Abstract

This study explores the development of adhesive joints incorporating embedded resistive heating elements, fabricated using Multi-Material Additive Manufacturing. By embedding conductive circuits within the adherends, localized heating enables controlled curing of the adhesive, optimizing its mechanical properties according to the specific application. This study focused on modifying the stiffness of the adhesive in order to reduce edge effects in the joints and allow for better load distribution. The adherends were made of PLA, the resistive heating elements were fabricated using carbon black-filled conductive PLA, and an epoxy resin served as the adhesive. Thermal and mechanical characterizations were conducted, evaluating the effects of different curing temperatures on joint strength. The tensile strength for joints cured at 120 °C exhibited a 58% increase in maximum breaking force and a 144% increase in elongation at break compared to the joints cured at room temperature. These findings highlight the potential of AM-integrated resistive heating for precise adhesive curing, enabling the local tailoring of the adhesive stiffness in the overlap volume.

1. Introduction

In modern manufacturing, the demand for lightweight, high-strength materials has led to the widespread use of advanced bonding techniques, particularly thermosetting adhesives [1,2]. Thermosetting adhesives offer mechanical performance, thermal stability, and chemical resistance, making them ideal for applications in the aerospace, automotive, and electronics industries. However, their curing process and overall effectiveness depend on multiple factors, including thermal management, material compatibility, surface preparation, and joint design [3,4]. Additive Manufacturing (AM) has emerged as a key technology to enhance adhesive joint performance by enabling precise material deposition [5], integration of functional elements [6,7,8,9], and improved process efficiency [10,11,12].

1.1. Multi-Material Additive Manufacturing

Additive Manufacturing, also referred to 3D printing, is a production process that creates objects by adding material layer by layer, rather than removing material from a solid block [5]. This method allows for the rapid creation of customized geometries, offering designers a cost-effective and flexible means of developing prototypes [13,14,15,16,17,18]. One of the most widely used AM techniques is Fused Deposition Modeling (FDM), which builds objects by extruding and depositing a thermoplastic filament through a heated nozzle, layer by layer [13,14,19,20,21,22,23,24].

A significant advancement in AM is Multi-Material Additive Manufacturing (MM-AM), which enables the deposition of different materials within a single printing process. Unlike traditional single-material printing, MM-AM enables the fabrication of objects with varied mechanical, thermal, and electrical properties by combining diverse materials [15]. These materials range from standard thermoplastics to composites reinforced with carbon or glass fibers, and even conductive materials for embedded electronics [11,16,17,18]. MM-AM offers enhanced potential for designing and manufacturing multifunctional components by integrating different material properties without requiring additional assembly steps. Among the AM techniques supporting MM-AM, FDM is widely used, due to its ability to produce functional objects with tailored characteristics [25,26,27,28,29,30,31,32,33,34].

1.2. Curing of Thermosetting Adhesives

Thermosetting adhesives are a class of adhesives that undergo a chemical reaction during curing, forming a permanent and rigid bond. Unlike thermoplastic adhesives, which can be re-melted and reshaped, thermosetting adhesives create crosslinked polymer structures that enhance mechanical strength, thermal stability, and chemical resistance. These properties make them suitable for applications in the aerospace, automotive, and electronics industries, where high-performance bonding is required [1].

To improve or tailor the mechanical properties of thermosetting adhesives, various techniques are employed. These include microwave curing, ultraviolet (UV) curing, and electron beam curing, all of which offer advantages such as faster processing times and reduced energy consumption [35]. Additionally, reinforcing thermosetting adhesives with nanoparticles, fibers, or microstructures can significantly affect their toughness, impact resistance, and durability [36,37].

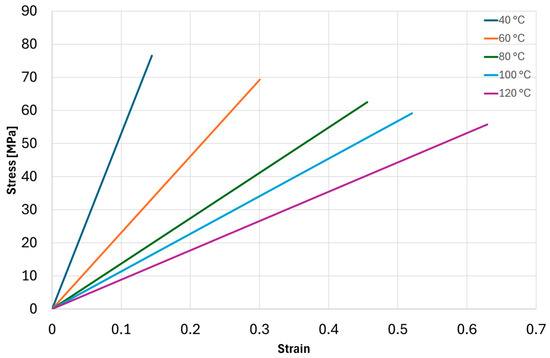

Among these methods, thermal curing remains one of the most widely used processes [3]. This technique involves applying heat to initiate and complete the crosslinking reaction, ensuring strong adhesive bonds [38]. Properly controlled thermal curing can optimize bonding strength and minimize residual stress. Moreover, curing at different temperatures can result in an adhesive stiffness variation (Figure 1) [39], which may be beneficial for specific applications, like structural load bearing and energy absorption during crashes [1,40,41].

Figure 1.

The influence of curing temperature on the equivalent modulus of elasticity mechanical properties of a thermoset adhesive, adapted from [39].

As reported in several studies [42,43,44], the curing temperature significantly influences the structural and mechanical properties of epoxy adhesives, primarily through its effect on the degree of crosslinking and the modulus of elasticity. As the curing temperature increases, the molecular mobility within the resin system improves, allowing reactive groups to interact more effectively and form a denser, more interconnected polymer network. This increase in crosslink density enhances the adhesive’s stiffness, as reflected by a higher modulus of elasticity. A well-developed crosslinked network provides better resistance to deformation and contributes to superior mechanical performance. Conversely, curing at suboptimal (lower) temperatures results in incomplete crosslinking, yielding a softer material with reduced mechanical strength and flexibility. High curing temperatures can lead to thermal degradation, oxidative crosslinking, or microcracking, which can lower the modulus.

However, thermal curing also presents challenges, particularly when applied to joints with thermally insulating substrates or those with significant thickness. In such cases, uniform heat distribution becomes difficult, preventing effective localized heating and potentially leading to ineffectively controlled curing of the adhesive layer [45].

With the rise of multi-material additively manufactured components, the proposed thermal curing method could solve this limitation and add momentum to the application of adhesive bonding joining techniques [46].

1.3. Adhesive Tailoring for Single-Lap Joints Improves Stress Distribution

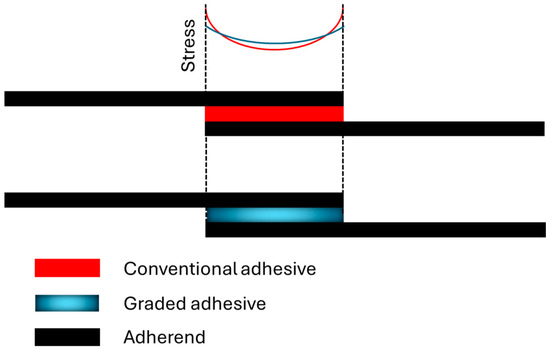

One of the most commonly used adhesive joint configurations is the single-lap joint (SLJ), where two overlapping material sections are bonded together. A primary challenge in SLJs is uneven stress distribution along the joint profile, which can lead to premature failure (Figure 2) [47,48].

A relevant method for optimizing the stress distribution is to adjust the geometric parameters of the joint [49,50]; however, the geometry of the component or the applied loads do not always allow for such modifications.

Figure 2.

Distribution of stress in SLJs with conventional and graded adhesive, adapted from [51]. Uniform adhesive color represent the isocured, graded color represent a graded cured adhesive, the dotted lines are the overlapping boundaries.

To address this issue, functionally graded adhesive (FGA) joints have been developed using AM techniques to create adhesive layers with tailored properties that optimize stress distribution [45,52]. By leveraging MM-AM, adhesive joints with customized mechanical and thermal characteristics can be fabricated to enhance joint performance [51,53].

1.4. Multi-Material Additively Manufactured Embedded Circuits

The feasibility of the multi-material additively manufactured embedded circuits has been assessed in previous studies [6,8,9]. The integration of conductive circuits into adhesive joints presents an innovative approach for enhancing the functionality of bonded components. By embedding resistive heating elements within the adherends, localized and controlled heating can be achieved, enabling efficient curing of bonded structures, even in components with thick or heat-insulating adherends. Moreover, embedded circuits can facilitate smart joint monitoring, providing real-time data on joint integrity and enabling predictive maintenance strategies. The combination of MM-AM and integrated conductive elements opens up new possibilities for improved adhesive bonding solutions [5,54]. Moreover, this approach can be used to dismantle bonded joints in a more sustainable way, allowing the adhesive to be heated to degradation while preserving the adherends.

1.5. Proposed Method

This study aims to develop an adhesive joint with an integrated circuit that enhances joint strength by modifying the mechanical properties of the adhesive using a localized thermal curing process. In particular, the focus is on conducting the curing process in the central region of the joint to locally reduce the rigidity of the adhesive. This modification allows for a more uniform stress distribution across the overlapping area of the joint, improving its overall mechanical performance.

The innovation of this work, which differentiates it from previous studies, lies in the creation of a curing process that allows for better stress distribution, regardless of the substrate thickness or substrate material of the joint, and can be implemented even with insulating substrates using a simple setup. Moreover, a localized heating system can enable adhesive tailoring, despite smaller overlap areas, with tailored heating patterns. In addition, the integrated heating system can be used for joint healing and demanufacturing.

By embedding resistive heating elements within the adherends using MM-AM, controlled heat application can be achieved, optimizing the curing process to enhance adhesion and structural reliability.

Future work, after process tuning and design optimization, will focus on quantitative comparisons with existing curing methods to identify the best process to obtain the optimal energy efficiency, curing uniformity, process time, and heating control strategy for different applications [55].

2. Materials and Methods

2.1. Materials

Two types of materials were used for 3D printing the adherents and circuits of the specimens. The main body of the samples was printed using a PLA (Polylactic Acid) filament, specifically the gray Prusament PLA filament, PRUSA RESEARCH, Prague, Czech Republic. PLA is a semi-crystalline thermoplastic polymer and one of the most commonly used materials for FDM printing. Its low melting temperature, minimal deformation during cooling, and good mechanical properties make it suitable for creating complex geometries [56,57].

The glass transition temperature of PLA, which is the point at which it becomes more flexible, is around 60–65 °C. The melting temperature ranges from 160 to 180 °C, which often coincides with the extrusion temperature of the filament nozzle.

For the resistor, a conductive filament from Proto Pasta (ProtoPlant, Vancouver, Washington USA) was used, composed of a PLA matrix filled with carbon black (CB) particles. Incorporating conductive particles into the polymer matrix enables the creation of conduction paths, which facilitate the transport of electric charge. This CB-PLA filament is designed for FDM 3D printing, providing a semiconductor material [58]. It is particularly suitable for creating an electrical resistor to heat the adhesive at the joint.

The printing was carried out using a Prusa i3 MK3S, which is capable of multi-material 3D printing. The components were first modeled in Creo Parametric v11, then converted into STL files using the dedicated Prusa Slicer software v2.9.1, before being sent to the printer. The printing parameters for each filament were set according to the manufacturer datasheet. This choice resembled the real component setup, where printing parameters are usually selected to optimize the material processing for optimal adhesion performance.

Before performing the adhesion bonding, the adherends were cleaned by wiping them with isopropyl alcohol [59,60,61].

Loctite EA 9466, Henkel Adhesives, Düsseldorf, Germany, is a two-component epoxy resin, and was selected as the adhesive in this study. Once mixed, the two-component epoxy cures at room temperature, forming a tough bond line that develops high peel resistance and excellent shear strength. When fully cured, it withstands a wide range of solvents and chemicals and exhibits excellent electrical insulation properties. Its typical applications include industrial uses, where long curing times are beneficial for potential repositioning of parts during assembly.

2.2. Adherend Design

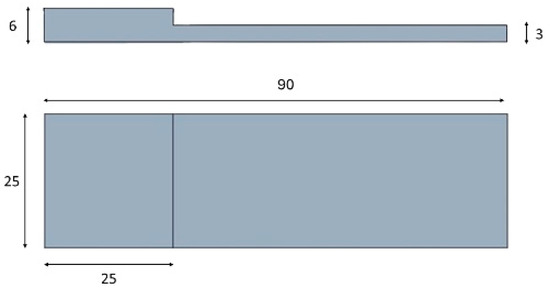

ISO 4587:2003 was used as a reference for the design of the adherents composing the joints [39]. The adherends’ dimensions are reported in Figure 3.

Figure 3.

Additively manufactured adherend dimensioning.

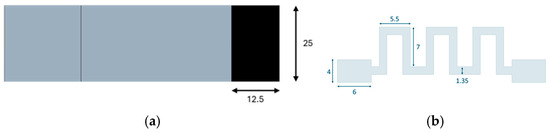

The overlap and the “serpentine”-shaped resistance dimensions were selected based on the electrical resistance and single-lap joint design published in [5]. The overlap dimensions are reported in Figure 4a, and the resistance dimensions are reported in Figure 4b.

Figure 4.

Dimensioning of the overlap area (in black color) (a) and of the embedded resistance (b).

The additively manufactured resistance was embedded in the adherend under the overlapping area using the MM-AM process.

During preliminary thermal characterization of the adherends, no relevant thermal gradients were measured across the overlap area; therefore, the adhesive could be considered iso-cured [5].

2.3. Thermal Modeling and Characterization of Adherends with Embedded Resistance

Electrical power was applied to the circuitduring the curing process and by using an embedded heater to raise the adhesive’s temperature. The target temperature range spanned from a minimum of 23 °C (room temperature) to a maximum of 120 °C, with specific setpoints at 23 °C, 40 °C, 80 °C, 100 °C, and 120 °C. The aim was to determine what voltage should be applied to obtain the target temperature and maintain it for a steady-state period. Therefore, the physics of the thermal phenomena was modeled as follows.

The resistance wire had a width of 1.35 mm and a thickness of 1.8 mm. The target temperature was set to 120 °C, while the ambient temperature was continuously monitored. The resistivity of the conductive wire was 12 Ω·cm, and its emissivity, a dimensionless value ranging from 0 to 1, was 0.9 in this specific case.

Based on these parameters, the required voltage and the current flowing through the electric resistance could be determined by calculating key auxiliary variables. These included Rayleigh, Nusselt, and Prandtl numbers, which describe the thermal behavior of the fluid flow around the resistance and the resulting heat transfer rate.

Other important factors to consider include the heat transfer exchange area, the perimeter of the exchange zone, the wire’s cross-sectional area, the film temperature, the electrical resistance value, and the supplied electrical power.

The main steps for calculating the electrical power P, which corresponds to the dissipated thermal power needed to reach the target temperature, are outlined below.

Equation (1) denotes how the present application represents the typical case of a natural convection heat transfer mechanism (represented by the corresponding thermal power ) combined with the radiative one (expressed by the thermal power ). The convective and radiative heat exchange mechanisms between the specimen at the temperature Tmax (to be reached) and the surrounding air at the temperature T∞ involve the following terms:

- h = the convective heat transfer coefficient [W/m2K];

- Ase = the exposed heat exchange surface of the specimen [m2];

- Tmax = the specimen temperature to be reached [K];

- T∞ = the surrounding ambient temperature [K];

- ε = the emissivity of the wire;

- σ = 5.67 × 10-8, which is the Stefan-Boltzmann constant [W/m2K4].

The present thermal fluid dynamics problem is typical of a horizontal hot plate with the surface facing up. The next step is calculating the characteristic length Lc, using Equation (2):

where Ase is the exposed heat transfer surface of the specimen and p is its perimeter. The Rayleigh number RaLc, based on the characteristic length, must be computed as described in Equation (3):

where

- β = the thermal expansion coefficient at constant pressure [1/K];

- g = the gravitational acceleration [m/s2];

- Pr = the Prandtl number;

- ν = the cinematic viscosity [m2/s].

The quantities in Equation (3) are evaluated at the film mean temperature Tfilm, defined according to Equation (4):

This enables the evaluation of the thermal expansion coefficient at constant pressure, using Equation (5), and the Prandtl number, using Equation (6):

where a is the thermal diffusivity [m2/s] at the temperature Tfilm.

To evaluate the convective heat coefficient h in Equation (1), the Nusselt number NuLc, based on the characteristic length, must be evaluated according to Equations (7) and (8), depending on the estimated Ra value:

Equation (7) applies in the case of 104 < Ra < 107 (i.e., the convective fluid flow regime is laminar).

Equation (8) applies in the case of 107 < Ra < 1011 (i.e., the convective fluid flow regime is turbulent).

Then, the convective heat transfer coefficient h in Equation (1) is obtained using Equation (9):

where k is the thermal conductivity of the ambient air evaluated at the temperature Tfilm [W/mK].

Finally, once P has been evaluated, it is crucial to determine the values of electrical resistance and electrical power, which must be applied in order to obtain the output values of current and voltage. The calculation of electrical resistance (Equation (10)) is as follows:

where

- Ltot = the total length [m];

- ρ = the resistivity of the conductive wire [Ω cm];

- s = the cross-sectional area of the wire [mm2].

With these quantities, it is possible to determine the value of the electric current, as shown in Equation (11):

One the value of the current has been obtained, it is then possible to calculate the voltage using Equation (12):

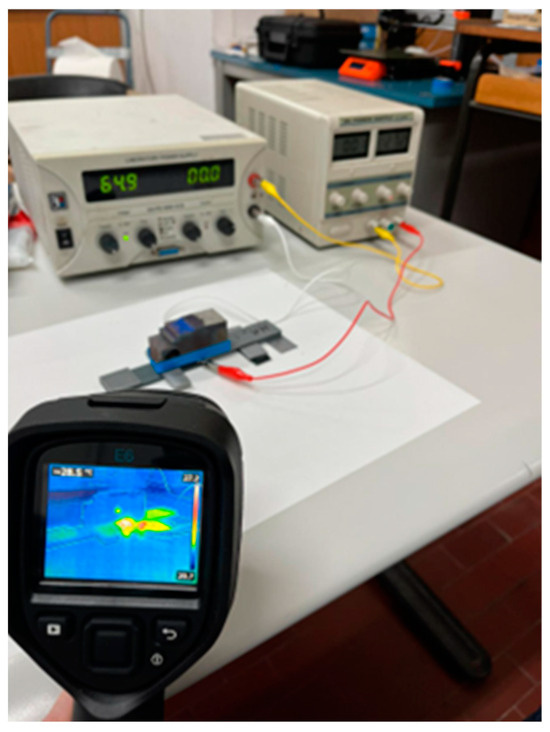

The presented theoretical method was experimentally validated using 1 to 4 electric generators connected in series, along with a PeackTech 3442 digital multimeter, PeakTech Prüf- und Messtechnik GmbH, Ahrensburg, Germany, to verify the supplied voltage, a chronograph to record the time taken to reach the target temperature, and a Flir E6 PRO thermal camera, Teledyne FLIR, Oregon, USA, to visualize the full-field thermal mapping.

The experimental characterization pointed out that the presented theoretical method tends to underestimate the voltage (V) by approximately 10–15% compared to the value used in the actual test, resulting in a deviation of 0.5–1 W in the corresponding power (P) values. It was observed that the accuracy of the theoretical method is highly sensitive to the assigned value of Ase, which must be carefully estimated by considering all contributions from the entire exposed heat transfer surface (including both the specimen and the plate).

By accurately determining and assigning the appropriate Ase value, the deviation between theoretical and experimental results can be minimized. Specifically, the theoretical prediction for V was 79.6 V, while the experimentally imposed value was 75 V. Similarly, the predicted power (PP) was 2.79 W, compared to the experimentally obtained 2.44 W, both of which meet the requirements for reaching the target temperature of 120 °C.

2.4. Single-Lap Joint Manufacturing and Testing

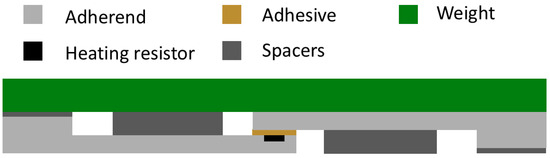

The manufacturing of the SLJ specimens was carried out using the setup reported in Figure 5.

Figure 5.

Jig configuration to manufacture SLJ specimens.

The setup consisted of calibrated spacers and 1000 g of weight. The spacers ensured proper alignment of the two substrates and maintained a precise and uniform adhesive thickness within the joint. A weight was applied to stabilize the components and exert the necessary pressure to expel excess adhesive. The SLJ specimen manufacturing process involved isopropyl alcohol wiping, applying adhesive to both bonding surfaces, aligning the substrates with the spacers, and subsequently placing a weight to remove excess adhesive. Finally, the generator clamps were connected to the integrated circuit terminals to initiate localized heating of the joint. The final setup for the assembly and adhesive curing is shown in Figure 6.

Figure 6.

Setup for specimen assembly and curing process.

The joints were manufactured using two different curing cycles: 23 °C for 24 h and 120 °C for 1.5 h. The temperature during the curing process, after calibration on the overlap area of the adherends, was controlled by using a thermal camera on the specimens’ outer surface. This approach, which does not involve a closed loop in the temperature control process, can introduce errors in the overlap area temperature during the assembly of the joints. However, the curing temperature error can be considered irrelevant compared to the temperature gap between the two investigated configurations (23 °C and 120 °C). Moreover, the outer target temperature was offset according to the presented thermal model and the calibration. After manufacturing, tensile strength tests were performed to evaluate the effect of adhesive curing using the embedded resistance of the additively manufactured components. The tests were performed using a Zwick Roell testing machine, following the DIN EN Tensile Test Thermoplastic program, which is designed for plastic materials. After testing, the collected data were processed using the TestXpertIII software, and subsequently converted into Excel files for in-depth analysis and graphical representation of the joint behavior.

3. Results and Discussion

To identify the results of each configuration, the specimens were named according to the following scheme: Configuration_CuringTemperature_RepetitionNumber.

- Configuration indicates the type of specimen.

- CuringTemperature represents the curing temperature.

- RepetitionNumber identifies the specimen number with that specific configuration.

For example, SLJ_23_1 refers to the first single-lap joint specimen, cured at 23 °C.

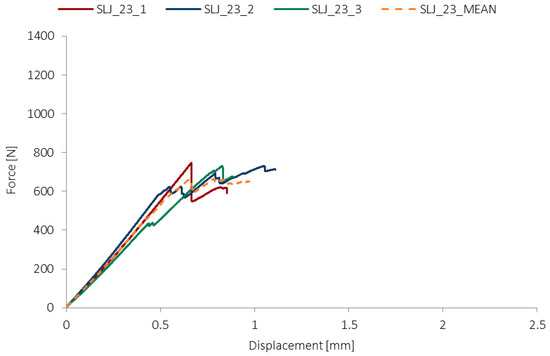

For the SLJ cured at 23 °C, three joints were tested, and the results are reported in Figure 7.

Figure 7.

The tensile test results for the SLJs manufactured using a 23 °C curing cycle.

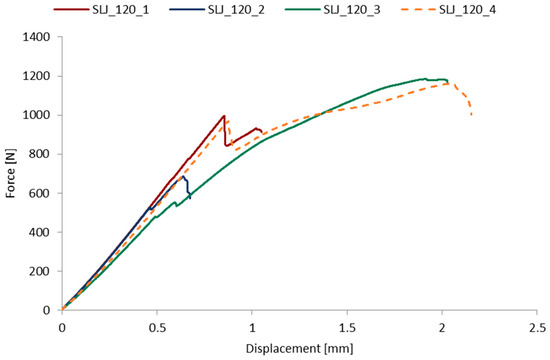

For the SLJ-120 joints, four joints were tested, and the results are reported in Figure 8.

Figure 8.

The tensile test results for the SLJs manufactured using a 120 °C curing cycle.

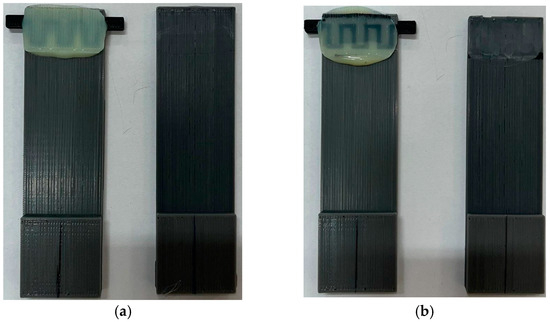

Post-test analysis of the fracture surfaces (Figure 9) revealed a mixed adhesive and cohesive failure mode in all specimens, regardless of the curing temperature. The mixed adhesive and cohesive failure point out a weak adhesion mechanism, which could be improved using a different surface preparation method, such as Low-Pressure Plasma [62,63]. However, the failure mechanism was the same in all specimen configurations, improving the comparability of the tests.

Figure 9.

The fracture surface of a specimen assembled at 23 °C (a) and one assembled at 120 °C (b), respectively.

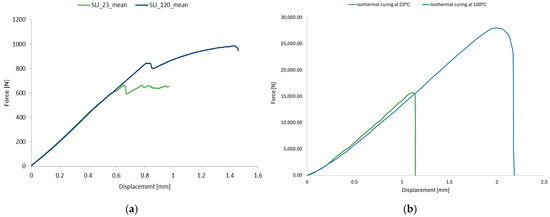

Figure 10a shows a comparison between the average test curve of SLJs cured at 23 °C and the average test curve of SLJs cured at 120 °C.

Figure 10.

Qualitative comparison between the effects of curing on two epoxy adhesives. (a) The average tensile test curve results for the plastic SLJs manufactured using 23 °C and 120 °C curing cycles with the embedded resistances. (b) The average tensile test curve results for the metallic SLJs manufactured using induction heating to 23 °C and 100 °C, adapted from [39]. It should be noted that in sub-figures (a) and (b), different axis scales are used.

The tensile strength and deformation at failure were used to evaluate the effectiveness of the proposed method, as proposed in previous work [42,43,44].

From the comparison, the following consideration can be drawn. The joints cured at 23 °C (SLJ-23) achieved an average force of 736 N ± 8.7 N, with an elongation of 0.97 mm. The highest-performing joint under tensile stress in this group, SLJ-23_1, reached a maximum force of 750 N, with an elongation of 0.85 mm. The joints cured at 120 °C (SLJ-120) demonstrated significantly higher strength, averaging 1006 N ± 179.8 N, with an elongation of 1.46 mm. SLJ-120_3 stood out with a maximum force of 1185 N and an elongation of 2.0 mm, showcasing a 58% strength increase compared to the SLJ-23 joints, and an elongation at break increased by 144%. Is it worth noting that the tested samples were limited both in terms of curing temperature levels and repetition. Moreover, high-temperature curing showed higher standard deviation compared to low-temperature curing. However, although this process should be further investigated and fine-tuned in future work, is can be concluded that the proposed curing method is effective.

Figure 10b shows a comparison between the average test curve of SLJs cured at 23 °C and the average test curve of SLJs cured at 100 °C, adapted from [31]. The results were obtained using metallic adherends, a different epoxy adhesive, and external induction heating elements. From a qualitative comparison between Figure 10a,b, it can be seen that the effect of raising the curing temperature shows the same trend in both configurations, producing an increase in the maximum force and displacement at failure. Figure 10b showcases a 56% increase in strength in terms of maximum force between the two curing cycles. This result, similar to the 56% strength increase shown in Figure 10a, suggests that the force increase can be related to adhesive modification in both setups. This is relevant information to the studied setup, which involved plastic adherends, in which diffusion phenomena could occur.

Overall, joints cured at higher temperatures using embedded resistance consistently exhibited superior mechanical properties compared to those cured at ambient temperature or at lower temperatures. These findings underscore the potential of the proposed curing method, which couples a material tailoring approach with an Additive Manufacturing-based design.

The experimental curve confirms the expected results in terms of both tensile strength and elongation at break, demonstrating the method’s capability to produce the desired mechanical performance.

This result can be used to enhance the strength and durability of adhesive joints in practical applications, e.g., to obtain functionally graded adhesive by integrating the resistive circuit exclusively within designated regions, or to use adhesive thermal curing in setups with thermal-insulating adherends. Relevant applications could be additively manufactured carbon fiber-reinforced polymer components for aerospace applications (e.g., wings and fuselages panels), for automotives (e.g., body panels, frames, and suspension components), or for custom-designed products, such as custom-designed prostheses or sports equipment [64,65,66,67,68,69,70,71,72,73,74,75,76].

4. Conclusions

This study demonstrates the effectiveness of integrating resistive heating elements into adhesive joints using MM-AM to enable localized thermal curing. By embedding conductive circuits within the adherends, precise control over the curing process was achieved, leading to significant improvements in joint performance. The experimental results confirmed that curing at elevated temperatures, specifically 120 °C, resulted in a 58% increase in maximum breaking force compared to room-temperature-cured joints, and the elongation nearly doubled. This enhancement is attributed to changed adhesive mechanical properties within the joint.

The findings validate the feasibility of the MM-AM process for creating multifunctional adhesive joints with tailored mechanical properties using embedded additively manufactured resistances. The proposed approach offers a versatile solution for applications requiring functionally graded adhesives, enabling better stress management and superior mechanical performance. Furthermore, the method presents opportunities for efficient, sustainable, and reworkable adhesive bonding solutions by facilitating controlled disassembly when needed. Future work will focus on refining the thermal control strategy, exploring alternative materials, and extending the approach to complex geometries and varying joint configurations.

Author Contributions

Conceptualization, M.F. and F.M.; data curation, F.D.; investigation, M.F., M.M., S.M., K.M.U., and F.D.; methodology, M.F.; resources, M.F., F.M., M.Z. and M.A.; writing—original draft, M.F., M.M., and F.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Handbook of Adhesion Technology; Springer International Publishing: Cham, Germany, 2018. [Google Scholar]

- Petrie, E.M. Handbook of Adhesives and Sealants; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Wei, Y.; Jin, X.; Luo, Q.; Li, Q.; Sun, G. Adhesively bonded joints—A review on design, manufacturing, experiments, modeling and challenges. Compos. Part B Eng. 2024, 276, 111225. [Google Scholar] [CrossRef]

- Tong, L.; Luo, Q. Analytical Approach to Joint Design. In Handbook of Adhesion Technology; Da Silva, L.F.M., Öchsner, A., Adams, R.D., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 597–627. [Google Scholar]

- Frascio, M.; Morchio, S.; Musiari, F.; Usman, K.M.; Dittamo, F.; Minuto, M.; Avalle, M. Investigating Multi-Material Additive Manufacturing for Disassembly and Reparability of Adhesive Joints by Precision Heating. Adhesives 2025, 1, 4. [Google Scholar] [CrossRef]

- Kwok, S.W.; Goh, K.H.H.; Tan, Z.D.; Tan, S.T.M.; Tjiu, W.W.; Soh, J.Y.; Ng, Z.J.G.; Chan, Y.Z.; Hui, H.K.; Goh, K.E.J. Electrically conductive filament for 3D-printed circuits and sensors. Appl. Mater. Today 2017, 9, 167–175. [Google Scholar] [CrossRef]

- Saurabh, A.; Seung, Y.K. Revolutionizing 3D electronics: Single-step femtosecond laser fabrication of conductive embedded structures and circuitry. Mater. Today Adv. 2025, 25, 100544. [Google Scholar] [CrossRef]

- Jangid, A.R.; Strong, E.B.; Chuang, J.; Martinez, A.W.; Martinez, N.W. Evaluation of commercially-available conductive filaments for 3D printing flexible circuits on paper. PeerJ Mater. Sci. 2022, 4, e21. [Google Scholar] [CrossRef]

- Niese, B.; Stichel, T.; Amend, P.; Urmoneit, U.; Roth, S.; Schmidt, M. Manufacturing of conductive circuits for embedding stereolithography by means of conductive adhesive and laser sintering. Phys. Procedia 2014, 56, 336–344. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Ravoori, D.; Alba, L.; Prajapati, H.; Jain, A. Investigation of process-structure-property relationships in polymer extrusion based additive manufacturing through in situ high speed imaging and thermal conductivity measurements. Addit. Manuf. 2018, 23, 132–139. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Li, L.; Sun, Q.; Bellehumeur, C.; Gu, P. Composite modeling and analysis for fabrication of FDM prototypes with locally controlled properties. J. Manuf. Process. 2002, 4, 129–141. [Google Scholar] [CrossRef]

- Gajdos, I.; Slota, J. Influence of printing conditions on structure in FDM prototypes. Teh. Vjesn.-Tech. Gaz. 2013, 20, 231–236. [Google Scholar]

- Singh, R.; Singh, G.; Singh, J.; Kumar, R. On printability of PLA-PEKK-HAp-CS based functional prototypes with FDM: Thermo-mechanical investigations. Mater. Res. Express 2019, 6, 115338. [Google Scholar] [CrossRef]

- Lin, E.; Li, Y.; Ortiz, C.; Boyce, M.C. 3D printed, bio-inspired prototypes and analytical models for structured suture interfaces with geometrically-tuned deformation and failure behavior. J. Mech. Phys. Solids. 2014, 73, 166–182. [Google Scholar] [CrossRef]

- Suresh, G.; Narayana, K.L. A review on fabricating procedures in rapid prototyping. 3D Printing: Breakthroughs in Research and Practice. Inf. Resour. Manag. Assoc. 2016, 1, 1–21. [Google Scholar] [CrossRef]

- Tello, J.A.; Zapata, M.; Paillacho, D. Advances in Additive Manufacturing, Modeling Systems and 3D Prototyping. In Proceedings of the AHFE 2019 International Conference on Additive Manufacturing, Modeling Systems and 3D Prototyping, Washington, DC, USA, 24–28 July 2019; Springer: Berlin/Heidelberg, Germany, 2020; Volume 975, pp. 108–118. [Google Scholar] [CrossRef]

- Haryńska, A.; Carayon, I.; Kosmela, P.; Szeliski, K.; Łapiński, M.; Pokrywczyńska, M.; Kucińska-Lipka, J.; Janik, H. A comprehensive evaluation of flexible FDM/FFF 3D printing filament as a potential material in medical application. Eur. Polym. J. 2020, 138, 109958. [Google Scholar] [CrossRef]

- Knoop, F.; Schoeppner, V. Mechanical and Thermal Properties of Fdm Parts Manufactured. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015. [Google Scholar]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical behaviour of ABS: An experimental study using FDM and injection moulding techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Kiendl, J.; Gao, C. Controlling toughness and strength of FDM 3D-printed PLA components through the raster layup. Compos. Part B Eng. 2020, 180, 107562. [Google Scholar] [CrossRef]

- Yadav, D.; Chhabra, D.; Garg, R.K.; Ahlawat, A.; Phogat, A. Optimization of FDM 3D printing process parameters for multi-material using artificial neural network. Mater. Today Proc. 2020, 21, 1583–1591. [Google Scholar] [CrossRef]

- Schumacher, C.; Schöppner, V.; Fels, C. A method to evaluate the process-specific warpage for different polymers in the FDM process. AIP Conf. Proc. 2019, 2065. [Google Scholar] [CrossRef]

- Leicht, H.; Orf, L.; Hesselbach, J.; Vudugula, H.; Kraus, E.; Baudrit, B.; Hochrein, T.; Bastian, M. A bonding of 3D-printed plastic components. J. Adhes. 2020, 96, 48–63. [Google Scholar] [CrossRef]

- Kumar, S.; Wardle, B.L.; Arif, M.F.; Ubaid, J. Stress Reduction of 3D Printed Compliance-Tailored Multilayers. Adv. Eng. Mater. 2018, 20, 1700883. [Google Scholar] [CrossRef]

- Khan, M.A.; Kumar, S.; Cantwell, W.J. Additively manufactured cylindrical systems with stiffness-tailored interface: Modeling and experiments. Int. J. Solids Struct. 2018, 152–153, 71–84. [Google Scholar] [CrossRef]

- Liu, T.; Liu, L.; Zeng, C.; Liu, Y.; Leng, J. 4D printed anisotropic structures with tailored mechanical behaviors and shape memory effects. Compos. Sci. Technol. 2020, 186, 107935. [Google Scholar] [CrossRef]

- Khan, M.A.; Kumar, S. Interfacial stresses in single-side composite patch-repairs with material tailored bondline. Mech. Adv. Mater. Struct. 2016, 25, 304–318. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S. A design for the additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J. Manuf. Process. 2011, 13, 160–170. [Google Scholar] [CrossRef]

- Sekiguchi, Y.; Nakanouchi, M.; Haraga, K.; Takasaki, I.; Sato, C. Experimental investigation on strength of stepwise tailored single lap adhesive joint using second-generation acrylic adhesive via shear and low-cycle shear tests. Int. J. Adhes. Adhes. 2019, 95, 102438. [Google Scholar] [CrossRef]

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. Multiple material additive manufacturing—Part 1: A review: This review paper covers a decade of research on multiple material additive manufacturing technologies which can produce complex geometry parts with different materials. Virtual Phys. Prototyp. 2013, 8, 19–50. [Google Scholar] [CrossRef]

- Bohidar, S.K.; Sharma, R.; Mishra, P.R. Functionally Graded Materials: A Critical Review. Int. J. Res. 2014, 1, 289–301. [Google Scholar]

- Alfaify, A.; Saleh, M.; Abdullah, F.M.; Al-Ahmari, A.M. Design for Additive Manufacturing: A Systematic Review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Pethrick, R.A. Design and ageing of adhesives for structural adhesive bonding—A review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2015, 229, 349–379. [Google Scholar] [CrossRef]

- Engels, T. Thermoset adhesives: Epoxy resins, acrylates and polyurethanes. In Thermosets; Elsevier: Amsterdam, The Nederlands, 2012; pp. 228–253. [Google Scholar]

- Banea, M.D. Debonding on Demand of Adhesively Bonded Joints: A Critical Review. Rev. Adhes. Adhes. 2019, 7, 33–50. [Google Scholar] [CrossRef]

- Jahani, Y.; Baena, M.; Barris, C.; Perera, R.; Torres, L. Influence of curing, post-curing and testing temperatures on mechanical properties of a structural adhesive. Constr. Build. Mater. 2022, 324, 126698. [Google Scholar] [CrossRef]

- Carbas, R.; Silva Lda Critchlow, G. Effect of post-cure on adhesively bonded functionally graded joints by induction heating. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2015, 229, 419–430. [Google Scholar] [CrossRef]

- dos Reis, M.Q.; Marques, E.A.S.; Carbas, R.J.C.; da Silva, L.F.M. Functionally graded adherends in adhesive joints: An overview. J. Adv. Join. Process. 2020, 2, 100033. [Google Scholar] [CrossRef]

- Carbas, R.J.C.; Da Silva, L.F.M.; Critchlow, G.W. Adhesively bonded functionally graded joints by induction heating. Int. J. Adhes. Adhes. 2014, 48, 110–118. [Google Scholar] [CrossRef]

- Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M.; Lopes, A.M. Effect of Cure Temperature on the Glass Transition Temperature and Mechanical Properties of Epoxy Adhesives. J. Adhes. 2014, 90, 104–119. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Carbas, R.J.C.; de Barros, S. Debonding on command of multi-material adhesive joints. J. Adhes. 2016, 93, 756–770. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Adams, R.D. Joint strength predictions for adhesive joints to be used over a wide temperature range. Int. J. Adhes. Adhes. 2007, 27, 362–379. [Google Scholar] [CrossRef]

- Dong, W.; Gu, X.; Han, J.; You, L. Universal Adhesives- Different Curing Methods and Applications. E3S Web Conf. 2021, 290, 01021. [Google Scholar] [CrossRef]

- Cavalcanti, D.K.K.; Medina, M.; de Queiroz, H.F.M.; Neto, J.d.S.e.S.; Chaves, F.J.P.; Banea, M.D. Recent Advances in Adhesive Bonding of 3D-Printed Parts and Methods to Increase their Mechanical Performance. Ann. Dunarea De Jos Univ. Galati Fascicle XII Weld. Equip. Technol. 2023, 34, 17–24. [Google Scholar] [CrossRef]

- Barbosa, N.G.C.; Campilho, R.D.S.G.; Silva, F.J.G.; Moreira, R.D.F. Comparison of different adhesively-bonded joint types for mechanical structures. Appl. Adhes. Sci. 2018, 6, 15. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Introduction to Adhesive Bonding Technology. In Handbook of Adhesion Technology; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–7. [Google Scholar]

- Abbasi, M.; Ciardiello, R.; Goglio, L. Experimental Study on the Effect of Bonding Area Dimensions on the Mechanical Behavior of Composite Single-Lap Joint with Epoxy and Polyurethane Adhesives. Appl. Sci. 2023, 13, 7683. [Google Scholar] [CrossRef]

- Abbasi, M.; Ciardiello, R.; Goglio, L. Effect of bonding area geometry on the behavior of composite single lap joints (SLJ) and estimation of adhesive properties using finite element method. J. Adhes. 2024, 100, 686–708. [Google Scholar] [CrossRef]

- Borges, C.S.P.; Akhavan-Safar, A.; Tsokanas, P.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. From fundamental concepts to recent developments in the adhesive bonding technology: A general view. Discov. Mech. Eng. 2023, 2, 8. [Google Scholar] [CrossRef]

- Nakanouchi, M.; Sato, C.; Sekiguchi, Y.; Haraga, K.; Uno, H. Development of application method for fabricating functionally graded adhesive joints by two-component acrylic adhesives with different elastic moduli. J. Adhes. 2019, 95, 529–542. [Google Scholar] [CrossRef]

- Frascio, M.; Marques, E.A.d.S.; Carbas, R.J.C.; da Silva, L.F.M.; Monti, M.; Avalle, M. Review of Tailoring Methods for Joints with Additively Manufactured Adherends and Adhesives. Materials 2020, 13, 3949. [Google Scholar] [CrossRef]

- Frascio, M.; Moroni, F.; Marques, E.; Carbas, R.; Reis, M.; Monti, M.; Avalle, M.; da Silva, L. Feasibility study on hybrid weld-bonded joints using additive manufacturing and conductive thermoplastic filament. J. Adv. Join. Process. 2021, 3, 100046. [Google Scholar] [CrossRef]

- Frascio, M.; Moroni, F.; Marques, E.; Carbas, R.; Reis, M.; Monti, M.; Avalle, M.; da Silva, L. Adhesive bonding of glass-fibre thermoplastic composite: Process optimisation and sustainability analysis using LCA methodology. Int. J. Adv. Manuf. Technol. 2024, 130, 5709–5726. [Google Scholar] [CrossRef]

- Senatov, F.S.; Niaza, K.V.; Stepashkin, A.A.; Kaloshkin, S.D. Low-cycle fatigue behavior of 3d-printed PLA-based porous scaffolds. Compos. Part B Eng. 2016, 97, 193–200. [Google Scholar] [CrossRef]

- Batista, M.; Valerga, A.P.; Salguero, J.; Vidal, S.R.F. State of the art of the fused deposition modeling using PLA: Improving the performance. In Additive and Subtractive Manufacturing; De Gruyter: Berlin, Germany, 2019. [Google Scholar]

- Flowers, P.F.; Reyes, C.; Ye, S.; Kim, M.J.; Wiley, B.J. 3D printing electronic components and circuits with conductive thermoplastic filament. Addit. Manuf. 2017, 18, 156–163. [Google Scholar] [CrossRef]

- Abbasi, M.; Ciardiello, R.; Goglio, L. A novel approach for damage assessment in adhesively bonded composite joints using backface strain technique. Compos. Part B Eng. 2024, 286, 111766. [Google Scholar] [CrossRef]

- Abbasi, M.; Ciardiello, R.; Goglio, L. Backface strain as an index to detect damage initiation in composite single-lap bonded joints: Effects of adhesive type and joint dimensions. Int. J. Adhes. Adhes. 2024, 134, 103791. [Google Scholar] [CrossRef]

- Pizzorni, M.; Benvenuto, M.; Lertora, E.; Mandolfino, C. Adhesive bonding of CFRP with a 3D-printed short-fiber composite: An experimental study on the effects of geometry and adhesive system on joint performance. Compos. Part B Eng. 2025, 294, 112155. [Google Scholar] [CrossRef]

- Frascio, M.; Mandolfino, C.; Moroni, F.; Jilich, M.; Lagazzo, A.; Pizzorni, M.; Bergonzi, L.; Morano, C.; Alfano, M.; Avalle, M. Appraisal of surface preparation in adhesive bonding of additive manufactured substrates. Int. J. Adhes. Adhes. 2021, 106, 102802. [Google Scholar] [CrossRef]

- Jilich, M.; Frascio, M.; Avalle, M.; Zoppi, M. Development of a gripper for garment handling designed for additive manufacturing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 235, 1799–1810. [Google Scholar] [CrossRef]

- Vijayan, V.; Kumar, S.A.; Gautham, S.; Masthan, M.M.; Piraichudan, N. Design and analysis of prosthetic foot using additive manufacturing technique. Mater. Today. Proc. 2021, 37, 1665–1671. [Google Scholar] [CrossRef]

- Kathrotiya, D.; Yusuf, A.; Bhagchandani, R.K.; Gupta, S. A Study for the development of prosthetic foot by additive manufacturing. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 187. [Google Scholar] [CrossRef]

- Bhatt, S.; Joshi, D.; Rakesh, P.K.; Godiyal, A.K. Advances in additive manufacturing processes and their use for the fabrication of lower limb prosthetic devices. Expert Rev. Med. Devices 2023, 20, 17–27. [Google Scholar] [CrossRef]

- Aryal, M.R.; Pun, S. Additive manufacturing of prosthetic hands: A brief overview. Int. J. Interact. Des. Manuf. (IJIDeM) 2022, 16, 1099–1112. [Google Scholar] [CrossRef]

- Fasel, U.; Keidel, D.; Baumann, L.; Cavolina, G.; Eichenhofer, M.; Ermanni, P. Composite additive manufacturing of morphing aerospace structures. Manuf. Lett. 2020, 23, 85–88. [Google Scholar] [CrossRef]

- Chen, W.; Hu, Z.; Li, X.; He, J.; Wang, S.; Zhao, Y.; Li, M.; Zhang, J. Additive manufacturing of high-strength polyamide 6 composites reinforced with continuous carbon fiber prepreg. Polym. Compos. 2024, 45, 668–679. [Google Scholar] [CrossRef]

- Wang, H.H.; Huo, S.; Chevali, V.; Hall, W.; Offringa, A.; Song, P.; Wang, H. Carbon Fiber Reinforced Thermoplastics: From Materials to Manufacturing and Applications. Adv. Materials. 2025, 1, e2418709. [Google Scholar] [CrossRef]

- Elsayed, R.; Teow, Y.H. Advanced functional polymer materials for biomedical applications. J. Appl. Polym. Sci. 2025, 142, e56391. [Google Scholar] [CrossRef]

- Adil, S.; Lazoglu, I. A review on additive manufacturing of carbon fiber-reinforced polymers: Current methods, materials, mechanical properties, applications and challenges. J. Appl. Polym. Sci. 2023, 140, e53476. [Google Scholar] [CrossRef]

- Karaş, B.; Smith, P.J.; Fairclough, J.P.A.; Mumtaz, K. Additive manufacturing of high density carbon fibre reinforced polymer composites. Addit. Manuf. 2022, 58, 103044. [Google Scholar] [CrossRef]

- Rashvand, K.; Eder, M.A.; Sarhadi, A. In-situ and adhesive repair of continuous fiber composites using 3D printing. Addit. Manuf. 2024, 80, 103975. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M.; Ghobakhloo, M.; Mordas, G.; Skotnicová, K. Additive manufacturing of continuous carbon fiber reinforced polymer composites using materials extrusion process. Mechanical properties, process parameters, fracture analysis, challenges, and future prospect. A review. Adv. Compos. Hybrid. Mater. 2024, 7, 202. [Google Scholar] [CrossRef]

- Stacchiotti, F.; Bregoli, C.; Ferrari, R.; Fiocchi, J.; Morellato, K.; Biffi, C.A.; Frascio, M.; Minuto, M.; Tuissi, A.; Gruppioni, E. A patient-matched prosthesis for thumb amputations: Design, mechanical and functional evaluation. Med. Eng. Phys. 2025, 137, 104296. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).