Influence of Interlayer Temperature and Deposition Method on the Wall Geometry and Vickers Microhardness Profile of ER70S-6 Parts Manufactured by Additive Manufacturing Using CMT

Abstract

1. Introduction

2. Methodology

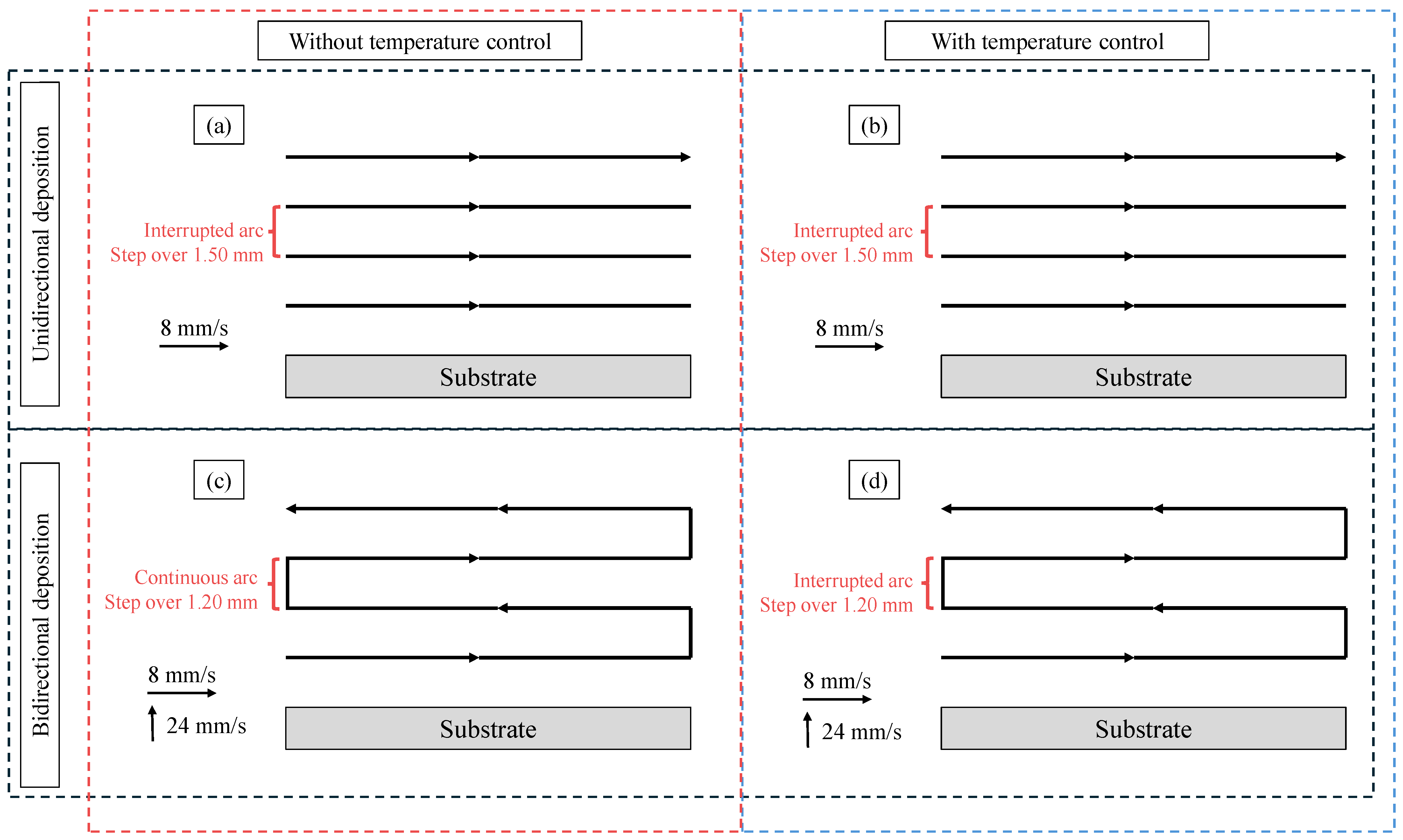

2.1. Deposition Method

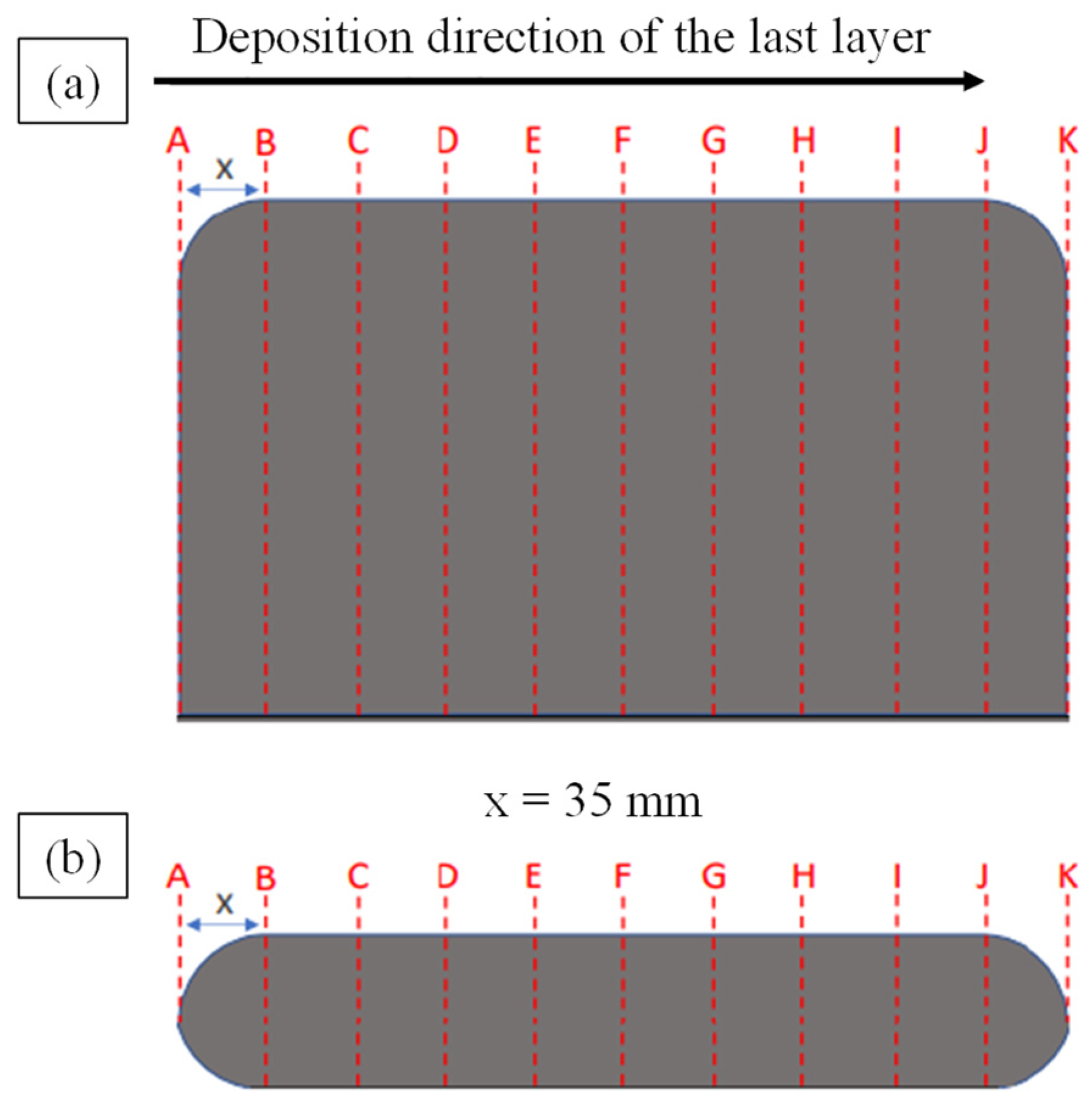

2.2. Geometric Analysis

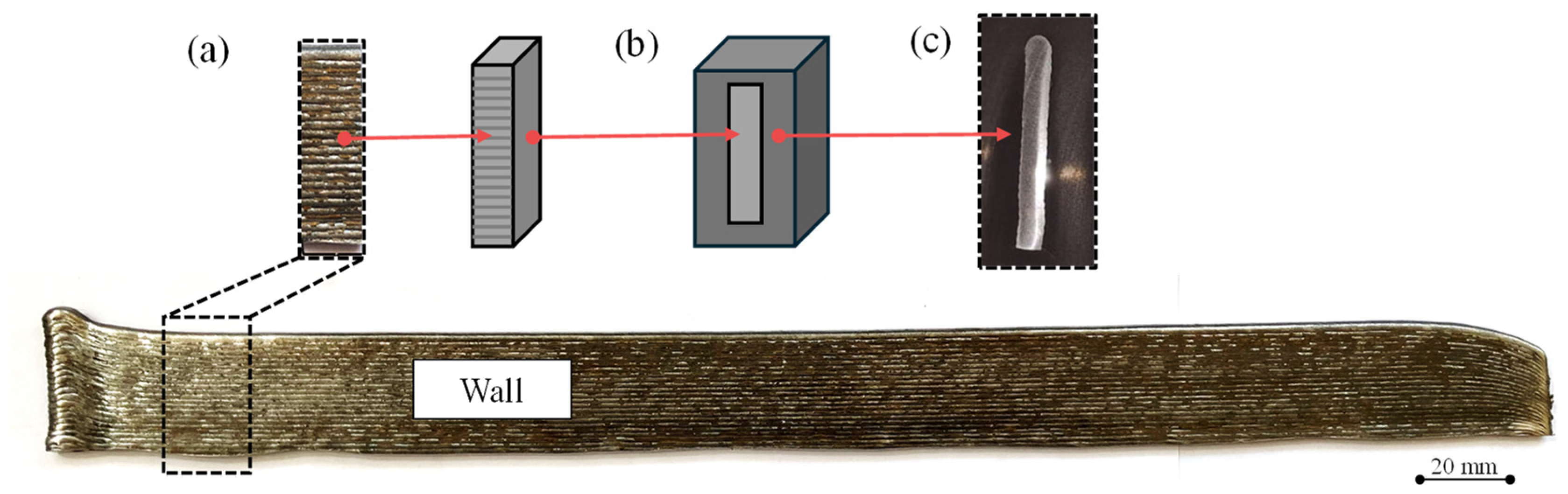

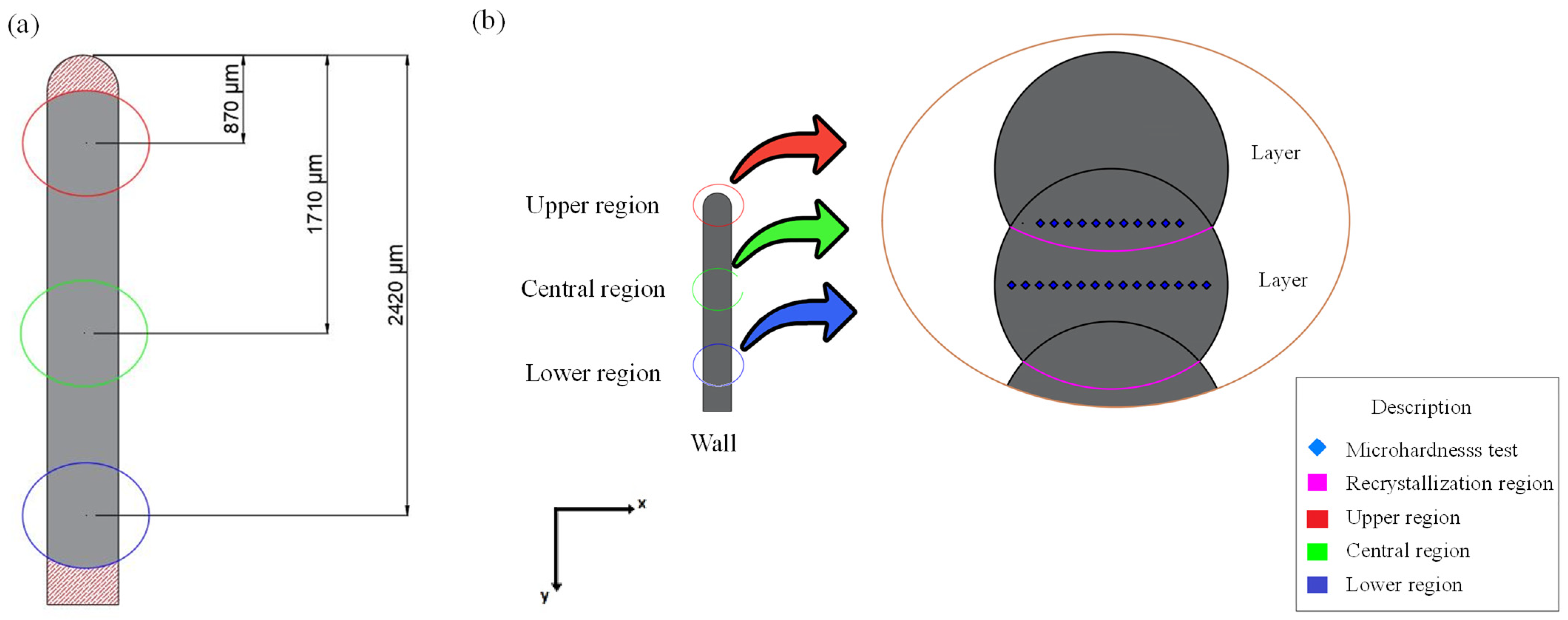

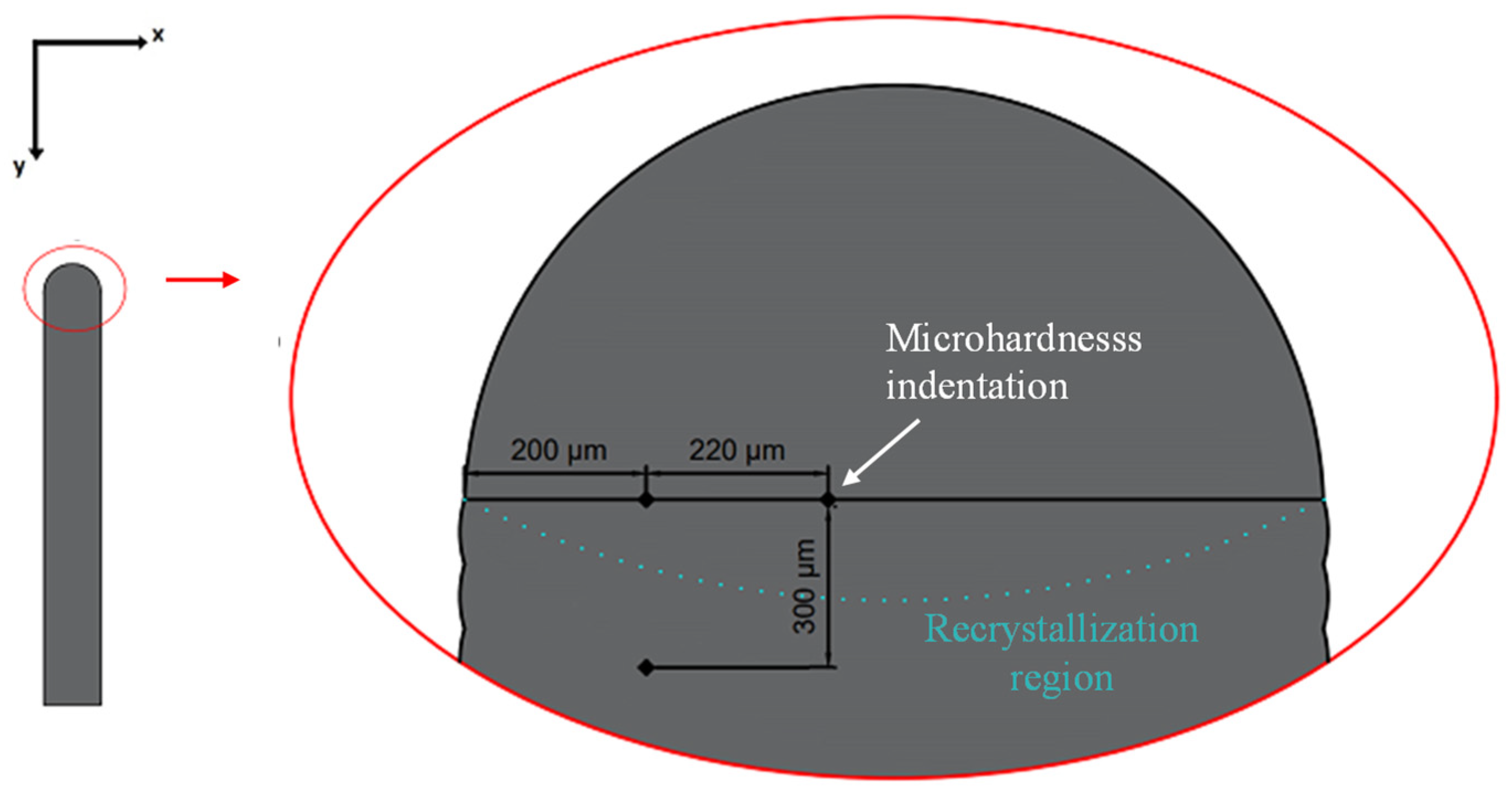

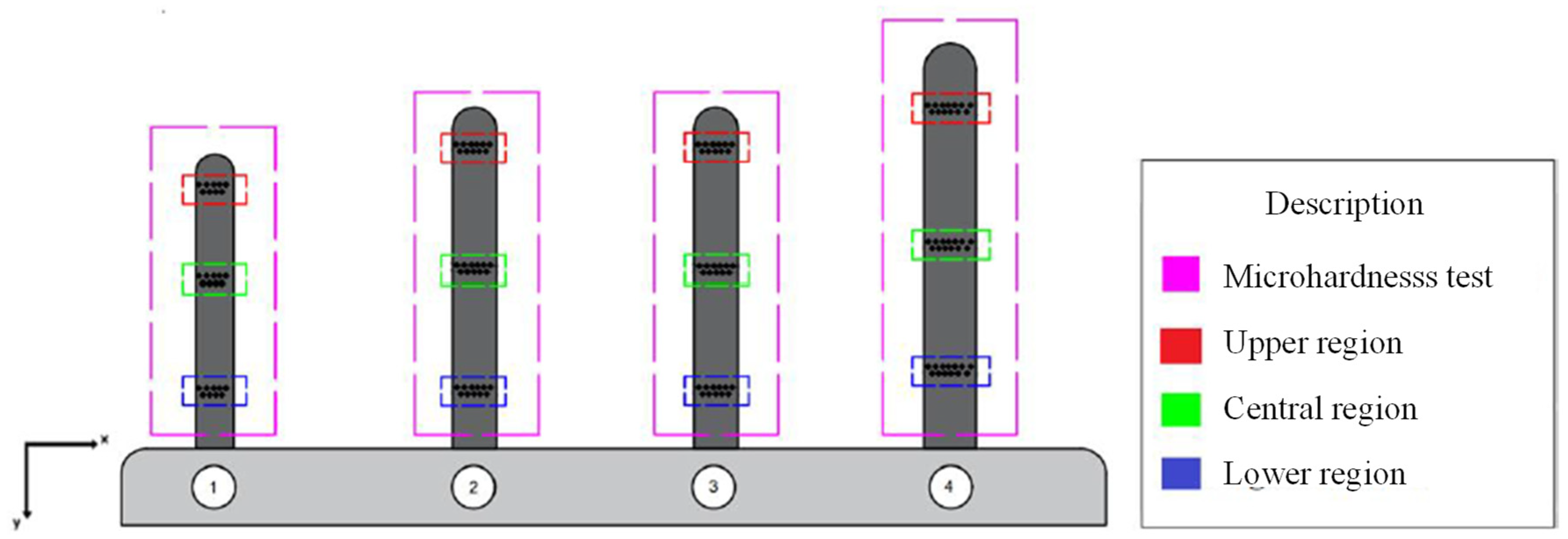

2.3. Wall Preparation and Microhardness Measurements

3. Results and Discussion

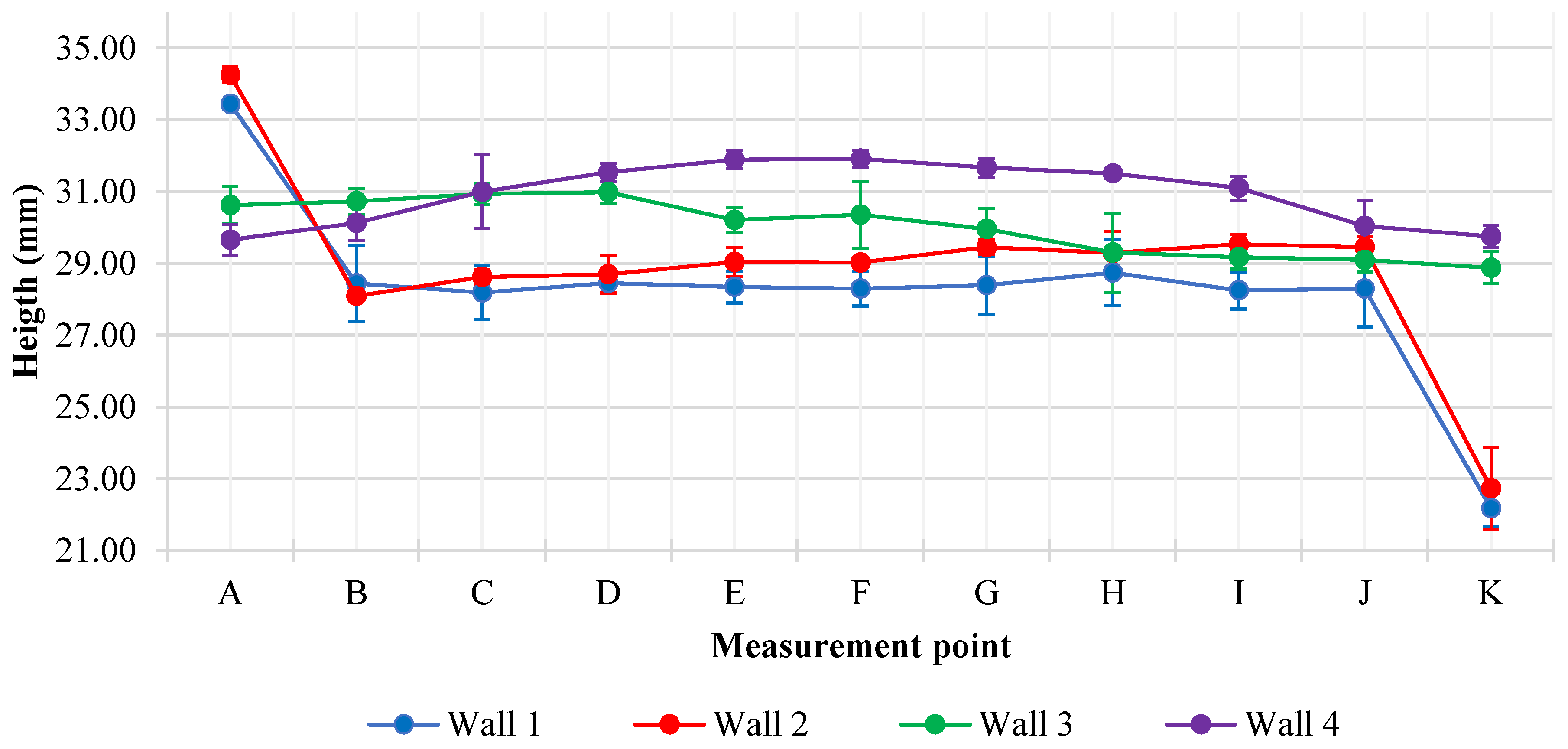

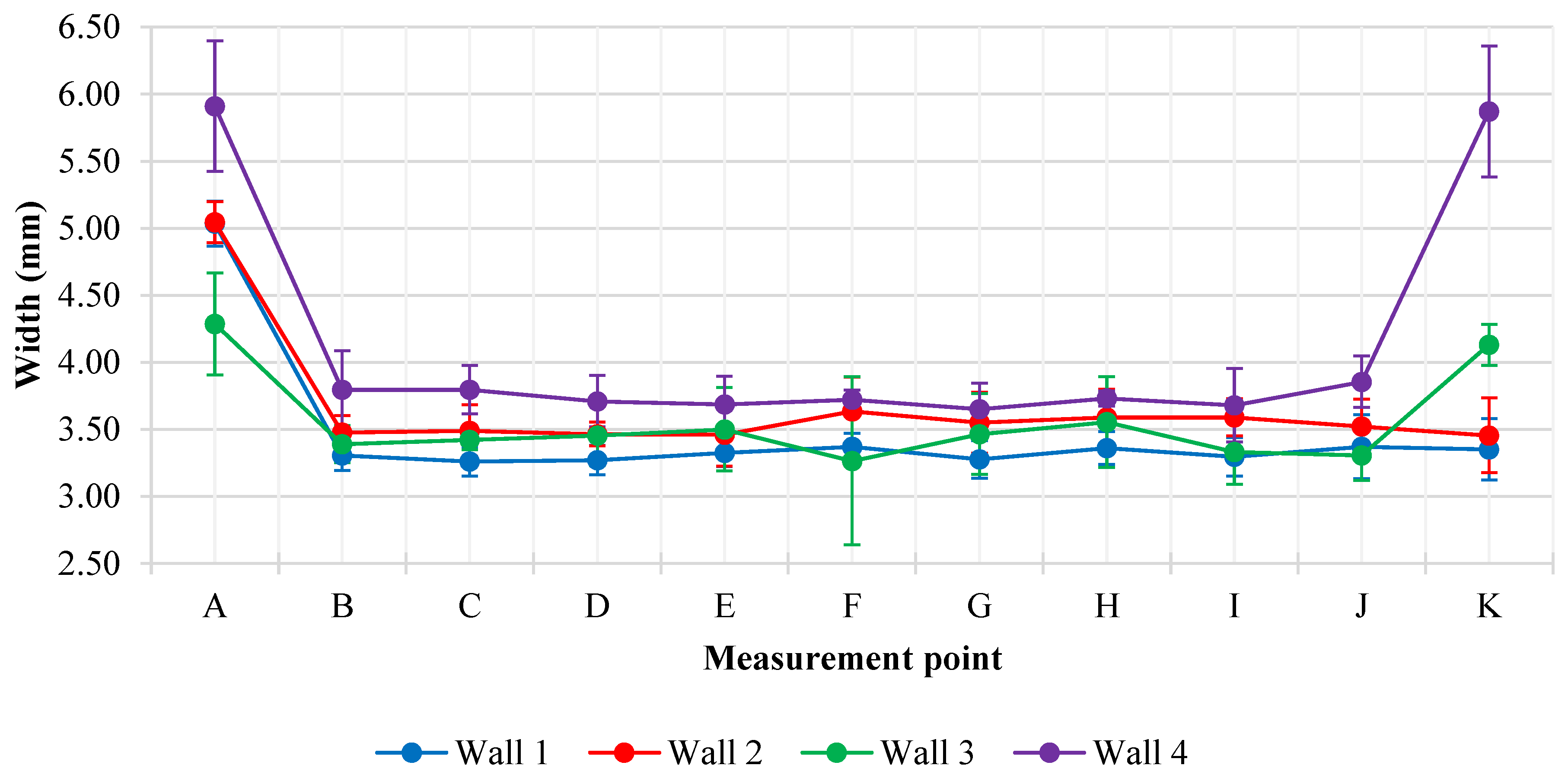

3.1. Dimensional Analysis

3.2. Microhardness

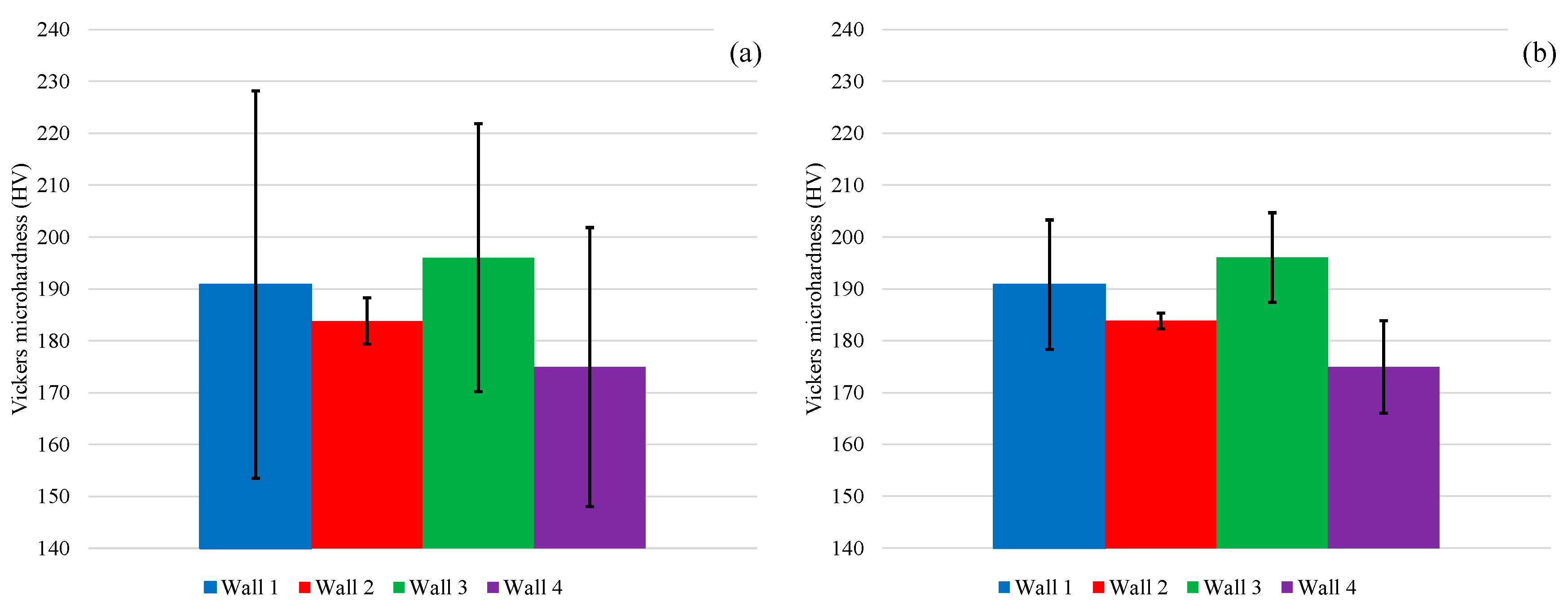

3.2.1. Overall Microhardness Analysis

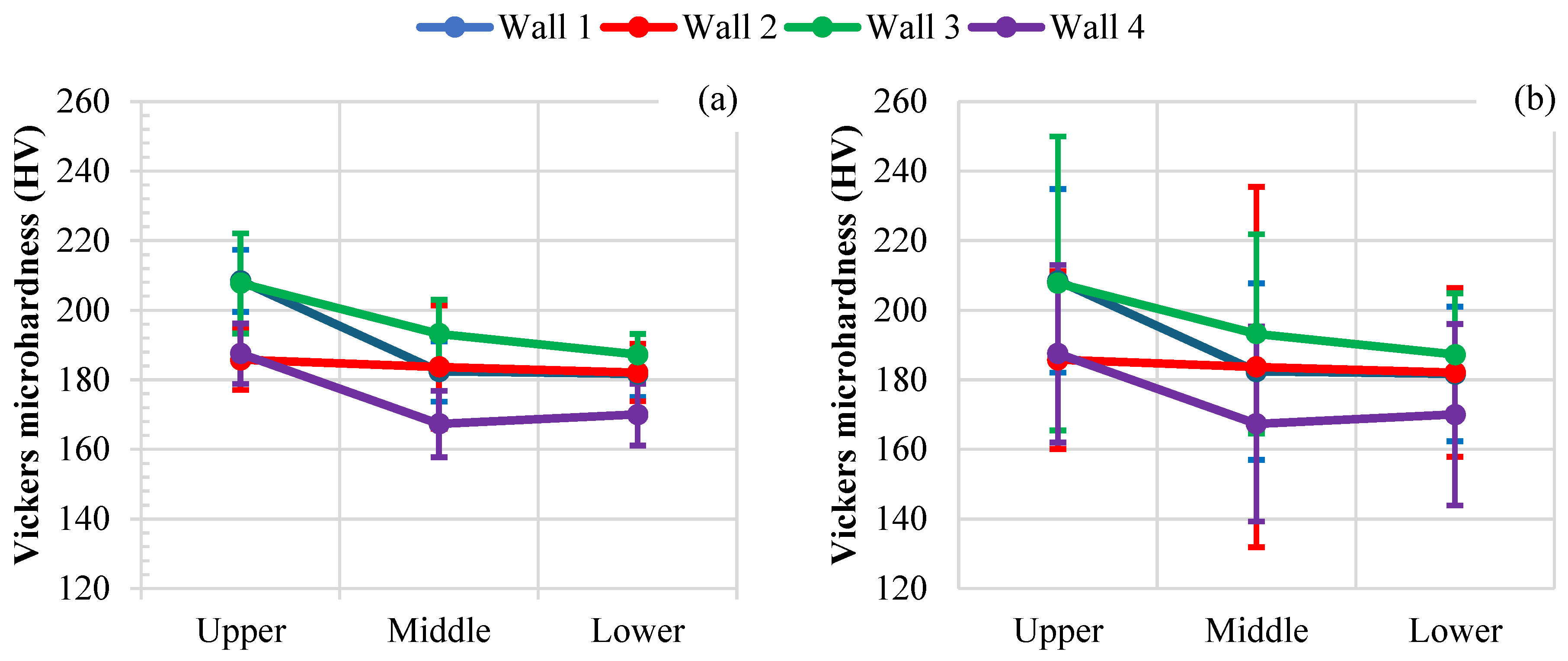

3.2.2. Vertical Microhardness Analysis

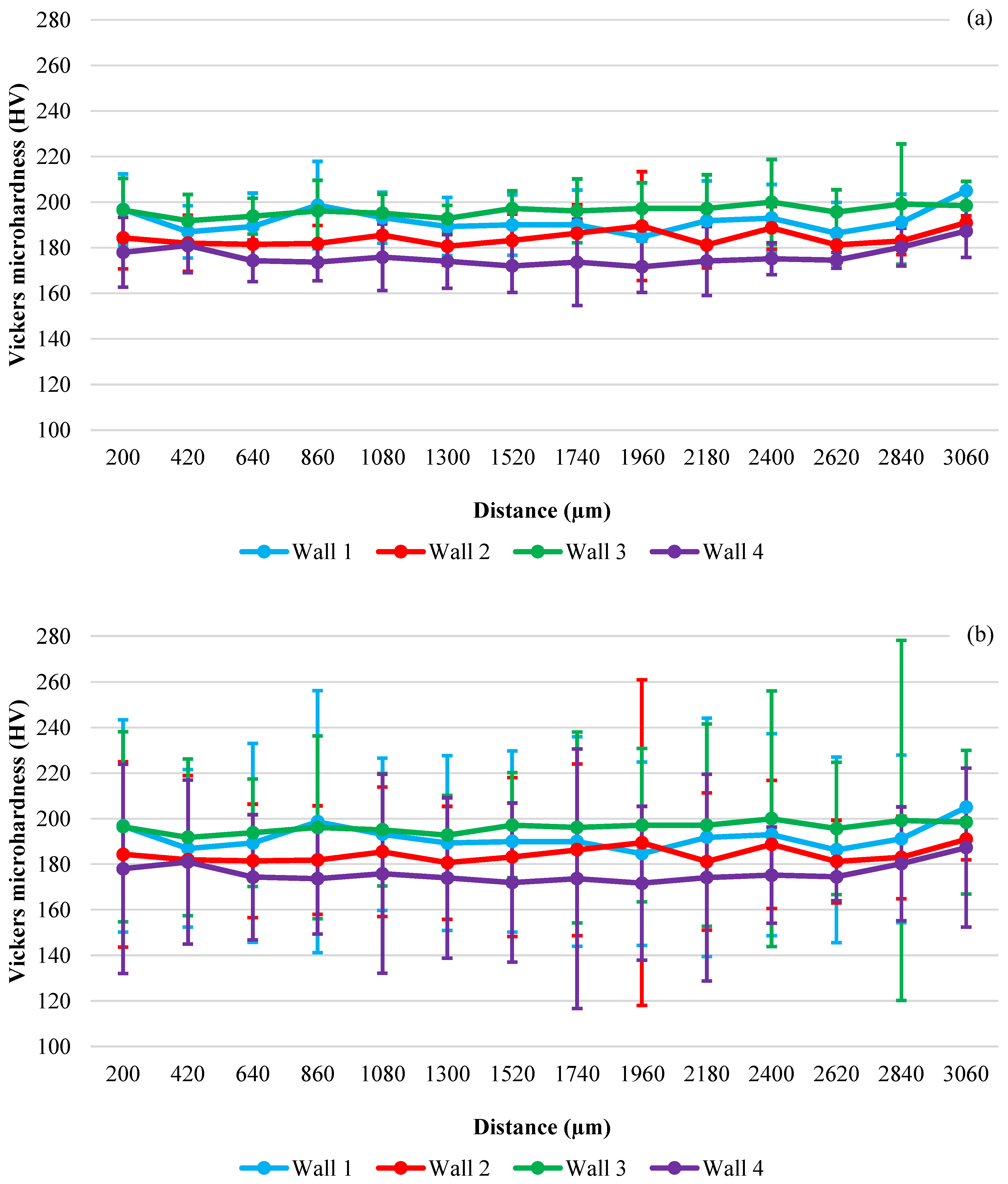

3.2.3. Horizontal Microhardness Analysis

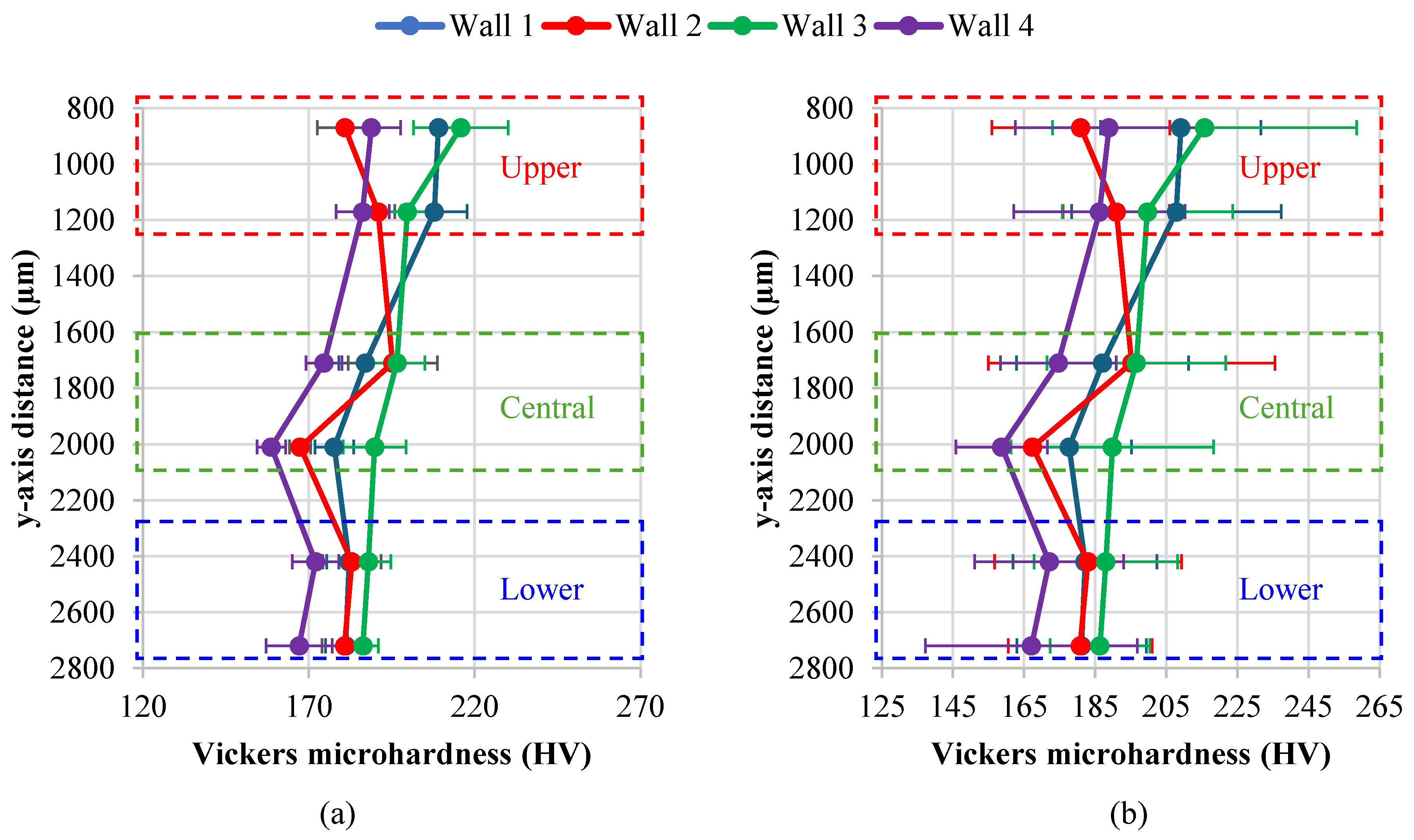

3.2.4. Microhardness Mapping Analysis

4. Conclusions

- The unidirectional deposition with no temperature control presented the lowest height and a progressive drop along the wall’s length. Temperature control slightly increased the wall’s height, while the bidirectional deposition without temperature control resulted in a more uniform height. The combination of bidirectional deposition and temperature control further improved the wall’s height and distribution.

- The bidirectional deposition with temperature control increased the wall’s average width by up to 26.14%. The lowest average width was found for wall 1 (unidirectional deposition without temperature control). A more uniform width was observed after bidirectional deposition with no temperature control (wall 3).

- Regardless of the deposition method, the wall region (lower, central or upper) influenced the microhardness. The highest and lowest microhardness were found in the upper and lower regions, respectively. As a transition region, the center of the wall can present high microhardness value variation.

- Considering the strategies evaluated in this work, the bidirectional method resulted in lower microhardness variation. Applying temperature control contributes to more homogeneous microhardness distribution. When both methods are combined, it is possible to achieve a taller and thicker wall, with less than 15 HV microhardness variation.

- For future research directions, it is suggested to evaluate distinct control temperatures and analyze the material’s microstructure to further comprehend the microhardness variation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.-G.; Lee, J.-H.; Zhang, J. Additive Manufacturing of Metallic Materials: A Review. J. Mater. Eng. Perform. 2018, 27, 1–13. [Google Scholar] [CrossRef]

- Kumar, M.B.; Sathiya, P. Methods and materials for additive manufacturing: A critical review on advancements and challenges. Thin-Walled Struct. 2021, 159, 107228. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Norrish, J.; Polden, J.; Richardson, I. A review of wire arc additive manufacturing: Development, principles, process physics, implementation and current status. J. Phys. D Appl. Phys. 2021, 54, 473001. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W. Wire Arc Additive Manufacturing of Stainless Steels: A Review. Appl. Sci. 2020, 10, 1563. [Google Scholar] [CrossRef]

- Barroqueiro, B.; Andrade-Campos, A.; Valente, R.A.F.; Neto, V. Metal Additive Manufacturing Cycle in Aerospace Industry: A Comprehensive Review. J. Manuf. Mater. Process. 2019, 3, 52. [Google Scholar] [CrossRef]

- da Silva, C.P.; Silva, G.P.; Santos, M.C.; Ziberov, M.; Malcher, L. Hybrid search methodology for mechanical characterization of material produced via WAAM assuming Gurson porous material. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 1–16. [Google Scholar] [CrossRef]

- Albannai, A.I.; León-Henao, H.; Ramirez, A.J. Preventing columnar grains growth during hybrid wire arc additive manufacturing of austenitic stainless steel 316L. Eng. Rep. 2024, 6, e12914. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A Review of the Recent Developments and Challenges in Wire Arc Additive Manufacturing (WAAM) Process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Ron, T.; Levy, G.K.; Dolev, O.; Leon, A.; Shirizly, A.; Aghion, E. Environmental Behavior of Low Carbon Steel Produced by a Wire Arc Additive Manufacturing Process. Metals 2019, 9, 888. [Google Scholar] [CrossRef]

- Novelino, A.; Carvalho, G.; Ziberov, M. Influence of WAAM-CMT deposition parameters on wall geometry. Adv. Ind. Manuf. Eng. 2022, 5, 100105. [Google Scholar] [CrossRef]

- Dekis, M.; Tawfik, M.; Egiza, M.; Dewidar, M. Unveiling the Characteristics of ER70S-6 low Carbon Steel Alloy Produced by wire arc Additive Manufacturing at Different Travel Speeds. Met. Mater. Int. 2024, 31, 325–338. [Google Scholar] [CrossRef]

- de Araújo Soares, M.A.; Novelino, A.L.B.; Ziberov, M. Geometry Study on 410NiMo Alloy Parts Printed by WAAM-CMT. In Brazilian Manufacturing Engineering Congress; Springer Nature: Cham, Switzerland, 2024; pp. 114–125. [Google Scholar] [CrossRef]

- Zhai, W.; Wu, N.; Zhou, W. Effect of Interpass Temperature on Wire Arc Additive Manufacturing Using High-Strength Metal-Cored Wire. Metals 2022, 12, 212. [Google Scholar] [CrossRef]

- Vieira, R.D.A.d.M.; Liskevych, O.; de Oliveira, D.; Ziberov, M. Influence of parameter variation and interlayer temperature control in wall angle, curvature and measurement methodology of ER70S-6 parts obtained by WAAM. Manuf. Lett. 2024, 42, 40–45. [Google Scholar] [CrossRef]

- Kesarwani, S.; Yuvaraj, N.; Niranjan, M.S. Impact of depositional direction and current on microstructure and mechanical properties of the bimetallic wall of ER5356/ER4043 fabricated by cold metal transfer based wire arc additive manufacturing. CIRP J. Manuf. Sci. Technol. 2024, 53, 17–33. [Google Scholar] [CrossRef]

- Zhang, C.; Qiu, Z.; Zhu, H.; Wang, Z.; Muránsky, O.; Ionescu, M.; Pan, Z.; Xi, J.; Li, H. On the Effect of Heat Input and Interpass Temperature on the Performance of Inconel 625 Alloy Deposited Using Wire Arc Additive Manufacturing–Cold Metal Transfer Process. Metals 2022, 12, 46. [Google Scholar] [CrossRef]

- Zhai, W.; Guo, Y.; Aishwarya; Canturri, C.; Shandro, R.; Zhou, W. Wire arc additive manufacturing of ER70S-6/S355 bimetal component. Mater. Sci. Eng. A 2024, 900, 146498. [Google Scholar] [CrossRef]

- Safarzade, A.; Sharifitabar, M.; Afarani, M.S. Effects of heat treatment on microstructure and mechanical properties of Inconel 625 alloy fabricated by wire arc additive manufacturing process. Trans. Nonferr. Met. Soc. China 2020, 30, 3016–3030. [Google Scholar] [CrossRef]

- Kumar, V.; Mandal, A.; Das, A.K.; Kumar, S. Parametric study and characterization of wire arc additive manufactured steel structures. Int. J. Adv. Manuf. Technol. 2021, 115, 1723–1733. [Google Scholar] [CrossRef]

- Das, B.; Panda, B.N.; Dixit, U.S. Microstructure and Mechanical Properties of ER70S-6 Alloy Cladding on Aluminum Using a Cold Metal Transfer Process. J. Mater. Eng. Perform. 2022, 31, 9385–9398. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Avila, J.A.; Santos, T.G.; Miranda, R.; Oliveira, J. Wire and arc additive manufacturing of HSLA steel: Effect of thermal cycles on microstructure and mechanical properties. Addit. Manuf. 2019, 27, 440–450. [Google Scholar] [CrossRef]

- Shen, C.; Pan, Z.; Cuiuri, D.; Ding, D.; Li, H. Influences of deposition current and interpass temperature to the Fe3Al-based iron aluminide fabricated using wire-arc additive manufacturing process. Int. J. Adv. Manuf. Technol. 2016, 88, 2009–2018. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Fei, Z. The effects of forced interpass cooling on the material properties of wire arc additively manufactured Ti6Al4V alloy. J. Mech. Work. Technol. 2018, 258, 97–105. [Google Scholar] [CrossRef]

- Raja, M.; Tiwari, Y.; Mukherjee, M.; Maji, B.; Chatterjee, A. Effect of bidirectional and switchback deposition strategies on microstructure and mechanical properties of wire arc additive manufactured Inconel 625. Int. J. Adv. Manuf. Technol. 2022, 119, 4845–4861. [Google Scholar] [CrossRef]

| Parameter | Wall 1 | Wall 2 | Wall 3 | Wall 4 |

|---|---|---|---|---|

| Step over (mm) | 1.50 | 1.50 | 1.20 | 1.20 |

| Current (A) | 75.00 | 75.00 | 75.00 | 75.00 |

| Tension (V) | 14.00 | 13.76 | 13.50 | 13.84 |

| TTS (mm/s) | 8.00 | 8.00 | 8.00 horizontal | 8.00 horizontal |

| Direction | Unidirectional | Unidirectional | Bidirectional | Bidirectional |

| Arc | Interrupted | Interrupted | Continuous | Interrupted |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Costa, A.L.S.; de Paiva, R.L.; de Oliveira, D.; Ziberov, M. Influence of Interlayer Temperature and Deposition Method on the Wall Geometry and Vickers Microhardness Profile of ER70S-6 Parts Manufactured by Additive Manufacturing Using CMT. J. Manuf. Mater. Process. 2025, 9, 93. https://doi.org/10.3390/jmmp9030093

da Costa ALS, de Paiva RL, de Oliveira D, Ziberov M. Influence of Interlayer Temperature and Deposition Method on the Wall Geometry and Vickers Microhardness Profile of ER70S-6 Parts Manufactured by Additive Manufacturing Using CMT. Journal of Manufacturing and Materials Processing. 2025; 9(3):93. https://doi.org/10.3390/jmmp9030093

Chicago/Turabian Styleda Costa, André Luis Silva, Raphael Lima de Paiva, Déborah de Oliveira, and Maksym Ziberov. 2025. "Influence of Interlayer Temperature and Deposition Method on the Wall Geometry and Vickers Microhardness Profile of ER70S-6 Parts Manufactured by Additive Manufacturing Using CMT" Journal of Manufacturing and Materials Processing 9, no. 3: 93. https://doi.org/10.3390/jmmp9030093

APA Styleda Costa, A. L. S., de Paiva, R. L., de Oliveira, D., & Ziberov, M. (2025). Influence of Interlayer Temperature and Deposition Method on the Wall Geometry and Vickers Microhardness Profile of ER70S-6 Parts Manufactured by Additive Manufacturing Using CMT. Journal of Manufacturing and Materials Processing, 9(3), 93. https://doi.org/10.3390/jmmp9030093