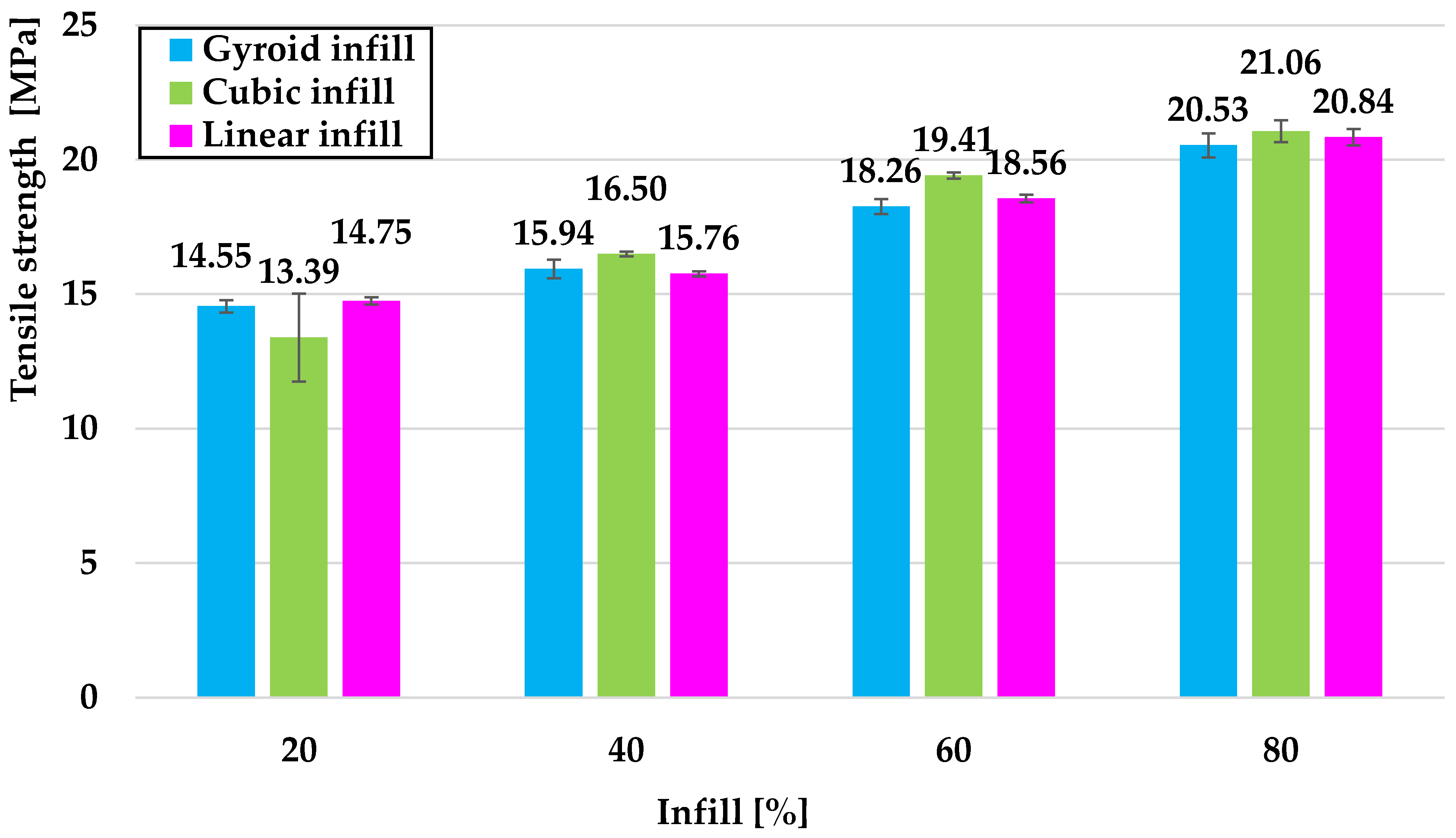

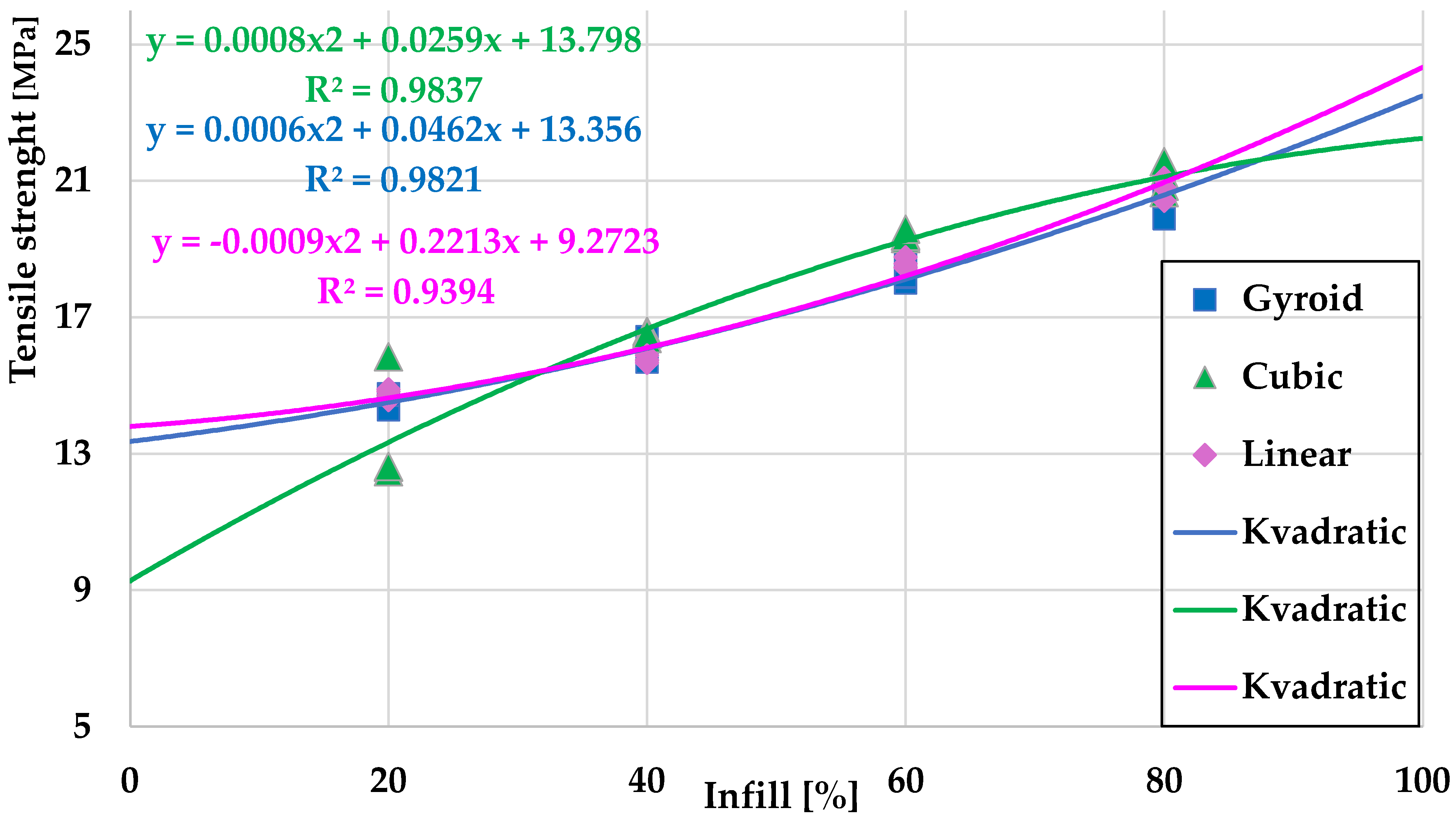

Currently, 3D printing is becoming one of the most important manufacturing technologies with its use ranging from prototyping to the production of functional parts in various industrial sectors. The mechanical properties of 3D-printed components are fundamentally influenced by printing parameters, including the infill geometry and the bulk density of the infill. These factors affect not only the strength and stiffness of the resulting part but also its ability to absorb mechanical loads and resist deformations. The correct choice of infill structure is therefore crucial in optimizing the mechanical properties and functionality of printed components. At 20% volume infill, significant differences in tensile strength were observed between the individual geometries (

Figure 5), where the best results were achieved by the linear infill (14.75 MPa), which was closely followed by the gyroid geometry (14.55 MPa). The cubic infill showed the lowest strength (13.39 MPa). In the yield strength region (

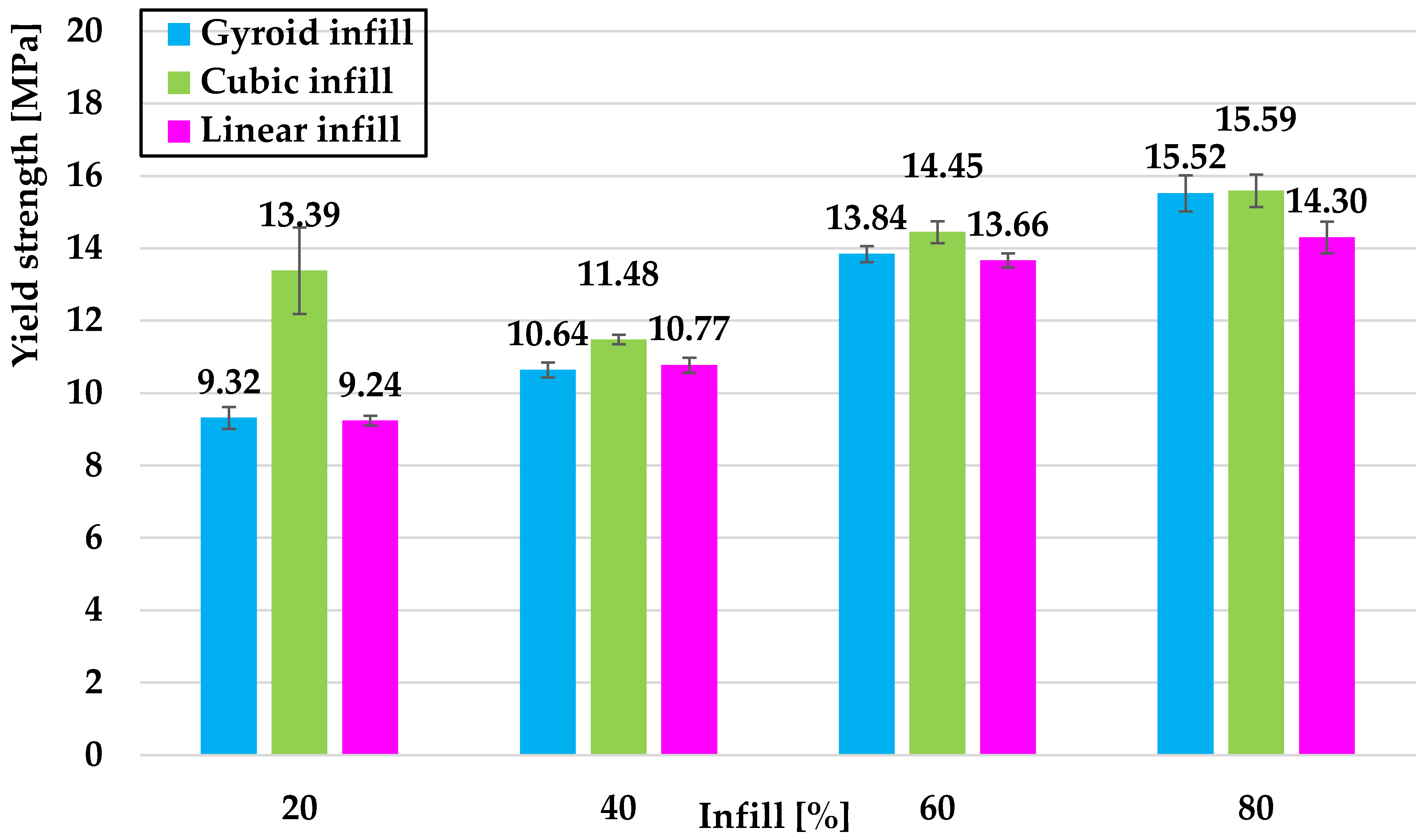

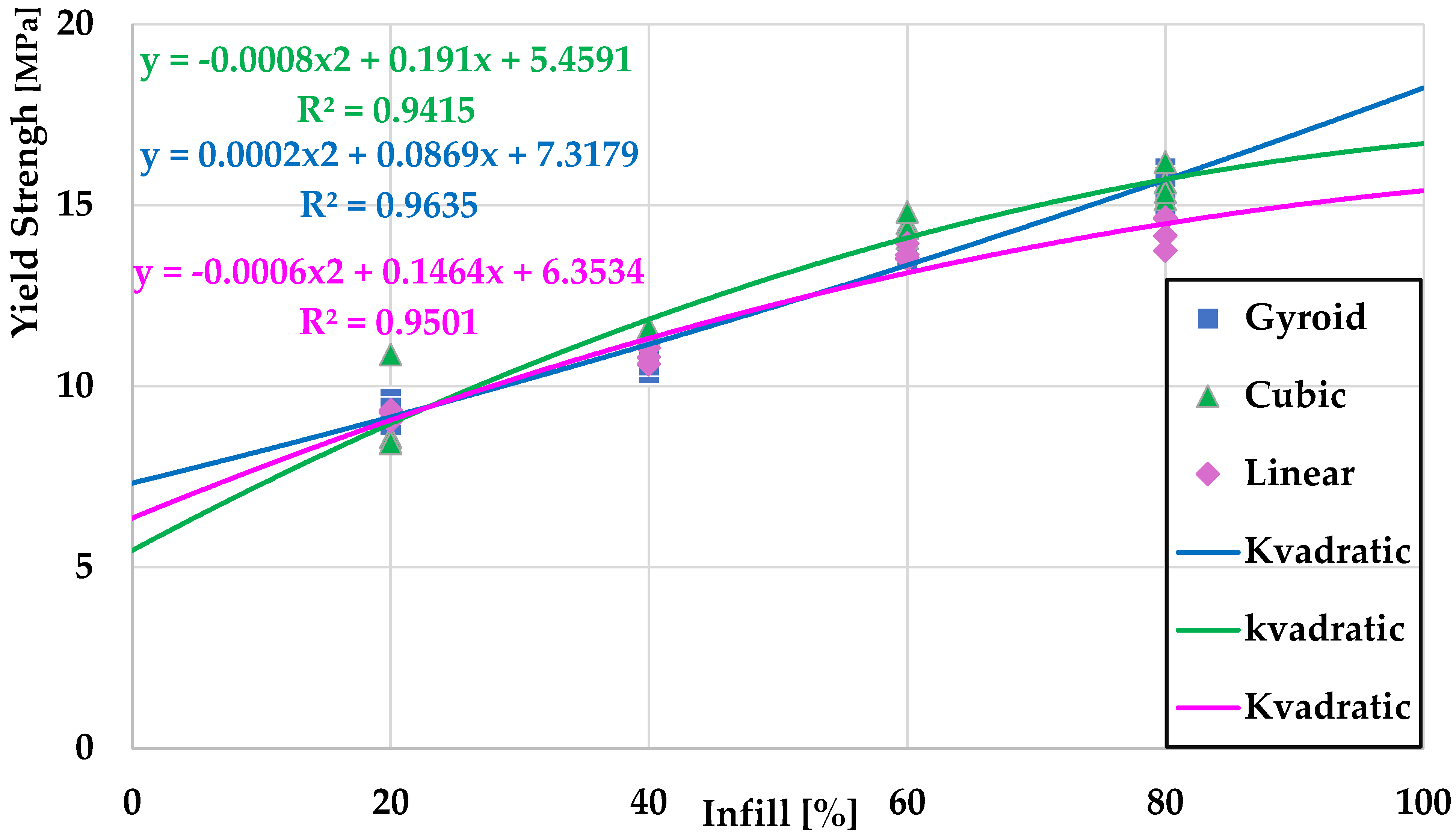

Figure 6), cubic filling dominated (13.39 MPa), while the linear (9.24 MPa) and gyroid (9.32 MPa) fillings showed similar values. The elastic modulus (

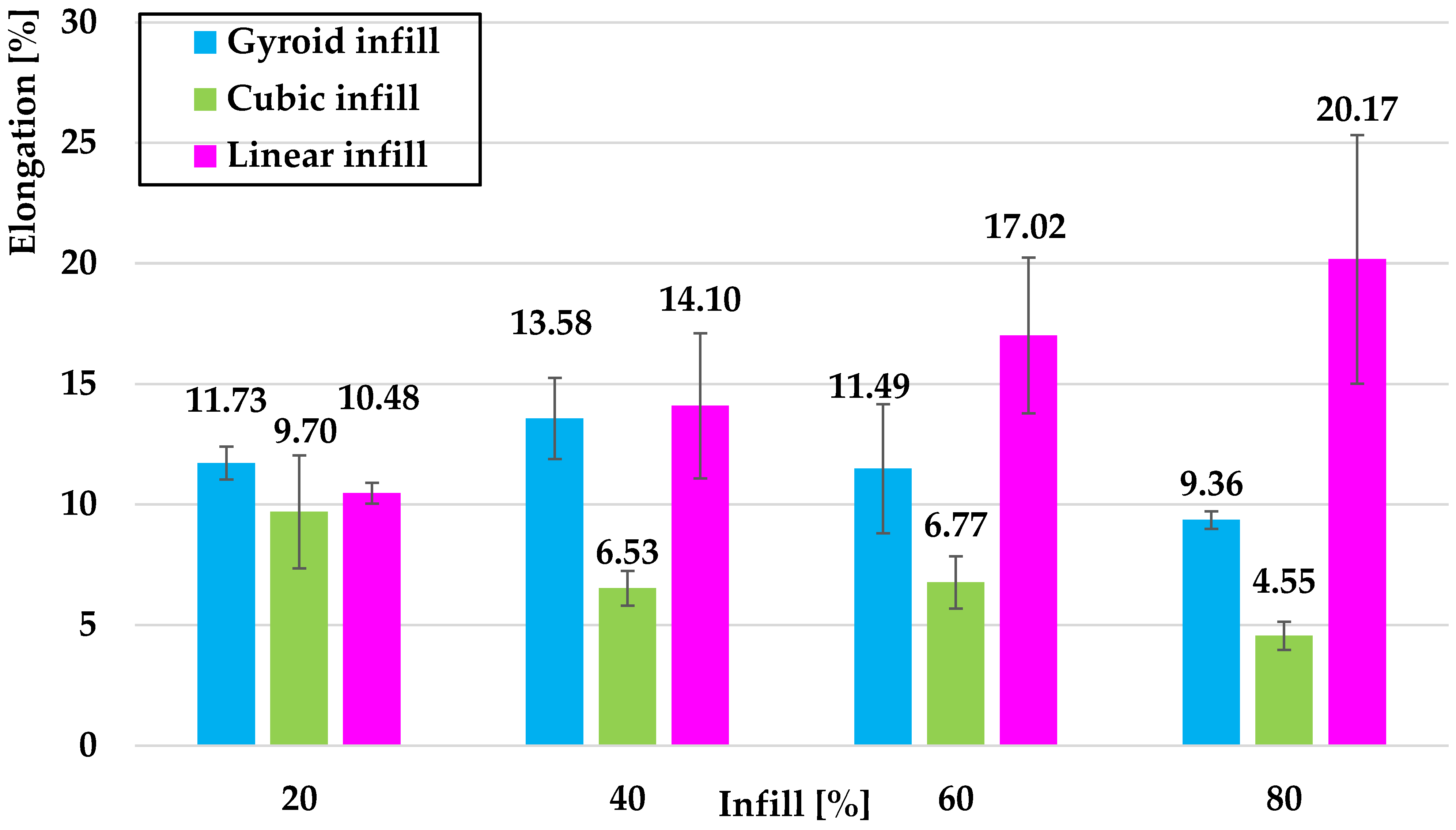

Figure 7) was highest for gyroid filling (872.51 MPa), while the ductility (

Figure 8) reached a maximum for gyroid geometry (11.73%), indicating a better ability to absorb deformations before failure. Increasing the volumetric filling to 40% improved all monitored parameters. The highest tensile strength (

Figure 5) was achieved by cubic filling (16.50 MPa), which was followed by gyroid (15.94 MPa) and linear (15.76 MPa) fillings. The yield strength (

Figure 6) was again highest for the cubic filling (11.48 MPa), while the gyroid (10.64 MPa) and linear (10.77 MPa) fillings achieved slightly lower values. The elastic modulus (

Figure 7) improved especially for the cubic filling (1073.24 MPa), while the linear filling showed the highest elongation (

Figure 8) (14.10%), which for the cubic filling was only 6.53%.

At 60% filling, the trend of improving mechanical properties was maintained. The tensile strength (

Figure 5) was highest for the cubic filling (19.41 MPa), which was followed by the gyroid (18.26 MPa) and linear (18.56 MPa) fillings. The highest yield strength (

Figure 6) was recorded for the cubic filling (14.45 MPa), while the gyroid (13.84 MPa) and linear (13.66 MPa) fillings reached only slightly lower values. The elastic modulus (

Figure 7) again dominated for the cubic filling (1335.37 MPa), but on the contrary, the linear filling had the highest ductility (

Figure 8), indicating its higher ability to absorb stress before failure. At the highest bulk density of the filling (80%), the mechanical properties stabilized. The highest tensile strength (

Figure 5) was again achieved for the cubic filling (21.06 MPa), which was followed by the gyroid (20.53 MPa) and linear (20.84 MPa) fillings. The yield strength (

Figure 6) showed the highest value for the cubic infill (15.59 MPa), while the gyroid infill reached 15.52 MPa and the linear infill reached 14.30 MPa. The elastic modulus (

Figure 7) was the highest for the cubic infill (1414.19 MPa), while the ductility (

Figure 8) reached the maximum for the linear infill (20.17%), which for the cubic infill showed the lowest value (4.55%).

The results indicate that the mechanical properties of 3D-printed structures are significantly affected by the infill geometry and bulk density of the infill. At higher infill densities, the cubic infill shows the best strength properties but with a significant loss of ductility. The linear infill excels in stress absorption before failure, while the gyroid infill represents a balanced compromise between strength, stiffness and deformation properties. This knowledge is key to optimizing the mechanical properties of 3D-printed parts depending on the requirements for strength, stiffness, and the ability to absorb mechanical loads.

3.1. Prediction of Mechanical Properties of Filling Structures

Based on the experimental data, prediction models for tensile strength, yield strength and elastic modulus were created with the analysis including all filling structures—cubic, gyroid and rectilinear. The prediction of mechanical properties (

Figure 9) was carried out using quadratic regression models, which made it possible to identify nonlinear trends and more accurately describe the development of mechanical characteristics depending on the filling volume. The results showed that with increasing filling fraction, strength increases in all investigated structures with quadratic regression showing high accuracy with R

2 values in the range of 0.9394–0.9837, which indicates a significant agreement of the prediction models with the experimental data. The cubic and gyroid fillings showed a similar growth trend with the cubic filling achieving slightly higher strength values at higher volume percentages. The linear infill showed a consistent but slightly lower strength increase compared to the cubic structure.

A similar trend was observed at the yield point (

Figure 10), where the prediction models confirmed a nonlinear increase in strength with increasing volume filling. The R

2 values reached 0.9415–0.9501, which confirms the reliability of quadratic models in predicting this mechanical characteristic. At higher volume fillings, the cubic and gyroid structures stabilized at comparable values, while the rectilinear filling slightly lagged behind. This result corresponds to experimental observations, where a higher resistance of the cubic filling to plastic deformation was identified.

In the case of the elastic modulus (

Figure 11), the prediction models showed a significant increase depending on the volume of the filling with R

2 values ranging from 0.9198 to 0.9427, indicating a high accuracy of the prediction trends. The highest elastic modulus at higher volume fillings was achieved by the cubic filling, which was followed by the gyroid and rectilinear fillings. This trend reflected the increased stiffness of the cubic structure, which allowed for a better distribution of mechanical load.

The results of the prediction models confirmed the nonlinear growth of mechanical properties with increasing volume filling, while the quadratic regression models provided a reliable approximation of the mechanical behavior of the material. The cubic filling systematically showed the highest values of strength and stiffness, while the gyroid filling represented a balanced alternative between strength and elasticity. The linear filling achieved slightly lower values of mechanical properties but provided higher ductility, which can be advantageous in applications requiring increased ability to absorb mechanical stress. The prediction models thus provide a useful tool for optimizing filling structures depending on the requirements for the strength, stiffness or deformation capacity of printed parts.

3.2. DMA Analysis

Dynamic mechanical analysis (DMA) is a key method for evaluating the viscoelastic properties of materials, especially polymers such as thermoplastics, thermosets and elastomers. This technique allows the measurement of the mechanical properties of materials as a function of temperature, time and frequency of the applied oscillating load. In DMA, a sample is subjected to periodic mechanical stress, and its response to such stress is analyzed. This analysis provides valuable information on the behavior of the material, such as its stiffness, damping properties and phase transitions, which is essential for optimizing materials for specific applications.

3.2.1. Storage Modulus

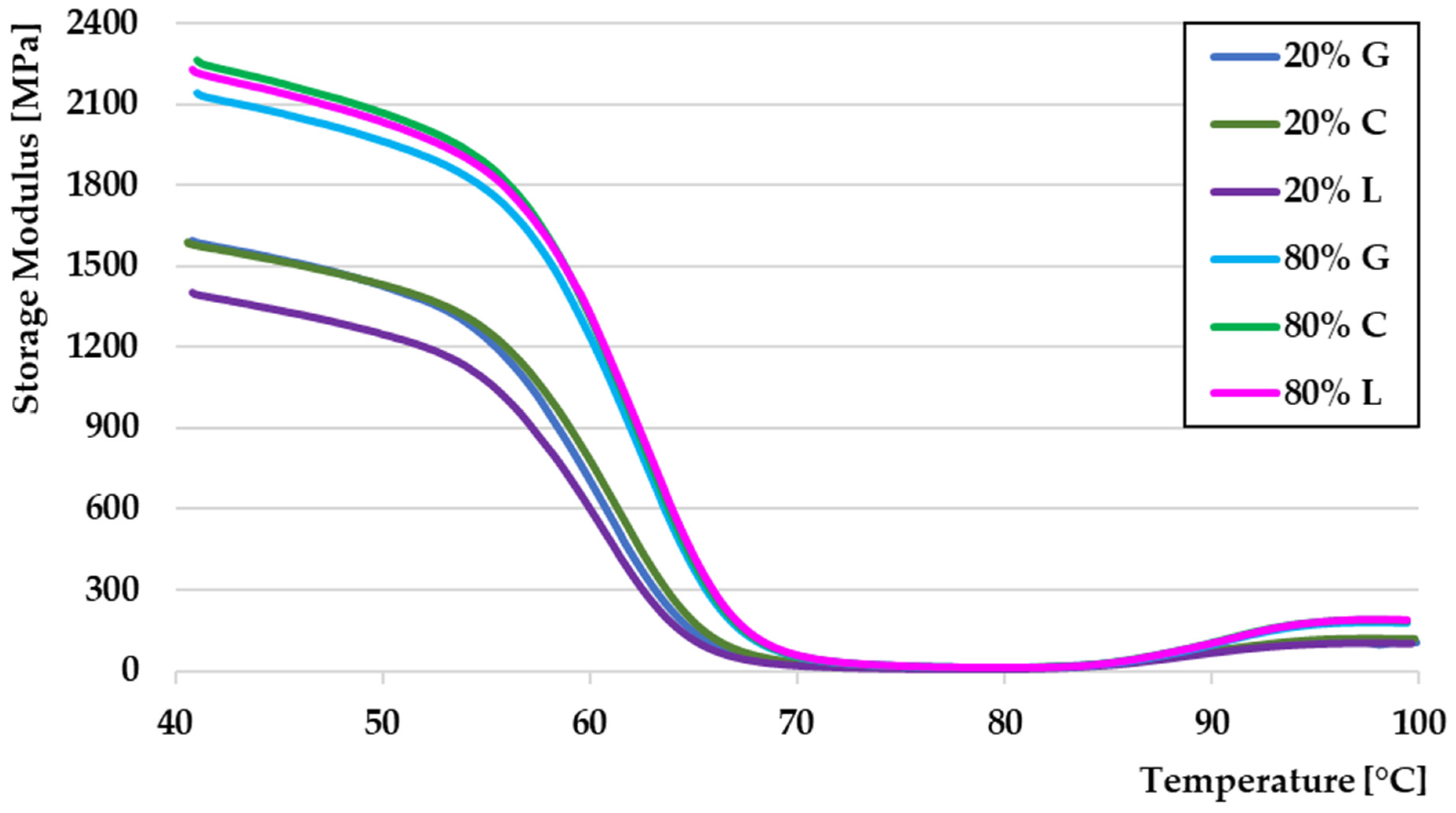

The results of the dynamic mechanical analysis (

Figure 12) show a persistent dependence of the storage modulus (E’) on temperature under dynamic loading with a frequency of 1 Hz, reflecting the mechanical properties of the material under different temperature conditions.

At the beginning of the measurement, at temperatures around 40 °C, all samples are in a solid state and show high values of storage modulus. The highest stiffness is achieved by samples with 80% filling, while the samples with 20% filling have lower values, indicating that lower filling density reduces the overall strength of the material.

As the temperature increases in the range of 50–70 °C, there is a gradual decrease in the storage modulus. A significant decrease occurs at approximately 60–70 °C, which corresponds to the glass transition region (Tg), where the material passes from a solid to a softened state. In this range, it is visible that samples with a higher filler content retain higher E’ values, indicating better mechanical stability. After Tg is exceeded, the storage modulus drops sharply, and the samples lose most of their stiffness.

At temperatures above 70 °C, all samples enter a rubbery state, where the differences between them are significantly reduced. The storage modulus in this region reaches low values, which means that the material no longer has sufficient stiffness to effectively transmit mechanical loads. The differences between the samples disappear at this stage, indicating that the filler structure plays a key role only in the solid state, while at higher temperatures, its influence on the mechanical properties decreases.

A comparison between different types of fillings—cubic (C), gyroid (G) and rectilinear (L)—showed that in the solid state, there are slight differences between the individual filling geometries. Samples with gyroid filling showed slightly higher values of storage modulus compared to cubic and rectilinear filling, which may be due to a more uniform distribution of mechanical stress in the structure. At lower temperatures, samples with rectilinear filling were characterized by the lowest values of storage modulus, which indicates a lower resistance to mechanical loading in this phase.

Overall, the results confirm that higher filler density (80%) leads to improved mechanical properties at lower temperatures with different filler structures affecting the storage modulus mainly in the solid state. After exceeding Tg, the differences between the samples disappear, and the mechanical stability of the material decreases regardless of the filler structure.

3.2.2. Loss Modulus

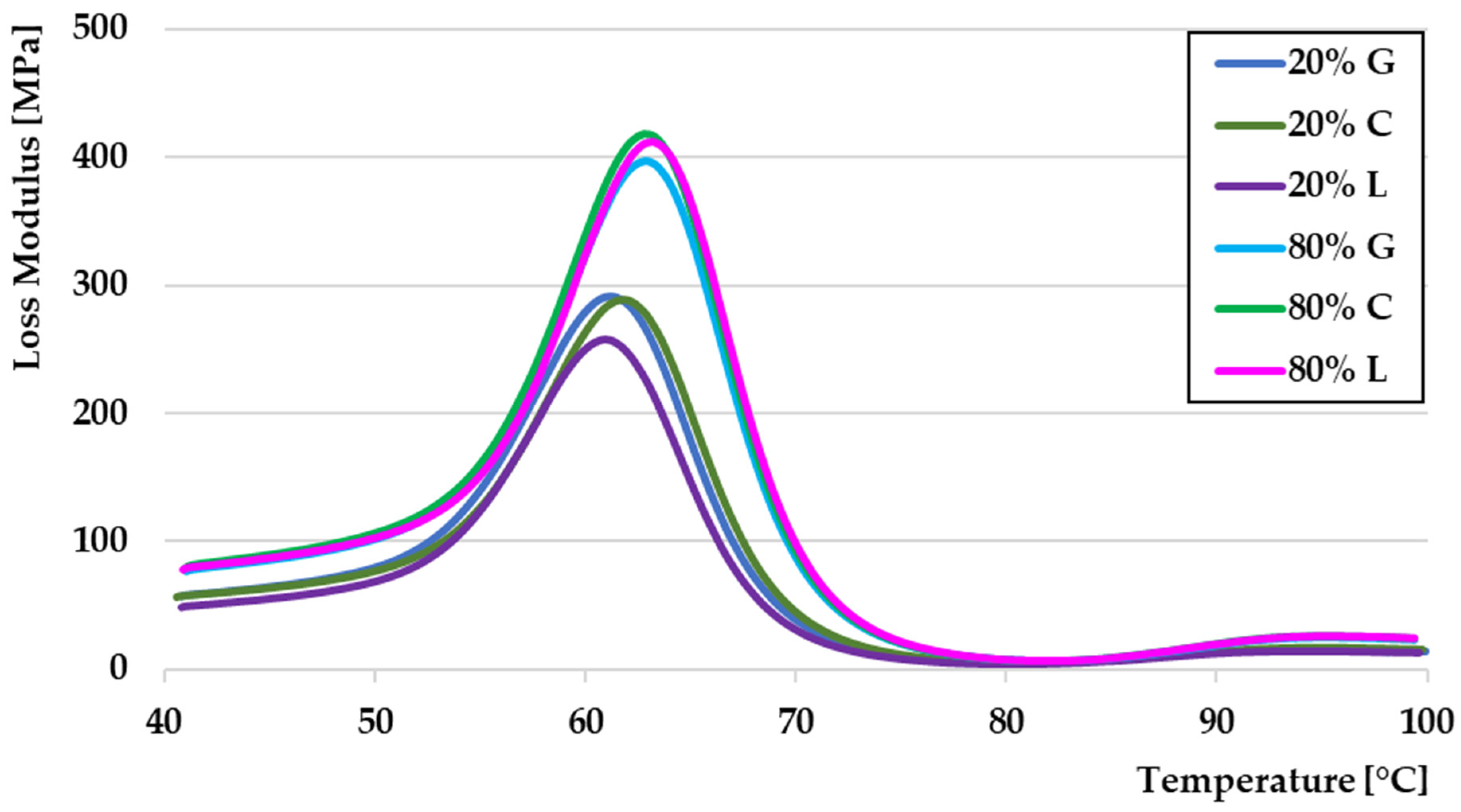

A comparison of the loss modulus (E′′) (

Figure 13) for PLA material with different filling patterns and different filling densities shows significant differences in mechanical energy dissipation under 10 Hz dynamic loading.

Dynamic mechanical analysis (DMA) measurements revealed that the maximum value of the loss modulus is located in the temperature range of 60–70 °C, which correlates with the glass transition temperature (Tg) of the PLA material.

The highest loss modulus at Tg is shown by the sample with cubic filling (C) at 20% filling density, reaching approximately 500 MPa. This result indicates that the cubic structure allows for a higher rate of mechanical energy dissipation compared to other filling patterns. Gyroid (G) and linear (L) fillings show similar behavior, but linear (L) fillings achieve the lowest loss modulus values, indicating their lower ability to effectively dissipate internal stresses during dynamic loading.

The results also show the influence of the filling density on the mechanical properties of the material. Samples with a lower filling density (20%) show higher values of the loss modulus compared to samples with a filling density of 80%. This phenomenon may be due to the higher degree of internal friction between the layers at a lower filling, which leads to a higher attenuation of mechanical vibrations. Conversely, a higher filling density (80%) causes a lower loss modulus, which indicates better structural integrity and a lower rate of energy dissipation.

At higher temperatures, exceeding 80 °C, the loss modulus values are equalized between individual samples, which indicates a reduced influence of the filler structure in the rubbery state of the material. The results indicate that under dynamic loading, the choice of filler pattern and its density is a key factor in optimizing the mechanical properties of PLA, especially in the temperature range close to Tg.

3.2.3. Tan Delta

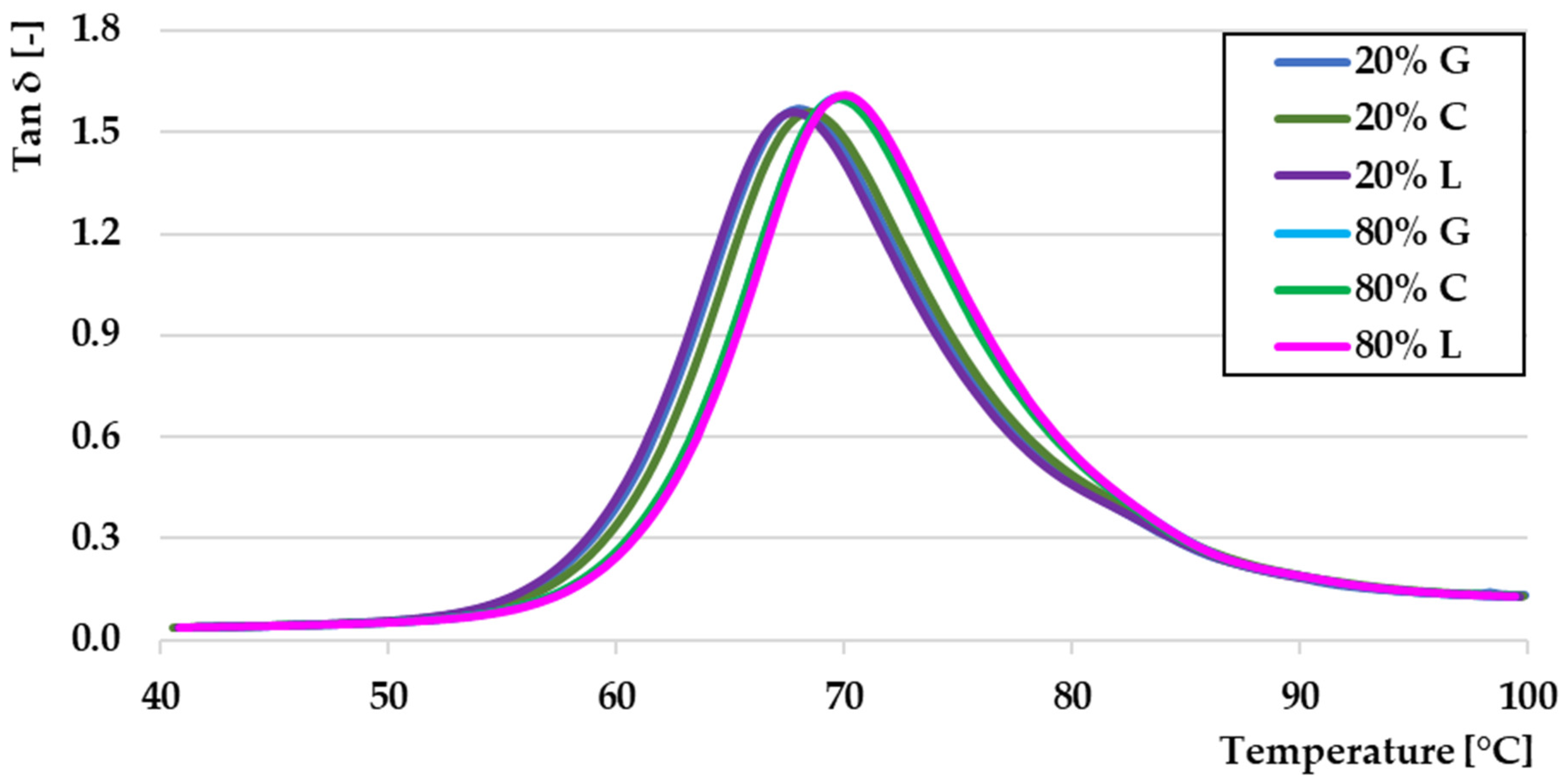

The graph shows the dependence of the loss factor (tan δ) (

Figure 14) on the temperature under dynamic loading with a frequency of 10 Hz. The loss factor expresses the ratio between the loss (E″) and the storage modulus (E’) and characterizes the viscoelastic behavior of the material. Higher values of tan δ indicate a greater ability of the material to absorb mechanical energy and convert it into heat.

At low temperatures (40–50 °C), tan δ values are close to zero, indicating a predominantly elastic behavior of the material. With increasing temperature, tan δ gradually increases and reaches a maximum in the range of 65–70 °C, which corresponds to the glass transition (Tg). In this region, the material changes from a rigid to a soft state and exhibits the most pronounced viscoelastic properties. After Tg is exceeded, tan δ values decrease again, indicating that the material transitions to a rubbery state with a lower rate of internal losses.

A comparison of the samples shows that the density of the filler (20% and 80%) and its geometry (cubic, gyroid, rectilinear) have only a minimal effect on the tan δ values. All samples show a similar glass transition temperature and almost the same maximum tan δ values, indicating that the filler structure does not play a significant role in the damping properties of the material. The results confirm that the internal dissipative processes are primarily influenced by the material itself, while the filler has only a small effect on its viscoelastic behavior.

3.2.4. Glass Transition Temperature

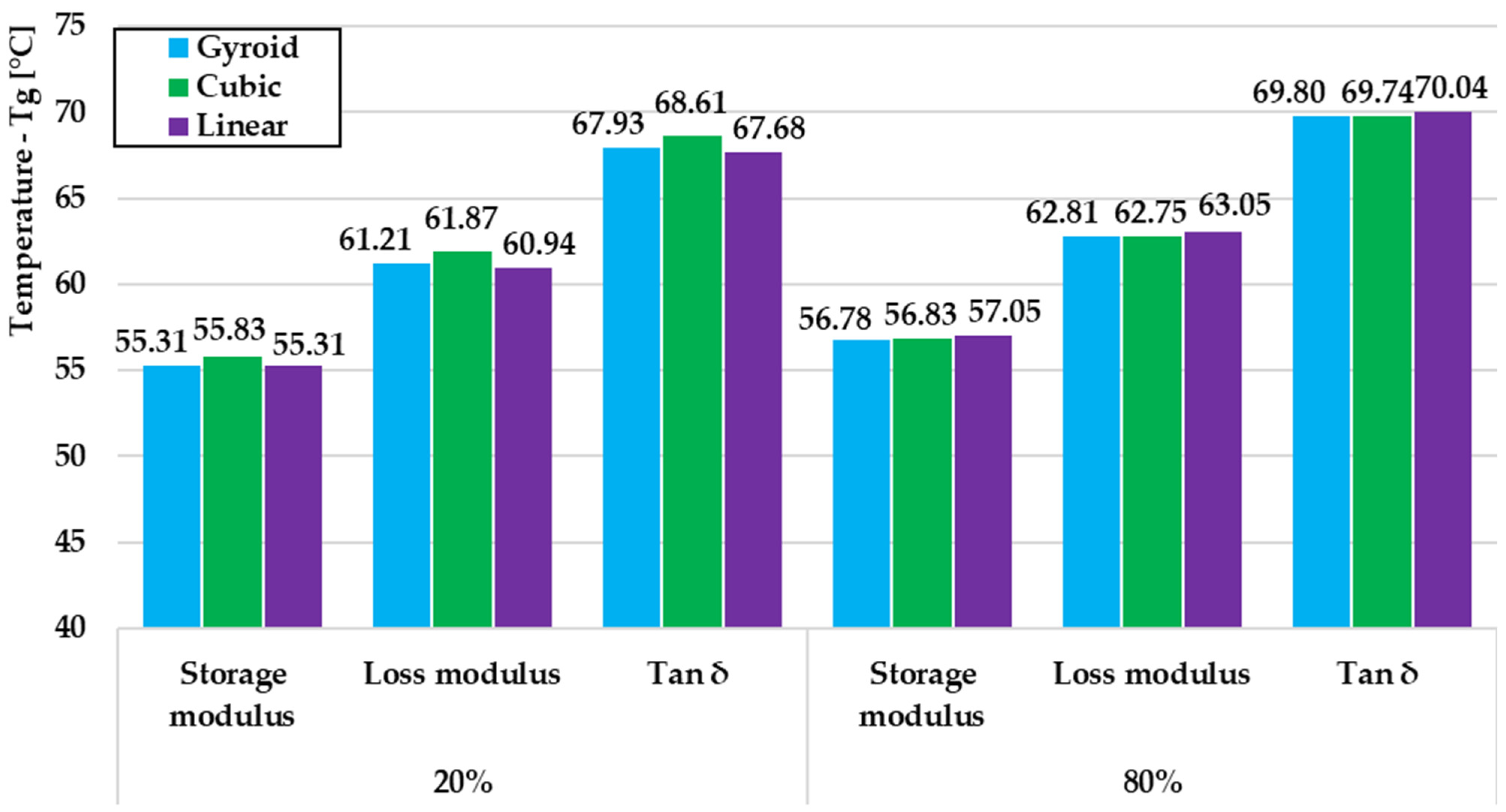

A comparison of the glass transition temperature (T

g) for PLA (

Figure 15) material shows that the filler pattern and its density significantly affect the mechanical properties. At 20% filler, the cubic filler achieves the highest glass transition temperature for both the storage modulus (55.83 °C) and loss modulus (61.87 °C), indicating a higher energy dissipation capability. At tan δ, the differences between the patterns are minimized with the cubic filler again achieving the highest value.

At 80% filling, the glass transition temperature shifts to higher values, improving the thermal stability of the material. The differences between the filling patterns are less pronounced with the linear filling achieving the highest loss modulus (63.05 °C) and tan δ (70.04 °C). This trend suggests that higher filling density leads to improved resistance to temperature changes and a better preservation of mechanical properties. The results show that at lower filling densities, the cubic filling is the most effective in energy dissipation, while at higher densities, the properties of the patterns become more even. Optimization of the filling is therefore crucial for applications where high stability at elevated temperatures is required.

3.3. SEM Analysis

Scanning electron microscopy (SEM) is an effective method for analyzing the fracture surfaces of plastic samples, allowing for a detailed assessment of the fracture mechanism and microstructural properties of the material. Thanks to its high magnification and large depth of field, it provides an accurate image of surface characteristics, which is crucial for investigating failures and assessing the quality of materials.

SEM analysis of the walls of PLA samples with different filler volumes revealed significant differences in the material microstructure and the quality of layer adhesion. The comparison was performed for three types of fillers: rectilinear, gyroid and cubic, and samples with 20% and 80% filler volumes were analyzed.

At 20% infill volume (L 20%) (

Figure 16a), the surface structure is rougher, with higher porosity, which indicates weaker adhesion between layers and a greater susceptibility to microcrack formation. These defects are probably the result of uneven sintering of the material during printing.

On the contrary, at 80% volume infill (L 80%) (

Figure 16b), the microstructure is more compact and homogeneous. The surface texture is finer and defects are less pronounced, which indicates a more efficient sintering process. A higher volume of filling contributes to a more uniform temperature distribution during printing, thereby improving the mechanical stability of the sample.

Overall, a higher volume of rectilinear infill positively affects the quality of the sample wall, while a lower volume can lead to structural irregularities and the weakening of mechanical properties.

At 20% volume filling (G 20%) (

Figure 16c), the surface structure of the wall is significantly stratified with visible voids and irregular transitions between layers. The material exhibits higher porosity and in some places inhomogeneous adhesion, which may indicate weaker material coherence due to uneven heat distribution during printing. This phenomenon may increase the susceptibility of the wall to delamination or microcracking under mechanical loading.

At 80% infill volume (G 80%) (

Figure 16d), the microstructure of the wall is significantly more compact and homogeneous. The surface is less fragmented with fewer cracks and visibly better adhesion between layers. The higher infill volume probably ensured a more uniform temperature distribution during printing, thus eliminating defects typical of samples with lower infill volume.

The results show that a higher gyroid infill volume improves the quality of the sample wall, reduces structural defects and increases its mechanical stability. On the contrary, a lower infill volume leads to more pronounced porosity, which may negatively affect the strength of the printed part.

At 20% volume infill (C 20%) (

Figure 16e), the wall structure is significantly porous with visible voids and peeling layers. The surface is rough and stratified with microcracks and inhomogeneous material adhesion. The lower density of the cubic fill probably caused a weaker sintering of the inner layers, which can lead to a weakening of the mechanical properties and an increased susceptibility to delamination.

At 80% volume infill (C 80%) (

Figure 16f), the sample wall is more compact and homogeneous with better adhesion between layers. The surface texture is less rough and the porosity is significantly lower. The higher volume infill provides a stronger internal support, thus optimizing heat distribution during printing and improving the adhesion of individual layers. This leads to a higher mechanical stability and durability of the printed part. Overall, the results indicate that a higher cubic filler volume favorably affects the structural integrity of the sample wall, reduces defects caused by discontinuous sintering, and minimizes the risk of microcracks. Conversely, a lower infill volume leads to higher porosity and possible weakening of the material, which can negatively affect its strength and durability under mechanical loading. Overall, the given images show that the microstructure of the sample walls is significantly influenced by the infill density. At a lower infill volume, structural defects such as microcracks, delamination and increased porosity are formed. On the contrary, at a higher infill volume, the material is more compact, with better layer adhesion and a more homogeneous structure, which positively affects the mechanical stability of the printed parts.

At 20% infill volume (L 20%) (

Figure 17a), the microstructure is significantly porous with large voids between individual infill elements. Areas of insufficient material interconnection are visible, indicating poor adhesion during the printing process. Empty spaces between infill segments reduce the mechanical stability of the sample and can lead to local stress concentrations under mechanical loading.

At 80% infill volume (L 80%) (

Figure 17b), the infill is more compact and significantly denser. The joints between individual infill segments are more homogeneous, and the porosity is significantly reduced. This difference indicates better material continuity and higher sample strength. The higher infill volume likely ensured a more uniform temperature distribution during printing, thus eliminating some of the defects typical of samples with lower infill volume.

The results show that a higher volume of rectilinear infill significantly improves the structural integrity of the sample center, reduces the occurrence of voids, and increases the overall strength of the material. Conversely, a lower infill volume leads to greater porosity and an increased risk of mechanical failure due to stress concentration in the voids.

At 20% infill volume (G 20%) (

Figure 17c), high porosity is visible with extensive voids between individual infill segments. The bonds between the fibers are weakened and the infill structures are not sufficiently interconnected, which can lead to low mechanical stability. The surface texture is rougher, with broken edges, which indicates inhomogeneous sintering of the layers. This effect can be caused by uneven heat distribution during printing, while the lower infill volume did not allow sufficient support during sintering of the individual layers.

At 80% infill volume (G 80%) (

Figure 17d), the structure is significantly more compact and better interconnected. The infill segments are more tightly connected with minimized voids and more homogeneous sintering of the material. The surface texture is smoother and the material shows better coherence between the layers. The higher infill volume in the gyroid geometry allows for more efficient temperature distribution during printing, leading to higher mechanical stability and a lower risk of delamination.

The results show that a higher gyroid infill volume significantly improves the strength and homogeneity of the material, while a lower infill volume leads to structural weakening, increased porosity and potential mechanical failure under load.

At 20% infill volume (C 20%) (

Figure 17e), the microstructure is significantly porous with large voids between the infill segments. The structure is non-uniform, with individual infill elements not sufficiently sintered, indicating poor adhesion between layers. Fragmented parts and material peeling are visible, which may be a consequence of insufficient support of the internal infill elements during printing. Increased porosity can negatively affect the mechanical properties of the sample, reducing its strength and increasing the risk of local failures under mechanical loading.

At 80% volume of infill (C 80%) (

Figure 17f), the microstructure is more compact with better adhesion between individual infill elements. The visibly reduced porosity and more uniform structure indicate better sintering of the material during printing. The surface texture is more homogeneous and less prone to peeling, which indicates a higher strength and stability of the sample. The higher volume of cubic infill allows for more uniform heat distribution and minimizes structural defects caused by inconsistent sintering.

The results show that the higher volume of cubic infill significantly improves the mechanical properties of the sample, reduces the occurrence of structural defects and increases its overall strength.

Overall, the given images show that the microstructure of the center of the sample is significantly affected by the infill density. At lower infill volume, large voids are formed, and weakened connections between filling segments and increased porosity occur, which can negatively affect the mechanical stability of the material. On the contrary, at higher infill volume, the structure is more compact with more homogeneous adhesion between segments and better mechanical stability.