrossRef]

- Safdar, A.; He, H.; Wei, L.Y.; Snis, A.; Chavez de Paz, L.E. Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp. J. 2012, 18, 401–408. [Google Scholar] [CrossRef]

- Klingvall Ek, R.; Rännar, L.E.; Bäckstöm, M.; Carlsson, P. The effect of EBM process parameters upon surface roughness. Rapid Prototyp. J. 2016, 22, 495–503. [Google Scholar] [CrossRef]

- Biffi, C.A.; Fiocchi, J.; Ferrario, E.; Fornaci, A.; Riccio, M.; Romeo, M.; Tuissi, A. Effects of the scanning strategy on the microstructure and mechanical properties of a TiAl6V4 alloy produced by electron beam additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 4913–4924. [Google Scholar] [CrossRef]

- Wang, P.; Sin, W.; Nai, M.; Wei, J. Effects of Processing Parameters on Surface Roughness of Additive Manufactured Ti-6Al-4V via Electron Beam Melting. Materials 2017, 10, 1121. [Google Scholar] [CrossRef]

- Thalavai Pandian, K.; Lindgren, E.; Roychowdhury, S.; Neikter, M.; Hansson, T.; Pederson, R. Characterization of surface asperities to understand its effect on fatigue life of electron beam powder bed fusion manufactured Ti-6Al-4 V. Int. J. Fatigue 2024, 188, 108516. [Google Scholar] [CrossRef]

- Zhao, X.; Dadbakhsh, S.; Rashid, A. Contouring strategies to improve the tensile properties and quality of EBM printed Inconel 625 parts. J. Manuf. Processes 2021, 62, 418–429. [Google Scholar] [CrossRef]

- Karimi, P.; Schnur, C.; Sadeghi, E.; Andersson, J. Contour design to improve topographical and microstructural characteristics of Alloy 718 manufactured by electron beam-powder bed fusion technique. Addit. Manuf. 2020, 32, 101014. [Google Scholar] [CrossRef]

- Deng, D.; Moverare, J.; Peng, R.L.; Söderberg, H. Microstructure and anisotropic mechanical properties of EBM manufactured Inconel 718 and effects of post heat treatments. Mater. Sci. Eng. A 2017, 693, 151–163. [Google Scholar] [CrossRef]

- Roos, S.; Rännar, L.E. Surface roughness reduction in electron beam powder bed fusion additive manufacturing of super duplex stainless steel 2507: Investigating optimisation techniques and face orientation-dependent irregularities. Prog. Addit. Manuf. 2024, 10, 2487–2503. [Google Scholar] [CrossRef]

- Amigo, A. Generative Design F1 Brake Caliper. 2018. Available online: https://grabcad.com/library/generative-design-f1-brake-caliper-1 (accessed on 1 July 2025).

- Kupfer, T.; Leimbach, S.; Spano, L.; Pohl, S.; Körner, C.; Markl, M. Spot melting sequences for complex geometries in electron beam powder bed fusion. Prog. Addit. Manuf. 2025. [Google Scholar] [CrossRef]

- Kirka, M.M.; Lee, Y.; Greeley, D.A.; Okello, A.; Goin, M.J.; Pearce, M.T.; Dehoff, R.R. Strategy for Texture Management in Metals Additive Manufacturing. JOM 2017, 69, 523–531. [Google Scholar] [CrossRef]

- Kruskal, J.B. On the shortest spanning subtree of a graph and the traveling salesman problem. Proc. Am. Math. Soc. 1956, 7, 48–50. [Google Scholar] [CrossRef]

- Hagberg, A.; Swart, P.J.; Schult, D.A. Exploring Network Structure, Dynamics, and Function Using NetworkX; Technical Report; Los Alamos National Laboratory (LANL): Los Alamos, NM, USA, 2008. [Google Scholar]

- Arnold, C.; Pobel, C.; Osmanlic, F.; Körner, C. Layerwise monitoring of electron beam melting via backscatter electron detection. Rapid Prototyp. J. 2018, 24, 1401–1406. [Google Scholar] [CrossRef]

- Franke, M.; Arnold, C.; Körner, C. In-situ quality assurance for electron-based additive manufacturing by electron optical observation. Prog. Addit. Manuf. 2023, 8, 55–60. [Google Scholar] [CrossRef]

- van der Walt, S.; Schönberger, J.L.; Nunez-Iglesias, J.; Boulogne, F.; Warner, J.D.; Yager, N.; Gouillart, E.; Yu, T. scikit-image: Image processing in Python. PeerJ 2014, 2, e453. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. Automatica 1975, 11, 23–27. [Google Scholar] [CrossRef]

- Juechter, V.; Scharowsky, T.; Singer, R.; Körner, C. Processing window and evaporation phenomena for Ti–6Al–4V produced by selective electron beam melting. Acta Mater. 2014, 76, 252–258. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kupfer, T.; Spano, L.; Pohl, S.; Körner, C.; Markl, M. Spot Melting Strategy for Contour Melting in Electron Beam Powder Bed Fusion. J. Manuf. Mater. Process. 2025, 9, 303. https://doi.org/10.3390/jmmp9090303

Kupfer T, Spano L, Pohl S, Körner C, Markl M. Spot Melting Strategy for Contour Melting in Electron Beam Powder Bed Fusion. Journal of Manufacturing and Materials Processing. 2025; 9(9):303. https://doi.org/10.3390/jmmp9090303

Chicago/Turabian StyleKupfer, Tobias, Lukas Spano, Sebastian Pohl, Carolin Körner, and Matthias Markl. 2025. "Spot Melting Strategy for Contour Melting in Electron Beam Powder Bed Fusion" Journal of Manufacturing and Materials Processing 9, no. 9: 303. https://doi.org/10.3390/jmmp9090303

APA StyleKupfer, T., Spano, L., Pohl, S., Körner, C., & Markl, M. (2025). Spot Melting Strategy for Contour Melting in Electron Beam Powder Bed Fusion. Journal of Manufacturing and Materials Processing, 9(9), 303. https://doi.org/10.3390/jmmp9090303