Advancements in Hole Quality for AISI 1045 Steel Using Helical Milling

Abstract

1. Introduction

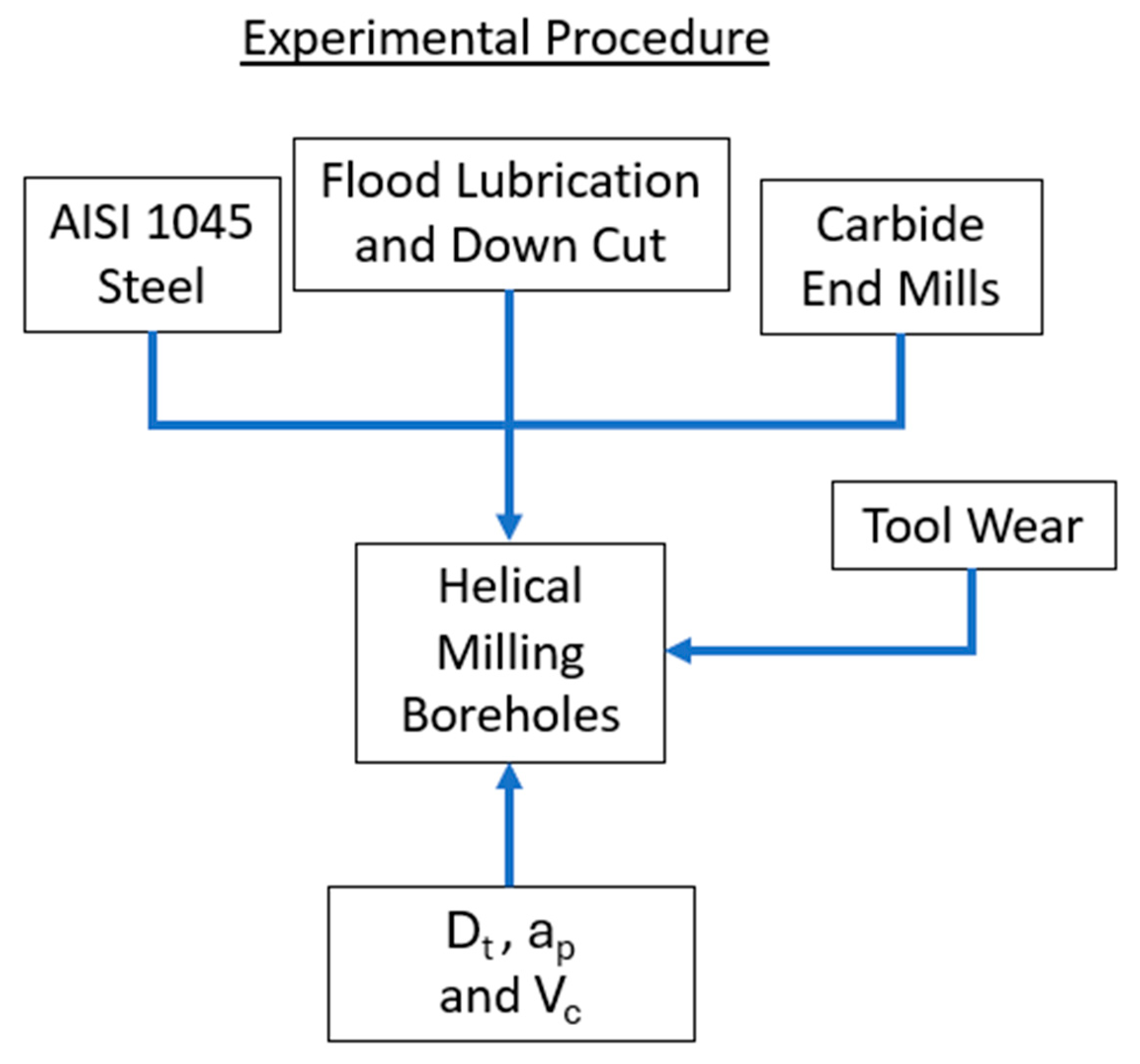

2. Experimental Methodology

2.1. Equipment

2.2. Material

2.3. Cutting Tools

2.4. Cutting Parameters and Experimental Design

2.5. Quality Indicators

3. Results and Discussion

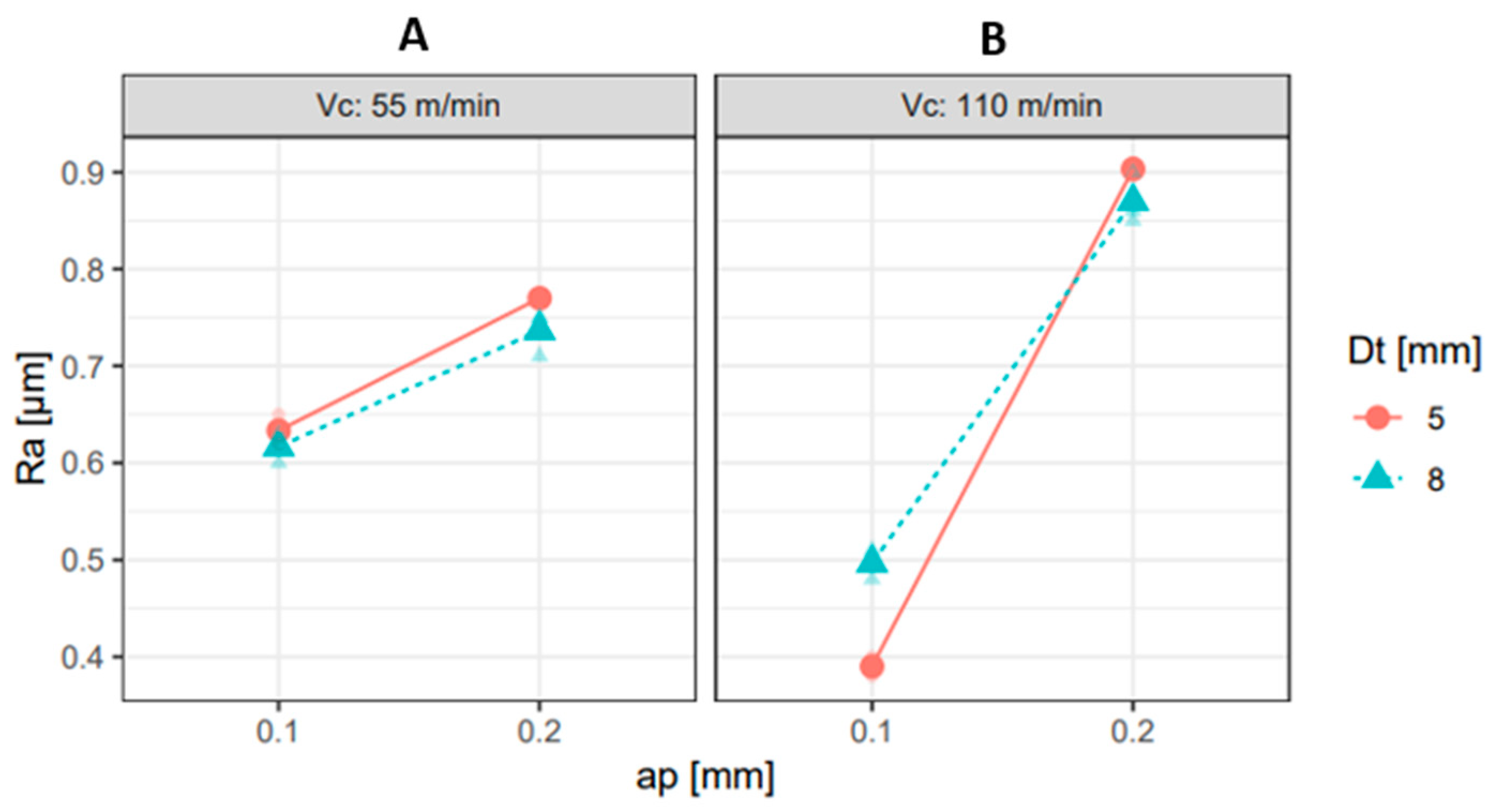

3.1. Surface Topography

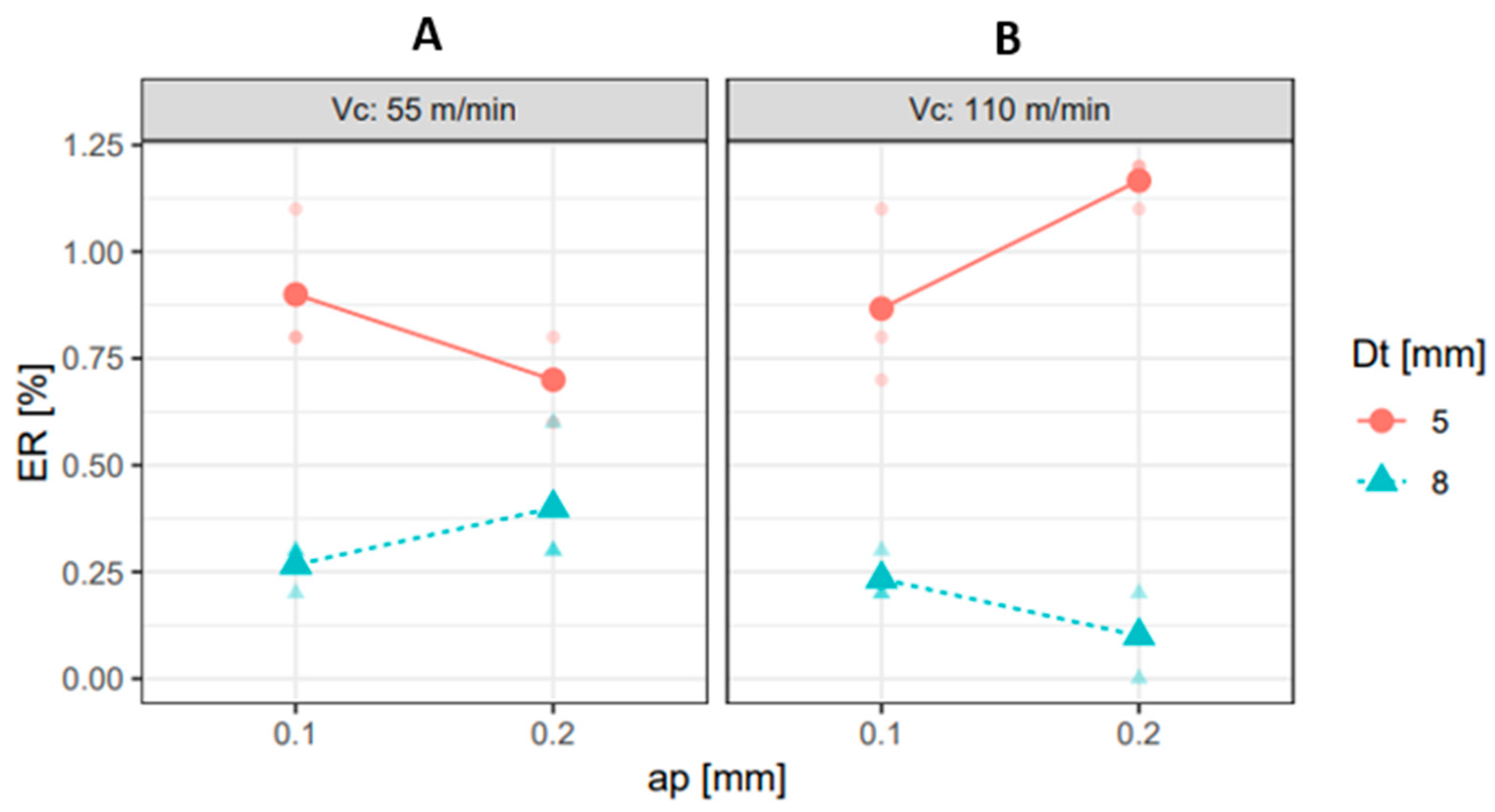

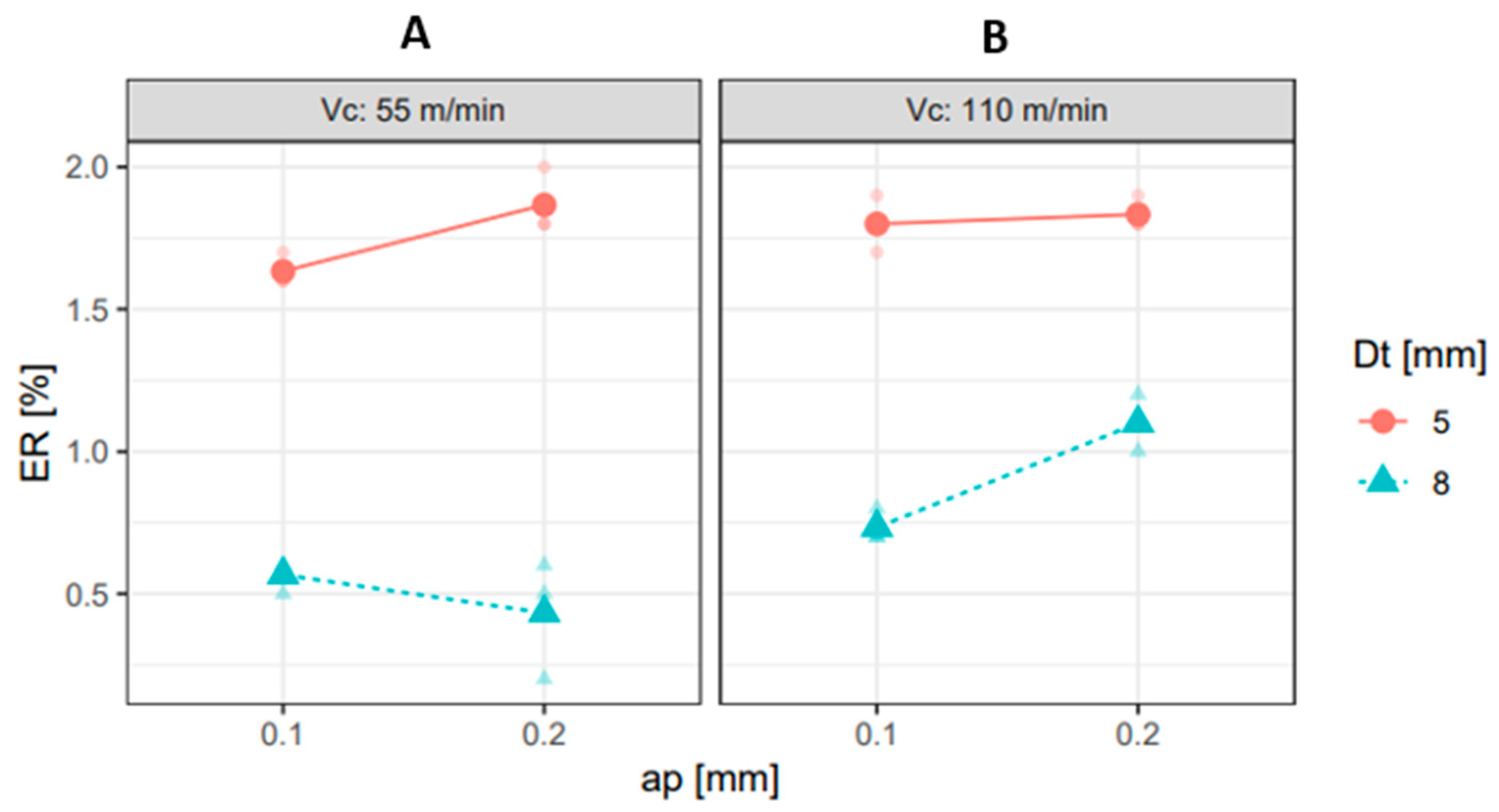

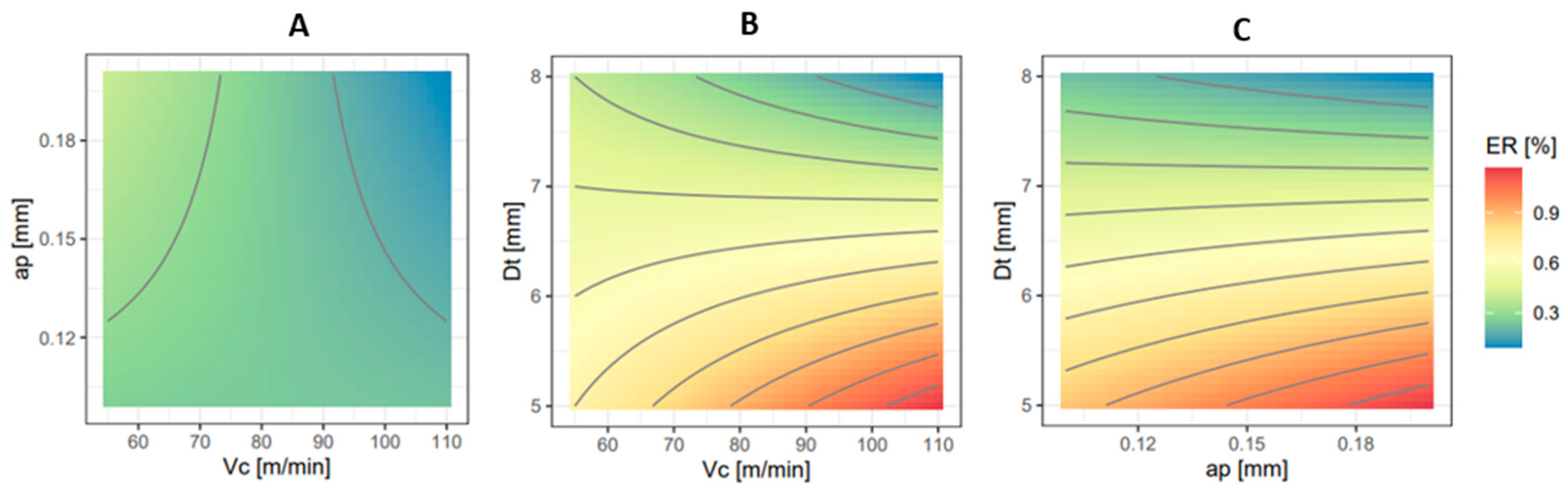

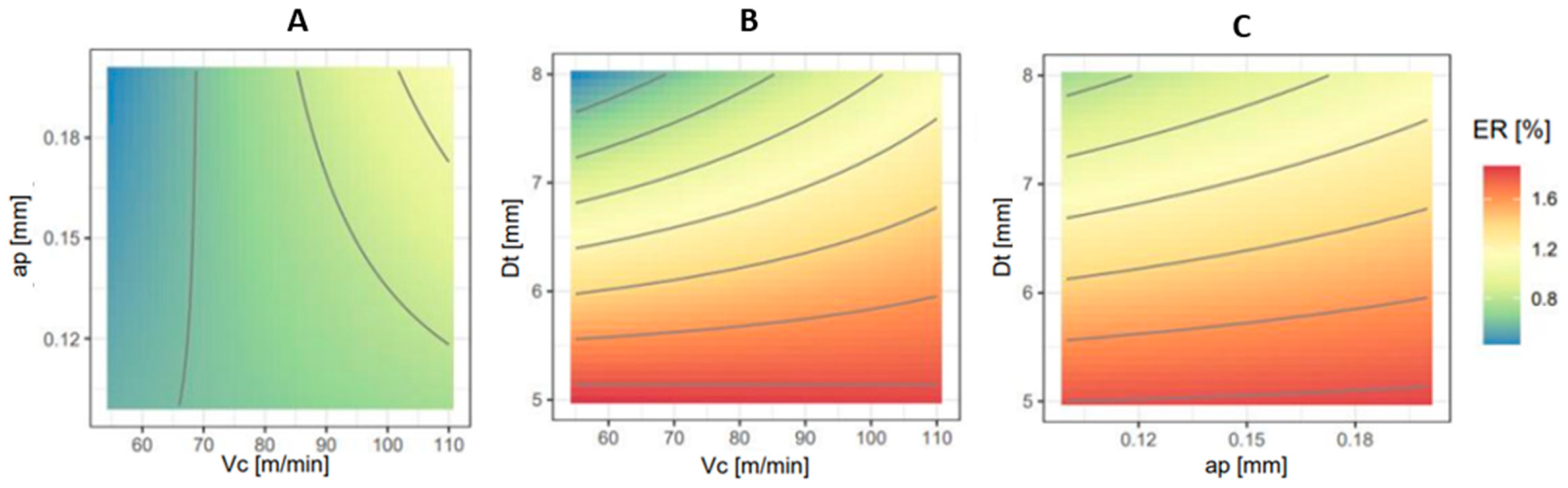

3.2. Nominal Diameter

3.3. Burr and Chip Formation

3.4. Tool Wear

4. Conclusions

- 1.

- The doubling of ap resulted in a 50% increase in Ra, whereas the doubling of Vc resulted in a 30% to 40% (100% − 100() decrease in Ra (relatively speaking when), while Dt had no significant effect on Ra. The effect of ap is the most significant according to the ANOVA, followed by the combination of Vc and ap and then ap and Dt.

- 2.

- When relating Ra values with dimensional tolerances, the HM process was able to achieve an IT7 grade.

- 3.

- The diameter’s geometric accuracy improved with higher Dt values (reduction of around 1% in geometric error, 100% − 100()), while it decreased with increased ap and Vc (increases of 0.5% in the geometric error at the hole’s lower end). The most influential parameter was Dt, due to its impact on tool deflection.

- 4.

- The most influential parameter for geometric accuracy was Dt, according to the ANOVA test. It was also found that the geometric accuracy was closer to the desired dimension DB at the upper end of the hole than at the lower end, meaning that the relative error was reduced at the upper end.

- 5.

- For burr formation, the results demonstrated that the burr width was generally higher at the lower end of the hole than at the upper end.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| AISI | American Iron and Steel Institute |

| Al | Aluminium |

| ANOVA | Analysis of variance |

| ap | Axial depth of cut |

| C | Carbon |

| CD | Conventional drilling |

| CNC | Computer numeric control |

| Cr | Chromium |

| DB | Hole diameter |

| Dh | Helix diameter |

| Dt | Tool diameter |

| ER | Relative error |

| F | Feed speed in the CNC programme |

| fz | Feed per tooth |

| HM | Helical milling |

| m/min | Metre per minute |

| Mm | Millimetre |

| mm/min | Millimetre per minute |

| mm/rev | Millimetre per revolution |

| mm/tooth | Millimetre per tooth |

| Mn | Manganese |

| Mo | Molybdenum |

| μm | Micrometre |

| Νi | Nickel |

| P | Phosphorus |

| PVD | Physical vapour deposition |

| RPM | Rotation per minute |

| Ra | Arithmetic average roughness |

| Rt | Total height of the roughness profile |

| Rp | Maximum profile peak height |

| S | Sulphur |

| SD | Standard deviation |

| Si | Silica |

| TCP | Tool centre point |

| Ti | Titanium |

| Vc | Cutting speed |

| Vf | Feed velocity |

| Vfp | Peripheral feed velocity |

| Vbmax | Maximum tool flank wear |

| z | Tool’s teeth number |

References

- Shanmugam, R.; Baloor, S.S.; Koklu, U.; Polishetty, A.; Bolar, G. Machining Temperature, Surface Integrity and Burr Size Investigation during Coolant-Free Hole Milling in Ti6Al4V Titanium Alloy. Lubricants 2023, 11, 349. [Google Scholar] [CrossRef]

- Pereira, R.B.D.; Brandão, L.C.; de Paiva, A.P.; Ferreira, J.R.; Davim, J.P. A review of helical milling process. Int. J. Mach. Tools Manuf. 2017, 120, 27–48. [Google Scholar] [CrossRef]

- Iyer, R.; Koshy, P.; Ng, E. Helical milling: An enabling technology for hard machining precision holes in AISI D2 tool steel. Int. J. Mach. Tools Manuf. 2007, 47, 205–210. [Google Scholar] [CrossRef]

- Akula, S.; Nayak, S.N.; Bolar, G.; Managuli, V. Comparison of conventional drilling and helical milling for hole making in Ti6Al4V titanium alloy under sustainable dry condition. Manuf. Rev. 2021, 8, 12. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Fangmann, S.; Meyer, I. Orbital drilling kinematics. Prod. Eng. 2008, 2, 277–283. [Google Scholar] [CrossRef]

- Denkena, B.; De Leon, L.; Dege, J.H. Kinematik und Spanungsformen beim Zirkularfräsen. Materwiss. Werksttech. 2008, 39, 610–615. [Google Scholar] [CrossRef]

- Costa, D.D.D.; Marques, A.; Amorim, F.L. Hole quality and cutting time evaluation in the interpolated helical milling. Int. J. Manuf. Res. 2015, 10, 313. [Google Scholar] [CrossRef]

- Saadatbakhsh, M.H.; Imani, H.; Sadeghi, M.H.; Farshi, S.S. Experimental study of surface roughness and geometrical and dimensional tolerances in helical milling of AISI 4340 alloy steel. Int. J. Adv. Manuf. Technol. 2017, 93, 4063–4074. [Google Scholar] [CrossRef]

- Cao, S.; Zhang, X.; Wu, C.; Tang, Y.; Yang, M.; Huang, W.; Zhu, D.; Zhan, W. Experimental investigation on tool wear and hole quality in helical milling of CFRPs. Int. J. Adv. Manuf. Technol. 2024, 130, 4791–4803. [Google Scholar] [CrossRef]

- Li, Z.; Liu, Q. Surface topography and roughness in hole-making by helical milling. Int. J. Adv. Manuf. Technol. 2012, 66, 1415–1425. [Google Scholar] [CrossRef]

- Kharka, V.; Mujumdar, S.; Shukla, S. Manufacturing Letters Study on Helical Milling of SS 304 with Small Diameter Tools Under the Influence of Minimum Quantity Lubrication (MQL)-NC-ND License. Available online: https://creativecommons.org/licenses/by-nc-nd/4.0 (accessed on 12 June 2024).

- Wang, J.; Ge, J.; Chen, G.; Liu, J.; Wang, Z.; Ren, C. Sustainable cooling/lubrication induced thermo-mechanical effects on ultrasonic vibration helical milling of CFRP/Ti–6Al–4V stacks. Int. J. Light. Mater. Manuf. 2023, 6, 311–328. [Google Scholar] [CrossRef]

- Amini, S.; Baraheni, M.; Hakimi, E. Enhancing dimensional accuracy and surface integrity by helical milling of carbon fiber reinforced polymers. Int. J. Light. Mater. Manuf. 2019, 2, 362–372. [Google Scholar] [CrossRef]

- Zhou, L.; Ke, Y.; Dong, H.; Chen, Z.; Gao, K. Hole diameter variation and roundness in dry orbital drilling of CFRP/Ti stacks. Int. J. Adv. Manuf. Technol. 2016, 87, 811–824. [Google Scholar] [CrossRef]

- Jiao, A.; Yuan, J.; Zhang, Y.; Zhang, J.; Miao, Y.; Liu, G. Study on Variable Parameter Helical Milling of TC4 Titanium Alloy Tube. Int. J. Precis. Eng. Manuf. 2023, 24, 1947–1959. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, L.; Fang, Q.; Sun, Z.; Qu, W. Study on tool deflection compensation method based on cutting force observer for orbital drilling of CFRP/Ti stacks. J. Manuf. Process. 2022, 75, 450–460. [Google Scholar] [CrossRef]

- Puerta-Morales, F.J.; Gomez, J.S.; Fernandez-Vidal, S.R. Study of the influence of helical milling parameters on the quality of holes in the UNS R56400 alloy. Appl. Sci. 2020, 10, 845. [Google Scholar] [CrossRef]

- DIN 4772:1979-11; Electrical Contact (Stylus) Instruments for the Measurement of Surface Roughness by the Profile Method. Deutsches Institut für Normung (DIN)—German Institute for Standardisation: Berlin, Germany, 1979.

- ISO 8688-2:1989; Tool Life Testing in Milling—Part 2: End Milling. International Organisation for Standardization (ISO): Geneve, Switzerland, 1989.

- Li, Z.; Liu, Q.; Ming, X.; Wang, X.; Dong, Y. Cutting force prediction and analytical solution of regenerative chatter stability for helical milling operation. Int. J. Adv. Manuf. Technol. 2014, 73, 433–442. [Google Scholar] [CrossRef]

- Bolar, G.; Sridhar, A.K.; Ranjan, A. Drilling and helical milling for hole making in multi-material carbon reinforced aluminum laminates. Int. J. Light. Mater. Manuf. 2022, 5, 113–125. [Google Scholar] [CrossRef]

- ISO 3685; Tool-Life Testing with Single-Point Turning Tools. International Organisation for Standardization (ISO): Geneve, Switzerland, 1993.

- Pereira, R.B.D.; Lauro, C.H.; Brandão, L.C.; Ferreira, J.R.; Davim, J.P. Tool wear in dry helical milling for hole-making in AISI H13 hardened steel. Int. J. Adv. Manuf. Technol. 2018, 101, 2425–2439. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr+Mo+Ni | |

|---|---|---|---|---|---|---|

| Min % | 0.42 | - | 0.50 | - | - | - |

| Max % | 0.50 | 0.40 | 0.80 | 0.035 | 0.035 | 0.063 |

| Test | Vc (mm/min) | ap (mm/rev) | Dt (mm) |

|---|---|---|---|

| A | 110 | 0.1 | 5 |

| B | 55 | 0.1 | 5 |

| C | 110 | 0.2 | 5 |

| D | 55 | 0.2 | 5 |

| E | 110 | 0.1 | 8 |

| F | 55 | 0.1 | 8 |

| G | 110 | 0.2 | 8 |

| H | 55 | 0.2 | 8 |

| Test | 1st Hole | 2nd Hole | 3rd Hole | |||

|---|---|---|---|---|---|---|

| Ra (μm) | SD (μm) | Ra (μm) | SD (μm) | Ra (μm) | SD (μm) | |

| A | 0.40 | 0.03 | 0.39 | 0.05 | 0.38 | 0.04 |

| B | 0.62 | 0.01 | 0.63 | 0.02 | 0.65 | 0.02 |

| C | 0.90 | 0.03 | 0.91 | 0.02 | 0.90 | 0.05 |

| D | 0.77 | 0.04 | 0.77 | 0.03 | 0.77 | 0.03 |

| E | 0.48 | 0.01 | 0.51 | 0.02 | 0.50 | 0.03 |

| F | 0.62 | 0.04 | 0.63 | 0.04 | 0.60 | 0.04 |

| G | 0.90 | 0.05 | 0.85 | 0.01 | 0.86 | 0.06 |

| H | 0.75 | 0.06 | 0.75 | 0.03 | 0.71 | 0.06 |

| Factors | Degrees of Freedom | Sum of Squares | Mean of Squares | F-Value | p-Value |

|---|---|---|---|---|---|

| Vc | 1.00 | 4.00 × 10−3 | 4.00 × 10−3 | 1.36 × 101 | 2.00 × 10−3 |

| ap | 1.00 | 4.90 × 10−1 | 4.90 × 10−1 | 18.97 × 102 | <2.00 × 10−16 |

| Dt | 1.00 | 1.00 × 10−3 | 1.00 × 10−3 | 7.90 × 10−1 | <3.87 × 10−1 |

| Vc × ap | 1.00 | 1.49 × 10−1 | 1.49 × 10−1 | 57.61 × 102 | 5.65 × 10−14 |

| Vc × Dt | 1.00 | 6.00 × 10−3 | 6.00 × 10−3 | 2.21 × 101 | 1.00 × 10−3 |

| ap × Dt | 1.00 | 9.00 × 10−3 | 9.00 × 10−3 | 3.56 × 101 | 1.96 × 10−5 |

| Vc × ap × Dt | 1.00 | 6.00 × 10−3 | 6.00 × 10−3 | 2.21 × 101 | 1.00 × 10−3 |

| Residuals | 16.00 | 4.00 × 10−3 | 3.00 × 10−3 | Not calculated | |

| Total | 23.00 | 6.67 × 10−1 | 2.90 × 10−2 | ||

| Test | Dtop 1 (mm) | ER 1 (%) | Dtop 2 (mm) | ER 2 (%) | Dtop 3 (mm) | ER 3 (%) |

|---|---|---|---|---|---|---|

| A | 8.90 | 1.1 | 8.93 | 0.80 | 8.94 | 0.7 |

| B | 8.93 | 0.80 | 8.93 | 0.80 | 8.91 | 1.1 |

| C | 8.90 | 1.2 | 8.91 | 1.1 | 8.89 | 1.2 |

| D | 8.95 | 0.60 | 8.93 | 0.80 | 8.94 | 0.7 |

| E | 8.97 | 0.30 | 8.98 | 0.20 | 8.98 | 0.2 |

| F | 8.98 | 0.30 | 8.98 | 0.30 | 8.98 | 0.2 |

| G | 9.00 | 0 | 8.98 | 0.20 | 9.00 | 0.1 |

| H | 8.95 | 0.60 | 8.98 | 0.30 | 8.98 | 0.3 |

| Test | Dbottom 1 (mm) | ER 1 (%) | Dbottom 2 (mm) | ER 2 (%) | Dbottom 3 (mm) | ER 3 (%) |

|---|---|---|---|---|---|---|

| A | 8.83 | 1.90 | 8.85 | 1.70 | 8.84 | 1.80 |

| B | 8.85 | 1.70 | 8.86 | 1.60 | 8.86 | 1.60 |

| C | 8.84 | 1.80 | 8.84 | 1.80 | 8.83 | 1.90 |

| D | 8.84 | 1.80 | 8.82 | 2.00 | 8.84 | 1.80 |

| E | 8.93 | 0.80 | 8.94 | 0.70 | 8.94 | 0.70 |

| F | 8.96 | 0.50 | 8.95 | 0.60 | 8.95 | 0.60 |

| G | 8.98 | 0.20 | 8.96 | 0.50 | 8.95 | 0.60 |

| H | 8.91 | 1.00 | 8.90 | 1.10 | 8.91 | 1.00 |

| Factors | Degrees of Freedom | Sum of Squares | Mean of Squares | F-Value | p-Value |

|---|---|---|---|---|---|

| Vc | 1.00 | 4.00 × 10−3 | 4.00 × 10−3 | 2.25 × 10−1 | 6.42 × 10−1 |

| ap | 1.00 | 4.00 × 10−3 | 4.00 × 10−3 | 2.25 × 10−1 | 6.42 × 10−1 |

| Dt | 1.00 | 0.26 × 101 | 0.26 × 101 | 1.56 × 102 | 1.15 × 10−9 |

| Vc × ap | 1.00 | 2.00 × 10−2 | 2.00 × 10−2 | 0.12 × 101 | 2.85 × 10−1 |

| Vc × Dt | 1.00 | 2.20 × 10−1 | 2.20 × 10−1 | 1.32 × 101 | 2.00 × 10−3 |

| ap × Dt | 1.00 | 4.00 × 10−3 | 4.00 × 10−3 | 2.25 × 10−1 | 6.42 × 10−1 |

| Vc × ap × Dt | 1.00 | 2.20 × 10−1 | 2.20 × 10−1 | 1.32 × 101 | 2.00 × 10−3 |

| Residuals | 16.00 | 2.67 × 10−1 | 1.70 × 10−2 | Not calculated | |

| Total | 23.00 | 4.50 × 10−1 | 1.34 × 10−1 | ||

| Factors | Degrees of Freedom | Sum of Squares | Mean of Squares | F-Value | p-Value |

|---|---|---|---|---|---|

| Vc | 1.00 | 3.50 × 10−1 | 3.50 × 10−1 | 0.31 × 101 | 4.14 × 10−5 |

| ap | 1.00 | 9.40 × 10−2 | 9.40 × 10−2 | 0.83 × 101 | 1.00 × 10−2 |

| Dt | 1.00 | 0.69 × 101 | 0.69 × 101 | 6.16 × 102 | 3.34 × 10−14 |

| Vc − ap | 1.00 | 3.40 × 10−2 | 3.40 × 10−2 | 0.30 × 101 | 1.02 × 10−1 |

| Vc − Dt | 1.00 | 1.84 × 10−1 | 1.84 × 10−1 | 1.63 × 101 | 1.00 × 10−3 |

| ap − Dt | 1.00 | 0 | 0 | 3.37 × 10−2 | 8.50 × 10−1 |

| Vc − ap − Dt | 1.00 | 1.84 × 10−1 | 1.84 × 10−1 | 1.63 × 101 | 1.00 × 10−3 |

| Residuals | 16.00 | 1.80 × 10−1 | 1.10 × 10−2 | Not calculated | |

| Total | 23.00 | 3.37 × 10−1 | 3.29 × 10−1 | ||

| Test | Burr Width 1 (μm) | SD 1 (μm) | Burr Width 2 (μm) | SD 2 (μm) | Burr Width 3 (μm) | SD 3 (μm) |

|---|---|---|---|---|---|---|

| A | 53.84 | 9.95 | 58.22 | 8.43 | 50.59 | 11.01 |

| B | 64.05 | 21.36 | 39.80 | 2.13 | 39.41 | 5.65 |

| C | 48.08 | 1.54 | 47.17 | 8.51 | 68.75 | 30.77 |

| D | 54.37 | 7.13 | 56.14 | 5.28 | 84.00 | 1.00 |

| E | 60.79 | 8.71 | 70.97 | 24.51 | 58.02 | 9.80 |

| F | 53.75 | 13.83 | 54.26 | 8.07 | 58.55 | 6.84 |

| G | 75.65 | 15.71 | 47.70 | 3.75 | 49.61 | 10.84 |

| H | 68.70 | 8.75 | 8 82.86 | 15.51 | 74.53 | 7.08 |

| Test | Burr Width 1 (μm) | SD 1 (μm) | Burr Width 2 (μm) | SD 2 (μm) | Burr Width 3 (μm) | SD 3 (μm) |

|---|---|---|---|---|---|---|

| A | 257.63 | 10.12 | 274.55 | 31.52 | 164.69 | 39.75 |

| B | 350.88 | 88.20 | 270.15 | 17.11 | 195.41 | 35.81 |

| C | 76.35 | 1.28 | 115.81 | 5.51 | 113.59 | 37.92 |

| D | 153.05 | 102.18 | 73.87 | 12.89 | 73.43 | 23.26 |

| E | 63.24 | 14.42 | 222.53 | 18.56 | 149.27 | 14.85 |

| F | 51.43 | 8.35 | 55.55 | 9.83 | 64.17 | 11.60 |

| G | 89.23 | 21.44 | 73.27 | 2.76 | 56.07 | 9.94 |

| H | 132.13 | 39.74 | 70.10 | 18.80 | 84.99 | 11.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, P.M.; Festas, A.J.d.F.; Pereira, R.B.D.; Davim, J.P. Advancements in Hole Quality for AISI 1045 Steel Using Helical Milling. J. Manuf. Mater. Process. 2025, 9, 256. https://doi.org/10.3390/jmmp9080256

Silva PM, Festas AJdF, Pereira RBD, Davim JP. Advancements in Hole Quality for AISI 1045 Steel Using Helical Milling. Journal of Manufacturing and Materials Processing. 2025; 9(8):256. https://doi.org/10.3390/jmmp9080256

Chicago/Turabian StyleSilva, Pedro Mendes, António José da Fonseca Festas, Robson Bruno Dutra Pereira, and João Paulo Davim. 2025. "Advancements in Hole Quality for AISI 1045 Steel Using Helical Milling" Journal of Manufacturing and Materials Processing 9, no. 8: 256. https://doi.org/10.3390/jmmp9080256

APA StyleSilva, P. M., Festas, A. J. d. F., Pereira, R. B. D., & Davim, J. P. (2025). Advancements in Hole Quality for AISI 1045 Steel Using Helical Milling. Journal of Manufacturing and Materials Processing, 9(8), 256. https://doi.org/10.3390/jmmp9080256