Study on the Deformation Behavior and Mechanical Properties of Lightweight Economic Stainless Steels with Varying Al and Mn Contents

Abstract

1. Introduction

2. Materials and Methods

3. Results

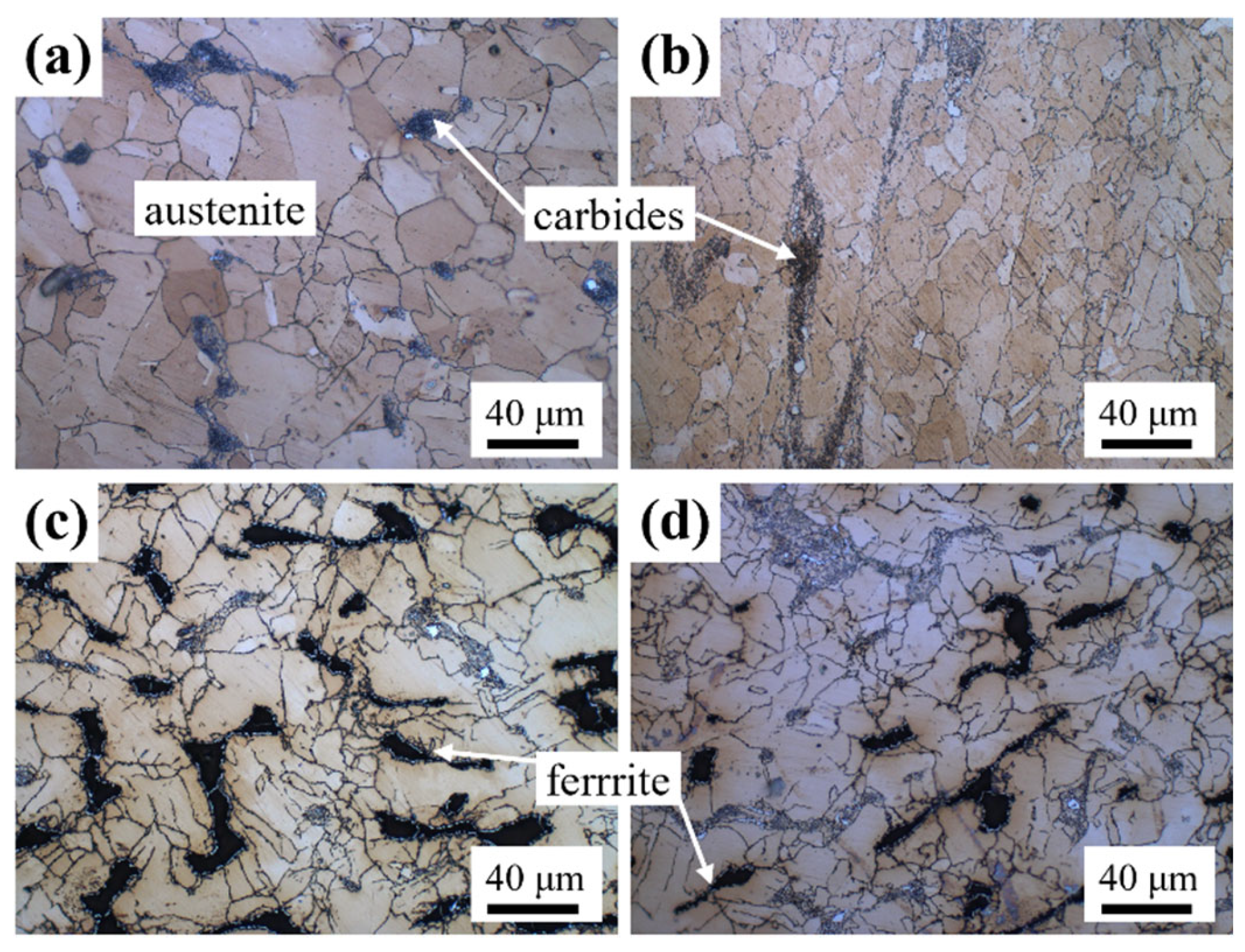

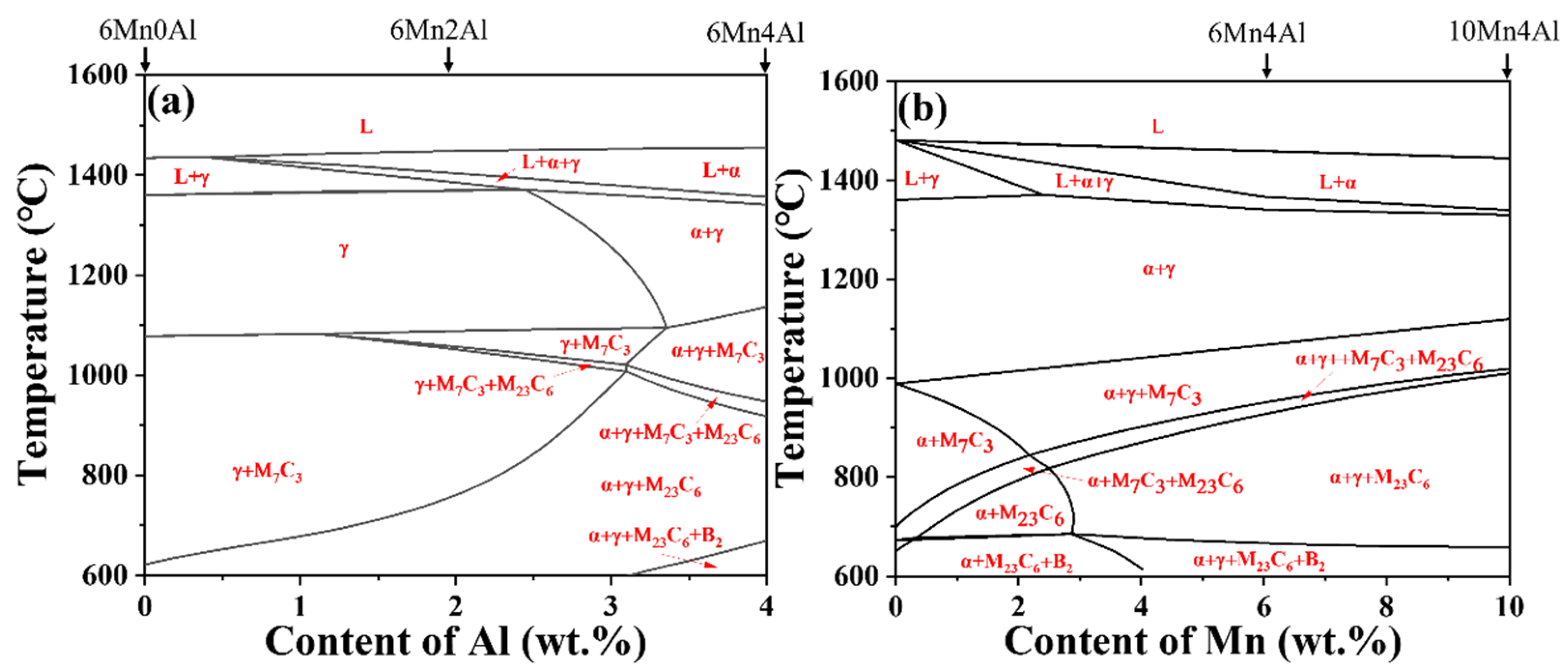

3.1. Initial Microstructure

3.2. Tensile Tests

3.2.1. Deformed Microstructure

3.2.2. StressStrain Curve Analyses

3.3. Impact Toughness Tests

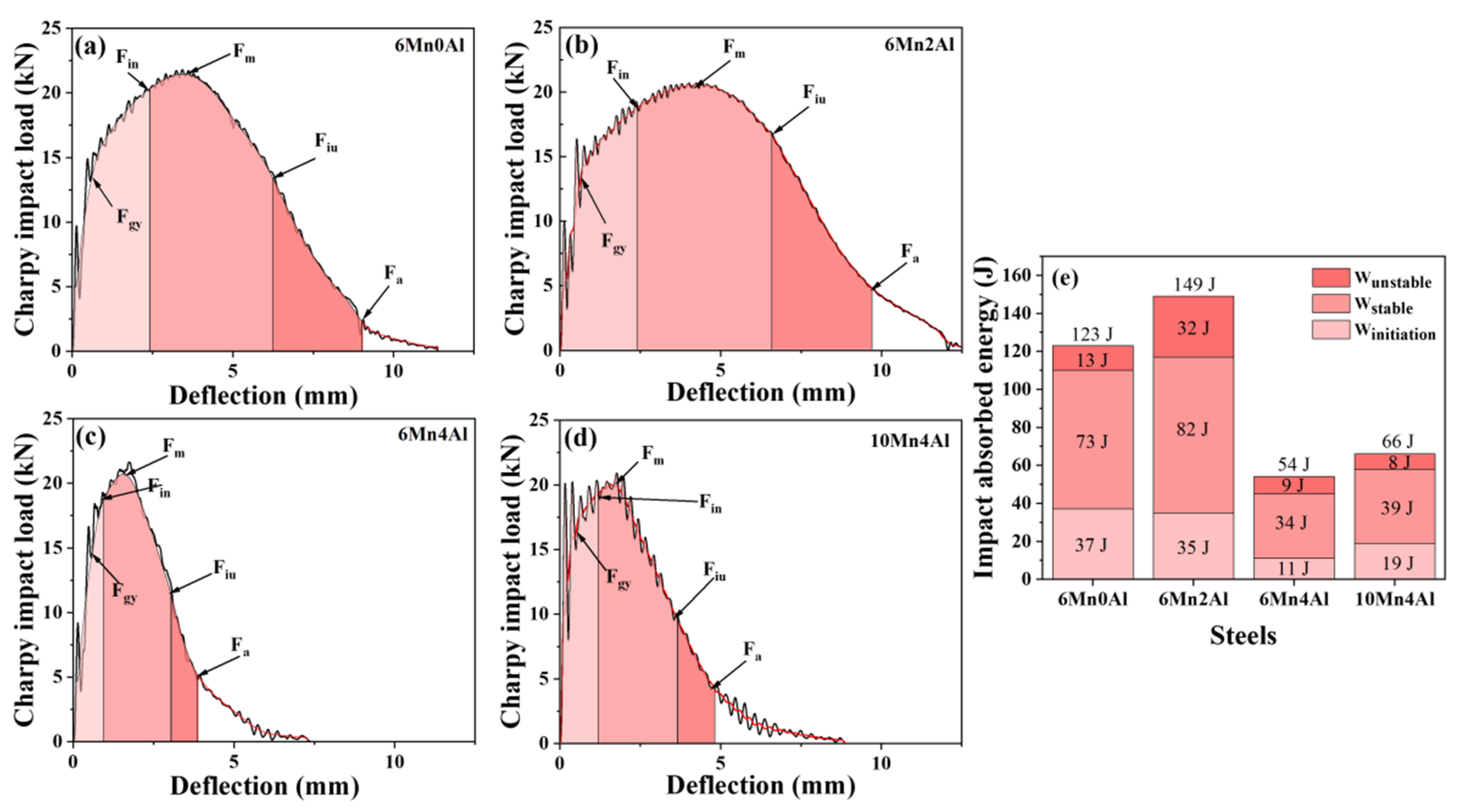

3.3.1. LoadDeflection Curve Analyses

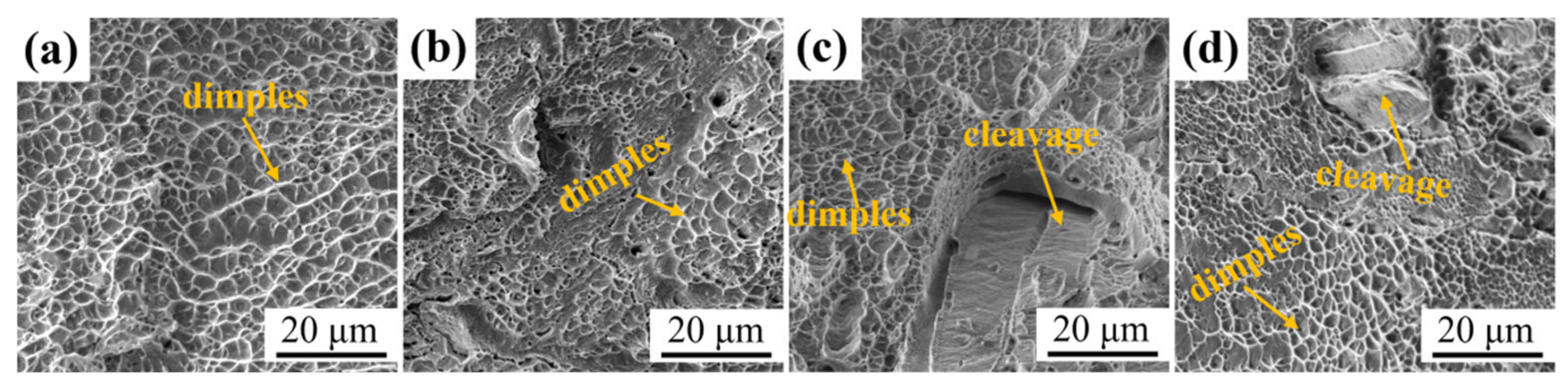

3.3.2. Impact Fracture Surface

4. Conclusions

- (1)

- A high C content led to the formation of carbides. Increasing the Al content led to the formation of the austenite−ferrite duplex microstructure. Increasing the Mn content reduced the ferrite fraction.

- (2)

- The occurrence of DIMT and mechanical twinning improved the work hardening rate, leading to high UTS and UE. The addition of 2 wt.% Al suppressed DIMT but promoted mechanical twinning by increasing SFE, resulting in a lower work hardening rate, UTS, and UE. As Al content increased to 4 wt.%, the ferrite induced cleavage, deteriorating elongation. Increasing the Mn content improved ductility by reducing the ferrite fraction.

- (3)

- The 6Mn0Al steel exhibited a lower crack growth energy compared to 6Mn2Al steel due to the formation of brittle DIM. TRIP still provided a high toughness for 6Mn0Al. The high toughness and crack growth energy of 6Mn2Al were attributed to the formation of mechanical twins. The occurrence of ferrite in duplex steels resulted in a low crack initial energy and crack growth energy, consequently a low toughness. The higher Mn content increased toughness by reducing the ferrite fraction.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DIMT | Deformation-induced martensitic transformation |

| OM | Optical microscopy |

| SEM | Scanning electron microscope |

| EBSD | Electron backscatter diffraction |

| TRIP | Transformation induced plasticity |

| TWIP | Twinning-induced plasticity |

| IPF | Inverse pole figure |

| SFE | Stacking fault energy |

| YS | Yield strength |

| UTS | Ultimate tensile strength |

| UE | Uniform elongation |

| TE | Total elongation |

| PSE | Product of strength and elongation |

| DIM | Deformation-induced martensite |

References

- Wu, L.; Hu, C.; Ke, R.; Misra, R.D.K.; Zhong, M.; Li, G.; Xu, D.; Wan, X.; Wu, K. Insights into the Plasticization Mechanism in Different 18Cr–8Ni Austenitic Stainless Steel: Study of the Phase Reverted Structure Versus Cold-Deformed Structure. Steel Res. Int. 2022, 93, 2200122. [Google Scholar] [CrossRef]

- Hu, C.Y.; Wan, X.L.; Wu, K.M.; Xu, D.M.; Li, G.Q.; Xu, G.; Misra, R.D.K. On the impacts of grain refinement and strain-induced deformation on three-body abrasive wear responses of 18Cr–8Ni austenitic stainless steel. Wear 2020, 446–447, 203181. [Google Scholar] [CrossRef]

- Wang, Y.; Sukenaga, S.; Shibata, H.; Wang, Q.; Mu, W. Combination of In Situ Confocal Microscopy and Calorimetry to Investigate Solidification of Super- and Hyper-Duplex Stainless Steels. Steel Res. Int. 2023, 94, 2200960. [Google Scholar] [CrossRef]

- Sui, L.X.; Yin, C.F.; Li, X.C.; Chen, P.G.; Zhu, B.Q. Preparation of a modified phosphate-based adhesive and its hot bonding performance on 316L stainless steel. Ceram. Int. 2021, 47, 15585–15593. [Google Scholar] [CrossRef]

- He, C.; Zhu, X.; Hu, C.; Dong, H.; Wan, X.; Liu, E.; Li, G.; Wu, K. Processing an 18Cr-8Ni Austenitic Stainless Steel Without the Dilemma of the Strength and Ductility Trade-Off. JOM 2024, 76, 829–842. [Google Scholar] [CrossRef]

- Sun, Z.; Tang, J.; Chen, S.; Chen, Y.; Hu, Z.; Wang, Z.R.; Lu, X.; Chen, X. Mesh stiffness and dynamic response analysis of modified gear system with thin web and weight reduction holes. J. Sound Vib. 2023, 546, 117437. [Google Scholar] [CrossRef]

- Chen, W.J.; Xu, Y.; Song, H.W.; Zhang, S.H.; Chen, S.F.; Xia, L.L.; Wang, Y.; Khina, B.B.; Pokrovsky, A.I. A Novel Hydroforming Process by Combining Internal and External Pressures for High-Strength Steel Wheel Rims. Materials 2022, 15, 6820. [Google Scholar] [CrossRef]

- Guo, S.; Zhu, H.; Zhao, J.; Song, M.M.; Li, J.L.; Xue, Z.L. Effects of Nitrogen on the Microstructure and Mechanical Properties of Fe–28Mn–10Al–0.8 C Low-Density Steel. Steel Res. Int. 2022, 93, 2100643. [Google Scholar] [CrossRef]

- Wang, W.S.; Zhu, H.Y.; Zhou, J.; Song, M.M.; Wang, L.Q. Interaction Between Oxide Inclusions and Low-Density Steel During Heat Treatment. Metall. Mater. Trans. B 2022, 53, 2991–3002. [Google Scholar] [CrossRef]

- Guo, S.; Zhu, H.Y.; Zhou, J.; Song, M.M.; Dong, S. An in situ scanning electron microscope study of void formation induced by typical inclusions in low-density steel during tensile deformation. Steel Res. Int. 2022, 93, 2200388. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Wang, W.S.; Li, B.; Guo, S.; Li, Y. A novel method for preparing diffusion couple to investigate the interaction between AlN and low-density steel at 1373 K. Mater. Lett. 2022, 324, 132634. [Google Scholar] [CrossRef]

- Chen, G.H.; Xu, G.; Biermann, H.; Mola, J. Microstructure and mechanical properties of Co-added and Al-added austenitic stainless steels. Mater. Sci. Eng. A 2022, 854, 143832. [Google Scholar] [CrossRef]

- Chen, G.H.; Rahimi, R.; Xu, G.; Biermann, H.; Mola, J. Impact of Al addition on deformation behavior of Fe–Cr–Ni–Mn–C austenitic stainless steel. Mater. Sci. Eng. A 2020, 797, 140084. [Google Scholar] [CrossRef]

- Rahimi, R.; Ullrich, C.; Klemm, V.; Rafaja, D.; De Cooman, B.C.; Biermann, H.; Mola, J. Influence of Al on the temperature dependence of strain hardening behavior and glide planarity in Fe–Cr–Ni–Mn–C austenitic stainless steels. Mater. Sci. Eng. A 2016, 649, 301–312. [Google Scholar] [CrossRef]

- Ke, R.; Wan, X.; Zhang, Y.; Hu, C.; Wu, K. The impact of annealing temperature on the microstructure—Properties relationship of reversion-induced austenitic stainless steels. Mater. Sci. Eng. A 2022, 843, 143100. [Google Scholar] [CrossRef]

- Hu, C.; He, C.; Zhu, X.; Dong, H.; Wan, X.; Li, G.; Wu, K. The significant role of bimodal lamellar heterostructure for Lüders deformation and TRIP effect in 18Cr–8Ni austenitic stainless steel. Mater. Sci. Eng. A 2023, 887, 145748. [Google Scholar] [CrossRef]

- Hu, S.; Zheng, Z.; Yang, W.; Yang, H. Fe–Mn–C–Al Low-Density Steel for Structural Materials: A Review of Alloying, Heat Treatment, Microstructure, and Mechanical Properties. Steel Res. Int. 2022, 93, 2200191. [Google Scholar] [CrossRef]

- Scherbring, S.; Chen, G.H.; Veltel, B.; Bartzsch, G.; Richter, J.; Vollmer, M.; Blankenburg, M.; Shyamal, S.; Volkova, O.; Niendorf, T.; et al. Microstructural constituents and mechanical properties of low-density Fe-Cr-Ni-Mn-Al-C stainless steels. Materials 2022, 15, 5121. [Google Scholar] [CrossRef]

- Wang, Y.; Mu, W. Effect of Cooling Rate on Crystallization Behavior during Solidification of Hyper Duplex Stainless Steel S33207: An In Situ Confocal Microscopy Study. Crystals 2023, 13, 1114. [Google Scholar] [CrossRef]

- Chen, J.; Ren, J.; Liu, Z. Deformation microstructures as well as strengthening and toughening mechanisms of low-density high Mn steels for cryogenic applications. J. Mater. Res. Technol. 2021, 13, 947–961. [Google Scholar] [CrossRef]

- Khorrami, M.; Hanzaki, A.Z.; Abedi, H.R.; Moallemi, M.; Mola, J.; Chen, G.H. On the effect of Mn-content on the strength-ductility balance in Ni-free high N transformation induced plasticity steels. Mater. Sci. Eng. A 2021, 814, 141260. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. China Standard Press: Beijing, China, 2021.

- ASTM E23; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- Chen, G.H.; Rahimi, R.; Harwarth, M.; Motylenko, M.; Xu, G.H.; Biermann, J.; Mola, J. Non-cube-on-cube orientation relationship between M23C6 and austenite in an austenitic stainless steel. Scr. Mater. 2022, 213, 114597. [Google Scholar] [CrossRef]

- Rahimi, R.; Biermann, H.; Volkova, O.; Mola, J. On the origin of subgrain boundaries during conventional solidification of austenitic stainless steels. IOP Conf. Ser. Mater. Sci. Eng. 2018, 373, 012005. [Google Scholar] [CrossRef]

- Hu, B.; Luo, H.; Yang, F.; Dong, H. Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 2017, 33, 1457–1464. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Naghizadeh, M.; Mirzadeh, H. Deformation-induced martensite in austenitic stainless steels: A review. Arch. Civ. Mech. Eng. 2020, 20, 124. [Google Scholar] [CrossRef]

- Mikmeková, Š.; Man, J.; Ambrož, O.; Jozefovič, P.; Čermák, J.; Järvenpää, A.; Jaskari, M.; Materna, J.; Kruml, T. High-Resolution Characterization of Deformation Induced Martensite in Large Areas of Fatigued Austenitic Stainless Steel Using Deep Learning. Metals 2023, 13, 1039. [Google Scholar] [CrossRef]

- Lai, Z.H.; Sun, Y.H.; Lin, Y.T.; Tu, J.F.; Yen, H.W. Mechanism of twinning induced plasticity in austenitic lightweight steel driven by compositional complexity. Acta Mater. 2021, 210, 116814. [Google Scholar] [CrossRef]

- Pham, M.S.; Dovgyy, B.; Hooper, P.A. Twinning induced plasticity in austenitic stainless steel 316L made by additive manufacturing. Mater. Sci. Eng. A 2017, 704, 102–111. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Stylianos, A.; Campbell, J. Dynamic fracture toughness of Al–7Si–Mg (A357) aluminum alloy. Mech. Mater. 2013, 58, 55–68. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Stylianos, A. Impact mechanical behaviour of Al–7Si–Mg (A357) cast aluminum alloy. The effect of artificial aging. Mater. Sci. Eng. A 2011, 528, 6303–6312. [Google Scholar] [CrossRef]

- Yoshinaka, F.; Sawaguchi, T.; Takamori, S.; Emura, S. Transformation-induced plasticity via γ → ε → α’ and γ → ε → γ martensitic transformations in Fe–15Mn–10Cr–8Ni–4Si alloy. Mater. Sci. Eng. A 2022, 833, 142583. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Su, Y.; Xu, P.; Shinohara, T. Cryogenic impact fracture behavior of a high-Mn austenitic steel using electron backscatter diffraction and neutron Bragg-edge transmission imaging. Mater. Sci. Eng. A 2023, 887, 145768. [Google Scholar] [CrossRef]

- Zhang, W.; Jin, M.; Hao, S.; Huo, M.; Huang, Z.; Chen, L.; Xia, W. The interfacial damage of the deformation heterogeneity in the transformation-induced plasticity (TRIP)-assisted duplex stainless steel. Int. J. Plast. 2025, 184, 104209. [Google Scholar] [CrossRef]

- Hilders, O.; Zambrano, N. The effect of aging on impact toughness and fracture surface fractal dimension in SAF 2507 super duplex stainless steel. J. Microsc. Ultrastruct. 2014, 2, 236–244. [Google Scholar] [CrossRef]

| Steel ID | C | Al | Mn | Cr | Ni | Fe |

|---|---|---|---|---|---|---|

| 6Mn0Al | 0.35 | 0.01 | 5.81 | 11.58 | 4.82 | Bal. |

| 6Mn2Al | 0.34 | 2.12 | 6.17 | 12.19 | 4.82 | Bal. |

| 6Mn4Al | 0.32 | 3.70 | 5.80 | 12.10 | 5.01 | Bal. |

| 10Mn4Al | 0.35 | 4.24 | 10.07 | 11.72 | 4.89 | Bal. |

| Steel ID | YS/MPa | UTS/MPa | UE/% | TE/% | PSE/MPa·% |

|---|---|---|---|---|---|

| 6Mn0Al | 552 ± 8 | 1102 ± 12 | 38 ± 3 | 52 ± 3 | 57,946 |

| 6Mn2Al | 512 ± 15 | 786 ± 20 | 18 ± 5 | 54 ± 2 | 43,480 |

| 6Mn4Al | 626 ± 14 | 844 ± 21 | 15 ± 6 | 32 ± 3 | 25,964 |

| 10Mn4Al | 554 ± 10 | 722 ± 16 | 16 ± 5 | 38 ± 4 | 27,238 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, N.; Chen, G.; Zhang, Q.; Hu, H.; Xu, G. Study on the Deformation Behavior and Mechanical Properties of Lightweight Economic Stainless Steels with Varying Al and Mn Contents. J. Manuf. Mater. Process. 2025, 9, 206. https://doi.org/10.3390/jmmp9070206

Xu N, Chen G, Zhang Q, Hu H, Xu G. Study on the Deformation Behavior and Mechanical Properties of Lightweight Economic Stainless Steels with Varying Al and Mn Contents. Journal of Manufacturing and Materials Processing. 2025; 9(7):206. https://doi.org/10.3390/jmmp9070206

Chicago/Turabian StyleXu, Nuoteng, Guanghui Chen, Qi Zhang, Haijiang Hu, and Guang Xu. 2025. "Study on the Deformation Behavior and Mechanical Properties of Lightweight Economic Stainless Steels with Varying Al and Mn Contents" Journal of Manufacturing and Materials Processing 9, no. 7: 206. https://doi.org/10.3390/jmmp9070206

APA StyleXu, N., Chen, G., Zhang, Q., Hu, H., & Xu, G. (2025). Study on the Deformation Behavior and Mechanical Properties of Lightweight Economic Stainless Steels with Varying Al and Mn Contents. Journal of Manufacturing and Materials Processing, 9(7), 206. https://doi.org/10.3390/jmmp9070206