Knot-TPP: A Unified Deep Learning Model for Process Incidence and Tool Wear Monitoring in Stacked Drilling

Abstract

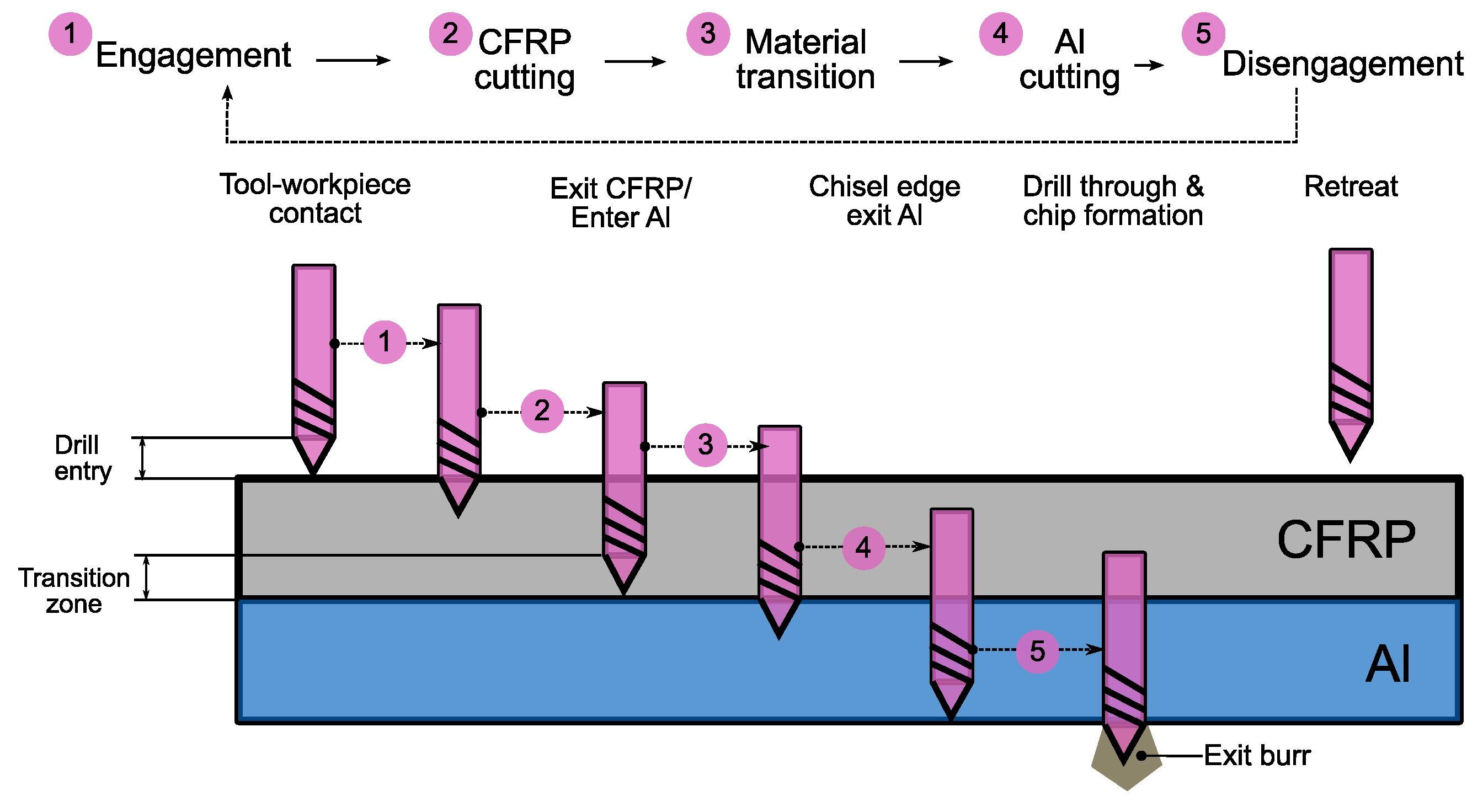

1. Introduction

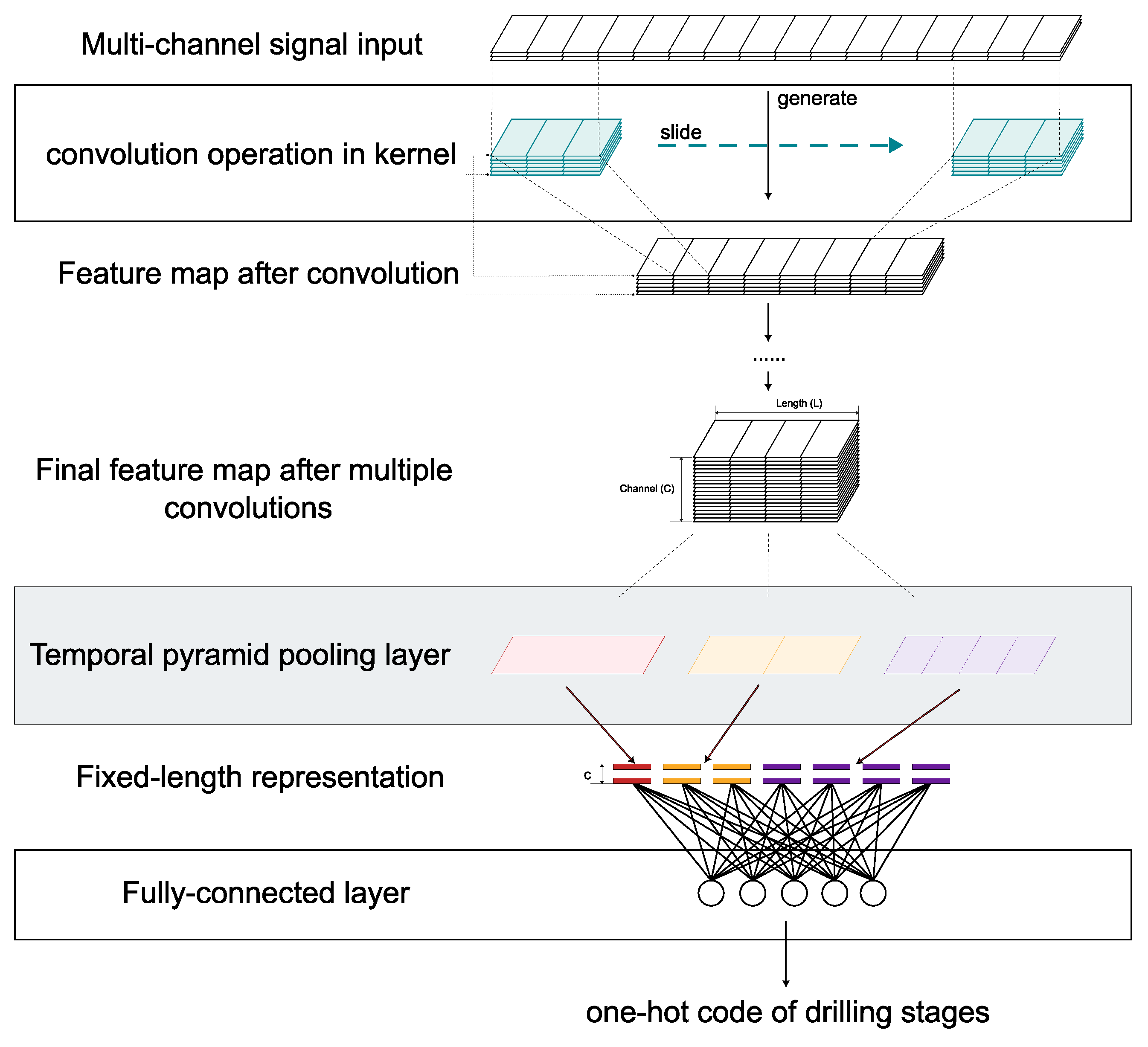

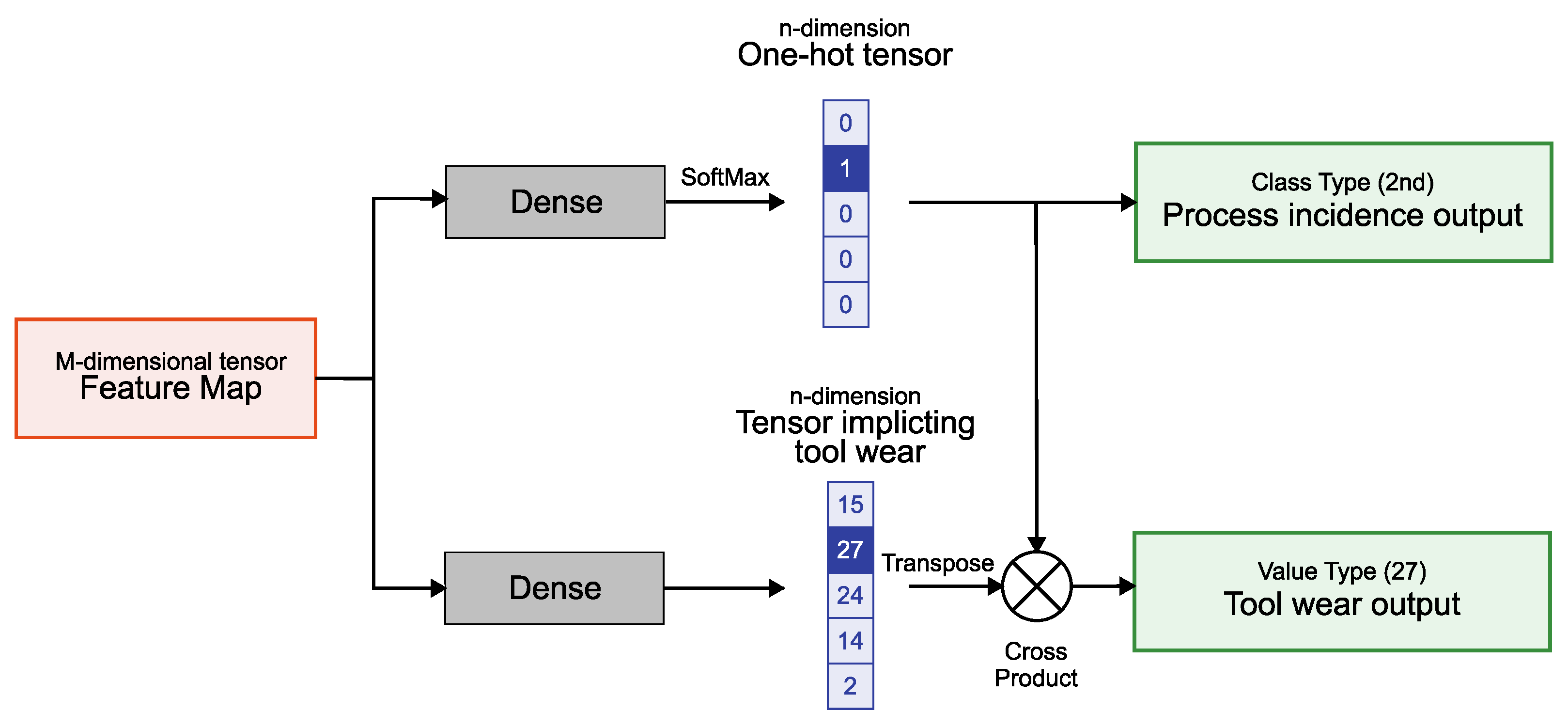

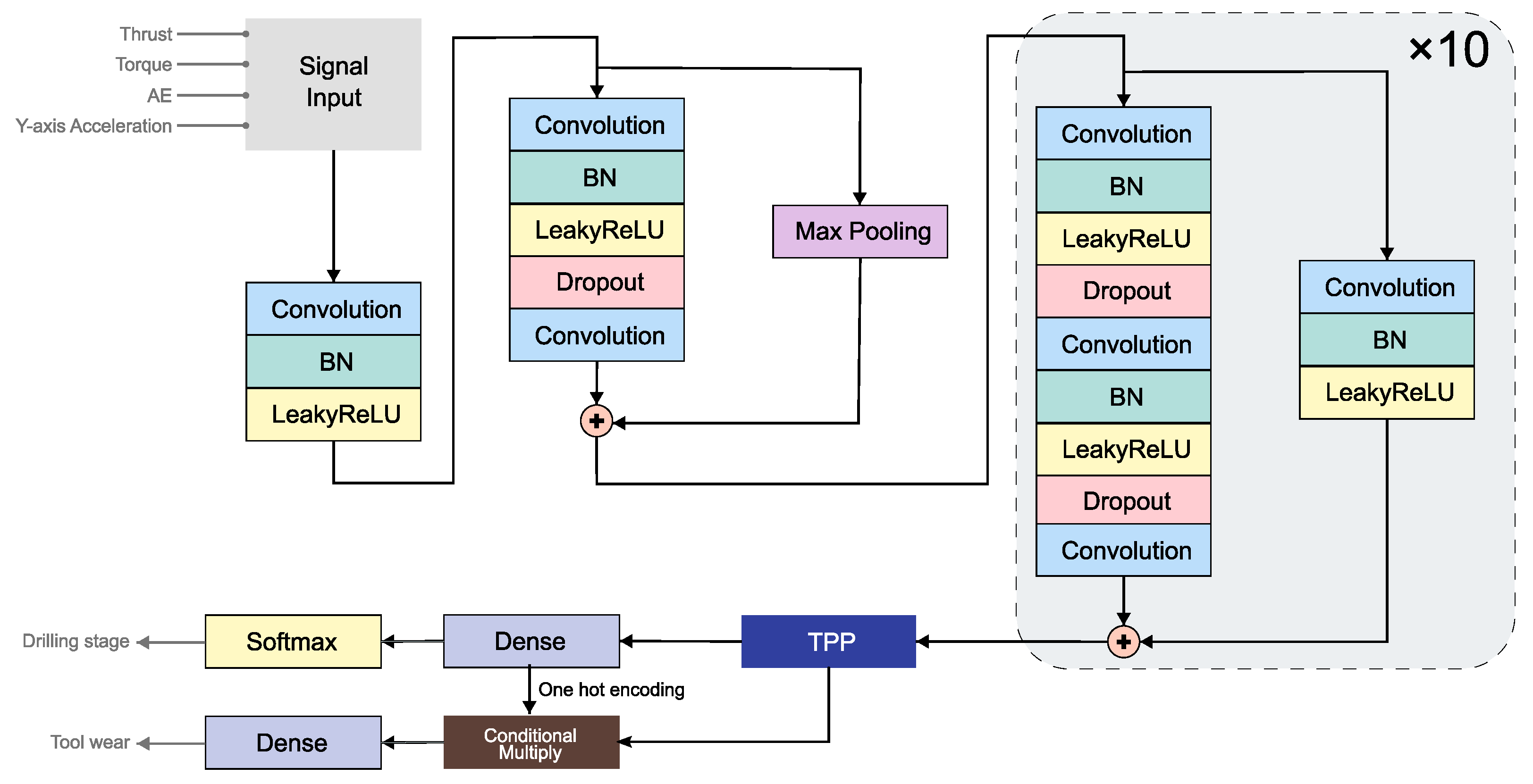

2. Methodology

2.1. Temporal Pyramid Pooling

2.2. Knot Structure to Integrate Tool Wear Prediction with Process Incidence

2.3. Knot TPP Model for Unified Prediction

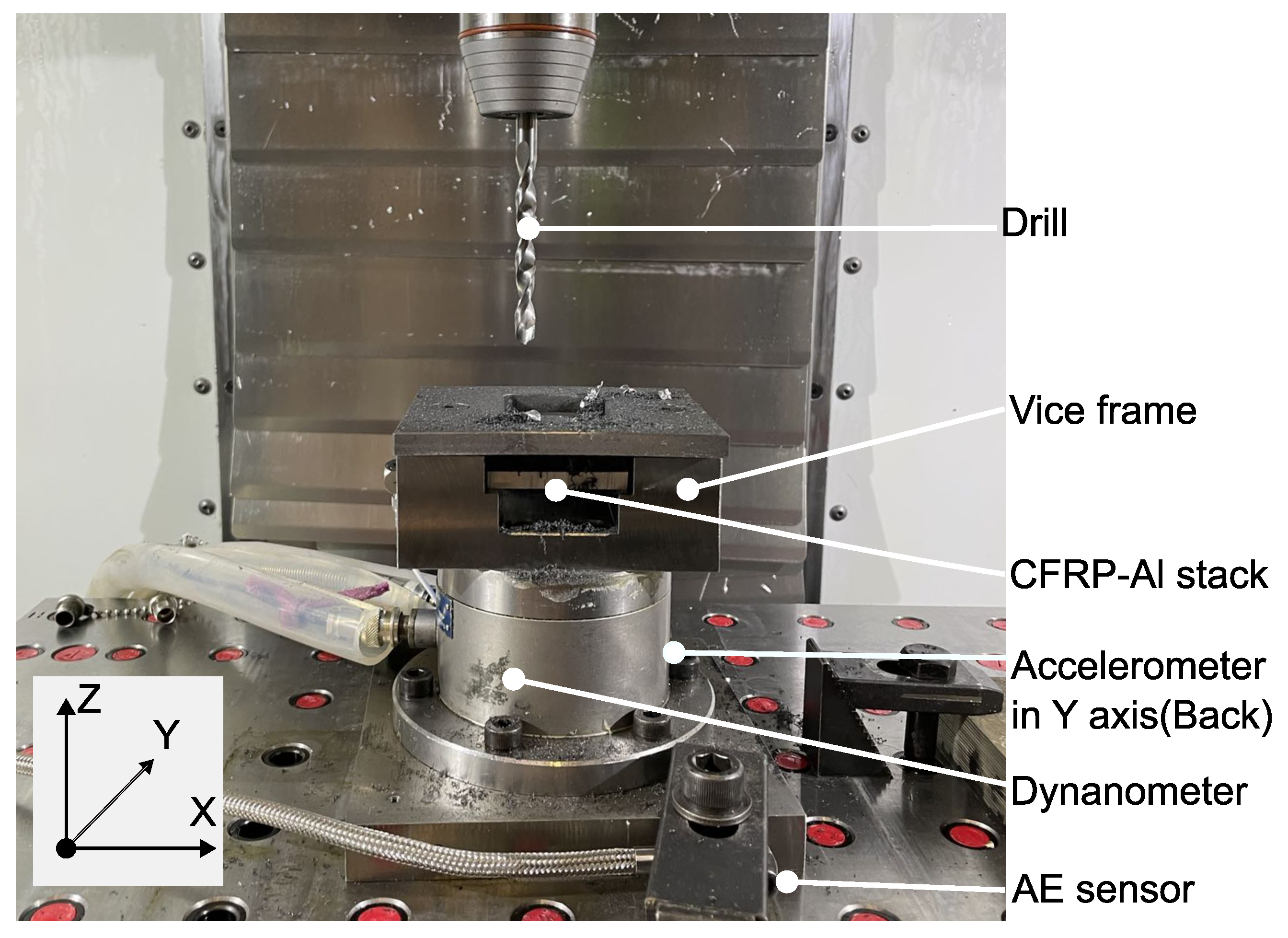

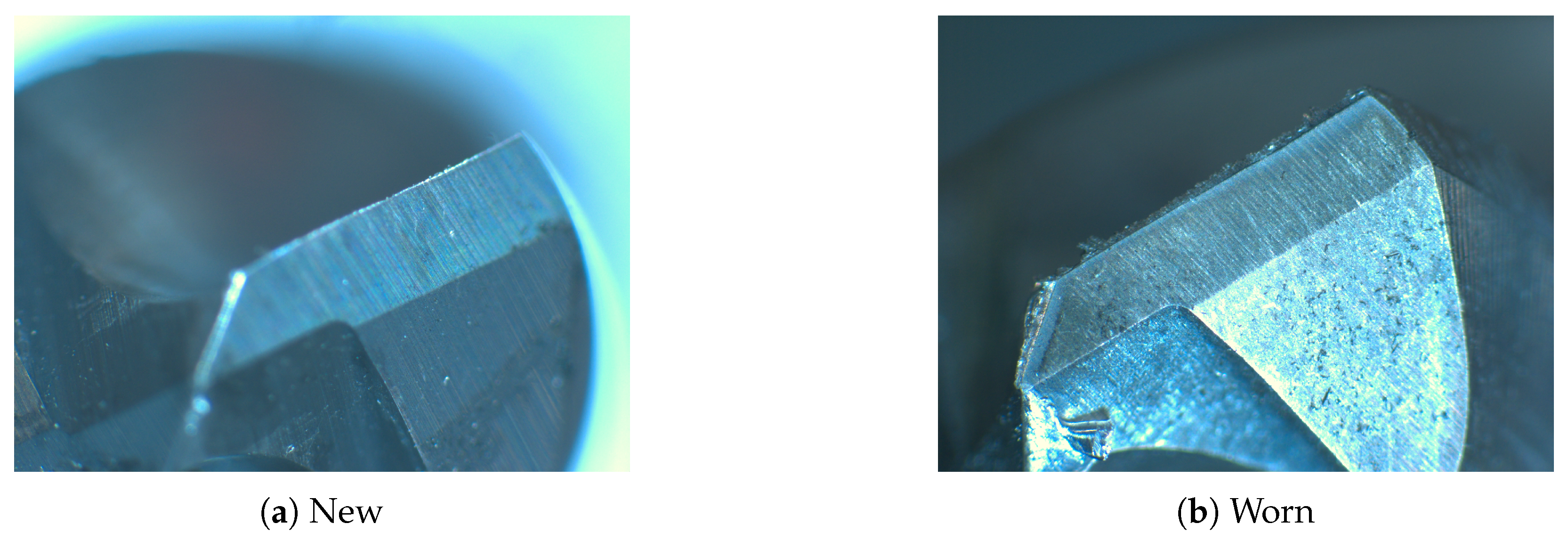

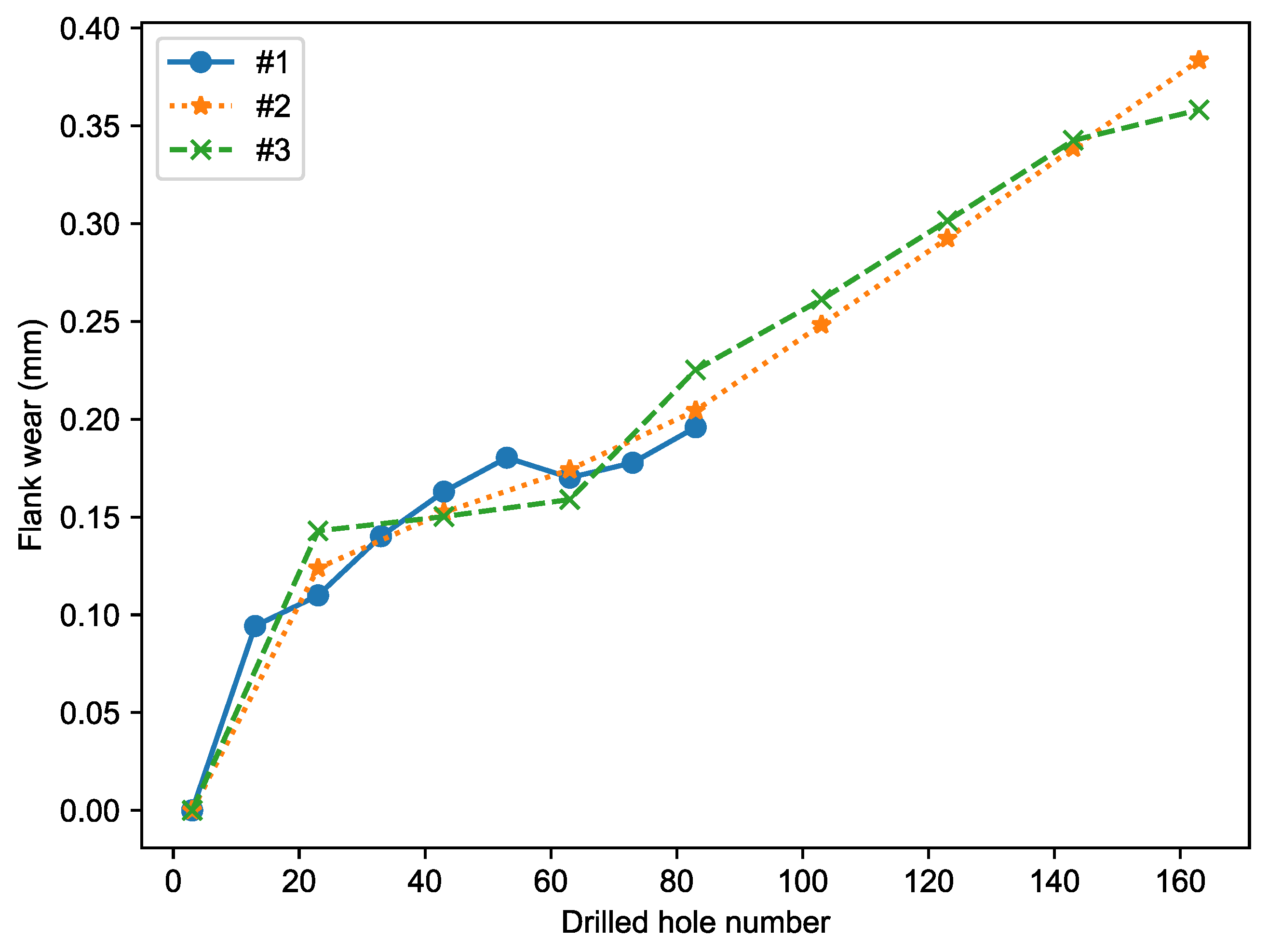

3. Experiment

4. Result

4.1. Process Incidence Classification

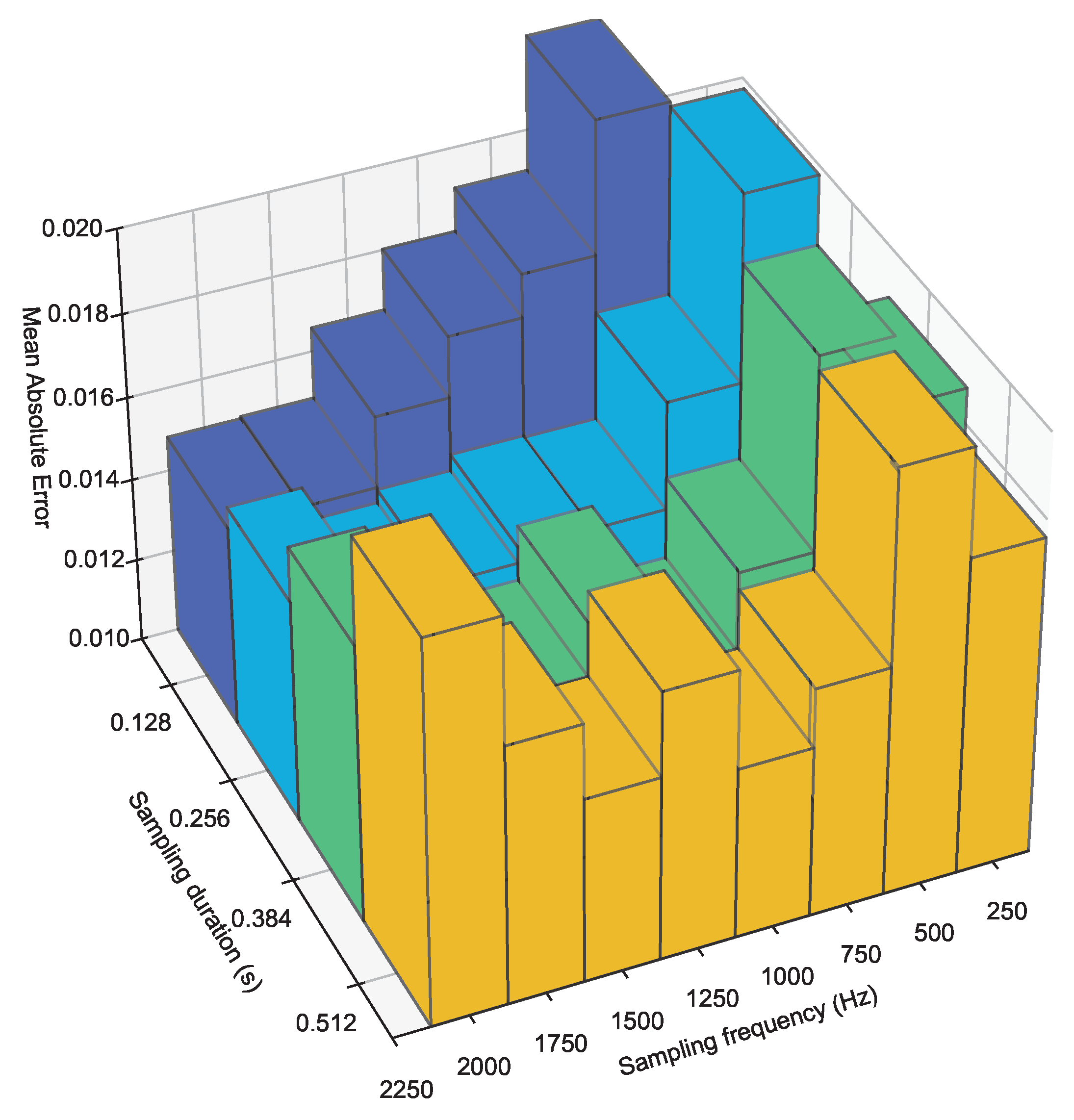

4.2. Tool Wear Prediction

5. Conclusions

- By incorporating TPP and knot structure within the deep learning framework, the knot–TPP model exhibits substantial accuracy in the classification of process incidence and the prediction of tool wear using one set of parameters.

- The knot–TPP model proposed in this study possesses the capability to process signals sampled at varying durations, thus rendering it adaptable for both brief and extended sampling periods. This flexibility permits immediate processing with a satisfactory level of accuracy for monitoring process incidences and enables extended sampling durations to enhance the reliability of predictions concerning progressive tool wear.

- The model can accurately identify incidences using signals sampled at frequencies above 800 Hz and up to 1500 Hz, without the need for creating and training multiple models. Using sampling frequencies below 800 Hz results in a significant loss in the model’s accuracy, whilst a much smaller but still noticeable decline in accuracy is observed in the case that the sampling frequency is increased above 1500 Hz.

- Increasing the length of the sample duration always improves the classification accuracy for process incidence regardless of sampling frequency. However, it also increases the response delay, which in extreme cases can lead to the model failing to match the parameters in adaptive drilling.

- The integration of process incidence into tool wear predictions contributes significantly to the enhancement of predictive accuracy. A more reliable and precise estimation of tool wear can be attained by computing the median value from a sequence of predictions generated throughout the process.

- To efficiently predict tool wear, reduce input dimensions while retaining key frequency components to avoid aliasing. Employing the frequency detailed in MSU can reduce the input size, facilitating extended sampling durations without significantly augmenting the input, thereby leveraging the advantages of the extension process.

- As tool wear becomes more pronounced, the variability in predictive accuracy increases, presenting difficulties in accurately monitoring tool wear due to marked signal fluctuations and substantial noise interference.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barik, T.; Parimita, S.; Pal, K. Parametric study and process monitoring on drilling of CFRP composites. In Proceedings of the 10th International Conference on Precision, Meso, Micro and Nano Engineering (COPEN 10), Chennai, India, 7–9 December 2017; pp. 953–957. [Google Scholar]

- Ge, J.; Zhang, J.; Xu, M.; Wu, M.; Yao, Z.; Fu, G.; Zhang, W.; Falzon, B.G.; Catalanotti, G.; Xu, J.; et al. Intelligent machining of CFRP composites via data-driven prediction and optimization: Advances, challenges and future prospects. ChemRxiv 2025, preprint. [Google Scholar] [CrossRef]

- Stephenson, D.A.; Agapiou, J.S. Metal Cutting Theory and Practice; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Pardo, A.; Majeed, M.; Heinemann, R. Process signals characterisation to enable adaptive drilling of aerospace stacks. Procedia CIRP 2020, 88, 479–484. [Google Scholar] [CrossRef]

- Zhang, J.; Heinemann, R.; Jan, B.O. Process incidence monitoring in material identification during drilling stacked structures using support vector machine. Int. J. Adv. Manuf. Technol. 2025, 136, 827–840. [Google Scholar] [CrossRef]

- Sadek, A.; Shi, Z.; Meshreki, M.; Sultana, I.; Attia, H. Drilling of Fibre Reinforced Polymers and Hybrid Stacked Materials. In Advances in Machining of Composite Materials: Conventional and Non-Conventional Processes; Springer: Berlin/Heidelberg, Germany, 2021; pp. 253–284. [Google Scholar]

- Xu, J.; Mkaddem, A.; El Mansori, M. Recent advances in drilling hybrid FRP/Ti composite: A state-of-the-art review. Compos. Struct. 2016, 135, 316–338. [Google Scholar] [CrossRef]

- Lee, J.H.; Ge, J.C.; Song, J.H. Study on burr formation and tool wear in drilling CFRP and its hybrid composites. Appl. Sci. 2021, 11, 384. [Google Scholar] [CrossRef]

- Faas, S.; Weber, R.; Graf, T. Heat accumulation controlled surface functionalization of stainless steel with structuring rates up to 500 mm2/s. Procedia CIRP 2018, 74, 324–327. [Google Scholar] [CrossRef]

- Abdelhafeez, A.; Soo, S.; Aspinwall, D.; Dowson, A.; Arnold, D. Burr formation and hole quality when drilling titanium and aluminium alloys. Procedia CIRP 2015, 37, 230–235. [Google Scholar] [CrossRef]

- Suresh, R.; Basavarajappa, S.; Gaitonde, V. Experimental studies on the performance of multilayer coated carbide tool in hard turning of high strength low alloy steel. J. Mater. Res. 2015, 30, 3056–3064. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, J.; Mo, R.; Zhang, X. In-process tool condition forecasting based on a deep learning method. Robot. Comput. Integr. Manuf. 2020, 64, 101924. [Google Scholar] [CrossRef]

- Sun, H.; Pan, J.; Zhang, J.; Cao, D. Non-linear Wiener process–based cutting tool remaining useful life prediction considering measurement variability. Int. J. Adv. Manuf. Technol. 2020, 107, 4493–4502. [Google Scholar] [CrossRef]

- Faraz, A.; Biermann, D.; Weinert, K. Cutting edge rounding: An innovative tool wear criterion in drilling CFRP composite laminates. Int. J. Mach. Tools Manuf. 2009, 49, 1185–1196. [Google Scholar] [CrossRef]

- Neugebauer, R.; Ben-Hanan, U.; Ihlenfeldt, S.; Wabner, M.; Stoll, A. Acoustic emission as a tool for identifying drill position in fiber-reinforced plastic and aluminum stacks. Int. J. Mach. Tools Manuf. 2012, 57, 20–26. [Google Scholar] [CrossRef]

- Zhang, J.; Heinemann, R.; Bakker, O.J.; Li, S.; Xiao, X.; Ding, Y. Minimum sufficient signal condition of identifying process incidence in stacked drilling through deep learning. Mech. Syst. Signal Process. 2025, 229, 112499. [Google Scholar] [CrossRef]

- Ramirez, C.; Poulachon, G.; Rossi, F.; M’Saoubi, R. Tool wear monitoring and hole surface quality during CFRP drilling. Procedia CIRP 2014, 13, 163–168. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Chen, M.; El Mansori, M.; Davim, J.P. On the analysis of temperatures, surface morphologies and tool wear in drilling CFRP/Ti6Al4V stacks under different cutting sequence strategies. Compos. Struct. 2020, 234, 111708. [Google Scholar] [CrossRef]

- Teti, R.; Segreto, T.; Caggiano, A.; Nele, L. Smart multi-sensor monitoring in drilling of CFRP/CFRP composite material stacks for aerospace assembly applications. Appl. Sci. 2020, 10, 758. [Google Scholar] [CrossRef]

- Caggiano, A.; Mattera, G.; Nele, L. Smart tool wear monitoring of CFRP/CFRP stack drilling using autoencoders and memory-based neural networks. Appl. Sci. 2023, 13, 3307. [Google Scholar] [CrossRef]

- Zhang, J.; Heinemann, R.; Bakker, O.J.; Zhu, M. In-process tool incidence identification based on temporal pyramid pooling and convolutional neural network. Procedia CIRP 2024, 126, 486–491. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Spatial pyramid pooling in deep convolutional networks for visual recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 37, 1904–1916. [Google Scholar] [CrossRef]

- Wang, P.; Cao, Y.; Shen, C.; Liu, L.; Shen, H.T. Temporal pyramid pooling-based convolutional neural network for action recognition. IEEE Trans. Circuits Syst. Video Technol. 2016, 27, 2613–2622. [Google Scholar] [CrossRef]

- Lazebnik, S.; Schmid, C.; Ponce, J. Beyond bags of features: Spatial pyramid matching for recognizing natural scene categories. In Proceedings of the 2006 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR’06), New York, NY, USA, 17–22 June 2006; IEEE: Piscataway, NJ, USA, 2006; Volume 2, pp. 2169–2178. [Google Scholar]

- Radford, A.; Metz, L.; Chintala, S. Unsupervised representation learning with deep convolutional generative adversarial networks. arXiv 2015, arXiv:1511.06434. [Google Scholar]

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

- Fernández-Pérez, J.; Domínguez-Monferrer, C.; Miguélez, M.H.; Cantero, J.L. Analysis of tool wear and hole delamination for large-diameter drilling of CFRP aircraft fuselage components: Identifying performance improvement drivers and optimization opportunities. J. Manuf. Mater. Process. 2023, 7, 76. [Google Scholar] [CrossRef]

- Sadek, A.; Hassan, M.; Attia, M. A new cyber-physical adaptive control system for drilling of hybrid stacks. CIRP Ann. 2020, 69, 105–108. [Google Scholar] [CrossRef]

| Tool diameter | 8 mm |

| Point geometry | 4-facet with notches |

| Tool substrate | WC/Co, uncoated |

| Point angle | 118 degrees |

| Spindle speed | 4000 rpm |

| Feed velocity | 200 mm/min |

| Cooling | Dry machining |

| Precision | Recall | F1 | |

|---|---|---|---|

| Engagement | 0.9974 | 0.9925 | 0.9949 |

| Cutting CFRP | 0.9895 | 0.9977 | 0.9936 |

| Material transition | 0.9956 | 0.9845 | 0.9900 |

| Cutting Al | 0.9868 | 0.9928 | 0.9898 |

| Disengagement | 0.9905 | 0.9923 | 0.9914 |

| Accuracy | 0.9919 | ||

| Classifier | Accuracy | F1 |

|---|---|---|

| SVM [5] | 0.9766 | 0.9766 |

| RF [5] | 0.9709 | 0.9709 |

| GB [5] | 0.9718 | 0.9718 |

| ResNet [16] | 0.9837 | 0.9837 |

| Knot-TPP | 0.9961 | 0.9961 |

| Metrics | Knot-TPP | Cyber-Physical Adaptive Control System [28] |

|---|---|---|

| MAE | 10 μm | - |

| RMSE | 5 μm | 6 μm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Heinemann, R.; Bakker, O.J. Knot-TPP: A Unified Deep Learning Model for Process Incidence and Tool Wear Monitoring in Stacked Drilling. J. Manuf. Mater. Process. 2025, 9, 160. https://doi.org/10.3390/jmmp9050160

Zhang J, Heinemann R, Bakker OJ. Knot-TPP: A Unified Deep Learning Model for Process Incidence and Tool Wear Monitoring in Stacked Drilling. Journal of Manufacturing and Materials Processing. 2025; 9(5):160. https://doi.org/10.3390/jmmp9050160

Chicago/Turabian StyleZhang, Jiduo, Robert Heinemann, and Otto Jan Bakker. 2025. "Knot-TPP: A Unified Deep Learning Model for Process Incidence and Tool Wear Monitoring in Stacked Drilling" Journal of Manufacturing and Materials Processing 9, no. 5: 160. https://doi.org/10.3390/jmmp9050160

APA StyleZhang, J., Heinemann, R., & Bakker, O. J. (2025). Knot-TPP: A Unified Deep Learning Model for Process Incidence and Tool Wear Monitoring in Stacked Drilling. Journal of Manufacturing and Materials Processing, 9(5), 160. https://doi.org/10.3390/jmmp9050160