Measuring Transient Friction Coefficient Affected by Plastic Heat Generation Using a Warm Ring Compression Test with an In Situ Measurement System Measuring Ring Expansion Velocity

Abstract

1. Introduction

2. Material and Methods

2.1. Overview of the Warm Ring Compression Test with an In Situ Measurement System

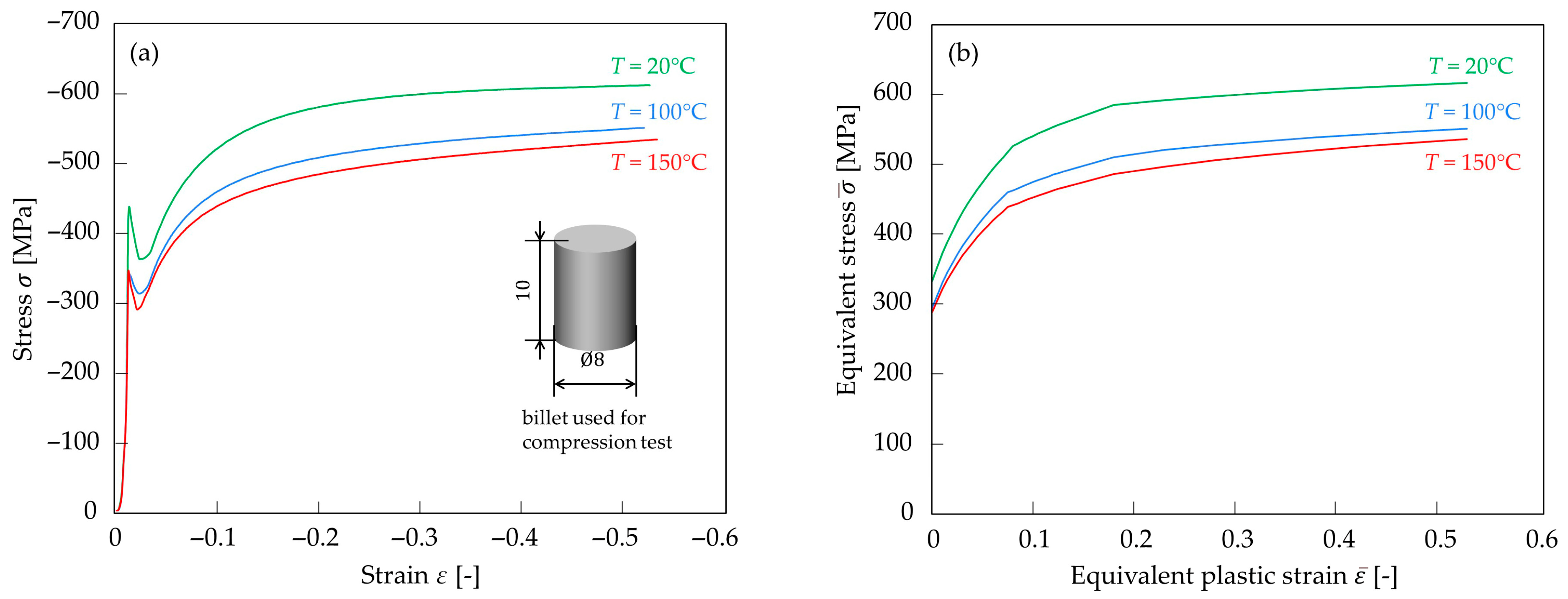

2.2. Methods for Determining Test Temperature and Flow Stress Measurement in Warm Conditions

2.3. Modification of Ring Height Reduction Measured by Contact Displacement Sensor

2.4. Measurement of Outer Diameter Expansion of Ring During Compression and Extraction of Expansion Velocity

3. Results and Discussion

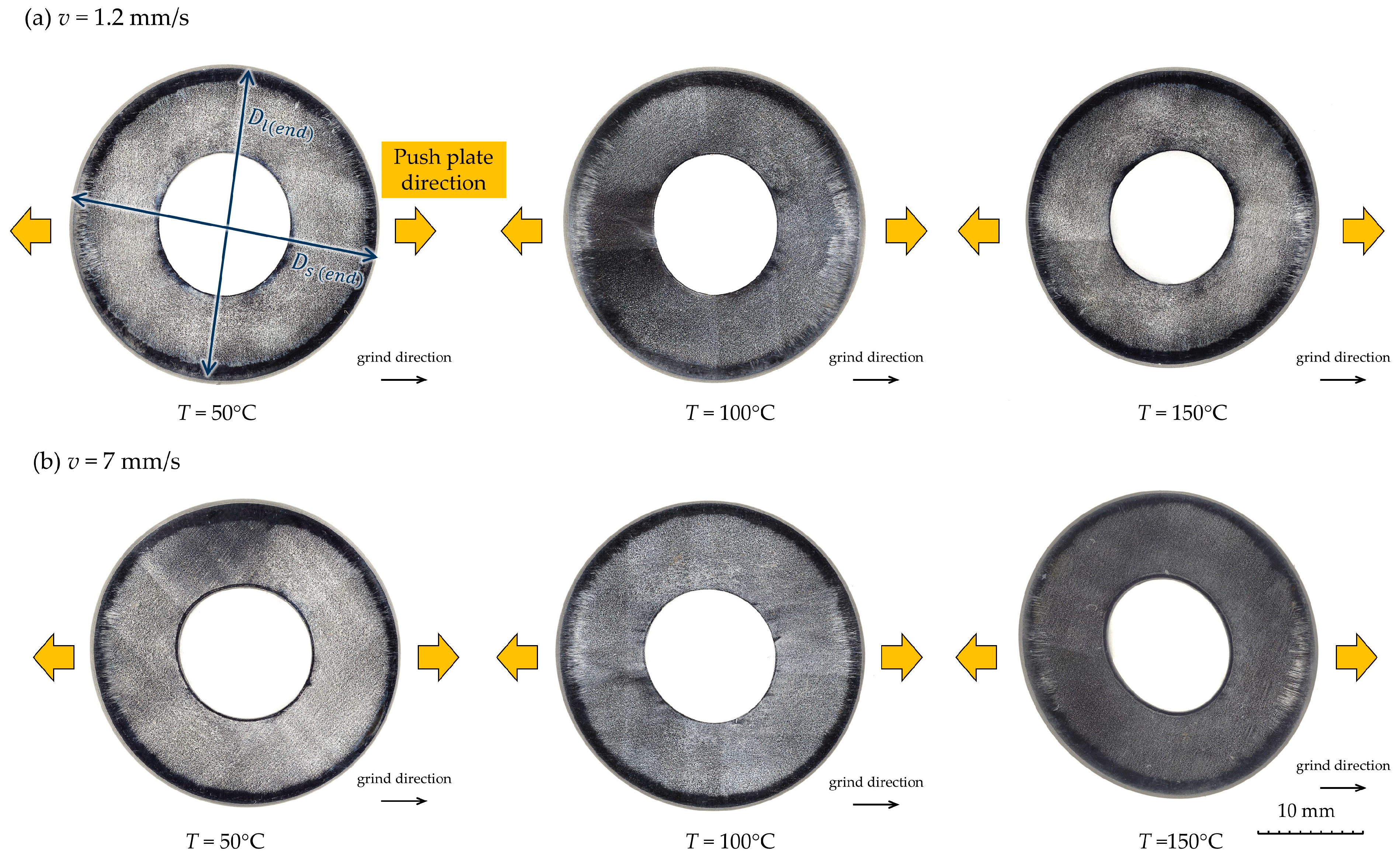

3.1. Shape of Compressed Ring and Modification of Non-Uniform Outer Diameter Expansion

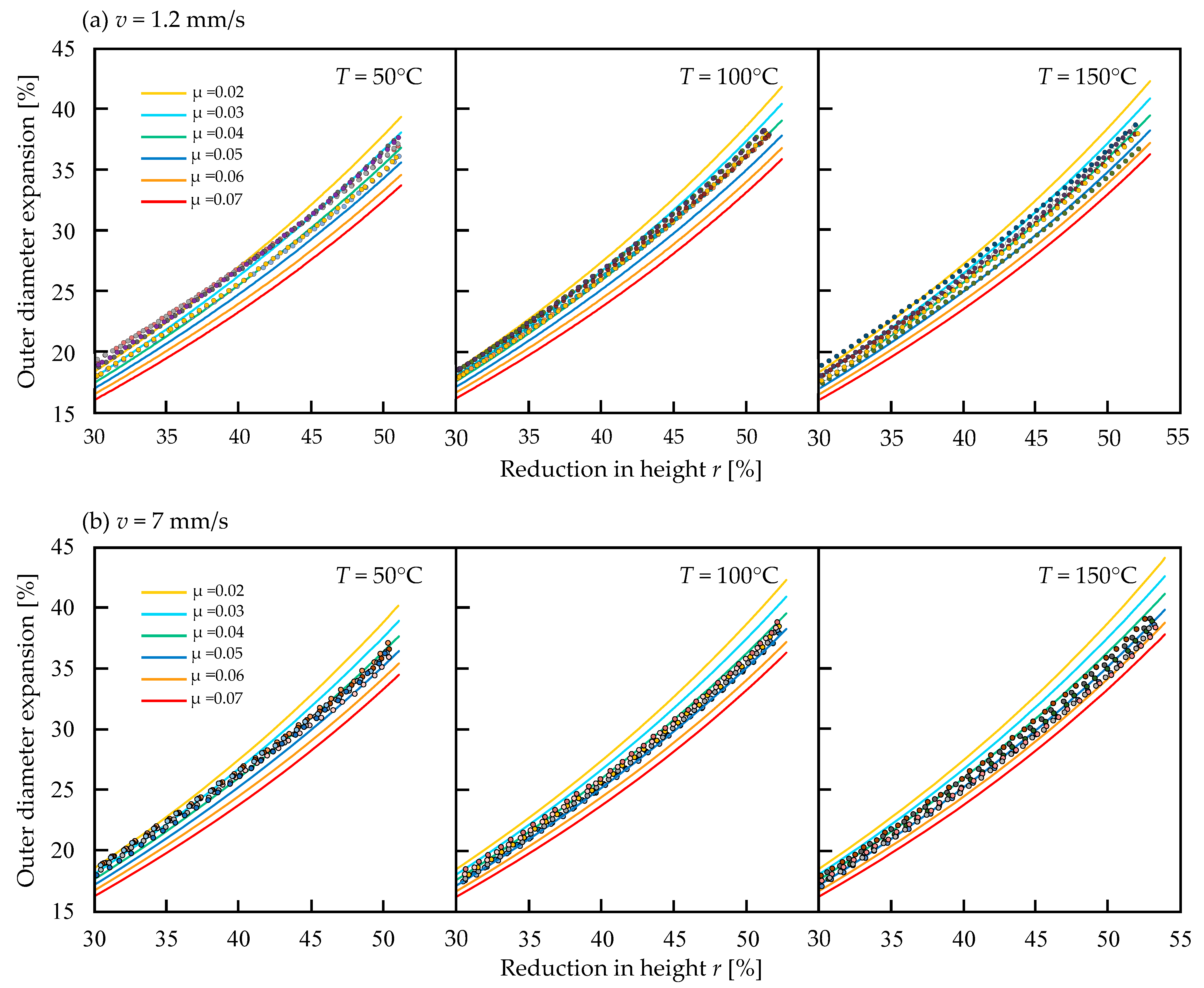

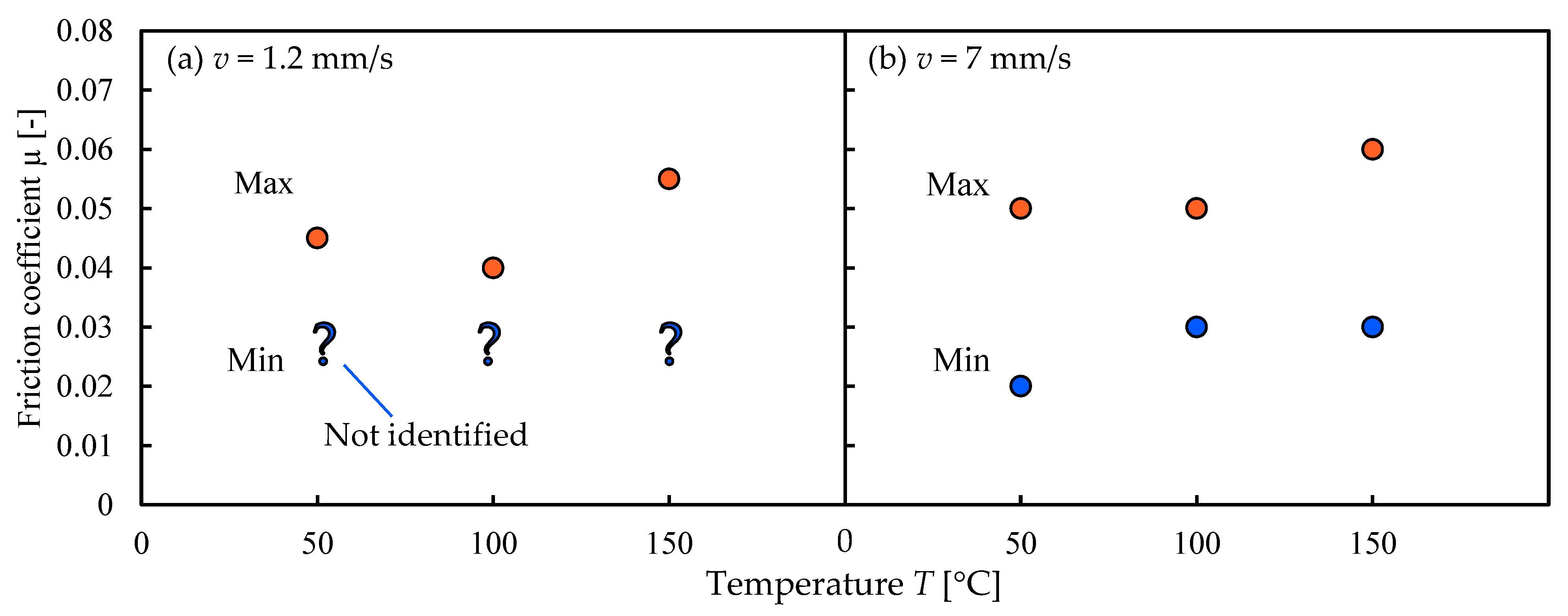

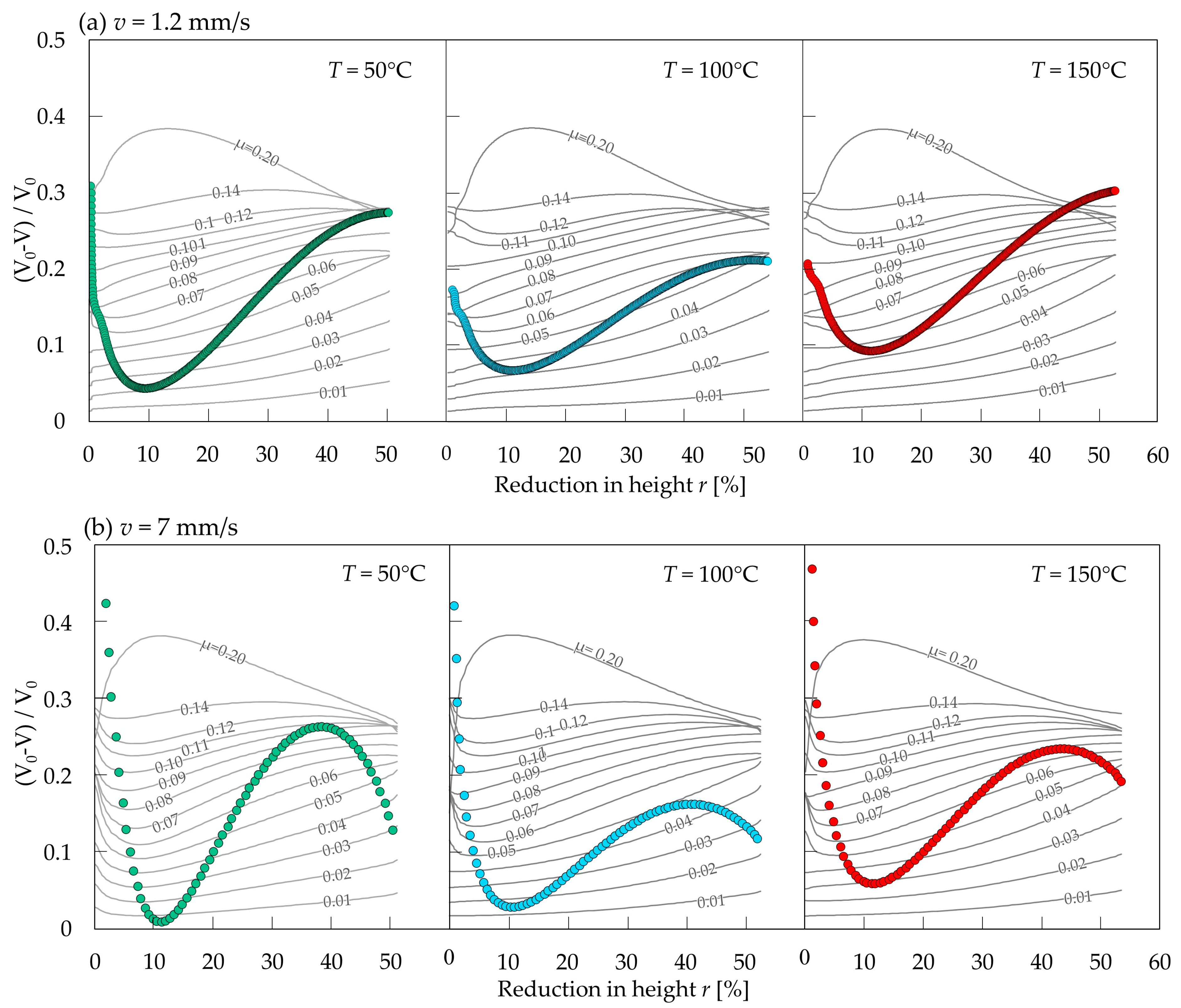

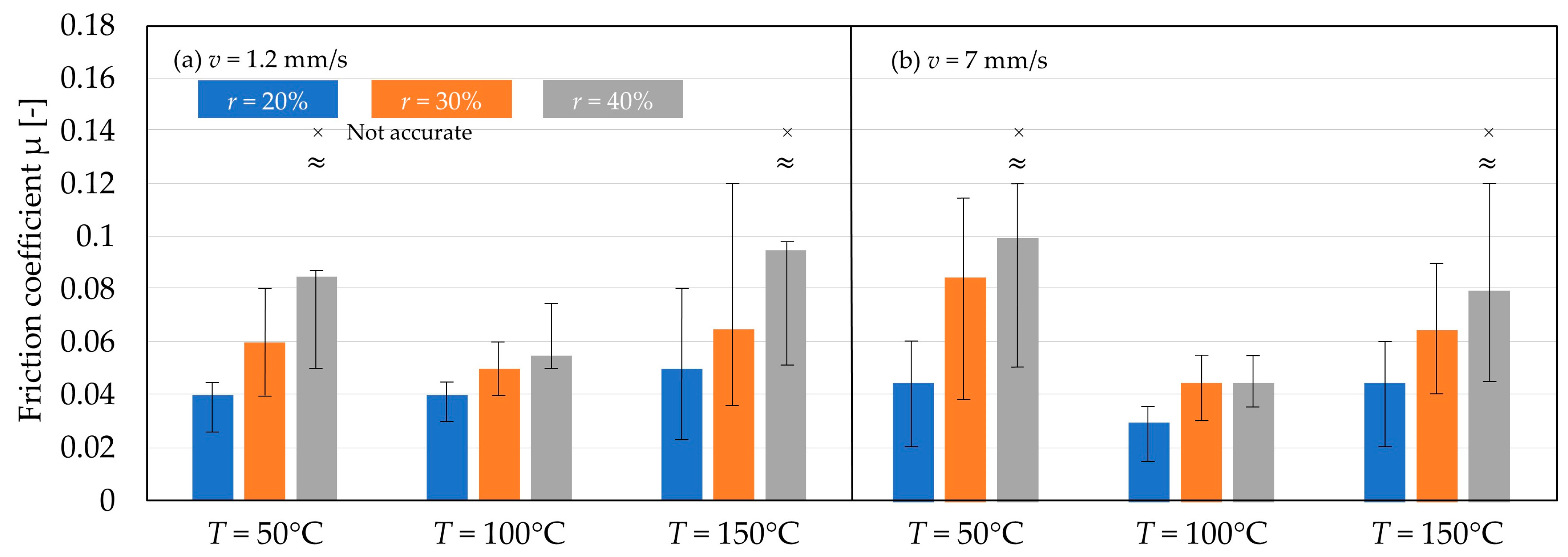

3.2. Effect of Temperature on Friction Coefficient Obtained from Outer Diameter Expansion Nomograph

3.3. Using Expansion Velocity to Determine Transient Friction Coefficient

3.4. Comparison Between Experimentally Compressed Ring and Simulated Compressed Ring with Transient Friction Coefficient

4. Summary and Conclusions

5. Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhushan, B. Introduction to Tribology; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Farren, W.; Taylor, G. The heat developed during plastic extrusion of metals. Proc. R. Soc. Lond. 1925, 107, 422–451. [Google Scholar]

- Bay, N.; Azushima, A.; Groche, P.; Ishibashi, I.; Merklein, M.; Morishita, M.; Nakamura, T.; Schmid, S.; Yoshida, M. Environmentally benign tribo-systems for metal forming. CIRP Ann. 2010, 59, 760–780. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, S.M.; Kim, Y.H.; Kim, M.S.; Park, C.Y. Finite element analysis for temperature distributions in a cold forging. J. Mech. Sci. Technol. 2013, 27, 2979–2984. [Google Scholar] [CrossRef]

- Volke, P.; Groche, P. Interfacial heat transfer coefficients in cold forging of stainless steel. Int. J. Mater. Form. 2022, 15, 32. [Google Scholar] [CrossRef]

- Kuhn, C.; Volke, P.; Groche, P. Thermochromically Enhanced Lubricant System for Temperature Measurement in Cold Forming. Processes 2025, 13, 513. [Google Scholar] [CrossRef]

- Groche, P.; Zang, S.; Müller, C.; Bodenmüller, D. A study on the performance of environmentally benign lubricants at elevated temperatures in bulk metal forming. J. Manuf. Process. 2015, 20, 425–430. [Google Scholar] [CrossRef]

- Asadauskas, S.J.; Biresaw, G.; McClure, T.G. Effects of Chlorinated Paraffin and ZDDP Concentrations on Boundary Lubrication Properties of Mineral and Soybean Oils. Tribol. Lett. 2010, 37, 111–121. [Google Scholar] [CrossRef]

- Yan, L.; Yao, X.; Zhang, T.; Jiang, F.; Shui, Y.; Xie, H.; Xiang, Z.; Li, Y.; Lin, L. Passivation Effect of the Chlorinated Paraffin Added in the Cutting Fluid on the Surface Corrosion Resistance of the Stainless Steel. Molecules 2023, 28, 3648. [Google Scholar] [CrossRef] [PubMed]

- Groche, P.; Müller, C.; Stahlmann, J.; Zang, S. Mechanical conditions in bulk metal forming tribometers—Part one. Tribol. Int. 2013, 62, 223–231. [Google Scholar] [CrossRef]

- Waanders, D.; Hazrati Marangalou, J.; Kott, M.; Gastebois, S.; Hol, J. Temperature dependent friction modelling: The influence of temperature on product quality. Procedia Manuf. 2020, 47, 535–540. [Google Scholar] [CrossRef]

- Veldhuis, M.; Heingärtner, J.; Krairi, A.; Waanders, D.; Hazrati, J. An industrial-scale cold forming process highly sensitive to temperature-induced frictional start-up effects to validate a physical-based friction model. Procedia Manuf. 2020, 47, 578–585. [Google Scholar] [CrossRef]

- Li, L.X.; Peng, D.S.; Liu, J.A.; Liu, Z.Q. An experimental study of the lubrication behavior of graphite in hot compression tests of Ti–6Al–4V alloy. Tribol. Int. 2001, 112, 1–5. [Google Scholar] [CrossRef]

- Hardell, J.; Kassfeldt, E.; Prakash, B. Friction and wear behavior of high-strength boron steel at elevated temperatures of up to 800 °C. Wear 2008, 264, 788–799. [Google Scholar] [CrossRef]

- Du, S.; Li, Z.; He, Z.; Ding, H.; Wang, X.; Zhang, Y. Effect of temperature on the friction and wear behavior of electroless Ni–P–MoS2–CaF2 self-lubricating composite coatings. Tribol. Int. 2018, 128, 197–203. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, B.; Wang, K.; Li, S.; Zhang, Y. Friction behaviors of 6061 aluminum alloy sheets in hot stamping under dry and lubricated conditions based on hot strip drawing test. Tribol. Int. 2020, 151, 106504. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Q.; Zheng, Y.; Liu, X.; Politis, D.; El Fakir, O.; Wang, L. Investigation of the friction coefficient evolution and lubricant breakdown behavior of AA7075 aluminum alloy forming processes at elevated temperatures. Int. J. Extrem. Manuf. 2021, 3, 025002. [Google Scholar] [CrossRef]

- Noder, J.; George, R.; Butcher, C.; Worswick, M.J. Friction characterization and application to warm forming of a high-strength 7000-series aluminum sheet. J. Mater. Process. Technol. 2021, 293, 117066. [Google Scholar] [CrossRef]

- Soleymanipoor, A.; Maeno, T. Effect of Pulsating Motion Conditions on Relubrication Behavior and Dimensions of Laterally Extruded Internal Gears. J. Manuf. Mater. Process. 2025, 9, 190. [Google Scholar] [CrossRef]

- Wang, Z.; Dohda, K.; Haruyama, Y. Effects of entraining velocity of lubricant and sliding velocity on friction behavior in stainless steel sheet rolling. Wear 2005, 258, 203–211. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Fejkiel, R. On the influence of deformation of deep drawing quality steel sheet on surface topography and friction. Tribol. Int. 2017, 115, 78–88. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L.; Gao, H.; Zhang, J.; Reddyhoff, T. The friction coefficient evolution of a TiN coated contact during sliding wear. Appl. Surf. Sci. 2015, 345, 109–115. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, L.; Politis, D.J.; Masen, M.A. Development of an interactive friction model for the prediction of lubricant breakdown behavior during sliding wear. Tribol. Int. 2017, 110, 370–377. [Google Scholar] [CrossRef]

- Hua, Y.; Zheng, Y.; Politis, D.J.; Masen, M.A.; Cui, J.; Wang, L. Development of an interactive friction model to predict aluminum transfer in a pin-on-disc sliding system. Tribol. Int. 2019, 130, 216–228. [Google Scholar] [CrossRef]

- Yang, X.; Liu, H.; Zhang, L.; Hu, Y.; Politis, D.J.; Gharbi, M.M.; Wang, L. Interactive mechanism and friction modeling of transient tribological phenomena in metal forming processes: A review. Friction 2024, 12, 375–395. [Google Scholar] [CrossRef]

- Kunogi, M. A new method of cold extrusion. J. Sci. Res. Inst. 1956, 50, 215–246. [Google Scholar] [CrossRef]

- Male, A.T.; Cockcroft, M.G. A method for the determination of the coefficient of friction of metals under conditions of bulk plastic deformation. J. Inst. Met. 1964, 93, 38–46. [Google Scholar] [CrossRef]

- Matsumoto, R.; Harada, S.; Utsunomiya, H. Influence of oxide scale formed on chrome steel surface in steam atmosphere on deformation behavior of chrome steel in hot ring compression. ISIJ Int. 2015, 55, 1711–1720. [Google Scholar] [CrossRef]

- Ohata, T.; Asai, K.; Kitamura, K.; Matsunaga, K. Ring compression test for high-strength steel at high reduction in height under dry condition. J. Mech. Eng. Sci. 2023, 10, 23–00057. [Google Scholar] [CrossRef]

- Hartley, R.S.; Cloete, T.J.; Nurick, G.N. An experimental assessment of friction effects in the split Hopkinson pressure bar using the ring compression test. Int. J. Impact Eng. 2007, 34, 1705–1728. [Google Scholar] [CrossRef]

- Shahriari, D.; Sadeghi, M.; Ebrahimi, G.; Kim, K. Effects of lubricant and temperature on friction coefficient during hot forging of Nimonic 115 superalloy. Kovove Mater. 2011, 49, 375–383. [Google Scholar] [CrossRef]

- Mirahmadi, S.J.; Hamedi, M.; Cheraghzadeh, M. Investigating friction factor in forging of Ti-6Al-4V through isothermal ring compression test. Tribol. Trans. 2015, 58, 778–785. [Google Scholar] [CrossRef]

- Hu, C.L.; Ou, H.; Zhao, Z. An alternative evaluation method for friction condition in cold forging by ring with boss compression test. J. Mater. Process. Technol. 2015, 224, 18–25. [Google Scholar] [CrossRef]

- Hu, C.; Yin, Q.; Zhao, Z.; Ou, H. A new measuring method for friction factor by using ring with inner boss compression test. Int. J. Mech. Eng. Mater. Sci. 2017, 123, 133–140. [Google Scholar] [CrossRef]

- Goetz, R.L.; Jain, V.K.; Morgan, J.T.; Wierschke, M.W. Effects of material and processing conditions upon ring calibration curves. Wear 1991, 143, 71–86. [Google Scholar] [CrossRef]

- Sofuoglu, H.; Rasty, J. On the measurement of friction coefficient utilizing the ring compression test. Tribol. Int. 1999, 32, 327–335. [Google Scholar] [CrossRef]

- Saiki, H.; Meng, Y.G.; Sakamoto, H. An experimental study of transient friction during forging processes. Trans. Jpn. Soc. Mech. Eng. 1989, 55, 2184–2191. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.23–0.28 | 0.15–0.35 | 0.60–0.90 | 0.030 or less | 0.030 or less | 0.25 or less | 0.90–1.20 | 0.15–0.30 |

| Parameter | Temperature [°C] | Compression Speed [mm/s] | Ring Size [mm] | Reduction in Height [%] | Lubricant |

|---|---|---|---|---|---|

| Value | 50, 100, 150 | 1.2, 7 | Outer diameter: Inner diameter: Height = 24:12:8 | 50–55 | 10 µL chlorine-based lubricant |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soleymanipoor, A.; Maeno, T.; Tosaka, K.; Kakudo, M.; Takahashi, K.; Yanagisawa, M.; Tsukamoto, O. Measuring Transient Friction Coefficient Affected by Plastic Heat Generation Using a Warm Ring Compression Test with an In Situ Measurement System Measuring Ring Expansion Velocity. J. Manuf. Mater. Process. 2025, 9, 241. https://doi.org/10.3390/jmmp9070241

Soleymanipoor A, Maeno T, Tosaka K, Kakudo M, Takahashi K, Yanagisawa M, Tsukamoto O. Measuring Transient Friction Coefficient Affected by Plastic Heat Generation Using a Warm Ring Compression Test with an In Situ Measurement System Measuring Ring Expansion Velocity. Journal of Manufacturing and Materials Processing. 2025; 9(7):241. https://doi.org/10.3390/jmmp9070241

Chicago/Turabian StyleSoleymanipoor, Alireza, Tomoyoshi Maeno, Kosuke Tosaka, Masato Kakudo, Kazuhito Takahashi, Motoki Yanagisawa, and Osami Tsukamoto. 2025. "Measuring Transient Friction Coefficient Affected by Plastic Heat Generation Using a Warm Ring Compression Test with an In Situ Measurement System Measuring Ring Expansion Velocity" Journal of Manufacturing and Materials Processing 9, no. 7: 241. https://doi.org/10.3390/jmmp9070241

APA StyleSoleymanipoor, A., Maeno, T., Tosaka, K., Kakudo, M., Takahashi, K., Yanagisawa, M., & Tsukamoto, O. (2025). Measuring Transient Friction Coefficient Affected by Plastic Heat Generation Using a Warm Ring Compression Test with an In Situ Measurement System Measuring Ring Expansion Velocity. Journal of Manufacturing and Materials Processing, 9(7), 241. https://doi.org/10.3390/jmmp9070241