Abstract

The miniaturization of smart materials has become a new trend in the modern manufacturing industry due to its enormous application in the aerospace, biomedical, and automobile sectors. Nickel–titanium (NiTi)-based binary shape memory alloys (SMAs) are one of the smart materials with certain supreme features like shape memory effect, pseudo-elasticity, high ductility, strong corrosion-resistance, and elevated wear resistance. For this, several micro-machining processes have been developed to machine NiTi SMAs. This paper summarizes all of the conventional and non-conventional micro-machining processes employed to machine NiTi SMAs. In this review process, the surface integrity, dimensional accuracy of the machined surface, cutting force and tool wear analysis during conventional and non-conventional micro-machining of NiTi SMA are evaluated mostly with the aid of input process variables like cutting speed, depth of cut, width of cut, types of coolants, tool coating, discharge voltage, capacitance, laser fluence, pulse duration, scan speed, electrolysis concentration and gap voltage. The optimization of process parameters using different methods during conventional and non-conventional micro-machining of NiTi SMAs is also analyzed. The problems faced during conventional micro-machining of NiTi SMAs are overcome by non-conventional micro-machining processes as discussed. The present study aims to recognize potential developments in the improvement of the micro-machinability of NiTi SMAs.

1. Introduction

Micro-machining is used with greater dimensional precision and accuracy to manufacture micro (1 to 500 μm) and meso (500 μm to 10 mm) scale parts. With the rapid increase in the development of micro-electro-mechanical-system systems (MEMS), the market for micro-machining is growing in the industry [1,2,3]. Miniaturization of components is beneficial for the aerospace, biomedical, automobile, electronics, and robotics industries. Micro-systems have vast applications such as in medical stents, actuators and sensors of aerospace, fuel cells, fuel injection nozzles, etc., which can improve our daily life and health care [4,5,6]. As per the “Micro Meso Mechanical Manufacturing (4M) Association”, more than one part in meso size is considered a micro-part. Micro-machining is broadly categorized into two parts: one is the conventional or traditional tool-based micro-machining techniques, and another is the non-conventional or non-traditional advanced micro-machining techniques. The micro-tool and the workpiece make direct physical contact in traditional micro-machining processes. Due to that, the tool life is shorter in these processes. The cutting tool should be 30–35% harder than the job in the conventional micro-machining process. The energy is utilized to rotate the tool or move the job in the conventional micro-machining process. In non-conventional micro-machining, on the other hand, there is no physical contact between the micro-tool and the workpiece.

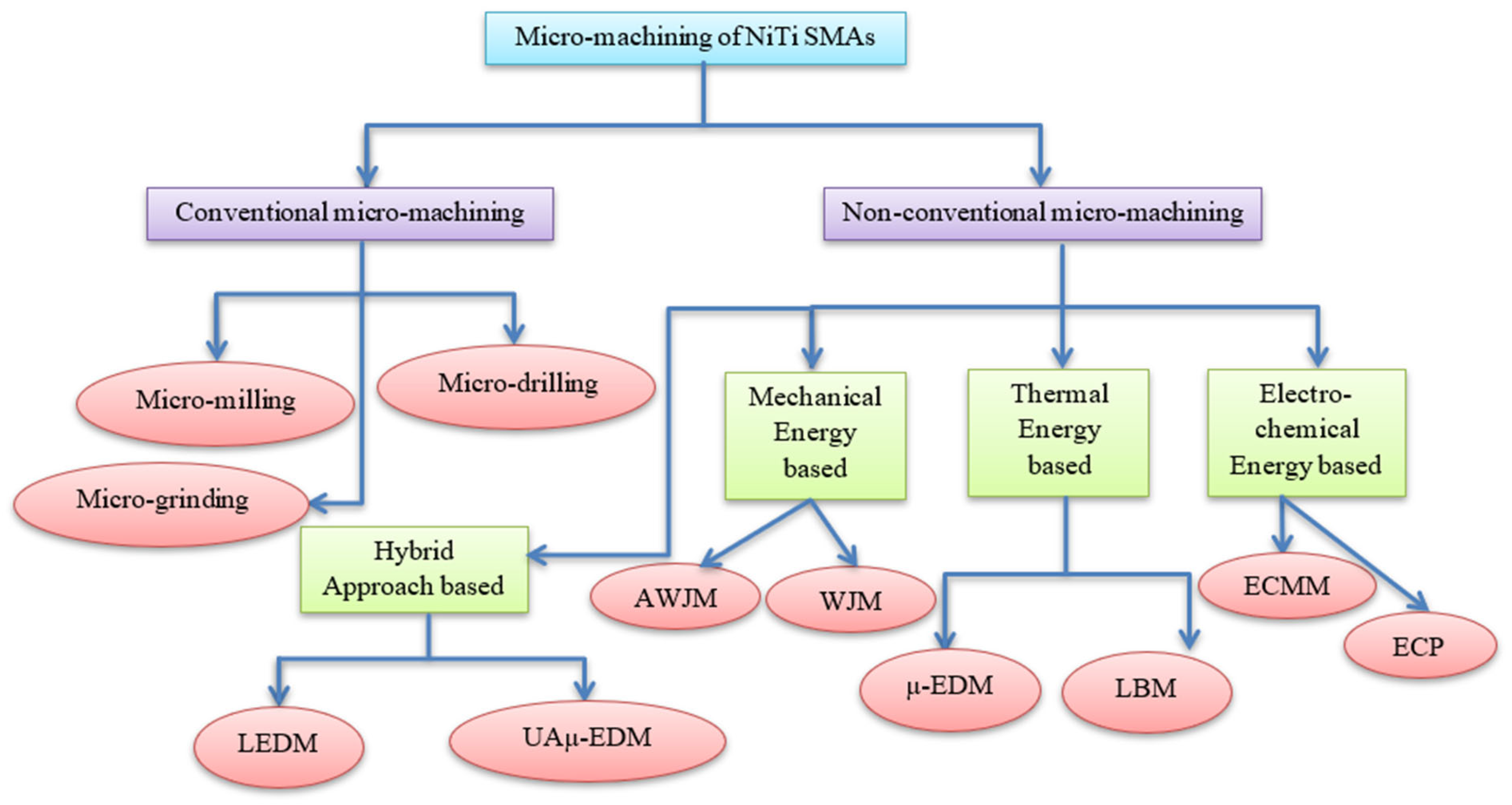

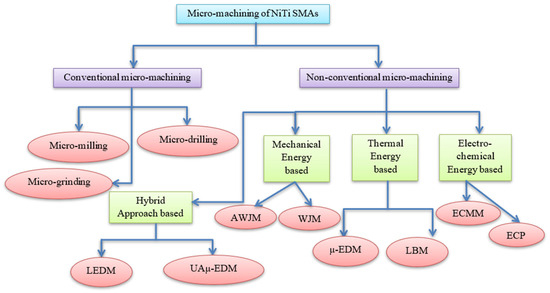

The energy (thermal, mechanical, electrical, etc.) is directly utilized here to remove the material. The efficiency of the non-conventional micro-machining process does not depend upon the physical and mechanical properties of the workpiece material. Due to no physical contact, tool life is longer in non-conventional machining processes. Micro-turning, micro-milling, micro-drilling, etc., are categorized into traditional micro-machining processes. Non-conventional micro-machining processes are subdivided into three categories, i.e., thermal energy-induced micro-machining, mechanical energy-induced micro-machining, and electrochemical energy-induced micro-machining. Some of the micro-machining processes under this category are micro-electrical discharge machining (µ-EDM), laser beam machining (LBM), electrochemical micro-machining (ECMM), micro-ultrasonic machining (µ-USM), micro-water jet machining (µ-WJM), etc. [7]. The micro-machining processes used for NiTi SMAs are given in Figure 1.

Figure 1.

Micro-machining techniques for NiTi SMAs.

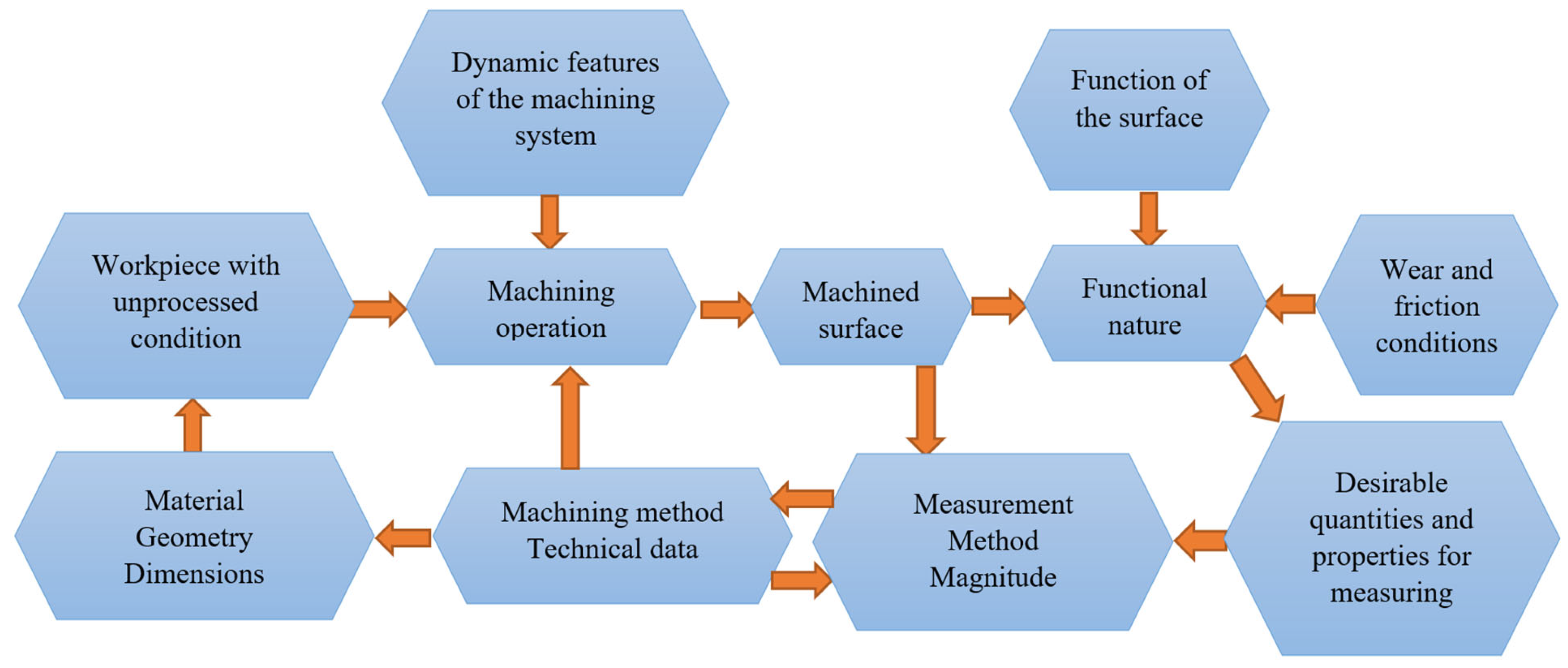

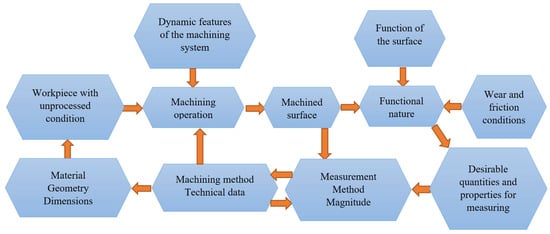

The quality of a product is the measure of its surface finish. The machined surface layer is plastically deformed by the variation in temperature during the machining process. The flow strain due to temperature variation can be managed by selecting optimum machining parameters. Actual optimum process parameters control the temperature generated during machining [8]. The product development can be measured by introducing micro- or nano-level complex structures in the machined surfaces without affecting their natural performance. There is a relationship between the process variables, surface functions, and machined surface, as described in Figure 2 [9]. Some kinds of alloys have high mechanical strength, large deformation, and corrosion resistance. Machining these types of hard materials is a big challenge for the manufacturing sector. The properties of such work material positively influence the machining parameters.

Figure 2.

Relationship between surface function, process characteristics, and machined surface [9].

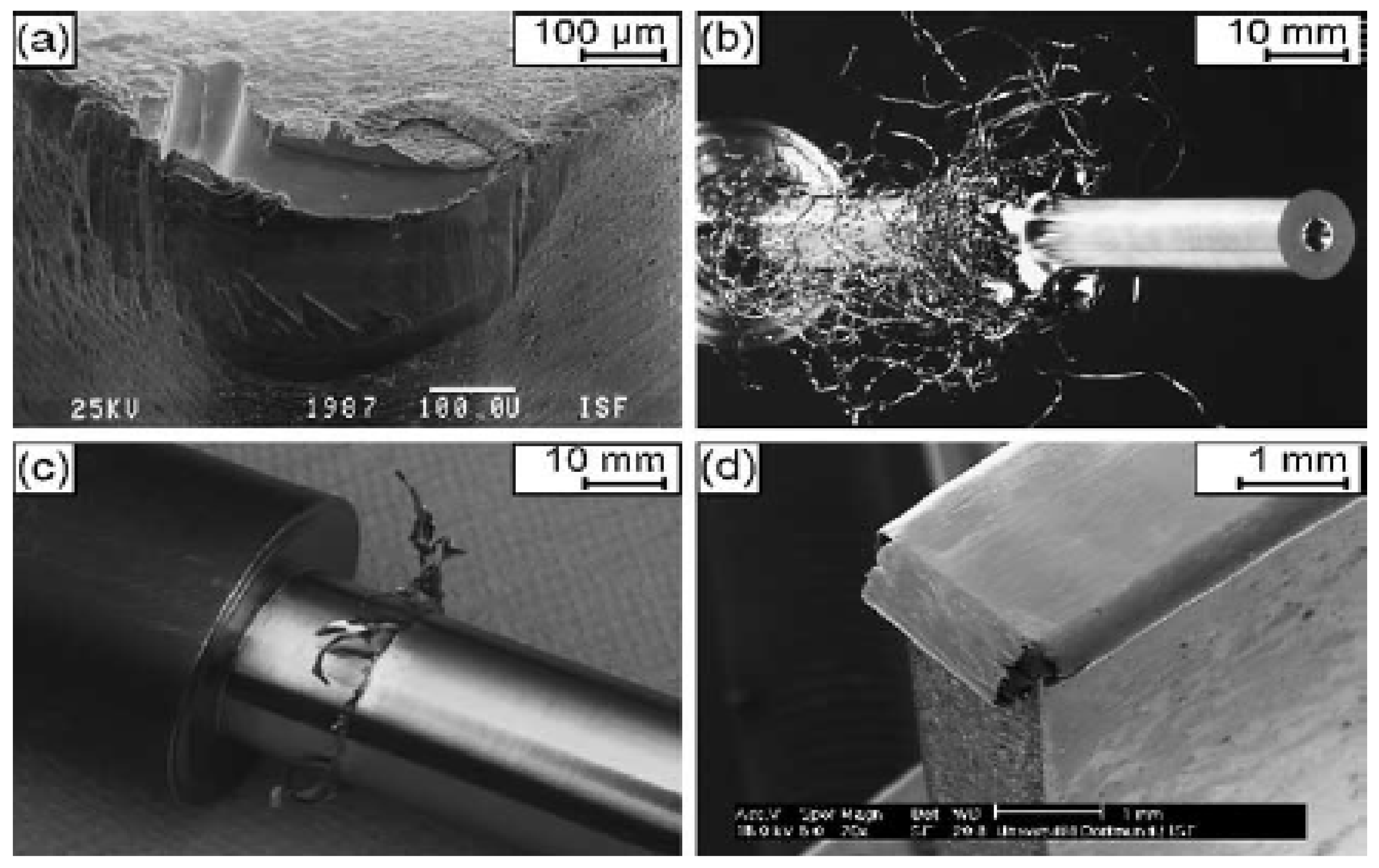

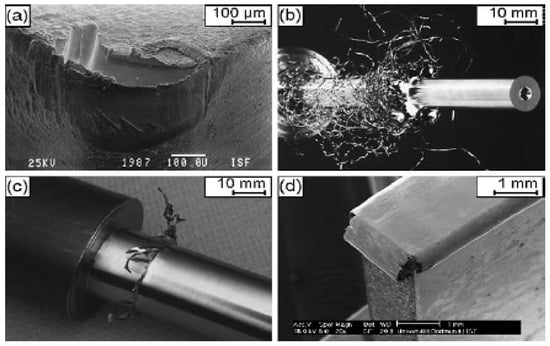

A large amount of burr formation occurred during the machining of NiTi SMAs due to its high ductility and strain recovery rate [10]. Due to the formation of stressed martensite, work-hardening impact, undesirable breaking of chips phenomena, and adhesion behavior, the machining of NiTi SMAs is very hard (Figure 3). These characteristics are responsible for generating extensive tool wear, which degrades the machinability [11,12]. NiTi SMAs are one of the hardest materials to cut because of their excellent mechanical strength, high ductility, and massive corrosion resistance. They have a lot of applications in the aerospace, automotive, and biomedical fields because of their special characteristics, such as shape memory effect (SME) and super elasticity.

Figure 3.

Difficulties during machining of NiTi SMAs; (a) immense tool wear, (b) adhesive types of chip formation, (c) Burr creation after turning, (d) grinding [12].

Nowadays, NiTi components have a vast application in the MEMS industry due to their large strain recovery rate [13]. Therefore, miniaturization of NiTi components is required to produce micro-elements for many of these industries. Various micro-machining processes are used to fabricate NiTi SMAs, which are required for the medical and aerospace industries. However, due to the advancement of the industry, it is needed to illustrate a comparison between various micro-fabrication processes for NiTi SMAs. It determines the flaws for the micro-fabrication of NiTi SMAs and helps to choose the best suitable micro-machining process for NiTi SMAs. It also gives the future direction of the industry for the micro-fabrication of NiTi SMAs. Few review articles presented the machining of NiTi SMAs in a broad aspect [14,15,16,17]. A very limited review was carried out for micro-machining of NiTi SMAs in a descriptive manner [18].

This paper briefly lists and illustrates all the micro-machining processes used to machine NiTi SMAs. All the measurements during micro-machining processes to fabricate NiTi SMA are conducted as per the ASTM standard in the respective literature. A minimum of three repetitions were conducted by the respective literature during the micro-machining process of NiTi SMA. The study outlines the micro-machining processes for NiTi SMAs, such as micro-milling, micro-drilling, micro-grinding, µ-AWJM, μ-EDM, LBM, etc. The second section of this research article deals with the surface integrity of any machining product. The third section discusses the properties of NiTi SMA and its various phase structures. The fourth and fifth sections review the conventional and non-conventional micro-machining of NiTi SMAs. The sixth section covers the use of optimization tools applied during the micro-machining of NiTi SMAs. The last section talks about the future trends and directions, followed by critical observations.

2. Nickel–Titanium (NiTi) SMAs

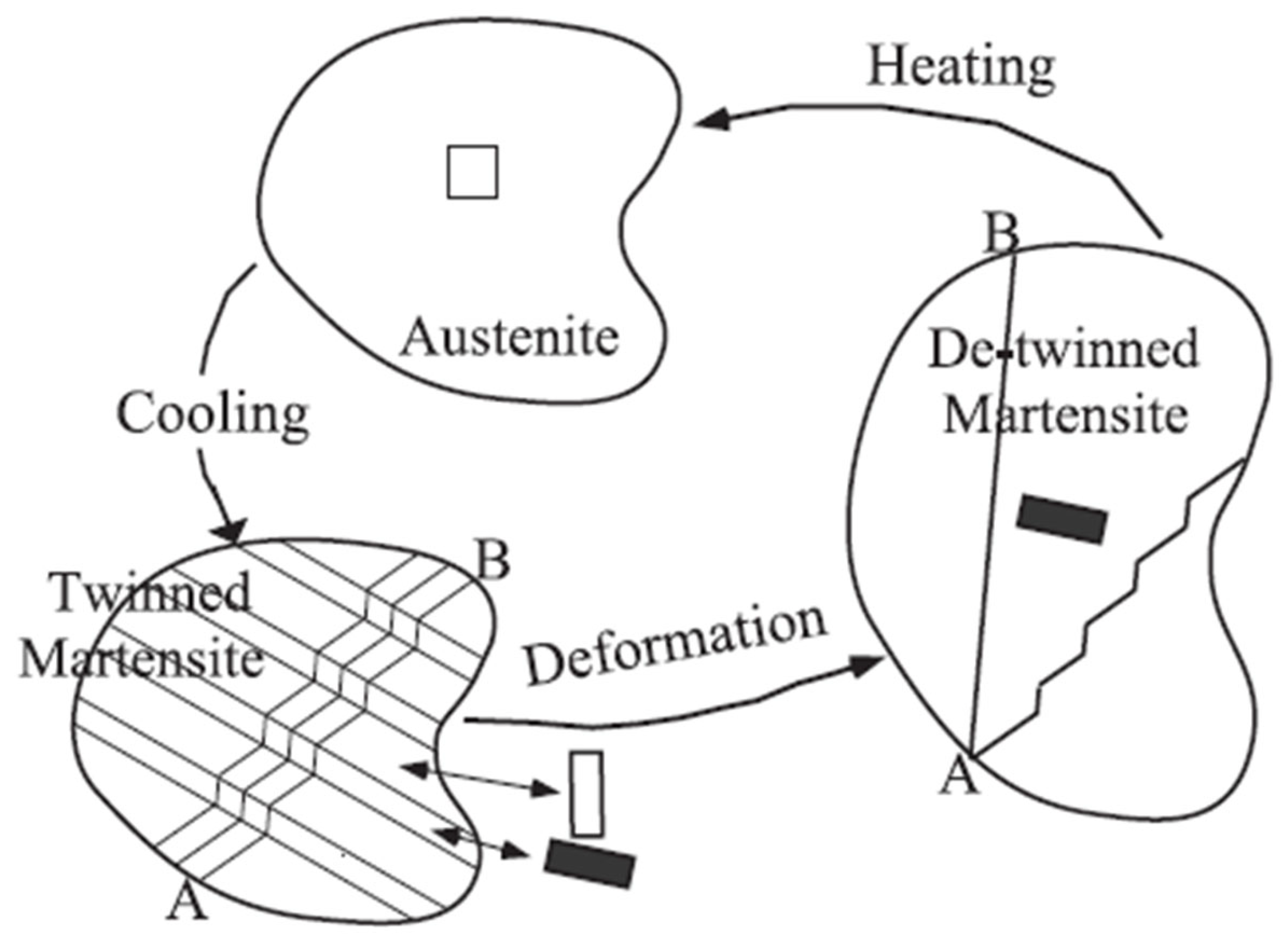

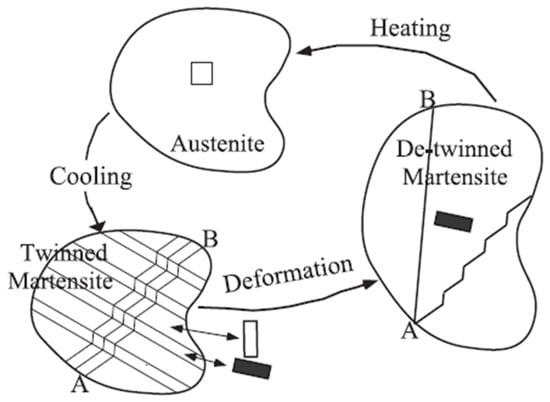

NiTi SMAs are one of the unique smart alloys that have several characteristics that can be seriously bartered in a controlled manner by the external application of stress, temperature, and chemical compounds [19]. They have a special ability to memorise shape at a low temperature and regain immense deformation delivered at a low temperature on thermal activation [20,21]. The property by which it recovers a large amount of strain at low temperature upon heating is known as SME. Olender first discovered shape memory alloys in 1932 in the Au–Cd alloy system [22]. Nickel–titanium, nickel–copper–aluminium, copper–zinc–aluminium, and silicon–iron–manganese-based SMAs are commercially available in the industry. NiTi alloys, discovered by Buehler and Wiley in 1961 [23] and known as Nitinol, are the most applicable SMAs and show a much higher SME and superelastisity (SE) than the other SMAs in the present smart industry. The alloy consisted of nickel at 55% wt and titanium at 45% wt. NiTi is one of the most sensitive SMAs in terms of its superior ductility, high resistance to corrosion and abrasion, and higher tensile strength [24]. All the useful smart properties, such as shape memory effect and SE, were discovered in NiTi alloys. No influence took the place of the other elements on the equilibrium of NiTi alloys. Over twenty-five binary, ternary, and other alloys contribute to the SME in the current manufacturing sector [25]. The NiTi SMA is available in two distinct phases, i.e., low-temperature and high-temperature phases [26]. At high temperature, it is in the austenite phase, which is a BCC structure, and at low temperature, it is in the martensite phase, which is an FCC structure. The application of heat and force can be accomplished by martensite to austenite or conversion to the opposite. This conversion is a diffusionless solid-to-solid phase conversion [27]. This alteration gave a few intermediate phase structures, such as R-phase, bainite formation, and a structure similar to rubber. Chemical composition, thermal treatment, and manufacturing procedure regulated this phase transformation. The manufacturing process has a large dominance on the features of NiTi SMA [28]. Austenite is transferred to martensite upon cooling in the absence of external stress, known as the forward phase transformation. Upon heating, martensite is again transformed to the austenite phase, known as reverse phase transformation [29]. SME and pseudo-elasticity are the two most versatile properties of NiTi SMA. Under no stress condition, the austenite, upon cooling, is transformed into the twinned martensite; after that, when mechanical stress is applied, it transforms into the detwinned martensite. Upon heating, the detwinned martensite is again transformed to the previous austenite phase. This transition is called a one-way shape memory effect (OWSME) since the shape shift occurred only at the time of heating (Figure 4). There are four temperatures associated with OWSME called martensite start (Ms), martensite finish (Mf), austenite start (As) and austenite finish (Af) [30].

Figure 4.

OWSME of NiTi SMAs [21].

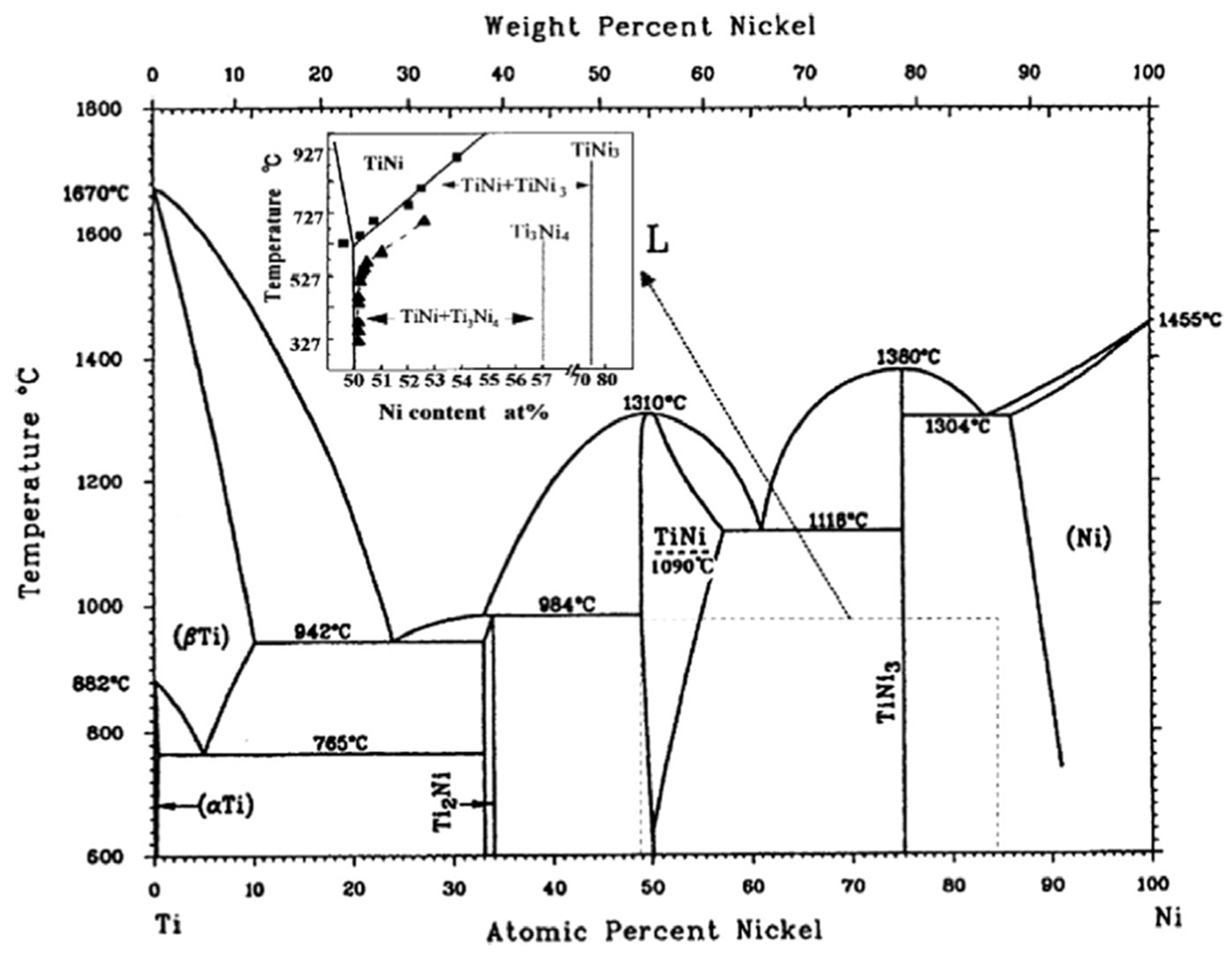

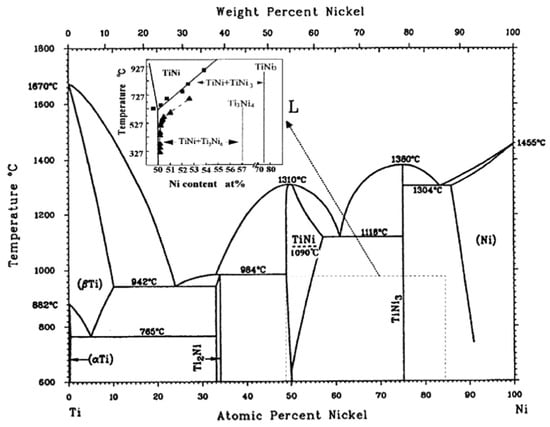

The phase transformation temperatures (Af, Mf, As, and Ms) are affected by the fabrication process, heat treatment process, and chemical composition of the NiTi SMA [31]. When the NiTi SMA remembers both the high and low-temperature shapes, it is called the two-way shape memory effect (TWSME) [32,33]. Other hand, when external stress is applied to NiTi alloys (above As temperature) beyond the critical stress, then the austenite becomes unstable and stress-induced martensite starts to form. Upon unloading, the martensite becomes unstable and transforms back to austenite, and this phenomenon is called pseudo-elasticity or SE [34]. It has been used for storing energy from deformation [35]. NiTi SMA has a large application in the medical, automobile, aerospace, and electronics industries [36,37,38,39] due to its superior SME and SE. The phase diagram of NiTi shape memory alloy is discussed in Figure 5 [40]. It contains thermodynamically stable phases of NiTi, Ni3Ti, and Ti2Ni. The central region consists of the pure binary equiatomic NiTi phase. It is bounded by Ni3Ti and Ti2Ni phases at the two boundaries [40,41]. There is a new phase, Ni4Ti3, observed during the ageing of Ni-rich NiTi SMA at low temperature and a shorter time duration. This new phase (Ni4Ti3) modifies the phase transformation temperature and improves the shape memory properties [42,43]. Zhang et al. [44] improve the elastocaloric effect of nitinol SMA through Ni4Ti3 nano-particle precipitations. It lowers the thermal hysterics, which increases the cyclic stability at enhanced the mechanical strength.

Figure 5.

Binary phase diagram of NiTi SMA [40].

3. Applications of NiTi SMAs

NiTi SMA has a huge application in the automobile, aerospace, biomedical, civil structure, and robotics industries due to its unique properties like SMA, biocompatibility, corrosion resistance, nonmagnetic, and pseudo-elasticity [45,46]. Due to large strain recovery and high corrosion resistance, NiTi has many applications in the components of the MEMS industry [47,48]. NiTi SMA can also be used as a sensor and actuator in the modern manufacturing industry. Most of the equiatomic NiTi alloys are used in the biomedical and automotive industry [49,50,51]. SMA micro-actuators have a huge application in the aerospace, medical, electronic, and robotics industries [52]. The number of actuators and sensors is increasing rapidly in modern vehicles due to the demand for more comfort and safety and better performance. Most of the demands are fulfilled by nitinol as its operational temperature lies in the environmental range for which a passenger vehicle exists [53]. Nitinol SMAs are used as an alternative to electromagnetic actuators in the present automotive industry [54].

Due to the unique properties of nitinol, it can handle high dynamic loads and geometric complexities. It made nitinol a perfect smart alloy for aerospace applications. Nitinol has been used as an actuator, vibration damper, manipulator, sensor, and inflatable structure in the modern aerospace industry [55,56]. Variable geometry chevron (VGC), an aerodynamic device made of an SMA actuator developed by Boeing, has been successfully installed in the GE90-115B jet engine. It reduces the noise by enhancing the chevron deflection and increases the cruise efficiency by reducing the chevron deflection during the flight [57]. Nitinol SMAs have successfully replaced the conventional hydraulic actuator system, which is very heavy and costly. NiTi SMA is embedded in the control surfaces of fighter jets. It quickly controlled the movement of the jet by its SME, which was created by thermal activation [58].

NiTi SMAs have some notable applications in the medical industry, such as implants, eyeglass covers, stents, guide wires, smart springs, orthodontic wires, etc. The first implementation of NiTi took place in the fluid fitting coupling, which linked the pipes using SME [59]. Nitinol SMA has been used to fabricate filtration devices for surgical purposes in the medical industry due to its high resistance against corrosion, biocompatibility, and SME [60,61]. Filtration devices made of traditional material require more invasive deployment in the human body. The entry of nitinol allowed for the development of a less invasive process for the deployment of the filtration devices. The filtration devices, like inferior vena cava (IVC) filters and carotid artery filters fabricated by nitinol, deformed to a much smaller size during insertion and later on regained their original shape due to phase transformation [62]. Nitinol SMA has been used to fabricate rehabilitation and assistive devices in the medical industry. These devices include hand prostheses and ankle, limb, and elbow orthotics. Nitinol wire is applied as artificial muscles to mimic the movement of various body parts [63]. A 3-DoF-based wire prototype was developed for home rehabilitation therapy [64]. A double-blinded clinical trial has been conducted for the application of a superelastic nitinol spinal rod in the treatment of adolescent idiopathic scoliosis. The five-year study gave an acceptable result [65].

The majority of SMA robotic applications are now biologically inspired (biomechanics) and widely used in biomedical fields. NiTi micro-actuators are used as artificial muscle in robotics. They can replace the multi-actuator systems in robotics for the movement of the grippers [66].

4. Surface Integrity Analysis

The integrity of the surface is characterized by the surface properties and sub-surface characteristics responsible for the quality of the machined surface [67]. Many modifications took place on the sample surface after machining, which are described by surface integrity analysis. The transformation of the machined surface is carried out to enhance the efficiency of the product. The leading features of the machined surface quality are described by surface roughness [68], surface hardness [69], residual stress [70], surface-induced layer [71], fatigue [72], and phase transformation [73].

The modern industry has some new innovative technologies to enrich the integrity of the machined surface by application of coating on the cutting tool, texturing on the cutting tool [74], application of minimum quality lubrication (MQL) on the cutting zone [75], use of a self-lubricating cutting tool, etc. The induced temperature during machining has a unique impact on the surface integrity of the machined surface [76,77]. The surface integrity characteristics rely on the tool, the workpiece, the process parameters, and the machining atmosphere. These parameters improve the surface quality through temperature variations, friction between the workpiece and tool, tool texturing, application of MQL on the cutting zone, and creating a cryogenic environment on the machining area. The machined surface integrity analysis can be further divided into conventional, non-conventional, and finishing operations. The surface features induced by the physical interaction between the tool and the job belong to the conventional category. During machining operations like milling, turning, drilling, etc., traditional surface characteristics have been developed. The non-conventional surface characteristics are defined when there is no direct physical contact between the job and the tool. These types of surfaces were generated by non-traditional machining processes like EDM, WEDM, AJM, AWJM, LBM, etc. Many finishing operations took place after the conventional or non-conventional machining process to modify the surface and sub-surface properties of the machined surface [78]. Residual stresses (either tensile or compressive) are developed on the surface of the machined product after manufacturing processes. A short peening process developed compressive residual stress on the machined surface, reducing the crack occurrence and propagation and enhancing the finished product’s fatigue life. Cracks are not developed in a compressive stress environment. Therefore, Peening is one of the best alternatives to produce surface compressive residual stress and improve the fatigue life of the machined surface [79,80]. The machined surface and sub-surface undergo several plastic deformations, which change the micro-structure, phase, hardness, residual stress, cracks, and recast layer thickness. These surface quality features of the finished product can be categorized into the following categories: (a) metallurgical surface quality like micro-structure, phase transformation, shape and size of the grain etc.; (b) mechanical surface quality like surface hardness, the thickness of recast layer, residual stress etc.; (c) topographical surface quality such as surface roughness, surface waviness, texture etc., [81,82,83].

This research article reviews the entire surface and sub-surface integrity analysis of micro-machining (either traditional or non-traditional) for NiTi SMAs by considering all the process variables.

5. Conventional Micro-Machining of NiTi SMAs

The NiTi SMAs have many unique properties, like SME, SE, etc., that make them capable of launching in the medical and aerospace industry. There are a few problems associated with micro-machined NiTi alloys, like high mechanical strength, high corrosion resistance, and phase transformation. Some advanced conventional micro-machining processes, like micro-drilling, micro-milling, micro-grinding, etc., can make complicated micro-structures on NiTi SMAs with high accuracy and precision.

5.1. Micro-Milling

Mechanical micro-machining is one of the most commonly used traditional μ-machining processes, which creates complex 3D micro-structures in different materials (metals, alloys, composites, etc.) [84]. One of the widely used mechanical micro-machining techniques is the micro-milling process [85,86,87]. It is a very time and cost-effective process to fabricate a high aspect ratio and complex geometry of micro-components with large MRR [88,89]. It does not require a high economic setup like other lithographical micro-machining processes [90].

Research Progress:

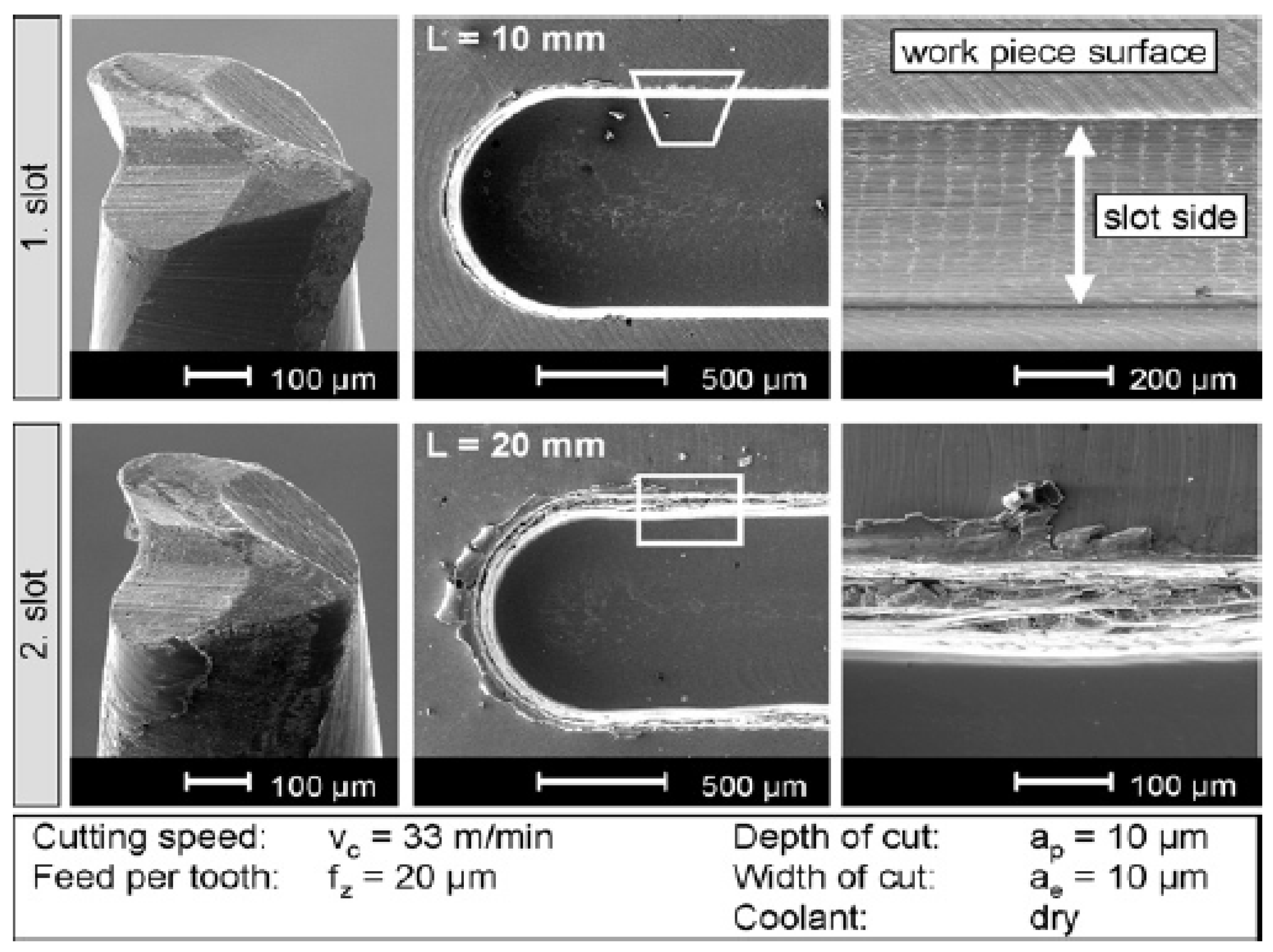

There are several comparative studies between the dry and MQL-based micro-milling of NiTi SMA. Due to the strong adherence of the tool and workpiece in a dry situation, the tool life is diminished in a short period, even in optimum cutting conditions (Figure 6). The burr formation and flank wear are very high in dry conditions, whereas the tool life is enhanced under MQL-based cutting conditions. A small depth of cut and large cutting width in MQL-based conditions supported the chip formation and enhanced the tool life, but the burr formation cannot be avoided entirely [91]. Another study of micro-milling of NiTi SMA was carried out on a five-axis micro-milling machine using a ball nose cutter. The effects of different inclination angles and phases (martensite and austenite) on tool wear and surface quality were studied. High width of cut and low depth of cut were found for minimum tool wear. A simulating tool, NCChip, was used for validation. The chip grid study from the simulator reveals that the tool movement is always perpendicular with chip thickness gradient to restrict the burr formation. In this process, the cutting velocity was limited to 50 m/min. Tool inclination was very much needed to control the surface quality. More burr formation for good adhesion occurred due to elevated tensile strength and ductility of the martensite structure. Therefore, the machining strategy and inclination angle played a dominant role in µ-milling of NiTi SMA [92]. A simulator tool was used to optimize the inclination angles during the micro-milling of the NiTi SMA by the end mill cutter. The simulation results were verified by conducting experimentation in a reference workpiece. Afterward, micro-holes were drilled on NiTi SMA by single-lip drills as well as twist drills of diameters 0.5, 1, and 1.5 mm. It was found that due to the asymmetric design of single lip drills, the adhesion wear is greater compared to the symmetric twist drill. The integrity of the surface is characterized by the surface properties and sub-surface characteristics responsible for the quality of the machined surface [67]. Many modifications have taken place.

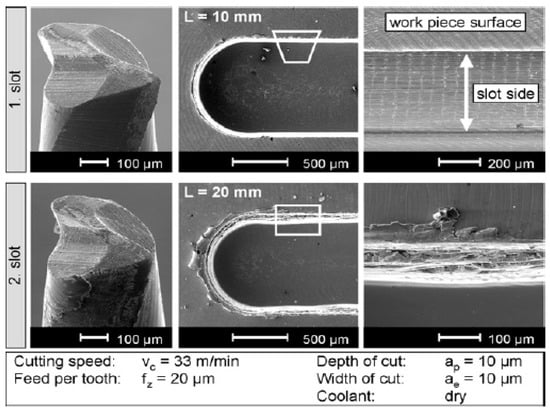

Figure 6.

Dry micro-milling at optimum cutting conditions [91].

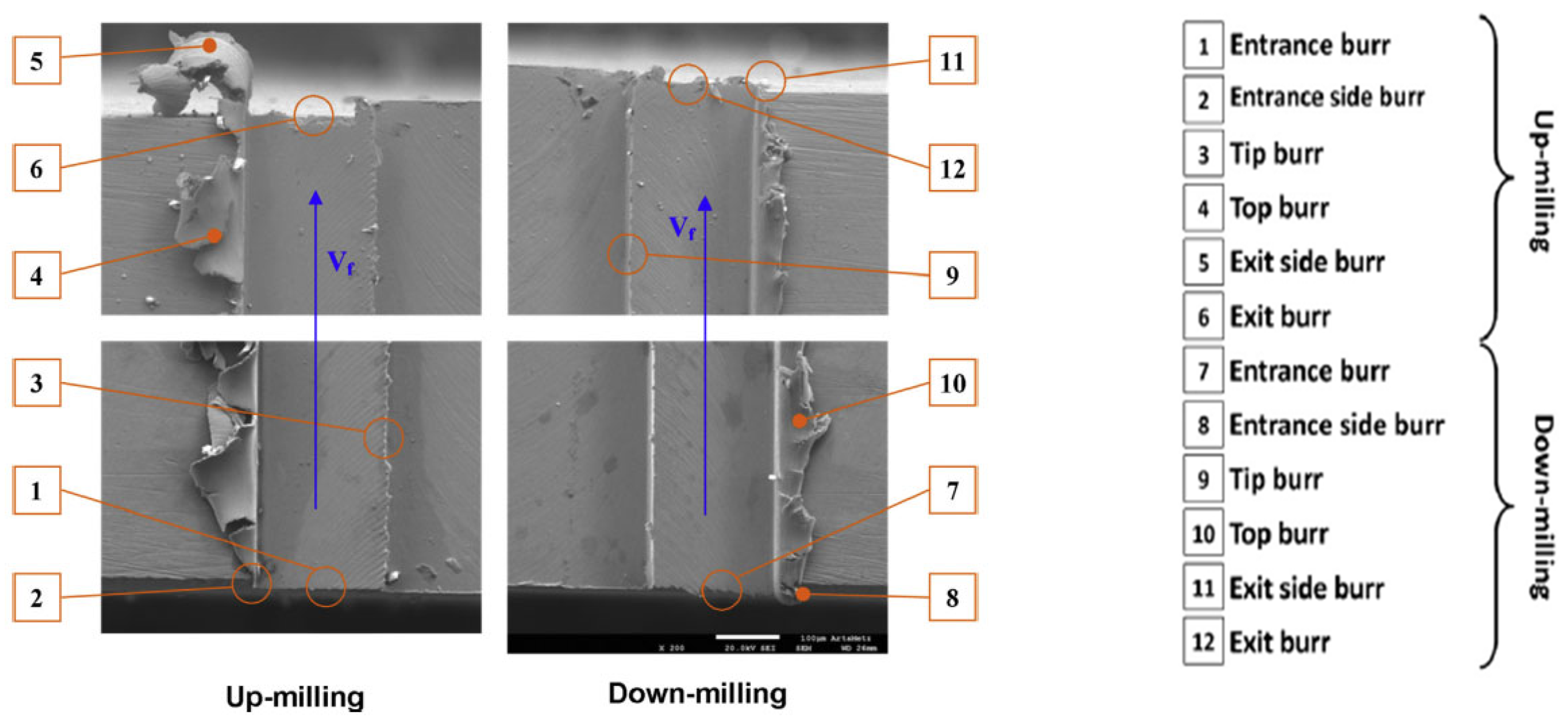

High cutting speed reduces the radial component of the symmetric load, which decreases the friction between the tool and the hole wall. A twist drill has no radial component of load due to its symmetric design. The highest cutting depth was achieved by using twist drills at a higher cutting speed (50 m/min) [93]. There was a study carried out where the burr formation was examined during micro-milling of nitinol foil, which is used in biomedical devices. The effect on burr height was determined by the spindle speed, the adhesive used to connect the foil, feed and backing material. It was noticed that larger burrs were formed during down-milling at a low spindle speed, high feed with a fragile adhesive bond and softer backing material [94]. The burr formation and phase transformation analysis were carried out for biomedical NiTi SMA during micro-milling operation. A total of 12 varieties of burr have been found during micro-milling of NiTi SMA, as shown in Figure 7. The study was brought to pass for two different phase structures of NiTi SMA named austenite and martensite. The impact of the machining parameters (fabrication strategy, cutting speed, cutting depth, cutting width and structure of the material phase) on the top burr was analyzed. The post-machining surface characteristics were also explored. It was established that the dimension of the top burr was highly affected by the design of the experimental data, and the machining strategy (up-milling and down-milling) influenced the entrance and exit burr. It was observed that a significantly smaller amount of tool wear took place during machining.

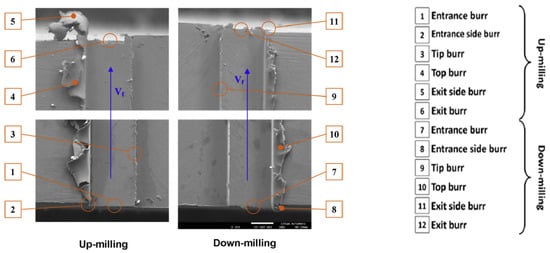

Figure 7.

Different kinds of burr found during entry and exit from the micro-slot [95].

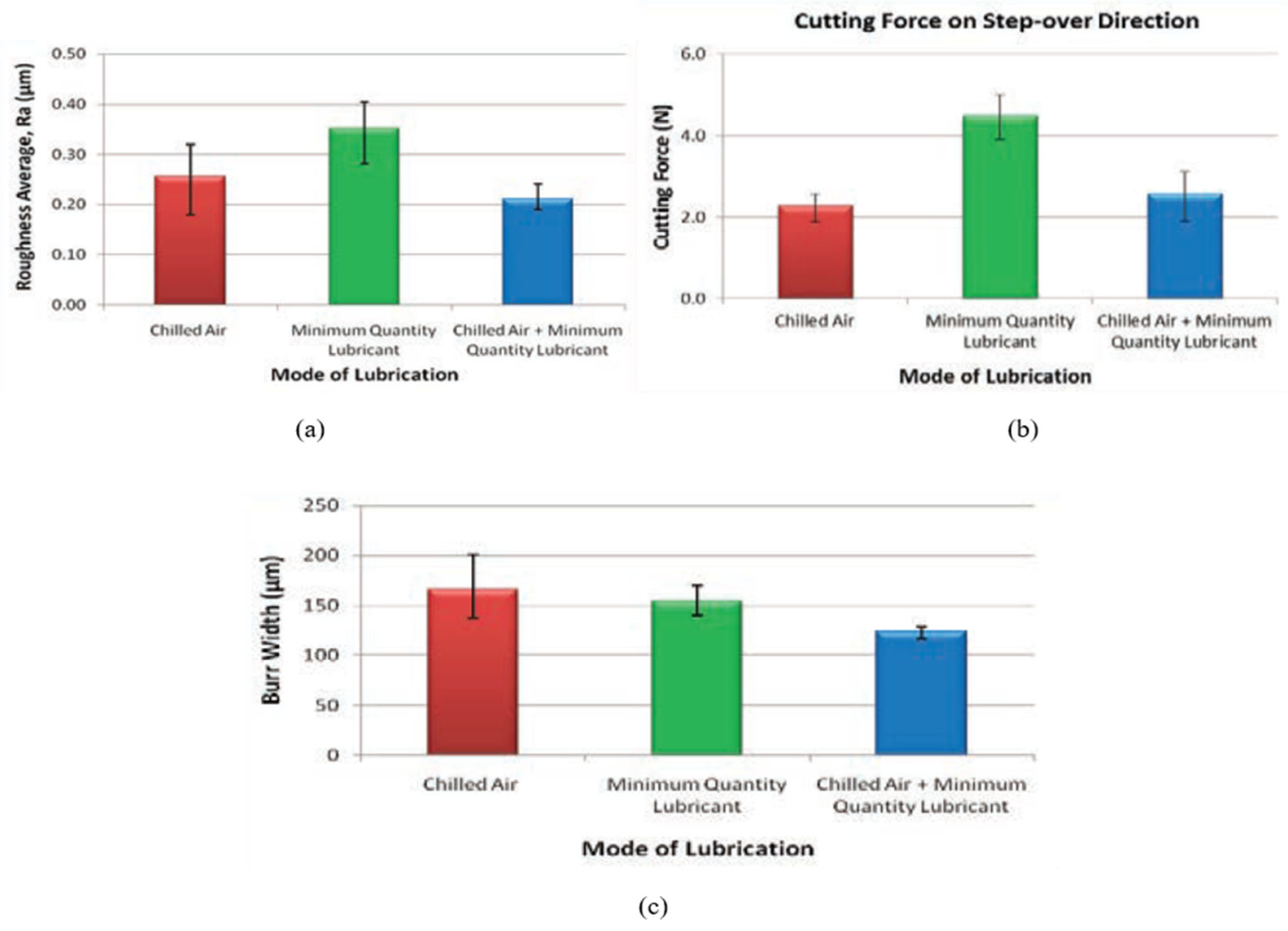

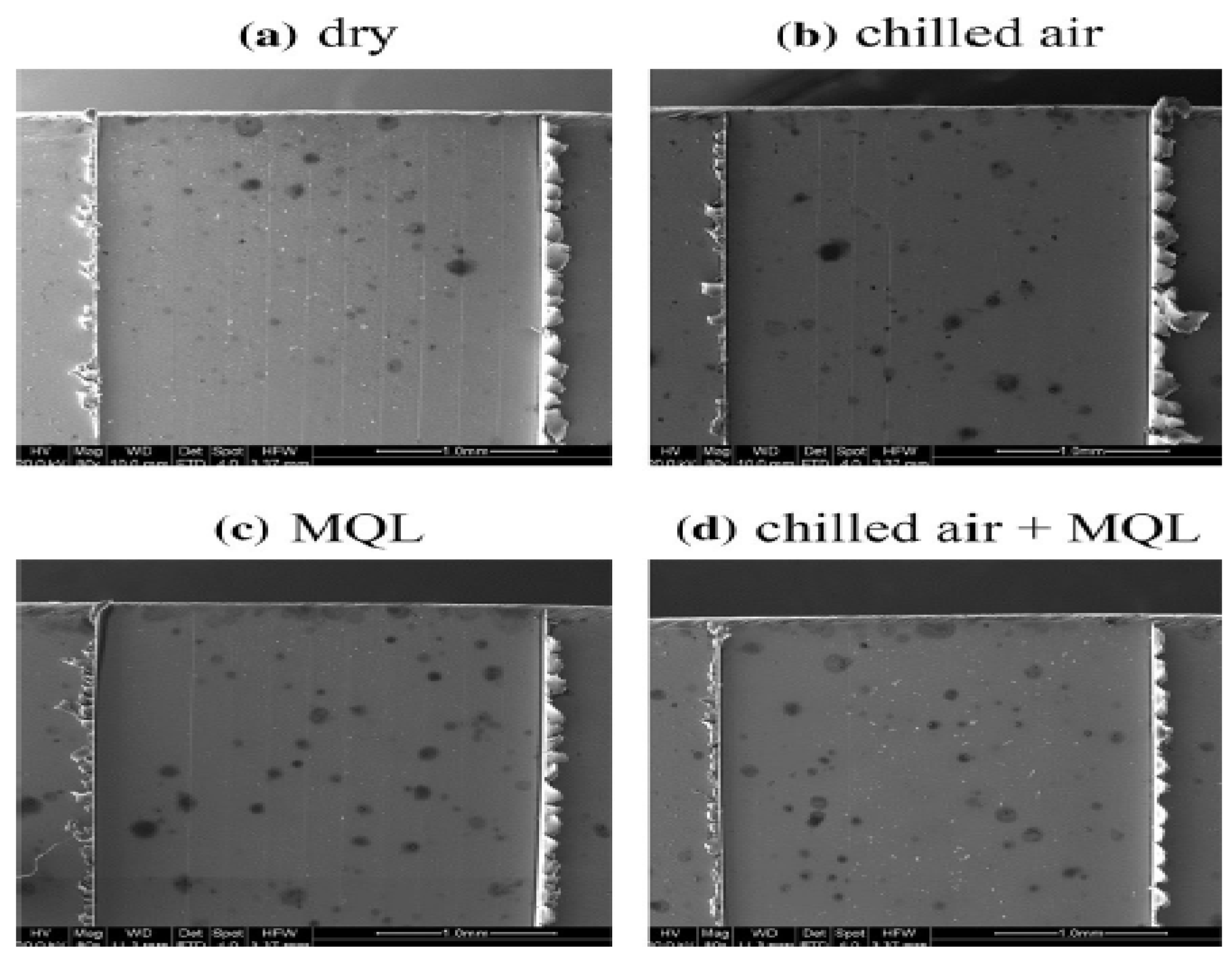

Some deposition of Ni molecules took place on the tool rake face. Stress-induced martensite was formed below the machined surface while machining the austenite structure, and martensite–austenite transformation was also taking place. The ANOVA analysis determined that the height and width of the burr were remarkably governed by feed per tooth and cut width. Small burrs were formed by the conjunction of high feed per tooth and low cutting width. Wider burrs were formed during up-milling relative to the down-milling operation. In contrast to down-milling, thinner burrs were produced during up-milling. Up-milling of martensitic structure leads to thick burr formation [95]. The cutting speed has a great influence during the micro-machining of NiTi SMAs. A specific cutting speed range was responsible for maximizing tool life and minimizing burr formation during high-speed micro-milling of NiTi SMA. The differential scanning calorimetry (DSC) test established the presence of the R-phase transition in NiTi SMA. Finally, the cutting speed was established as the most influential parameter for cutting force and burr size, followed by feed per tooth and cut depth. The minimum cutting force value and the maximum surface hardness value have been discovered at a cutting velocity of 15 m/min. This concludes that there was a phase transformation that took place from austenite to stress-induced martensite. Due to the phase transformation, the lowest value of tool–workpiece contact stress was found between 15 and 20 m/min. Less burr formation took place for a cutting speed of 15 to 25 m/min. High surface hardness was responsible for the major growth of flank wear at a 15 m/min cutting speed [96]. There was an investigation carried out that assessed the effect of chilled air during micro-milling of NiTi SMA. The effect of chilled air, chilled air + MQL and MQL on the output machining characteristics like tool wear, surface roughness, cutting force, burr height and burr width was determined comparatively. It was established that chilled air produced a more homogenous structure. The combined application of chilled air along with MQL reduces the cutting forces relative to the single application of MQL cutting conditions (Figure 8b). The surface performance of the machined surface is enhanced by chilled air along with the MQL (Figure 8a). Chilled air prevents the phase transition of an NiTi alloy from the structure of martensite to austenite, resulting in improved machinability. It was found that chilled air keeps the post-machining surface hardness value very close to the received NiTi alloy. Burr width was decreased by the application of chilled air (Figure 8c). The best approach for reducing flank wear and edge chipping is the combined application of chilled air and MQL [97]. Another study reveals the influence of chilled air and the size effect during micro-milling of NiTi SMA. The total four-machining environments, i.e., dry, MQL, chilled air, and MQL with chilled air, were developed. The combined application of chilled air and MQL reduces the temperature of the machining zone and keeps the temperature of NiTi SMA below its austenite finish (in this case, Af = 47 °C).

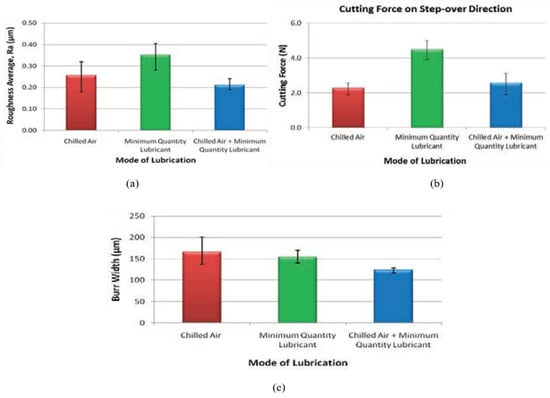

Figure 8.

Variation in (a) surface roughness, (b) cutting force and (c) burr width with different types of lubricant [97].

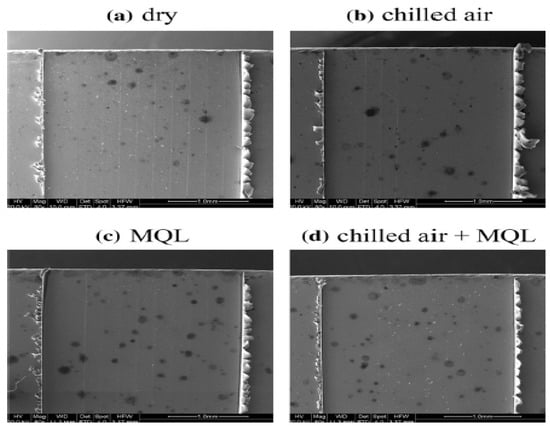

Thus, it inhibits the conversion of NiTi SMA from the structure of martensite to austenite. Flank wear, cutting force, and surface roughness were substantially diminished by the application of chilled air and MQL. The burr dimension was highly minimized by the use of chilled air, as shown in Figure 9. The ratio of un-deformed chip thickness to cutting edge radius (size effect) has a massive influence on the cutting force, burr formation and tool wear. Due to the ploughing effect, the small uncut chip thickness contributes to a rise in the specific cutting force. As the un-deformed chip thickness was more significant than the cutting edge radius, subtle surface finish and lower burr formation took place [98]. Kaynak et al. [99] validate the Helmholtz free energy-based micro-structure model through orthogonal machining of NiTi SMA. The developed modified model successfully predicted the experimentally measured response variables.

Figure 9.

Burr patterns of NiTi SMA for micro-milling under (a) dry (b) chilled air (c) MQL (d) chilled air + MQL cutting conditions [98].

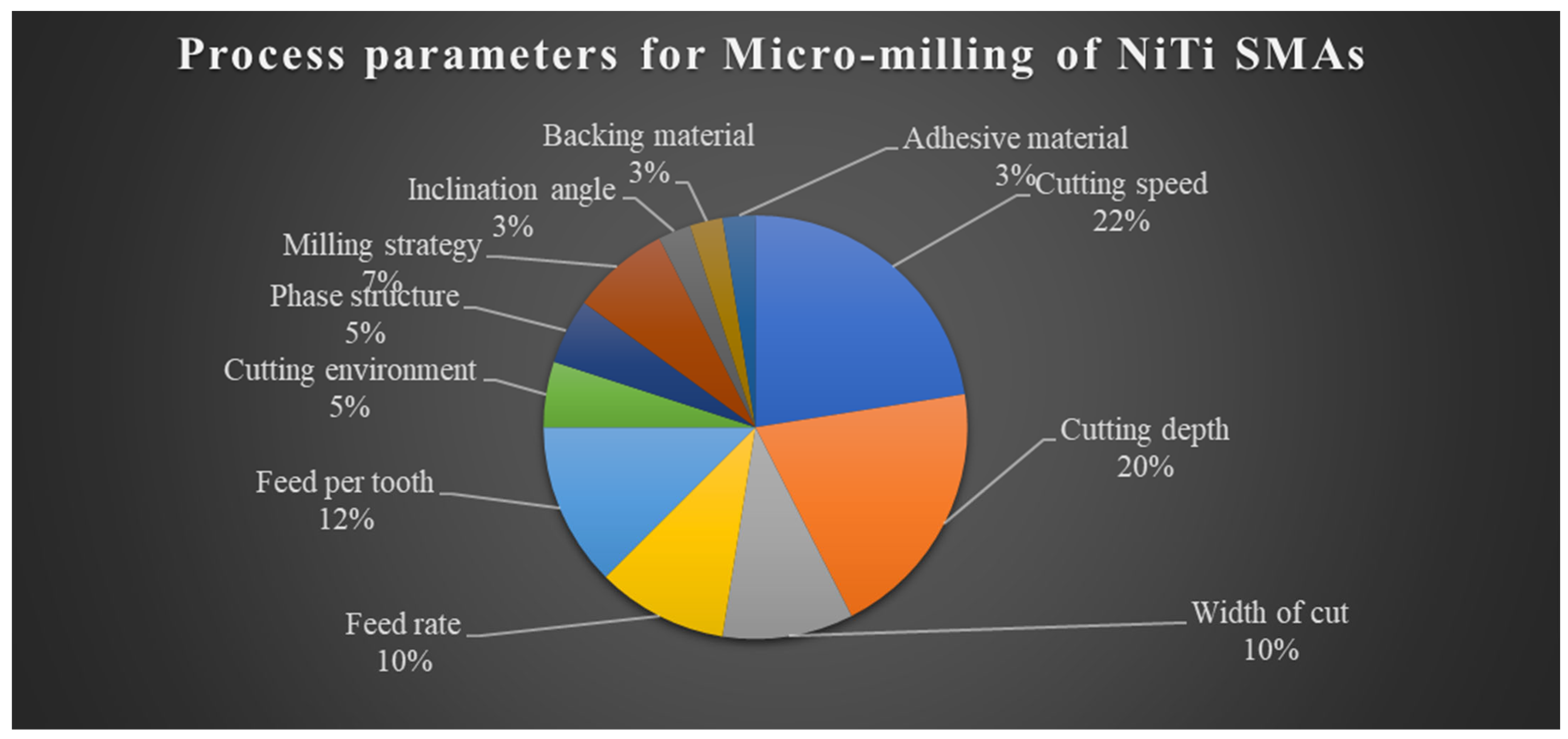

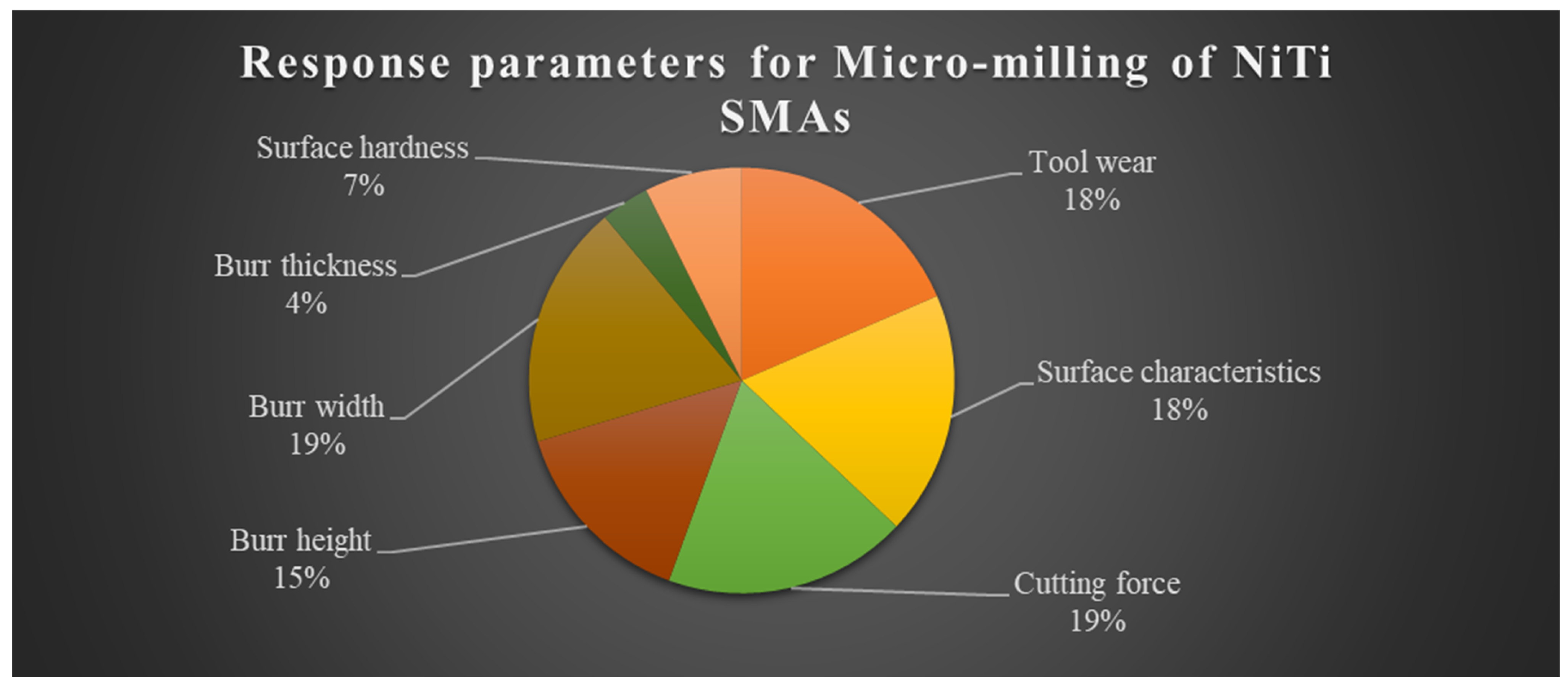

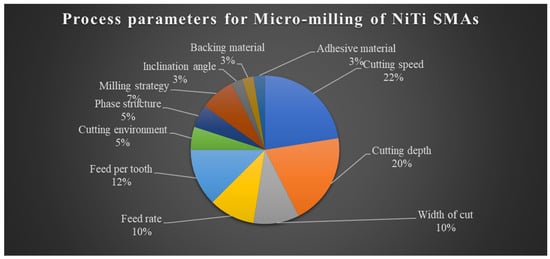

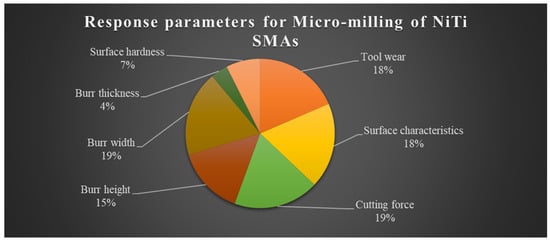

Figure 10 represents the process parameters in micro-milling of NiTi SMAs. The collected data were calculated by using the work mentioned in [91,92,93,94,95,96,97,98,99]. Figure 11 expresses the response parameters during micro-milling of NiTi SMAs. The collected data were calculated by using the work mentioned in [91,92,93,94,95,96,97,98,99].

Figure 10.

Process parameters in micro-milling of NiTi SMAs.

Figure 11.

Response parameters in micro-milling of NiTi SMAs.

5.2. Micro-Grinding

The major problems associated with the mechanical micro-machining processes are that it produces a larger amount of burrs. Micro-grinding is one of the finishing operations that produces superior surface finish in optical range along with minimum burr formation [100]. This process uses a micro-tool, which has super abrasives like a diamond, CBN, etc., for finishing micro-sized complex structures in brittle materials [101,102,103]. Low cutting forces and smooth surface generation are the key properties of this finishing process, which makes it capable of dealing with difficult-to-cut materials [104,105]. Super finishing of thin walls, micro-slots, and 3D complex geometries in different materials can easily be achieved by this process [106].

Research Progress:

The abrasive nature of NiTi SMAs creates difficulties during the grinding operation. However, material removal is possible by the grinding process. Various grinders, such as sand blaster, surface grinder, belt sanders, etc., were used for the fabrication of NiTi SMAs, but the centerless grinding process was found to be the most suitable operation for NiTi alloys [107]. Micro-grinding is commercially used for machining guide wires [108]. Centreless grinding is capable of fabricating nitinol needles with a fine surface finish (Ra = 0.4 µm) [109].

6. Non-Conventional Micro-Machining of NiTi SMAs

The conventional micro-machining of NiTi SMAs has some disadvantages due to physical engagement between the tool and the job. This resulted in heat generation, elevated wear of the tool and strain hardening. Non-conventional micro-machining processes like μ-EDM, LBM, WJM and ECMM can solve these problems. Non-traditional machining processes produced less heat, which could improve the surface characteristics.

6.1. Abrasive Water Jet Machining (AWJM)

AWJM process is one of the non-traditional machining processes that has an extensive application in the manufacturing industry to cut various materials like metals, alloys, composites, etc. [110]. This fabrication process does not produce too much heat in the cutting zone, resulting in less thermal distortion [111]. It can generate good surface quality with minimum burr formation due to its low machining force [112]. It can be easily applied to fabricate difficult-to-cut materials [113].

Research Progress:

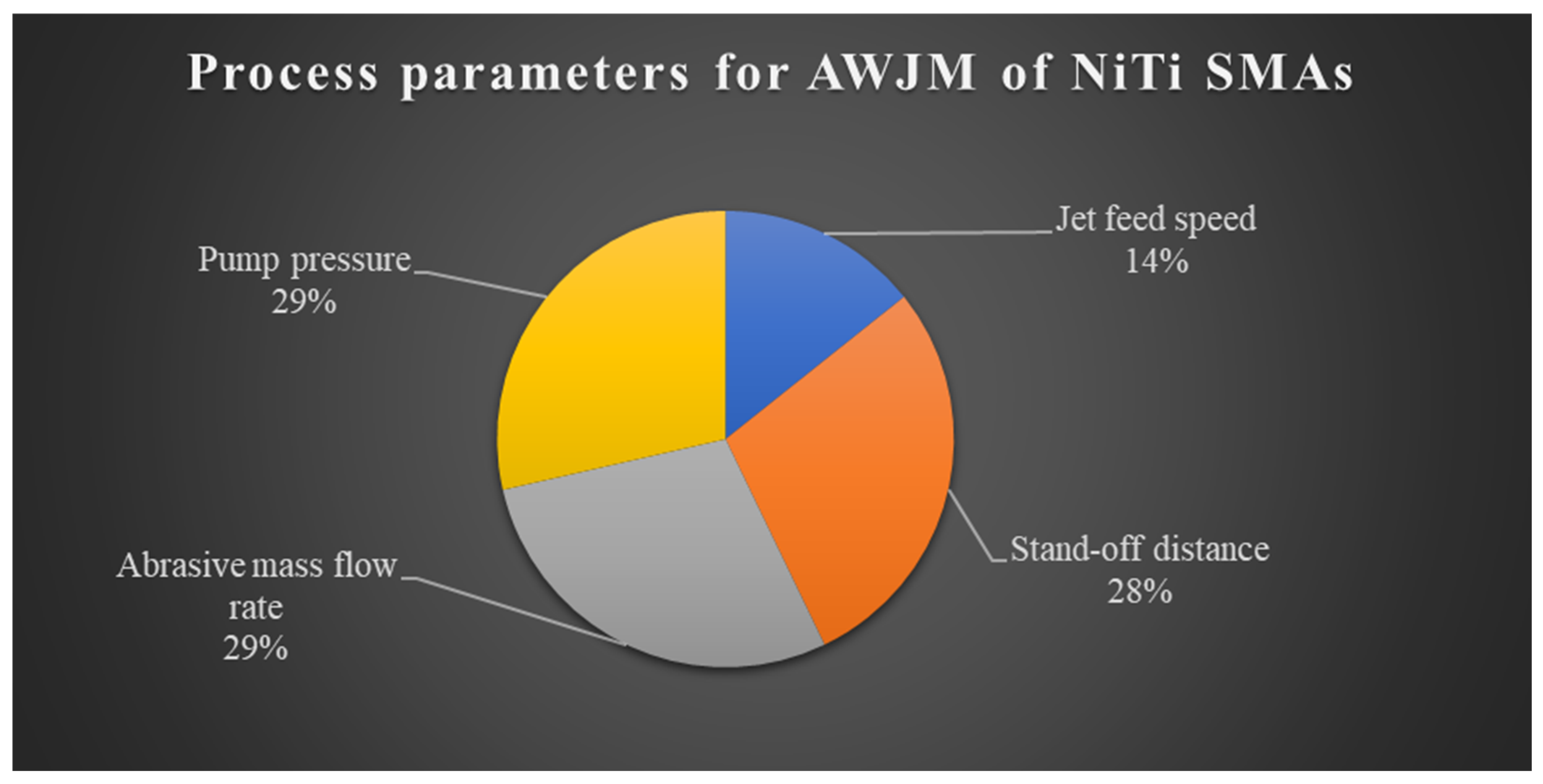

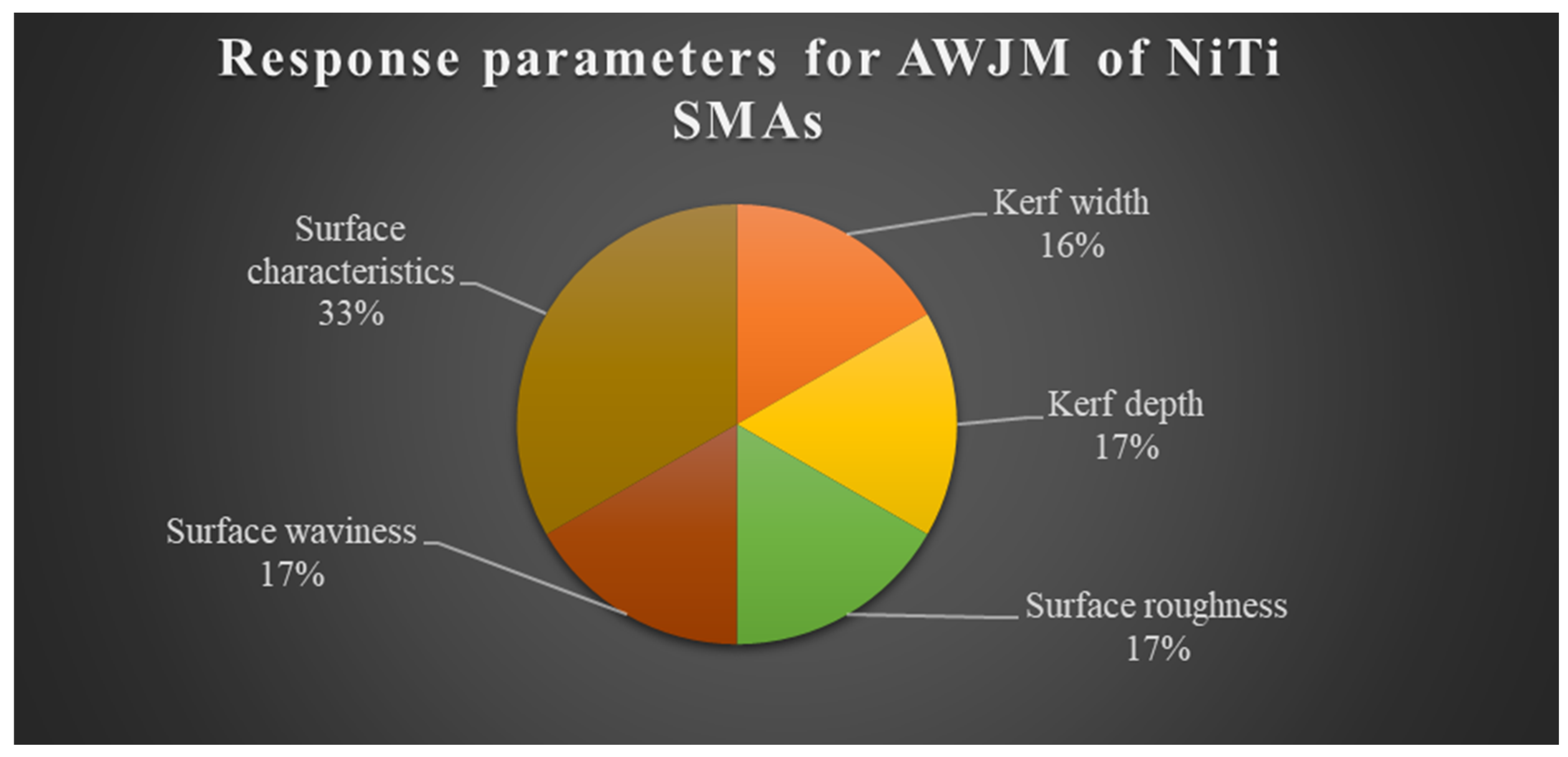

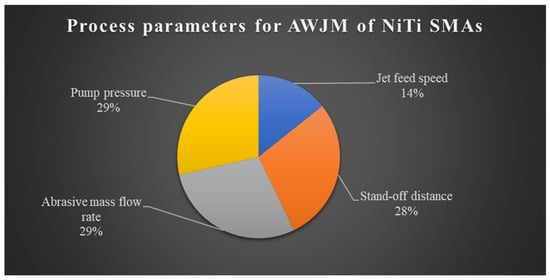

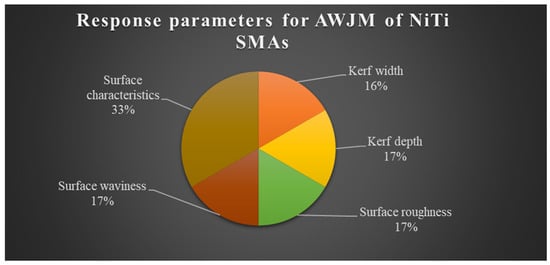

A comparative investigation was conducted on machine nitinol by WJM and AWJM processes. The influence of these two machining processes on the phase transformation temperature of NiTi SMA was evaluated. The study reveals that the penetration depth cannot be controlled during water-jet milling of NiTi SMA. It happened due to the strain hardening effect of the martensitic structure. The phase transformation (martensite to austenite) took place during abrasive water jet machining of NiTi SMA. The penetration depth can be controlled properly during AWJM of NiTi SMA. Although due to grit attachment on the surface, the surface integrity of NiTi SMA was degraded during the AWJM process but it was due to the impingement of abrasive particles with a very high velocity. Therefore, the study recommended AWJ milling followed by water-jet milling (for cleaning purposes) to machine NiTi SMA [114]. The AWJM and µ-milling processes were compared to achieve a small structure in NiTi sheets for medical applications. During AWJM of NiTi sheets, the bending of the cut edges took place. It was recommended that AWJM is not suitable for machining NiTi sheets of thickness less than 0.5 mm. Non-abrasive water-jet machining yields good results for NiTi sheets of thickness 0.1 mm at a pass velocity of 3–9 mm/min. During water-jet machining, heavy plastic deformation occurs on the backside of the sheet, which results in the blowing away of some micro parts. Besides this, a few micro-cracks were also found by scanning electron microscopy (SEM) analysis. The transmission electron microscopy (TEM) analyses validate the findings from the SEM analysis. After that, a 0.4 mm diameter micro-mill tool was used to create a stent-like structure in NiTi sheets of 0.2 mm thickness. The optimum collection of cutting parameters was found to be 10 μm of cutting depth and 5 μm of feed per tooth. The combination of lower feeding and higher cutting depth contributes to greater burr formation. Wavy nature cut edges were found in WJM due to vibration of NiTi sheets, whereas a precise amount of burr formation took place during micro-milling operation. Therefore, in the case of shape accuracy, the milled structure was found to be better, but burr formation could not be avoided entirely [115]. Kong et al. [116] have done multi-mode AWJM of NiTi SMA and determined the impact of process variables on the geometrical accuracy and mechanical transformation after the machining process. The optimal condition was established to cut superior profiles, which is applicable in the aerospace industry. Figure 12 represents the process parameters in AWJM of NiTi SMAs. The collected data were calculated by using the work mentioned in [114,115,116]. Figure 13 expresses the response parameters during AWJM of NiTi SMAs. The collected data were calculated by using the work mentioned in [114,115,116].

Figure 12.

Process parameters in AWJM of NiTi SMAs.

Figure 13.

Response parameters in AWJM of NiTi SMAs.

6.2. Micro-Electrical Discharge Machining (µ-EDM)

The properties of the tool and workpiece, such as fatigue life, thermal expansion, stiffness, etc., are essential during mechanical micro-machining processes [117]. These machining processes have some difficulties like high tool wear, poor surface finish, induction of mechanical stress, etc., which need to be resolved. The µ-EDM process is one of the micro-machining processes used to solve these obstacles due to its non-contact material removal mechanism [118]. This method can machine any conductive material, regardless of its hardness or toughness [119]. This non-traditional micro-machining process is free from mechanical stress, vibration, and chatter [120]. This fabrication process has gained huge attention in the automobile, aerospace, and biomedical industries [121,122].

Research Progress:

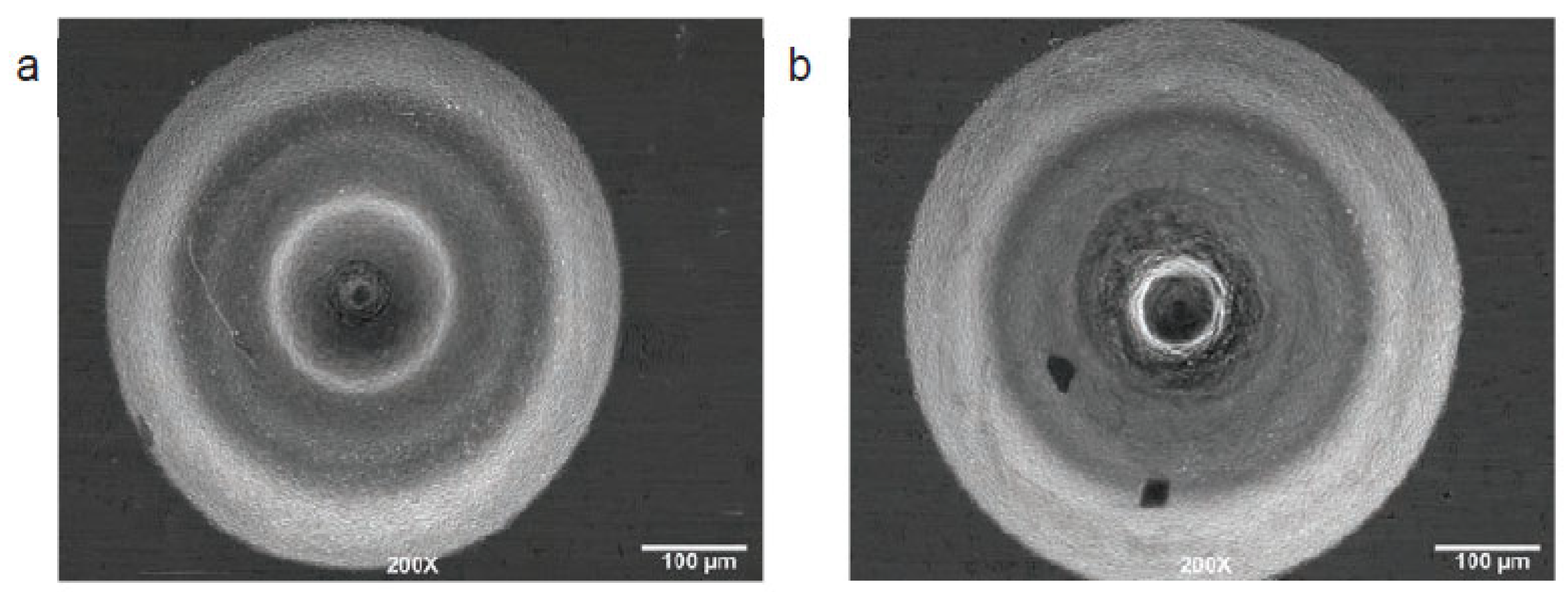

Rasheed et al. [123] carried out research where micro-holes were drilled in NiTi SMA by the µ-EDM process. The major objective of this assessment was to calculate the impact of the μ-EDM parameters, i.e., capacitance, discharge voltage, and electrode material, while the response variables were considered as material removal rate (MRR), tool wear rate (TWR), and surface roughness (Ra). The optimum result for minimum TWR was capacitance 155 pF, discharge voltage 80 V, and tungsten electrode. On the other hand, for maximum MRR, the capacitance was 475 pF and discharge voltage 100 V with a brass electrode. Similarly, for minimum Ra, the capacitance value was 155 pF and the discharge voltage was 80 V, with a tungsten electrode. For every case of MRR, TWR, and Ra, the capacitance value was defined. The discharge energy increases due to an increase in capacitance and discharge voltage, which aims to enhance MRR and TWR. TWR was low for the tungsten electrode compared to the brass electrode. The brass electrode was suitable for higher MRR, and the tungsten electrode was endorsed for better dimensional accuracy and Ra of the drilled micro-hole. The dimensional precision of the micro-machined profiles is tremendously dominated by μ-EDM process variables. Another study was performed on the micro-EDM process, where micro-holes were drilled in NiTi SMA by a full factorial design of experiments. Micro-holes were analyzed by SEM micrograph. The impact of machining variables on the MRR, TWR, Ra, and circularity was determined. Mathematical models were developed for each response parameter. Capacitance and discharge voltage were settled as notable factors for the total response variables. Due to the rise in discharge energy, both the MRR and TWR were boosted. For higher MRR, brass electrodes were recommended, and all other output responses were fitted better for tungsten electrode material. The developed mathematical model was able to predict the response variables within an acceptable range (Rasheed et al. [124]). As NiTi SMAs have a massive application in the field of the biomedical industry [38], the biocompatibility analysis is in demand for these alloys. A comparative study was carried out between NiTi and Ti-6Al-4V alloy about their biocompatibility behavior. The smoother machined surface was obtained for NiTi alloys relative to the Ti-6Al-4V alloy. It occurred because a lower amount of debris was generated on the machined surface of NiTi, as shown in Figure 14. A large spark concentration was developed at the center of the micro-hole compared to the edges. The heat generation during μ-EDM migrated carbon and oxygen to the machined surface. The atoms (C and W) have transferred into the micro-machined surface from the dielectric and electrode material. The formation of TiO2 and WO2 on the machined Ti-6Al-4V surface was observed. NiTiO3 was the most influential type of compound found in the machined NiTi alloy. The formed oxide layer worked as a protective layer for NiTi and Ti-6Al-4V alloys in their biomedical applications. As a result of the recast layer formation, the surface micro-hardness was enhanced for both the NiTi and Ti-6Al-4V alloys. The oxide coating acted as a protective layer that prevented corrosion of the biomedical implants (Jahan et al. [125]). Multi-objective optimization approaches played a dominant role over the single-response optimization problem in the present scenario (Kumar and Singh, [126]).

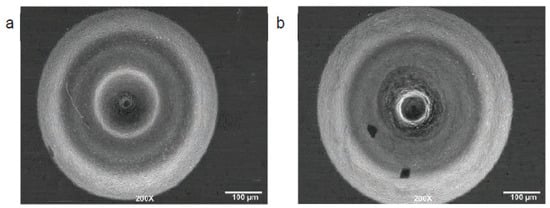

Figure 14.

SEM of micro-drilled hole in (a) NiTi and (b) Ti-6Al-4V alloys [125].

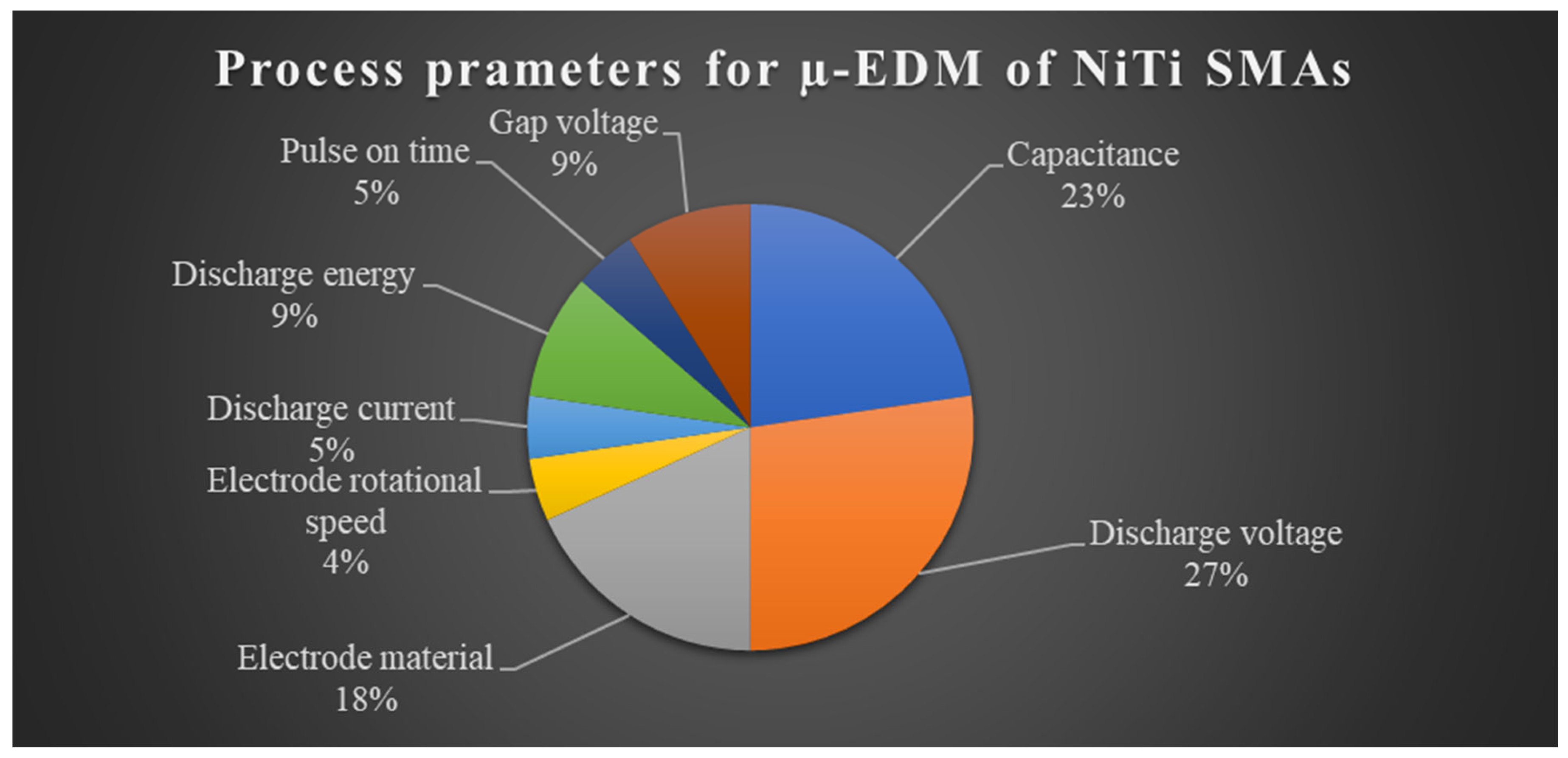

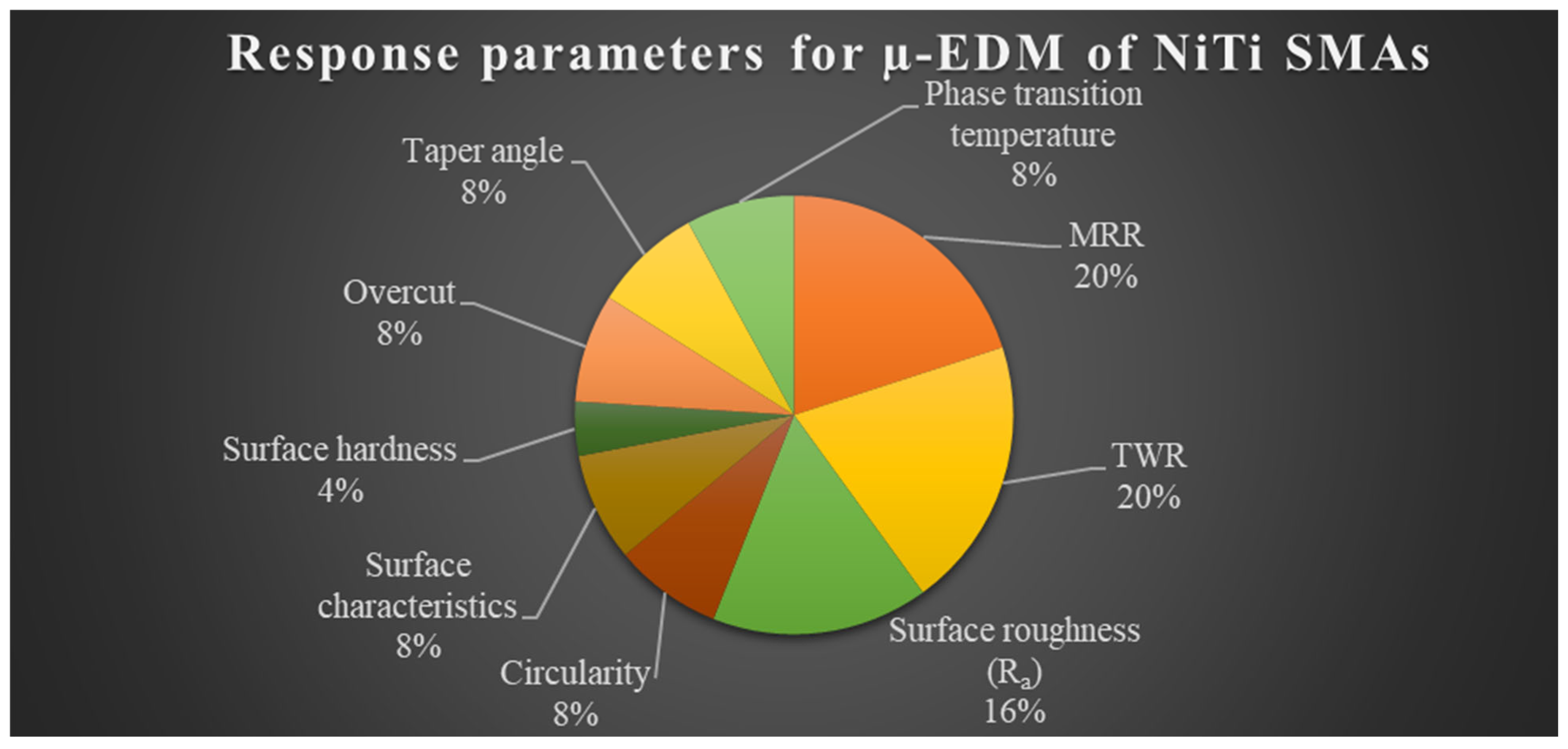

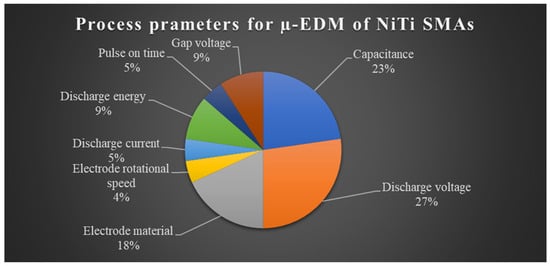

Abidi et al. [127] investigated improving the quality of micro-holes produced by µ-EDM on NiTi SMA. Multi-response optimization was accomplished by Taguchi’s PCA approach to upgrade the overcut, surface roughness, and taper angle of the fabricated micro-hole on NiTi SMA. The optimized machining parameters showed the difference between the single response and Taguchi’s PCA-based multi-response optimization technique. Taguchi’s PCA approach was found to be more accurate compared to the single-response optimization problem. The optimum machining parameters were capacitance 455 pF, discharge voltage 80 V, and brass electrode material. It was observed that electrode material, followed by discharge voltage and capacitance, has the highest effect on the normalized multiple responses. There was a need for a non-conventional multi-objective optimization tool that concurrently optimizes all the output responses of the µ-EDM process. Abidi et al. [128] carried out experimentation for simultaneous optimization of the µ-EDM process parameters for MRR, TWR, Ra, overcut, taper angle, and circularity using the multi-objective genetic algorithm-II-II (MOGA-II) during drilling a micro-hole in NiTi SMA. Capacitance was found to be the most influential parameter for Ra, TWR, and MRR, led by electrode materials and discharge voltage. Capacitance affected the overcut, electrode material controlled the taper angle, and the interconnection of capacitance and electrode material impacted the circularity error. An excellent surface finish was obtained for the tungsten electrode due to its poor electrical conductivity. The tungsten electrode gave low TWR for its high heat and wear resistance capabilities compared to the brass electrode. Brass electrodes exhibit high MRR because of their low thermal conductivity. The workpiece absorbs the additional heat for the brass electrode, which leads to high MRR compared to the tungsten electrode. The tungsten electrode achieved the lowest taper angle at higher capacitance, while a higher overcut was obtained by the brass electrode. The circularity error was lowest for the tungsten electrode due to its lower TWR and MRR. The optimum result was capacitance 315 pF, discharge voltage 80 V, and tungsten electrode material. The variation in electrode material and dielectric fluid plays a dominant role in the µ-EDM process. James et al. [129] investigated a comparative study between dry and wet µ-EDM of NiTi SMA. The surface finish of the micro-cavities on an NiTi alloy obtained from dry-µEDM was considered better compared to the wet-µEDM. The reduction in discharge energy in the air dielectric leads to a decrease in the MRR for dry-µEDM compared to the wet-µEDM. The TWR was higher for wet-µEDM compared to the dry-µEDM. The liquid dielectric needs more energy for chemical breakdown than the air, concentrated on a small area, resulting in high tool wear. The low viscosity of air results in less discharge energy, which is responsible for the minimum TWR. An investigation was done to determine the effect of the discharge energy of µ-EDM on the phase transformation temperatures of medical-grade nitinol. DSC analysis was used for this study. After applying Jet ECM on the received NiTi SMA, LBM was used to compare the results. It was found that high discharge energy has a large influence on altering the phase transition temperature of NiTi SMA. It reduces the thermal hysteresis as well as alters the internal stress of NiTi SMA. Therefore, there was a need to establish an optimum discharge energy range where high MRR can be achieved without affecting the phase transition temperatures (Mwangi et al. [130]). In another study, the effect of arcing phenomena was established during µ-EDM on the medical-grade nitinol. It was found that while arcing, the mechanical property of NiTi SMA deteriorates. It was proved by its poor performance under cyclic loading conditions. Therefore, the discharge energy in the µ-EDM process that causes arcing must be avoided to increase the product life cycle of medical-grade nitinol (Mwangi et al. [131]). Dutta and Sarma [132] conducted a multi-objective optimization of the µ-EDM parameters by Taguchi’s GRA and RSM-based desirability function to minimize the overcut and circularity error of the drilled µ-hole on NiTi SMA. Electrode material is the most significant parameter for both responses, followed by discharge voltage and capacitance. The final optimum result has a close agreement with the adopted literature model. Chaurasia et al. [133] mixed phosphorus powder with bio-oil during µ-EDM of NiTi SMA. The influence of process parameters on the MRR and Ra has been determined, followed by a cytotoxicity test for biocompatibility analysis. Sahoo et al. [134] optimize the machining variables during µ-hole drilling on nitinol SMA by GRG coupled with the GA technique. The confirmation experiments at optimal conditions gave superior results. Chaurasia et al. [135] investigate the impact of process variables on the MRR, surface roughness, and DD during sustainable µ-channels fabrication on NiTi SMA by µ-EDM process. ANN-GA provides optimal machining conditions, followed by a cytotoxicity test for biocompatibility analysis. Dutta and Sarma [136] applied graphene nano-particles during micro-ED drilling on NiTi SMA. The grey desirability optimal condition provided superior MRR, Ra, MH, and sub-surface characteristics of the micro-machined surface of nitinol SMA. Kowalczyk et al. [137] determine the measurement uncertainties during WEDM of NiTi SMA. The impact of process variables, i.e., current, gap voltage, and energy parameters, on the surface condition of NiTi SMA has been discussed after machining. Figure 15 represents the process parameters in µ-EDM of NiTi SMAs. Figure 16 expresses the response parameters during µ-EDM of NiTi SMAs. Capacitance and discharge voltage have the highest percentage contribution as machining parameters towards response variables during µ-EDM of NiTi SMAs. MRR and TWR have the highest percentage contribution as response variables during µ-EDM of NiTi SMAs (Figure 15 and Figure 16). The collected data were calculated by using the work mentioned in [123,124,125,126,127,128,129,130,131,132,133,134,135,136,137].

Figure 15.

Process parameters in µ-EDM of NiTi SMAs.

Figure 16.

Response parameters in µ-EDM of NiTi SMAs.

6.3. Laser Beam Machining (LBM)

The laser is a coherent, unidirectional, and amplified beam of electromagnetic radiation (light amplification by stimulated emission). Practically, the laser is achieved by the incidence of photons, which causes stimulated emission. All the photons in LBM are in the same phase, wavelength, and frequency. Due to that, it has a high-power density and strong focusing capacity [138]. The medium of the laser may be liquid (dye), solid (Nd: YAG or neodymium-doped yttrium–aluminum–garnet), or gas (CO2, He, Ne) [139]. Nd: YAG and CO2 are the two most commonly used lasers. The CO2 laser has elevated beam power and improved efficiency. It is used for cutting sheet metal [140]. Nd: YAG laser has a low beam power, but its long pulse mode is capable of cutting large thickness [141]. Various lasing techniques, such as femtosecond laser, fiber laser, Nd-YAG laser, etc., are applied to NiTi SMAs for micro-machining purposes. The variation in several LBM variables like laser power, laser fluence, scan speed, wavelength, frequency, pass no, etc., on the kerf profile, ablation rate, surface integrity, etc., is evaluated. Low single pulse energy with a larger number of passes gave a narrower kerf profile. Low laser fluence along with high scan speed resulted in recast-free free better surface finish on NiTi SMAs. High frequency, medium speed, low layer thickness, and track displacement gave maximum MRR and better surface finish during Nd: YAG laser machining of NiTi sheets. Post laser machining operations like pickling, electro polishing, etc., removed the oxide layer as well as improved the dimensional accuracy of the micro-channel on NiTi SMAs. The selection of an alternative path in the femtosecond laser doubled the ablation rate and reduced the HAZ production on the machined micro-channel. Mixed topography with a high striation ratio reduced the surface roughness, created a neat kerf profile, and maintained a neater recast layer. It is established that the femtosecond laser cut surface of NiTi SMA at underwater conditions is free from recast layer and debris particles. Surface roughness was decreased with the increase in cutting speed, and the enhancement of laser power raises the surface roughness as well. A comparative study took place between µ-EDM and LBM for the micro-machining of NiTi SMA. MRR is higher for LBM compared to the µ-EDM process. Low dimensional accuracy of the drilled micro-hole and high amount of HAZ, recast layer, and spatter around the micro-hole is found for LBM over µ-EDM of NiTi SMA.

Research Progress:

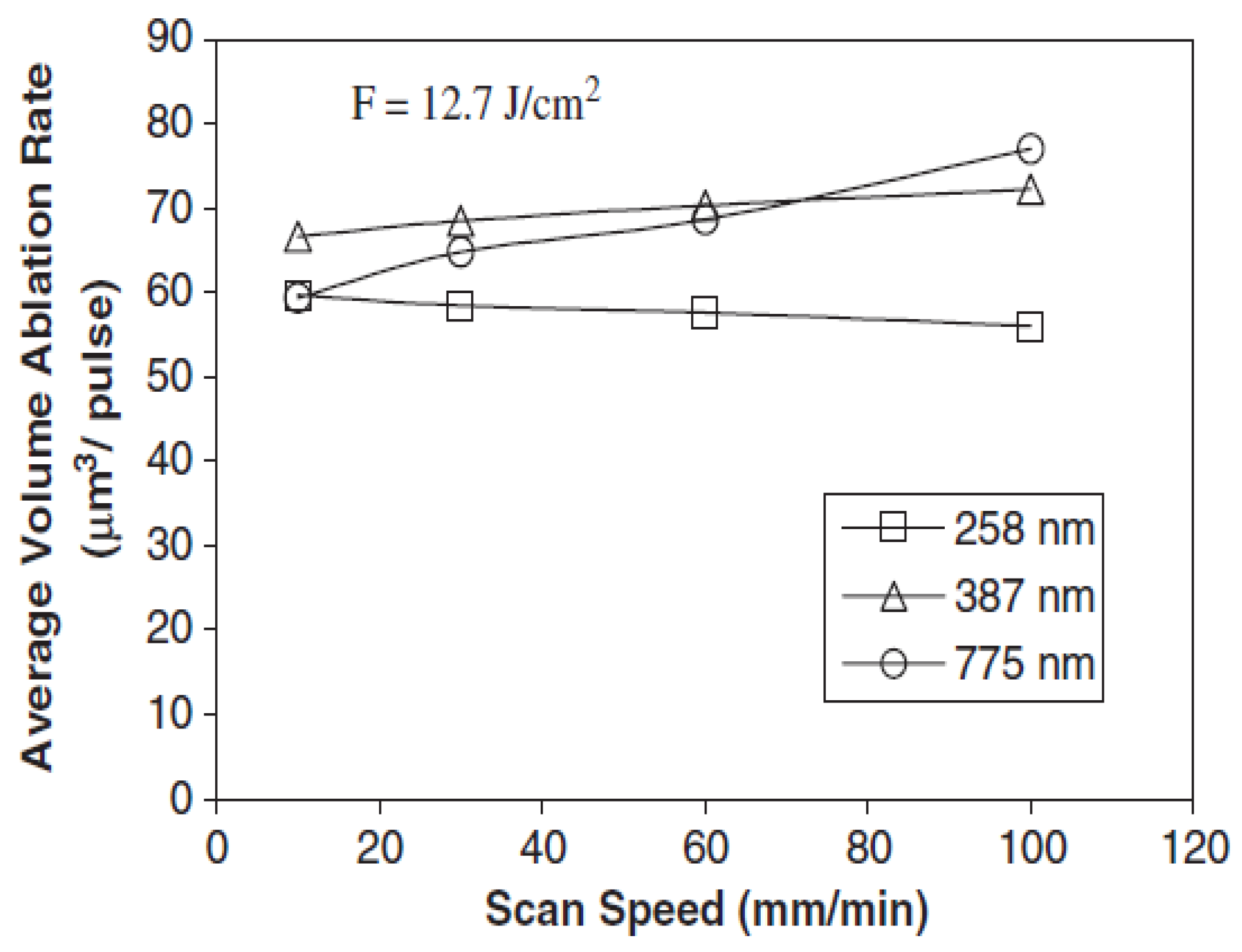

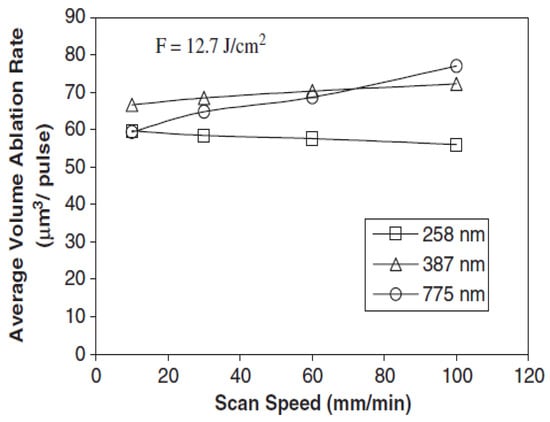

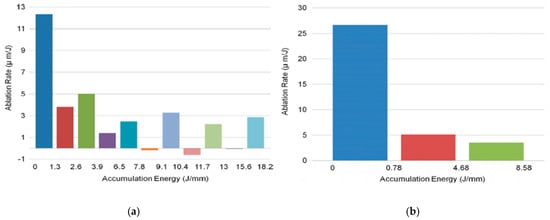

Laser machining is among the fastest and most flexible non-traditional machining processes compared to other machining processes [142,143]. Laser machining is preferred as the process for biomedical applications such as stents in NiTi tubes [38]. It can produce highly accurate and precise complex micro-structures in NiTi plates or sheets. An investigation was conducted to discover the impact of machining variables on the kerf profile and surface quality by using a 355 nm Nd: YAG laser during the micro-cutting of the NiTi sheets. The theoretical relationship between the lasing parameters, such as pass number, laser power, and laser velocity, to the kerf profile and surface quality was successfully validated by the experimentation process. The depth of the micro-grooves increases with the pass number. As the laser velocity increases, the depth of the micro-grooves decreases, but this velocity is dependent on the laser power. The debris was removed from the machining zone by increasing the pass number. The pass number was the most influential parameter for the kerf profile. The enhancement of kerf width took place by increasing laser power up to 1 W; after that, the increment became very slow. Single pulse energy with a larger number of passes was useful for obtaining a narrow kerf profile. However, lower pulse energy leads to lower productivity [144]. A study was carried out to see how different laser machining methods, such as Nd: YAG solid-state laser and Ti: sapphire laser, affected the shape memory capabilities of nitinol. Micro-holes were drilled by changing different parameters of the LBM process to achieve the goal. It was established that by using a Ti: sapphire laser with high power density and ultra-short pulses, it is possible to machine micro-holes in nitinol without affecting its shape memory properties. Due to high power density and ultra-short pulses, the material sublimates immediately and retains its key properties [145]. Other hand, the femtosecond laser has many advantages over conventional lasing processes [146]. Systematic experimentation of femtosecond lasers on NiTi sheets was performed using a simple wavelength of 775 nm from the Ti: Sapphire laser. The experiment reported that a high degree of monitoring of the ablation depth was feasible. The higher scan rate provides the surrounding materials with a finer track with lower heat dissipation. For constant laser fluence (optical energy of a laser pulse per unit area), the volume of ablation rate remains almost fixed for different scan speeds, as shown in Figure 17. A better result was obtained from high scan speeds compared to the slow scanning speeds. The volume ablation rate per pulse in mm3 rises with laser fluence due to the ablated plume’s missing energy shielding effect. It causes significant recast and poor surface quality.

Figure 17.

Variation in volume ablation rate with different feeds at a constant laser fluence [147].

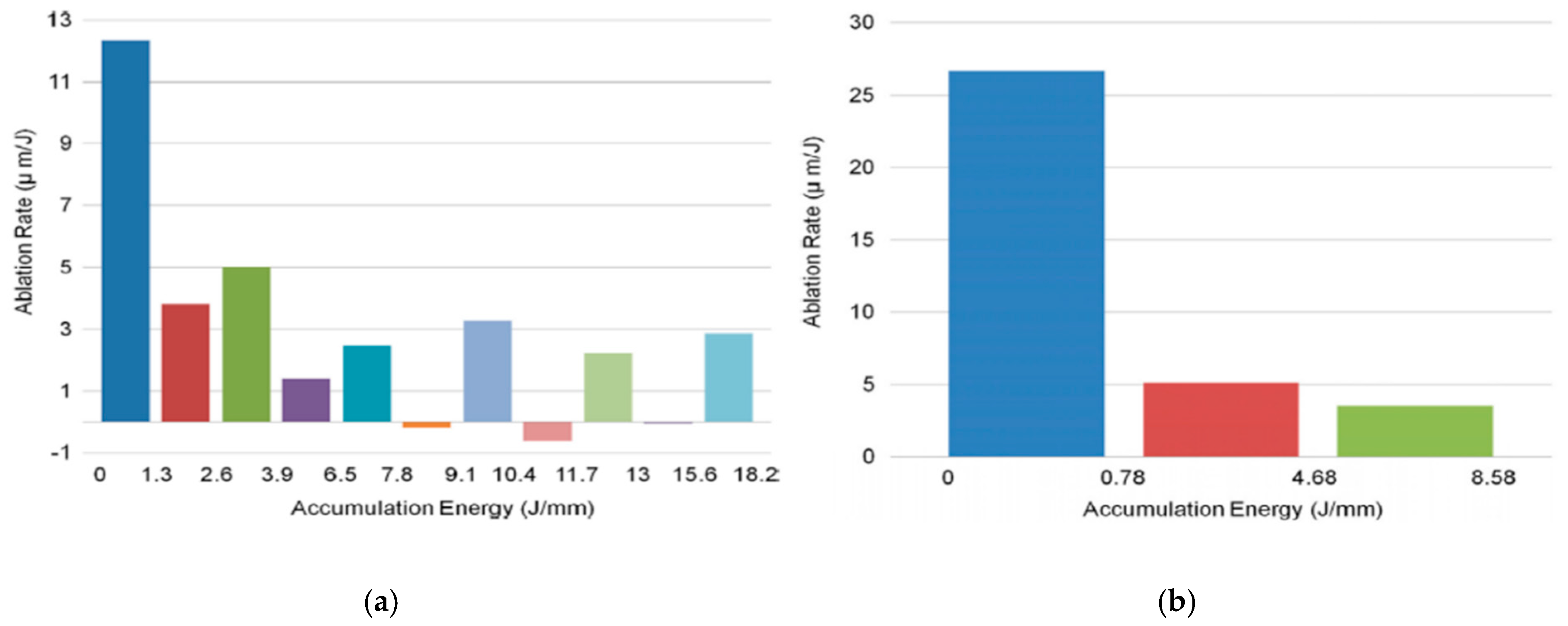

Laser fluences below 15 J/cm2 produced precisely recast free-cutting surfaces on NiTi sheets [147]. Uppal et al. [148] studied the single and multi-shot ablation fluence, morphological changes at fluences, and various zones of ablation phases during micro-machining of NiTi sheets by femtosecond laser. The allocation of Gaussian beam intensity resulted in three different areas of the ablated damage area, i.e., ripple pattern, alteration region, and ablated region. In the gentle ablation area, which yields a smaller spot size, the energy at the outward edge of the beam was below the threshold energy level. In a strong ablation regime, the outward edge of the beam has enough energy to enhance the width of the channel. In comparison to regular engineering metals, nitinol has a high incubation coefficient that has not produced a high accumulation effect. Low heat accumulation of nitinol gave an advantage in micro-machining by increasing MRR as well as maintaining dimensional accuracy and surface quality. Micro-profiling of nitinol-made medical stents is generally done by laser beam machining. A comparative analysis was carried out between dry and underwater micro-fabrication of NiTi tubes by a femtosecond pulse laser. The machined surface was analyzed after each machining condition. It was established that the cut surface under underwater conditions was free from recast layer and debris. Ultrasonic cleaning operation was required after dry cutting of nitinol by femtosecond laser. At optimum cutting conditions, both cutting qualities were similar, but the surface quality at dry conditions degrades due to recast layer formation and accumulation of debris particles [149]. NiTi SMA has multiple applications in the field of micro-actuation [150]. Nespoli et al. [151] investigated the thermo-mechanical and calorimetric features of NiTi SMA by constructing a snake-like micro-structure followed by chemical and electrochemical polishing with the aid of a pulsed fiber laser source. The top surface of the snake-like micro-channel was clean and accurate compared to the bottom surface, as to did not affect the electro polishing due to the presence of TiO2 coating. These two electrochemical processes formed an oxide layer, which provides better surface quality and fatigue performance. The long pulse width was used on the bottom surface. The lasing process was accompanied by pickling and electro polishing due to the accumulation of Ti oxides and modification of micro-structural properties. It is the most effective technique that yields a reduction in thickness and width, besides an increase in overall curvature of the micro-channel. The modification of micro-actuator groove dimension, except thickness pickling of NiTi stents, is essential in the medical industry in the form of these self-expanding stents, which are used to reform the circulation of blood flow in a human artery. Liu et al. [152] carried out research by micro-machining of NiTi tubes with the help of a fiber laser. The impact of machining parameters (power density, frequency, pulse width, and speed) on surface morphology, kerf characteristics, surface roughness, and heat-affected zone (HAZ) was examined after machining NiTi thin tubes. High power density increases the volume of molten material. When the power density was less than 2 J/mm, limited molten metal formed in the kerf, which prevented the creation of regular striation topography. No pure striation topography was created due to accelerated cooling and solidification of the molten metal. The average Ra was increased with power density. Together with a fast cooling effect, low cutting speed creates more re-solidified metal that produces a rough surface machining. With intermediate power density, low cutting speed, and powerful cooling effect conditions, narrow kerfs were developed. The largest HAZ was obtained at a higher power density with a higher cutting speed. Compared to the other topographies, mixed topography, along with a high striation ratio, offered a better surface finish. Hung et al. [153] established an improved processing path to control the depth, line width, and laser ablation rate (material removed per pulse) during micro-machining of the NiTi tube. The alternative laser processing path doubled the laser ablation rate (12.3 to 26.7 μm/J) for micro-machining of the NiTi tube (Figure 18a,b). The alternative path reduces the amount of accumulated energy by 50%, which improves the productivity of medical devices. By using air assistance, the new route provides enough space to clear debris.

Figure 18.

Ablation rate for (a) type 1 path and (b) alternative path of laser machining [145].

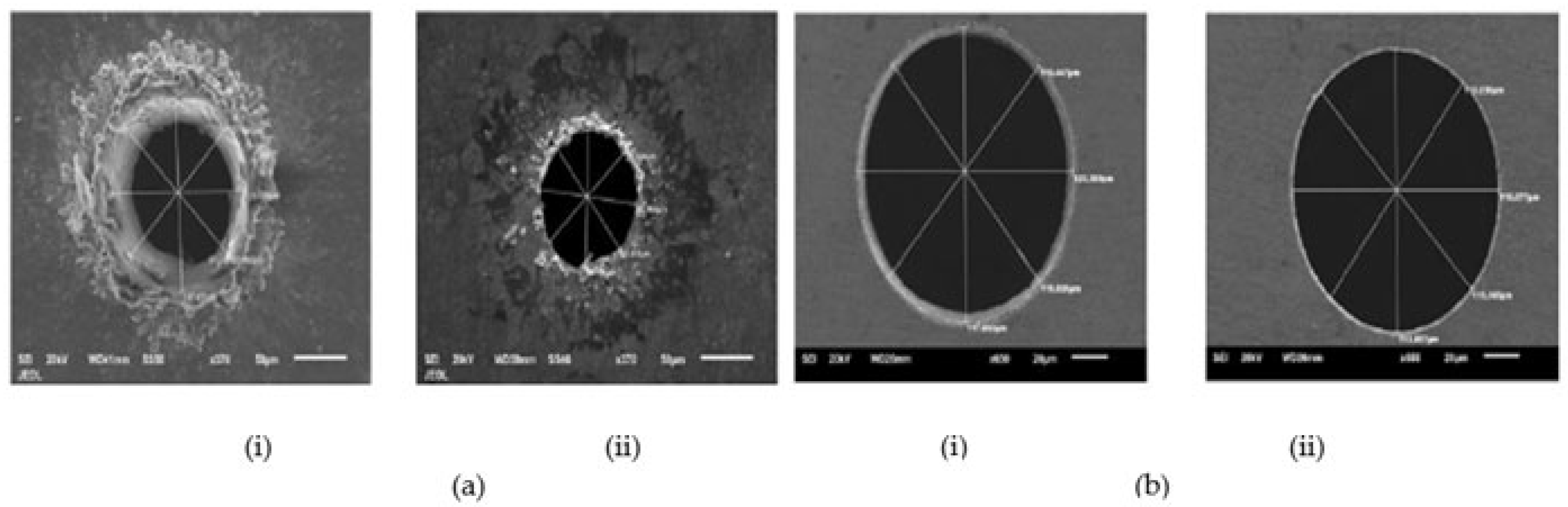

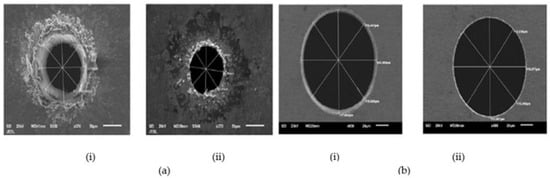

The extra laser energy used to ablate the NiTi workpiece reduces the manufacturing cost of medical devices. A comparative study was carried out between µ-EDM and laser micro-machining of NiTi SMA. The comparison took place based on MRR, dimensional accuracy, and surface finish of the drilled micro-holes produced by both machining processes. Compared to laser machining, μ-EDM is a very slow operation. The MRR was large enough for laser machining compared to the µ-EDM of NiTi SMA. Also, in laser machining, the deviation of input and output diameter of the micro-hole was lower than the μ-EDM process. LBM produces a greater micro-hole overcut in NiTi SMA compared with the μ-EDM process. The high amount of laser power and convergence–divergence characteristics of the laser beam influence a larger overcut in LBM. Micro-holes produced by LBM obtained high degrees of taper, high circularity error, a large heat-affected zone (HAZ), high recast layer thickness, and massive spatter around the circumference of the holes as compared to the µ-EDM process (Figure 19).

Figure 19.

SEM images of micro-hole at (i) entrance and (ii) exit produced by (a) LBM and (b) µ-EDM process [154].

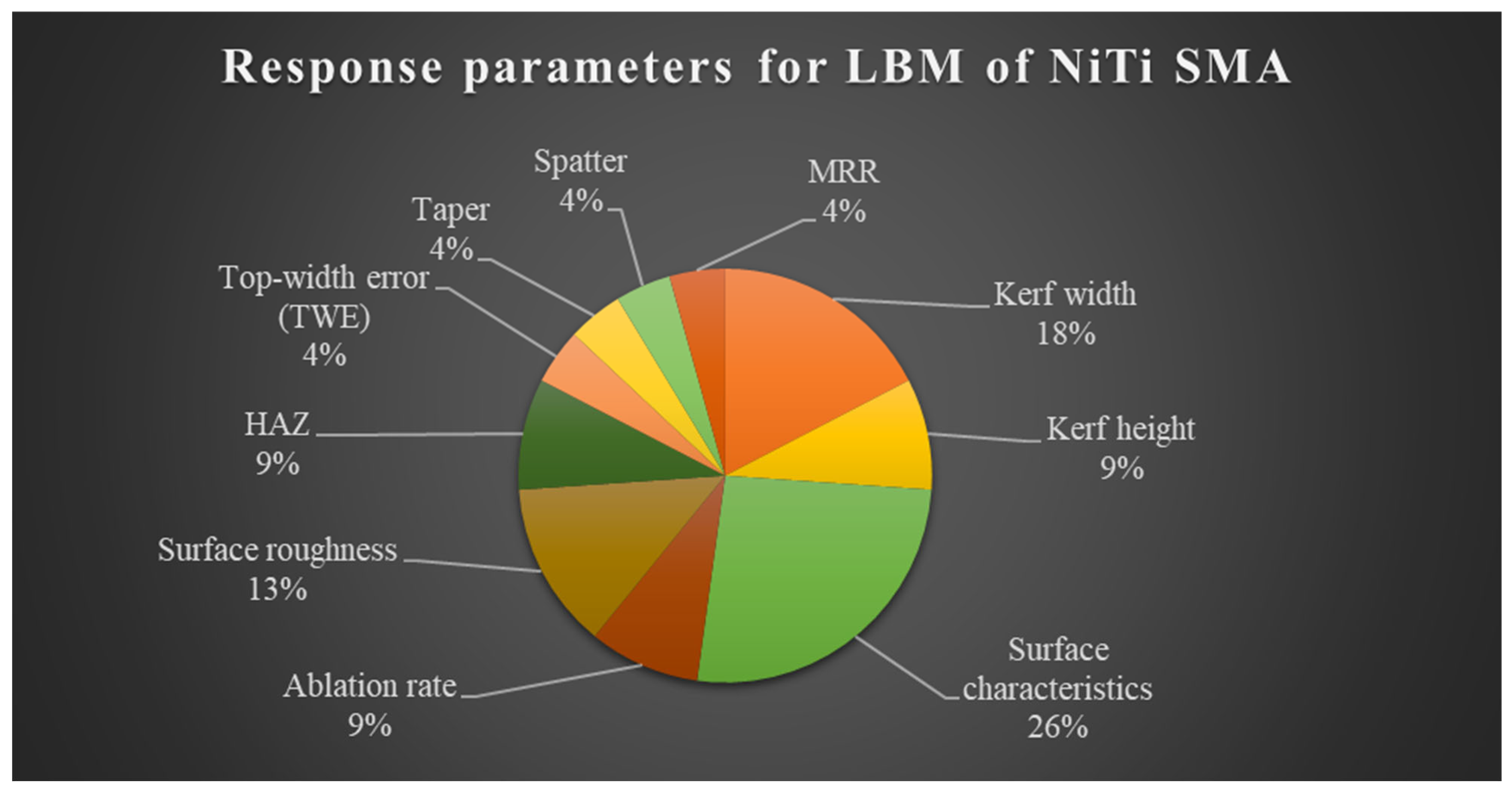

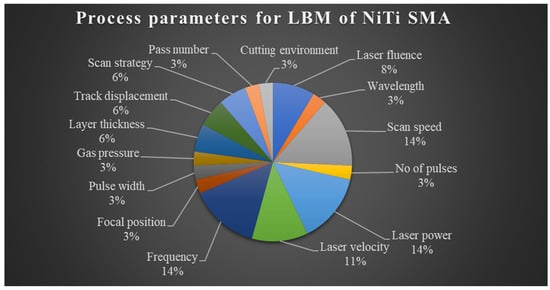

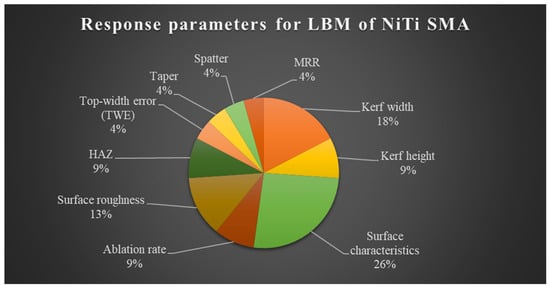

High MRR and the laser beam’s clash with the micro-hole’s top surface led to an increase in its taper angle. The quality of the micro-holes produced by µ-EDM was found to be much better in comparison with the LBM process [154]. Research was carried out by Mohammed et al. [155] where micro-channels were drilled on NiTi SMA by an Nd: YAG laser of wavelength 1064 nm. The study aimed to find the optimum lasing parameter for lower taper angle, less spatter, minimum tool wear rate, and maximum MRR. A multi-objective optimization tool named MOGA-II was applied for the simultaneous optimization of lasing variables. It was established that high laser speed, along with large layer thickness and a scan strategy, increase the dimensional accuracy of the micro-channel. The lowest taper angle was discovered for a low layer thickness of the laser. Higher MRR can be obtained for large speed, track displacement and layer thickness. MOGA indicated that the desired response variables were obtained by high frequency, medium speed, low layer thickness and track displacement. Muralidharan et al. [156] carried out a parametric study during Pulsed Nd:YAG laser machining of NiTi SMA. The influence of laser power, frequency and cutting speed on the surface roughness was determined. Surface roughness was decreased with the increase in cutting speed and the enhancement of laser power raises the surface roughness as well. Ebenezer et al. [157] applied a short pulse laser while laser drilling of NiTi SMA. The application of a short pulse laser reduces the energy density and provides a superior surface finish of the micro-fabricated part of nitinol. Ryu et al. [158] improve the actuation energy of NiTi SMA by introducing laser surface texturing through a nanosecond laser. The actuation performance of the nitinol has been enhanced twice that of the pristine sample. Figure 20 represents the process parameters in LBM of NiTi SMAs. Figure 21 expresses the response parameters during LBM of NiTi SMAs. The collected data were calculated by using the work mentioned in [144,145,146,147,148,149,150,151,152,153,154,155,156,157].

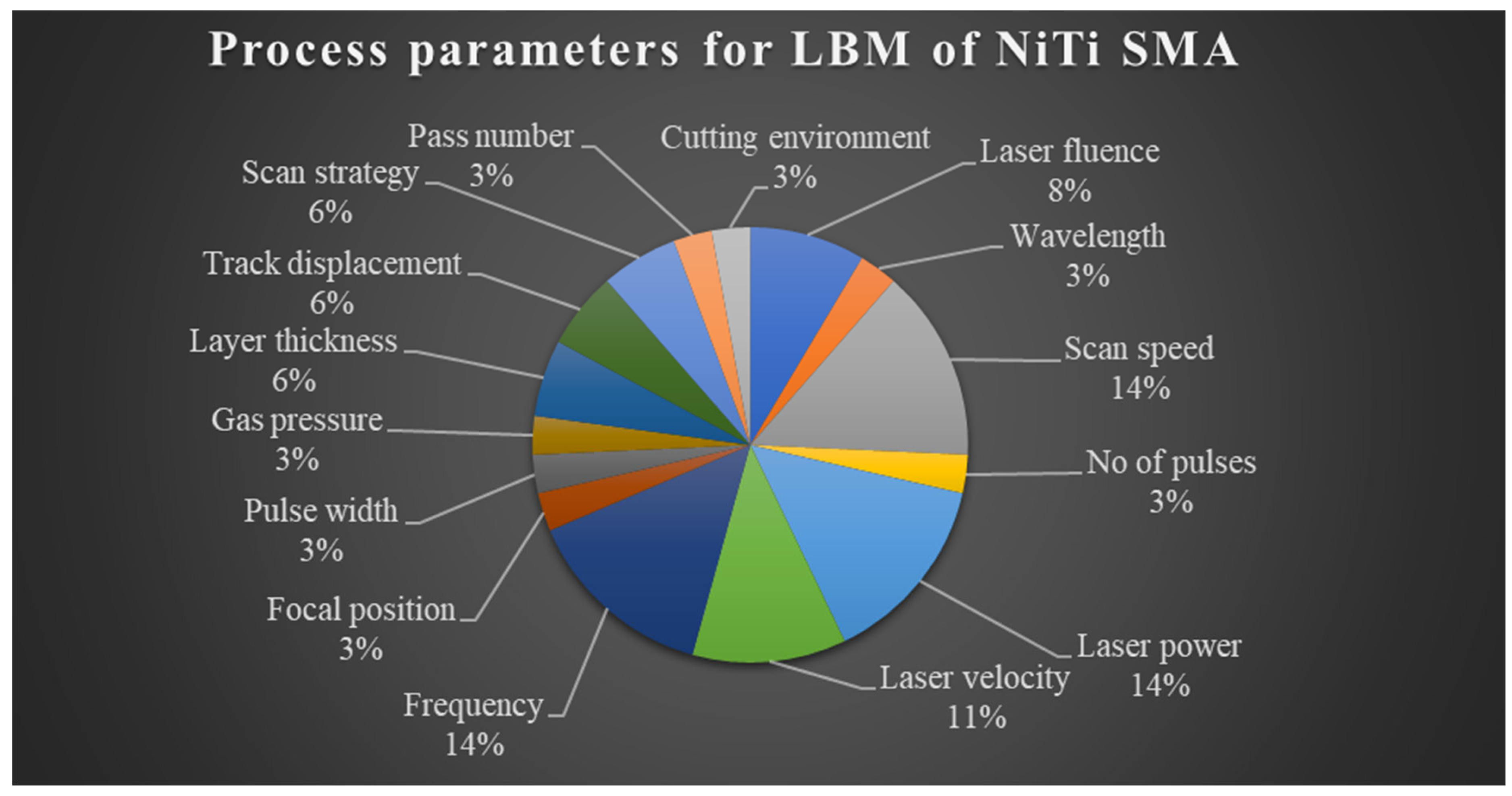

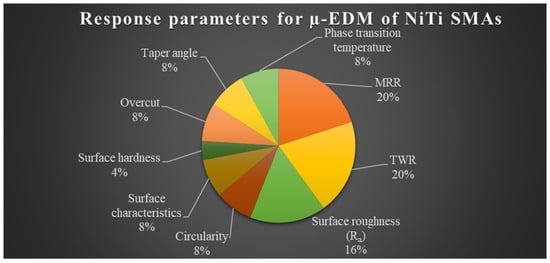

Figure 20.

Process parameters in LBM of NiTi SMAs.

Figure 21.

Response parameters in LBMAWJM of NiTi SMAs.

6.4. Electrochemical Micro-Machining (ECMM)

Most of the thermally influenced non-conventional processes, such as LBM, EBM, etc., produce thermal stresses on the fabricated surface [159]. ECM is a chemical machining process that can produce stress-free surfaces. Electrochemical micro-machining (ECMM) is the advanced version of the ECM process. It is one of the non-conventional processes of micro-machining that has an immense application in the aerospace, automotive, biomedical, and electronic industries [160,161,162,163]. In ECMM, the material is removed at a micron level from the workpiece surface to produce high aspect ratio holes, complex µ-shapes, and tools [164]. Owing to its high MRR, low machining time, and environmentally friendly behavior, ECMM is a popular micro-machining technique [165]. ECMM with ultra-short pulses produced mask-free, strain-free, and heat-free surfaces on NiTi sheets. Three-dimensional complex micro-structures are produced by changing the electrolyte concentration on NiTi foil during the ECMM process. The depth of the micro-grooves is increased with current density and duty factor during SPECMM of NiTi sheets. Adding a certain amount of ethanol to the electrolyte solution improves the surface quality and machining precision during ECMM of NiTi SMA. NPE gave higher MRR, and improved geometrical features were achieved by PE. Duty cycle was found to be the most influential parameter for both cases. CPE gave less surface roughness and better surface integrity compared to the PE and NPE, as it has both the PE and NPE. The SMA properties remain unaffected after the laser-assisted ECMM process. In the ECP finishing operation, the acid electrolyte is faster than the neutral electrolyte while micro-machining of NiTi SMA. Acid electrolyte established a better surface finish compared to the neutral electrolyte.

Research Progress:

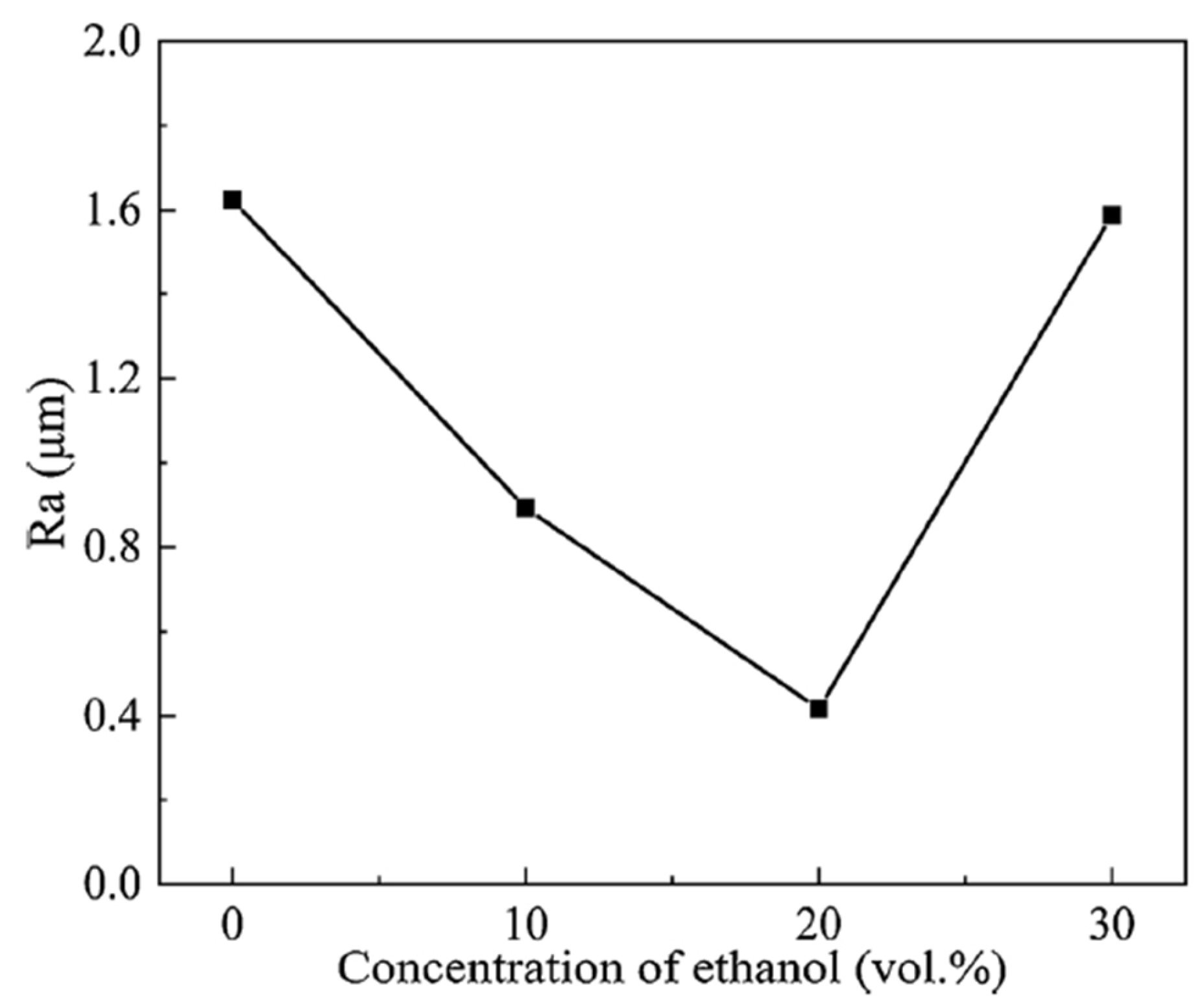

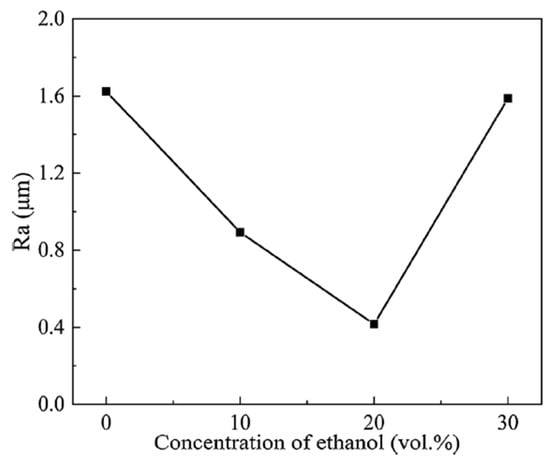

Electrochemical micro-machining (ECMM) is adapted to create some micro-structure on NiTi SMAs. It can be applied in various fields like medical, aerospace, automobile, etc. ECMM with ultra-short was applied for making micro-structures on the NiTi sheet. The current density was increased within a small segment of the gap voltage. It was established that sometimes, unknown material was deposited on the micro-structure spotted on NiTi SMA. ECMM developed surfaces on NiTi SMA, which were free of strain, heat, and mask [166]. Ma et al. [167] reported a confined etchant layer technique (CELT) with a triple-electrode method for the micro-manufacture of 3D complex form on NiTi SMA. Etching solution containing F− and NO− was used to perfom micro-machining on NiTi SMA. The micro-machining method was dominated by the etchant’s OH- ion concentration. Electrolyte composition was optimized by selecting the different concentrations of NaOH to achieve a precise micro-machined surface. CELT was found to be successful in fabricating 3D complex structures for both micro- and nano-patterns on NiTi SMAs. An experimental analysis was carried out by milling micro-grooves on nitinol by a short pulse electrochemical micro-machining (SPECMM) process. The effect of different machining factors on the dimension of the micro-grooves was calculated. The MRR was simulated and correlated with the findings from the experiment. It was noticed that the simulated MRR was not close enough to the experimentally measured MRR due to the assumption of continuous pulse power. The depth of the micro-grooves was increased with current density and duty factor. Higher current gave a poor surface finish. The enhancement of machining time decreases the deviation of depths of the micro-grooves [168]. Ao et al. [169] carried out an investigation where micro-grooves were fabricated on NiTi SMA by the ECMM process. Ethanol was mixed with the glycol-NaCl electrolyte solution at different concentrations to enhance the machining accuracy and surface quality. It was found that ethanol can produce a TiCl4 layer on the NiTi surface, which prevents the oxide layer formation. An improved surface roughness was obtained at a 20 vol% ethanol mixed electrolyte solution. However, an excess amount of ethanol can damage the surface quality and machining accuracy (Figure 22). Mouliprasanth et al. [170] investigated surface roughness and surface integrity during ECMM of NiTi SMA in passivating electrolyte (PE), non-passivating electrolyte (NPE), and composite electrolyte (CPE). CPE gave less surface roughness and better surface integrity compared to the PE and NPE, as it has both the PE and NPE. A comparative investigation was conducted to machine nitinol by WJM and AWJM processes.

Figure 22.

Variation in surface roughness with concentration of ethanol [169].

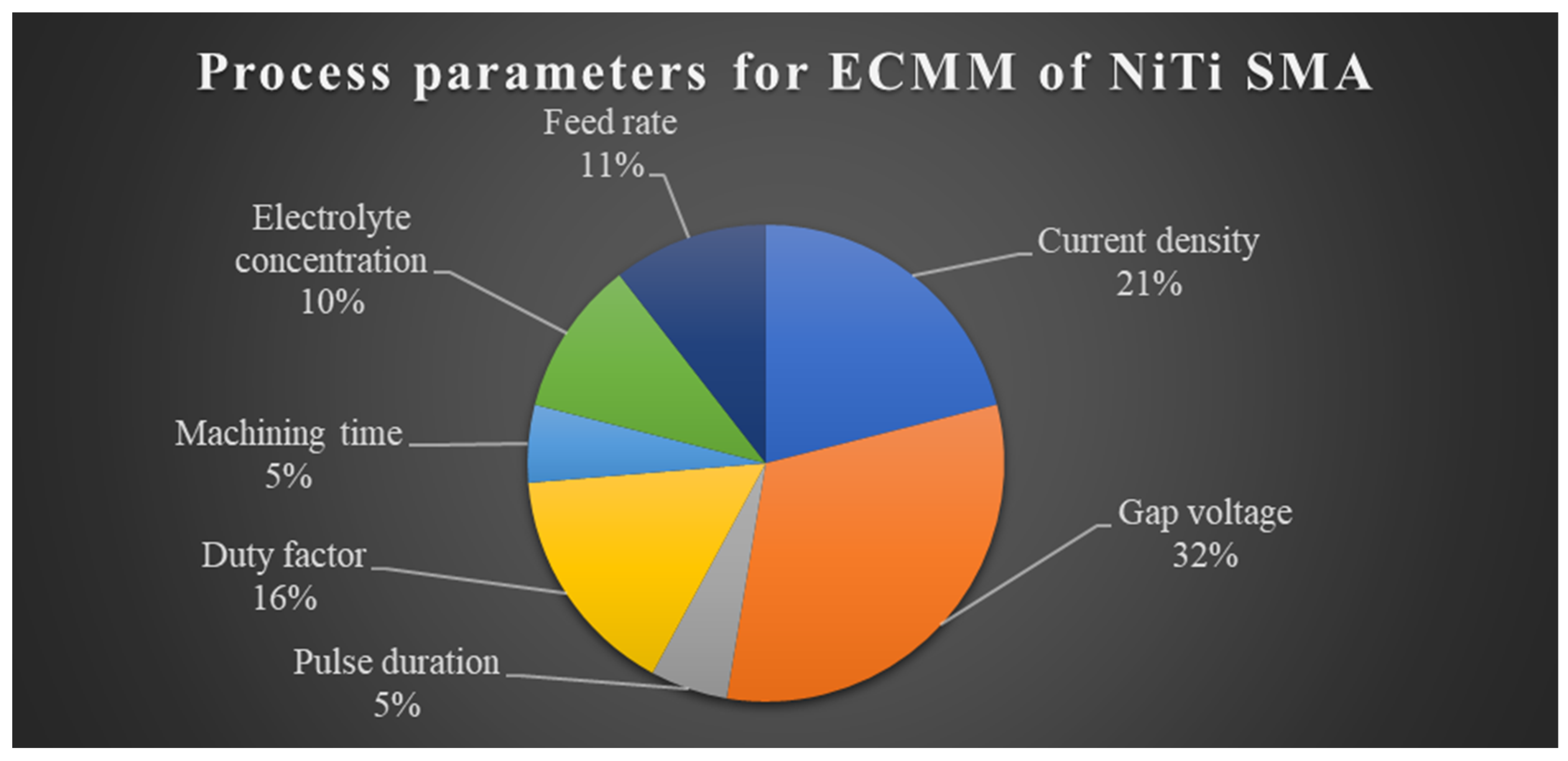

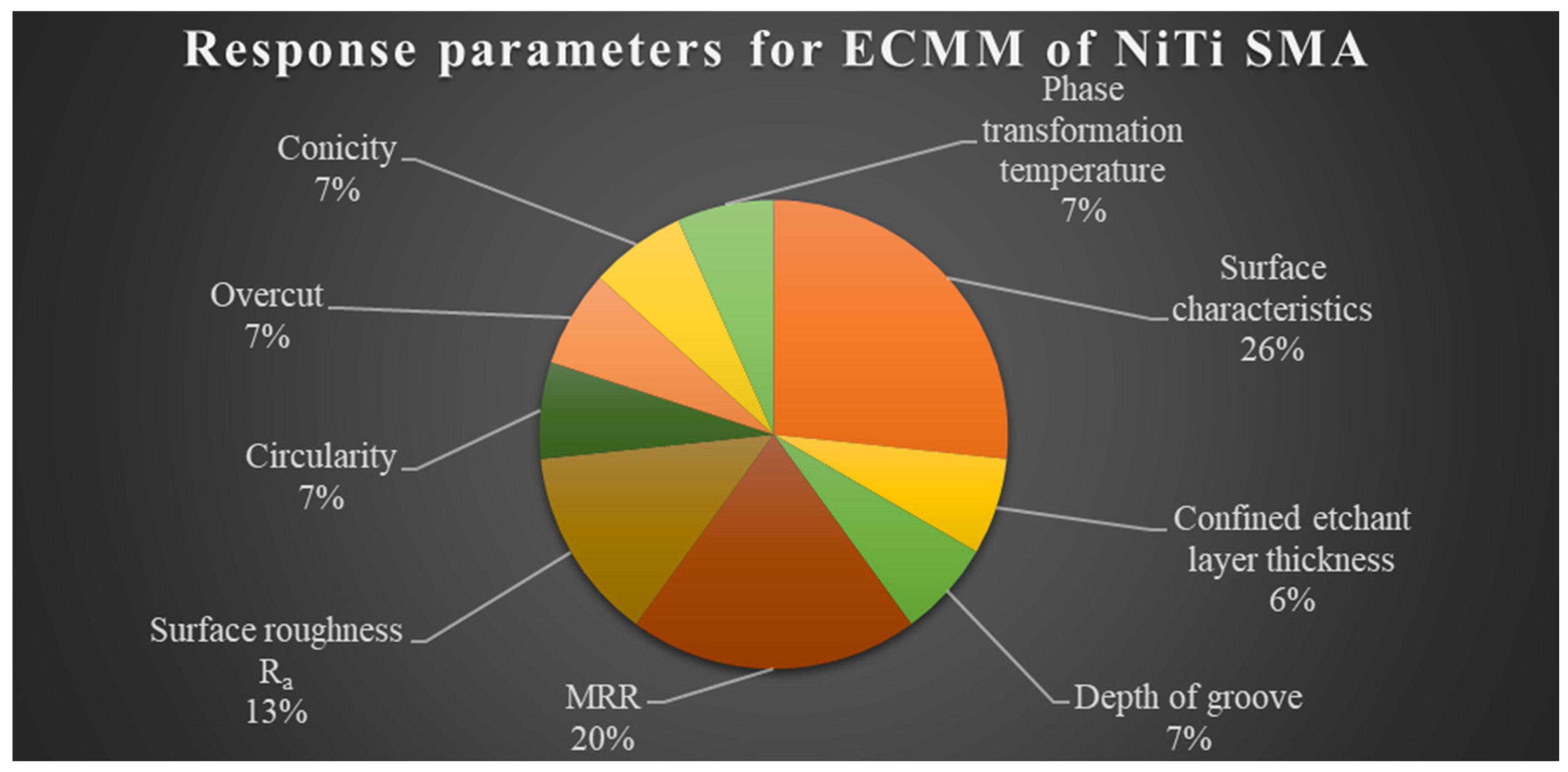

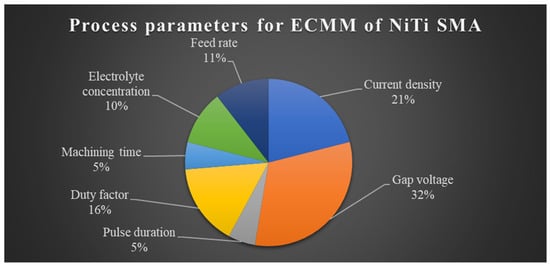

Mouliprasanth et al. [171] identify the influence of passivating (PE) and non-passivating electrolytes (NPE) on the overcut, MRR, circularity, and conicity of the drilled micro-holes on NiTi SMA by the ECMM process. NPE gave higher MRR, and improved geometrical features were achieved by PE. Duty cycle was found to be the most influential parameter for both PE and NPE conditions, followed by voltage and feed rate for MRR, overcut, and conicity of the drilled micro-hole. Saxena et al. [172] conducted a study for the ECMM of actuator-grade nitinol SMA with laser assistance. The SMA properties remain unaffected after the laser-assisted ECMM process. There was an increase in machining speed and surface integrity after introducing a laser in ECMM for actuator-grade nitinol SMA. Das et al. [173] determine the impact of process variables on the MRR, overcut, taper angle, and circularity error by using different electrode materials like copper, brass, and tungsten during micro-ECM of NiTi SMA. Tungsten electrode provides superior results in comparison to other electrodes. Sethi et al. [174] applied different electrolytes to investigate the electrochemical dissolution behavior during ECMM of NiTi SMA. The ethylene glycol-based NaNO3 provided superior dimensional accuracy as compared to the aqueous NaNO3 electrolyte solution. Besekar et al. [175] mixed 0.1 M citric acid with 0.1 M H2SO4 electrolyte during WECM of NiTi SMA. The mixed electrolyte provided better surface finish and less slit width as compared to 0.1 M H2SO4 electrolyte for all the sets of process parameters. Sethi et al. [176] identify the influence of pulse frequency and micro-tools rotational speed on the surface roughness and dimensional deviation during ECMM of NiTi SMA. Precise micro-channels were successfully fabricated at 1 MHz, 2 MHz, and 3 MHz pulse frequencies, respectively. Sethi et al. [177] investigate the machining dimensions and 3D surface roughness during single-pass ECMM of NiTi SMA. RSM-based desirability was utilized for optimization, and the multi-pass ECMM has been obtained at the optimal condition. Figure 23 represents the process parameters in ECMM of NiTi SMAs. Figure 24 expresses the response parameters during ECMM of NiTi SMAs. The collected data were calculated by using the work mentioned in [166,167,168,169,170,171,172,173,174,175,176,177].

Figure 23.

Process parameters in ECMM of NiTi SMAs.

Figure 24.

Response parameters in ECMM of NiTi SMAs.

6.5. Electrochemical Polishing (ECP)

Electrochemical polishing is a non-traditional non-contact surface finishing operation that can generate a micro-level surface finish of any complex geometry in any conductive material regardless of its hardness, toughness and other bulk properties [178]. It has the ability to generate a smooth, bright, and shiny surface as well as a high level of corrosion resistance [179]. This process would eliminate the additional deburring process if a contact-type surface finish operation were applied [180].

Research Progress:

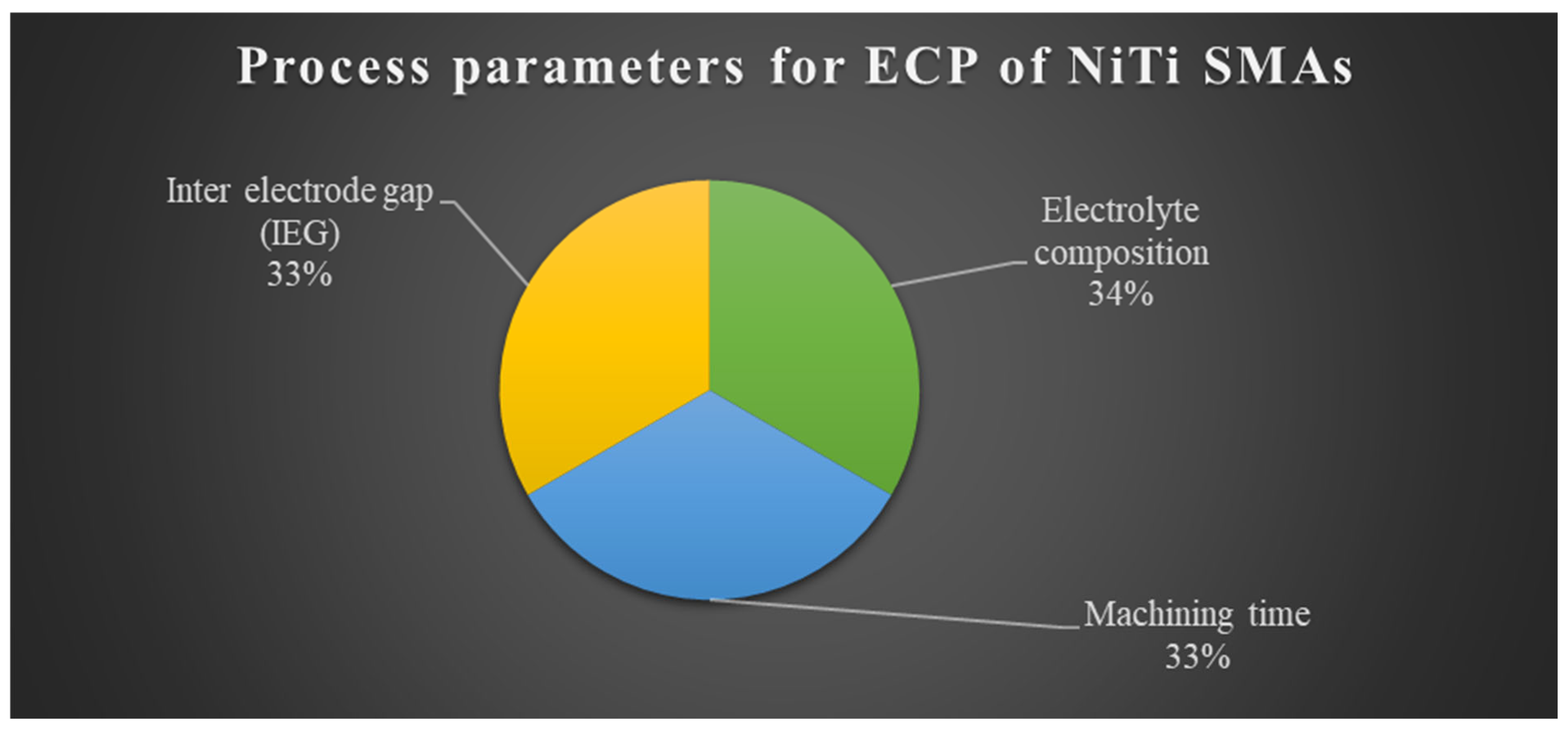

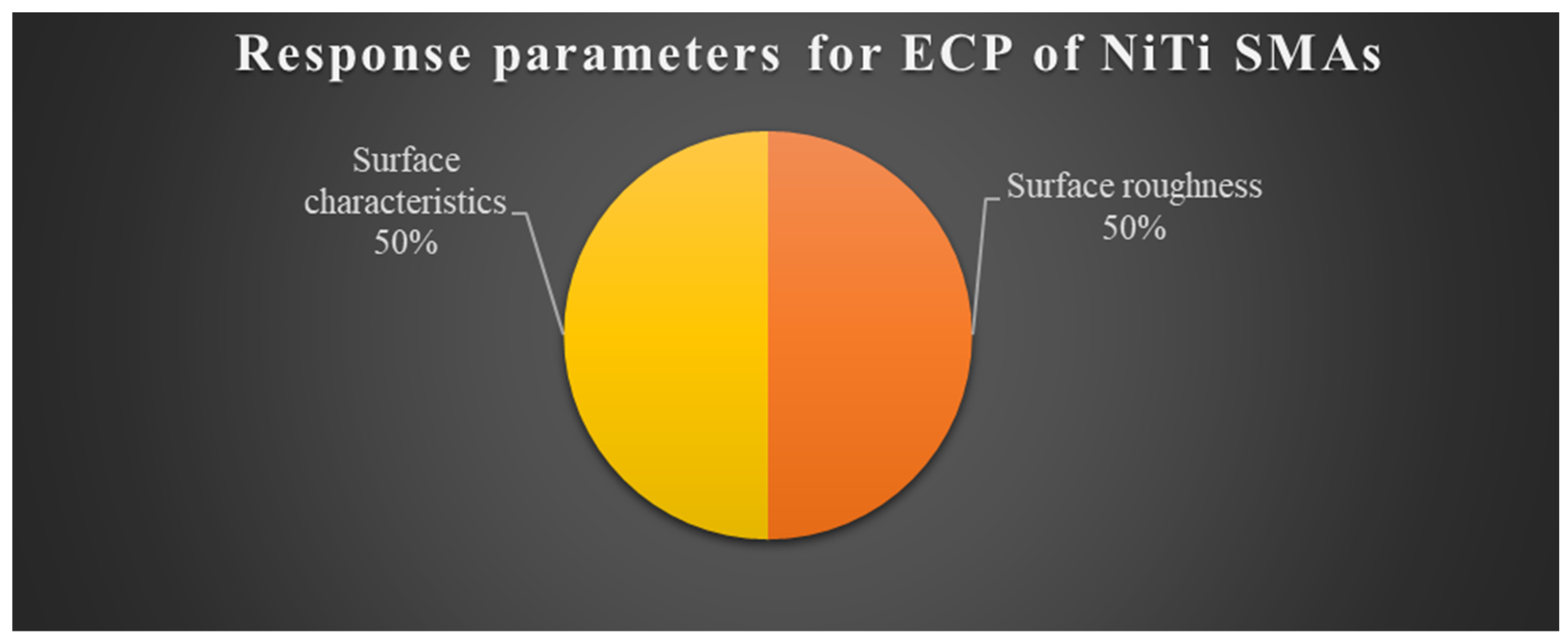

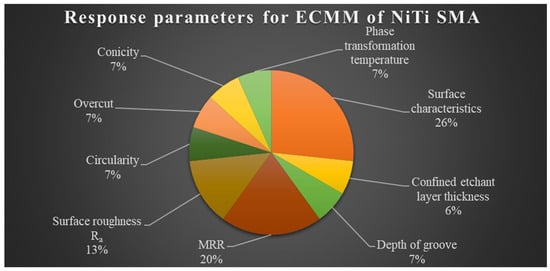

Equiatomic NiTi SMA has a huge application in the biomedical industry [38]. A highly accurate and precise machined surface of NiTi was needed during application in the biomedical industry. Electrochemical polishing (ECP) is one of the finishing operations applied to generate a superior surface finish [181]. ECP was done on NiTi SMA to investigate the most suitable process parameters (composition of electrolyte, applied current, time for machining, and inter-electrode gap (IEG)), which generate a superior finish on NiTi SMA. The acid electrolyte (H2SO4 (17.8 M) + H3PO4 (14.6 M) + H2O) was found to be faster compared to the neutral electrolyte (NaNO2 (1.5 M) + Na2C4H4O6 (0.1 M)) during ECP on the NiTi plate. The dissolution of NiTi in neutral electrolyte was found to be more compared to the acid electrolyte. Acid electrolyte produces a large amount of oxygen on NiTi SMA after the ECP process. A higher amount of current produces a better surface finish, but the machining process becomes unstable at higher current density. The less IEG, the better the surface finish, although a very small IEG makes the process unstable, which produces bubble marks on the nitinol surface. Therefore, it was recommended to carry out ECP on the rough surface of the NiTi SMA after the normal machining process [182]. Lopes et al. [183] established an optimal electrolytic solution of 3.5 mol/L methanolic H2SO4 electrolyte at 20 °C, which successfully improved the surface roughness and provided corrosion resistance by generating a thin TiO2 protective layer. This surface modification enhances the application of NiTi wires in medical devices. Figure 25 represents the process parameters in the ECP of NiTi SMAs. Figure 26 expresses the response parameters during ECP of NiTi SMAs. The collected data were calculated by using the work mentioned in [182,183].

Figure 25.

Process parameters in ECP of NiTi SMAs.

Figure 26.

Response parameters in ECP of NiTi SMAs.

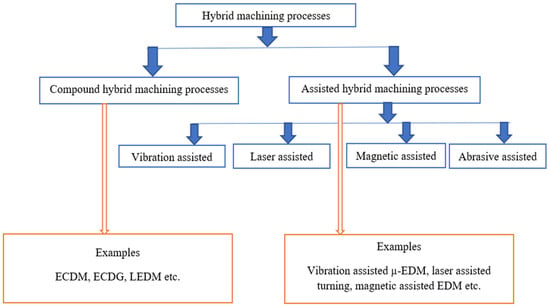

6.6. Hybrid Machining

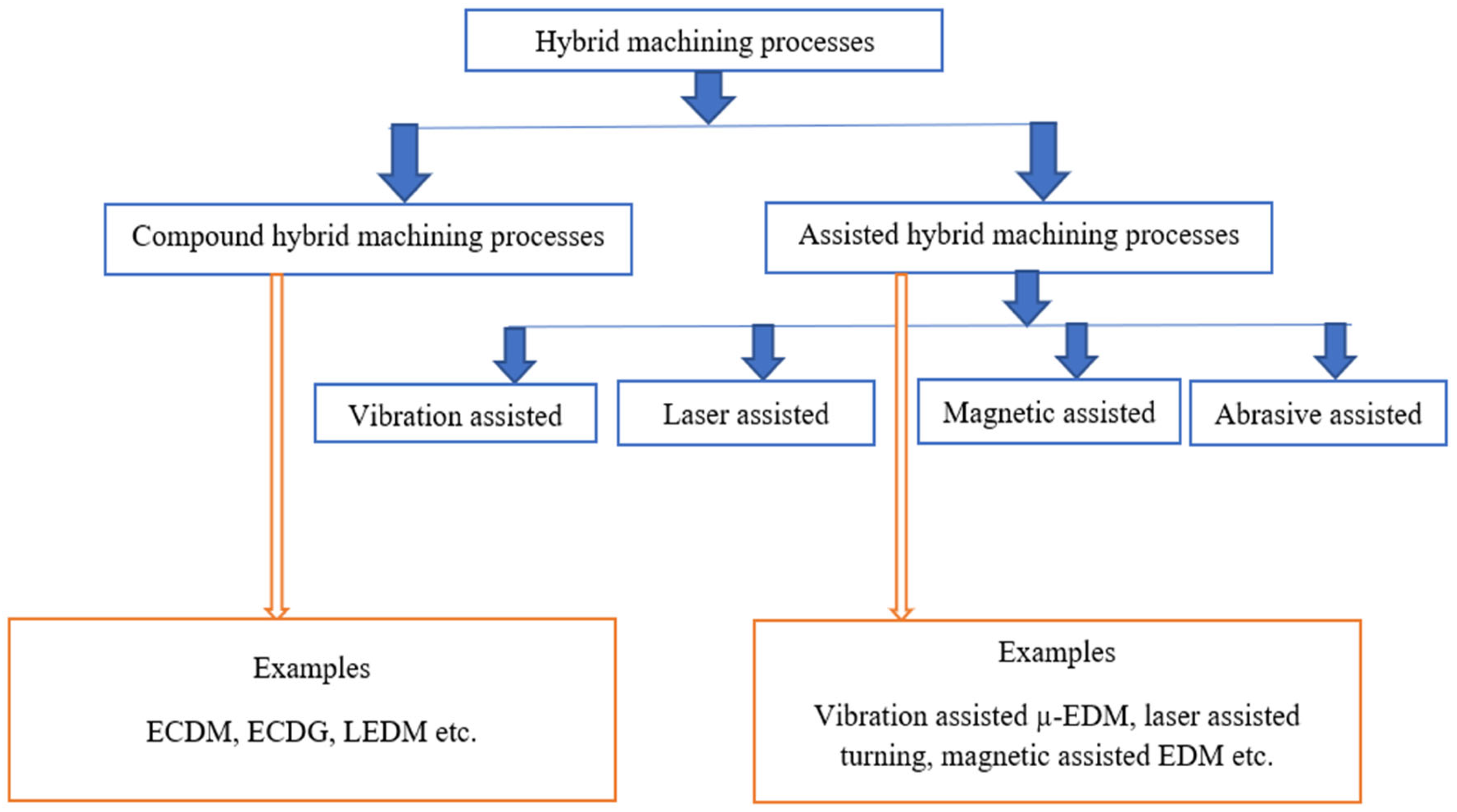

A single machining operation always has some disadvantages towards machining efficiency. Hybrid fabrication approaches come into the picture in the present manufacturing industry to overcome these challenges of single machining processes. In hybrid machining, two or more machining processes are combined with each other and decrease the adverse effect of a single machining process [184]. There is no fixed definition of a hybrid machining process [185]. Various researchers [186,187,188,189] gave their views about hybrid machining processes. According to [184], there are two categories of hybrid machining processes: compound hybrid machining processes and assisted hybrid machining processes.

In the case of compound hybrid fabrication, at least two machining processes are compounded, and material is removed through one-by-one machining processes, providing substantial changes eventually [190]. Material is extracted by the primary machining process in the assisted hybrid machining process. Some energy is put into the secondary machining process to increase machining performance [191]. The classification of hybrid machining processes is described in Figure 27 [192].

Figure 27.

Classification of hybrid machining processes [192].

Research Progress:

Al-Ahmari et al. [193] studied the hybrid machining process named laser electro-discharge machining (LEDM) by combining LBM and µ-EDM to machine micro-holes in NiTi sheets. Micro-holes were drilled by an Nd: YAG laser and rimmed out by µ-EDM. Proper flushing in the LEDM process reduces the debris as well as secondary spark formation between the tool and the workpiece. For such a reason, the overcut in the LEDM process was lower relative to the μ-EDM process. The taper angle in the LEDM process was immensely reduced compared to the µ-EDM process. Proper flushing reduces debris in the machining zone, which controls a short circuit’s chance during the LEDM process. Compared to the normal μ-EDM process, a higher MRR was maintained in the LEDM process. The total TWR was reduced by 30–45% in the LEDM process for proper flushing of dielectrics. There was a huge upgrade in the micro-hole created by LEDM compared to the LBM process. Micro-machining aided by ultrasonic vibration enhanced machining efficiency in a smart way [194]. When the vibration is introduced to the tool electrode of the micro-electrical discharge machine, it enhances the stirring effect of the dielectric, which leads to an increase in the machining efficiency. Huang et al. [195] carried out research where micro-holes were drilled on the NiTi SMA by a ultrasonic-assisted micro-electro-discharge machining (UAµ-EDM) process. Ultrasonic vibration was applied to the tool electrode. The hole depth and electrode wear rate were analyzed by altering the amplitude of the vibration, sparking gap, and electrode size in different machining times. It was established that larger amplitude increases the machining efficiency up to a specific value, but beyond that, they damage the dimensional accuracy of the micro-holes. Elevated discharge voltage increases the tool wear rate. A larger pre-setting sparking gap and large tool size increase the flushing capability of the dielectric, which enhances the machining efficiency up to 60% at the expense of small tool wear. Che et al. [196] introduce ultrasonic vibration during ECP of NiTi SMA. The application ultrasonic vibration reduces the Ra value from 2 µm to 0.048 µm. It enhances the MRR and improves the surface quality of the NiTi SMA.

7. Optimization of Micro-Machining Process Parameters for NiTi SMAs

Optimization of process parameters improved the product quality proportionally [197]. Optimization took place according to the desirability of the response variables. The optimized machining parameters gave the most suitable environment for the output variables. It enhanced the product life-cycle in a very efficient manner [198]. Several advanced optimizations, as well as modeling tools, are used during micro-machining processes. These tools are used to increase the product quality and life cycle during the conventional as well as the non-conventional micro-machining process. Advanced non-conventional manufacturing processes have several advantages over conventional processes. These processes have many input factors or variables that affect each of the responses. Therefore, proper selection of these variables is very important. The situation becomes more complicated when more objectives are involved in the optimization problem. This kind of moment is not suitable for conventional optimization processes. For the past two decades, many advanced optimization tools have been developed, such as PSO, PCA, GA, RSM, fuzzy logic, etc., which can smoothly handle many objectives in the optimization problem [199]. These modeling and optimization processes are capable of dealing with many process parameters along with several optimization goals. Therefore, modern manufacturing industries have adopted these processes to increase their productivity with minimum cost [200].

Some of the advanced modelling and optimization tools used during micro/macro-machining processes are artificial neural network (ANN), response surface methodology (RSM), principal component analysis (PCA), genetic algorithm (GA), fuzzy logic (FL), particle swarm optimization (PSO), etc. The artificial neural network is a soft computing tool invented from biological neural networks [201]. It is one of the machine learning algorithms that is capable of processing complex input datasets. Such of system learn from the process and tries to mimic the performance of the process parameters [202]. ANN can successfully solve a variety of industrial problems such as image recognition, pattern recognition, function approximation, prediction, and optimization [203]. It has a high generalizing capability to work with incomplete knowledge or a dataset. ANN can handle more than one job at the same time. Several researchers applied ANN for modeling and optimization of micro-machining processes [204,205,206,207]. There have been no credible studies on the usage of ANN during micro-machining of NiTi SMAs.

RSM is a statistical modeling process that can solve for the response variable, which is influenced by various input factors [208]. This method produces the interaction between various factors, which is not possible in classical statistical methods [209]. RSM can design fewer experimental trials and graphically represent the combination of all possible factors. It can be easily used to solve multi-objective optimization problems. It creates mathematical regression models to depict the relationship between the response and the input variables [210]. RSM can be applied successfully in the micro-machining domain to optimize the process parameters [211,212,213,214]. There are no credible studies that show the application of RSM during micro-machining of NiTi SMAs. One of the oldest statistical techniques for multivariate data analysis is principle component analysis (PCA), which was first invented by Pearson [215] and established by Hotelling [216]. It uses vector transformation to reduce the dimensionality of a large dataset. It converts the largely correlated variables to the uncorrelated few variables called principal components while retaining much variation in the present dataset. PCA is prominently used in the field of micro-machining to optimize the process characteristics [217,218,219,220]. Abidi et al. [124] applied Taguchi’s PCA approach for multi-response optimization of machining variables during µ-EDM of NiTi SMA. It was found to be more accurate compared to the single-response optimization process. The optimized machining parameters gave an excellent surface finish in NiTi SMA.

Genetic algorithm (GA) is a popular search-based algorithm that is based on Darwin’s principle, i.e., survival-of-the-fittest. It is inspired by the natural evolution process [221]. It is one of the powerful optimization tools that can easily locate the global optimum. It uses a fitness or objective function to find the optimal solution. It starts to find the optimum solution from a group of points rather than a single point. GA uses three steps, i.e., reproduction, crossover and mutation, to compute the optimum solution [222]. Many researchers use GA to optimize the micro-machining process parameters in their study [223,224,225,226]. Abidi et al. [125] employed a multi-objective genetic algorithm- II (MOGA- II) for multi-response optimization of machining parameters during µ-EDM of NiTi SMA. It is successful in finding the optimal machining parameters based on the desirable response variables. Mohammed et al. [147] used MOGA- II for the simultaneous optimization of machining variables during LBM of NiTi SMA. It successfully identifies the optimal machining parameters based on response variables desire.