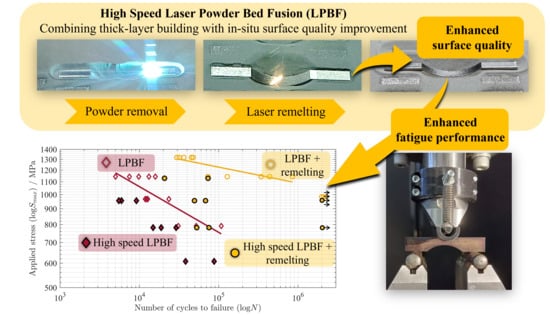

Enhancing Fatigue Life of Metal Parts Produced by High-Speed Laser Powder Bed Fusion Through In Situ Surface Quality Improvement

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Manufacturing

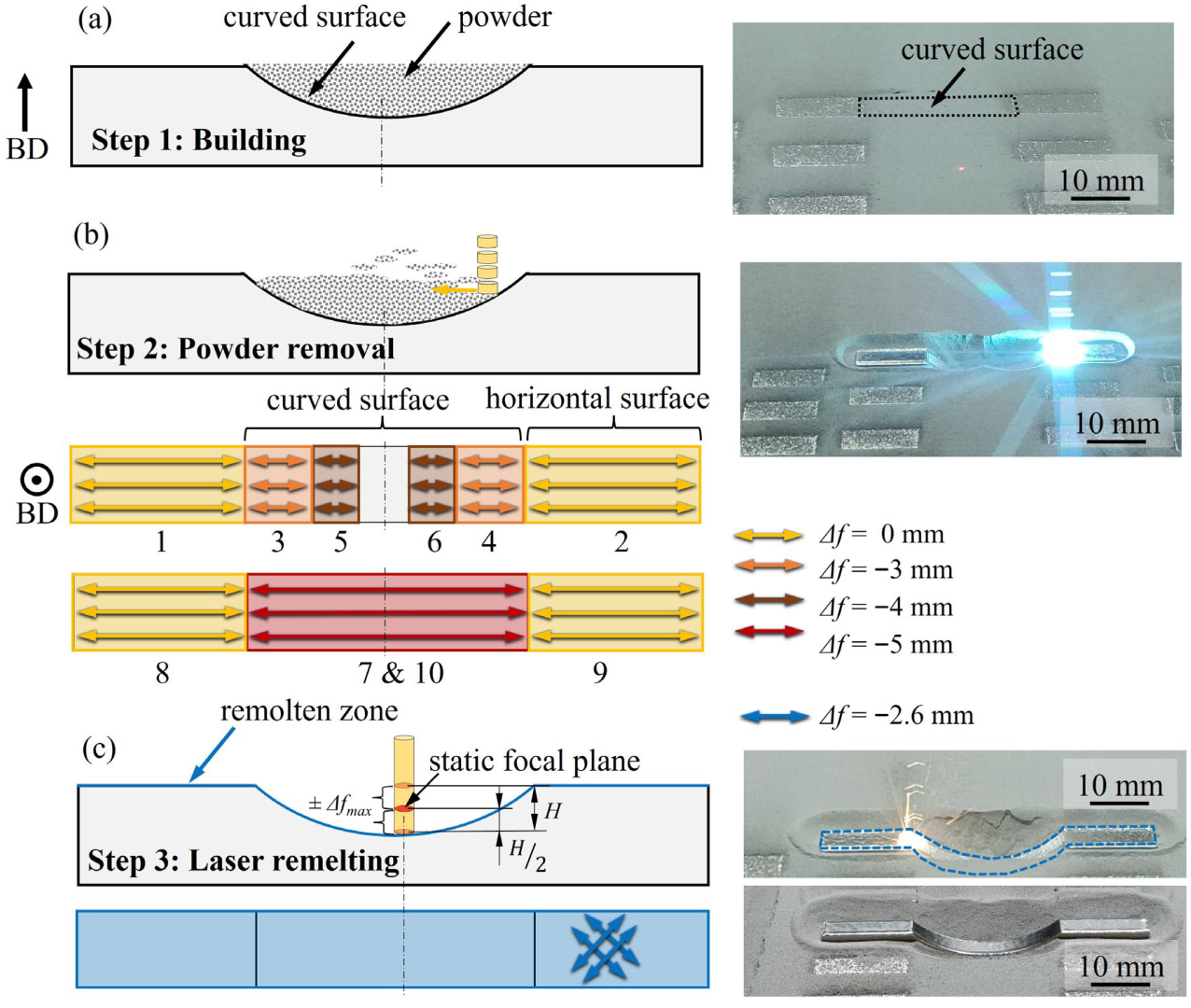

2.2. Dual-Laser Powder Bed Fusion Strategy

2.3. Surface Characterization

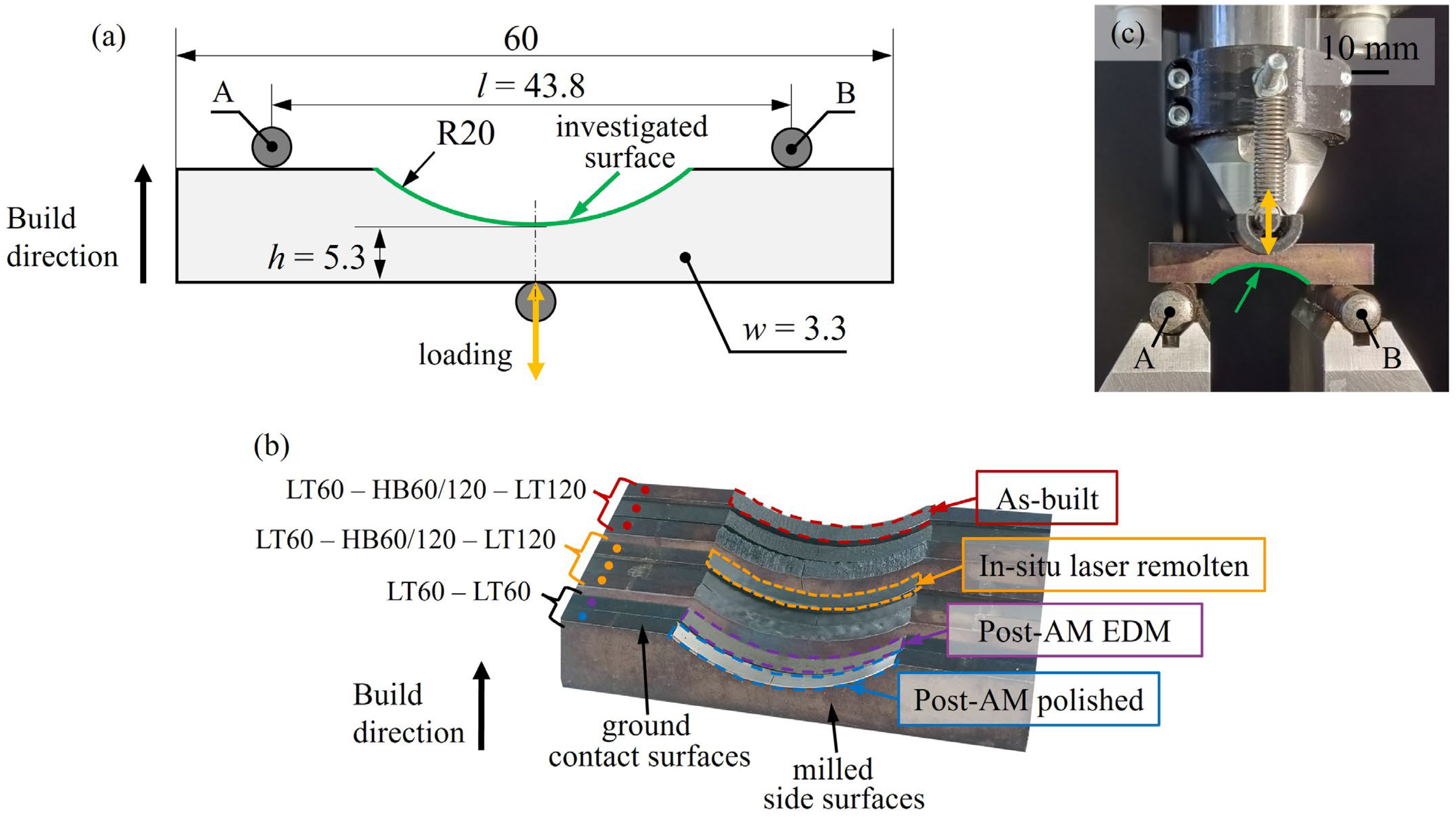

2.4. Fatigue Testing

3. Results

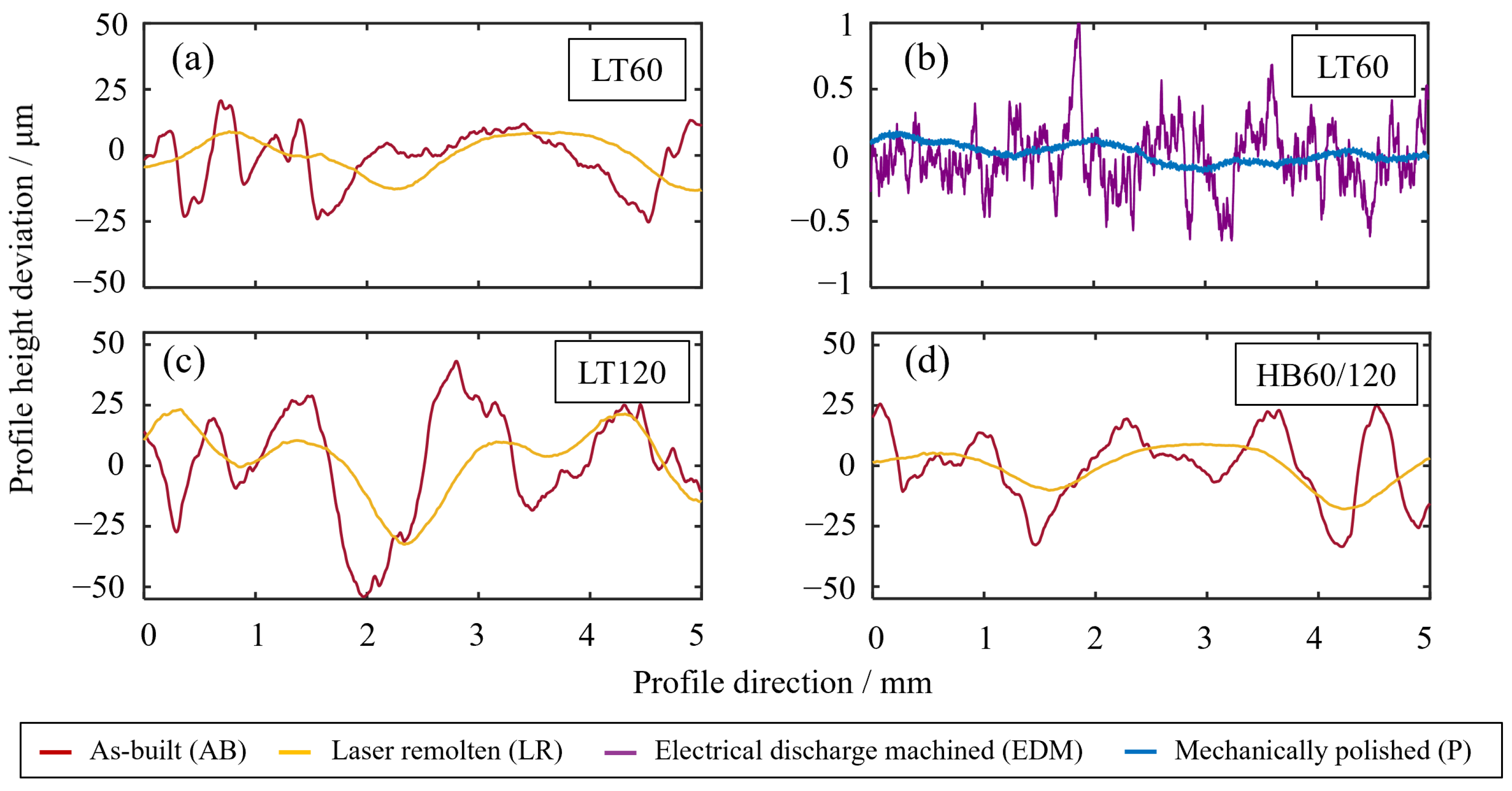

3.1. Surface Quality

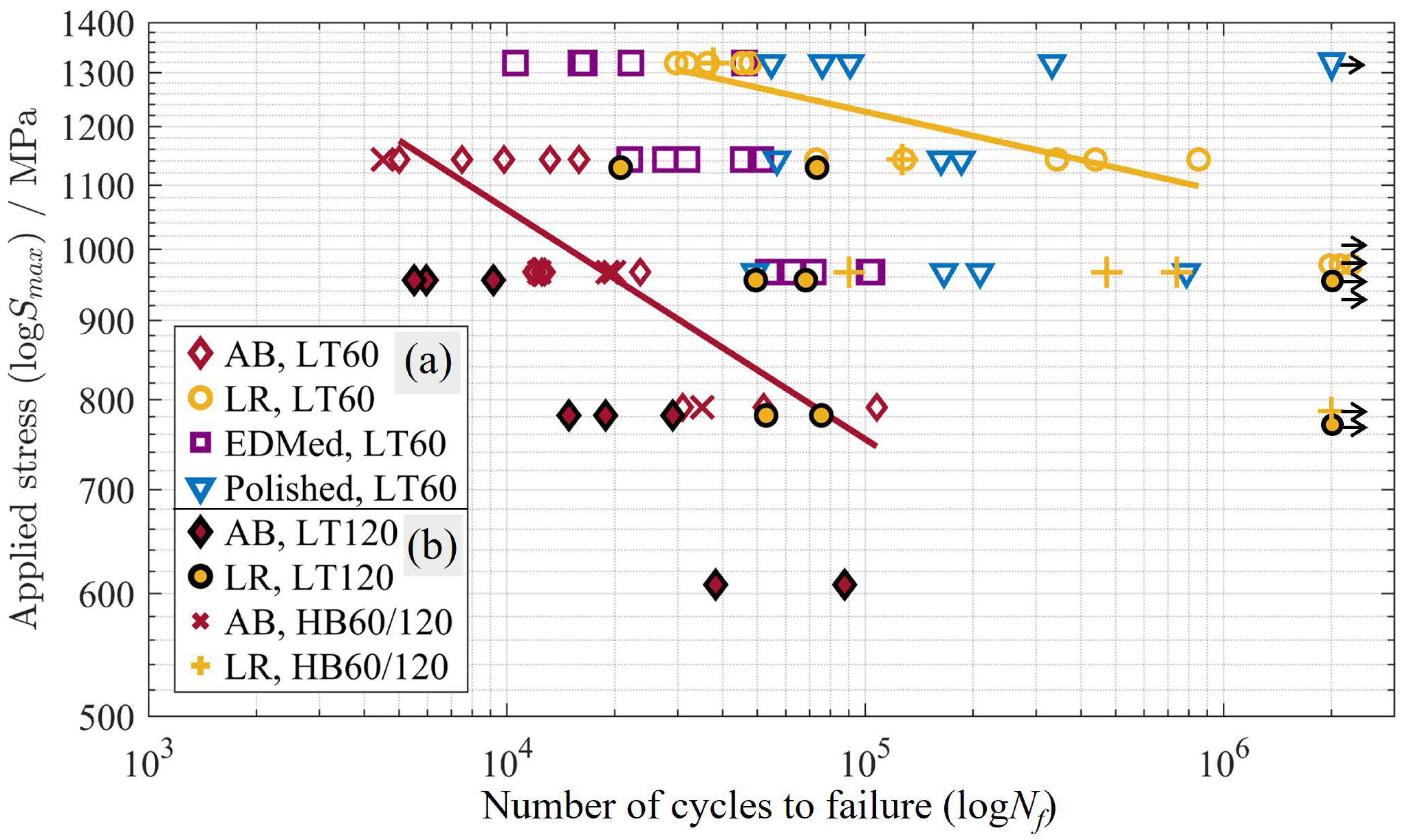

3.2. Fatigue Performance

4. Discussion

5. Conclusions

- Laser remelting demonstrated significant improvements in surface quality and hence fatigue life when applied to samples with variable initial surface states resulting from building strategies using different layer thicknesses. The fatigue life was consistently improved across the investigated as-built conditions, reaching a performance increase of up to a factor of 36.

- This significant improvement in fatigue life compared to the as-built reference samples was attributed to a smoothened surface morphology after remelting, shown by a reduction in surface roughness Ra and critical stress concentration factor kt,crit by up to 60% and 40%. Moreover, the smoothened surface morphology exhibited gradually changing features that were wider by up to a factor of four, as displayed by the autocorrelation length Ral, compared to the abrupt and rapidly changing surface features observed for the as-built reference samples.

- Laser remelting enabled notable improvements in fatigue life compared to the electrical discharge machined reference samples by up to a factor of 10, despite having a roughness 8 times greater. This was similarly quantified by the smoothened surface morphology of the laser remolten samples. Moreover, the laser remolten samples demonstrated an enhanced fatigue life compared to that of the mechanically polished reference samples at relatively low and intermediate stress levels, whereas the mechanically polished samples dominated at higher stress levels.

- In an attempt to combine increased productivity, surface quality, and, hence, fatigue performance, laser remelting was applied to samples fabricated using a high layer thickness of 120 μm. While this approach significantly reduced the build time compared to the standard strategy using a layer thickness of 60 μm, it also considerably deteriorated the as-built surface quality. The laser remelting samples produced using a high layer thickness of 120 μm demonstrated an improvement in fatigue life compared to the as-built reference samples produced using the standard layer thickness of 60 μm by up to a factor of four, while simultaneously reducing the production time by 30%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AB | As-built |

| BD | Build direction |

| HB | Hull-bulk |

| LPBF | Laser powder bed fusion |

| LR | Laser remolten |

| LT | Layer thickness |

| DLPBF | Dual-laser powder bed fusion |

| EDM | Electrical discharge machined |

| P | Mechanically polished |

References

- Asnafi, N. Application of Laser-Based Powder Bed Fusion for Direct Metal Tooling. Metals 2021, 11, 458. [Google Scholar] [CrossRef]

- Salmi, M. Additive Manufacturing Processes in Medical Applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef] [PubMed]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Jamshidinia, M.; Kovacevic, R. The influence of heat accumulation on the surface roughness in powder-bed additive manufacturing. Surf. Topogr. 2015, 3, 014003. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Surface Morphology in Selective Laser Melting of Metal Powders. Phys. Procedia 2011, 12, 264–270. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 1025–1035. [Google Scholar] [CrossRef]

- Kudzal, A.; McWilliams, B.; Hofmeister, C.; Kellogg, F.; Yu, J.; Taggart-Scarff, J.; Liang, J. Effect of scan pattern on the microstructure and mechanical properties of Powder Bed Fusion additive manufactured 17-4 stainless steel. Mater. Des 2017, 133, 205–215. [Google Scholar] [CrossRef]

- Li, Z.; Li, H.; Yin, J.; Li, Y.; Nie, Z.; Li, X.; You, D.; Guan, K.; Duan, W.; Cao, L.; et al. A Review of Spatter in Laser Powder Bed Fusion Additive Manufacturing: In Situ Detection, Generation, Effects, and Countermeasures. Micromachines 2022, 13, 1366. [Google Scholar] [CrossRef]

- Yasa, E.; Deckers, J.; Craeghs, T.; Badrossamay, M.; Kruth, J.P. Investigation on Occurrence of Elevated Edges in Selective Laser Melting. In Proceedings of the 2009 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 3–5 August 2009; pp. 180–192. [Google Scholar]

- Jiménez, A.; Bidare, P.; Hassanin, H.; Tarlochan, F.; Dimov, S.; Essa, K. Powder-based laser hybrid additive manufacturing of metals: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 63–96. [Google Scholar] [CrossRef]

- Elambasseril, J.; Rogers, J.; Wallbrink, C.; Munk, D.; Leary, M.; Qian, M. Laser powder bed fusion additive manufacturing (LPBF-AM): The influence of design features and LPBF variables on surface topography and effect on fatigue properties. Crit. Rev. Solid State Mater. Sci. 2023, 48, 132–168. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Razavi, N.; Riccio, M.; Bandini, M.; du Plessis, A.; Berto, F.; Guagliano, M. Fatigue behaviour of notched laser powder bed fusion AlSi10Mg after thermal and mechanical surface post-processing. Mater. Sci. Eng. A 2022, 829, 142145. [Google Scholar] [CrossRef]

- Zerbst, U.; Madia, M.; Klinger, C.; Bettge, D.; Murakami, Y. Defects as a root cause of fatigue failure of metallic components. I: Basic aspects. Eng. Fail. Anal. 2019, 97, 777–792. [Google Scholar] [CrossRef]

- du Plessis, A.; Beretta, S. Killer notches: The effect of as-built surface roughness on fatigue failure in AlSi10Mg produced by laser powder bed fusion. Addit. Manuf. 2020, 35, 101424. [Google Scholar] [CrossRef]

- Cheng, Z.; Liao, R.; Lu, W. Surface stress concentration factor via Fourier representation and its application for machined surfaces. Int. J. Solids Struct. 2017, 113–114, 108–117. [Google Scholar] [CrossRef]

- Cutolo, A.; Elangeswaran, C.; Muralidharan, G.K.; Van Hooreweder, B. On the role of building orientation and surface post-processes on the fatigue life of Ti-6Al-4V coupons manufactured by laser powder bed fusion. Mater. Sci. Eng. A 2022, 840, 142747. [Google Scholar] [CrossRef]

- Ordnung, D.; Metelkova, J.; Cutolo, A.; Van Hooreweder, B. Improving fatigue performance of metal parts with up-facing inclined surfaces produced by laser powder bed fusion and in-situ laser remelting. Addit. Manuf. Lett. 2022, 3, 100049. [Google Scholar] [CrossRef]

- Maleki, E.; Bagherifard, S.; Bandini, M.; Guagliano, M. Surface post-treatments for metal additive manufacturing: Progress, challenges, and opportunities. Addit. Manuf. 2021, 37, 101619. [Google Scholar] [CrossRef]

- Yasa, E.; Kruth, J.-P.; Deckers, J. Manufacturing by combining Selective Laser Melting and Selective Laser Erosion/laser re-melting. CIRP Ann. 2011, 60, 263–266. [Google Scholar] [CrossRef]

- Senol, S.; Cutolo, A.; Ordnung, D.; Datye, A.; Van Hooreweder, B.; Vanmeensel, K. Improved surface quality and fatigue life of high-strength, hybrid particle reinforced (Ti+B4C)/Al-Cu-Mg metal matrix composite processed by dual-laser powder bed fusion. Proc. Struct. Integr. 2024, 53, 12–28. [Google Scholar] [CrossRef]

- Sinico, M.; Metelkova, J.; Dalemans, T.; Thijs, L.; Van Hooreweder, B. High speed laser powder bed fusion of M789 tool steel with an optimized 120 µm layer thickness approach. In Procedia CIRP; Elsevier: Amsterdam, The Netherlands, 2022; Volume 113, pp. 162–165. [Google Scholar] [CrossRef]

- Böhler M789 Powder Composition. Available online: https://www.bohler-edelstahl.com/en/products/m789-ampo (accessed on 1 June 2025).

- 3DSystems. Certified M789 Material. Available online: https://www.3dsystems.com/materials/certified-m789-a (accessed on 16 May 2025).

- Tian, Y.; Palad, R.; Aranas, C. Microstructural evolution and mechanical properties of a newly designed steel fabricated by laser powder bed fusion. Addit. Manuf. 2020, 36, 101495. [Google Scholar] [CrossRef]

- Turk, C.; Zunko, H.; Aumayr, C.; Leitner, H.; Kapp, M. Advances in Maraging Steels for Additive Manufacturing. BHM Berg- Hüttenmänn. Monatshefte 2019, 164, 112–116. [Google Scholar] [CrossRef]

- Ordnung, D.; Mertens, T.; Metelkova, J.; Van Hooreweder, B. Novel strategy for automated quality enhancement of up-facing inclined surfaces by incremental dual laser powder bed fusion. Opt. Lasers Eng. 2024, 178, 108172. [Google Scholar] [CrossRef]

- ISO 16610-21; Geometrical Product Specifications (GPS)—Filtration—Part 21: Linear Profile Filters: Gaussian Filters. ISO: Geneva, Switzerland, 2011.

- ISO 21920-2; Geometrical Product Specifications (GPS). Surface Texture: Profile—Part 2: Terms, Definitions and Surface. ISO: Geneva, Switzerland, 2021.

- ISO 21920-3; Geometrical Product Specifications (GPS). Surface Texture: Profile—Part 3: Specific Operators. ISO: Geneva, Switzerland, 2021.

| Surface Condition | ||||||||

|---|---|---|---|---|---|---|---|---|

| Surface Parameters | AB | LR | P | EDM | ||||

| LT60 | LT120 | HB60/120 | LT60 | LT120 | HB60/120 | LT60 | LT60 | |

| Ra/μm | 14.0 ± 1.4 | 25.8 ± 4.2 | 15.7 ± 1.8 | 5.6 ± 1.0 | 18.7 ± 6.5 | 6.5 ± 0.7 | 0.21 ± 0.03 | 0.70 ± 0.04 |

| kt,crit | 2.14 ± 0.09 | 2.38 ± 0.20 | 2.27 ± 0.10 | 1.24 ± 0.02 | 1.60 ± 0.21 | 1.33 ± 0.04 | 1.03 ± 0.01 | 1.27 ± 0.01 |

| Ral/μm | 128 ± 11 | 307 ± 97 | 260 ± 50 | 474 ± 64 | 466 ± 125 | 508 ± 24 | 1182 ± 715 | 45 ± 15 |

| Rdq | 0.43 ± 0.02 | 0.48 ± 0.07 | 0.41 ± 0.02 | 0.12 ± 0.01 | 0.17 ± 0.01 | 0.12 ± 0.01 | 0.08 ± 0.0 | 0.19 ± 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ordnung, D.; Sinico, M.; Mertens, T.; Haitjema, H.; Van Hooreweder, B. Enhancing Fatigue Life of Metal Parts Produced by High-Speed Laser Powder Bed Fusion Through In Situ Surface Quality Improvement. J. Manuf. Mater. Process. 2025, 9, 207. https://doi.org/10.3390/jmmp9070207

Ordnung D, Sinico M, Mertens T, Haitjema H, Van Hooreweder B. Enhancing Fatigue Life of Metal Parts Produced by High-Speed Laser Powder Bed Fusion Through In Situ Surface Quality Improvement. Journal of Manufacturing and Materials Processing. 2025; 9(7):207. https://doi.org/10.3390/jmmp9070207

Chicago/Turabian StyleOrdnung, Daniel, Mirko Sinico, Thibault Mertens, Han Haitjema, and Brecht Van Hooreweder. 2025. "Enhancing Fatigue Life of Metal Parts Produced by High-Speed Laser Powder Bed Fusion Through In Situ Surface Quality Improvement" Journal of Manufacturing and Materials Processing 9, no. 7: 207. https://doi.org/10.3390/jmmp9070207

APA StyleOrdnung, D., Sinico, M., Mertens, T., Haitjema, H., & Van Hooreweder, B. (2025). Enhancing Fatigue Life of Metal Parts Produced by High-Speed Laser Powder Bed Fusion Through In Situ Surface Quality Improvement. Journal of Manufacturing and Materials Processing, 9(7), 207. https://doi.org/10.3390/jmmp9070207