Unveiling Surface Roughness Trends and Mechanical Properties in Friction Stir Welded Similar Alloys Joints Using Adaptive Thresholding and Grayscale Histogram Analysis

Abstract

1. Introduction

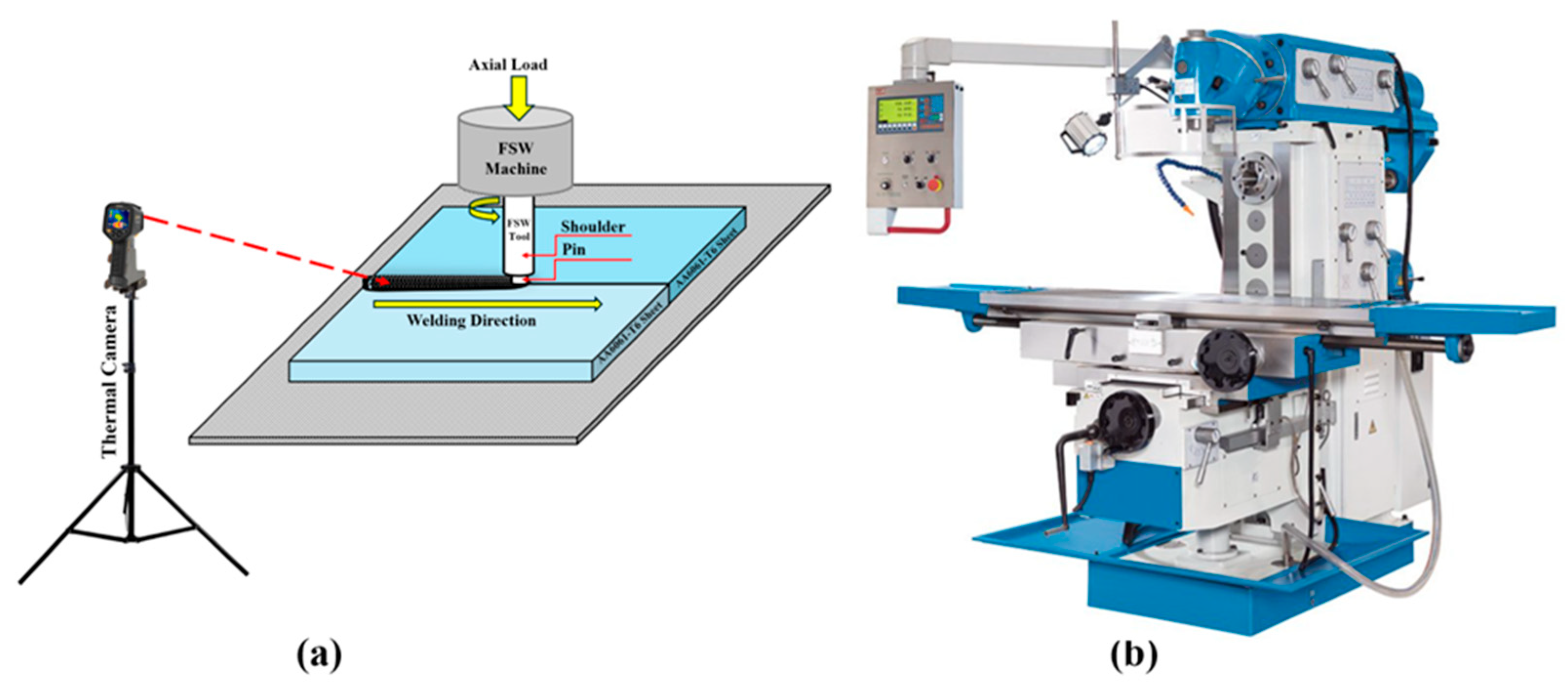

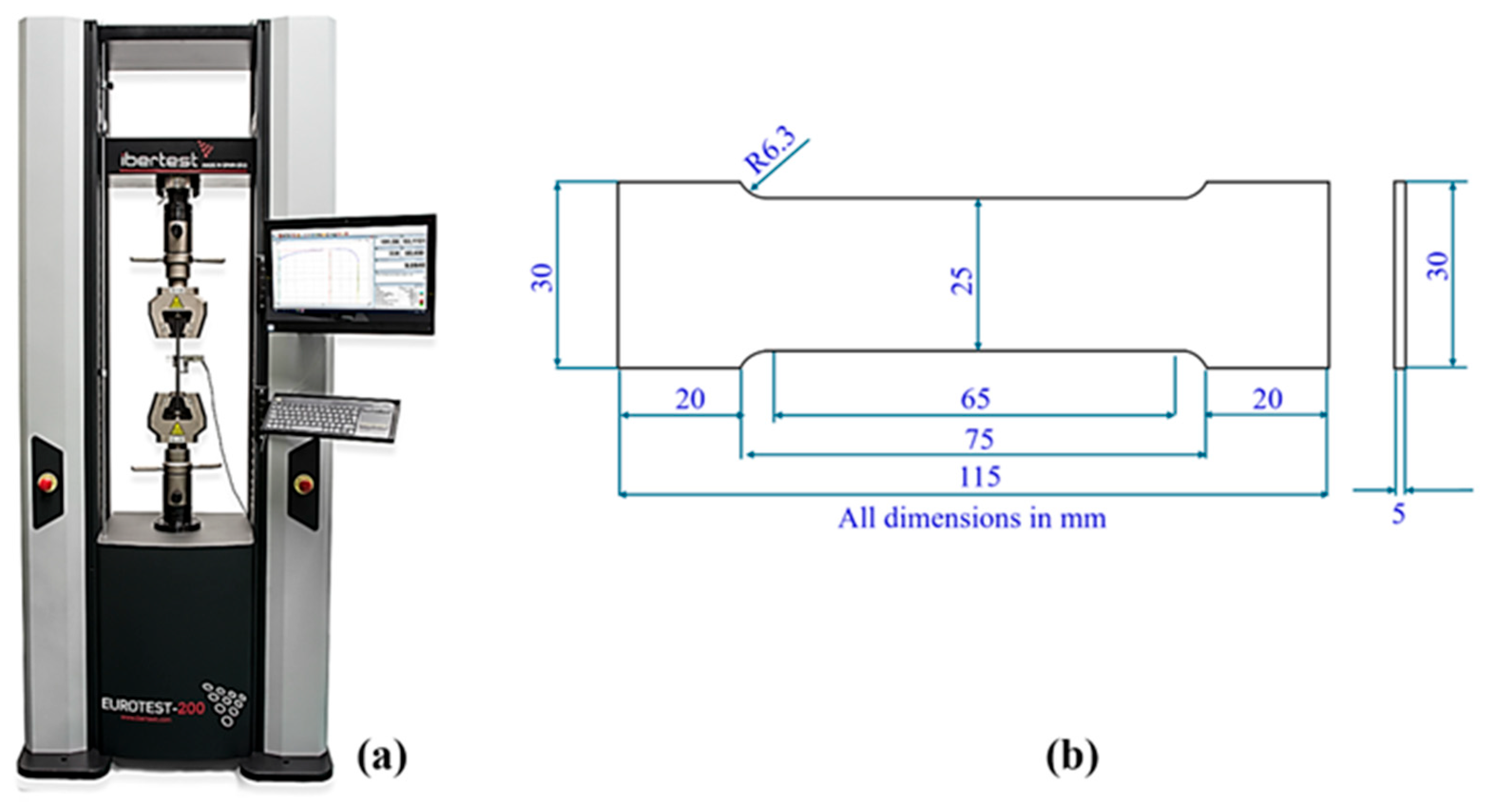

2. Materials and Methods

3. Results and Discussion

3.1. Temperature Profile Analysis

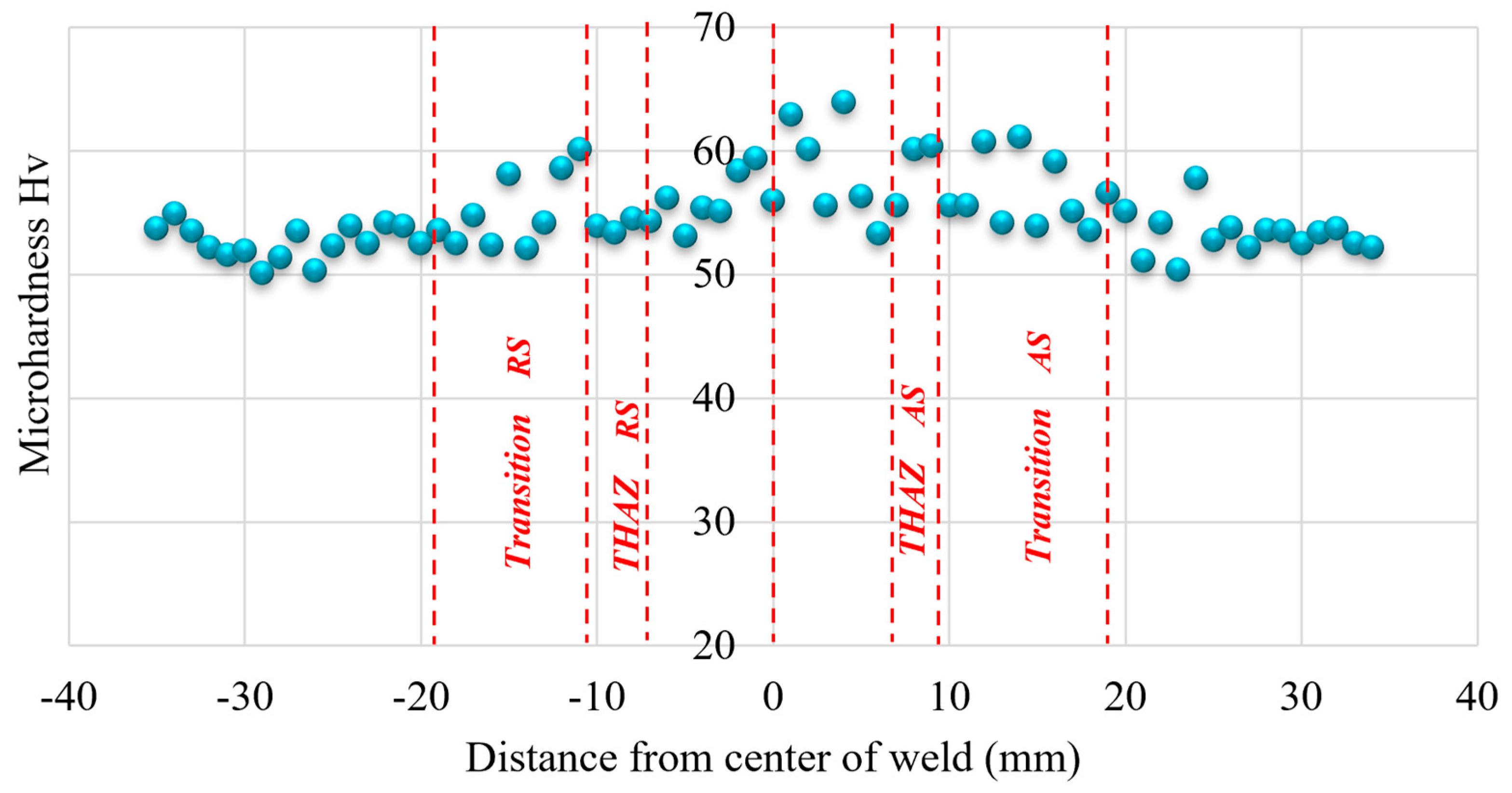

3.2. Tensile Strength and Hardness

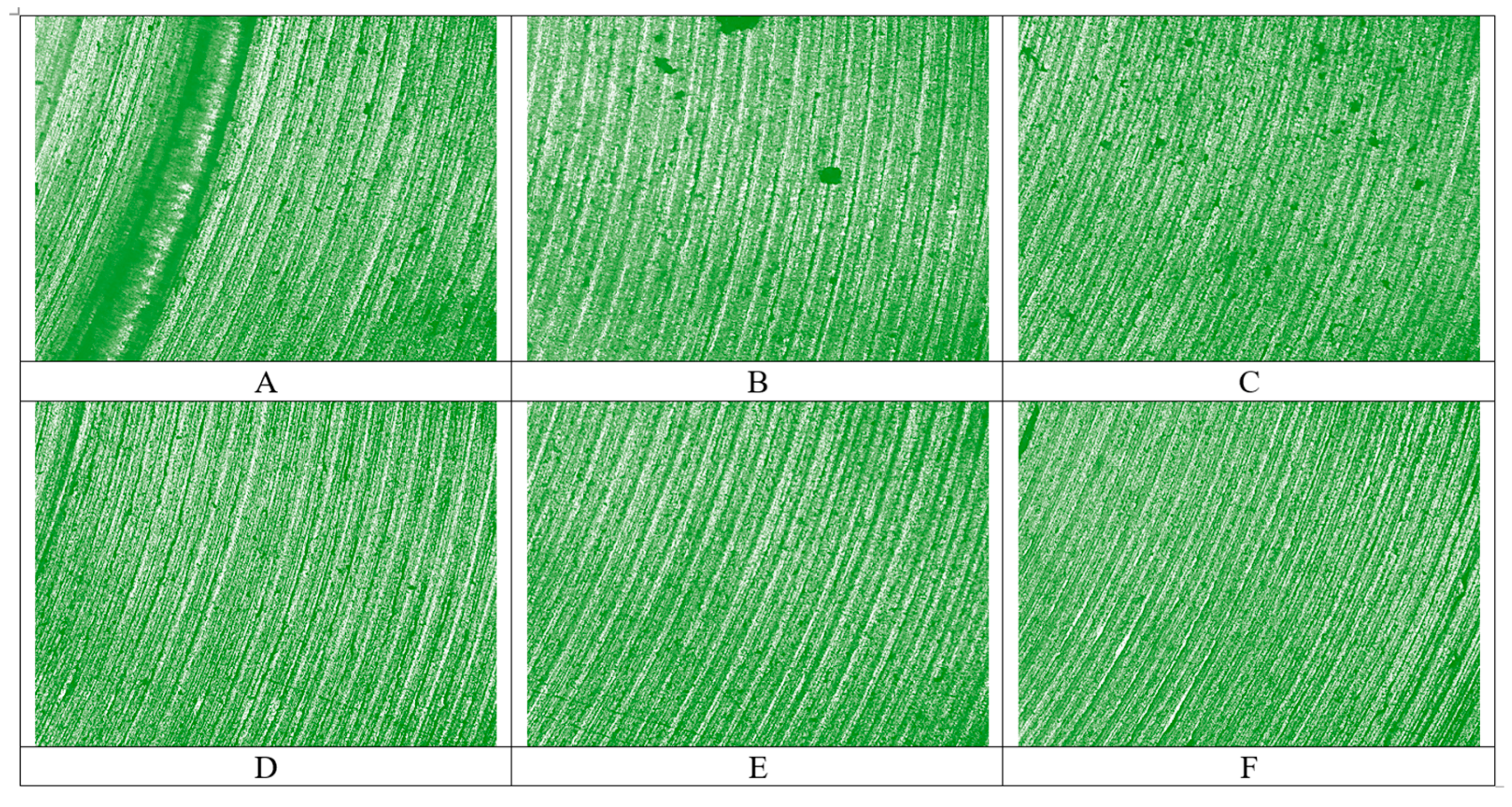

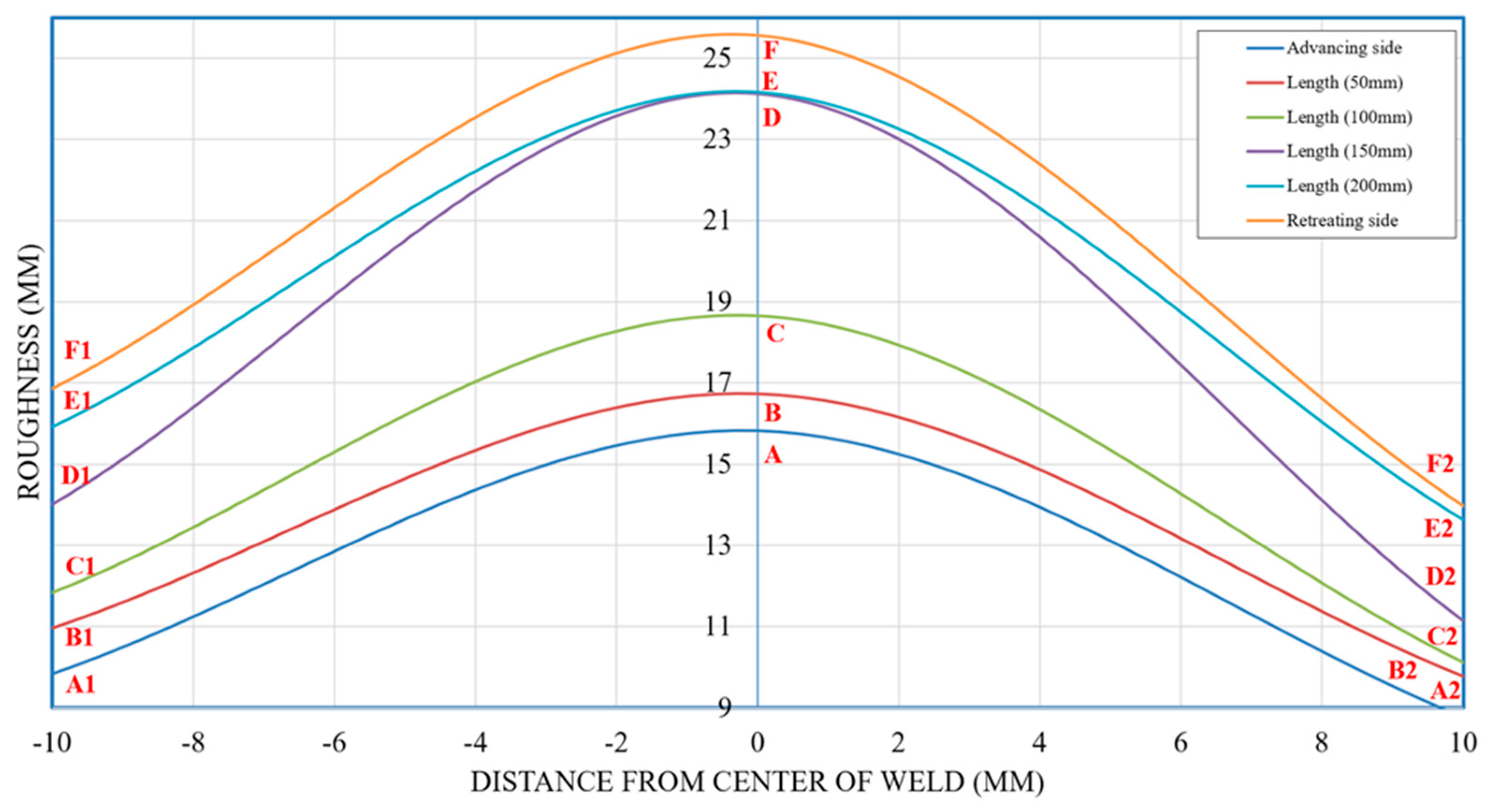

3.3. Surface Roughness Analysis

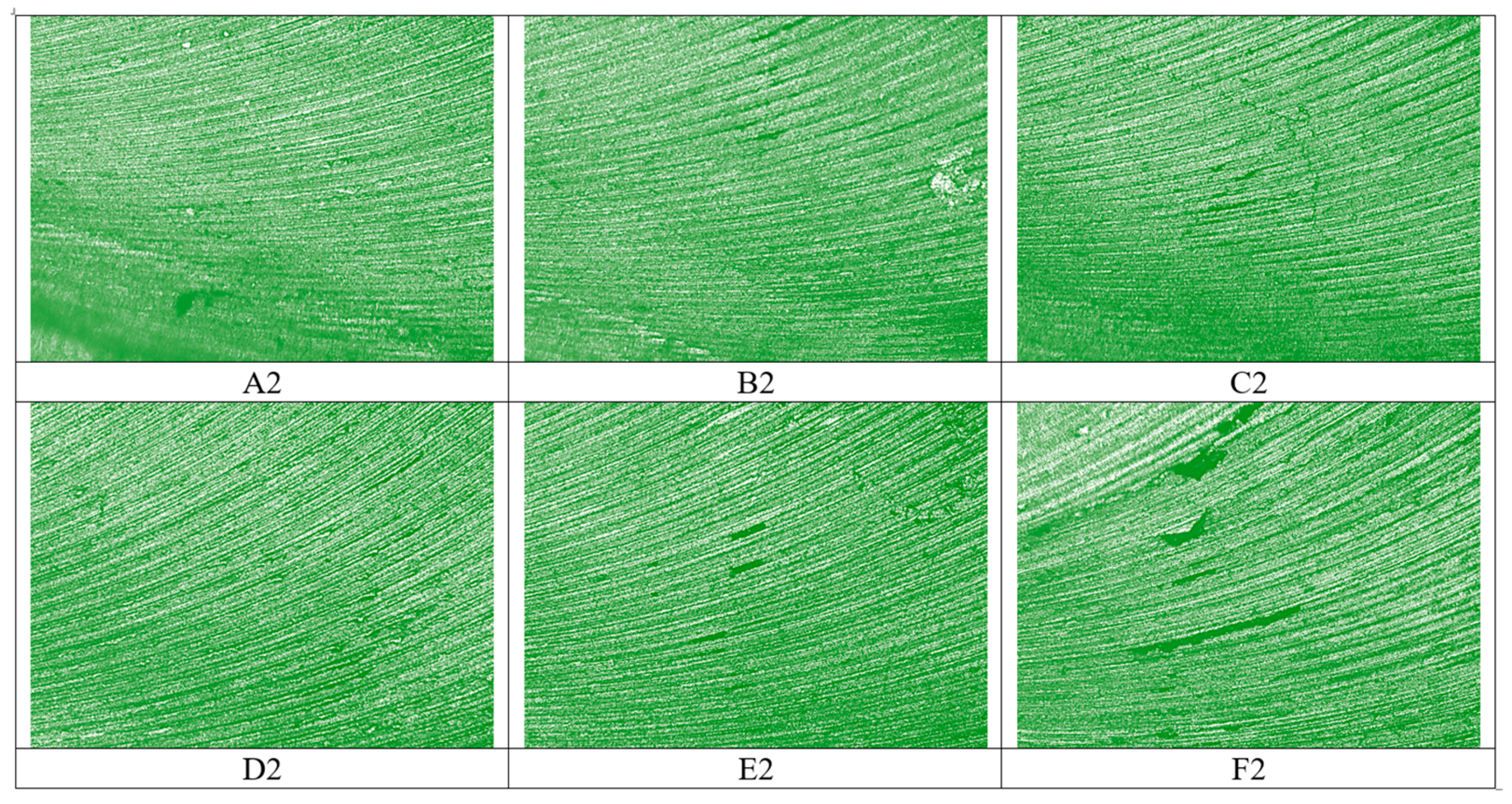

3.4. FSW Surfaces Topography Evaluation

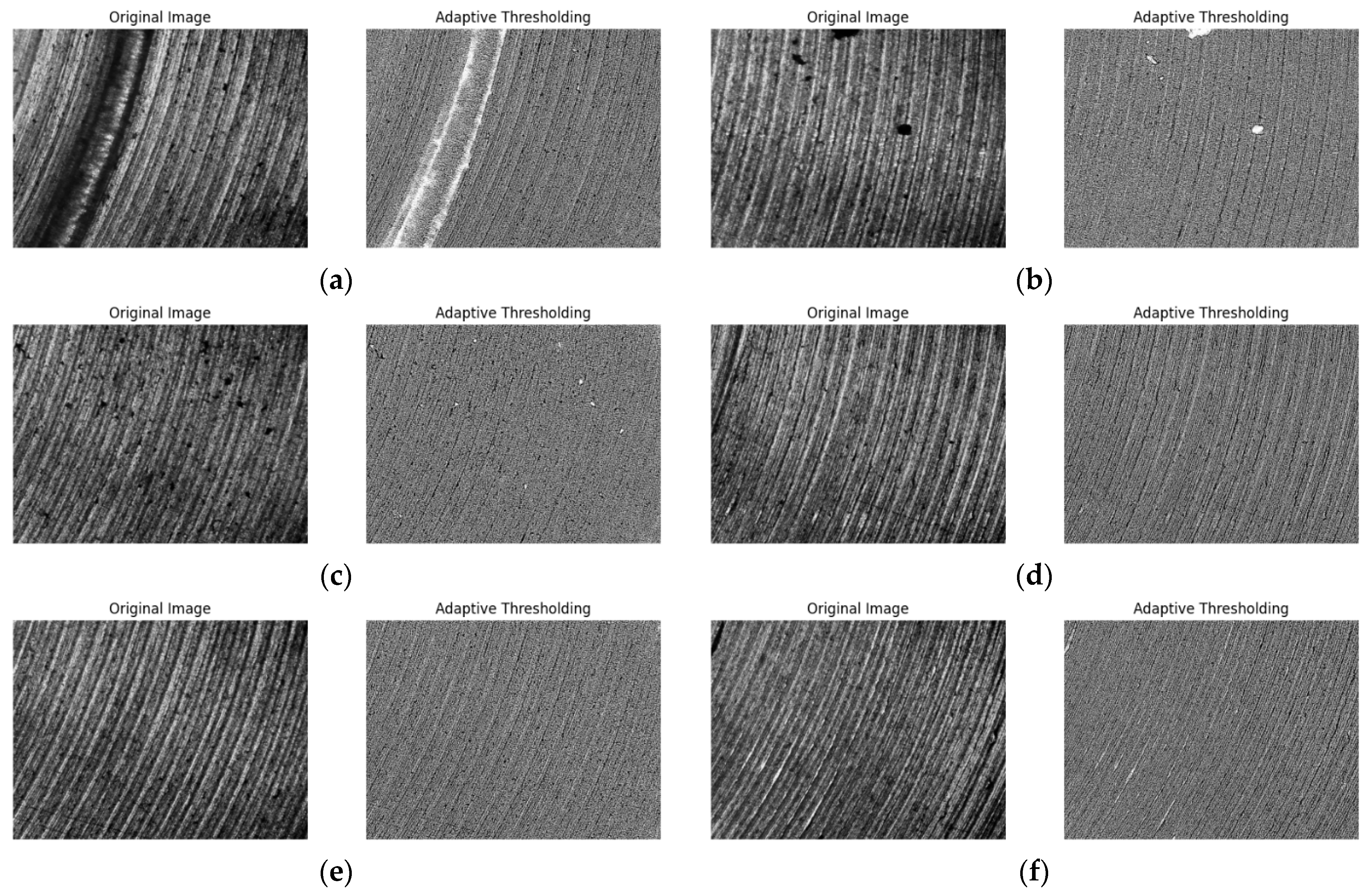

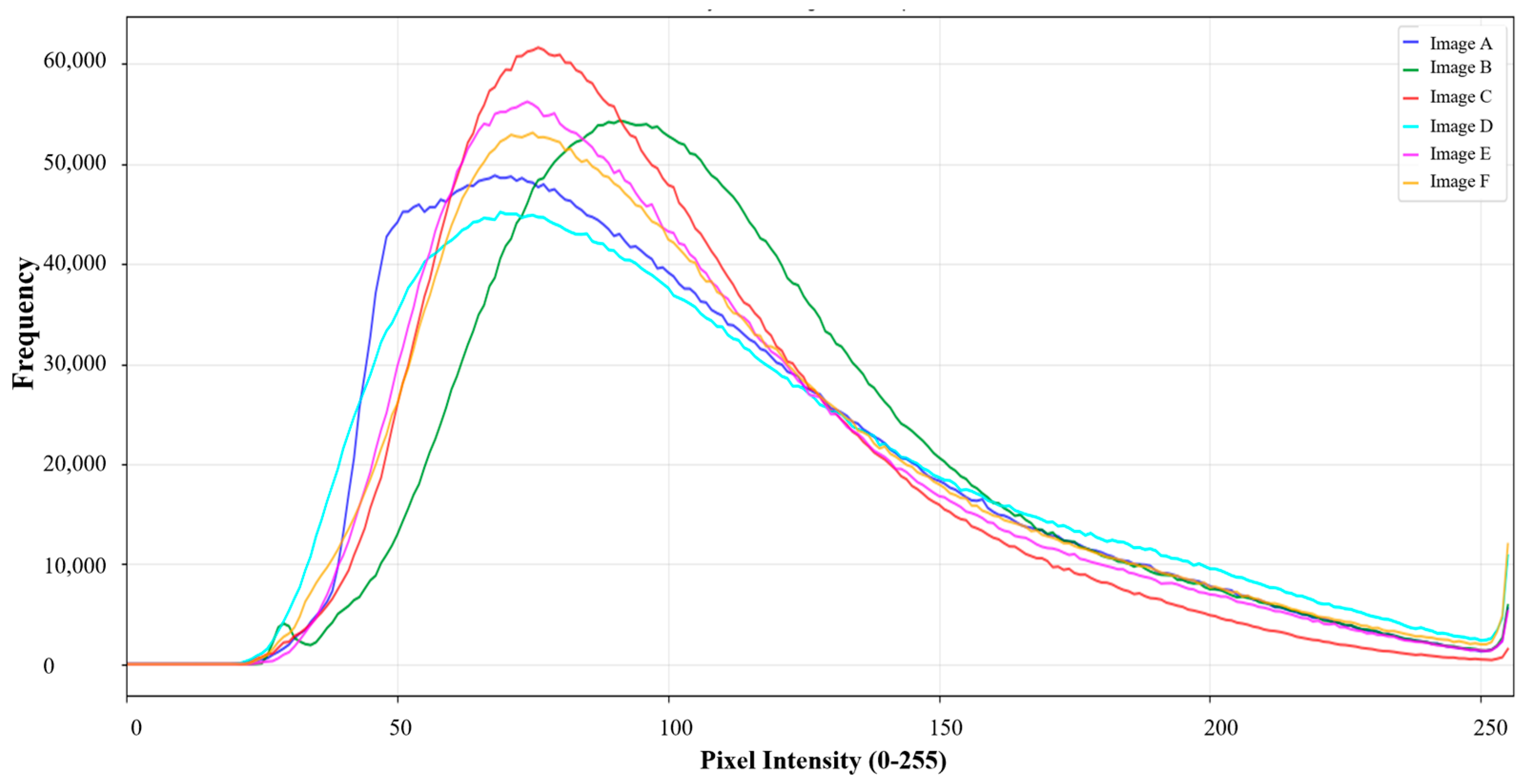

3.5. Weld Joint Image Analysis

4. Conclusions

- Monitoring the temperature before starting the welding process with a thermal camera can effectively contribute to obtaining a highly efficient weld joint. It was more suitable and effective to wait until the friction temperature reached 450 °C before moving the tool transversely.

- The macrostructure at the beginning of the weld line exhibits inhomogeneity, followed by the appearance of scattered gaps as we move away. Eventually, the homogeneity of the weld region improves until it reaches the end of the weld line.

- At the level of −10, the inhomogeneity macrostructure gets worse at the beginning of the welding line, and those spots and other flaws become more pronounced at different positions.

- From the beginning of the weld point A to point F, the surface roughness of the Ra, Rz, and Rt values shows an increasing pattern in the weld roughness (level 0). The situation remained similar at the corresponding locations 10 m to the left of the weld line (Level −10), with the value continuing to increase as we moved away from the beginning of the weld line to its end.

- The material flow on the advancing side (AS) is different from that on the retreating side (RS). Moreover, the roughness Rz varies from start to finish, ranging between 9.84 μm and 16.87 μm on the RS and 8.77 μm and 13.98 μm on the AS, leveling off slightly toward the end.

- Although a direct quantitative correlation was not established, the results indicate that regions exhibiting lower surface roughness also demonstrated higher tensile strength and microhardness. This relationship suggests that smoother weld surfaces may indicate improved material consolidation and microstructural uniformity within the stir zone.

- Adaptive thresholding image processing and grayscale histogram analysis provided valuable insights into the roughness characteristics of the FSW joint, enhancing the understanding of its microstructural features and consistency along the weld line.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Sabur, R.; Serier, M.; Siddiquee, A.N. Analysis and construction of a pneumatic-powered portable friction stir welding tool for polymer joining. Adv. Mater. Process. Technol. 2023, 10, 1052–1066. [Google Scholar] [CrossRef]

- Khalaf, H.I.; Al-Sabur, R. Friction Stir Techniques Exploring Fracture and Fatigue Behavior in Hybrid Composite Joints. In Utilizing Friction Stir Techniques for Composite Hybridization; IGI Global: Hershey, PA, USA, 2024; Chapter 7; pp. 108–134. [Google Scholar] [CrossRef]

- Khalaf, H.I.; Al-Sabur, R.; Demiral, M.; Tomków, J.; Łabanowski, J.; Abdullah, M.E.; Derazkola, H.A. The Effects of Pin Profile on HDPE Thermomechanical Phenomena during FSW. Polymers 2022, 14, 4632. [Google Scholar] [CrossRef] [PubMed]

- Karmakar, S.; Swarnkar, R.; Pal, S.K. A novel zero tool defect accelerated friction stir thin sheet welding technique for automotive light-weight structural component fabrication with dissimilar material. Mater. Chem. Phys. 2024, 316, 107759. [Google Scholar] [CrossRef]

- Zhang, M.; Cao, Z.; Zheng, G.; Zuo, D.; Guo, C.; Wang, Y. Quasi-static tensile failure mechanism analysis of CFRP/Al countersunk electromagnetic riveted joints with different rivet-hole clearances. Eng. Fail. Anal. 2024, 155, 107759. [Google Scholar] [CrossRef]

- Singh, V.P.; Kumar, D.; Mahto, R.P.; Kuriachen, B. Microstructural and Mechanical Behavior of Friction-Stir-Welded AA6061-T6 and AZ31 Alloys with Improved Electrochemical Corrosion. J. Mater. Eng. Perform. 2023, 32, 4185–4204. [Google Scholar] [CrossRef]

- Kumar, M.; Das, A.; Ballav, R. Influence of the Zn interlayer on the mechanical strength, corrosion and microstructural behavior of friction stir-welded 6061-T6 aluminium alloy and AZ61 magnesium alloy dissimilar joints. Mater. Today Commun. 2023, 35, 105509. [Google Scholar] [CrossRef]

- Mogahzy, Y. Friction and surface characteristics of synthetic fibers. In Friction in Textile Materials; Elsevier: Oxford, UK, 2008; pp. 292–328. [Google Scholar] [CrossRef]

- Han, C.; Liu, Q.; Cai, Z.; Sun, Q.; Huo, X.; Fan, M.; Li, K.; Pan, J. The effect of microstructure on the fatigue crack growth behavior of Ni-Cr-Mo-V steel weld metal. Int. J. Fatigue 2023, 176, 107859. [Google Scholar] [CrossRef]

- Fan, K.; Liu, D.; Liu, Y.; Wu, J.; Shi, H.; Zhang, X.; Zhou, K.; Xiang, J.; Wahab, M.A. Competitive effect of residual stress and surface roughness on the fatigue life of shot peened S42200 steel at room and elevated temperature. Tribol. Int. 2023, 183, 108422. [Google Scholar] [CrossRef]

- Das, D.; Bag, S.; Pal, S.; Amin, M.R. A Finite Element Model for the Prediction of Chip Formation and Surface Morphology in Friction Stir Welding Process. J. Manuf. Sci. Eng. Trans. ASME 2022, 144, 041015. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Korgal, A.; Shettigar, A.K.; Herbert, M.A.; Chandrashekharappa, M.P.G.; Pimenov, D.Y.; Giasin, K. A Review of Optimization and Measurement Techniques of the Friction Stir Welding (FSW) Process. J. Manuf. Mater. Process. 2023, 7, 181. [Google Scholar] [CrossRef]

- Bhushan, R.K.; Sharma, D. Investigation of mechanical properties and surface roughness of friction stir welded AA6061-T651. Int. J. Mech. Mater. Eng. 2020, 15, 7. [Google Scholar] [CrossRef]

- Farhang, M.; Farahani, M.; Nazari, M.; Sam-Daliri, O. Experimental Correlation Between Microstructure, Residual Stresses and Mechanical Properties of Friction Stir Welded 2024-T6 Aluminum Alloys. Int. J. Adv. Des. Manuf. Technol. 2022, 15, 1–9. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Gharde, S.; Gadge, M. Investigation of tool forces, weld bead micro-hardness and surface roughness during friction stir welding of Aluminium 6063 alloy. Adv. Mater. Process. Technol. 2022, 8 (Suppl. 1), 231–239. [Google Scholar] [CrossRef]

- Budin, S.; Hyie, K.M.; Maideen, N.C. The influence of rotational speed on welding strength and surface roughness of friction stir welded copper. J. Tribol. 2022, 32, 69–78. [Google Scholar]

- Gaikwad, V.S.; Chinchanikar, S. Investigation on surface roughness, ultimate tensile strength, and microhardness of friction stir welded AA7075-T651 joint. Mater. Today Proc. 2021, 46, 8061–8065. [Google Scholar] [CrossRef]

- Abdullah, I.; Mohammed, S.S.; Abdallah, S.A. Artificial neural network modelling of the surface roughness of friction stir welded AA7020-T6 aluminum alloy. Eng. Res. J. Shoubra Fac. Eng. 2020, 46, 1–5. [Google Scholar] [CrossRef]

- Osman, M.H.; Tamin, N. Influence of tool pin profile on the mechanical strength and surface roughness of AA6061-T6 overlap joint friction stir welding. J. Mech. Eng. Sci. 2023, 17, 9576–9585. [Google Scholar] [CrossRef]

- EL-Ghazawi, F.; Abdelhakeem, A.; Mohammed, S.; Mahmoud, T. Experimental study on the effect of tool rotational speed and welding speed on surface quality of FSW AA6063-O aluminum alloy. Eng. Res. J. 2021, 47, 57–65. [Google Scholar] [CrossRef]

- Hassan, K.S.; Abbass, M.K.; Mohammed, M.T. Effect of surface finishing on microstructure and corrosion behavior of friction stir welded joints for dissimilar aluminum alloys (AA2024-T3 with AA6061-T6). IOP Conf. Ser. Mater. Sci. Eng. 2021, 1105, 012047. [Google Scholar] [CrossRef]

- Eisa, A.; Mabrouk, O. Influence of process parameters of friction stir welding (FSW) on the mechanical properties and the surface quality of welded joint. ERJ Eng. Res. J. 2022, 45, 51–64. [Google Scholar] [CrossRef]

- Kumar, S.; Sethi, D.; Choudhury, S.; Das, R.; Saha, S.C.; Roy, B.S. Effect of tool pin profiles on surface roughness of friction stir welded 2050-T84 Al-Cu-Li alloys. J. Mines Met. Fuels 2022, 70, 108–113. [Google Scholar] [CrossRef]

- Belaziz, A.; Bouamama, M.; Zahaf, S. Experimental study of the influence of the surface roughness on the friction stir welding of FSW joints. Mater. Proc. 2022, 8, 9. [Google Scholar] [CrossRef]

- EN ISO 6892-1:2019; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. BSI: London, UK, 2019.

- Jassim, R.J.; Lieth, H.M.; Al-Sabur, R.; Alsahlani, A. Influence of welding parameters on optimization of the tensile strength and peak temperature in AISI 1020 alloy joints welded by SAW. AIP Conf. Proc. 2022, 2660, 020042. [Google Scholar] [CrossRef]

- Aydin, M. Effects of welding parameters and pre-heating on the friction stir welding of UHMW-polyethylene. Polym. Plast. Technol. Eng. 2010, 49, 595–601. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, M.; Trivedi, V.; Bhatnagar, R. Evaluation of mechanical and microstructural properties of cast iron with effect of pre heat and post weld heat treatment. Int. J. Mech. Eng. 2017, 4, 1–6. [Google Scholar] [CrossRef]

- Kermanidis, A.T.; Tzamtzis, A. An experimental approach for estimating the effect of heat affected zone (HAZ) microstructural gradient on fatigue crack growth rate in aluminum alloy FSW. Mater. Sci. Eng. A 2017, 691, 110–120. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; Xue, P.; Li, J.; Wang, W.; Ni, D.; Liu, F.; Xiao, B.; Ma, Z. Eliminating heat-affected zone of nuclear heat-resistant steel joint via low-temperature friction stir welding. Mater. Sci. Eng. A 2024, 916, 147340. [Google Scholar] [CrossRef]

- Abnar, B.; Gashtiazar, S.; Javidani, M. Friction Stir Welding of Non-Heat Treatable Al Alloys: Challenges and Improvements Opportunities. Crystals 2023, 13, 576. [Google Scholar] [CrossRef]

- Khalaf, H.I.; Al-Sabur, R.; Abdullah, M.E.; Kubit, A.; Derazkola, H.A. Effects of Underwater Friction Stir Welding Heat Generation on Residual Stress of AA6068-T6 Aluminum Alloy. Materials 2022, 15, 2223. [Google Scholar] [CrossRef]

- ISO 6507-1; Metallic Materials—Vickers Hardness Test. International Standard ISO: Geneva, Switzerland, 2018; Volume 2018.

- Uday, M.B.; Ahmad-Fauzi, M.N.; Noor, A.M.; Rajoo, S. An insight into microstructural evolution during plastic deformation in AA6061 alloy after friction welding with alumina-YSZ composite. Mech. Mater. 2015, 91, 50–63. [Google Scholar] [CrossRef]

- Yang, Q.; Mironov, S.; Sato, Y.S.; Okamoto, K. Material flow during friction stir spot welding. Mater. Sci. Eng. A 2010, 527, 4389–4398. [Google Scholar] [CrossRef]

- Buffa, G.; Ducato, A.; Fratini, L. FEM based prediction of phase transformations during friction stir welding of Ti6Al4V titanium alloy. Mater. Sci. Eng. A 2013, 581, 56–65. [Google Scholar] [CrossRef]

- Belaziz, A.; Bouamama, M.; Elmeguenni, I.; Zahaf, S. Experimental study of the roughness variation of friction stir welding FSW. Mater. Phys. Mech. 2023, 51, 115–125. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, H.; Du, S.; Zhang, Q.; Li, D.; Zuo, Y.; Li, X. Inhomogeneity of microstructure evolution in stir zone of 2195Al thick-plate FSW joints. Mater. Sci. Eng. A 2024, 896, 146265. [Google Scholar] [CrossRef]

- Wahab, M.A.; Dewan, M.W.; Huggett, D.J.; Okeil, A.M.; Liao, T.W.; Nunes, A.C. Challenges in the detection of weld-defects in friction-stir-welding (FSW). Adv. Mater. Process. Technol. 2019, 5, 258–278. [Google Scholar] [CrossRef]

- Patel, M.M.; Badheka, V.J. A review on friction stir welding (FSW) process for dissimilar aluminium to steel metal systems. Mater. Manuf. Process. 2024, 38, 91–115. [Google Scholar] [CrossRef]

- Jassim, A.K.; Al-Subar, R.K. Studying the Possibility to Weld AA1100 Aluminum Alloy by Friction Stir Spot Welding. Int. J. Mater. Metall. Eng. 2017, 11, 10008041. [Google Scholar]

- Marazani, T.; Jeje, S.O.; Shongwe, M.B.; Malatji, N. Mass flash reduction strategies in friction stir processing of aluminum alloys: A review. Eng. Rep. 2024, 6, e12981. [Google Scholar] [CrossRef]

- Ferreira, A.C.; Campanelli, L.C.; Suhuddin, U.F.H.; de Alcântara, N.G.; dos Santos, J.F. Investigation of internal defects and premature fracture of dissimilar refill friction stir spot welds of AA5754 and AA6061. Int. J. Adv. Manuf. Technol. 2020, 106, 3523–3531. [Google Scholar] [CrossRef]

- Belalia, S.E.; Serier, M.; Al-Sabur, R. Parametric Analysis for Torque Prediction in Friction Stir Welding Using Machine Learning and Shapley Additive Explanations. J. Comput. Appl. Mech. 2024, 55, 113–124. [Google Scholar] [CrossRef]

- ISO 3274; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Nominal Characteristics of Contact (Stylus) Instruments. International Standard ISO: Geneva, Switzerland, 2018; Volume 2018.

- Alkhafaji, A.; Camas, D.; Lopez-Crespo, P.; Al-Asadi, H. The Influence of Tool Geometry on the Mechanical Properties and the Microstructure of AA6061-T6 Aluminum Alloy Friction Stir Spot Welding. Materials 2023, 16, 4135. [Google Scholar] [CrossRef] [PubMed]

- Bahedh, A.S.; Mishra, A.; Al-Sabur, R.; Jassim, A.K. Machine learning algorithms for prediction of penetration depth and geometrical analysis of weld in friction stir spot welding process. Metall. Res. Technol. 2022, 119, 305. [Google Scholar] [CrossRef]

- Dong, S.; Sun, X.; Xie, S.; Wang, M. Automatic defect identification technology of digital image of pipeline weld. Nat. Gas Ind. B 2019, 6, 399–403. [Google Scholar] [CrossRef]

- Hossfeld, M. Shoulderless friction stir welding: A low-force solid state keyhole joining technique for deep welding of labile structures. Prod. Eng. 2022, 16, 389–399. [Google Scholar] [CrossRef]

- Tamadon, A.; Baghestani, A.; Bajgholi, M.E. Influence of WC-Based Pin Tool Profile on Microstructure and Mechanical Properties of AA1100 FSW Welds. Technologies 2020, 8, 34. [Google Scholar] [CrossRef]

- Burger, W.; Burge, M.J. Histograms and Image Statistics; Springer International Publishing: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Vetrivel, A.; Gerke, M.; Kerle, N.; Vosselman, G. Identification of damage in buildings based on gaps in 3D point clouds from very high resolution oblique airborne images. ISPRS J. Photogramm. Remote Sens. 2015, 105, 61–78. [Google Scholar] [CrossRef]

- Sen Gupta, S.; Kwon, T.H.; Kim, K.D. Color Based Image Processing Techniques to Detect Oxide Film During Welding. In Proceedings of the International Conference on Electronics, Information, and Communication (ICEIC), Barcelona, Spain, 19–22 January 2020. [Google Scholar] [CrossRef]

- Ranjan, R.; Khan, A.R.; Parikh, C.; Jain, R.; Mahto, R.P.; Pal, S.; Pal, S.K.; Chakravarty, D. Classification and identification of surface defects in friction stir welding: An image processing approach. J. Manuf. Process. 2016, 22, 237–253. [Google Scholar] [CrossRef]

| Material | Yield Force (kN) | Max Force (KN) | Elongation (mm) |

|---|---|---|---|

| Base material | 2.830 | 3.248 | 5.51 |

| Welded FSW | 1.801 | 2.759 | 3.50 |

| Parameter | Level | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|

| Rz (μm) | −10 | 3.88 | 3.84 | 5.3 | 6.48 | 4.82 | 4.83 |

| 0 | 5.6 | 5.92 | 6.6 | 8.48 | 8.54 | 9.04 | |

| 10 | 3.11 | 3.57 | 3.46 | 3.94 | 4.04 | 4.12 | |

| Ra (μm) | −10 | 9.84 | 10.97 | 11.84 | 14.01 | 15.92 | 16.87 |

| 0 | 15.83 | 16.74 | 18.66 | 24.12 | 24.16 | 25.56 | |

| 10 | 8.77 | 9.78 | 10.12 | 11.14 | 13.63 | 13.98 | |

| Rt (μm) | −10 | 9.94 | 11.08 | 12.72 | 14.24 | 15.12 | 17.24 |

| 0 | 15.99 | 16.9 | 18.85 | 25.44 | 25.81 | 26.4 | |

| 10 | 9.52 | 9.88 | 10.36 | 11.25 | 13.73 | 14.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khazal, H.; Belaziz, A.; Al-Sabur, R.; Khalaf, H.I.; Abdelwahab, Z. Unveiling Surface Roughness Trends and Mechanical Properties in Friction Stir Welded Similar Alloys Joints Using Adaptive Thresholding and Grayscale Histogram Analysis. J. Manuf. Mater. Process. 2025, 9, 159. https://doi.org/10.3390/jmmp9050159

Khazal H, Belaziz A, Al-Sabur R, Khalaf HI, Abdelwahab Z. Unveiling Surface Roughness Trends and Mechanical Properties in Friction Stir Welded Similar Alloys Joints Using Adaptive Thresholding and Grayscale Histogram Analysis. Journal of Manufacturing and Materials Processing. 2025; 9(5):159. https://doi.org/10.3390/jmmp9050159

Chicago/Turabian StyleKhazal, Haider, Azzeddine Belaziz, Raheem Al-Sabur, Hassanein I. Khalaf, and Zerrouki Abdelwahab. 2025. "Unveiling Surface Roughness Trends and Mechanical Properties in Friction Stir Welded Similar Alloys Joints Using Adaptive Thresholding and Grayscale Histogram Analysis" Journal of Manufacturing and Materials Processing 9, no. 5: 159. https://doi.org/10.3390/jmmp9050159

APA StyleKhazal, H., Belaziz, A., Al-Sabur, R., Khalaf, H. I., & Abdelwahab, Z. (2025). Unveiling Surface Roughness Trends and Mechanical Properties in Friction Stir Welded Similar Alloys Joints Using Adaptive Thresholding and Grayscale Histogram Analysis. Journal of Manufacturing and Materials Processing, 9(5), 159. https://doi.org/10.3390/jmmp9050159