Advances in the Additive Manufacturing of Superalloys

Abstract

1. Introduction

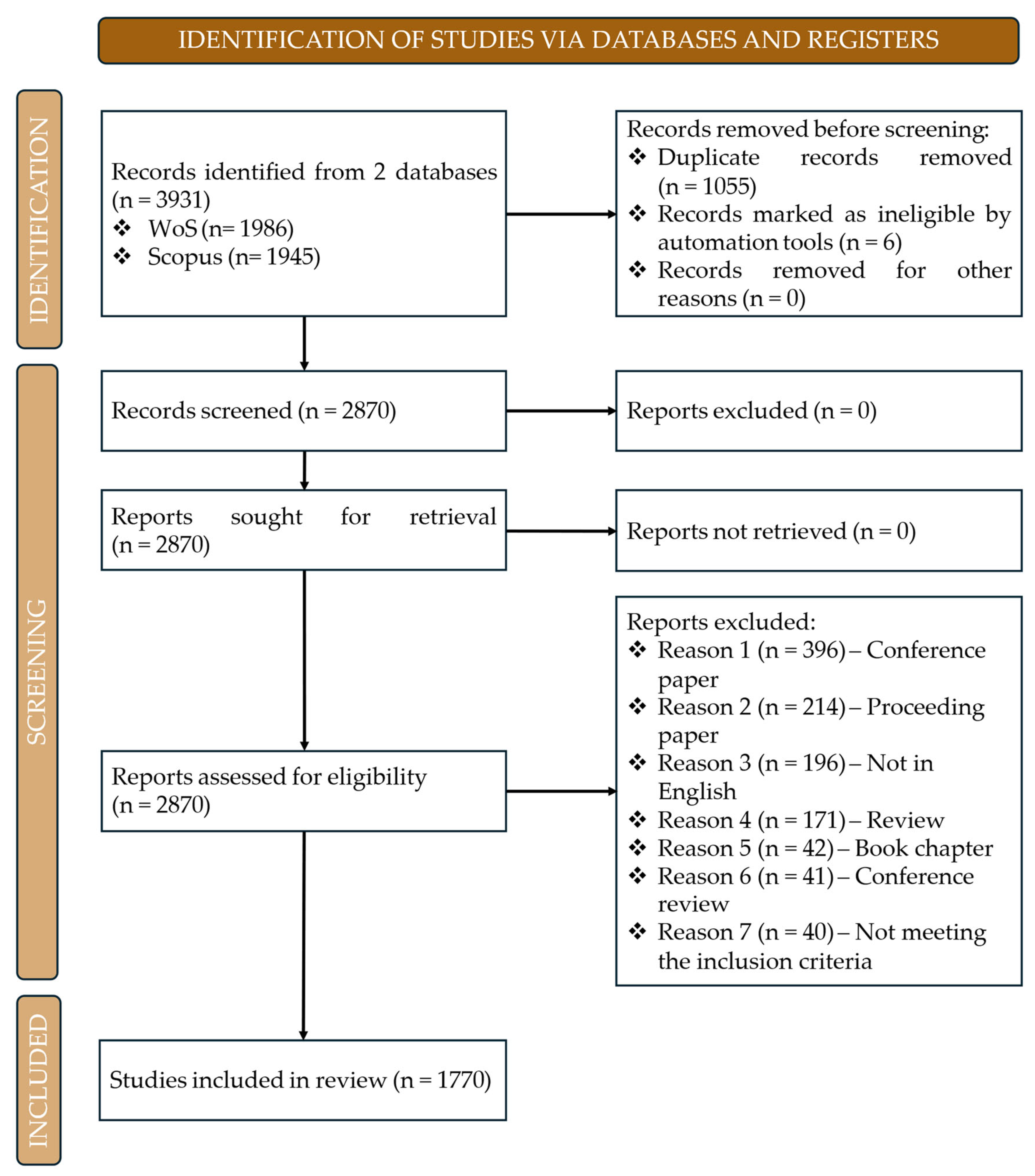

2. Materials and Methods

3. Results

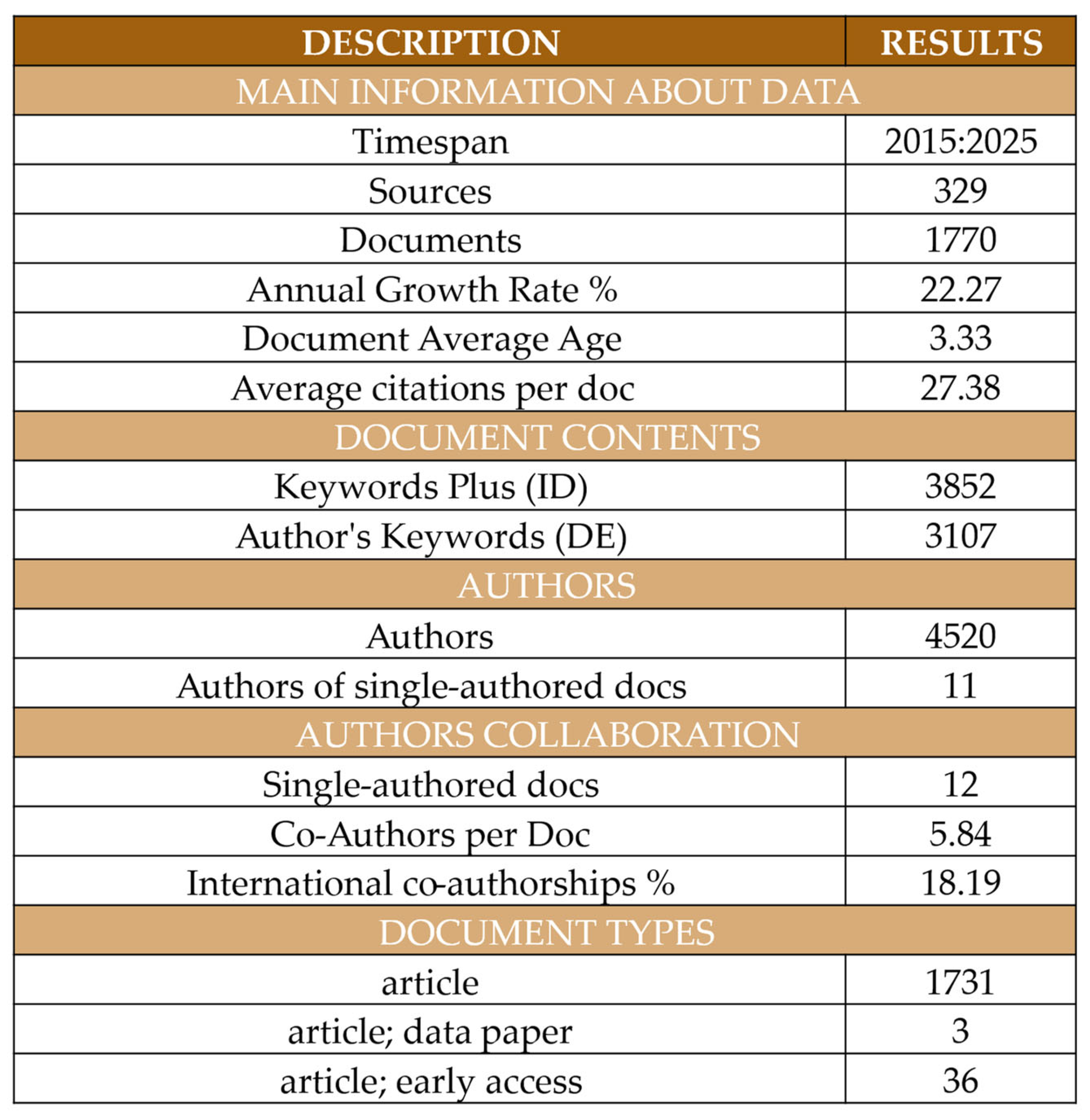

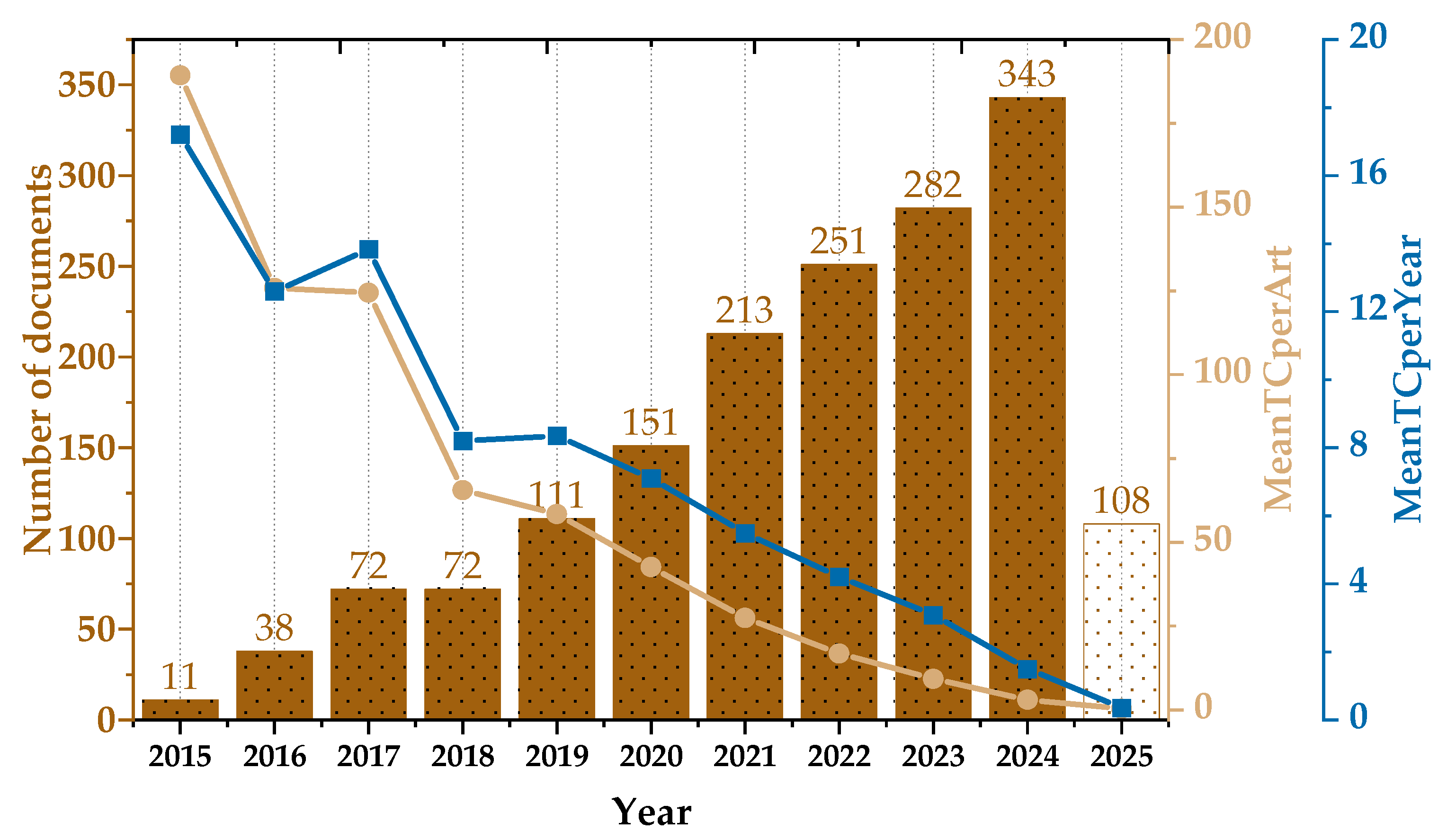

3.1. General Document Results

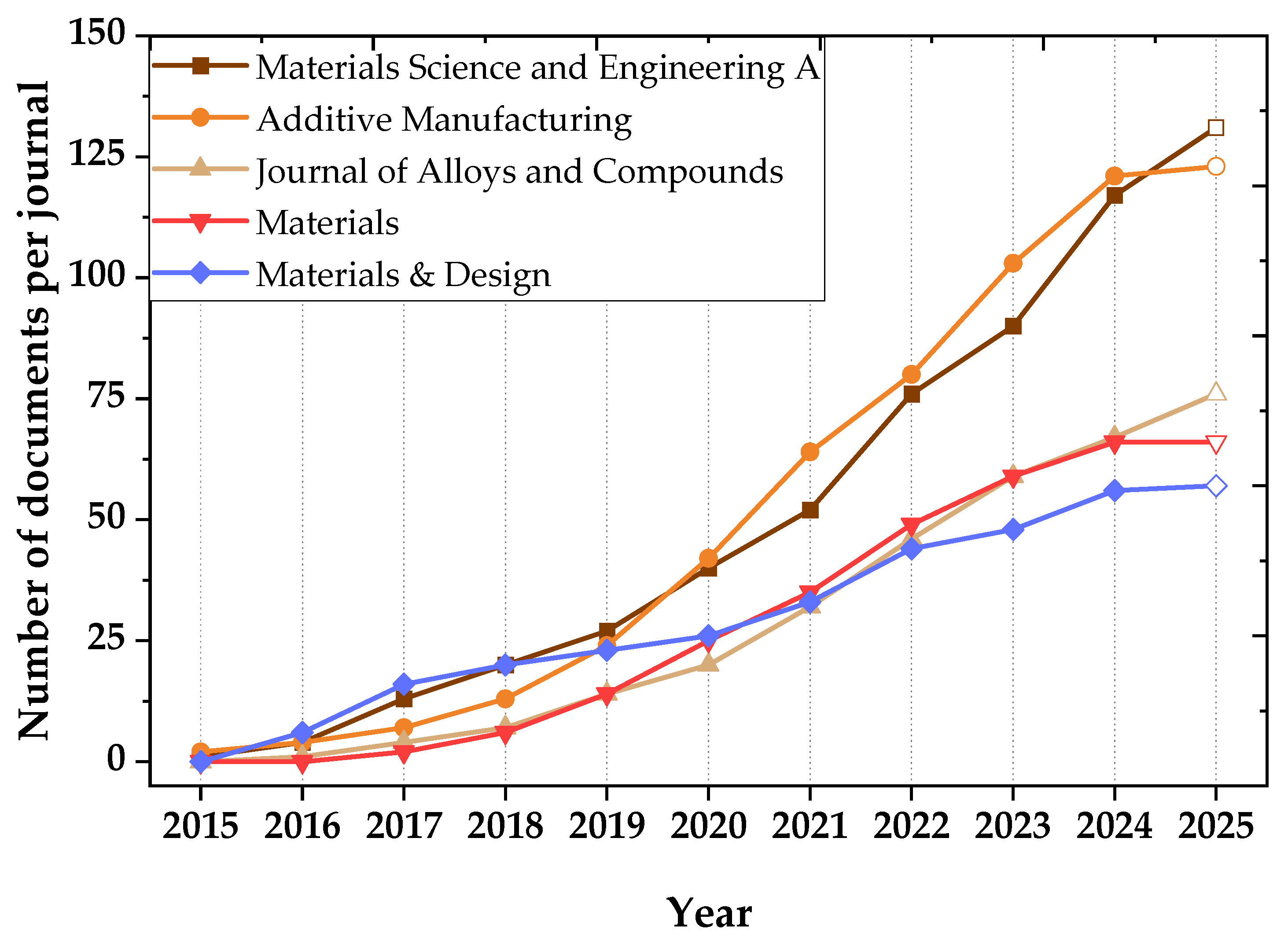

3.2. Scientific Journal Results

3.3. Author Results

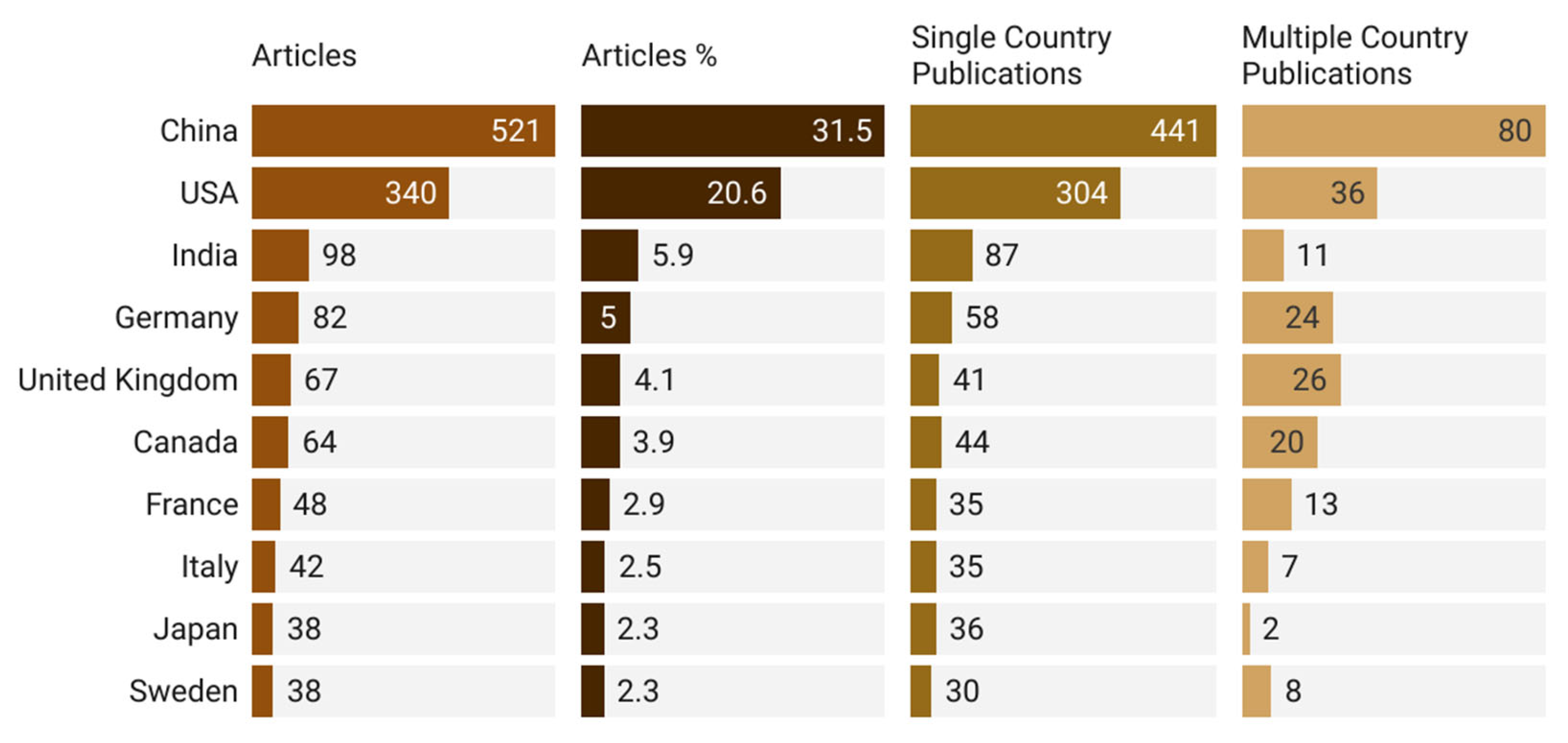

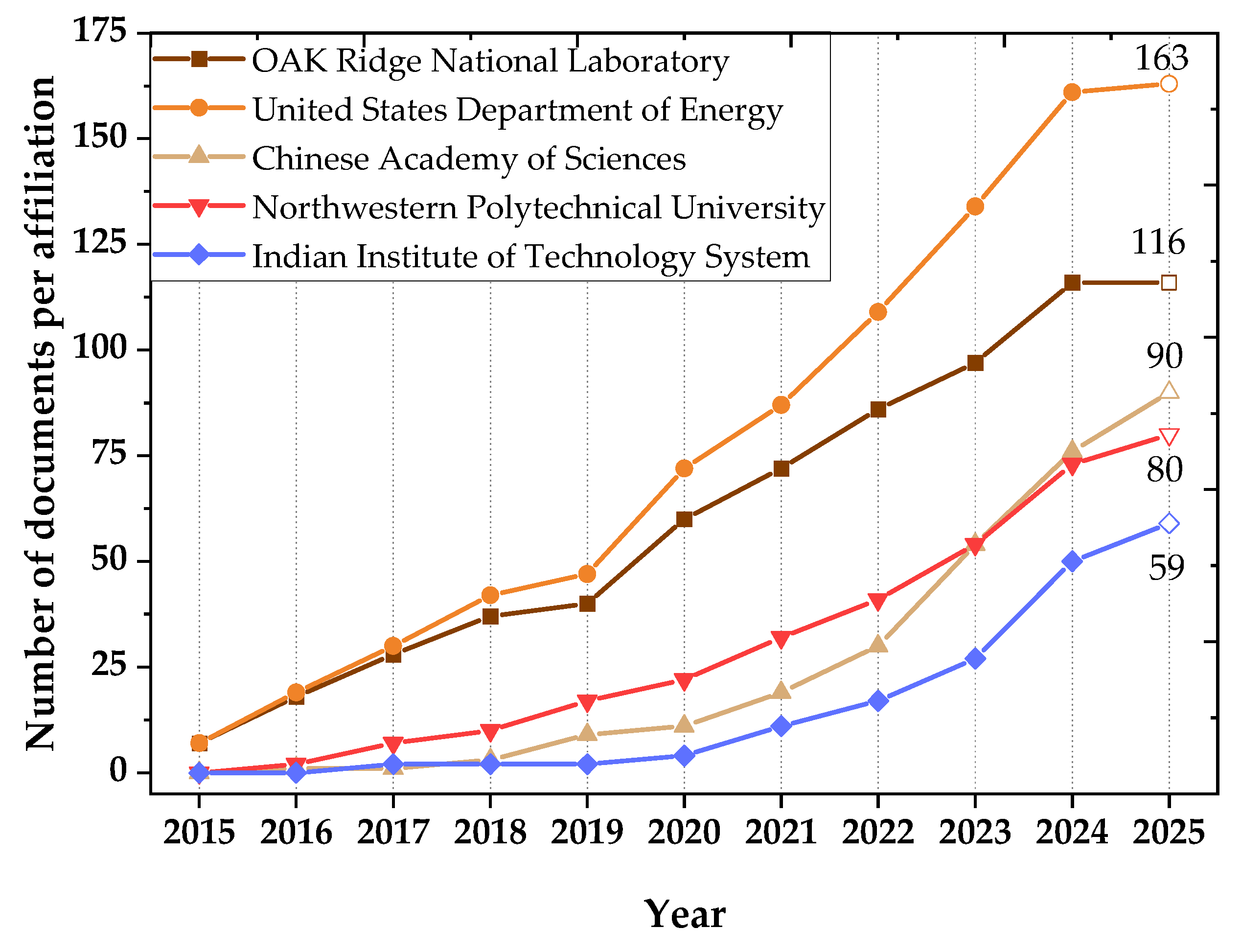

3.4. Country and Affiliation Results

4. Discussion

4.1. High-Impact Scientific Publications Evaluation

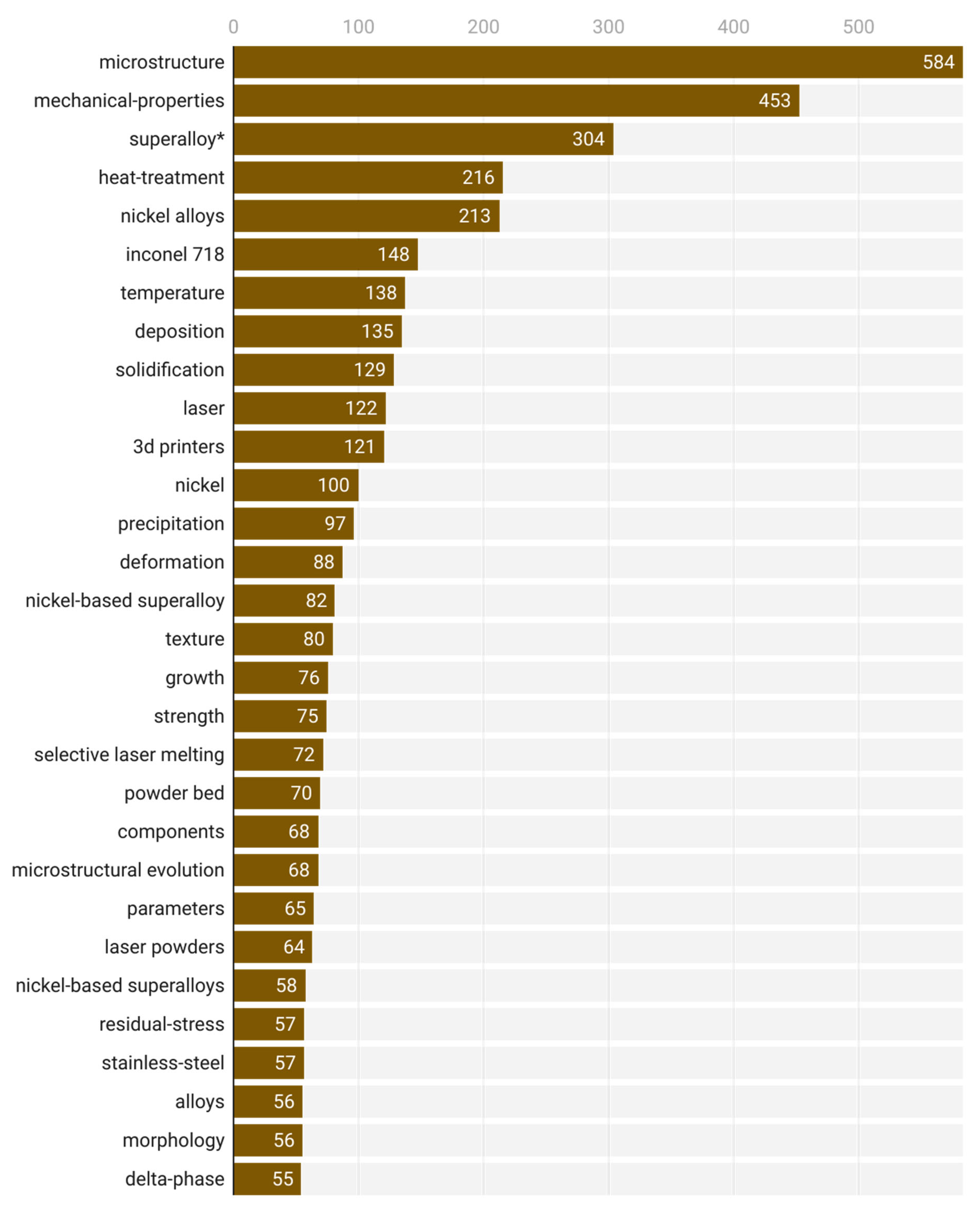

4.2. Keyword Occurence Evaluation

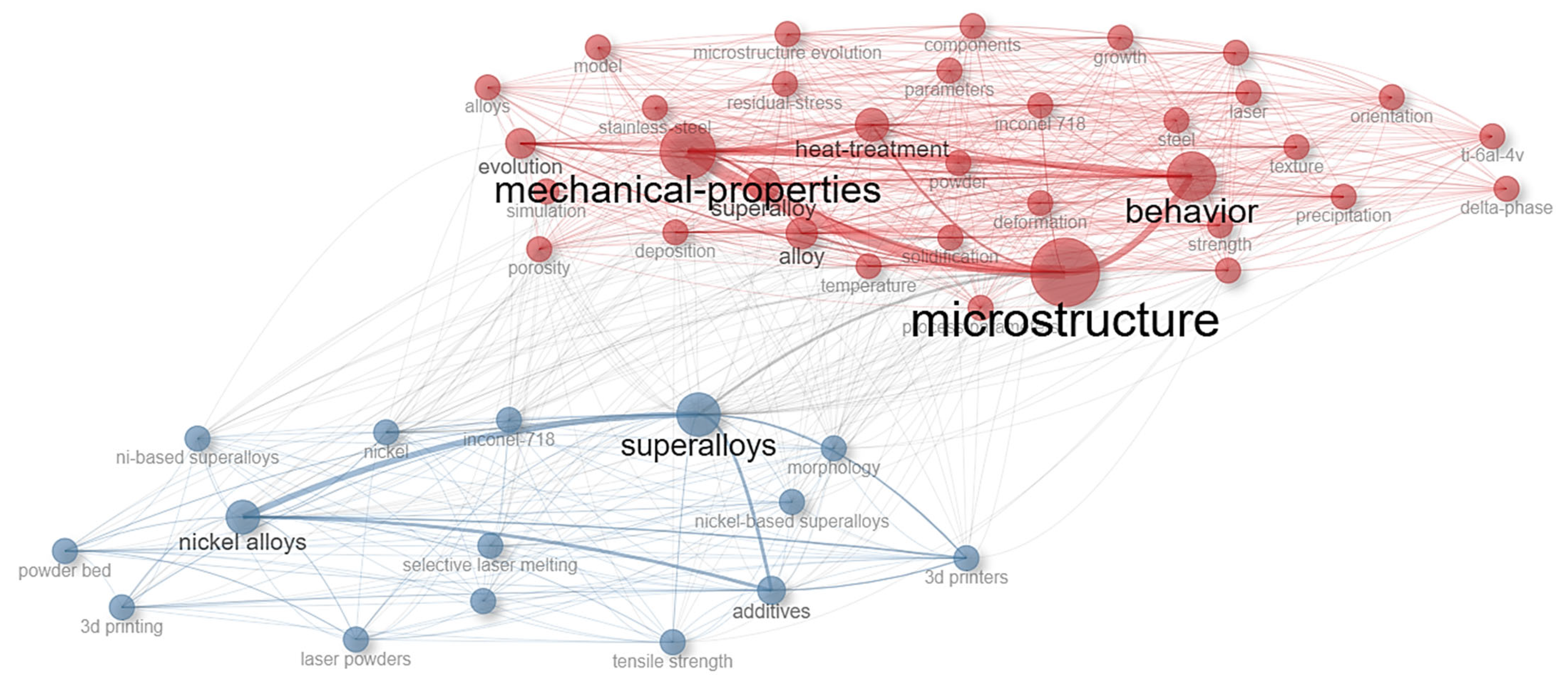

4.3. Keywords Co-Occurrence Analysis

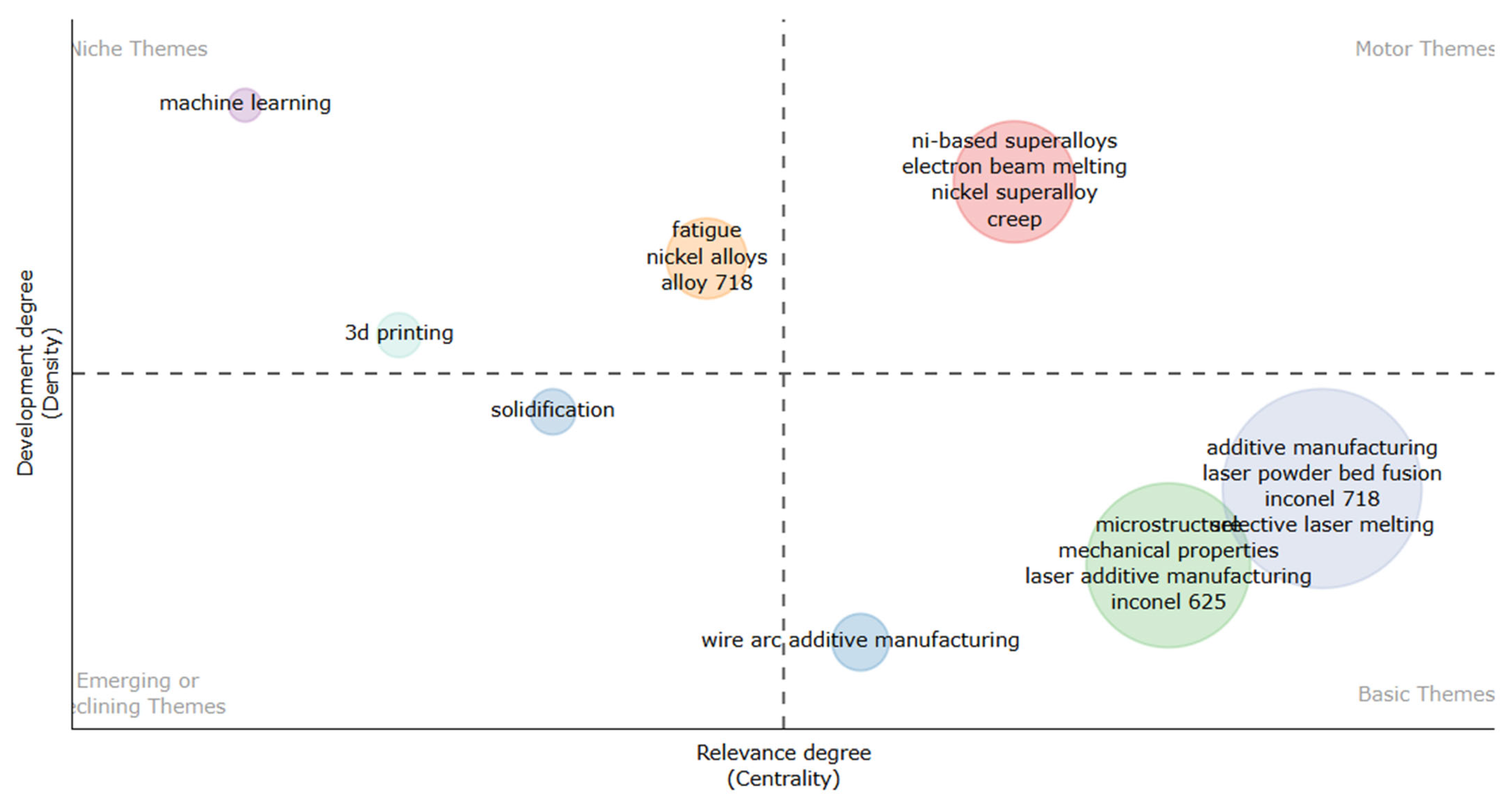

4.4. Thematic Evaluation

4.5. Comparative Evaluation of Microstructure, Texture, and Post-Treatment Effects Across AM Techniques

4.5.1. Ni-Based Superalloys

4.5.2. Co-Based Superalloys

4.5.3. Fe–Ni (Fe-Ni) Superalloys

4.6. Sector-Specific Applications and Industrial Relevance of Am Superalloys

5. Future Directions

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Wen, G.; Li, L.; Lei, Z.; Qi, X.; Huang, B.; Su, Y.; Zhang, Z.; Nie, X.; Zhang, Z. The Generation, Measurement, Prediction, and Prevention of Residual Stress in Nickel-Based Superalloys: A Review. Machines 2024, 12, 715. [Google Scholar] [CrossRef]

- Angel, N.M.; Basak, A. On the Fabrication of Metallic Single Crystal Turbine Blades with a Commentary on Repair via Additive Manufacturing. J. Manuf. Mater. Process. 2020, 4, 101. [Google Scholar] [CrossRef]

- Chowdhury, T.S.; Mohsin, F.T.; Tonni, M.M.; Mita, M.N.H.; Ehsan, M.M. A Critical Review on Gas Turbine Cooling Performance and Failure Analysis of Turbine Blades. Int. J. Thermofluids 2023, 18, 100329. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive Manufacturing: Scientific and Technological Challenges, Market Uptake and Opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Zhong, C.; Kittel, J.; Gasser, A.; Schleifenbaum, J.H. Study of Nickel-Based Super-Alloys Inconel 718 and Inconel 625 in High-Deposition-Rate Laser Metal Deposition. Opt. Laser Technol. 2019, 109, 352–360. [Google Scholar] [CrossRef]

- Lavella, M.; Cormier, J. Contact Properties and Wear Behaviour of Nickel Based Superalloy René 80. Metals 2016, 6, 159. [Google Scholar] [CrossRef]

- Rösler, J.; Götting, M.; Del Genovese, D.; Böttger, B.; Kopp, R.; Wolske, M.; Schubert, F.; Penkalla, H.J.; Seliga, T.; Thoma, A.; et al. Wrought Ni-Base Superalloys for Steam Turbine Applications beyond 700 °C. Adv. Eng. Mater. 2003, 5, 469–483. [Google Scholar] [CrossRef]

- Campos, M.; Cartón-Cordero, M.; García de la Cruz, L.; Caballero, F.G.; Poplawsky, J.D.; Torralba, J.M. Enhancement of γ/γ’ Microstructured Cobalt Superalloys Produced from Atomized Powder by Creating a Harmonic Structure. Metals 2024, 14, 70. [Google Scholar] [CrossRef]

- Barile, C.; Renna, G.; Günen, A.; Ergin, Ö. A Comparative Study on Characterization and High-Temperature Wear Behaviors of Thermochemical Coatings Applied to Cobalt-Based Haynes 25 Superalloys. Coatings 2023, 13, 1272. [Google Scholar] [CrossRef]

- Qin, H.; Bi, Z.; Li, D.; Zhang, R.; Lee, T.L.; Feng, G.; Dong, H.; Du, J.; Zhang, J. Study of Precipitation-Assisted Stress Relaxation and Creep Behavior during the Ageing of a Nickel-Iron Superalloy. Mater. Sci. Eng. A 2019, 742, 493–500. [Google Scholar] [CrossRef]

- Zhang, B.B.; Yan, F.K.; Zhao, M.J.; Tao, N.R.; Lu, K. Combined Strengthening from Nanotwins and Nanoprecipitates in an Iron-Based Superalloy. Acta Mater. 2018, 151, 310–320. [Google Scholar] [CrossRef]

- Pröbstle, M.; Neumeier, S.; Feldner, P.; Rettig, R.; Helmer, H.E.; Singer, R.F.; Göken, M. Improved Creep Strength of Nickel-Base Superalloys by Optimized γ/Γ′ Partitioning Behavior of Solid Solution Strengthening Elements. Mater. Sci. Eng. A 2016, 676, 411–420. [Google Scholar] [CrossRef]

- Fleischmann, E.; Miller, M.K.; Affeldt, E.; Glatzel, U. Quantitative Experimental Determination of the Solid Solution Hardening Potential of Rhenium, Tungsten and Molybdenum in Single-Crystal Nickel-Based Superalloys. Acta Mater. 2015, 87, 350–356. [Google Scholar] [CrossRef]

- Štamborská, M.; Lapin, J.; Kamyshnykova, K. Preparation, Microstructure, and Mechanical Behaviour of Ni3Al-Based Superalloy Reinforced with Carbide Particles. Intermetallics 2022, 149, 107667. [Google Scholar] [CrossRef]

- Cartón-Cordero, M.; Campos, M.; Freund, L.P.; Kolb, M.; Neumeier, S.; Göken, M.; Torralba, J.M. Microstructure and Compression Strength of Co-Based Superalloys Hardened by Γ′ and Carbide Precipitation. Mater. Sci. Eng. A 2018, 734, 437–444. [Google Scholar] [CrossRef]

- Dutta, R.S.; Sarkar, A.; Vishwanadh, B.; Tewari, R.; Sastry, P.U.; Dey, G.K. Precipitation-Hardening of Superalloy 693 and Modeling of Initial Stages of Hardening. Mater. Charact. 2018, 138, 127–135. [Google Scholar] [CrossRef]

- Ni, M.; Liu, S.; Chen, C.; Li, R.; Zhang, X.; Zhou, K. Effect of Heat Treatment on the Microstructural Evolution of a Precipitation-Hardened Superalloy Produced by Selective Laser Melting. Mater. Sci. Eng. A 2019, 748, 275–285. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Chua, C.K.; Zhu, Z.; Zhang, D. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Y.; Lv, L.; Deng, H.; Bian, Q.; Hu, Q.; Tan, L.; Liu, F. Effect of Powder Layer Thickness on the Microstructure and Properties of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Alloys Compd. 2025, 1020, 179465. [Google Scholar] [CrossRef]

- Chauvet, E.; Kontis, P.; Jägle, E.A.; Gault, B.; Raabe, D.; Tassin, C.; Blandin, J.J.; Dendievel, R.; Vayre, B.; Abed, S.; et al. Hot Cracking Mechanism Affecting a Non-Weldable Ni-Based Superalloy Produced by Selective Electron Beam Melting. Acta Mater. 2018, 142, 82–94. [Google Scholar] [CrossRef]

- Tadano, S.; Hino, T.; Nakatani, Y. A Modeling Study of Stress and Strain Formation Induced during Melting Process in Powder-Bed Electron Beam Melting for Ni Superalloy. J. Mater. Process. Technol. 2018, 257, 163–169. [Google Scholar] [CrossRef]

- Zhou, Z.; Lei, Q.; Yan, Z.; Wang, Z.; Shang, Y.; Li, Y.; Qi, H.; Jiang, L.; Liu, Y.; Huang, L. Effects of Process Parameters on Microstructure and Cracking Susceptibility of a Single Crystal Superalloy Fabricated by Directed Energy Deposition. Mater. Des. 2021, 198, 109296. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Xu, S.; Liu, B.; Sui, Q.; Zhao, F.; Gong, L.; Liu, J. Influence of Powder Characteristics on Microstructure and Mechanical Properties of Inconel 718 Superalloy Manufactured by Direct Energy Deposition. Appl. Surf. Sci. 2022, 583, 152545. [Google Scholar] [CrossRef]

- Jafari, D.; Vaneker, T.H.J.; Gibson, I. Wire and Arc Additive Manufacturing: Opportunities and Challenges to Control the Quality and Accuracy of Manufactured Parts. Mater. Des. 2021, 202, 109471. [Google Scholar] [CrossRef]

- Huang, H.; Ma, N.; Chen, J.; Feng, Z.; Murakawa, H. Toward Large-Scale Simulation of Residual Stress and Distortion in Wire and Arc Additive Manufacturing. Addit. Manuf. 2020, 34, 101248. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and Future Trends in Topology Optimization for Additive Manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Wang, X.; Xu, L.; Zhao, L.; Ren, W.; Li, Q.; Han, Y. Machine Learning Method for Estimating the Defect-Related Mechanical Properties of Additive Manufactured Alloys. Eng. Fract. Mech. 2023, 291, 109559. [Google Scholar] [CrossRef]

- del Bosque, A.; Vergara, D.; Fernández-Arias, P. An Overview of Smart Composites for the Aerospace Sector. Appl. Sci. 2025, 15, 2986. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef] [PubMed]

- Haddaway, N.R.; Page, M.J.; Pritchard, C.C.; McGuinness, L.A. PRISMA2020: An R Package and Shiny App for Producing PRISMA 2020-Compliant Flow Diagrams, with Interactivity for Optimised Digital Transparency and Open Synthesis. Campbell Syst. Rev. 2022, 18, e1230. [Google Scholar] [CrossRef] [PubMed]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Inf. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- del Bosque, A.; Lampropoulos, G.; Vergara, D. Nanocomposites for Multifunctional Sensors: A Comprehensive Bibliometric Exploration. Nanomaterials 2024, 15, 34. [Google Scholar] [CrossRef]

- del Bosque, A.; Vergara, D.; Lampropoulos, G.; Fernández-Arias, P. Energy Storage in Carbon Fiber-Based Batteries: Trends and Future Perspectives. Appl. Sci. 2024, 14, 10034. [Google Scholar] [CrossRef]

- Vergara, D.; del Bosque, A.; Lampropoulos, G.; Fernández-Arias, P. Trends and Applications of Artificial Intelligence in Project Management. Electronics 2025, 14, 800. [Google Scholar] [CrossRef]

- del Bosque, A.; Fernández-Arias, P.; Vergara, D. Titanium Additive Manufacturing with Powder Bed Fusion: A Bibliometric Perspective. Appl. Sci. 2024, 14, 10543. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D Printing of High-Strength Aluminium Alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Harrison, N.J.; Todd, I.; Mumtaz, K. Reduction of Micro-Cracking in Nickel Superalloys Processed by Selective Laser Melting: A Fundamental Alloy Design Approach. Acta Mater. 2015, 94, 59–68. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Zhang, D.; Bermingham, M.J.; Lui, E.W.; Brandt, M.; StJohn, D.H.; Qian, M. Grain Structure Control during Metal 3D Printing by High-Intensity Ultrasound. Nat. Commun. 2020, 11, 142. [Google Scholar] [CrossRef] [PubMed]

- Tucho, W.M.; Cuvillier, P.; Sjolyst-Kverneland, A.; Hansen, V. Microstructure and Hardness Studies of Inconel 718 Manufactured by Selective Laser Melting before and after Solution Heat Treatment. Mater. Sci. Eng. A 2017, 689, 220–232. [Google Scholar] [CrossRef]

- Cheng, B.; Shrestha, S.; Chou, K. Stress and Deformation Evaluations of Scanning Strategy Effect in Selective Laser Melting. Addit. Manuf. 2016, 12, 240–251. [Google Scholar] [CrossRef]

- Dehoff, R.R.; Kirka, M.; Sames, W.J.; Bilheux, H.; Tremsin, A.S.; Lowe, L.E.; Babu, S.S. Site Specific Control of Crystallographic Grain Orientation through Electron Beam Additive Manufacturing. Mater. Sci. Technol. 2015, 31, 931–938. [Google Scholar] [CrossRef]

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and Mechanical Properties of Selective Laser Melted Inconel 718 Compared to Forging and Casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Raghavan, N.; Dehoff, R.; Pannala, S.; Simunovic, S.; Kirka, M.; Turner, J.; Carlson, N.; Babu, S.S. Numerical Modeling of Heat-Transfer and the Influence of Process Parameters on Tailoring the Grain Morphology of IN718 in Electron Beam Additive Manufacturing. Acta Mater. 2016, 112, 303–314. [Google Scholar] [CrossRef]

- Wang, Z.; Xiao, Z.; Tse, Y.; Huang, C.; Zhang, W. Optimization of Processing Parameters and Establishment of a Relationship between Microstructure and Mechanical Properties of SLM Titanium Alloy. Opt. Laser Technol. 2019, 112, 159–167. [Google Scholar] [CrossRef]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.T.; Strayer, S.; Chang, K.C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.C.; Tin, S.; et al. Additive Manufacturing of Nickel-Based Superalloys: A State-of-the-Art Review on Process-Structure-Defect-Property Relationship. Prog. Mater. Sci. 2023, 136, 101108. [Google Scholar] [CrossRef]

- Shahwaz, M.; Nath, P.; Sen, I. A Critical Review on the Microstructure and Mechanical Properties Correlation of Additively Manufactured Nickel-Based Superalloys. J. Alloys Compd. 2022, 907, 164530. [Google Scholar] [CrossRef]

- Li, N.; Wang, C.; Li, C. Microstructures and High-Temperature Mechanical Properties of Inconel 718 Superalloy Fabricated via Laser Powder Bed Fusion. Materials 2024, 17, 3735. [Google Scholar] [CrossRef]

- Ni, M.; Chen, C.; Xu, R.; Hosseini, S.R.E.; Li, R.; Zhang, X.; Zhou, K. Microstructure and Mechanical Properties of Additive Manufactured Inconel 718 Alloy Strengthened by Oxide Dispersion with 0.3 Wt% Sc Addition. J. Alloys Compd. 2022, 918, 165763. [Google Scholar] [CrossRef]

- Qin, Z.; Li, B.; Chen, C.; Chen, T.; Chen, R.; Zhang, H.; Xue, H.; Yao, C.; Tan, L. Crack Initiation Mechanisms and Life Prediction of GH4169 Superalloy in the High Cycle and Very High Cycle Fatigue Regime. J. Mater. Res. Technol. 2023, 26, 720–736. [Google Scholar] [CrossRef]

- Yamashita, Y.; Murakami, T.; Mihara, R.; Okada, M.; Murakami, Y. Defect Analysis and Fatigue Design Basis for Ni-Based Superalloy 718 Manufactured by Selective Laser Melting. Int. J. Fatigue 2018, 117, 485–495. [Google Scholar] [CrossRef]

- Xu, J.; Gruber, H.; Deng, D.; Peng, R.L.; Moverare, J.J. Short-Term Creep Behavior of an Additive Manufactured Non-Weldable Nickel-Base Superalloy Evaluated by Slow Strain Rate Testing. Acta Mater. 2019, 179, 142–157. [Google Scholar] [CrossRef]

- Shaikh, A.S.; Schulz, F.; Minet-Lallemand, K.; Hryha, E. Microstructure and Mechanical Properties of Haynes 282 Superalloy Produced by Laser Powder Bed Fusion. Mater. Today Commun. 2021, 26, 102038. [Google Scholar] [CrossRef]

- Bhuvanesh Kumar, M.; Sathiya, P.; Senthil, S.M. A Critical Review of Wire Arc Additive Manufacturing of Nickel-Based Alloys: Principles, Process Parameters, Microstructure, Mechanical Properties, Heat Treatment Effects, and Defects. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 164. [Google Scholar] [CrossRef]

- Cheng, X.; Xu, J.; Yang, Z.; Guo, Q.; Li, C.; Zhou, J.; Chen, S.; Liu, S.; Ma, Z. A Novel Nickel-Based Superalloy with Excellent High Temperature Performance Designed for Laser Additive Manufacturing. Mater. Sci. Eng. A 2024, 911, 146926. [Google Scholar] [CrossRef]

- Behera, A.; Sahoo, A.K.; Mahapatra, S.S. Application of Ni-Based Superalloy in Aero Turbine Blade: A Review. Proc. Inst. Mech. Eng. Part. E J. Process Mech. Eng. 2023, 09544089231219104. [Google Scholar] [CrossRef]

- Darolia, R. Development of Strong, Oxidation and Corrosion Resistant Nickel-Based Superalloys: Critical Review of Challenges, Progress and Prospects. Int. Mater. Rev. 2019, 64, 355–380. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective Laser Melting Additive Manufacturing of Inconel 718 Superalloy Parts: Densification, Microstructure and Properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Schneider, J.; Lund, B.; Fullen, M. Effect of Heat Treatment Variations on the Mechanical Properties of Inconel 718 Selective Laser Melted Specimens. Addit. Manuf. 2018, 21, 248–254. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V.A. A Review of Mechanical Properties of Additively Manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, Y.; He, F.; Ma, J.; Li, J.; Wang, Z.; Wang, J.; Feng, J.; Wang, W.; Gao, L. Origins of the Mechanical Property Heterogeneity in a Hybrid Additive Manufactured Hastelloy X. Mater. Sci. Eng. A 2021, 823, 141716. [Google Scholar] [CrossRef]

- Kangazian, J.; Shamanian, M.; Kermanpur, A.; Sadeghi, F.; Foroozmehr, E. An Investigation on the Microstructure and Compression Properties of Laser Powder-Bed Fusion Fabricated Hastelloy X Ni-Based Superalloy Honeycomb Structures. Mater. Sci. Eng. A 2022, 853, 143797. [Google Scholar] [CrossRef]

- Hariharan, M.K.; Anderson, A.; Raghavan, K.; Nithya, S. Hot Corrosion Behaviour of Hastelloy X and Inconel 625 in an Aggressive Environment for Superalloys for High-Temperature Energy Applications. Appl. Nanosci. 2023, 13, 3359–3368. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, M.; He, C.; Huang, G.; Zhao, S.; Nie, F.; Xiong, Y.; Peng, X.; Huang, K. Microstructures and Mechanical Properties of Dissimilar Joints between Cobalt-Based Superalloy FSX-414 and Additively Manufactured 316L Stainless Steel. Mater. Today Commun. 2025, 42, 111087. [Google Scholar] [CrossRef]

- Li, K.; Zhan, J.; Zhang, M.; Ma, R.; Tang, Q.; Zhang, D.Z.; Murr, L.E.; Cao, H. A Functionally Graded Material Design from Stainless Steel to Ni-Based Superalloy by Laser Metal Deposition Coupled with Thermodynamic Prediction. Mater. Des. 2022, 217, 110612. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, H.; Zhang, Z.; Wang, Y.; Zhu, B.; Zhao, H. A Review of the Microstructure and Properties of Superalloys Regulated by Magnetic Field. J. Mater. Res. Technol. 2024, 30, 9285–9317. [Google Scholar] [CrossRef]

- Attard, B.; Cruchley, S.; Beetz, C.; Megahed, M.; Chiu, Y.L.; Attallah, M.M. Microstructural Control during Laser Powder Fusion to Create Graded Microstructure Ni-Superalloy Components. Addit. Manuf. 2020, 36, 101432. [Google Scholar] [CrossRef]

- Zuback, J.S.; Palmer, T.A. Effects of Nitride Precipitation on Delta Phase Formation in Additively Manufactured Nickel Superalloys. J. Alloys Compd. 2024, 976, 172936. [Google Scholar] [CrossRef]

- Sreekanth, S.; Hurtig, K.; Joshi, S.; Andersson, J. Effect of Process Parameters and Heat Treatments on Delta-Phase Precipitation in Directed Energy Deposited Alloy 718. Weld. World 2022, 66, 863–877. [Google Scholar] [CrossRef]

- Heep, L.; Schwalbe, C.; Heinze, C.; Dlouhy, A.; Rae, C.M.F.; Eggeler, G. Dislocation Networks in Gamma/Gamma’-Microstructures Formed during Selective Laser Melting of a Ni-Base Superalloy. Scr. Mater. 2021, 190, 121–125. [Google Scholar] [CrossRef]

- Park, J.U.; Jun, S.Y.; Lee, B.H.; Jang, J.H.; Lee, B.S.; Lee, H.J.; Lee, J.H.; Hong, H.U. Alloy Design of Ni-Based Superalloy with High Γ′ Volume Fraction Suitable for Additive Manufacturing and Its Deformation Behavior. Addit. Manuf. 2022, 52, 102680. [Google Scholar] [CrossRef]

- Zhou, W.; Tian, Y.; Tan, Q.; Qiao, S.; Luo, H.; Zhu, G.; Shu, D.; Sun, B. Effect of Carbon Content on the Microstructure, Tensile Properties and Cracking Susceptibility of IN738 Superalloy Processed by Laser Powder Bed Fusion. Addit. Manuf. 2022, 58, 103016. [Google Scholar] [CrossRef]

- Zhou, W.; Tian, Y.; Wei, D.; Tan, Q.; Kong, D.; Luo, H.; Huang, W.; Zhu, G.; Shu, D.; Mi, J.; et al. Effects of Heat Treatments on the Microstructure and Tensile Properties of IN738 Superalloy with High Carbon Content Fabricated via Laser Powder Bed Fusion. J. Alloys Compd. 2023, 953, 170110. [Google Scholar] [CrossRef]

- Pixner, F.; Warchomicka, F.; Lipińska, M.; Elmiger, S.; Jechtl, C.; Auer, P.; Riedlsperger, F.; Buzolin, R.; Domitner, J.; Lewandowska, M.; et al. Thermal Cycling Effects on the Local Microstructure and Mechanical Properties in Wire-Based Directed Energy Deposition of Nickel-Based Superalloy. Addit. Manuf. 2024, 83, 104066. [Google Scholar] [CrossRef]

- Praveenkumar, V.; Raja, S.; Jamadon, N.H.; Yishak, S. Role of Laser Power and Scan Speed Combination on the Surface Quality of Additive Manufactured Nickel-Based Superalloy. Proc. Inst. Mech. Eng. Part. L J. Mater. Des. Appl. 2024, 238, 1142–1154. [Google Scholar] [CrossRef]

- Wang, R.; Chen, C.; Liu, M.; Zhao, R.; Xu, S.; Hu, T.; Shuai, S.; Liao, H.; Ke, L.; Vanmeensel, K.; et al. Effects of Laser Scanning Speed and Building Direction on the Microstructure and Mechanical Properties of Selective Laser Melted Inconel 718 Superalloy. Mater. Today Commun. 2022, 30, 103095. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, J.; Wang, Y. Evolution, Control, and Mitigation of Residual Stresses in Additively Manufactured Metallic Materials: A Review. Adv. Eng. Mater. 2023, 25, 2300489. [Google Scholar] [CrossRef]

- Liu, B.; Ding, Y.; Xu, J.; Wang, X.; Gao, Y.; Hu, Y.; Chen, D. Achievement of Grain Boundary Engineering by Transforming Residual Stress in Selective Laser-Melted Inconel 718 Superalloy. Mater. Sci. Eng. A 2023, 866, 144683. [Google Scholar] [CrossRef]

- Tayon, W.A.; Pagan, D.C.; Yeratapally, S.R.; Phan, T.Q.; Hochhalter, J.D. Exploring the Role of Type-II Residual Stresses in a Laser Powder Bed Fusion Nickel-Based Superalloy Using Measurement and Modeling. Int. J. Fatigue 2024, 181, 108153. [Google Scholar] [CrossRef]

- Guo, C.; Li, G.; Li, S.; Hu, X.; Lu, H.; Li, X.; Xu, Z.; Chen, Y.; Li, Q.; Lu, J.; et al. Additive Manufacturing of Ni-Based Superalloys: Residual Stress, Mechanisms of Crack Formation and Strategies for Crack Inhibition. Nano Mater. Sci. 2023, 5, 53–77. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, H.; Liu, Y.; Wang, J. A Review on the Application of Superalloys Composition, Microstructure, Processing, and Performance via Machine Learning. JOM 2024, 77, 106–124. [Google Scholar] [CrossRef]

- Selvaraj, S.K.; Sundaramali, G.; Jithin Dev, S.; Srii Swathish, R.; Karthikeyan, R.; Vijay Vishaal, K.E.; Paramasivam, V. Recent Advancements in the Field of Ni-Based Superalloys. Adv. Mater. Sci. Eng. 2021, 2021, 9723450. [Google Scholar] [CrossRef]

- Prabhakar, P.; Sames, W.J.; Dehoff, R.; Babu, S.S. Computational Modeling of Residual Stress Formation during the Electron Beam Melting Process for Inconel 718. Addit. Manuf. 2015, 7, 83–91. [Google Scholar] [CrossRef]

- Bhowmik, A.; Praveen, K.N.R.; Bhosle, N.; Gagneja, K.; Talib, Z.M.; Chohan, J.S.; Alkhayyat, A.; Ramudu, M.J.; Santhosh, A.J. Performance Evaluation of Machine Learning Algorithms in Predicting Machining Responses of Superalloys. AIP Adv. 2024, 14, 105027. [Google Scholar] [CrossRef]

- Lu, X.; Li, M.V.; Yang, H. Comparison of Wire-Arc and Powder-Laser Additive Manufacturing for IN718 Superalloy: Unified Consideration for Selecting Process Parameters Based on Volumetric Energy Density. Int. J. Adv. Manuf. Technol. 2021, 114, 1517–1531. [Google Scholar] [CrossRef]

- Zhang, L.N.; Ojo, O.A. Corrosion Behavior of Wire Arc Additive Manufactured Inconel 718 Superalloy. J. Alloys Compd. 2020, 829, 154455. [Google Scholar] [CrossRef]

- Hasani, N.; Ghoncheh, M.H.; Kindermann, R.M.; Pirgazi, H.; Sanjari, M.; Tamimi, S.; Shakerin, S.; Kestens, L.A.I.; Roy, M.J.; Mohammadi, M. Dislocations Mobility in Superalloy-Steel Hybrid Components Produced Using Wire Arc Additive Manufacturing. Mater. Des. 2022, 220, 110899. [Google Scholar] [CrossRef]

- Lee, D.; Park, S.; Lee, C.H.; Hong, H.U.; Oh, J.; So, T.Y.; Kim, W.S.; Seo, D.; Han, J.; Ko, S.H.; et al. Correlation between Microstructure and Mechanical Properties in Additively Manufactured Inconel 718 Superalloys with Low and High Electron Beam Currents. J. Mater. Res. Technol. 2024, 28, 2410–2419. [Google Scholar] [CrossRef]

- Calleja-ochoa, A.; Gonzalez-barrio, H.; de Lacalle, N.L.; Martínez, S.; Albizuri, J.; Lamikiz, A. A New Approach in the Design of Microstructured Ultralight Components to Achieve Maximum Functional Performance. Materials 2021, 14, 1588. [Google Scholar] [CrossRef] [PubMed]

- Deshpande, A.; Nath, S.D.; Atre, S.; Hsu, K. Effect of Post Processing Heat Treatment Routes on Microstructure and Mechanical Property Evolution of Haynes 282 Ni-Based Superalloy Fabricated with Selective Laser Melting (SLM). Metals 2020, 10, 629. [Google Scholar] [CrossRef]

- Zhang, T.; Yuan, H. Effects of Heat Treatments on Microstructure and Mechanical Properties of Laser Melting Multi-Layer Materials. Mater. Sci. Eng. A 2022, 848, 143380. [Google Scholar] [CrossRef]

- Enrique, P.D.; Minasyan, T.; Toyserkani, E. Laser Powder Bed Fusion of Difficult-to-Print Γ′ Ni-Based Superalloys: A Review of Processing Approaches, Properties, and Remaining Challenges. Addit. Manuf. 2025, 106, 104811. [Google Scholar] [CrossRef]

- Ahmad, N.; Bidar, A.; Ghiaasiaan, R.; Gradl, P.R.; Shao, S.; Shamsaei, N. A Comparison of Microstructure and Mechanical Performance of Inconel 718 Manufactured via L-PBF, LP-DED, and WAAM Technologies. NASA Tech. Rep. Serv. 2023, 20230010244. [Google Scholar]

- Raspall, F.; Araya, S.; Pazols, M.; Valenzuela, E.; Castillo, M.; Benavides, P. Wire Arc Additive Manufacturing for Widespread Architectural Application: A Review Informed by Large-Scale Prototypes. Buildings 2025, 15, 906. [Google Scholar] [CrossRef]

- James, W.S.; Ganguly, S.; Pardal, G. Selection and Performance of AM Superalloys for High-Speed Flight Environments. Int. J. Adv. Manuf. Technol. 2022, 122, 2319–2327. [Google Scholar] [CrossRef]

- Wei, W.; Xiao, J.C.; Wang, C.F.; Cheng, Q.; Guo, F.J.; He, Q.; Wang, M.S.; Jiang, S.Z.; Huang, C.X. Hierarchical Microstructure and Enhanced Mechanical Properties of SLM-Fabricated GH5188 Co-Superalloy. Mater. Sci. Eng. A 2022, 831, 142276. [Google Scholar] [CrossRef]

- Murray, S.P.; Pusch, K.M.; Polonsky, A.T.; Torbet, C.J.; Seward, G.G.E.; Zhou, N.; Forsik, S.A.J.; Nandwana, P.; Kirka, M.M.; Dehoff, R.R.; et al. A Defect-Resistant Co–Ni Superalloy for 3D Printing. Nat. Commun. 2020, 11, 4975. [Google Scholar] [CrossRef]

- Zenk, C.H.; Volz, N.; Zenk, C.; Felfer, P.J.; Neumeier, S. Impact of the Co/Ni-Ratio on Microstructure, Thermophysical Properties and Creep Performance of Multi-Component Γ′-Strengthened Superalloys. Crystals 2020, 10, 1058. [Google Scholar] [CrossRef]

- Zhang, X.; Shang, H.; Gao, Q.; Ma, Q.; Zhang, H.; Li, H.; Sun, L. Coarsening Evolution of Γ′ Phase and Failure Mechanism of Co-Ni-Al-Ti-Based Superalloys During Isothermal Aging. Front. Mater. 2022, 9, 863305. [Google Scholar] [CrossRef]

- Gundgire, T.; Goel, S.; Klement, U.; Joshi, S. Response of Different Electron Beam Melting Produced Alloy 718 Microstructures to Thermal Post-Treatments. Mater. Charact. 2020, 167, 110498. [Google Scholar] [CrossRef]

- Shen, Q.; Xue, J.; Zheng, Z.; Yu, X.; Ou, N.; Jin, L. Microstructures and Mechanical Properties of Co-Based Elgiloy Fabricated by Wire Arc Additive Manufacturing. Sci. Technol. Weld. Join. 2024, 29, 347–355. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, B.; Zhao, F.; Li, J.; Wei, L.; Huang, X. Influence of Aging Treatment and Volume Fraction on Nano-Indentation Behavior of Ni-Based Single Crystal Superalloys. Materials 2024, 17, 6216. [Google Scholar] [CrossRef] [PubMed]

- Kurdi, A.; Tabbakh, T.; Basak, A.K. Microstructural and Nanoindentation Investigation on the Laser Powder Bed Fusion Stainless Steel 316L. Materials 2023, 16, 5933. [Google Scholar] [CrossRef]

- Jiang, W.; Deng, Y.; Guo, X. Effect of Heat Treatment on Microstructure and Mechanical Anisotropy of Selective Laser Melted Al–Mn-Sc Alloy. Mater. Sci. Eng. A 2023, 887, 145743. [Google Scholar] [CrossRef]

- Maleta, M.; Kulasa, J.; Kowalski, A.; Kwaśniewski, P.; Boczkal, S.; Nowak, M. Microstructure, Mechanical and Corrosion Properties of Copper-Nickel 90/10 Alloy Produced by CMT-WAAM Method. Materials 2023, 17, 50. [Google Scholar] [CrossRef]

- Vogiatzief, D.; Evirgen, A.; Gein, S.; Molina, V.R.; Weisheit, A.; Pedersen, M. Laser Powder Bed Fusion and Heat Treatment of an AlCrFe2Ni2 High Entropy Alloy. Front. Mater. 2020, 7, 566597. [Google Scholar] [CrossRef]

- Balachandramurthi, A.R.; Moverare, J.; Mahade, S.; Pederson, R. Additive Manufacturing of Alloy 718 via Electron Beam Melting: Effect of Post-Treatment on the Microstructure and the Mechanical Properties. Materials 2018, 12, 68. [Google Scholar] [CrossRef]

- Chowdhury, H.T.; Palleda, T.N.; Kakuta, N.; Kakehi, K. Effects of Preheating on Thermal Behavior in Inconel 718 Processed by Additive Manufacturing. Thermo 2024, 4, 48–64. [Google Scholar] [CrossRef]

- Tajyar, A.; Brooks, N.; Holtham, N.; Rowe, R.; Newell, D.J.; Palazotto, A.N.; Davami, K. Effects of a Modified Heat-Treatment on Microstructure and Mechanical Properties of Additively Manufactured Inconel 718. Mater. Sci. Eng. A 2022, 838, 142770. [Google Scholar] [CrossRef]

| Scientific Journal | Ranking | Frequency | Cumulative Frequency | Zone |

|---|---|---|---|---|

| Materials Science and Engineering A | 1 | 131 | 131 | Zone 1 |

| Additive Manufacturing | 2 | 123 | 254 | Zone 1 |

| Journal of Alloys and Compounds | 3 | 76 | 330 | Zone 1 |

| Materials | 4 | 66 | 396 | Zone 1 |

| Materials & Design | 5 | 57 | 453 | Zone 1 |

| Metals | 6 | 53 | 506 | Zone 1 |

| International Journal of Advanced Manufacturing Technology | 7 | 44 | 550 | Zone 1 |

| Journal of Materials Engineering and Performance | 8 | 44 | 594 | Zone 2 |

| Materials Characterization | 9 | 43 | 637 | Zone 2 |

| Acta Materialia | 10 | 34 | 671 | Zone 2 |

| Scientific Journal | Number of Publications | Total Citations | h-Index | g-Index | m-Index | Publication Year Start |

|---|---|---|---|---|---|---|

| Additive Manufacturing | 123 | 6420 | 46 | 77 | 4.18 | 2015 |

| Materials Science and Engineering A | 131 | 5177 | 35 | 70 | 3.18 | 2015 |

| Materials & Design | 57 | 3291 | 29 | 57 | 2.90 | 2016 |

| Journal of Alloys and Compounds | 76 | 2165 | 27 | 44 | 2.70 | 2016 |

| Acta Materialia | 34 | 3801 | 23 | 34 | 2.09 | 2015 |

| International Journal of Advanced Manufacturing Technology | 44 | 1019 | 20 | 31 | 2.00 | 2016 |

| Materials | 66 | 1070 | 20 | 30 | 2.22 | 2017 |

| Journal of Materials Science & Technology | 25 | 1121 | 17 | 25 | 1.54 | 2015 |

| International Journal of Fatigue | 26 | 889 | 16 | 26 | 1.60 | 2016 |

| Materials Characterization | 43 | 962 | 16 | 30 | 1.60 | 2016 |

| Author | Number of Publications | Total Citations | h-Index | g-Index | m-Index | Publication Year Start |

|---|---|---|---|---|---|---|

| M. Kirka | 28 | 1959 | 19 | 28 | 1.72 | 2015 |

| J. Li | 65 | 989 | 18 | 29 | 2 | 2017 |

| Y. Li | 43 | 1308 | 17 | 36 | 1.7 | 2016 |

| Y. Wang | 39 | 925 | 17 | 30 | 1.7 | 2016 |

| X. Lin | 29 | 963 | 16 | 29 | 1.6 | 2016 |

| X. Wang | 34 | 1256 | 16 | 34 | 1.6 | 2016 |

| Y. Zhang | 43 | 781 | 16 | 27 | 1.77 | 2017 |

| R. Dehoff | 16 | 1809 | 15 | 16 | 1.36 | 2015 |

| W. Huang | 21 | 1079 | 15 | 21 | 1.5 | 2016 |

| S. Babu | 15 | 1592 | 14 | 15 | 1.27 | 2015 |

| Ref | Authors | Scientific Journal | Total Citations | Total Citations Per Year | Normalized Total Citations |

|---|---|---|---|---|---|

| [39] | J. Martin et al. | Nature | 2077 | 230.78 | 17.71 |

| [40] | N. J. Harrison et al. | Acta Materialia | 521 | 47.36 | 3.62 |

| [41] | C. Todaro et al. | Nature Communications | 513 | 85.50 | 11.99 |

| [42] | W. Tucho et al. | Materials Science and Engineering A | 474 | 52.67 | 4.04 |

| [43] | B. Cheng et al. | Additive Manufacturing | 466 | 46.60 | 4.22 |

| [44] | R. Dehoff et al. | Materials Science and Technology | 425 | 38.64 | 2.95 |

| [45] | T. Trosch et al. | Materials Letters | 407 | 40.70 | 3.68 |

| [46] | N. Raghavan et al. | Acta Materialia | 406 | 40.60 | 3.67 |

| [22] | E. Chauvet et al. | Acta Materialia | 397 | 49.63 | 5.92 |

| [20] | D. Li et al. | Journal of Materials Science and Technology | 385 | 35.00 | 2.67 |

| Process | Ni-Based Superalloys | Co-Based Superalloys | Fe-Ni-Based Superalloys |

|---|---|---|---|

| SLM/ LPBF | Microstructure: Fine columnar/cellular grains (10–50 µm) along BD; strong dendritic segregation. Properties: Very high as-built UTS (often >800 MPa), low elongation, high hardness, but significant H/V anisotropy. Texture: Strong <001> fiber texture in the build direction (epitaxial growth). Post-HT: Solutionizing + aging dissolves Laves/δ and precipitates γ′/γ″; increases strength, partially homogenizes anisotropy. | Microstructure: Ultrafine (<1 µm cell) hierarchical grains with columnar texture; minor as-built γ′. Properties: Exceptional nano-hardness and tensile strength (>1.0 GPa) with good ductility in as-built. High crack susceptibility unless alloy is specially designed. Texture: Strong <001> fiber texture.Post-HT: Aging precipitates Co3(Al,W) γ′; further strengthens. | Microstructure: Similar to Ni alloys (fine γ dendrites), since Ni is dominant; no δ/γ″ phases present (e.g., in IN718). Properties: As-built strength intermediate; anisotropic. Texture: Columnar FCC grains along BD. Post-HT: Conventional 2-step aging to form Ni3Nb and Ni3Al γ″/γ′. Often requires higher solvus/aging due to Fe. |

| EBM | Microstructure: Coarser columnar grains (~20–200 µm) with reduced segregation and porosity; banded features by build height. Properties: High ductility; strength slightly lower than SLM; anisotropy typically arises from aligned pores, not texture. Texture: Weaker due to layer annealing; grains may recrystallize. Post-HT: HIP and solutionizing above γ′ solvus produce porosity-free, coarse equiaxed grains, subsequent aging yields uniform γ′. | Microstructure: Coarse, recrystallized grains (equiaxed or large columns) due to high preheat. Little in situ γ′; traces of planar segregates at layer boundaries. Properties: Good ductility, high residual strength after HIP. Texture: Weak, as large grains recrystallize. Post-HT: HIP + aging produces uniform γ′ (Co3Al) precipitates and eliminates defects. | Microstructure: Coarser γ grains than SLM, similar to Ni-EBM. Some planar segregation. Properties: Similar to EBM Ni alloys. Texture: Moderate; large FCC grains. Post-HT: Similar to Ni-based EBM; HIP homogenizes, then ages for γ″/γ′. |

| DED | Microstructure: Large (~50–200 µm) columnar grains with extensive reheating bands. Dendrites are coarser than SLM, but finer than WAAM. Significant microsegregation (Nb, Mo) persists. Properties: As-built UTS < SLM but > WAAM; ductility moderate. Porosity is generally lower than SLM. Texture: Strong columnar (build direction) with many annealing twins after solution heat. Post-HT: Often only solution + aging needed (similar to welded 718); HIP may be used to heal pores. Microstructure after HT still retains larger grains | Microstructure: Large columnar grains, similar to Ni-DED. Possibly some planar Co–Cr precipitation patterns. Properties: Good strength/ductility balance; anisotropic (build vs. transverse). Texture: Columnar FCC (Co/Ni) grains with <001> tendency. Post-HT: Solution + aging gives γ′ precipitation. HIP can reduce heterogeneity. | Microstructure: Similar to Ni-DED: large γ grains (often >200 µm). Dendritic segregation of Cr/Nb. Properties: As-built moderate strength. Texture: Columnar (FCC). Post-HT: Solution + aging, may require HIP if defects. |

| WAAM | Microstructure: Coarsest structure: very large (>100 µm) columnar/polygonal γ grains across walls. Pronounced interdendritic segregation (Nb, Mo, Nb) and often oxide inclusions. Properties: Lower strength (<SLM/DED) but high ductility. Very anisotropic—properties vary strongly between build and transverse directions. Fatigue life is generally the lowest. Texture: Strong epitaxial columns along deposition; little recrystallization. Post-HT: Even after solution + aging, grains remain large (no recrystallization after typical HT). HIP is often needed to close remaining pores; mechanical properties may still lack wrought strength. | Microstructure: Similar coarse columnar grains, though Co alloys may form more carbides (W/Ta carbides) and interdendritic phases. Properties: Moderately high ductility; strength limited by grain size. Texture: Strong fiber texture along weld path. Post-HT: Same as above; HIP + aging to induce γ′; grains remain coarse. | Microstructure: As with Ni alloys, extremely coarse grains and segregation. Properties: Lower strength; highest ductility. Texture: Strong columnar. Post-HT: Retains coarse grains; heavy forging/HIP may be needed to approach wrought properties. |

| Sector | Query Modification | Percentage |

|---|---|---|

| Aerospace | AND (“aerospace*” OR “jet engine” OR “turbine blade” OR “aircraft” OR “space” OR “propulsion”) | 17.5 |

| Power Generation | AND (“power plant” OR “gas turbine” OR “thermal” OR “energy” OR “combustor” OR “heat exchanger”) | 61.7 |

| Automotive | AND (“automot*” OR “vehicle” OR “car”) | 12.1 |

| Biomedical | AND (“biomedical” OR “implant” OR “prosthesis” OR “orthopedic” OR “bone” OR “dental”) | 4.3 |

| Marine | AND (“marine” OR “naval” OR “ship” OR “seawater” OR “propeller” OR “submarine”) | 4.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

del Bosque, A.; Fernández-Arias, P.; Vergara, D. Advances in the Additive Manufacturing of Superalloys. J. Manuf. Mater. Process. 2025, 9, 215. https://doi.org/10.3390/jmmp9070215

del Bosque A, Fernández-Arias P, Vergara D. Advances in the Additive Manufacturing of Superalloys. Journal of Manufacturing and Materials Processing. 2025; 9(7):215. https://doi.org/10.3390/jmmp9070215

Chicago/Turabian Styledel Bosque, Antonio, Pablo Fernández-Arias, and Diego Vergara. 2025. "Advances in the Additive Manufacturing of Superalloys" Journal of Manufacturing and Materials Processing 9, no. 7: 215. https://doi.org/10.3390/jmmp9070215

APA Styledel Bosque, A., Fernández-Arias, P., & Vergara, D. (2025). Advances in the Additive Manufacturing of Superalloys. Journal of Manufacturing and Materials Processing, 9(7), 215. https://doi.org/10.3390/jmmp9070215