Effect of Varying Layer Thickness by Interlayer Machining on Microstructure and Mechanical Properties in Wire Arc Additive Manufacturing

Abstract

1. Introduction

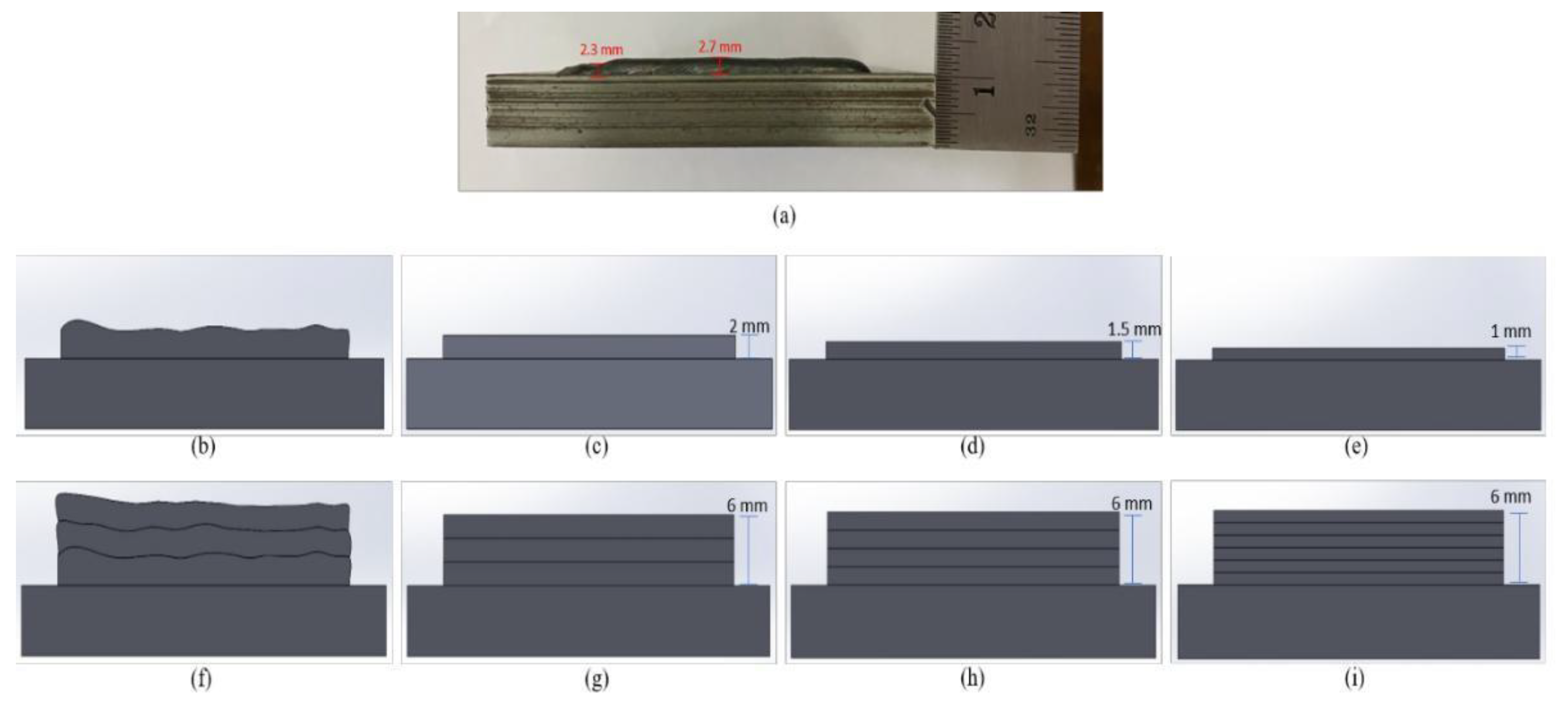

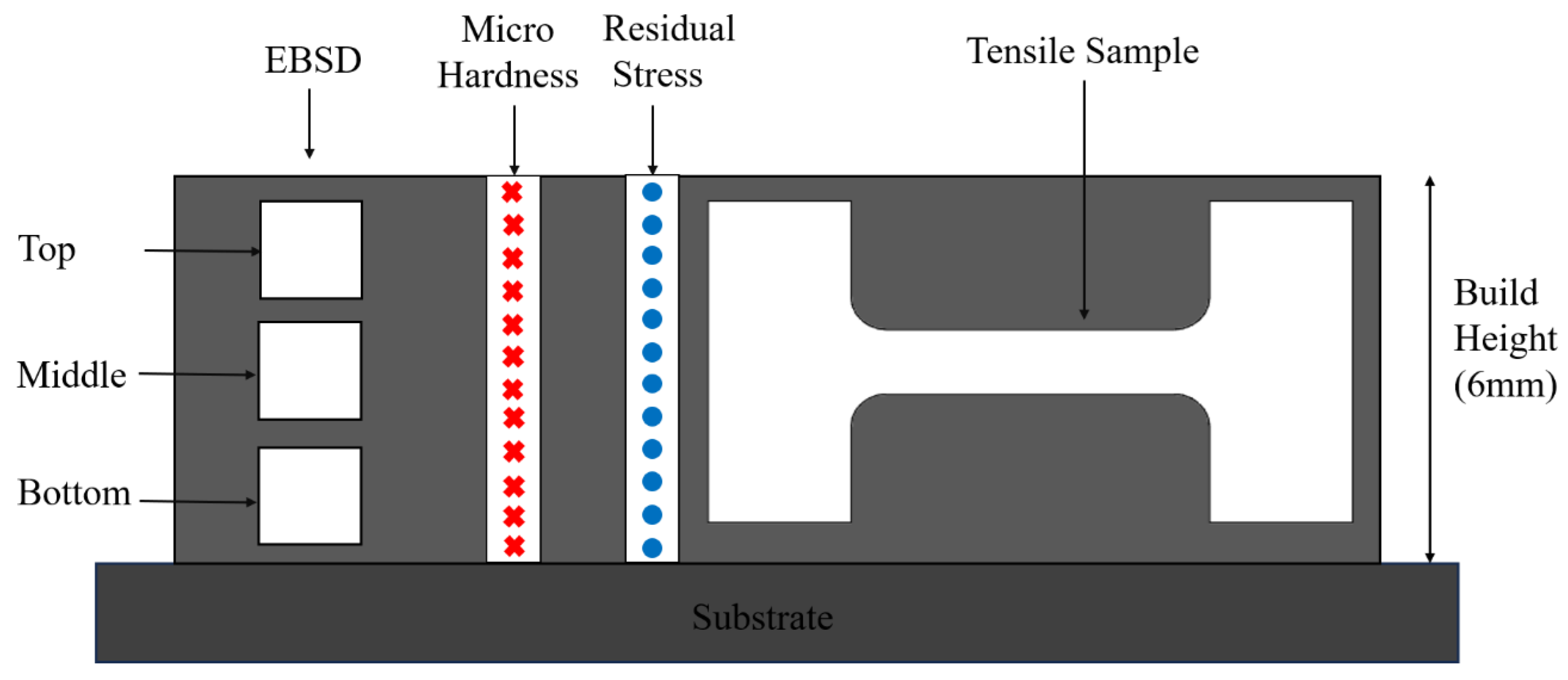

2. Materials and Methods

3. Results and Discussion

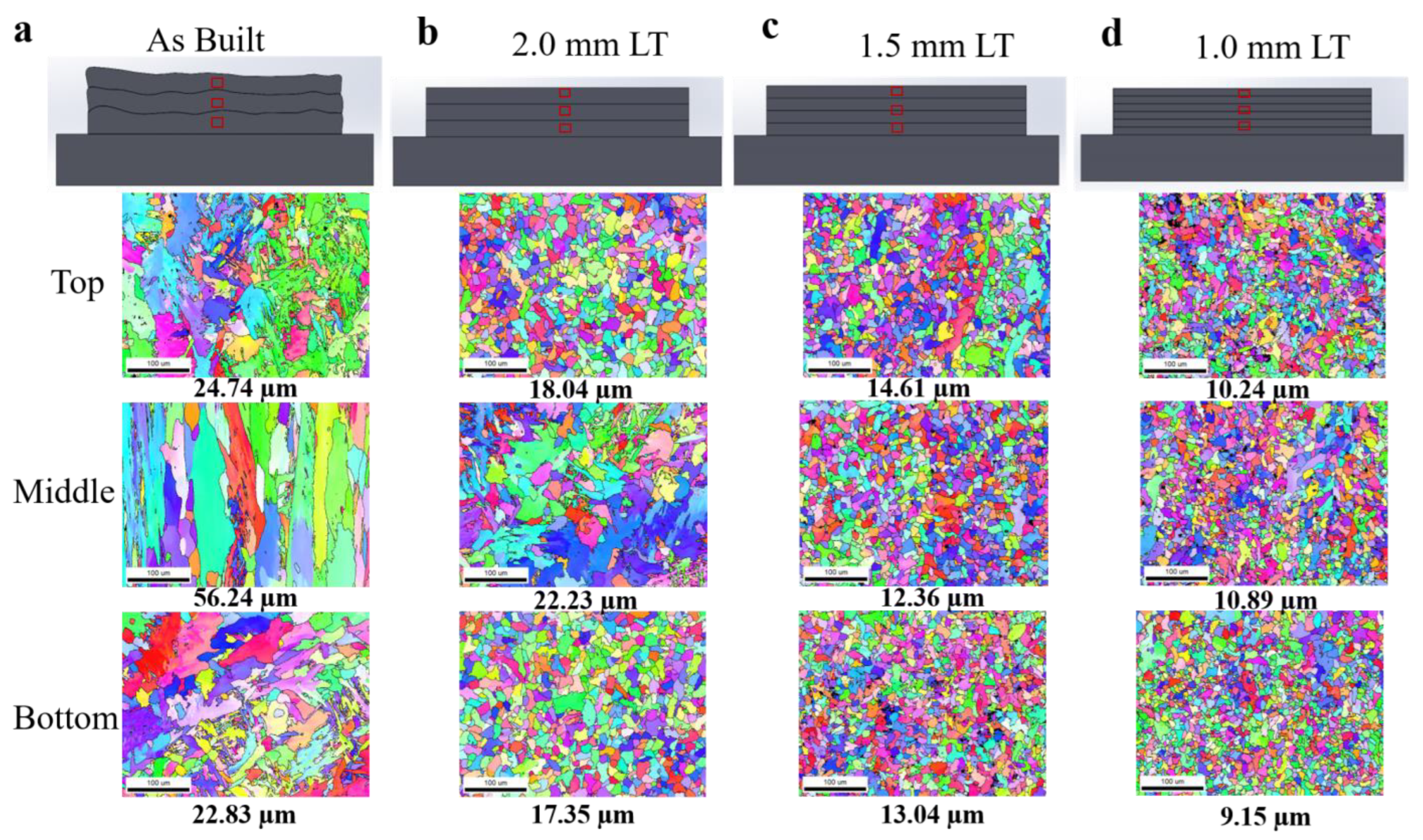

3.1. Microstructure Evolution

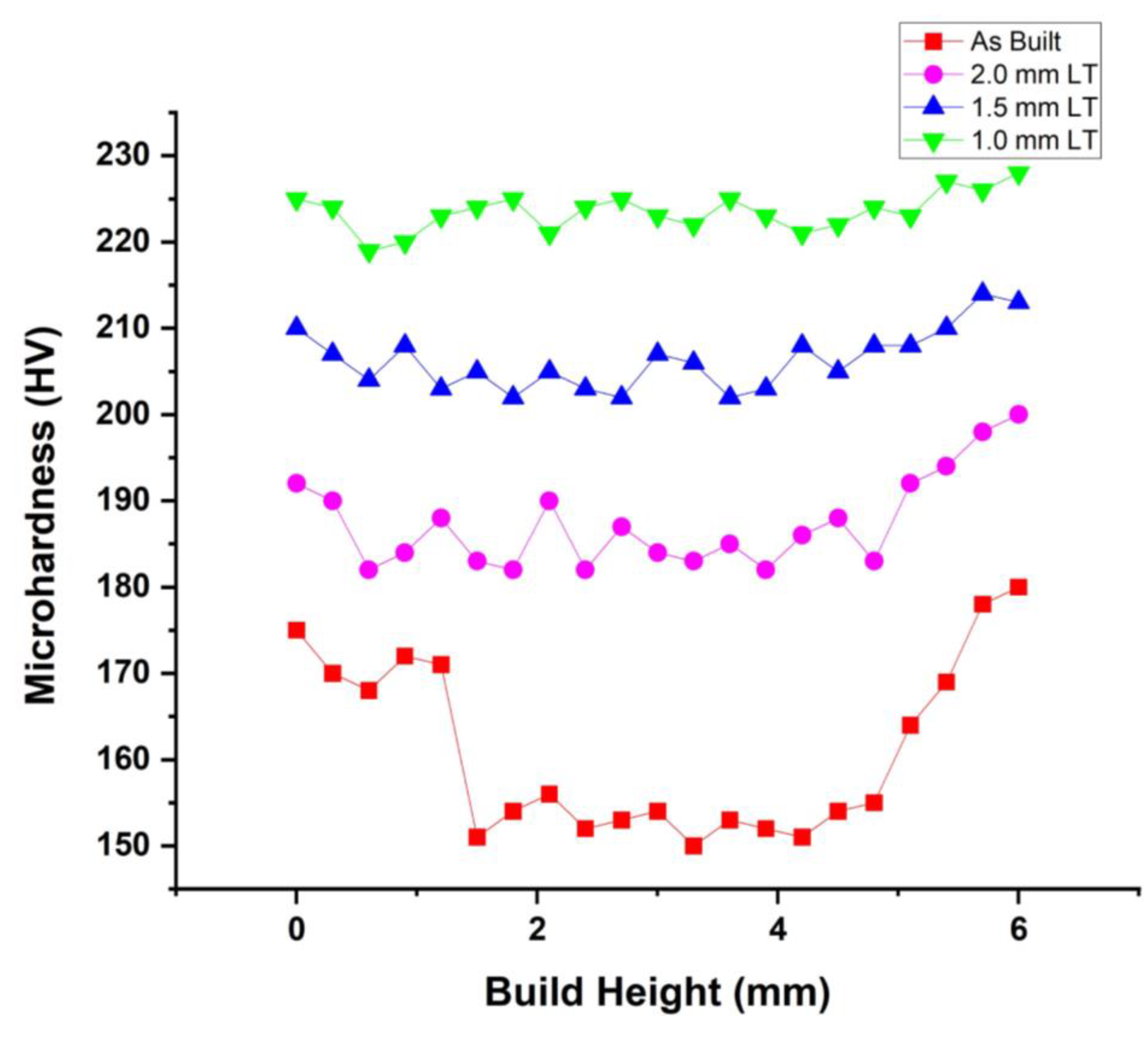

3.2. Microhardness

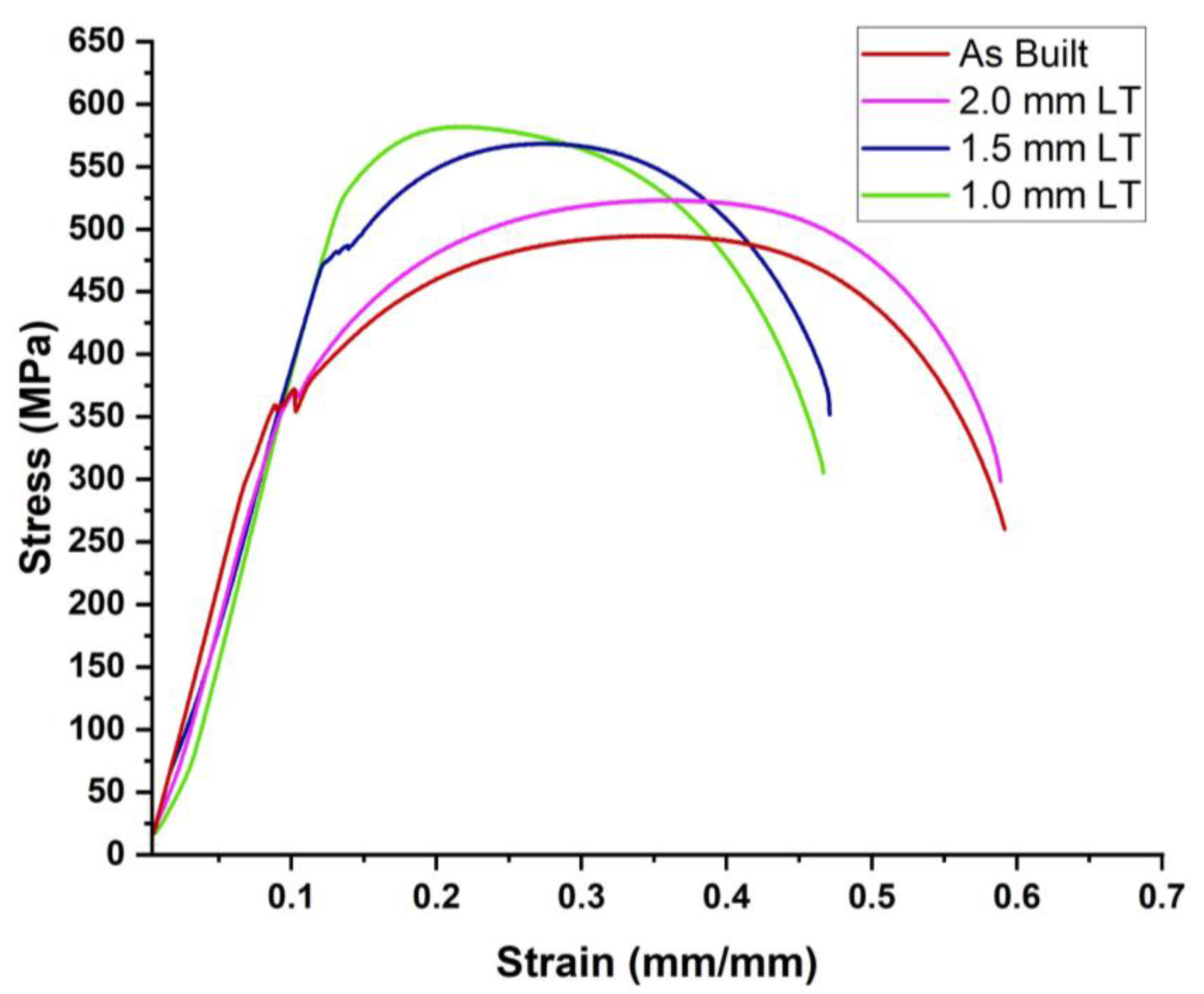

3.3. Stress–Strain Curves

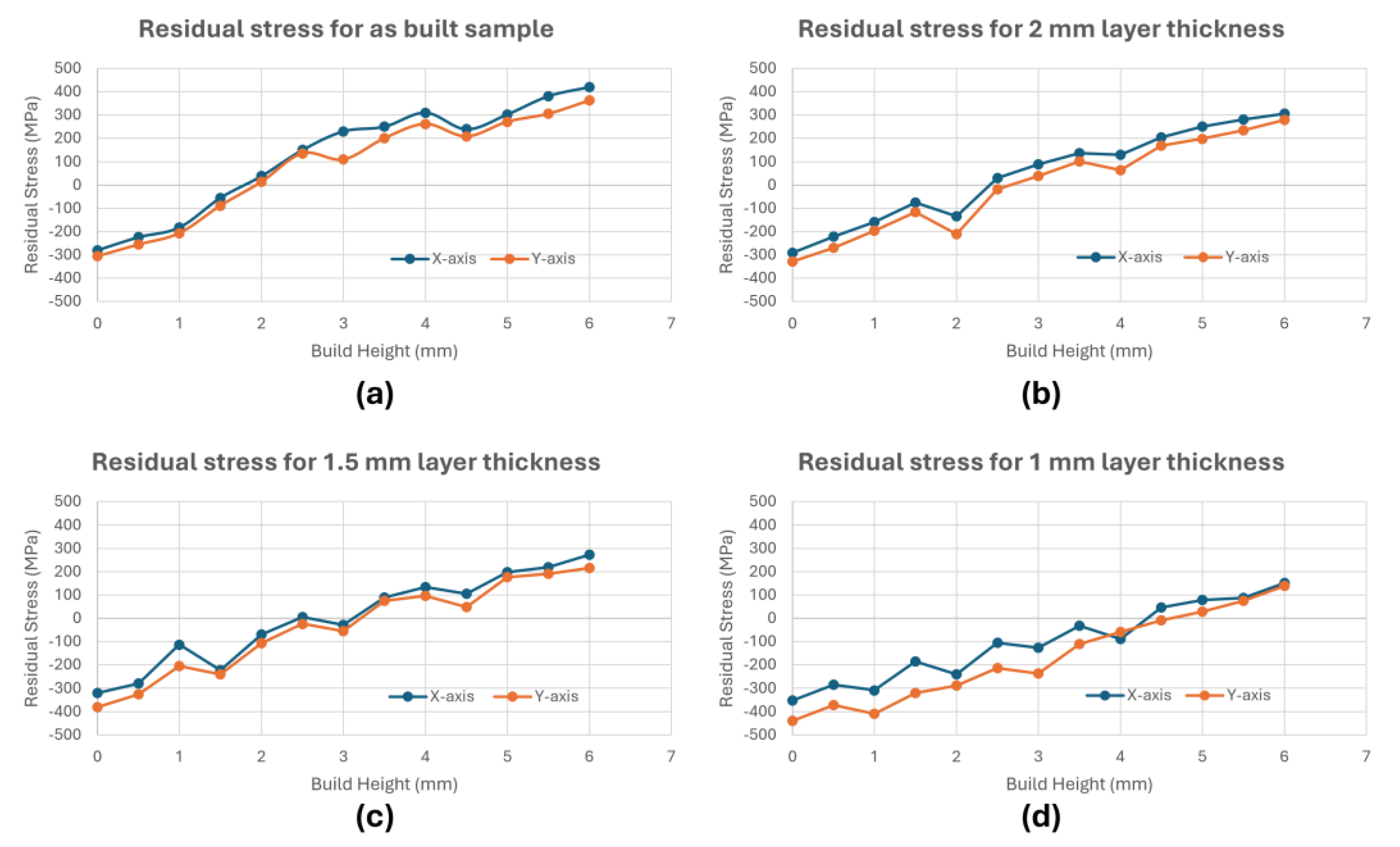

3.4. Residual Stress

4. Conclusions

- Grain refinement at 1.0 mm layer thickness achieves reductions of 62.7% (top), 77.6% (middle), and 64.3% (bottom), improving microstructural uniformity and mechanical properties through the Hall–Petch effect.

- Microhardness increases from 150 to 180 HV (as-built) to 210 to 230 HV, marking a 40–43% improvement due to dislocation strengthening.

- Tensile properties show significant enhancement: UTS rises from 494.72 MPa to 582.11 MPa (17.6% increase), and YS increases from 371 MPa to 471 MPa (26.9% increase) due to grain boundary strengthening and strain hardening.

- Ductility trade-off: Elongation decreases from 59% to 46% (22% reduction) as restricted dislocation movement enhances strength at the expense of ductility.

- Residual stress reduction of 55–60% at 1.0 mm layer thickness improves structural integrity by minimizing stress concentrations and reducing distortion or cracking risks.

- While decreasing layer thickness enhances material properties, it increases production time and cost, necessitating a balance between mechanical improvements and manufacturing efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ayrilmis, N. Effect of Layer Thickness on Surface Properties of 3D Printed Materials Produced from Wood Flour/PLA Filament E Ff Ect of Layer Thickness on Surface Properties of 3D Printed Materials Produced from Wood Fl Our/PLA Fi Lament Nadir Ayrilmis. Polym. Test. 2021, 71, 163–166. [Google Scholar] [CrossRef]

- Shergill, K.; Chen, Y.; Bull, S. An Investigation into the Layer Thickness Effect on the Mechanical Properties of Additively Manufactured Polymers: PLA and ABS. Int. J. Adv. Manuf. Technol. 2023, 126, 3651–3665. [Google Scholar] [CrossRef]

- Agrawal, A.P.; Kumar, V.; Kumar, J.; Paramasivam, P.; Dhanasekaran, S.; Prasad, L. An Investigation of Combined Effect of Infill Pattern, Density, and Layer Thickness on Mechanical Properties of 3D Printed ABS by Fused Filament Fabrication. Heliyon 2023, 9, e16531. [Google Scholar] [CrossRef]

- Gullane, A.; Murray, J.W.; Hyde, C.J.; Sankare, S.; Evirgen, A.; Clare, A.T. On the Use of Multiple Layer Thicknesses within Laser Powder Bed Fusion and the Effect on Mechanical Properties. Mater. Des. 2021, 212, 110256. [Google Scholar] [CrossRef]

- Hyer, H.C.; Petrie, C.M. Effect of Powder Layer Thickness on the Microstructural Development of Additively Manufactured SS316. J. Manuf. Process 2022, 76, 666–674. [Google Scholar] [CrossRef]

- Karunakaran, K.P.; Gupta, N.K.; Patel, A.K.; Rakeshkumar, K.; Ganesan, G.; Siddhartha; Sealy, M.; Bernard, A. Multi-Station Multi-Axis Hybrid Layered Manufacturing (MSMA-HLM). Manuf. Lett. 2022, 33, 630–639. [Google Scholar] [CrossRef]

- Karade, S.R.; Siddhartha, S.; Gupta, N.K.; Ganesan, G.; Karunakaran, K.P.; Zeidler, H. Hybridization in Metal Wire Additive Manufacturing: A Case Study of an Impeller. Metals 2025, 15, 71. [Google Scholar] [CrossRef]

- Chernovol, N.; Lauwers, B.; van Rymenant, P. Development of Low-Cost Production Process for Prototype Components Based on Wire and Arc Additive Manufacturing (WAAM). Procedia CIRP 2020, 95, 60–65. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-Feed Additive Manufacturing of Metal Components: Technologies, Developments and Future Interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Grossi, N.; Lazzeri, F.; Venturini, G. Deposition Strategies for Bar Intersections Using Dot-by-Dot Wire and Arc Additive Manufacturing. J. Manuf. Mater. Process. 2025, 9. [Google Scholar] [CrossRef]

- Sebok, M.; Lai, C.; Masuo, C.; Walters, A.; Carter, W.; Lambert, N.; Meyer, L.; Officer, J.; Roschli, A.; Vaughan, J.; et al. Slicing Solutions for Wire Arc Additive Manufacturing. J. Manuf. Mater. Process. 2025, 9, 112. [Google Scholar] [CrossRef]

- Zhou, N.; Peng, R.L.; Pettersson, R. Surface Integrity of 2304 Duplex Stainless Steel after Different Grinding Operations. J. Mater. Process Technol. 2016, 229, 294–304. [Google Scholar] [CrossRef]

- Bekker, A.C.M.; Verlinden, J.C. Life Cycle Assessment of Wire + Arc Additive Manufacturing Compared to Green Sand Casting and CNC Milling in Stainless Steel. J. Clean. Prod. 2018, 177, 438–447. [Google Scholar] [CrossRef]

- da Costa, A.L.S.; de Paiva, R.L.; de Oliveira, D.; Ziberov, M. Influence of Interlayer Temperature and Deposition Method on the Wall Geometry and Vickers Microhardness Profile of ER70S-6 Parts Manufactured by Additive Manufacturing Using CMT. J. Manuf. Mater. Process. 2025, 9, 93. [Google Scholar] [CrossRef]

- Šket, K.; Brezočnik, M.; Karner, T.; Belšak, R.; Ficko, M.; Vuherer, T.; Gotlih, J. Predictive Modelling of Weld Bead Geometry in Wire Arc Additive Manufacturing. J. Manuf. Mater. Process. 2025, 9, 67. [Google Scholar] [CrossRef]

- Sales, W.F.; Schoop, J.; da Silva, L.R.R.; Machado, Á.R.; Jawahir, I.S. A Review of Surface Integrity in Machining of Hardened Steels. J. Manuf. Process 2020, 58, 136–162. [Google Scholar] [CrossRef]

- Liao, Z.; la Monaca, A.; Murray, J.; Speidel, A.; Ushmaev, D.; Clare, A.; Axinte, D.; M’Saoubi, R. Surface Integrity in Metal Machining—Part I: Fundamentals of Surface Characteristics and Formation Mechanisms. Int. J. Mach. Tools Manuf. 2021, 162. [Google Scholar] [CrossRef]

- Cox, A.; Herbert, S.; Villain-Chastre, J.P.; Turner, S.; Jackson, M. The Effect of Machining and Induced Surface Deformation on the Fatigue Performance of a High Strength Metastable β Titanium Alloy. Int. J. Fatigue 2019, 124, 26–33. [Google Scholar] [CrossRef]

- Gupta, N.K.; Ganesan, G.; Siddhartha, S.; Karade, S.R.; Paul, A.K.; Dubey, S.; Ely, R.H.; Karunakaran, K.P. In Situ Pre-Heating in Wire Arc Additive Manufacturing: Design, Development, and Experimental Investigation on Residual Stresses and Metallurgical and Mechanical Properties. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Maity, M.; Tiwari, Y.; Manivannan, R.; Mukherjee, M. Influence of In-Situ Hammering on Microstructural, Mechanical and Residual Stress Behaviour of Inconel 718 during Wire Arc Additive Manufacturing. Prog. Addit. Manuf. 2024. [Google Scholar] [CrossRef]

- Gupta, N.K.; Ganesan, G.; Siddhartha, S.; Karade, S.R.; Singh, S.D.; Karunakaran, K.P. A Dual-Side Deposition Technique to Mitigate Deformation in Wire Arc Additive Manufacturing. Trans. Indian. Inst. Met. 2024, 77, 3425–3434. [Google Scholar] [CrossRef]

- West, J.; Betters, E.; Schmitz, T. Limited-Constraint WAAM Fixture for Hybrid Manufacturing. Manuf. Lett. 2023, 37, 66–69. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, B.; Bai, Q.; Kang, R.; Tang, J. Effect of Grain Size on Subsurface Characterization of Pure Iron Subjected to Orthogonal Cutting. Int. J. Adv. Manuf. Technol. 2022, 120, 5793–5806. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Cammett, J.T.; König, W.; Leskovar, P.; Peters, J.; Tönshoff, H.K. Residual Stresses—Measurement and Causes in Machining Processes. CIRP Ann. Manuf. Technol. 1982, 31, 491–510. [Google Scholar] [CrossRef]

- Arunachalam, R.M.; Mannan, M.A.; Spowage, A.C. Residual Stress and Surface Roughness When Facing Age Hardened Inconel 718 with CBN and Ceramic Cutting Tools. Int. J. Mach. Tools Manuf. 2004, 44, 879–887. [Google Scholar] [CrossRef]

- Pauza, J.; Rollett, A. Simulation Study of Hatch Spacing and Layer Thickness Effects on Microstructure in Laser Powder Bed Fusion Additive Manufacturing Using a Texture-Aware Solidification Potts Model. J. Mater. Eng. Perform. 2021, 30, 7007–7018. [Google Scholar] [CrossRef]

- Leicht, A.; Fischer, M.; Klement, U.; Nyborg, L.; Hryha, E. Increasing the Productivity of Laser Powder Bed Fusion for Stainless Steel 316L through Increased Layer Thickness. J. Mater. Eng. Perform. 2021, 30, 575–584. [Google Scholar] [CrossRef]

- Pan, Z.; Feng, Y.; Liang, S.Y. Material Microstructure Affected Machining: A Review. Manuf. Rev. 2017, 4, 5. [Google Scholar] [CrossRef]

- Rajaguru, J.; Arunachalam, N. Investigation on Machining Induced Surface and Subsurface Modifications on the Stress Corrosion Crack Growth Behaviour of Super Duplex Stainless Steel. Corros. Sci. 2018, 141, 230–242. [Google Scholar] [CrossRef]

- Atmani, Z.; Haddag, B.; Nouari, M.; Zenasni, M. Multi-Physics Modelling in Machining OFHC Copper—Coupling of Microstructure-Based Flow Stress and Grain Refinement Models. Procedia CIRP 2015, 31, 545–550. [Google Scholar] [CrossRef]

- Bissey-Breton, S.; Vignal, V.; Herbst, F.; Coudert, J.B. Influence of Machining on the Microstructure, Mechanical Properties and Corrosion Behaviour of a Low Carbon Martensitic Stainless Steel. Procedia CIRP 2016, 46, 331–335. [Google Scholar] [CrossRef]

- Abboud, E.; Attia, H.; Shi, B.; Damir, A.; Thomson, V.; Mebrahtu, Y. Residual Stresses and Surface Integrity of Ti-Alloys during Finish Turning—Guidelines for Compressive Residual Stresses. Procedia CIRP 2016, 45, 55–58. [Google Scholar] [CrossRef]

- Derekar, K.S.; Ahmad, B.; Zhang, X.; Joshi, S.S.; Lawrence, J.; Xu, L.; Melton, G.; Addison, A. Effects of Process Variants on Residual Stresses in Wire Arc Additive Manufacturing of Aluminum Alloy 5183. J. Manuf. Sci. Eng. Trans. ASME 2022, 144, 1–13. [Google Scholar] [CrossRef]

- Queguineur, A.; Asadi, R.; Ostolaza, M.; Valente, E.H.; Nadimpalli, V.K.; Mohanty, G.; Hascoët, J.Y.; Ituarte, I.F. Wire Arc Additive Manufacturing of Thin and Thick Walls Made of Duplex Stainless Steel. Int. J. Adv. Manuf. Technol. 2023, 127, 381–400. [Google Scholar] [CrossRef]

- Gupta, N.K.; Guna, G.; Siddhartha, S.; Karade, S.R.; Mehta, A.K.; Karunakaran, K.P. Effect of Multiple Technologies on Minimizing the Residual Stresses in Additive Manufacturing. In Proceedings of the ICRS 11—The 11th International Conference of Residual Stresses, SF2M, IJL, Nancy, France, 27–30 March 2022; Volume hal-040150. [Google Scholar]

- Jacob, K.; Yadav, D.; Dixit, S.; Hohenwarter, A.; Jaya, B.N. High Pressure Torsion Processing of Maraging Steel 250: Microstructure and Mechanical Behaviour Evolution. Mater. Sci. Eng. A 2021, 802, 140665. [Google Scholar] [CrossRef]

- Rashid, A.; Kota, A.; Boing, D.; Melkote, S.N. Effect of Interlayer Machining Interventions on the Geometric and Mechanical Properties of Wire Arc Directed Energy Deposition Parts. J. Manuf. Sci. Eng. 2024, 146, 091004. [Google Scholar] [CrossRef]

- Chen, C.; Feng, T.; Zhang, Y.; Ren, B.; Hao, W.; Zhao, X. Improvement of Microstructure and Mechanical Properties of TC4 Titanium Alloy GTAW Based Wire Arc Additive Manufacturing by Using Interpass Milling. J. Mater. Res. Technol. 2023, 27, 1428–1445. [Google Scholar] [CrossRef]

- Ron, T.; Levy, G.K.; Dolev, O.; Leon, A.; Shirizly, A.; Aghion, E. Environmental Behavior of Low Carbon Steel Produced by a Wire Arc Additive Manufacturing Process. Metals 2019, 9, 888. [Google Scholar] [CrossRef]

- Kumar Sinha, A.; Sreeja, V.; Yagati, K.P. Influence of Aloe-Vera Powder Addition on Microstructure and Mechanical Properties of Wire + Arc Additively Manufactured ER70S-6 Steel. Mater. Lett. 2024, 375, 137230. [Google Scholar] [CrossRef]

- Dekis, M.; Tawfik, M.; Egiza, M.; Dewidar, M. Unveiling the Characteristics of ER70S-6 Low Carbon Steel Alloy Produced by Wire Arc Additive Manufacturing at Different Travel Speeds. Metals Mater. Int. 2024, 31, 325–338. [Google Scholar] [CrossRef]

| Element | Fe | C | Mn | Si | Ni | Cr | P | S | V | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| % | Remaining | 0.07 | 1.50 | 0.90 | 0.15 | 0.15 | 0.025 | 0.035 | 0.03 | 0.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganesan, G.; Gupta, N.K.; Siddhartha, S.; Karade, S.R.; Zeidler, H.; Narasimhan, K.; Karunakaran, K.P. Effect of Varying Layer Thickness by Interlayer Machining on Microstructure and Mechanical Properties in Wire Arc Additive Manufacturing. J. Manuf. Mater. Process. 2025, 9, 135. https://doi.org/10.3390/jmmp9040135

Ganesan G, Gupta NK, Siddhartha S, Karade SR, Zeidler H, Narasimhan K, Karunakaran KP. Effect of Varying Layer Thickness by Interlayer Machining on Microstructure and Mechanical Properties in Wire Arc Additive Manufacturing. Journal of Manufacturing and Materials Processing. 2025; 9(4):135. https://doi.org/10.3390/jmmp9040135

Chicago/Turabian StyleGanesan, G., Neel Kamal Gupta, S. Siddhartha, Shahu R. Karade, Henning Zeidler, K. Narasimhan, and K. P. Karunakaran. 2025. "Effect of Varying Layer Thickness by Interlayer Machining on Microstructure and Mechanical Properties in Wire Arc Additive Manufacturing" Journal of Manufacturing and Materials Processing 9, no. 4: 135. https://doi.org/10.3390/jmmp9040135

APA StyleGanesan, G., Gupta, N. K., Siddhartha, S., Karade, S. R., Zeidler, H., Narasimhan, K., & Karunakaran, K. P. (2025). Effect of Varying Layer Thickness by Interlayer Machining on Microstructure and Mechanical Properties in Wire Arc Additive Manufacturing. Journal of Manufacturing and Materials Processing, 9(4), 135. https://doi.org/10.3390/jmmp9040135