1. Introduction

The automotive industry faces new challenges, especially with the use of lightweight and higher strength materials such as high-strength steel, carbon fiber composites, and alloys. These materials have significant advantages in terms of fuel efficiency, environmental impact, and passenger safety [

1]. Advanced High-Strength Steel (AHSS) is a popular material in automotive body structure production due to its low cost and high strength-to-elastic modulus ratio compared to other materials. However, the AHSS forming process is likely to encounter problems, such as fracture, wrinkling, and springback. Springback is a more significant issue in the AHSS forming process compared to conventional steels. This problem is the distortion of part dimensions that deviate from the desired shape and affects assembly processes. It is caused by elastic regions inside the material that are not fully transformed into plastic regions and try to return to their original shape after forming. Many researchers and engineers are trying to solve this problem by using Finite Element Method (FEM) simulations for experimental analysis. For example, one approach involves using a counter punch with end gaps to create spring-go, which compensates for the springback effect [

2]. Another method uses adjustable blank holder forces during the forming process [

3]. A third technique is two-step forming, where the single upper die is separated into a pad at the top of the workpiece, and forming occurs in the final step [

4]. On the other hand, the automotive parts often have complex geometries. Hence, a die compensation method has to be used for solving this problem [

5]. This method adjusts the die surface by using FEM analysis. The simulation replicates the forming process to identify shape distortions and compensates the die surface to achieve the desired workpiece shape. However, the process parameters used in forming must be optimized to minimize springback first for effective compensation [

6]. In the engineering field, the design of experiments (DOE) and regression are widely used for optimizing the most suitable parameters [

7]. The benefit of this method is not only optimizing the parameters but also reducing the time for various experiments. For instance, Özdemir [

8] used the Taguchi method and response surface methodology (RSM) to optimize the parameters for reducing springback with only 16 experiments. Ingarao et al. [

9] employed FEM and RSM to investigate the effect of friction and blank holder force on DP600 and DP1000 workpieces and parameters to minimize springback and thinning.

Currently, Artificial Intelligence (AI) [

10] has gained in popularity and seen a significant increase in performance [

11]. As a result, AI is increasingly used in several fields, including healthcare, education, language technology, economics, commerce, and industrial manufacturing [

12]. The most popular algorithm is the Artificial Neural Network (ANN). ANN is a learning technique in the field of machine learning (ML) that mimics the human brain system’s learning process. In 2006, ANN gained popularity with the introduction of deep learning (DL) [

13]. DL enhances ANN performance by using multiple hidden layers in the ANN model to train on complex data, especially in the manufacturing industry for analyzing defects in sheet metal forming, particularly the springback phenomenon [

14,

15,

16]. A common and effective strategy in such research is to develop a highly accurate predictive model. This model aims to map the complex non-linear relationships between process inputs and the resulting manufacturing outcome. ANN and Deep Neural Network (DNN) are exceptionally suited for this predictive task due to their ability to learn intricate patterns from data generated by experiments or FEM simulations.

Once such an accurate model is established, it can then be leveraged by various optimization algorithms to identify the optimal process parameters. While other AI driven optimization techniques, such as Genetic Algorithms (GAs) [

17] or Particle Swarm Optimization (PSO) [

18], are powerful for searching large parameter spaces and have been effectively used with ANN models, the initial development of a robust predictive model is a critical foundational step. Similarly, reinforcement learning (RL) [

19], another advanced AI technique, is typically more suited for sequential decision making or learning control policies in dynamic environments rather than for directly creating a static predictive map of the process parameters to springback. Therefore, for studies aiming to optimize processes based on accurate predictions, a strong focus on developing ANN/DNN-based models is a well-justified approach. Indeed, several studies have demonstrated the effectiveness of ANNs in springback analysis for solving or decreasing this problem. For instance, Spathopoulos and Stavroulakis [

14] developed an ANN model to predict springback at different locations on a S-rail part. The model yielded results that showed good agreement with those obtained from the FEM simulation, particularly in predicting springback trends and magnitudes. Narayanasamy and Padmanabhan [

15] compared the performance of regression and ANN models to predict springback angles. Their study showed that the ANN outperformed the regression model in terms of prediction accuracy. El Mrabti et al. [

16] simulated a deep drawing process using FEM simulation and conducted DOE experiments to collect data to train an ANN model. After training the ANN model, PSO was used to optimize the process parameters. Finally, by using the optimized parameters, they found that springback was reduced significantly.

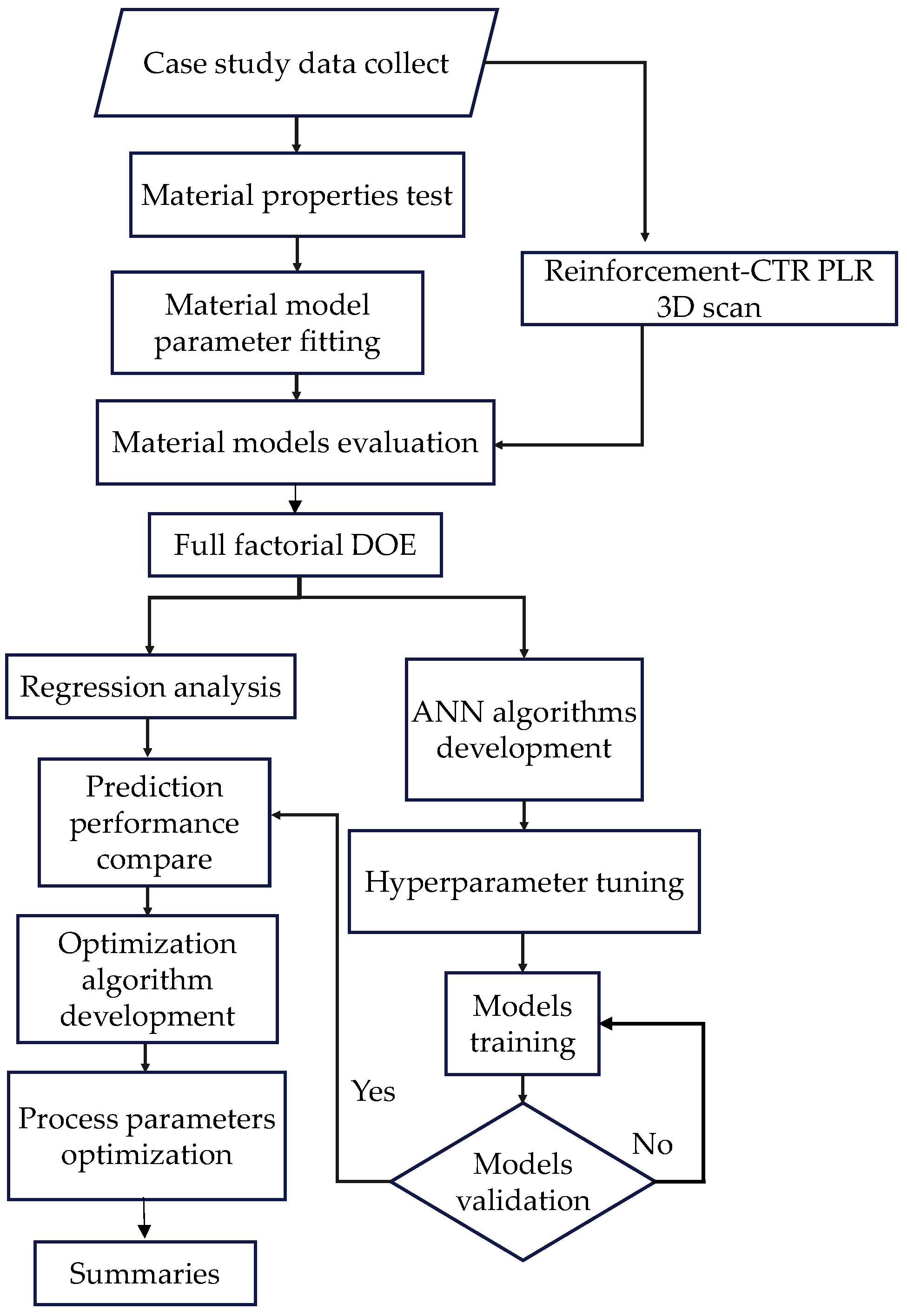

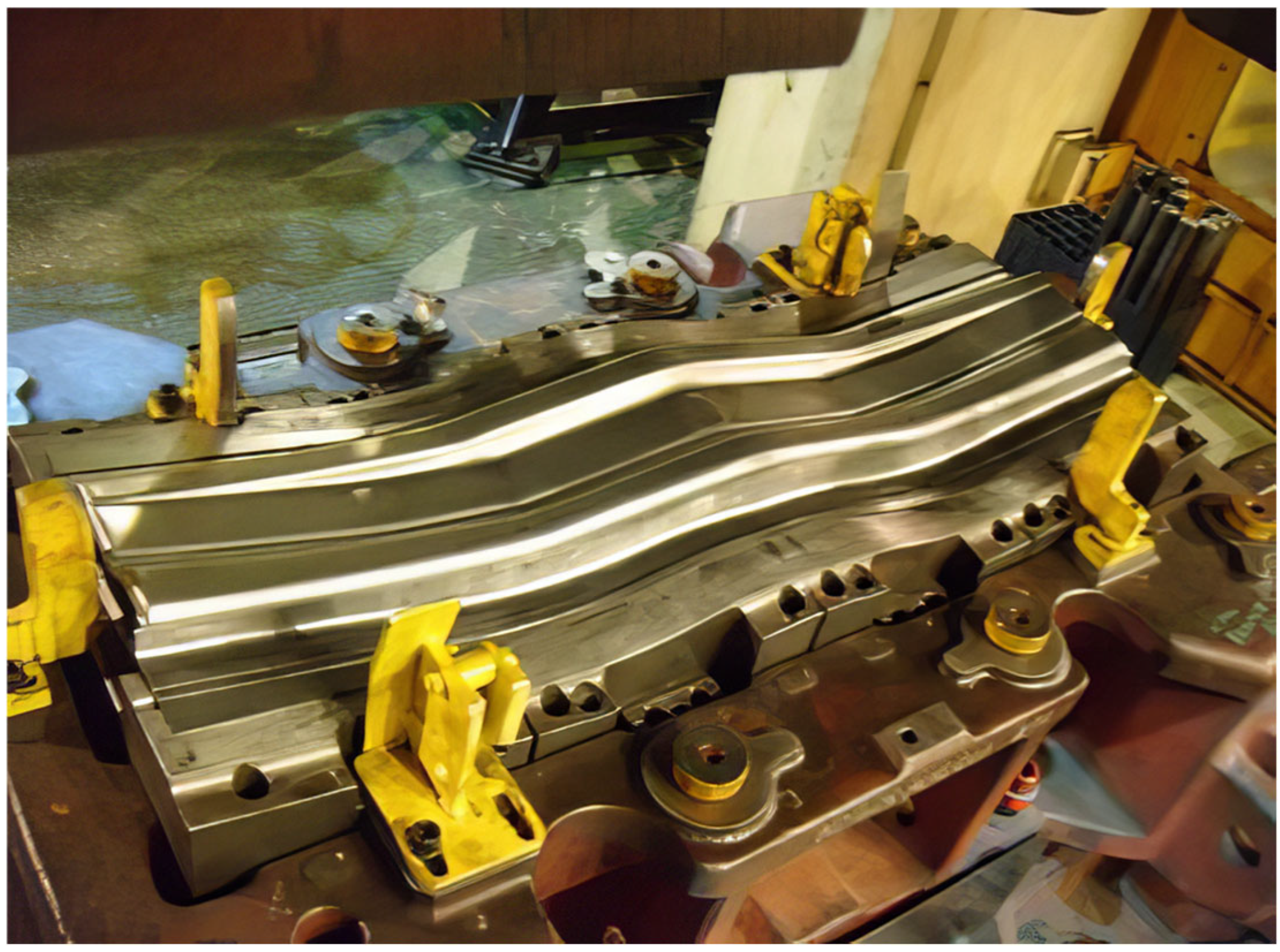

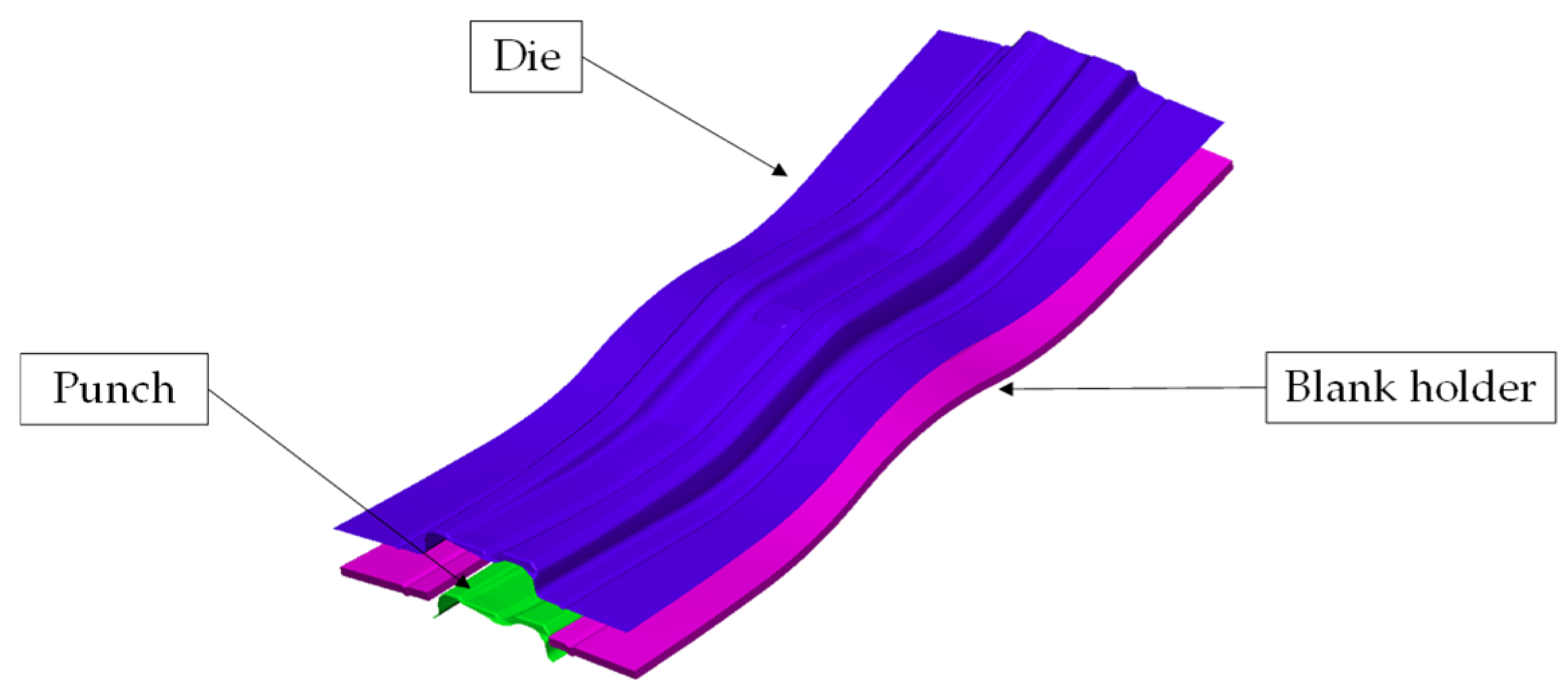

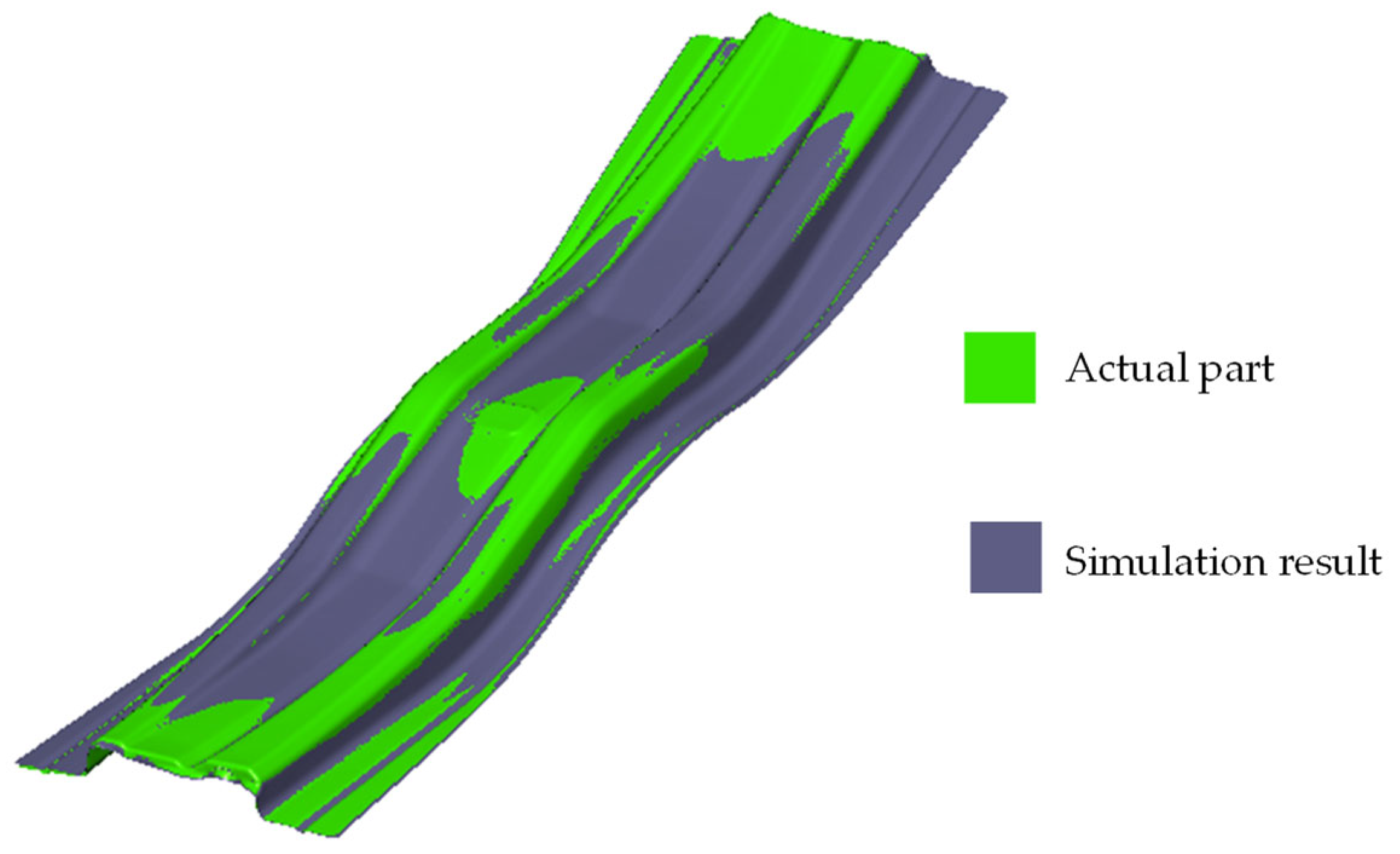

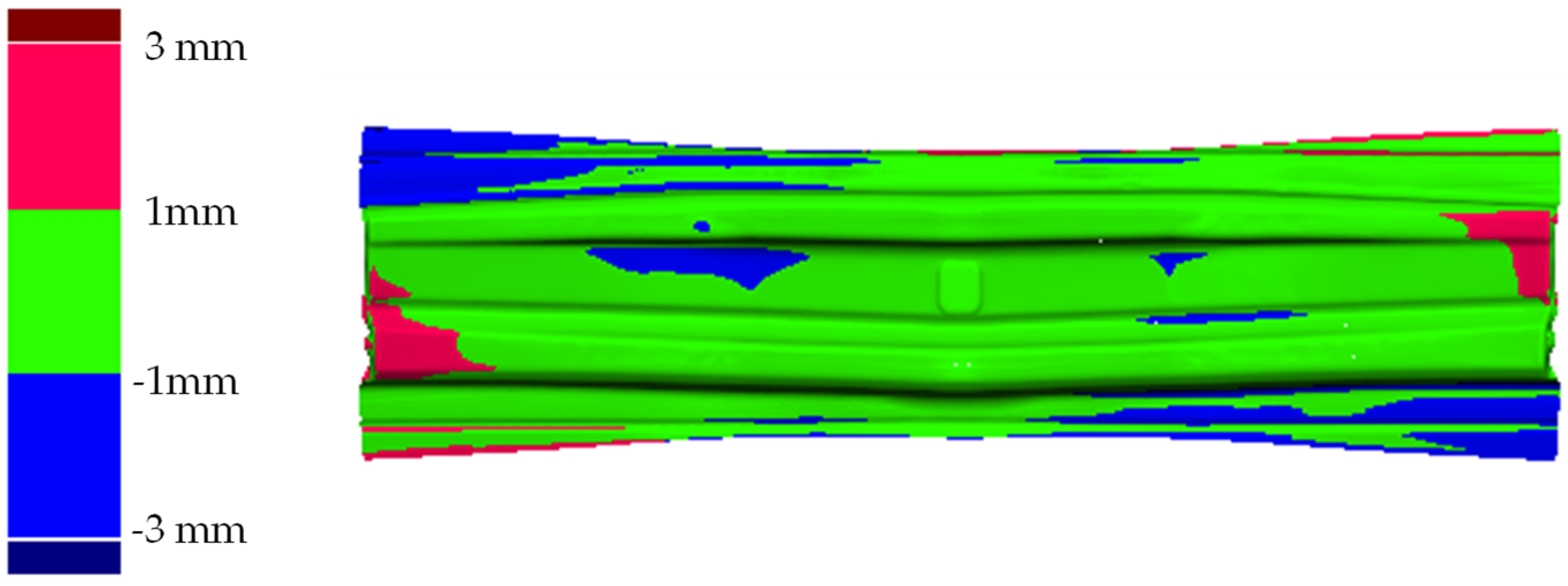

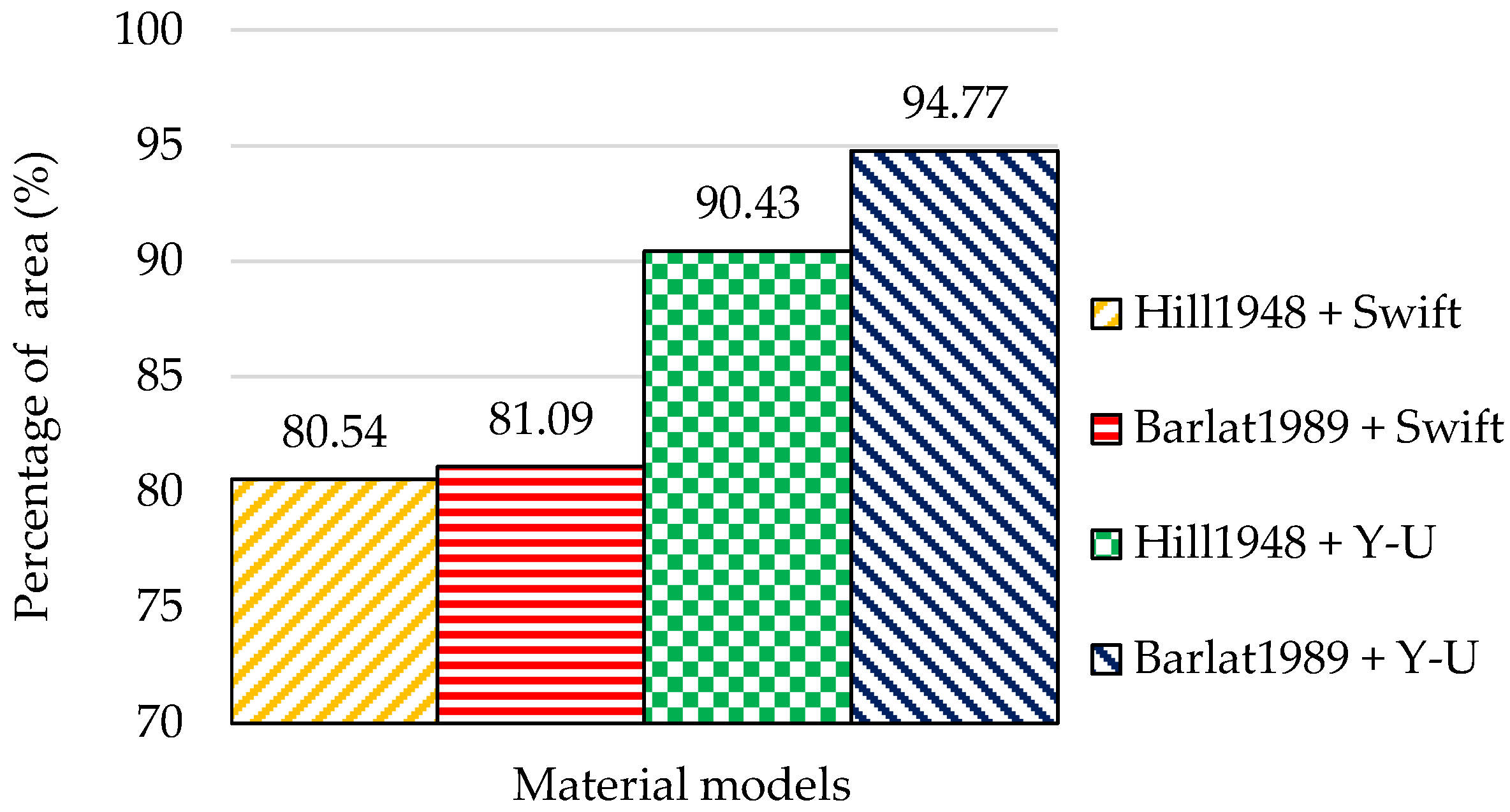

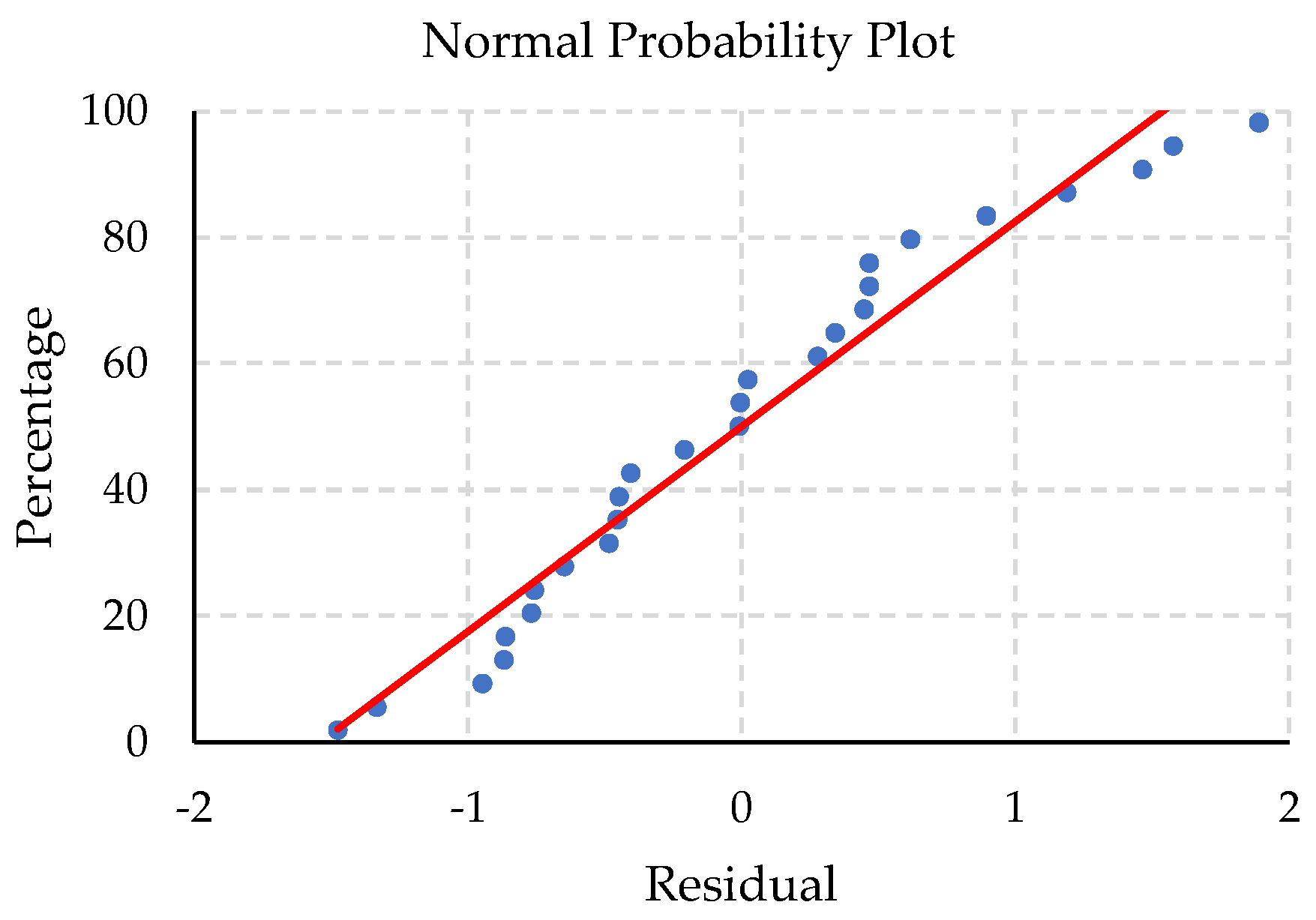

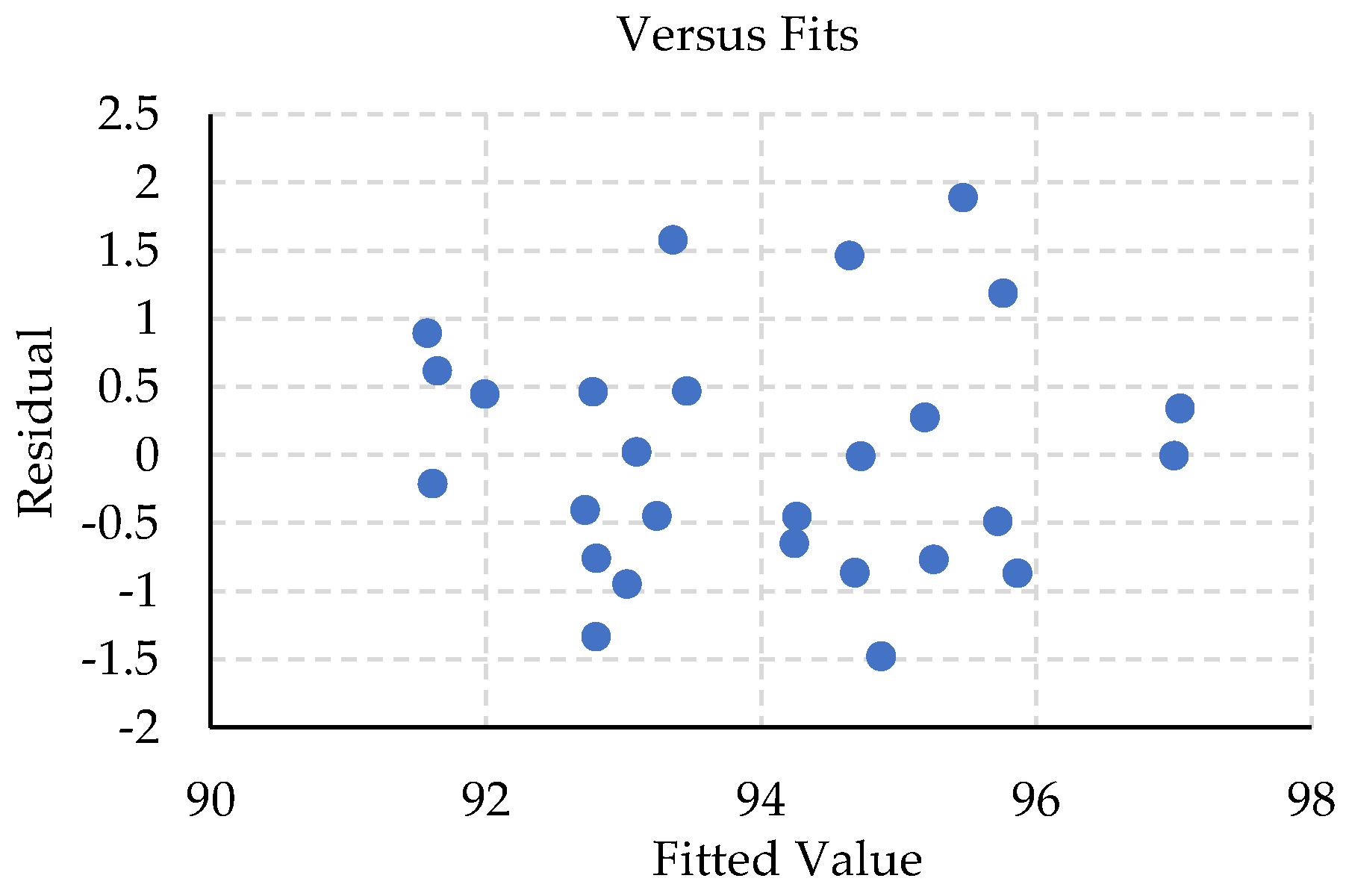

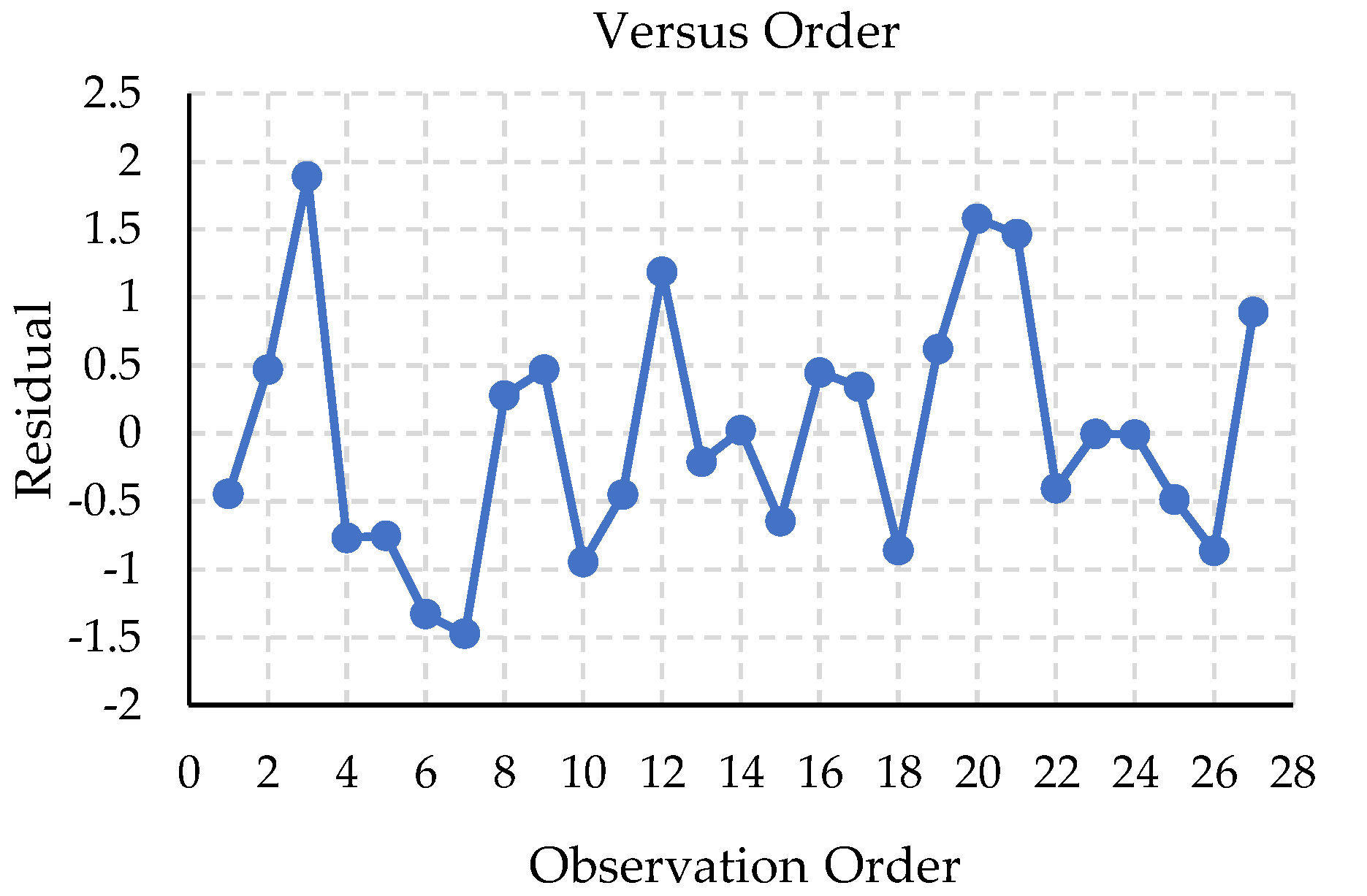

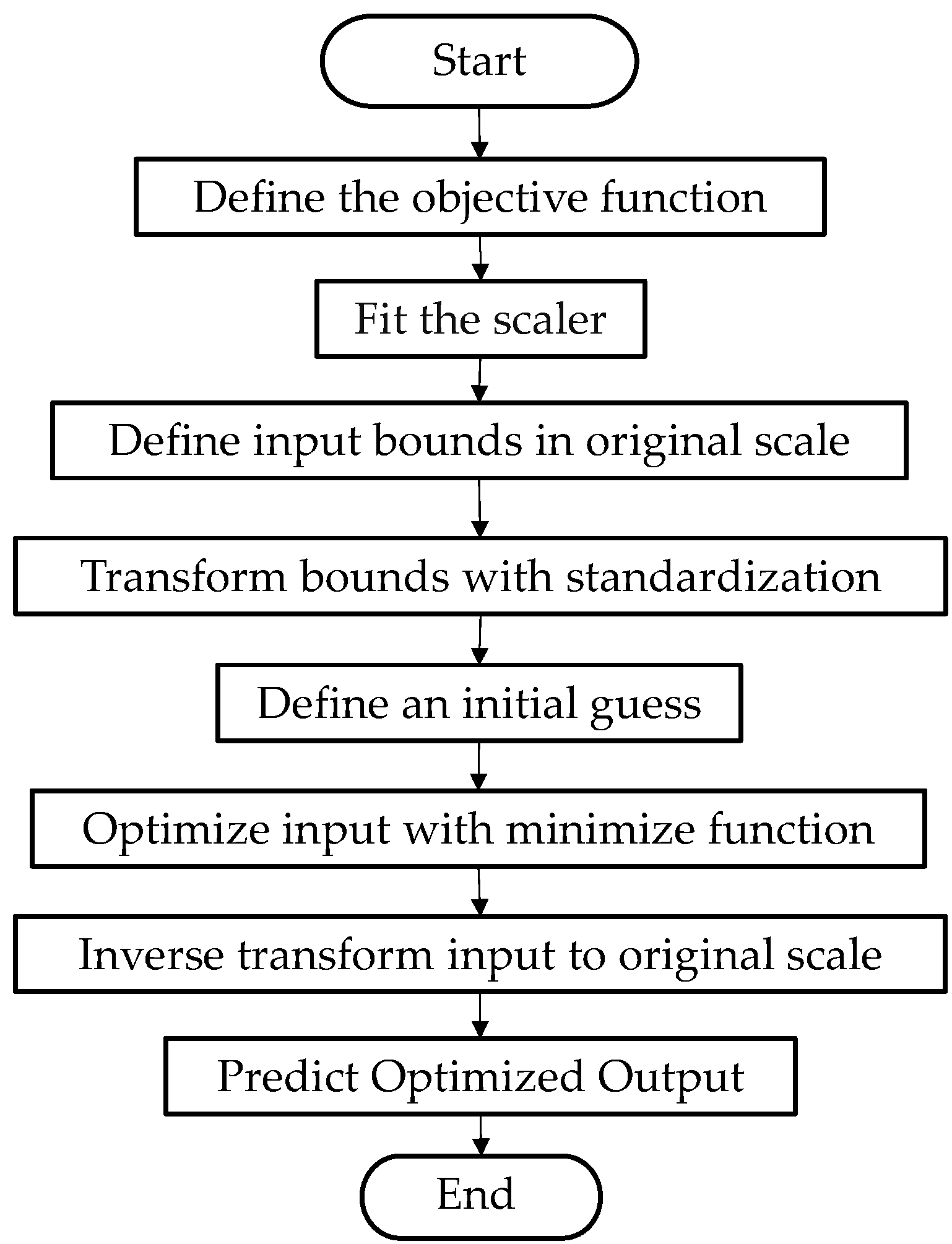

However, while FEM and traditional optimization methods are common, a comparison of various ANN architectures, particularly DNN with multiple hidden layers, for optimizing these process parameters to maximize the conforming area of a complex AHSS automotive part like the Reinforcement-CTR PLR remains an area requiring more detailed investigation. Specifically, the efficacy of different ANN complexities in capturing the springback behavior and their direct application to achieve strict dimensional tolerances over a large part area needs further exploration. Consequently, this research aims to use FEM simulation to predict the forming process of an industrial automotive part, the Reinforcement-CTR PLR. Four combinations of material models were compared in terms of prediction accuracy performance to select the most accurate springback prediction for use in optimization experiments. For the optimization experiments, a full factorial design was employed where three process parameters: blank holder force, die clearance, and blank width were varied. The springback result was obtained by measuring the percentage of area where the displacement between the predicted shape before and after springback occurred within the range of −1 to 1 mm. After the experiment, regression was used to create a prediction model. Meanwhile, different types of ANN algorithms were created and trained with data from simulation results, and all ANN models were compared to the regression model in terms of accuracy with data validation. The most accurate model was selected for use in optimizing the process parameters to minimize springback with an optimizing algorithm. Finally, the FEM simulation was conducted to verify the predicted result from the optimized procedure. For ease of understanding, the overall procedure workflow is shown in

Figure 1.

4. Conclusions

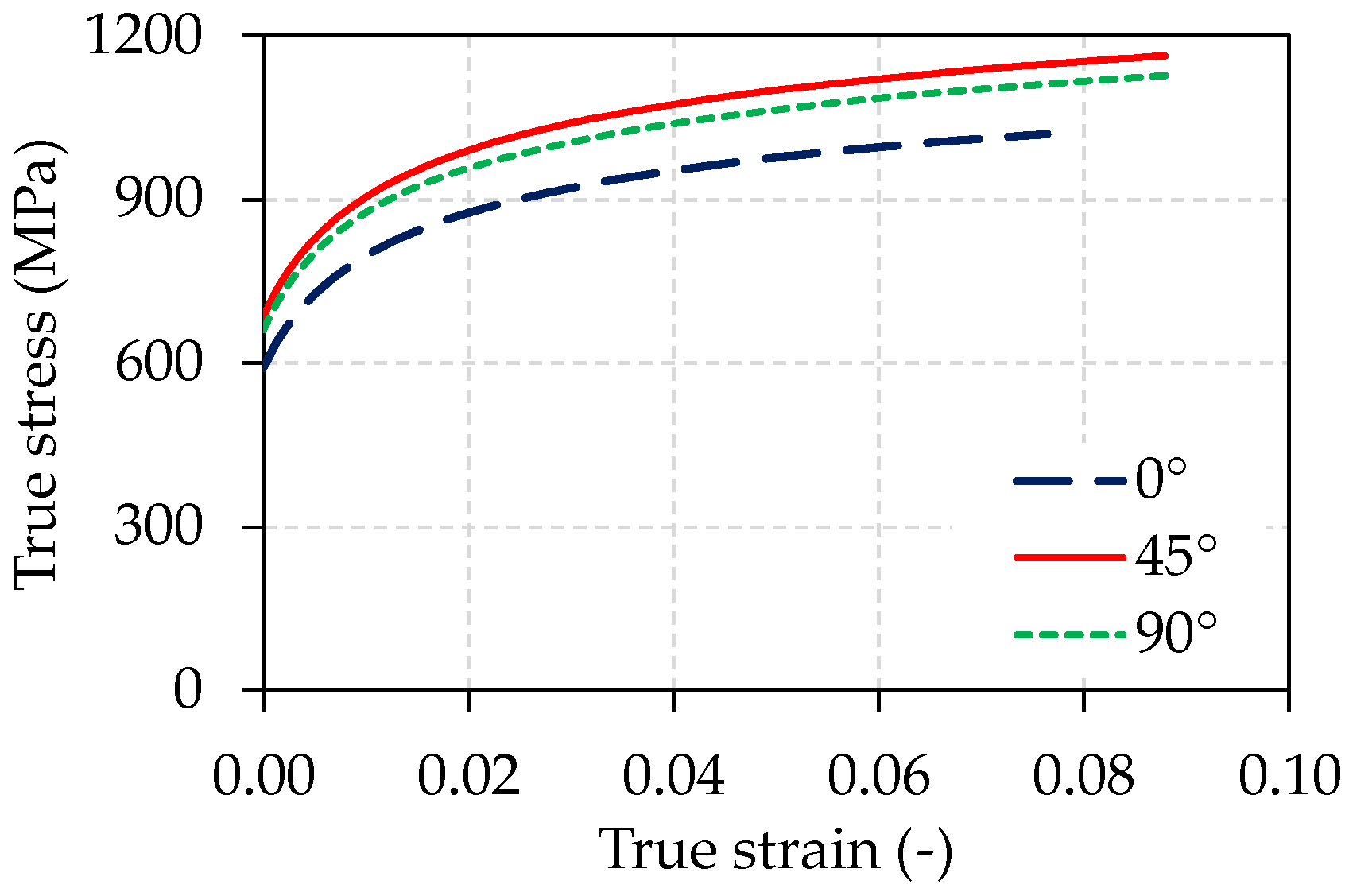

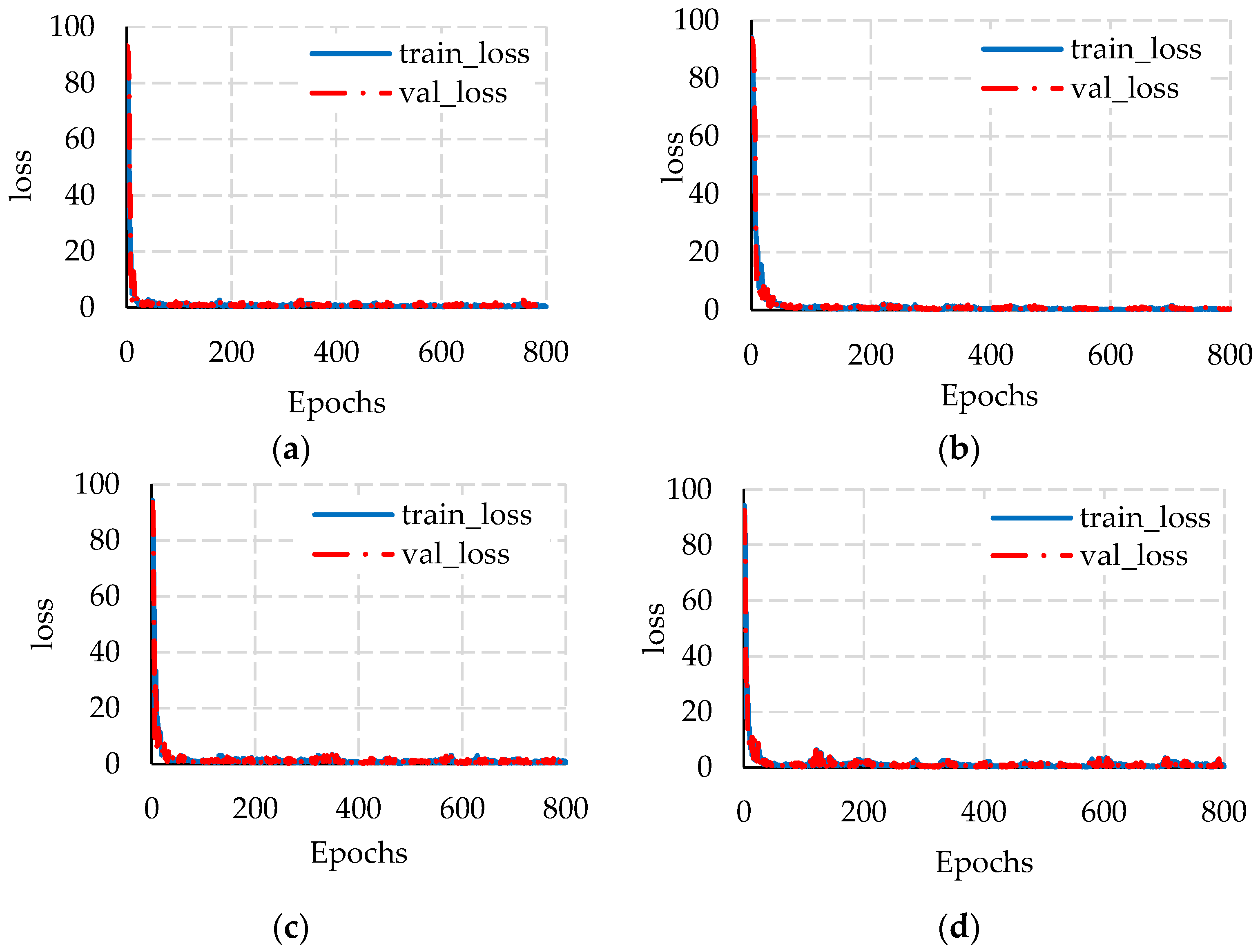

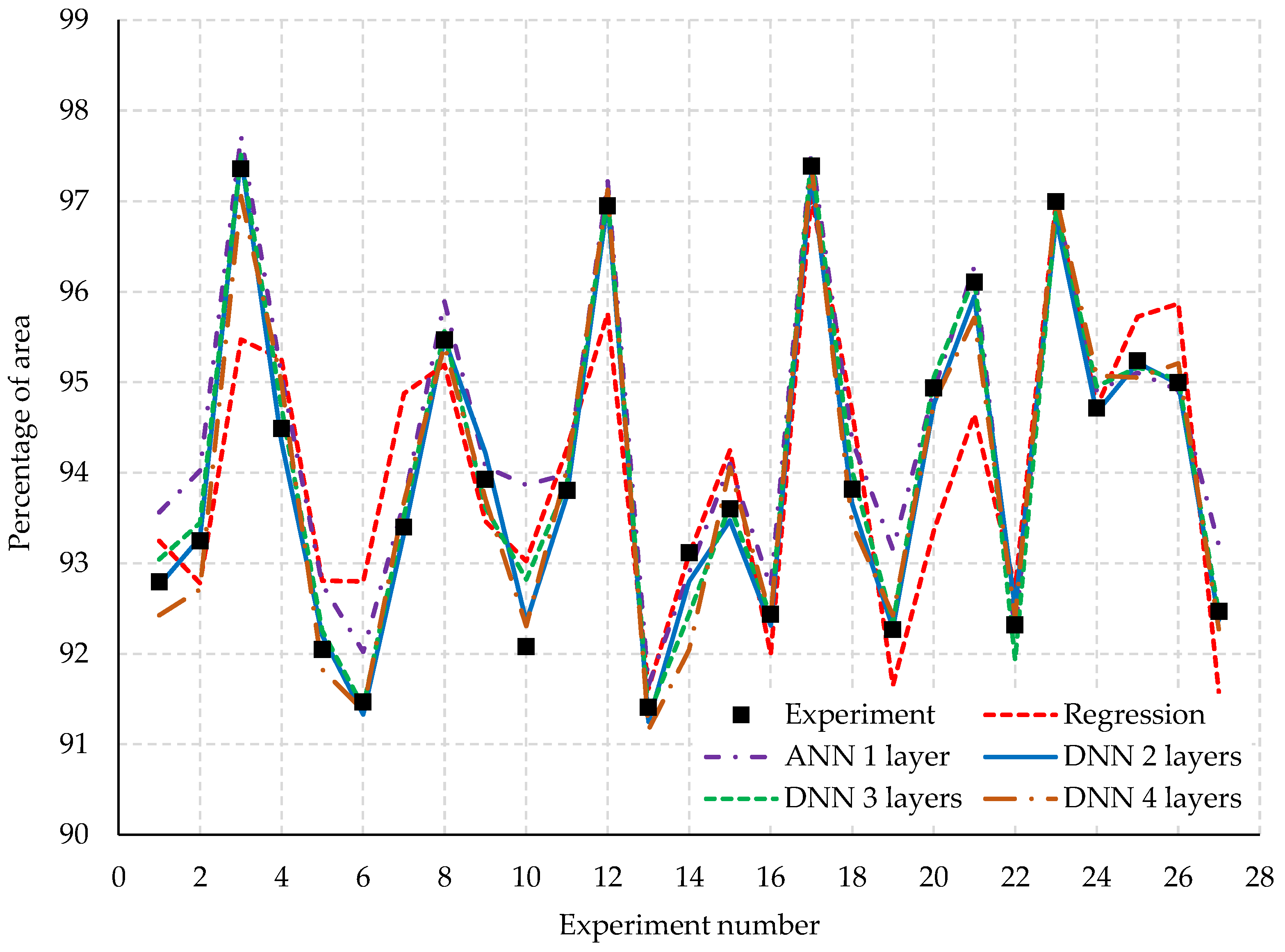

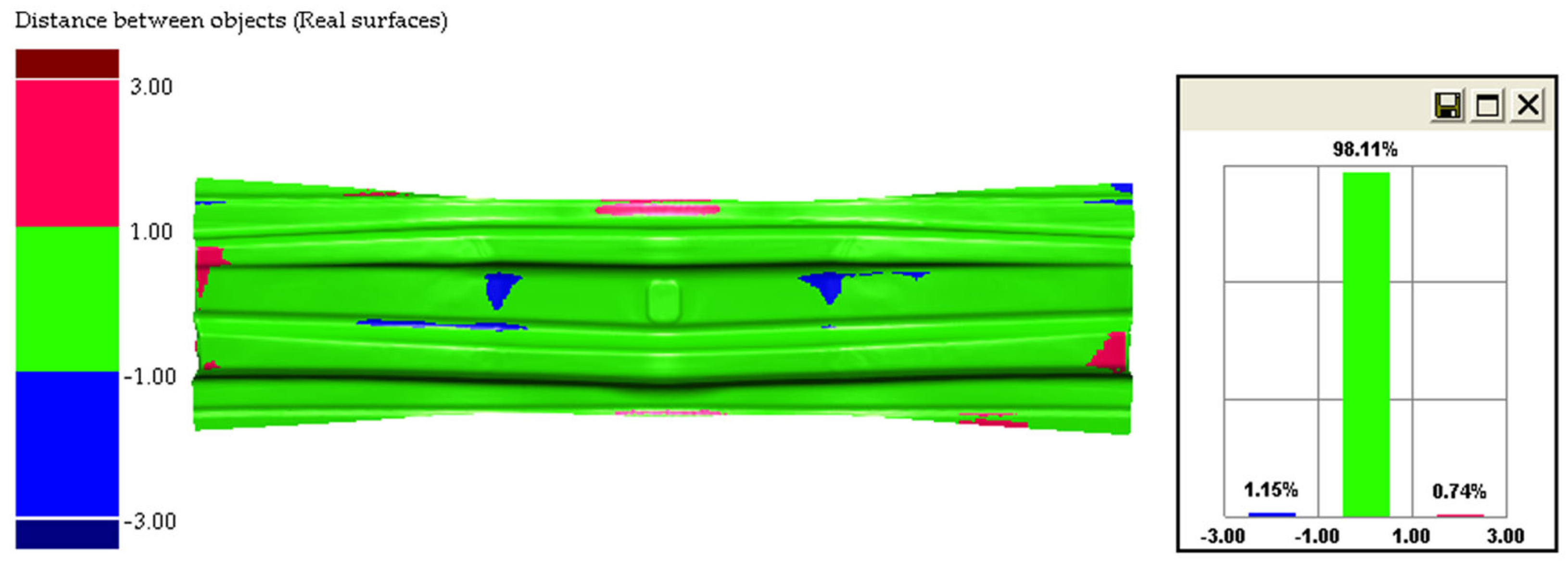

This research investigated the optimization of the process parameters to minimize springback in the Reinforcement-CTR PLR forming process. The automotive part was produced from AHSS grade JSC980Y. The four material models’ prediction performance was compared. Three process parameters: blank holder force, die clearance, and blank width were optimized. The optimization objective maximized the percentage of area within a specific displacement range between the desired shape and the predicted shape after springback occurred. In the simulation stage, the Barlat 1989 combined with the Y–U model was used in FEM simulation as the most accurate material model. The experiment was conducted with a full factorial design. Each process parameter varied with three levels. The experiment data were used for analysis with statistical regression. Additionally, the four types of ANN models were developed to compare the accuracy prediction performance with the regression model and the experimental results. Finally, the DNN with two hidden layers was selected to predict and optimize the process parameters to reach the maximum percentage of the area. The experimental results can be summarized as follows:

The use of the Y–U hardening model is more accurate than the isotropic hardening model.

The most accurate material model in the FEM simulation for this work is the Barlat 1989 combined with Y–U model.

The DNN with two hidden layers is the most accurate predictive tool compared to regression and other ANN models.

The ANN model can significantly exceed the regression models in terms of prediction accuracy.

The optimal process parameters of this work are a blank holder force of 27.62 tons, die clearance of 1 mm, and blank width of 290 mm, which achieved the percentage of area of 98.05% when optimized with an optimization algorithm and predicted by the two hidden layers DNN model at 98.11%, as obtained from the experiment.

These determined results suggest that DNN models offer a powerful and adaptable tool for optimizing complex forming processes. The method we presented is not just for this specific part or material. It combines accurate material modeling, FEM simulation, and DNN-based prediction for optimization. This creates a general approach that can be used for many different automotive parts and other AHSS types to reduce springback. As we showed, being able to accurately predict and reduce springback helps manufacturers achieve very precise shapes and, as demonstrated, can significantly improve manufacturing efficiency, reduce costly trial and error in die compensation, and enhance overall product quality. This contributes to faster development cycles and cost savings in the production of lightweight and safe vehicle structures in the automotive industry.

While the results of this study are promising, it is important to acknowledge certain limitations and highlight avenues for future research. The findings presented are specific to the AHSS grade JSC980Y and the Reinforcement-CTR PLR automotive part geometry.

For training and testing our ANN/DNN models, we split our data (80% for training, 10% for validation, and 10% for testing). This is a common way to start, especially when comparing several model designs. However, our dataset only had 27 experimental points. With such a small dataset, the way data are split can greatly affect the results. A method called K-fold cross-validation [

44] is often better for small datasets. It uses all data for both training and testing in different rounds, which shows a more reliable measure of how well the model performs with new data. K-fold does take more computing time, especially if we also need to adjust many model settings (hyperparameters) for different ANN designs. For future studies that need the most thorough model checking, using K-fold would be very helpful.

Furthermore, the Yoshida–Uemori hardening model was calibrated using single-cycle tension–compression data due to equipment limitations, as mentioned in

Section 2.2.2. While this provided the most accurate springback prediction among the models tested for the primarily monotonic loading conditions in critical regions of our specific forming process, incorporating multi-cycle test data for Y–U model calibration would undoubtedly enhance its predictive reliability for forming processes involving more complex cyclic loading paths.

Future research could therefore focus on (1) applying and validating this methodology with other AHSS grades and diverse automotive part complexities; (2) expanding the range and types of process parameters investigated, potentially exploring regions beyond the specific parameters established in this study; (3) incorporating more comprehensive material characterization data, including multi cycle tension–compression tests; (4) implementing K-fold cross-validation for more rigorous model evaluation and comparisons across all predictive techniques; and (5) exploring hybrid AI models or alternative machine learning techniques to potentially achieve further improvements in prediction and optimization accuracy for springback.