Comprehensive Experimental Analysis of Electrochemical Jet Machining (ECJM) for Advanced Material Processing

Abstract

1. Introduction

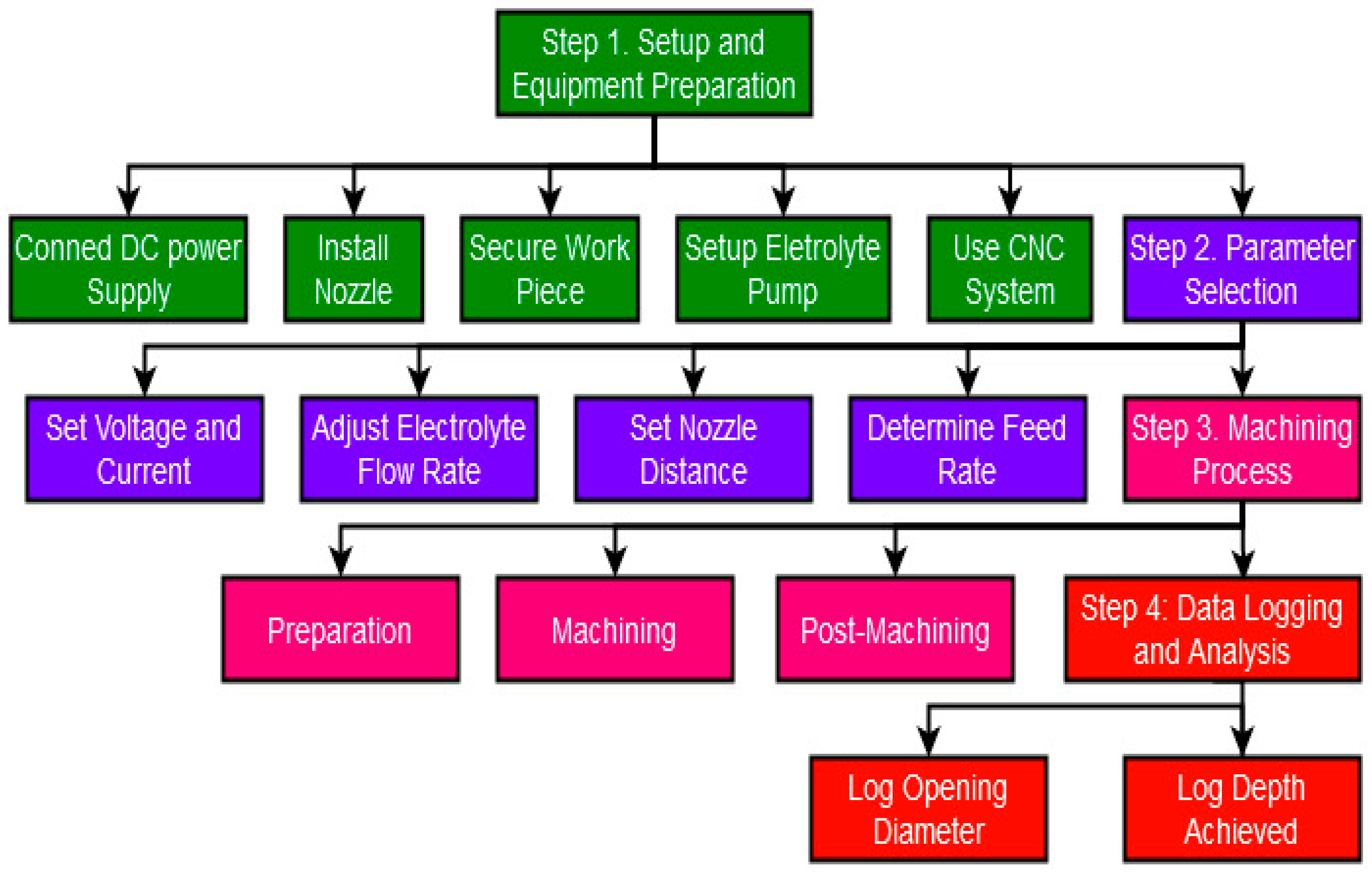

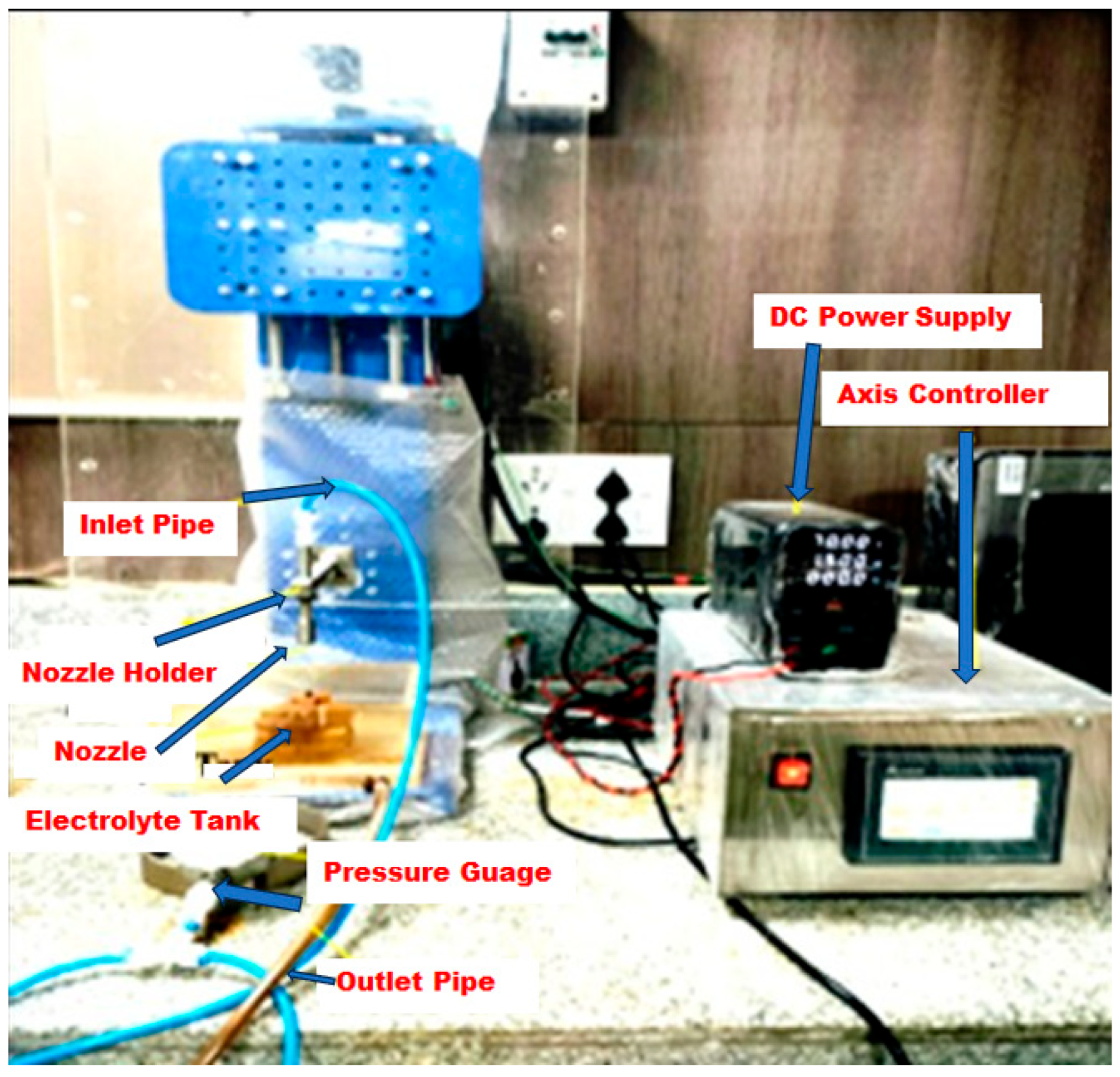

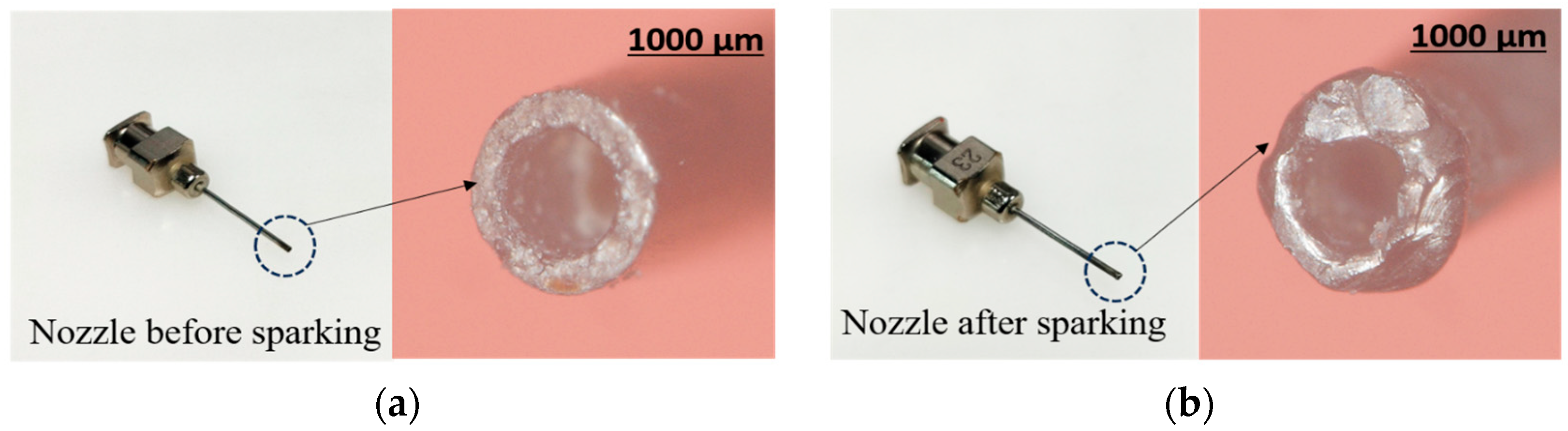

2. Materials and Methods

2.1. Parameter Selection

2.2. Machining Process

2.3. Data Logging and Analysis

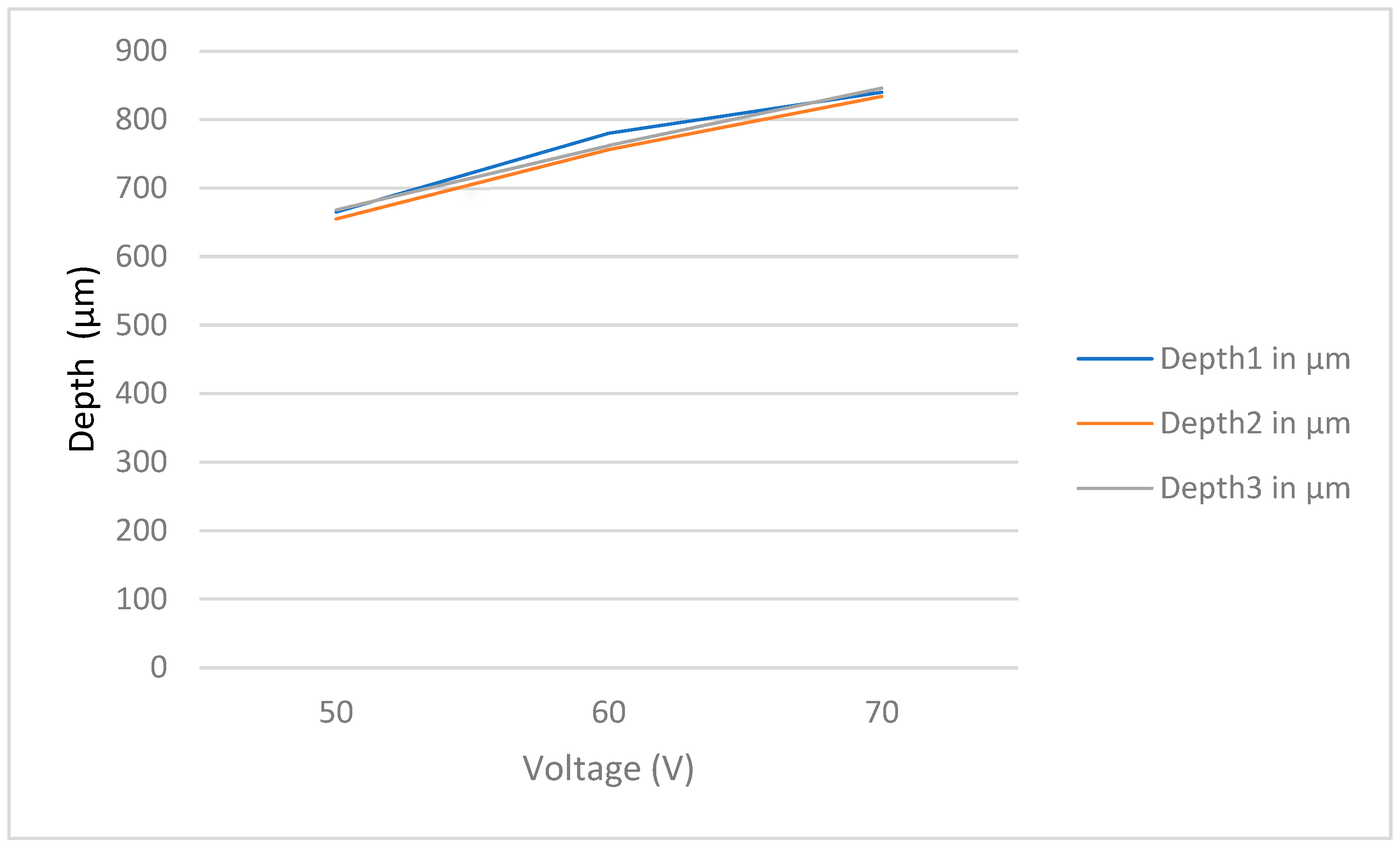

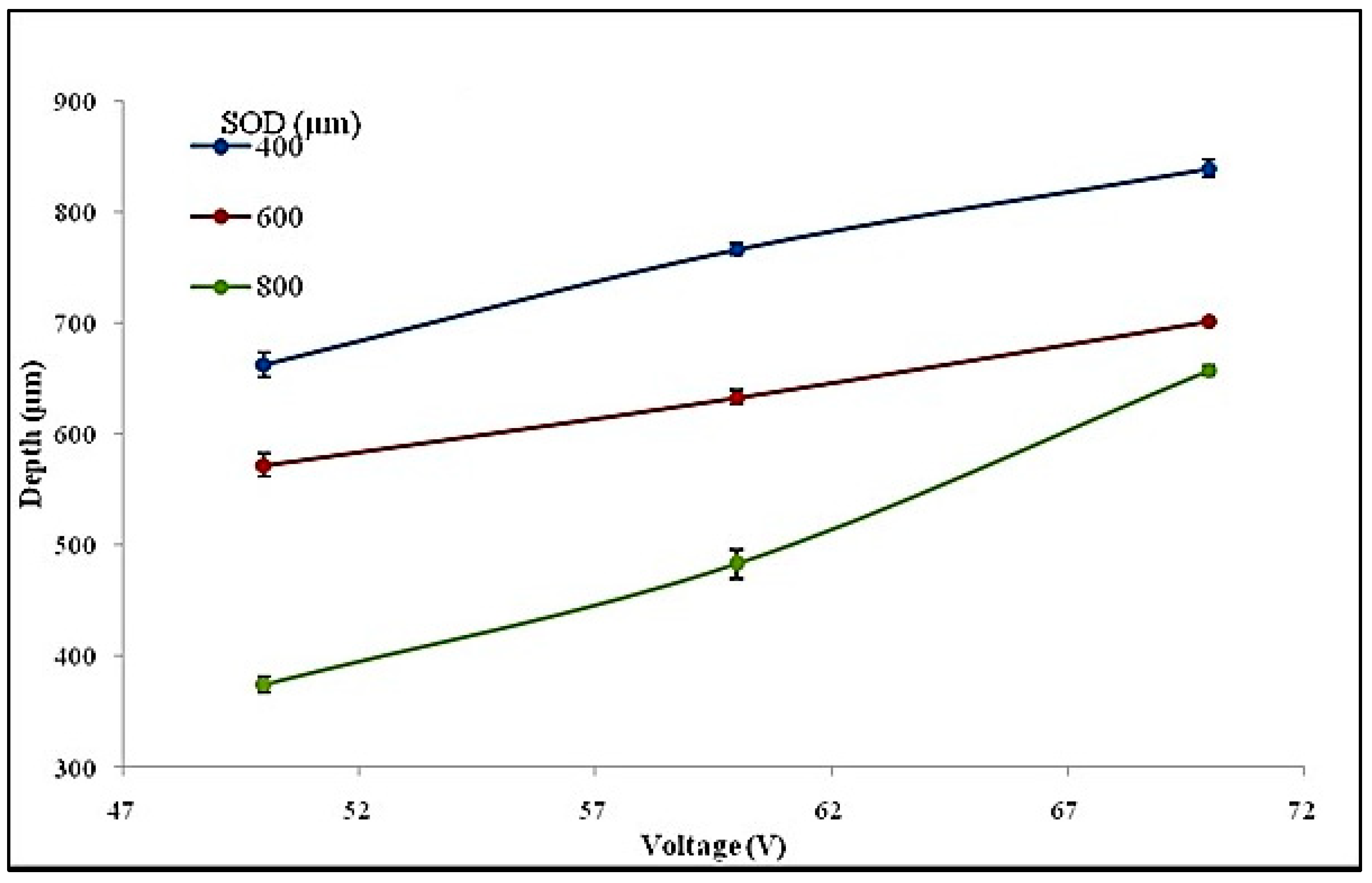

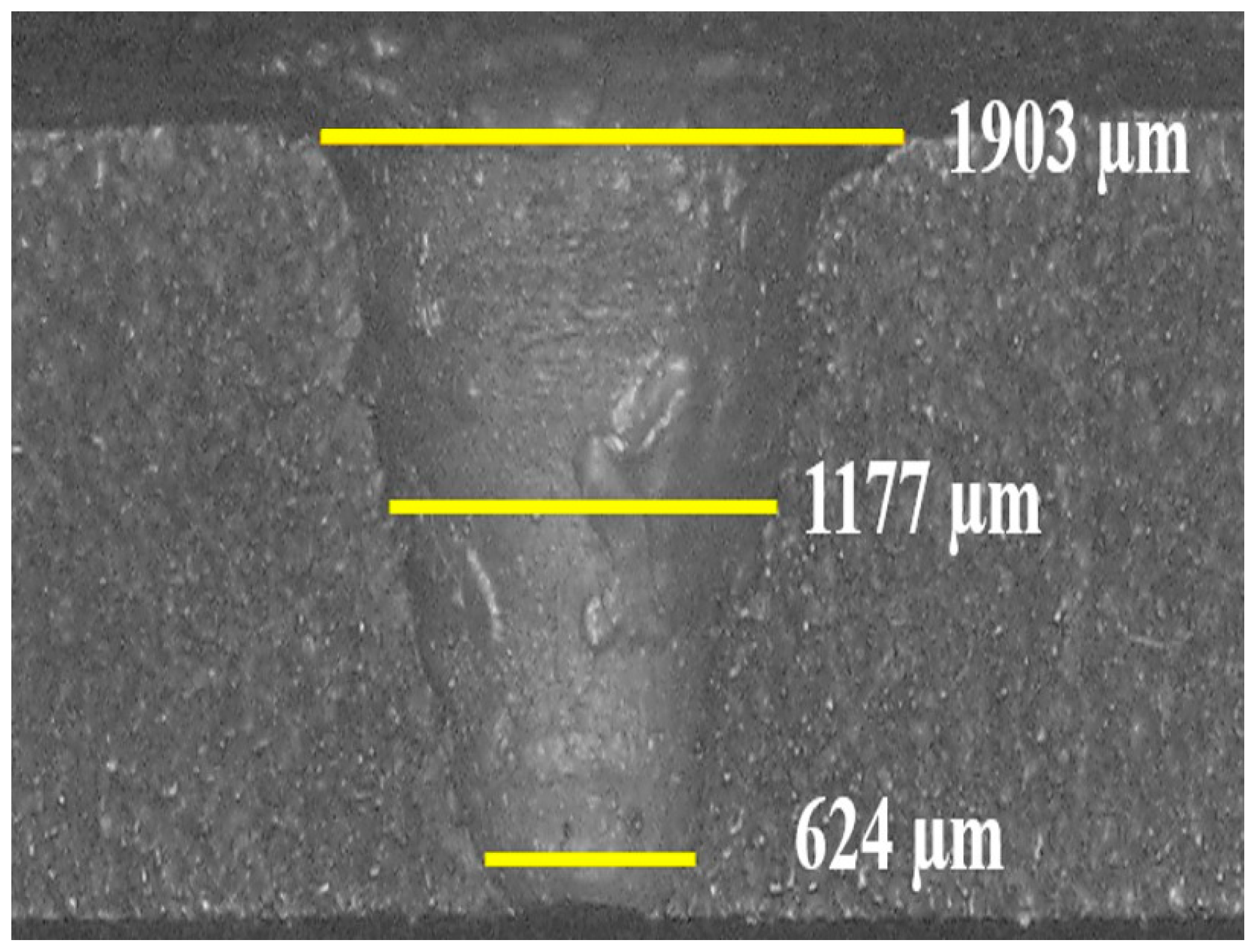

3. Results

4. Discussion

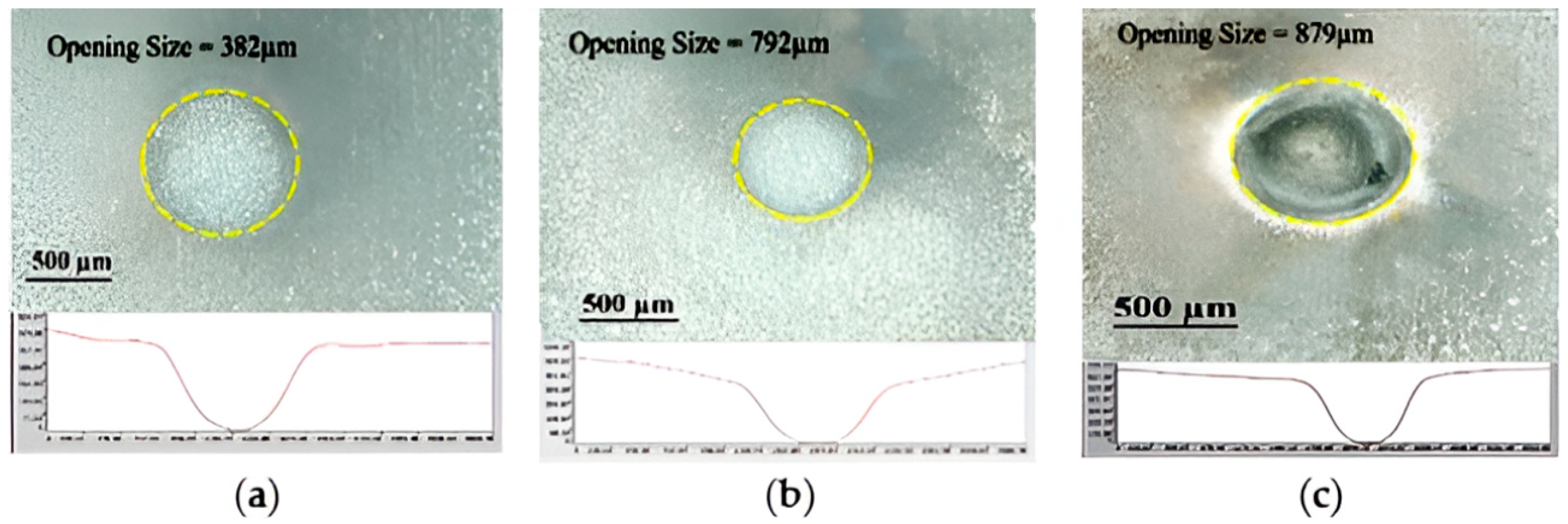

4.1. Constant SOD = 800 µm

- (a)

- 50 V: It shows that the material removal is modest since the machined aperture is shallow and wide.

- (b)

- At 60 V, the aperture is much broader and deeper than at 50 V. This symbolises superior machining performance.

- (c)

- 70 V: This voltage level affects maximum material removal since it has the broadest and deepest opening of all the possibilities.

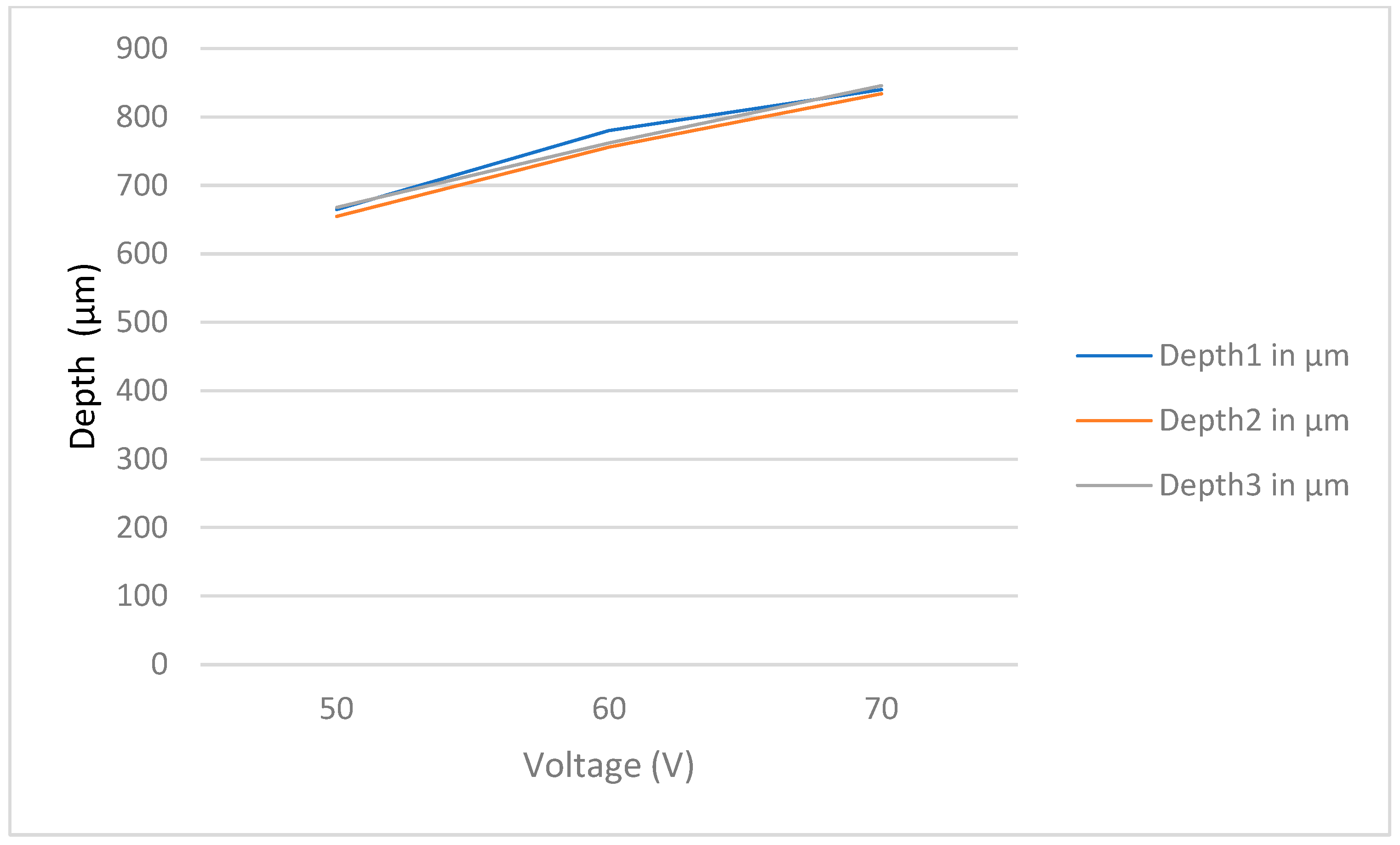

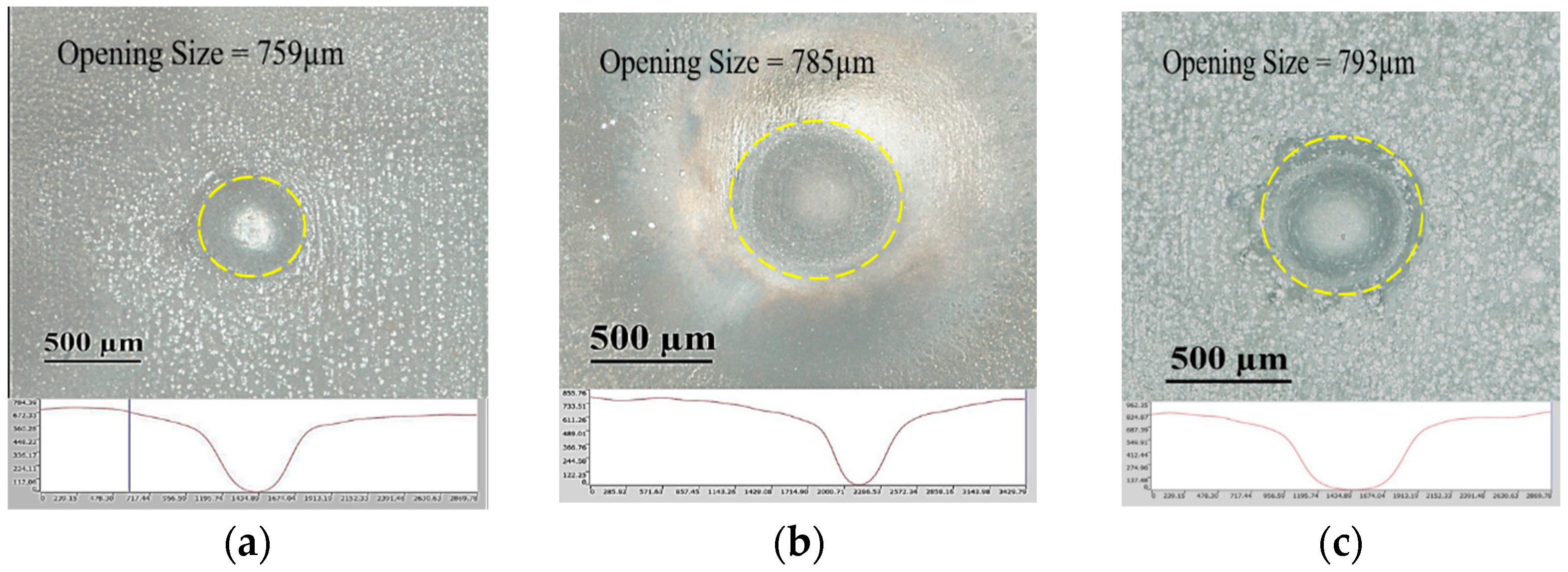

4.2. Constant SOD = 600 µm

- (a)

- 50 V: It can be seen that the machined opening was more profound and broader compared to the same voltage for an 800 µm SOD, which meant better material removal.

- (b)

- 60 V: The application of a subsequent increase to 60 V shows that more depths and widths have been obtained with improved machining efficiency.

- (c)

- 70 V: The broadest and most profound of the three, proving to have the highest material removal rate.

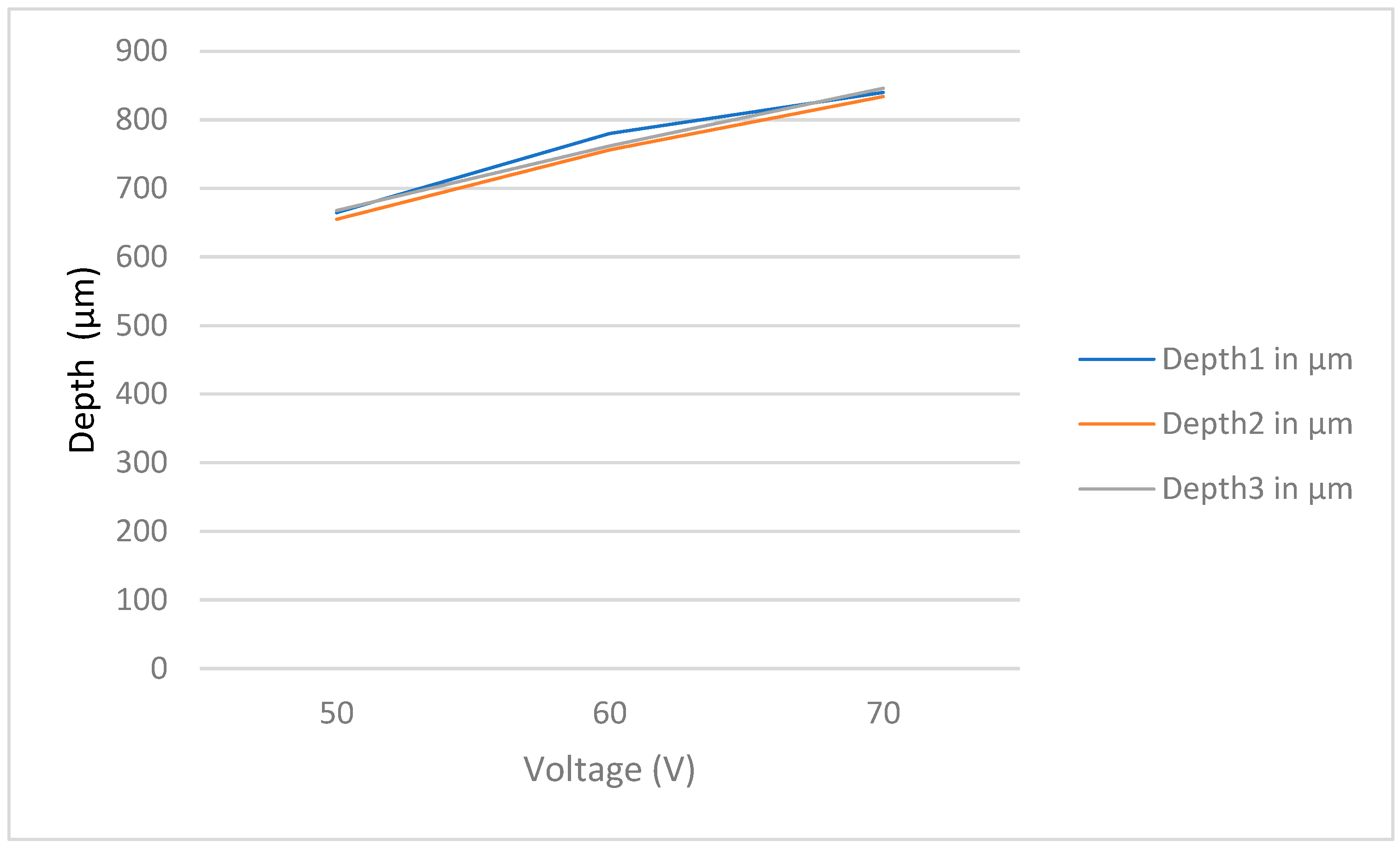

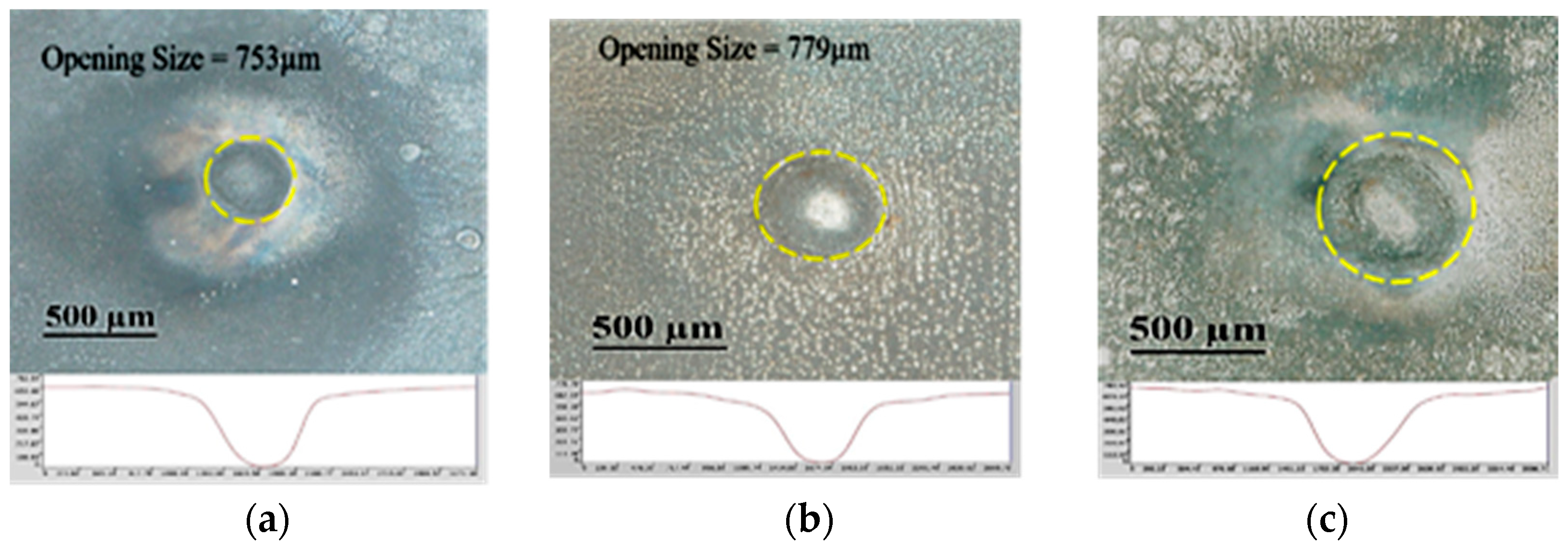

4.3. Constant SOD = 400 µm

- (a)

- 50 V: The depth and width are significantly high compared to higher SODs, which could be indicative of the material removal efficiency.

- (b)

- 60 V: Continuous increments in depth and size can suggest better machining performance.

- (c)

- 70 V: This is the deepest and largest opening, indicating the best performance within this voltage and SOD combination.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ECJM | Electrochemical Jet Machining |

| ECM | Electrochemical Machining |

| SOD | Stand-off distance |

| Jet-EPM | Jet-Electrolytic Plasma Micromachining |

| MRR | Material Removal Rate |

| CNC | Computer Numerical Control |

References

- Lu, J.; Zhan, S.; Liu, B.; Zhao, Y. Plasma-enabled electrochemical jet micromachining of chemically inert and passivating material. Int. J. Extrem. Manuf. 2022, 4, 045101. [Google Scholar] [CrossRef]

- Dalabehera, T.; Mullick, S.; Bartarya, G.; Shankar, R. Experimental analysis of electro-jet machining of thin metal sheets under the application of ultrasonic vibration, continuous and pulsed direct current. Proc. Inst. Mech. Eng. Part E 2022, 237, 2290–2299. [Google Scholar] [CrossRef]

- Netprasert, O.; Tangwarodomnukun, V.; Zhu, H.; Dumkum, C. Parametric analysis and modeling of electrochemical jet machining of titanium alloy. Int. J. Adv. Manuf. Tech. 2021, 118, 451–461. [Google Scholar] [CrossRef]

- Qu, N. Flow field simulation and experimental investigation on macro electrolyte jet electrochemical turning of TB6 titanium alloy. Int. J. Adv. Manuf. Tech. 2022, 120, 2617–2632. [Google Scholar] [CrossRef]

- Kendall, T.; Diver, C.; Gillen, D.; Bartolo, P. New insights on manipulating the material removal characteristics of Jet-Electrochemical machining through nozzle design. Int. J. Adv. Manuf. Technol. 2022, 118, 1009–1026. [Google Scholar] [CrossRef]

- Wu, M.; Arshad, H.M.; Krishna Saxena, K.K.; Liu, J. Experimental and Numerical Investigations on Fabrication of Surface Microstructures Using Mask Electrolyte Jet Machining and Duckbill Nozzle. J. Manuf. Sci. Eng. 2022, 145, 051006. [Google Scholar] [CrossRef]

- Kyttä, M. Systematic study of electrochemical machining processes for micromachining. In Handbook of Advanced Machining and Finishing Technologies, 1st ed.; CRC Press: New York, NY, USA, 2022; pp. 191–212. [Google Scholar] [CrossRef]

- Feng, Y.; Yan, Y.; Zhou, P.; Guo, D. High precision material removal of copper surface by jet electrochemical machining. IOP Conf. Ser. Mater. Sci. Eng. 2020, 715, 012052. [Google Scholar] [CrossRef]

- Wu, M.; Arshad, H.M.; Saxena, K.K.; Qian, J.; Reynaerts, D. Profile prediction in ECM using machine learning. Procedia CIRP 2022, 113, 410–416. [Google Scholar] [CrossRef]

- Liu, W.; Ao, S.; Li, Y.; Liu, Z.; Zhang, H.; Manladan, S.; Luo, Z.; Wang, Z. Effect of Anodic Behavior on Electrochemical Machining of TB6 Titanium Alloy. Electrochim. Acta 2017, 233, 190–200. [Google Scholar] [CrossRef]

- Hackert-Oschätzchen, M.; Paul, R.; Kowalick, M.; Martin, A.; Meichsner, G.; Schubert, A. Multiphysics Simulation of the Material Removal in Jet Electrochemical Machining. Proc. CIRP 2015, 31, 197–202. [Google Scholar] [CrossRef]

- Sen, M.; Shan, H. A review of electrochemical macro- to micro-hole drilling processes. Int. J. Mach. Tools Manuf. 2005, 45, 137–152. [Google Scholar] [CrossRef]

- Cénac, F.; Zitoune, R.; Collombet, F.; Deleris, M. Abrasive water-jet milling of aeronautic aluminum 2024-T3. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 2015, 229, 29–37. [Google Scholar] [CrossRef]

- Selvarajan, L.; Venkataramanan, K.; Srinivasa, P.; Arun, C.; Raj, Y.J.; Sivakumar, V.; Babu, M.; Kannan, S.; Katherasan, D.; Kasthuri, N. Spark eroding machining performance, surface textures and optimization strategies for ceramic composites: A review. Arch. Civ. Mech. Eng. 2025, 25, 87. [Google Scholar] [CrossRef]

- Srinivasa Perumal, K.P.; Selvarajan, L.; Mathan Kumar, P.; Shriguppikar, S. Enhancing mechanical and morphological properties of glass fiber reinforced epoxy polymer composites through rutile nanoparticle incorporation. Prog. Addit. Manuf. 2024, 10, 831–848. [Google Scholar] [CrossRef]

- Liu, Y.; Qu, N.; Li, H.; Zhang, Z. Boundary fluid constraints during electrochemical jet machining of large size emerging titanium alloy aerospace parts in gas-liquid flows: Experimental and numerical simulation. Chin. J. Aeronaut. 2024, 38, 103024. [Google Scholar] [CrossRef]

- Ao, S.; Qin, X.; Li, K.; Luo, Z. Effects of process parameters on jet electrochemical machining of SiC particle-reinforced aluminum matrix composites. Int. J. Adv. Manuf. Technol. 2021, 112, 3351–3361. [Google Scholar] [CrossRef]

- Prakash, A.; Kumar, A.; Ballav, R. Process capability of electrochemical discharge machining: A review. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 2023, 238, 282–300. [Google Scholar] [CrossRef]

- Hackert-Oschätzchen, M.; Lehnert, N.; Martin, A.; Schubert, A. Jet Electrochemical Machining of Particle Reinforced Aluminum Matrix Composites with Different Neutral Electrolytes. IOP Conf. Ser. Mater. Sci. Eng. 2016, 118, 012036. [Google Scholar] [CrossRef]

- Zanjani, M.Y.; Hackert-Oschätzchen, M.; Martin, A.; Meichsner, G.; Edelmann, J.; Schubert, A. Process Control in Jet Electrochemical Machining of Stainless Steel through Inline Metrology of Current Density. Micromachines 2019, 10, 261. [Google Scholar] [CrossRef]

- Zhao, Y.; Kunieda, M. Investigation on electrolyte jet machining of three-dimensional freeform surfaces. Precis. Eng. 2019, 60, 42–53. [Google Scholar] [CrossRef]

- Jia, J.L.; Fan, Z.J. Research on Higher Frequency, Short Pulses and Assisted Magnetic Field Electrochemical Machining. Adv. Mater. Res. 2011, 189–193, 3162–3165. [Google Scholar] [CrossRef]

- Fan, G.; Chen, X.; Saxena, K.K.; Liu, J.; Guo, Z. Jet Electrochemical Micromachining of Micro-Grooves with Conductive-Masked Porous Cathode. Micromachines 2020, 11, 557. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, N.; Kang, X.; Zhao, W. An experimental study on the effect of parameters on the depth of crater machined by electrostatic field–induced electrolyte jet micro electrical discharge machining. Adv. Mech. Eng. 2016, 8, 1687814016643886. [Google Scholar] [CrossRef]

- Kozak, J.; Kozak, J.; Rajurkar, K.P.; Balkrishna, R. Study of Electrochemical Jet Machining Process. J. Manuf. Sci. Eng. 1996, 118, 490–498. [Google Scholar] [CrossRef]

- Liu, W.; Ao, S.; Li, Y.; Liu, Z.; Wang, Z.; Luo, Z.; Wang, Z.; Song, R. Jet electrochemical machining of TB6 titanium alloy. Int. J. Adv. Manuf. Tech. 2017, 90, 2397–2409. [Google Scholar] [CrossRef]

- Kong, H.; Qu, N.; Chen, J. Machining behaviour modulation of electrochemical milling via manipulation of inter-electrode gap: From electrochemical machining to electrochemical discharge machining. J. Mater. Process. Technol. 2024, 333, 118584. [Google Scholar] [CrossRef]

- Bhattacharyya, B. Electrochemical Machining: Macro to Micro; William Andrew Publishing: Norwich, NY, USA, 2015; pp. 25–52. [Google Scholar] [CrossRef]

- Schalenbach, M.; Durmus, Y.E.; Tempel, H.; Kungl, H.; Eichel, R.A. Ion Transport and Limited Currents in Supporting Electrolytes and Ionic Liquids. Sci. Rep. 2022, 12, 6215. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Workpiece | SS304 (304 Stainless Steel) Chromium 17.5–19.5% Nickel 8.0–10.5% |

| Electrolyte | 2 M NaCl |

| Nozzle inner diameter | 300 µm |

| Electrolyte supply rate | 20 mL/min |

| SOD | 400 µm, 600 µm, 800 µm |

| Voltage | 50 V, 60 V, 70 V |

| Input Parameters | Output | ||||

|---|---|---|---|---|---|

| SN | Voltage (V) | SOD (µm) | Depth Achieved (µm) | ||

| 1 | 50 | 800 | 378 | 362 | 383 |

| 2 | 50 | 600 | 572 | 582 | 668 |

| 3 | 50 | 400 | 655 | 668 | 665 |

| 4 | 60 | 800 | 477 | 484 | 487 |

| 5 | 60 | 600 | 640 | 628 | 630 |

| 6 | 60 | 400 | 780 | 756 | 762 |

| 7 | 70 | 800 | 650 | 657 | 665 |

| 8 | 70 | 600 | 702 | 703 | 698 |

| 9 | 70 | 400 | 840 | 834 | 843 |

| Depth 1 (µm) | Depth 2 (µm) | Depth 3 (µm) | Voltage (V) |

|---|---|---|---|

| 383 | 378 | 362 | 50 |

| 477 | 484 | 487 | 60 |

| 657 | 665 | 650 | 70 |

| Depth 1 (µm) | Depth 2 (µm) | Depth 3 (µm) | Voltage (V) |

|---|---|---|---|

| 562 | 582 | 575 | 50 |

| 640 | 630 | 634 | 60 |

| 698 | 704 | 701 | 70 |

| Depth 1 (µm) | Depth 2 (µm) | Depth 3 (µm) | Voltage (V) |

|---|---|---|---|

| 665 | 655 | 668 | 50 |

| 780 | 756 | 762 | 60 |

| 840 | 834 | 846 | 70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shirguppikar, S.; Ašonja, A.; Desnica, E.; Ganachari, V.; Gavali, P.B.; Selvarajan, L.; Stojanović, B. Comprehensive Experimental Analysis of Electrochemical Jet Machining (ECJM) for Advanced Material Processing. J. Manuf. Mater. Process. 2025, 9, 240. https://doi.org/10.3390/jmmp9070240

Shirguppikar S, Ašonja A, Desnica E, Ganachari V, Gavali PB, Selvarajan L, Stojanović B. Comprehensive Experimental Analysis of Electrochemical Jet Machining (ECJM) for Advanced Material Processing. Journal of Manufacturing and Materials Processing. 2025; 9(7):240. https://doi.org/10.3390/jmmp9070240

Chicago/Turabian StyleShirguppikar, Shailesh, Aleksandar Ašonja, Eleonora Desnica, Vaibhav Ganachari, Pankaj B. Gavali, Lakshmanan Selvarajan, and Blaža Stojanović. 2025. "Comprehensive Experimental Analysis of Electrochemical Jet Machining (ECJM) for Advanced Material Processing" Journal of Manufacturing and Materials Processing 9, no. 7: 240. https://doi.org/10.3390/jmmp9070240

APA StyleShirguppikar, S., Ašonja, A., Desnica, E., Ganachari, V., Gavali, P. B., Selvarajan, L., & Stojanović, B. (2025). Comprehensive Experimental Analysis of Electrochemical Jet Machining (ECJM) for Advanced Material Processing. Journal of Manufacturing and Materials Processing, 9(7), 240. https://doi.org/10.3390/jmmp9070240