Process Development to Repair Aluminum Components, Using EHLA and Laser-Powder DED Techniques

Abstract

1. Introduction

1.1. Comparative Analysis of AM Technologies for Repair Application

1.2. Challenges of Aluminum Laser Deposition

- High reflectivity, which reduces laser energy absorption and makes consistent melting and adhesion difficult;

- High thermal conductivity, leading to rapid heat dissipation and insufficient melting;

- Susceptibility to oxidation, resulting in porous structures;

- Low viscosity when molten, potentially causing uneven deposition;

- High hydrogen solubility in its molten state, increasing the formation of porous structures [17].

2. Materials and Methods

2.1. Experimental Setup

2.2. Materials

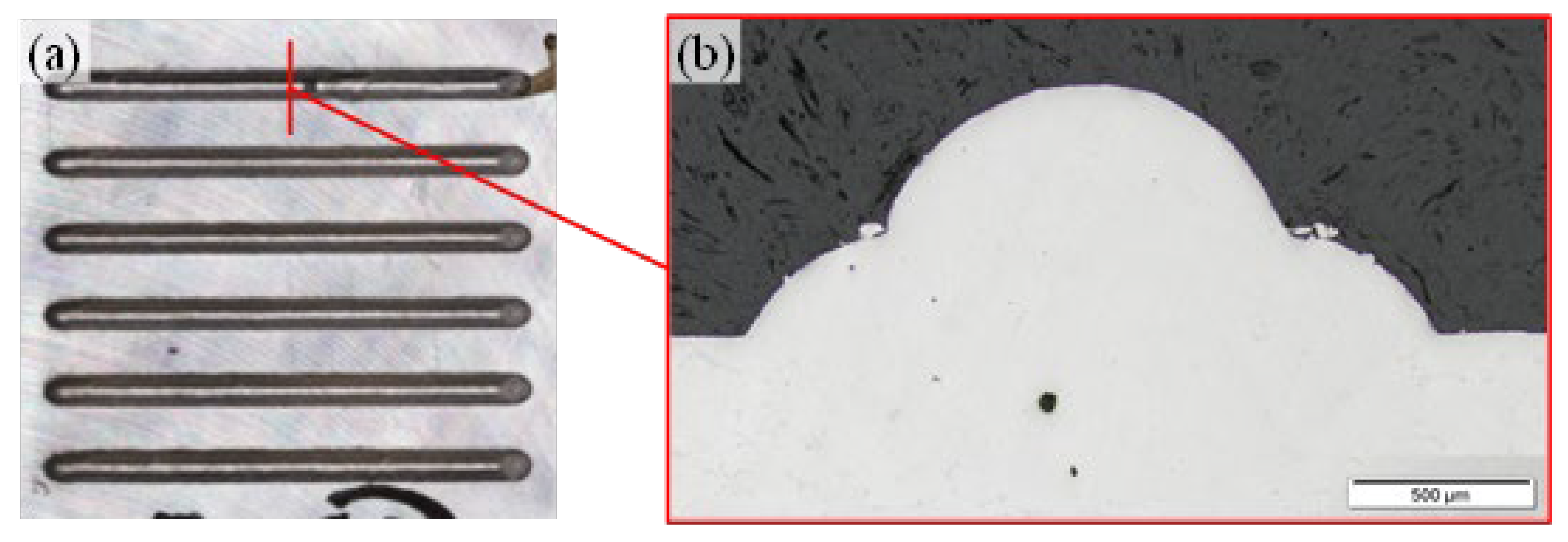

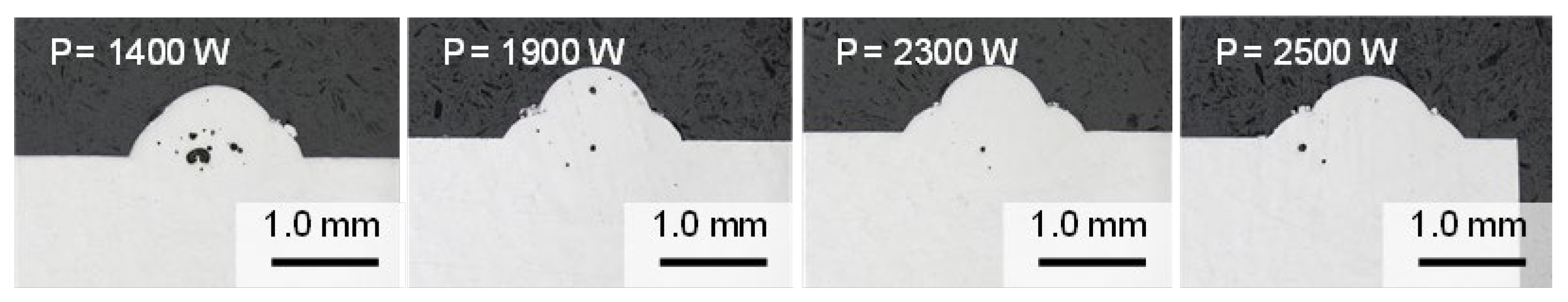

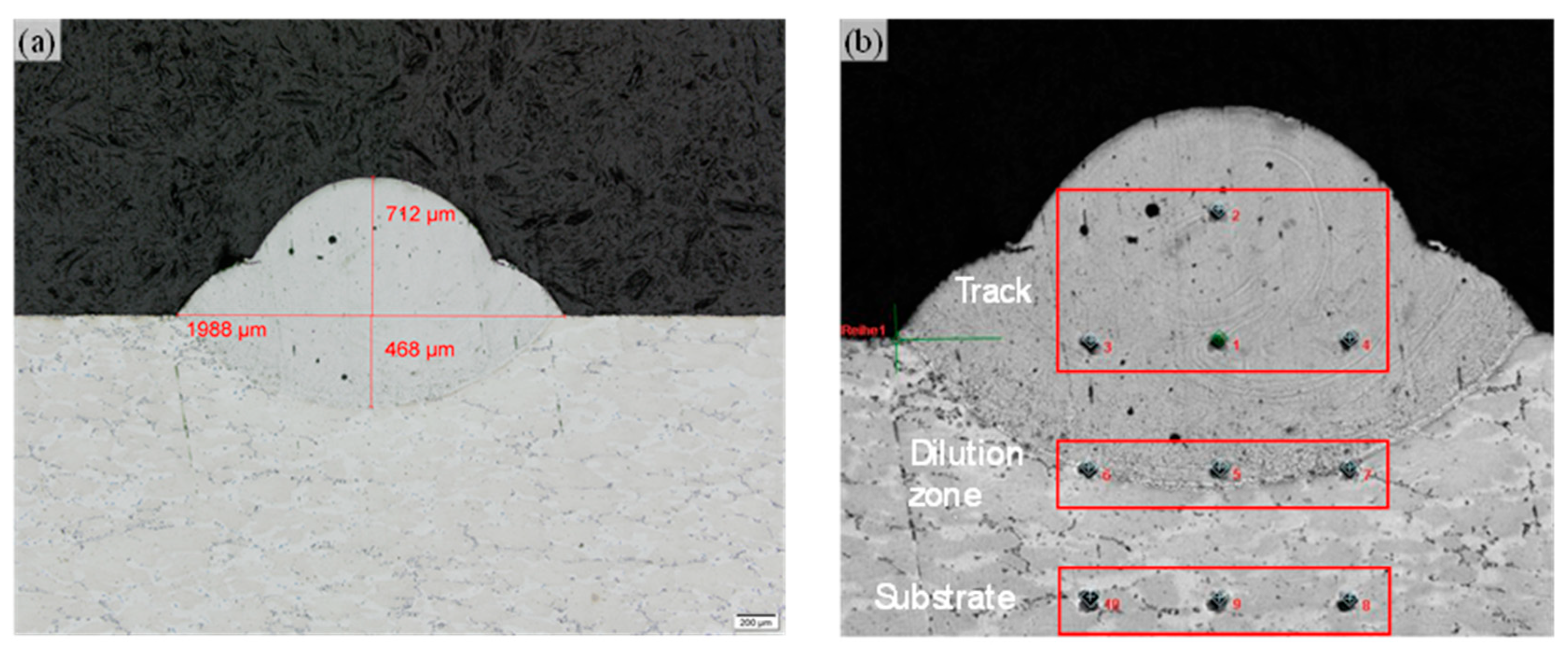

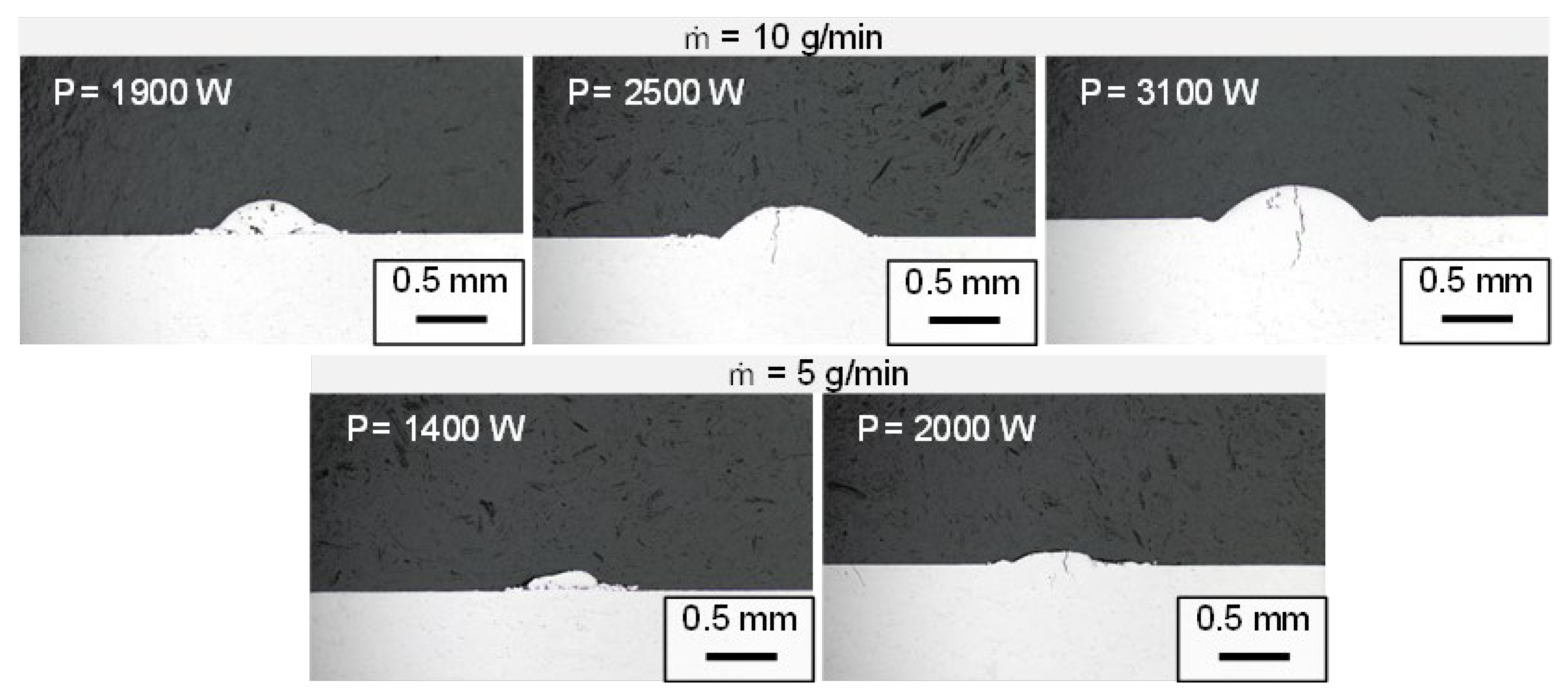

2.3. Single-Track Process Parameter Study

2.4. Single-Layer Process Parameter Study

3. Results and Discussion

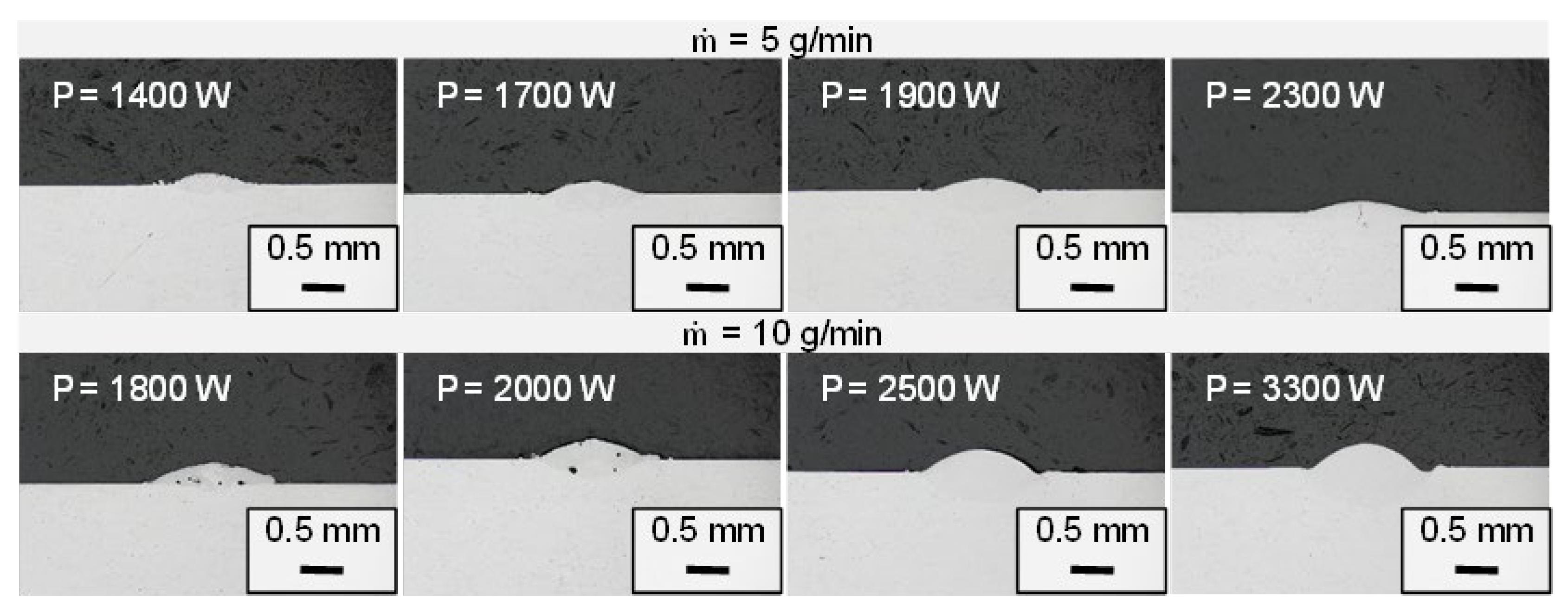

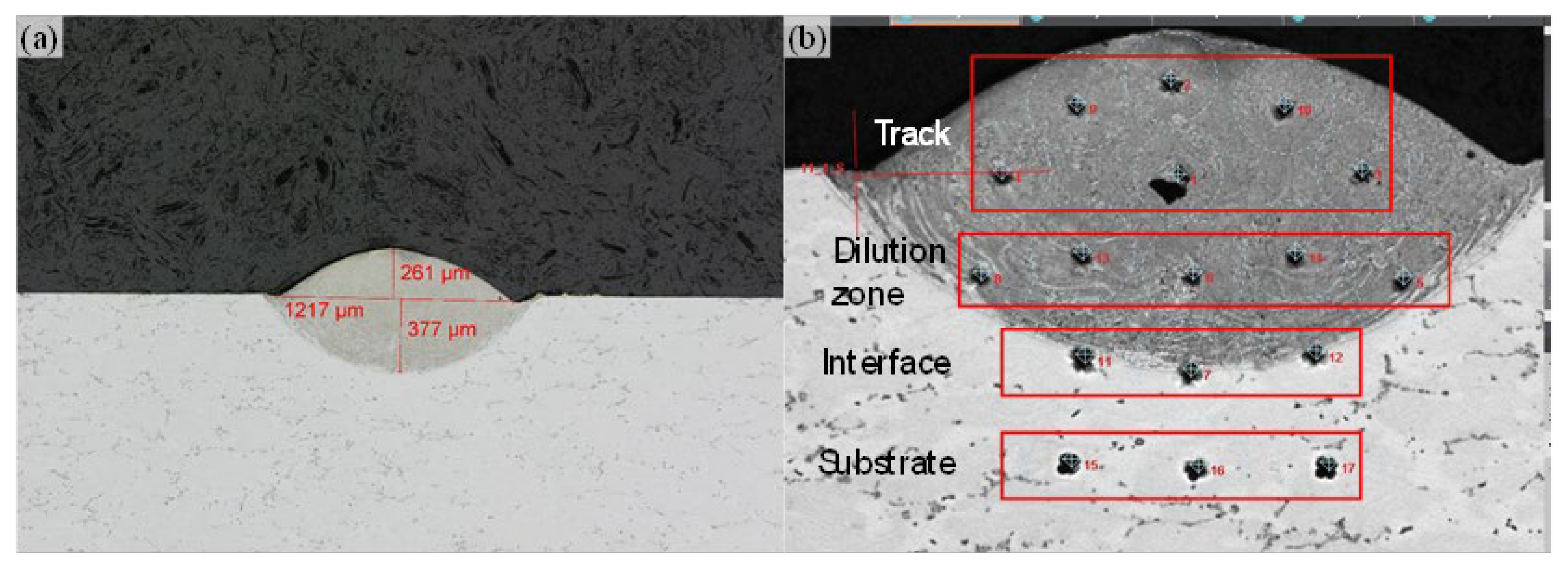

3.1. Single-Track Process Parameter Study

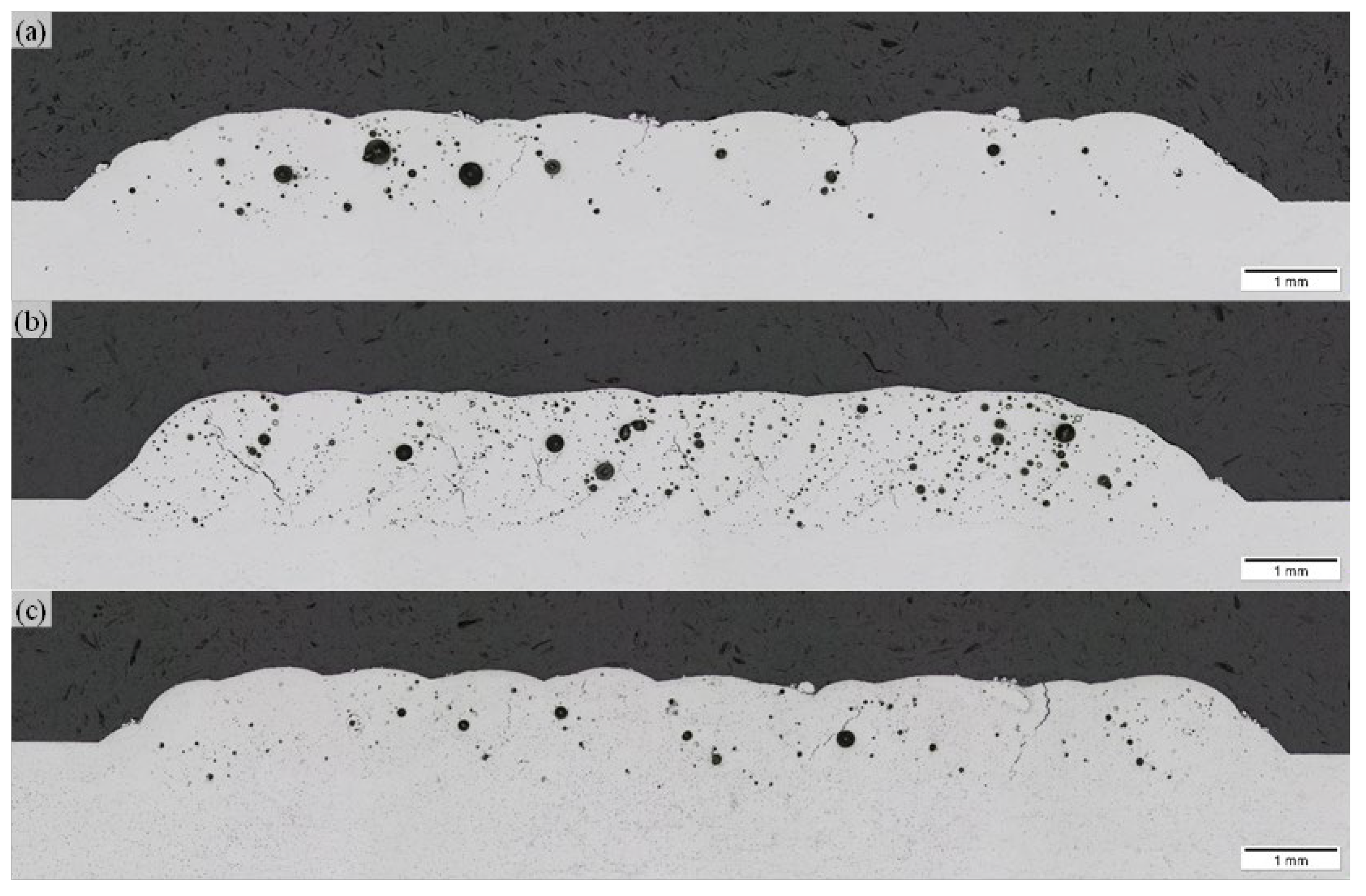

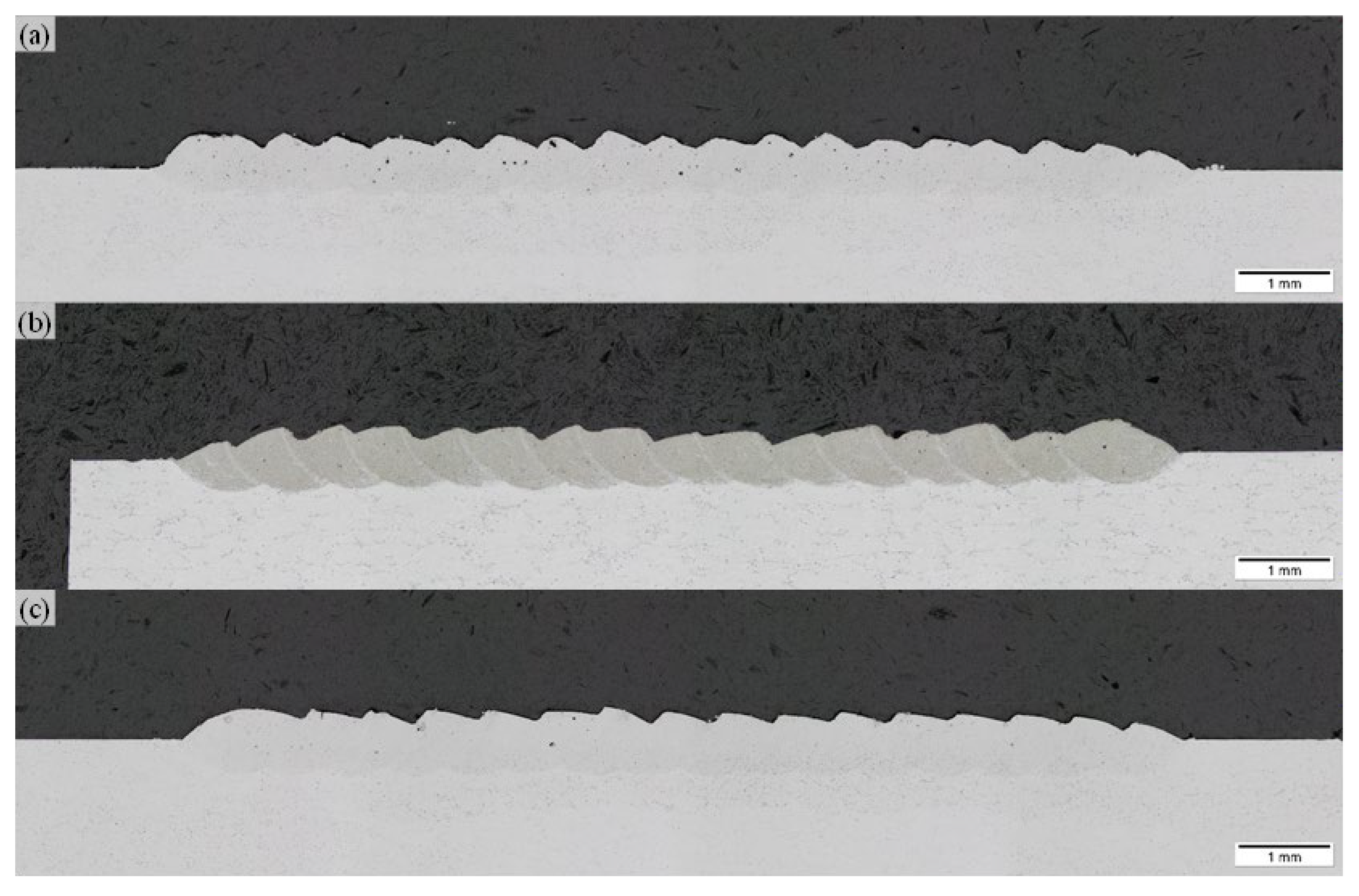

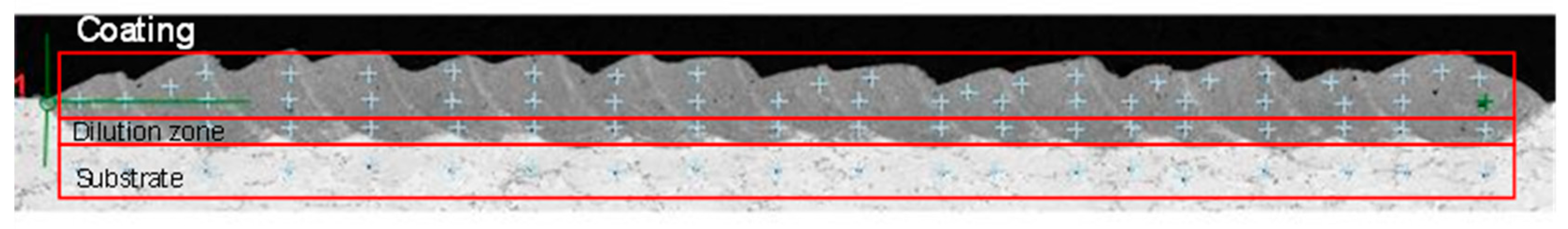

3.2. Coating Process

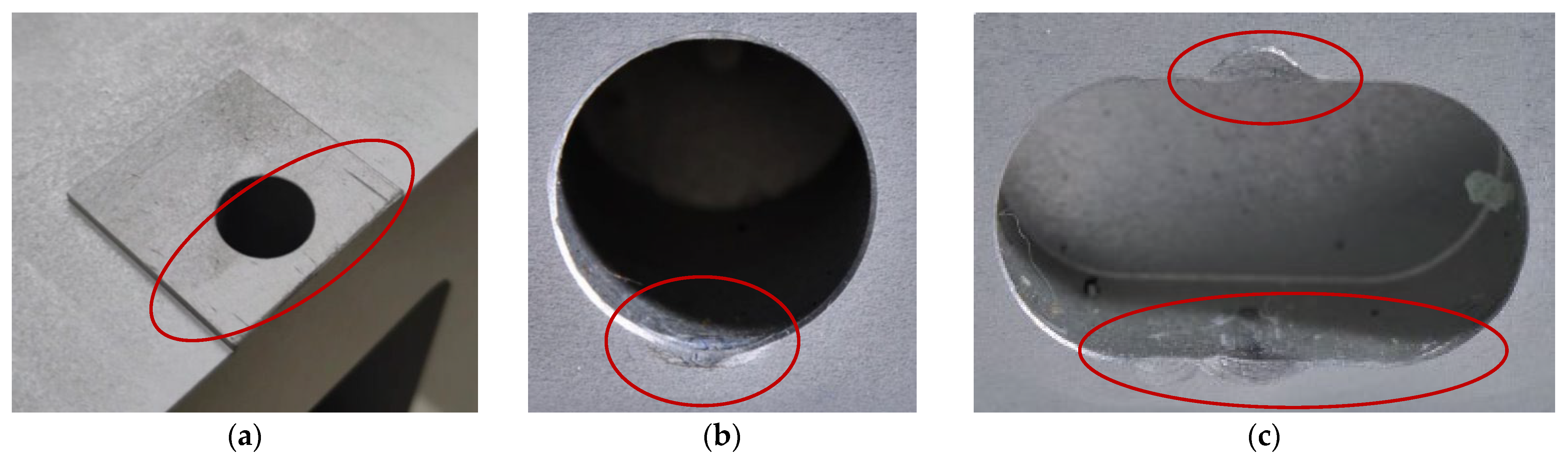

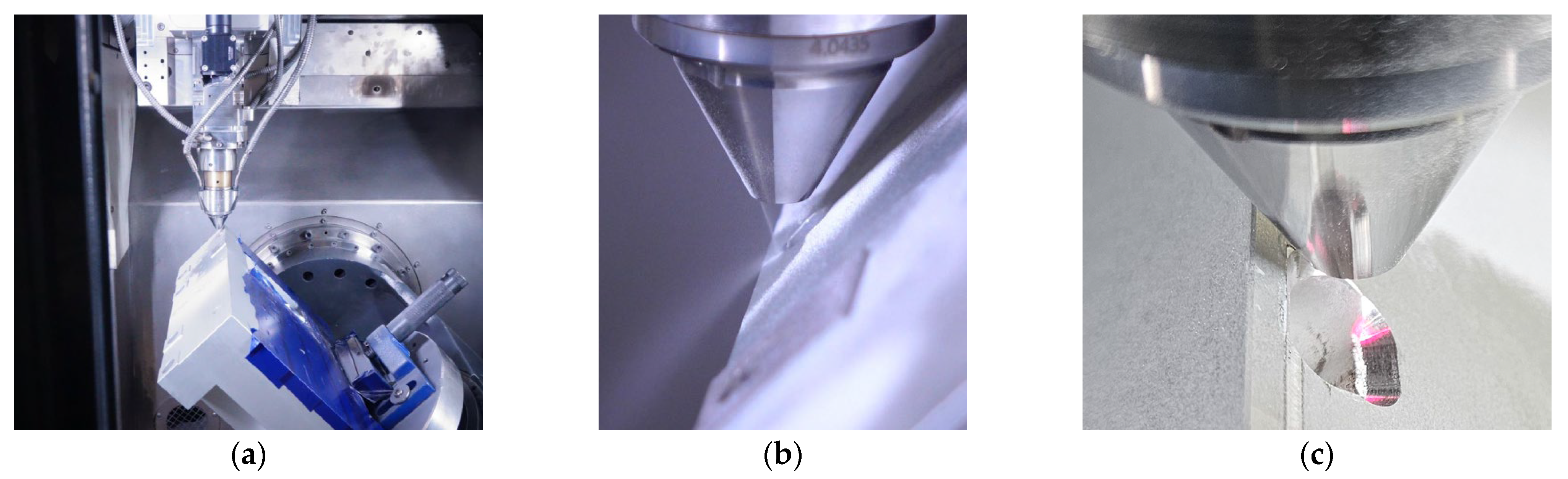

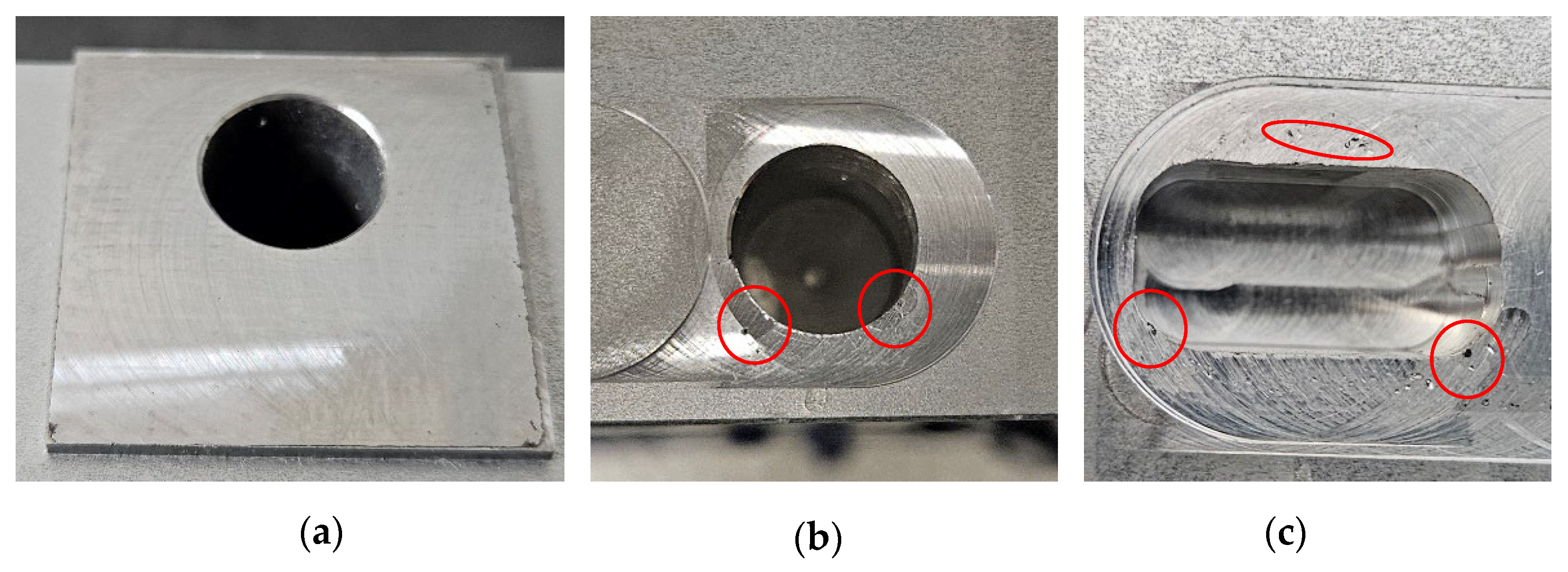

4. Case Study

5. Conclusions

- Our results highlight the potential of both LP-DED and EHLA techniques to deposit AlSi10Mg powder onto Al 6061 substrate, with the aim of repairing aluminum 6061 components. Especially EHLA shows good prospects for repairing surface defects due to its higher precision and speed.

- The Vickers measurement demonstrates increased microhardness (100 HV) of EHLA-deposited tracks for AlSi10Mg powder, compared to the Al6061 substrate (81 HV). To measure and adequately compare the microhardness of EHLA-deposited Al6061 tracks, further development of the process parameters is needed, considering the effects of surface treatment on microhardness.

- The EHLA deposition of Al6061 presents microcracks already in the single-track deposition. No defects were registered in our experiments with AlSi10Mg powder on the Al6061 substrate. Increased beam powers between P = 2600–2900 W result in crack- and pore-free single beads and single layers.

- For the Al6061 powder, based on single-track analysis, defect-free tracks were obtained in the LP-DED deposition, with vtool = 2 m/min, powder mass flow of 5 g/min, and laser power between 1900–2500 W.

- The initial investigation of repairing damages indicates a feasible repairing process of Al parts by LP-DED and EHLA technologies. However, there are other factors influencing the pore formation, such as heat transfer and surface conditions, which require further research. Future work should focus on advanced path-planning strategies, in situ monitoring, and adaptive control to mitigate porosity in complex geometries.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Al | Aluminum |

| DED | Directed Energy Deposition |

| EHLA | Extreme High-Speed Directed Energy Deposition |

| LPBF | Laser Powder Bed Fusion |

| LP-DED | Laser-powder Directed Energy Deposition |

References

- Liu, M.; Wei, K.; Zeng, X. High power laser powder bed fusion of AlSi10Mg alloy: Effect of layer thickness on defect, microstructure and mechanical property. Mater. Sci. Eng. 2022, 842, 143107. [Google Scholar] [CrossRef]

- Andersson, O.; Graichen, A.; Brodin, H.; Navrotsky, V. Developing Additive Manufacturing Technology for Burner Repair. J. Eng. Gas Turbines Power 2016, 139, 031506. [Google Scholar] [CrossRef]

- Sato, N.; Matsumoto, M.; Ogiso, H.; Sato, H. Challenges of Remanufacturing Using Powder Bed Fusion Based Additive Manufacturing. Int. J. Autom. Technol. 2022, 16, 773–782. [Google Scholar] [CrossRef]

- Priscopo, G.; Atzeni, E.; Saboori, A.; Salmi, A. An Overview of the Process Mechanisms in the Laser Powder Directed Energy Deposition. Appl. Sci. 2023, 13, 117. [Google Scholar] [CrossRef]

- Ko, M.-U.; Zhang, Z.; Schopphoven, T. Process development and process adaptation guidelines for the deposition of thin-walled structures with IN718 using extreme high-speed directed energy deposition (EHLA3D). J. Laser Appl. 2023, 35, 042059. [Google Scholar] [CrossRef]

- Schopphoven, T.; Gasser, A.; Backes, G. EHLA: Extreme High-Speed Laser Material Deposition, Economical and effective protection agains corrosion and wear. Laser Tech. J. 2017, 14, 26–29. [Google Scholar] [CrossRef]

- Liang, Y. A review on coatings deposited by high-speed laser cladding: Processes, materials and properties. Opt. Laser Technol. 2023, 164, 109472. [Google Scholar] [CrossRef]

- Koss, S.; Vogt, S.; Goebel, M.; Schleifenbaum, J.H. Coating of Aluminum with High Deposition Rates through Extreme High-Speed Laser Application. J. Therm. Spray Technol. 2023, 32, 1689–1697. [Google Scholar] [CrossRef]

- Guner, A.; Bidare, P.; Jiménez, A.; Dimov, S.; Essa, K. Nozzle design in powder-based direct laser deposition: A review. Int. J. Precis. Eng. Manuf. 2022, 23, 1077–1094. [Google Scholar] [CrossRef]

- DIRECT ENERGY DEPOSITION (LP-DED)—A Comparison of Multiple Metal 3D Printing Methods. Available online: http://www.ramlab.com/resources/ded-101/ (accessed on 10 January 2024).

- Schaible, J.; Hausch, D.; Schopphoven, T.; Haefner, C. Deposition strategies for generating cuboid volumes using extreme high-speed directed energy deposition. J. Laser Appl. 2022, 34, 042034. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. A systematic review of additive manufacturing-based remanufacturing techniques for component repair and restoration. J. Manuf. Process. 2023, 89, 220–283. [Google Scholar] [CrossRef]

- Oh, W.J.; Lee, W.J.; Kim, M.S.; Jeon, J.B.; Shim, D.S. Repairing additive-manufactured 316L stainless steel using direct energy deposition. Opt. Laser Technol. 2019, 117, 9–17. [Google Scholar] [CrossRef]

- Perini, M.; Bosetti, R.; Balc, N. Additive manufacturing for repairing; from damage identification and modeling to DLD. Rapid Prototyp. J. 2020, 26, 929–940. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, Q.; Tian, T.; Niu, L.; Li, H.; Han, B.; Zhu, H.; Wang, X. In-situ hot rolling directed energy deposition-arc repair of shafts. Addit. Manuf. 2023, 61, 103362. [Google Scholar] [CrossRef]

- Zhang, Y.; Lan, L.; Shi, Q. Microstructural evaluation and precipitated phase characteristics in the fusion zone for the as-repaired Inconel 718 alloy by directed energy deposition additive manufacturing. Mater. Charact. 2023, 204, 113222. [Google Scholar] [CrossRef]

- Rosito, M.; Vanzetti, M.; Padovano, E.; Gili, F.; Sampieri, R.; Bondioli, F.; Badini, C.F. Processability of A6061 Aluminum Alloy Using Laser Powder Bed Fusion by In Situ Synthesis of Grain Refiners. Metals 2023, 13, 1128. [Google Scholar] [CrossRef]

- Büßenschütt, K.; Köhnen, P.; Kies, F.; Koß, S.; Schleifenbaum, J.H.; Haase, C. High-Speed direct energy deposition as a high-throughput design tool for laser-based additive manufacturing. Addit. Manuf. Lett. 2024, 8, 100188. [Google Scholar] [CrossRef]

- Li, T.; Zhang, D.; Zhang, L.; Schopphoven, T.; Gasser, A.; Poprawe, R. Thermal features and its effect on the properties of AISI 4140 fabricated by conventional and extreme high-speed laser material deposition. J. Manuf. Process. 2024, 131, 1372–1387. [Google Scholar] [CrossRef]

- What is Exteme High-Speed Laser Application? (EHLA); Technical Data of TWI Ltd.: Cambridge, UK; Available online: https://www.twi-global.com/technical-knowledge/faqs/what-is-ehla (accessed on 26 July 2025).

- Madarieta-Churruca, M.; Arrizabalaga, J.L.; Garmendia-Sáez-de-Heredia, I.; Soriano, C. Comparative Study of Laser metal deposition (LMD) of coaxial wire and powder in the manufacture of Ti-6Al-4V structures. Dyna 2020, 95, 376–379. [Google Scholar] [CrossRef] [PubMed]

- Lv, F.; Shen, L.; Liang, H.; Xie, D.; Wang, C.; Tian, Z. Mechanical properties of AlSi10Mg alloy fabricated by laser melting deposition and improvements via heat treatment. Opt. Int. J. Light Electron Opt. 2019, 179, 8–18. [Google Scholar] [CrossRef]

- Hermann, F.; Vogt, S.; Göbel, M.; Möller, M.; Frey, K. Laser Metal Deposition of AlSi10Mg with high build rates. Procedia CIRP 2022, 111, 210–213. [Google Scholar] [CrossRef]

- Li, J.; Liu, Z.; Ning, H.; Ma, H.; Xie, R.; Kong, Y.; Fu, Y. Ni-based coating on 5083 Aluminum alloy with Cu-Ni interlayer fabricated by ultra-high-speed laser directed energy deposition. Surf. Coat. Technol. 2023, 474, 130068. [Google Scholar] [CrossRef]

- Dong, E.; Chang, T.; Zhao, L.; Xing, Y.; Chen, J.; Chen, M.; Lu, J.; Cheng, J. Laser metal deposition of AlSi10Mg for aeroengine casing repair: Microhardness, wear and corrosion behavior. Mater. Today Commun. 2024, 38, 108412. [Google Scholar] [CrossRef]

- Ferreira, N.M. Direct Energy Deposition Parametric Simulation Investigation in Gear Repair Application. Materials 2023, 16, 3549. [Google Scholar] [CrossRef]

- Wang, A.; Wei, Q.; Tang, Z.; Oliveira, J.P.; Leung, C.L.A.; Ren, P.; Zhang, X.; Wu, Y.; Wang, H.; Wang, H. Effects of hatch spacing on pore segregation and mechanical properties during blue laser directed energy deposition of AlSi10Mg. Addit. Manuf. 2024, 85, 104147. [Google Scholar] [CrossRef]

| Aspects | LP-DED | EHLA | References |

|---|---|---|---|

| Application | Freeform 3D geometry manufacturing; multi-material structures; coating and repair. | Coating and repair; thin-wall structures. | [5,6,7,8,9,12,13,14,15,16] |

| Feed rate | 0.2–2 m/min | >20 m/min, up to 100 m/min | [9,17] |

| Layer thickness | 200–1000 µm | 30–300 µm | [5,13] |

| Heat affected zone (dissipation) | 100–500 µm | 10–100 µm | [18,19] |

| Powder catchment efficiency | Around 70% | Around 90% | [20,21] |

| Material [%] | Al | Si | Mg | Fe | Ti | Zn | Mn | Cu | Cr | OE | OT |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bal. | 0.4–0.8 | 0.8–1.2 | ≤0.7 | ≤0.15 | ≤0.25 | ≤0.15 | 0.15–0.4 | 0.04–0.35 | ≤0.05 | ≤0.15 |

| dbeam [mm] | V [m/min] | P [W] | ṁ [g/min] |

|---|---|---|---|

| LP-DED | |||

| 1.2 | 2 | 1000–2500 | 5 |

| EHLA-Al6061 | |||

| 1.2 | 20 | 900–2000 | 5 |

| 1000–3100 | 10 | ||

| EHLA–AlSi10Mg4 | |||

| 1.2 | 20 | 800–2500 | 5 |

| 1200–3300 | 10 | ||

| dbeam [mm] | V [m/min] | P [W] | ṁ [g/min] | Hatch [mm] |

|---|---|---|---|---|

| LP-DED–Al6061 | ||||

| 1.2 | 2 | 2300 | 5 | 0.8 |

| 1.0 | ||||

| 1.2 | ||||

| EHLA–AlSi10Mg | ||||

| 1.2 | 20 | 2500 | 10 | 0.60 |

| 2600 | 0.65 | |||

| 2900 | 0.65 | |||

| Track | Dilution Zone | Substrate |

|---|---|---|

| 71 ± 1.9 HV | 77 ± 9.3 HV | 86 ± 3.8 HV |

| Track | Dilution Zone | Interface | Substrate |

|---|---|---|---|

| 103 ± 9.3 HV | 89 ± 3.0 HV | 80 ± 4.3 HV | 91 ± 0.3 HV |

| dbeam [mm] | V [m/min] | P [W] | ṁ [g/min] | QC [L/min] | QS [L/min] |

|---|---|---|---|---|---|

| LP-DED–Al6061 | |||||

| 1.2 | 2 | 2300 | 5 | 8 | 12 |

| EHLA–AlSi10Mg4 | |||||

| 1.2 | 20 | 2500 | 10 | 8 | 12 |

| 2600 | |||||

| 2900 | |||||

| Coating | Dilution Zone | Substrate |

|---|---|---|

| 91 ± 3.1 HV | 89 ± 4.5 HV | 87 ± 6 HV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matis, A.; Ko, M.-U.; Kraft, R.; Balc, N. Process Development to Repair Aluminum Components, Using EHLA and Laser-Powder DED Techniques. J. Manuf. Mater. Process. 2025, 9, 255. https://doi.org/10.3390/jmmp9080255

Matis A, Ko M-U, Kraft R, Balc N. Process Development to Repair Aluminum Components, Using EHLA and Laser-Powder DED Techniques. Journal of Manufacturing and Materials Processing. 2025; 9(8):255. https://doi.org/10.3390/jmmp9080255

Chicago/Turabian StyleMatis, Adrienn, Min-Uh Ko, Richard Kraft, and Nicolae Balc. 2025. "Process Development to Repair Aluminum Components, Using EHLA and Laser-Powder DED Techniques" Journal of Manufacturing and Materials Processing 9, no. 8: 255. https://doi.org/10.3390/jmmp9080255

APA StyleMatis, A., Ko, M.-U., Kraft, R., & Balc, N. (2025). Process Development to Repair Aluminum Components, Using EHLA and Laser-Powder DED Techniques. Journal of Manufacturing and Materials Processing, 9(8), 255. https://doi.org/10.3390/jmmp9080255