Research on Robot Cleaning Path Planning of Vertical Mixing Paddle Surface

Abstract

1. Introduction

- More reasonable sub-region division. Strategies must account for multiple factors, including the unique challenges posed by helical surfaces, as well as sub-region quantity and connectivity.

- More accurate path planning. Strategies must overcome curvature variations on blade surfaces while improving path smoothness.

- Higher cleaning efficiency. The model should minimize operation time and energy consumption without compromising cleaning quality.

- Adaptive Segmentation for Reasonable Sub-regions: A novel hybrid process (curvature, k-means++, parametric boundaries) achieves functionally relevant divisions for complex helical surfaces.

- Constraint-Driven Paths for Accurate Planning: Isoperimetric trajectories with parameters analytically derived from cleaning quality constraints and local geometry.

- GTSP Sequencing for Higher Efficiency: Unique GTSP formulation for inter-sub-region travel, globally optimizing multi-stage cleaning to minimize non-productive time.

- Validated Integrated Solution: The co-integration and physical robotic validation of these phases demonstrate a practical and effective system for cleaning vertical mixer blades.

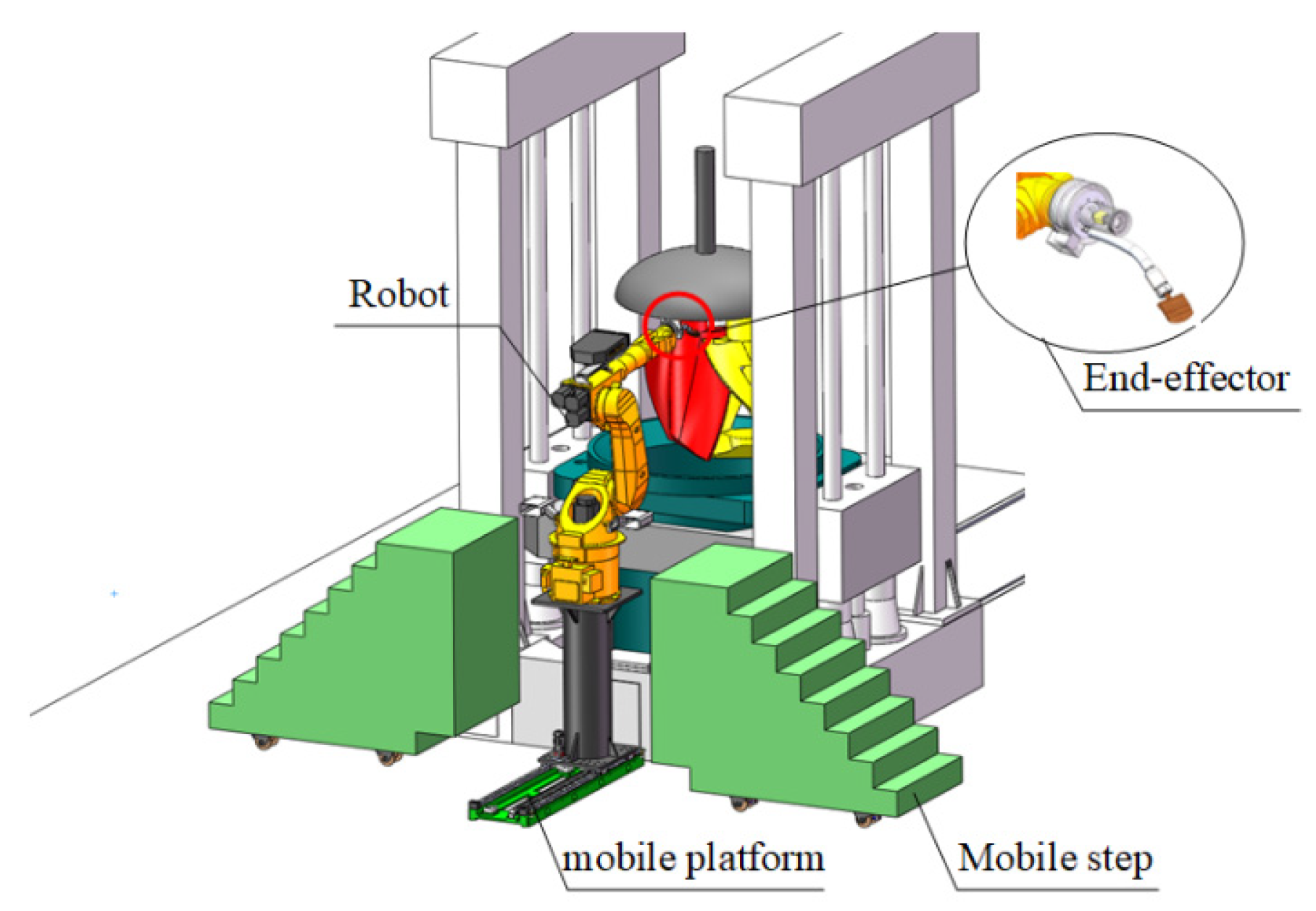

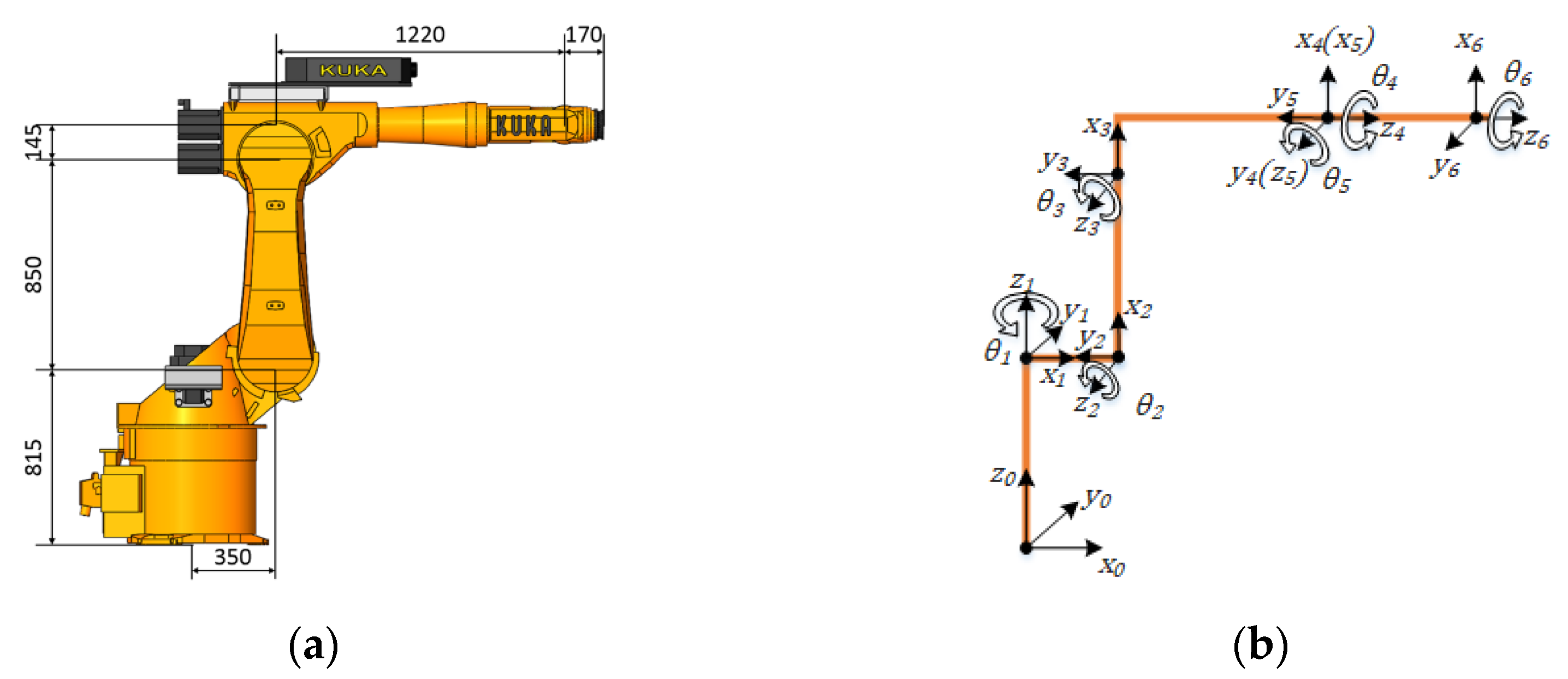

2. Robot Cleaning System of Blade Surface

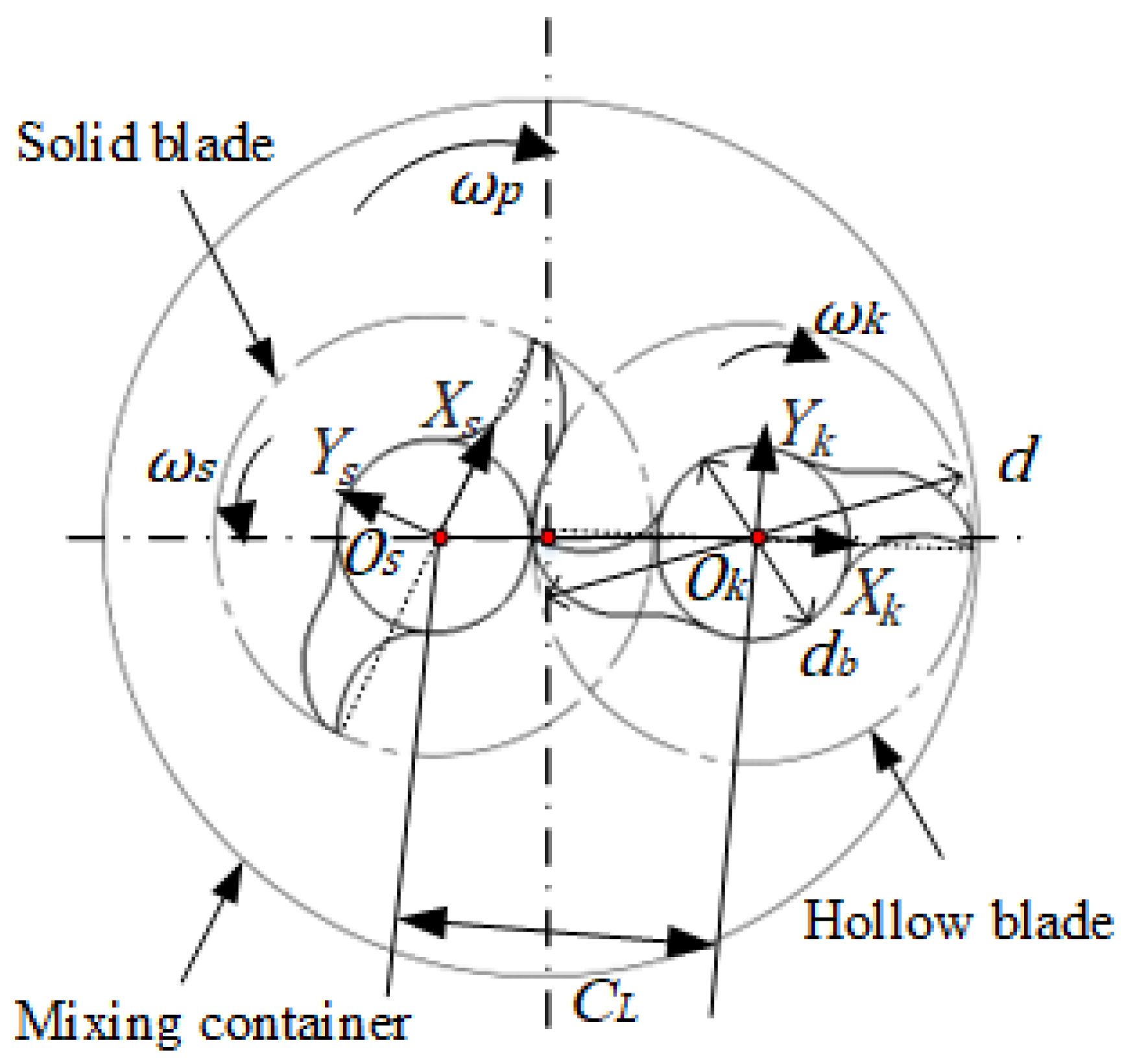

3. Mathematical Model

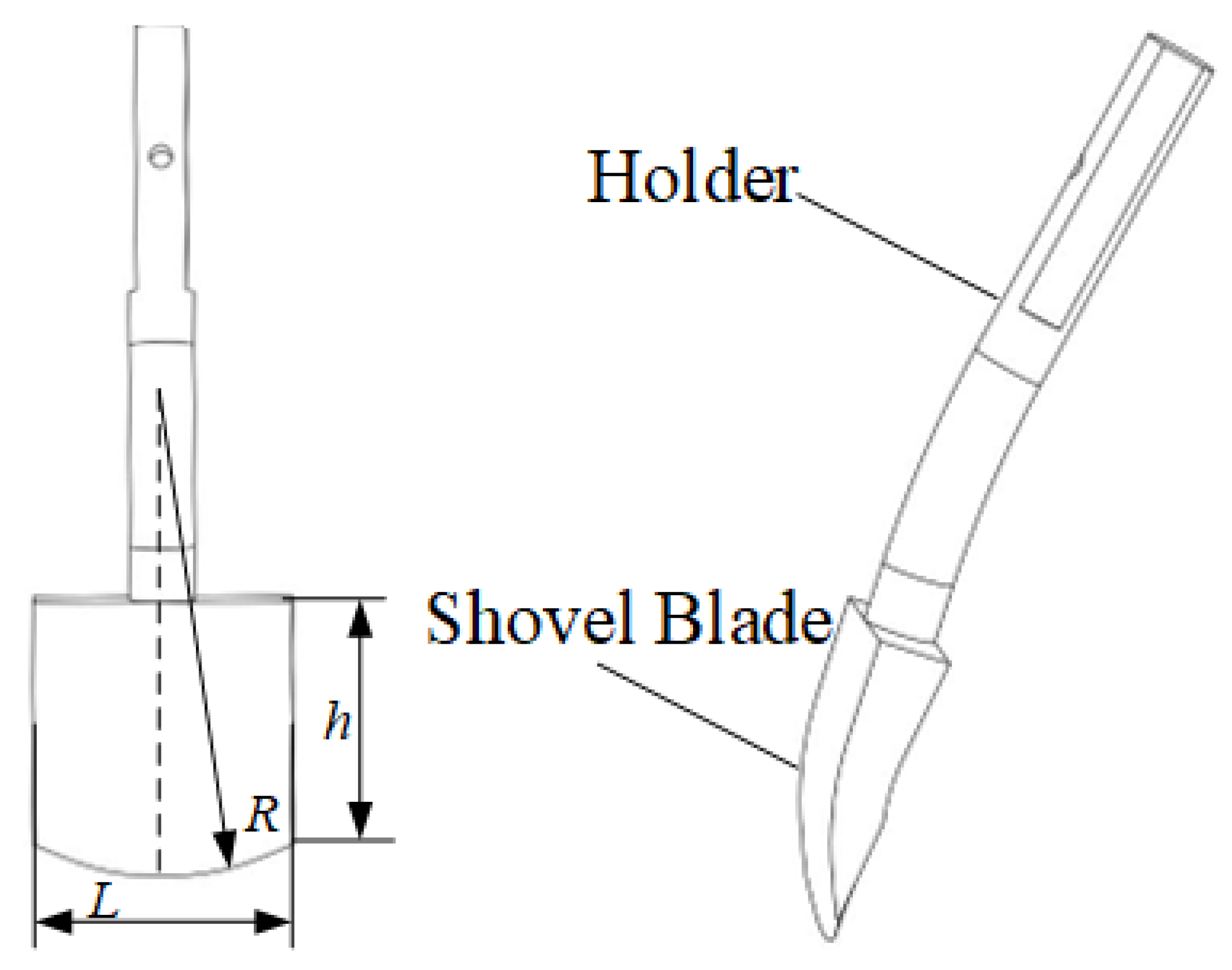

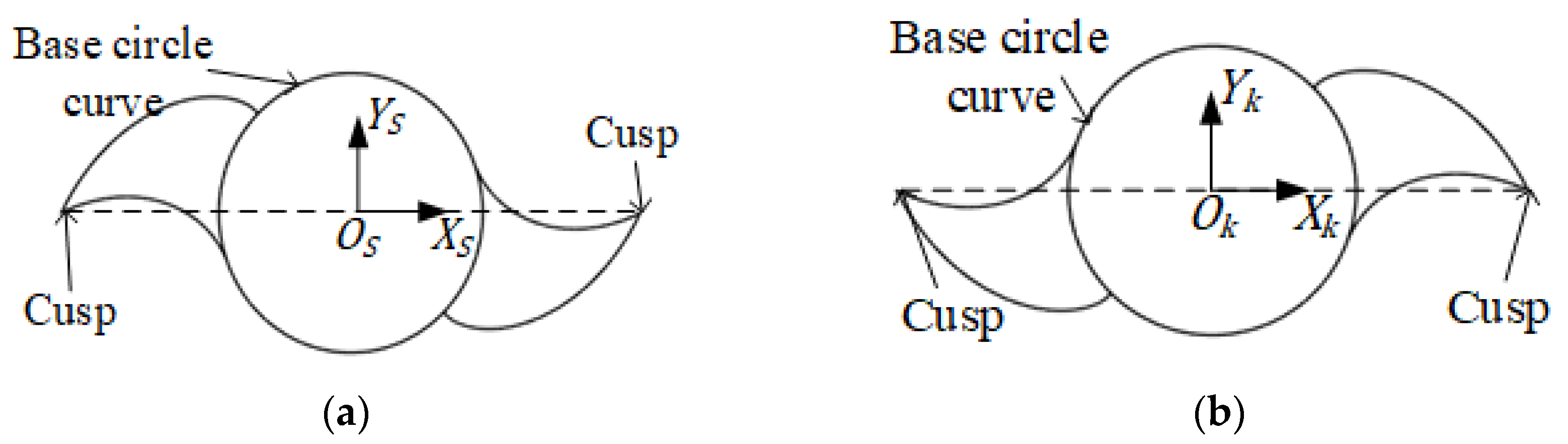

3.1. Mixer Blade Surface Modeling

3.2. Geometric Parameters of Mixer Blade Surface

4. Path Planning

4.1. Mixer Blade Surface Slice

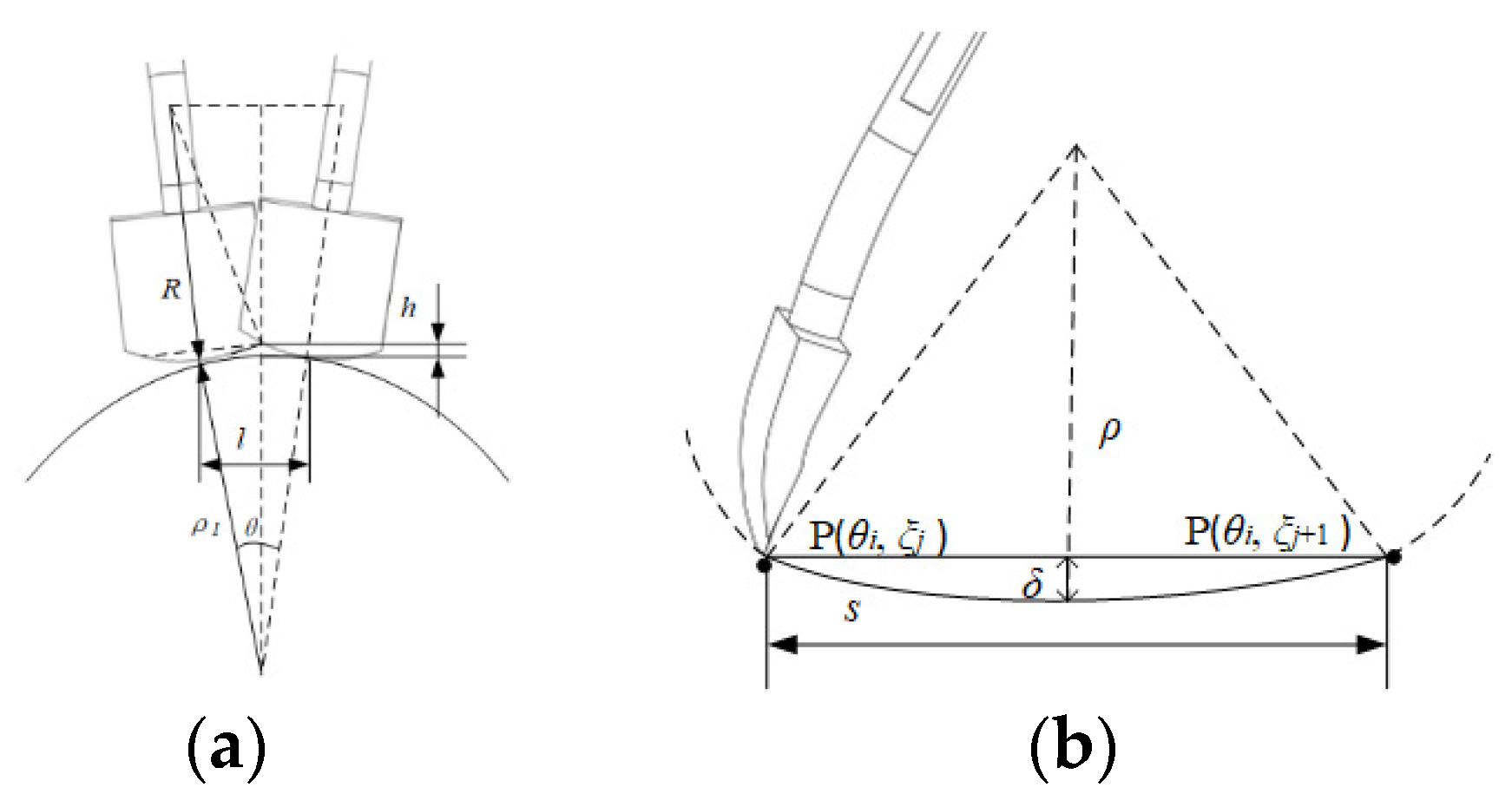

4.2. Robot Subpath Planning

4.3. Figures, Tables, and Schemes

5. Blade Path Planning Simulation and Experimental Verification

5.1. Surface Modeling of Solid Blade Part

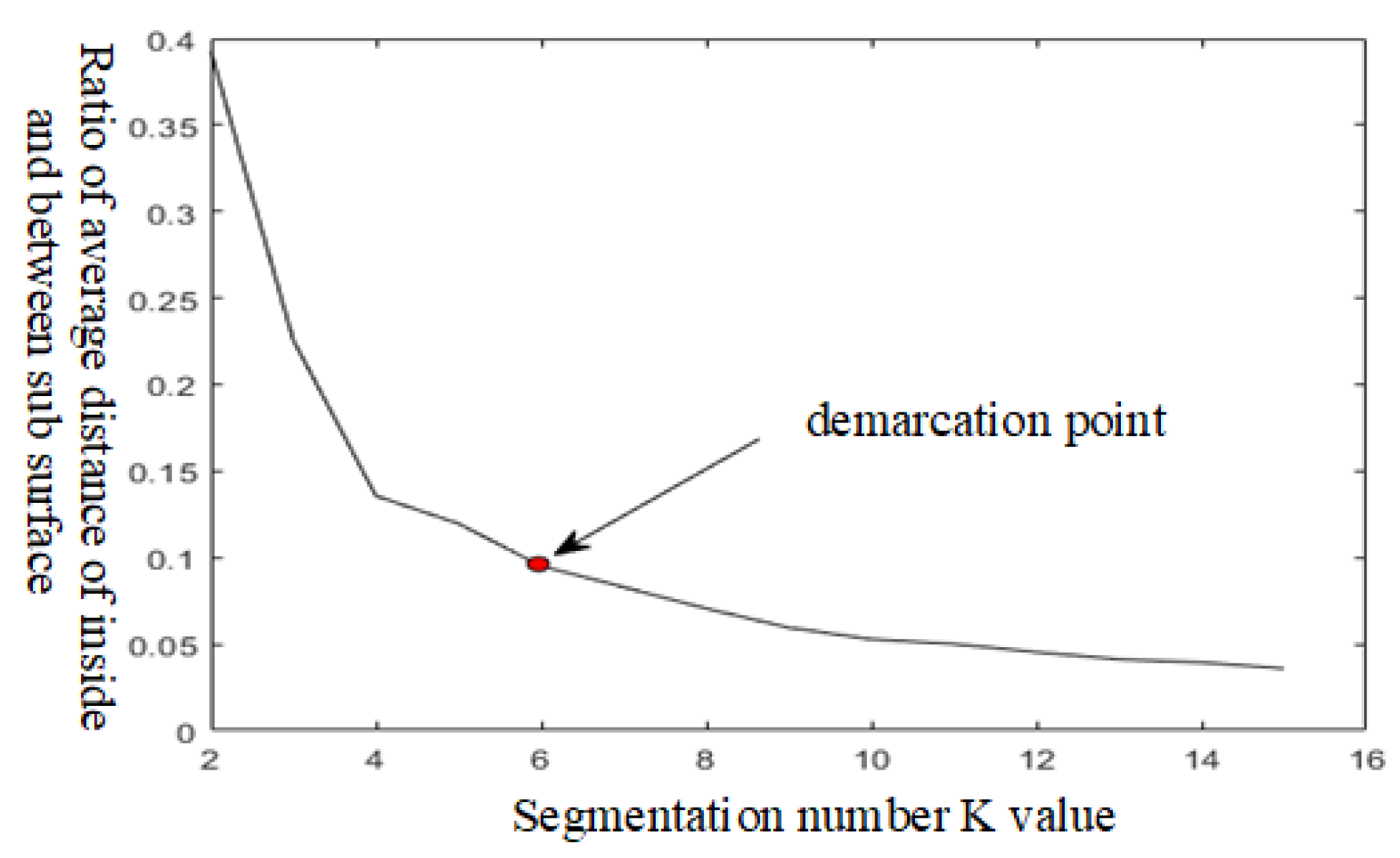

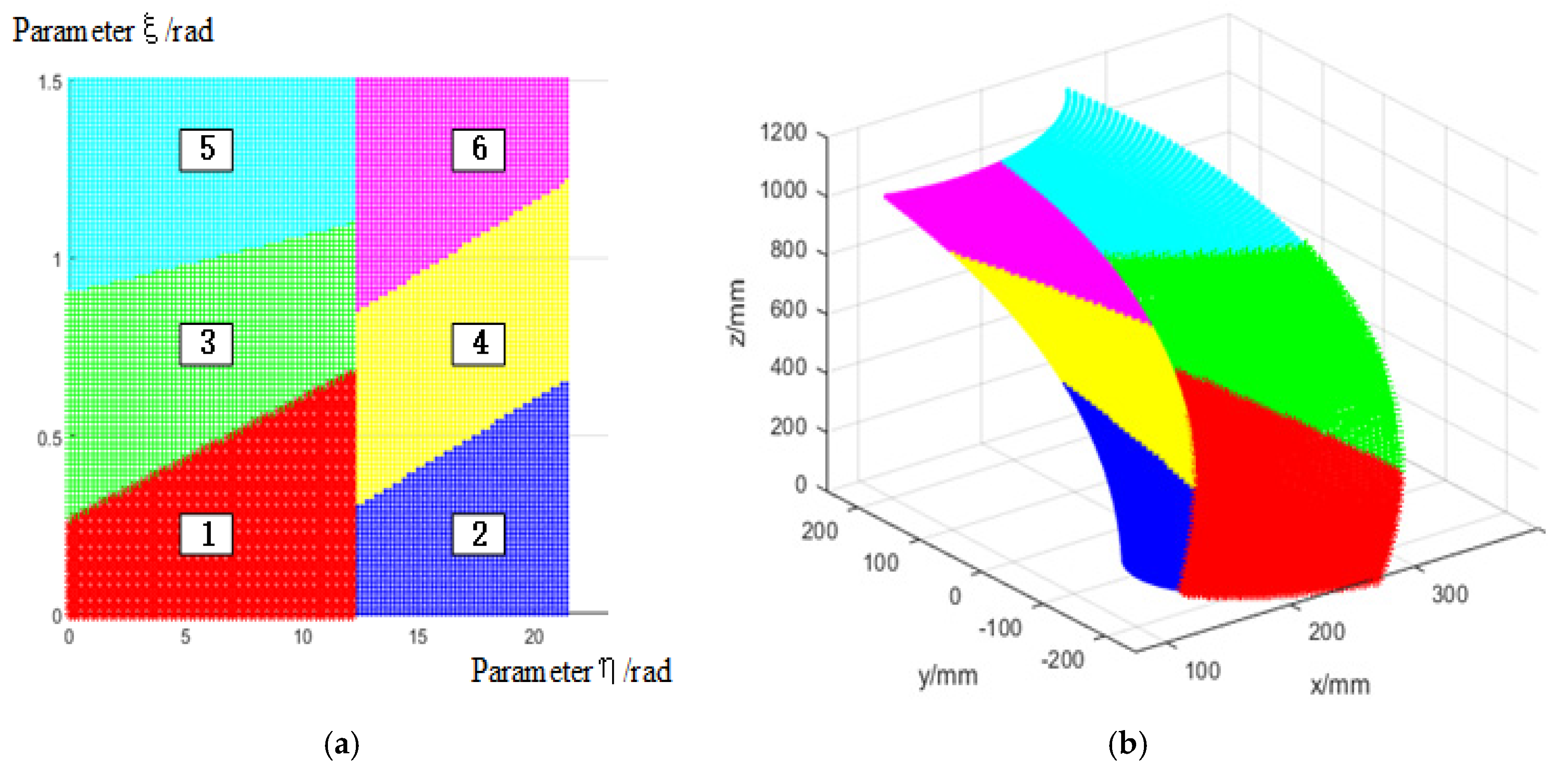

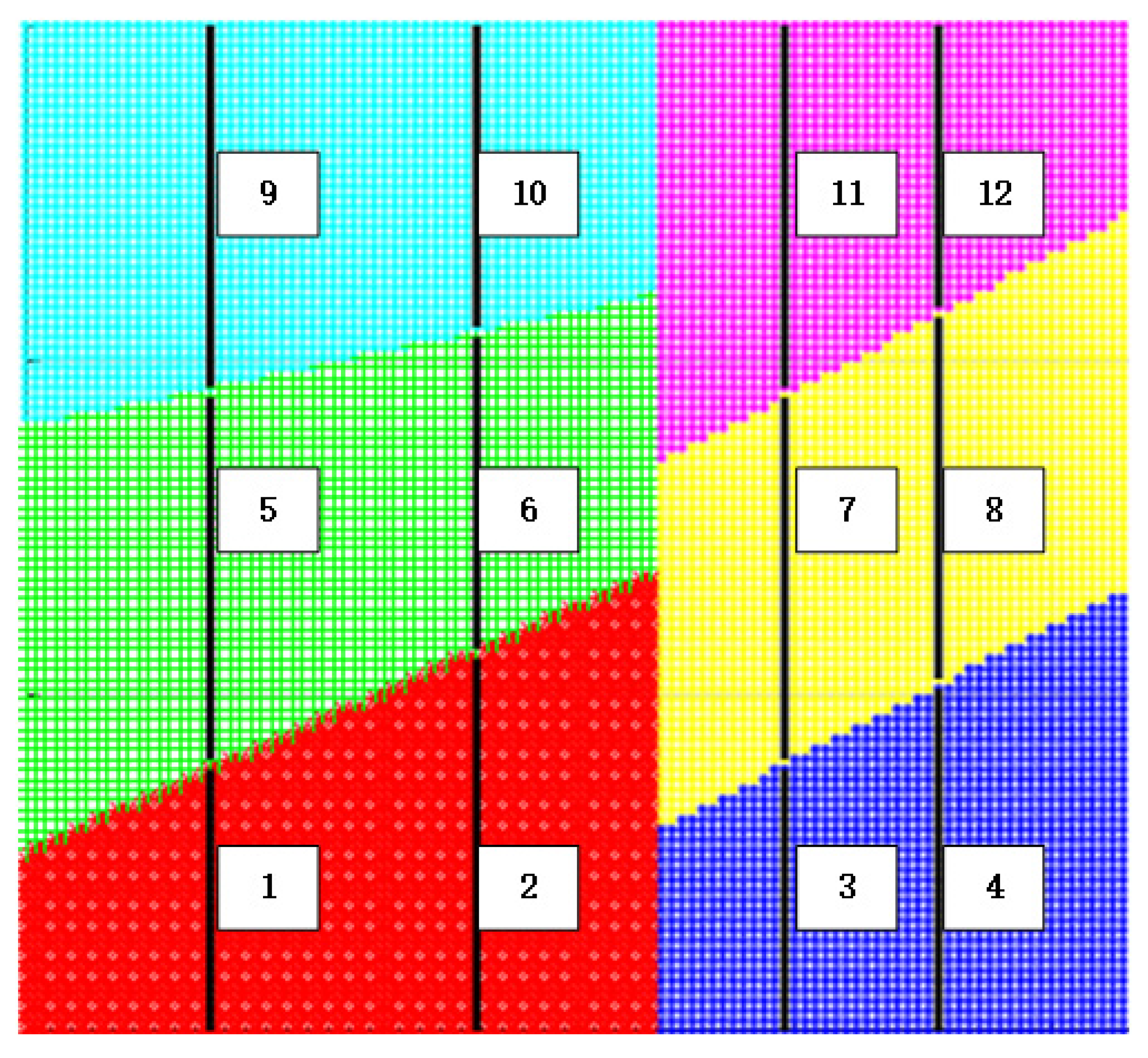

5.2. Surface Subdivision of the Solid Blade Partial Surface

5.3. Path Planning of Solid Blade Partial Surface

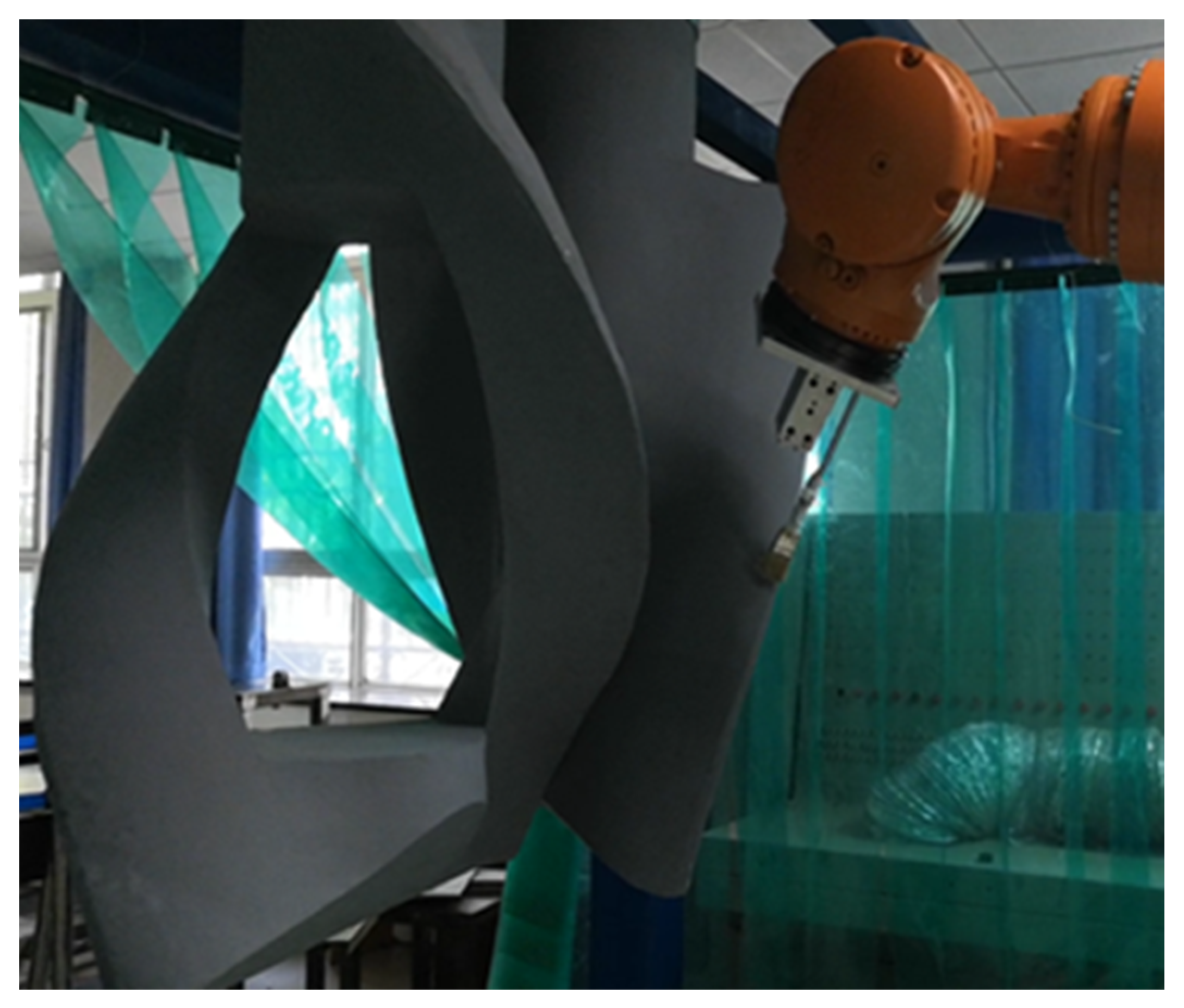

5.4. Experimental Verification of Robot Path Planning

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Takahashi, A.; Kitagawa, K.; Shimada, T. WITHDRAWN: Evaluation of safety distance for blast of hybrid rocket propellants. Fire Saf. J. 2020, 103145. [Google Scholar] [CrossRef]

- Furlong, A.J.; Bond, N.K.; Pegg, M.J.; Hughes, R.W. Evaluation of dust and gas explosion potential in chemical looping processes. J. Loss Prev. Process Ind. 2024, 89, 105277. [Google Scholar] [CrossRef]

- Kang, Y.; Xia, X.; Wu, Z.; Cheng, Z. Visualization of integrated failure consequences of hazardous chemical leakage and explosion. J. Loss Prev. Process Ind. 2024, 92, 105464. [Google Scholar] [CrossRef]

- Figgis, B.; Bermudez, V.; Garcia, J.L. PV module vibration by robotic cleaning. Sol. Energy 2023, 250, 168–172. [Google Scholar] [CrossRef]

- Shin, D.; Choi, Y.; Soon, Z.Y.; Kim, M.; Jang, M.-C.; Seo, J.-Y.; Kang, J.-H.; Shin, K.; Jung, J.-H. Chemical hazard of robotic hull in-water cleaning discharge on coastal embryonic fish. Ecotoxicol. Environ. Saf. 2023, 253, 114653. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.-Y.; Lin, W.-M.; Chen, A.-X. Path planning for the mobile robot: A review. Symmetry 2018, 10, 450. [Google Scholar] [CrossRef]

- Zhao, S.; Zheng, T.; Wang, C.; Yang, Z.; Xu, T.; Zhu, Y.; Zhao, J. Sigmoid angle-arc curves: Enhancing robot time-optimal path parameterization for high-order smooth motion. Robot. Comput. Integr. Manuf. 2025, 92, 102884. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, G.; Xu, X.; Zhao, Q. Research on Region Division of Large Workpiece Based on Dexterous Workspace of Robot. In Proceedings of the 2021 5th International Conference on Electrical, Automation and Mechanical Engineering (EAME 2021), Journal of Physics: Conference Series, Guangzhou, China, 17–18 September 2021; p. 012059. [Google Scholar]

- Li, L.; Shi, D.; Jin, S.; Yang, S.; Zhou, C.; Lian, Y.; Liu, H. Exact and heuristic multi-robot dubins coverage path planning for known environments. Sensors 2023, 23, 2560. [Google Scholar] [CrossRef]

- Sun, Y.; Sun, S.; Xu, J.; Guo, D. A unified method of generating tool path based on multiple vector fields for CNC machining of compound NURBS surfaces. Comput. Aided Des. 2017, 91, 14–26. [Google Scholar] [CrossRef]

- Yuan, E.-T.; Shao, B. Tool-path generation of multi-axis machining for subdivision surface. AASRI Procedia 2012, 3, 60–65. [Google Scholar] [CrossRef]

- Bendjebla, S.; Cai, N.; Anwer, N.; Lavernhe, S.; Mehdi-Souzani, C. Freeform machining features: New concepts and classification. Procedia CIRP 2018, 67, 482–487. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, E.; Sun, R.; Gao, W.; Fu, Z. Free-Form Surface Partitioning and Simulation Verification Based on Surface Curvature. Micromachines 2022, 13, 2163. [Google Scholar] [CrossRef]

- Sun, J.; Xiang, S.; Zhou, T.; Cheng, T. Sampling Point Planning for Complex Surface Inspection based on Feature Points under Area Division. Int. J. Adv. Manuf. Technol. 2023, 127, 717–732. [Google Scholar] [CrossRef]

- Han, X. Research on the Regional Division of Free Surface Machining Based On K-Means Clustering Algorithm. In Proceedings of the 2016 7th International Conference on Mechatronics, Control and Materials (ICMCM 2016), Changsha, China, 29–30 October 2016; pp. 312–317. [Google Scholar]

- Wang, G.; Hua, X.; Xu, J.; Song, L.; Chen, K. A deep learning based automatic surface segmentation algorithm for painting large-size aircraft with 6-DOF robot. Assem. Autom. 2020, 40, 199–210. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.J.; Yang, X.; Xu, H.; Xu, G. Point cloud surface segmentation based on volumetric eigenfunctions of the Laplace-Beltrami operator. Comput. Aided Geom. Des. 2019, 71, 157–175. [Google Scholar] [CrossRef]

- Kalogerakis, E.; Averkiou, M.; Maji, S.; Chaudhuri, S. 3D shape segmentation with projective convolutional networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 3779–3788. [Google Scholar]

- Vo, A.-V.; Truong-Hong, L.; Laefer, D.F.; Bertolotto, M. Octree-based region growing for point cloud segmentation. ISPRS J. Photogramm. Remote Sens. 2015, 104, 88–100. [Google Scholar] [CrossRef]

- Li, J.; Zou, L.; Luo, G.; Wang, W.; Lv, C. Enhancement and evaluation in path accuracy of industrial robot for complex surface grinding. Robot. Comput. Integr. Manuf. 2023, 81, 102521. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, L.; Ullah, S.; Hu, T.; Xu, Y.; Chen, L.; Hanif, M. An improved medial axis path generation algorithm for selective laser melting. Rapid Prototyp. J. 2020, 26, 1751–1759. [Google Scholar] [CrossRef]

- Chalvin, M.; Campocasso, S.; Hugel, V.; Baizeau, T. Layer-by-layer generation of optimized joint trajectory for multi-axis robotized additive manufacturing of parts of revolution. Robot. Comput. Integr. Manuf. 2020, 65, 101960. [Google Scholar] [CrossRef]

- Xu, K.; Li, Y.; Yang, M. Quasi-optimal tool trajectories for high speed 2.5 D process based on morphological transformation. Comput. Aided Des. 2020, 129, 102920. [Google Scholar] [CrossRef]

- Holowenko, O.; Troll, C.; Ihlenfeldt, S.; Majschak, J.-P. A Novel Adaptive Interpolation Approach for the Implementation of Operating-Speed-Dependent Motion Profiles in Processing Machines. Eng. Sci. Technol. Int. J. 2021, 24, 1308–1317. [Google Scholar] [CrossRef]

- Nieto Bastida, S.; Lin, C.-Y. Autonomous trajectory planning for spray painting on complex surfaces based on a point cloud model. Sensors 2023, 23, 9634. [Google Scholar] [CrossRef]

- Huang, Y.; Gu, Y.; Zheng, Z. Research on the path planning of hair-insertion robot arm based on ant colony optimization. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 5191–5195. [Google Scholar]

- Jiang, J.; Guo, Y.; Huang, Z.; Zhang, Y.; Wu, D.; Liu, Y. Adjacent surface trajectory planning of robot-assisted tooth preparation based on augmented reality. Eng. Sci. Technol. Int. J. 2022, 27, 101001. [Google Scholar] [CrossRef]

- Hauth, S.; Richterich, C.; Glasmacher, L.; Linsen, L. Constant cusp toolpath generation in configuration space based on offset curves. Int. J. Adv. Manuf. Technol. 2011, 53, 325–338. [Google Scholar] [CrossRef]

- Yang, X.; Yue, X.; Cai, Z.; Zhong, S. Research on the trajectory planning and global optimization strategy of cold spraying technique for complex products coating preparation. Robot. Intell. Autom. 2024, 44, 258–269. [Google Scholar] [CrossRef]

- Wang, N.; Wang, H.; Jiang, Y. Optimization on laser cutting process path based on bidirectional ant colony algorithm. Forg. Stamp. Technol. 2020, 45, 30–35. [Google Scholar]

| Parameter Name | Width L/mm | Height h/mm | Front Arc Radius/mm |

|---|---|---|---|

| numerical value | 100 | 80 | 95 |

| Subchip Number | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| 1842.49 | 2675.82 | 1842.49 | 2675.82 | 1842.49 | 2675.82 | |

| ρ/mm | 139.57 | 115.47 | 139.57 | 115.47 | 139.57 | 115.47 |

| Subpath Arrangement | Subpath Connection Time |

|---|---|

| 10→6→2→11→7→3→12→8→4→9→5→1 | 44.3172 s |

| 10→6→2→12→8→4→11→7→3→9→5→1 | 44.3396 s |

| 11→7→4→3→9→5→1→12→8→10→6→2 | 45.9039 s |

| 9→10→6→2→11→7→3→12→8→4→5→1 | 45.9275 s |

| 9→10→6→2→12→8→4→11→7→3→5→1 | 45.9281 s |

| 10→9→6→2→12→8→4→11→7→3→5→1 | 46.0785 s |

| 10→5→1→11→7→3→12→8→4→9→6→2 | 46.2415 s |

| 9→6→2→10→5→1→12→8→4→11→7→3 | 46.2861 s |

| 11→7→3→10→5→1→12→8→4→9→6→2 | 46.3252 s |

| 12→10→6→11→7→3→8→4→2→9→5→1 | 47.4891 s |

| 10→6→4→2→7→1→8→5→3→12→9→11 | 61.8584 s |

| Subchip Number | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| l/mm | 68.76 | 91.23 | 68.76 | 91.23 | 68.76 | 91.23 |

| s/mm | 171.65 | 206.87 | 171.65 | 206.87 | 171.65 | 206.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Z.; Guo, L.; Li, J.; Cao, N.; Qin, X.; Wang, Z. Research on Robot Cleaning Path Planning of Vertical Mixing Paddle Surface. J. Manuf. Mater. Process. 2025, 9, 198. https://doi.org/10.3390/jmmp9060198

Shi Z, Guo L, Li J, Cao N, Qin X, Wang Z. Research on Robot Cleaning Path Planning of Vertical Mixing Paddle Surface. Journal of Manufacturing and Materials Processing. 2025; 9(6):198. https://doi.org/10.3390/jmmp9060198

Chicago/Turabian StyleShi, Zhouzheng, Leiyang Guo, Jingde Li, Ni Cao, Xiansheng Qin, and Zhanxi Wang. 2025. "Research on Robot Cleaning Path Planning of Vertical Mixing Paddle Surface" Journal of Manufacturing and Materials Processing 9, no. 6: 198. https://doi.org/10.3390/jmmp9060198

APA StyleShi, Z., Guo, L., Li, J., Cao, N., Qin, X., & Wang, Z. (2025). Research on Robot Cleaning Path Planning of Vertical Mixing Paddle Surface. Journal of Manufacturing and Materials Processing, 9(6), 198. https://doi.org/10.3390/jmmp9060198