Use of Biobased Resins Derived from Renewable Monomers for Sustainable 3D Fabrication Through Two-Photon Polymerization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

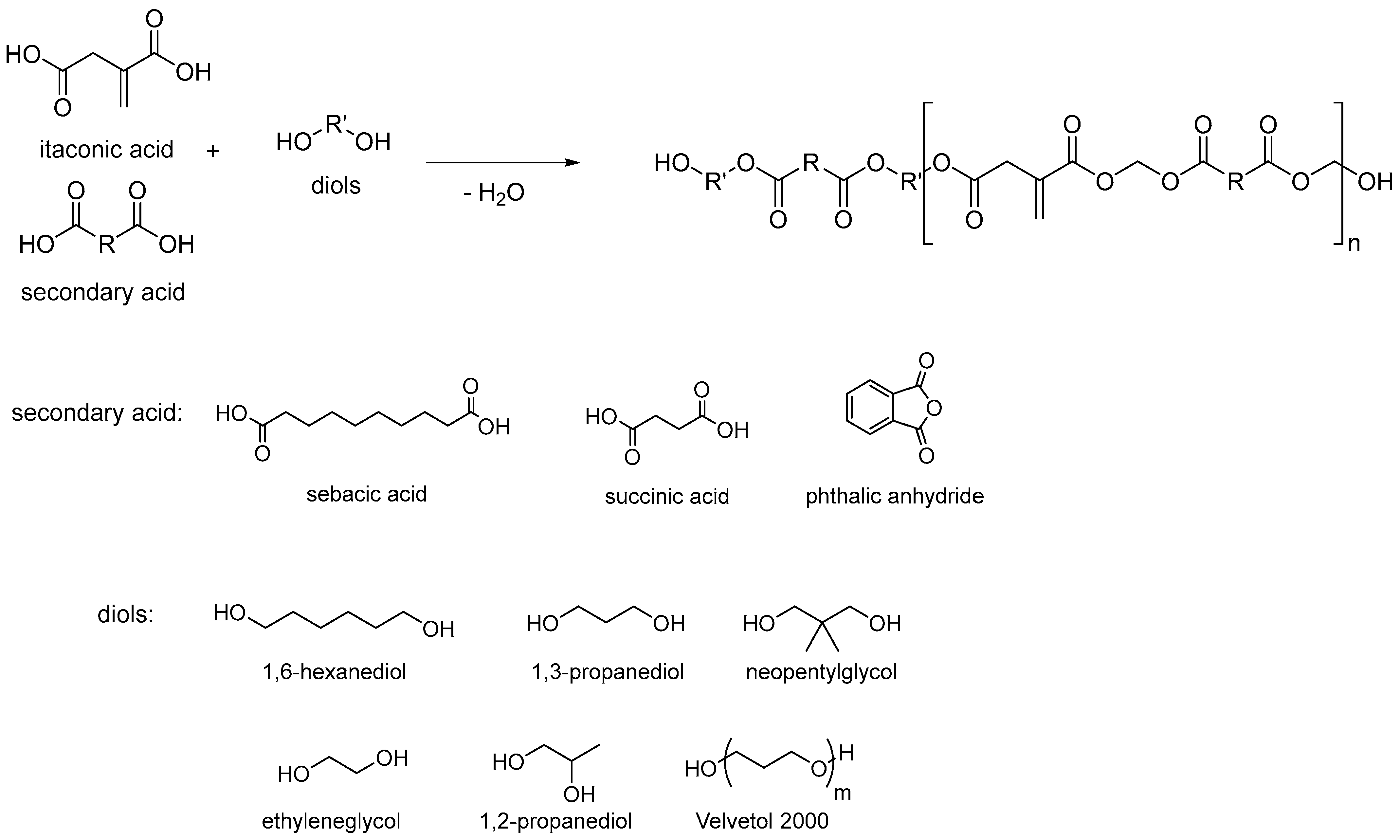

2.2. Polyester Synthesis

2.3. Formulation Preparation

2.4. TPP Process

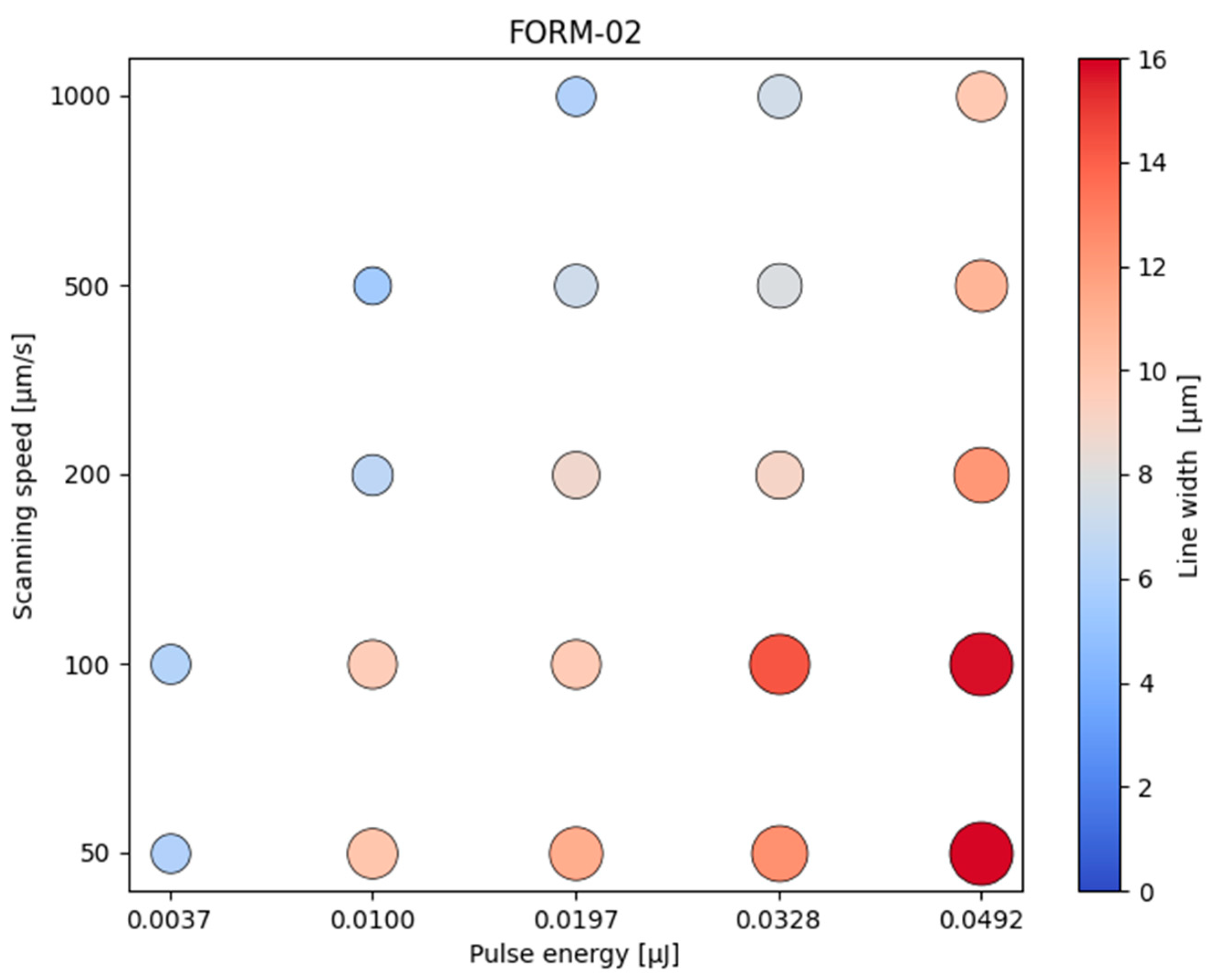

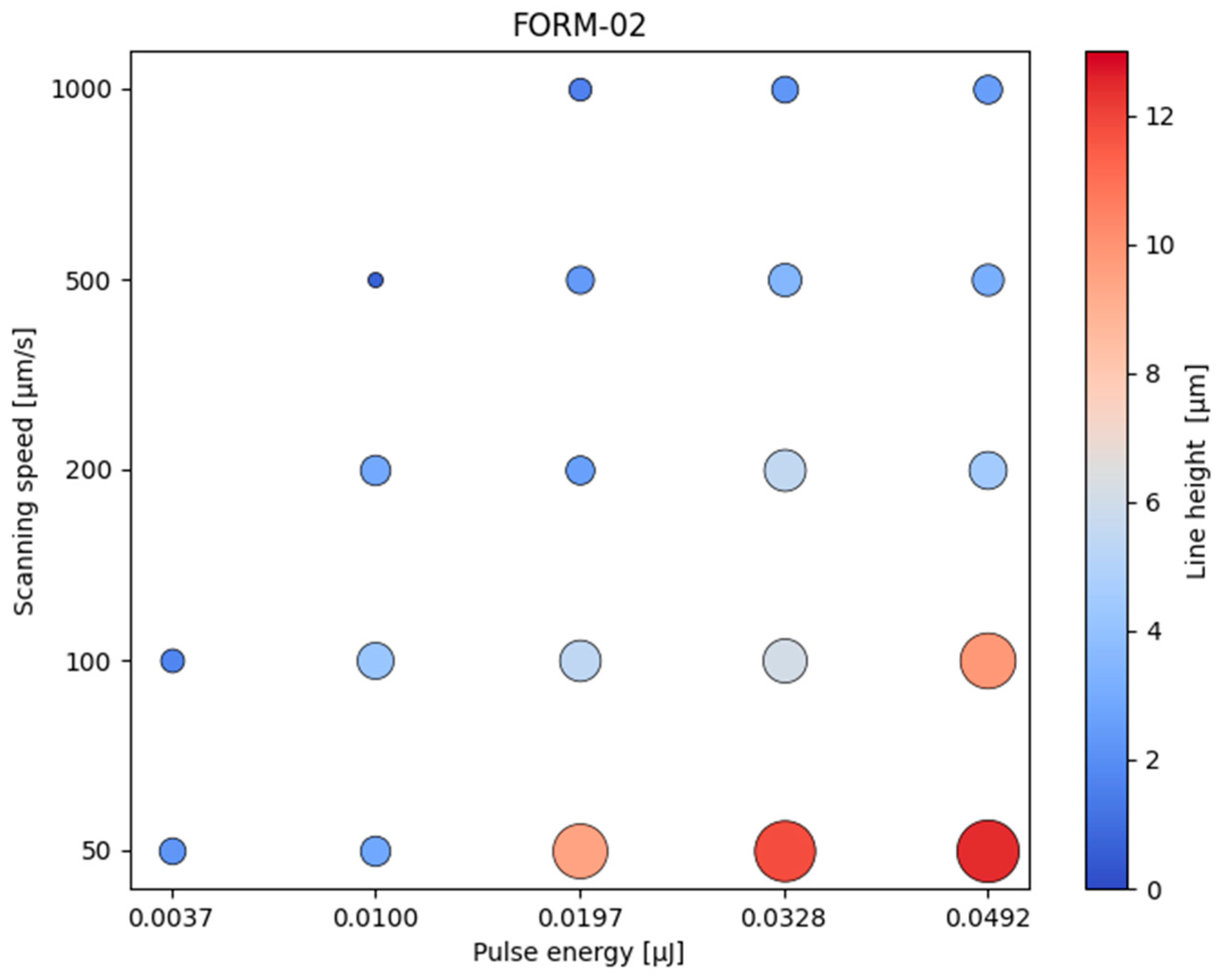

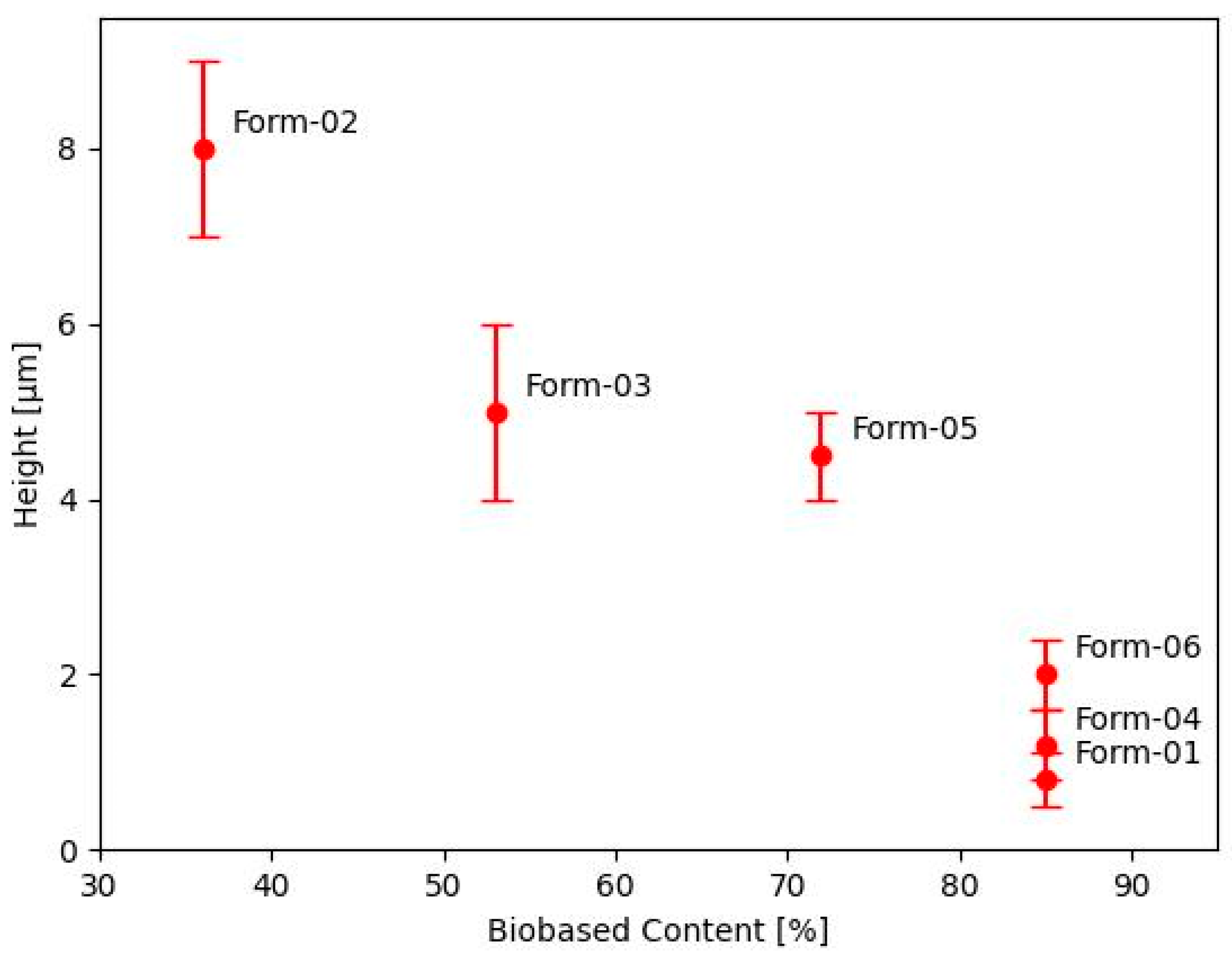

3. Results

Prepolymer Composition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Toyserkani, E.; Sarker, S.; Ibhadode, O.O.; Liravi, F.; Russo, P.; Taherkhani, K. Metal Additive Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2021; ISBN 1119210836/9781119210832. [Google Scholar]

- Cooke, S.; Ahmadi, K.; Willerth, S.; Herring, R. Metal additive manufacturing: Technology, metallurgy and modelling. J. Manuf. Process 2020, 57, 978–1003. [Google Scholar] [CrossRef]

- Armstrong, M.; Mehrabi, H.; Naveed, N. An overview of modern metal additive manufacturing technology. J. Manuf. Process 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Ann. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Galvanauskas, K.; Astrauskyte, D.; Balcas, G.; Gailevičius, D.; Grineviciute, L.; Malinauskas, M. High-transparency and heavy-durability 3D micro-optics made via ultrafast laser lithography combined with atomic layer deposition and calcination. In Proceedings of the Conference on Lasers and Electro-Optics/Europe (CLEO/Europe 2023) and European Quantum Electronics Conference (EQEC 2023), Munich, Germany, 26–30 June 2023; Technical Digest Series; paper ce_11_2. Optica Publishing Group: Washington, DC, USA, 2023. [Google Scholar]

- Schmid, M.D.; Toulouse, A.; Thiele, S.; Mangold, S.; Herkommer, A.M.; Giessen, H. 3D Direct Laser Writing of Highly Absorptive Photoresist for Miniature Optical Apertures. Adv. Funct. Mater. 2023, 33, 2211159. [Google Scholar] [CrossRef]

- Siegle, L.; Ristok, S.; Giessen, H. Complex aspherical singlet and doublet microoptics by grayscale 3D printing. Opt. Express 2023, 31, 4179–4189. [Google Scholar] [CrossRef] [PubMed]

- Tsilipakos, O.; Perrakis, G.; Farsari, M.; Kafesaki, M. Polymeric Optical Metasurfaces by Two-Photon Lithography: Practical Designs for Beam Steering. In Proceedings of the 2024 Eighteenth International Congress on Artificial Materials for Novel Wave Phenomena (Metamaterials), Chania, Greece, 9–14 September 2024. [Google Scholar]

- Zhang, S.; Wong, C.L.; Zeng, S.; Bi, R.; Tai, K.; Dholakia, K.; Olivo, M. Metasurfaces for biomedical applications: Imaging and sensing from a nanophotonics perspective. Nanophotonics 2021, 10, 259–293. [Google Scholar] [CrossRef]

- Weisgrab, G.; Guillaume, O.; Cao, Z.; Heimel, P.; Slezak, P.; Poot, A.; Grijpma, D.; Ovsianikov, A. 3D Printing of large-scale and highly porous biodegradable tissue engineering scaffolds from poly(trimethylene-carbonate) using two-photon-polymerization. Biofabrication 2020, 12, 045036. [Google Scholar] [CrossRef]

- Lvov, V.A.; Senatov, F.S.; Veveris, A.A.; Skrybykina, V.A.; Díaz Lantada, A. Auxetic Metamaterials for Biomedical Devices: Current Situation, Main Challenges, and Research Trends. Materials 2022, 15, 1439. [Google Scholar] [CrossRef]

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 202001379. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Ovsianikov, A.; Deiwick, A.; Van Vlierberghe, A.; Dubruel, P.; Möller, L.; Dräger, G.B.; Chichkov, G. Laser fabrication of three-dimensional CAD scaffolds from photosensitive gelatin for applications in tissue engineering. Biomacromolecules 2011, 12, 851–858. [Google Scholar] [CrossRef]

- She, A.; Zhang, S.; Shian, S.; Clarke, D.R.; Capasso, F. Large area metalenses: Design, characterization, and mass manufacturing. Opt. Express 2018, 26, 1573–1585. [Google Scholar] [CrossRef] [PubMed]

- Rosa, R.P.; Rosace, G. Nanomaterials for 3D Printing of Polymers via Stereolithography: Concept, Technologies, and Applications. Macromol. Mater. Eng. 2021, 306, 2100345. [Google Scholar] [CrossRef]

- Maines, E.M.; Porwal, M.K.; Ellison, C.J.; Reineke, T.M. Sustainable advances in SLA/DLP 3D printing materials and processes. Green. Chem. 2021, 23, 6863–6897. [Google Scholar] [CrossRef]

- Serbin, J.; Egbert, A.; Ostendorf, A.; Chichkov, B.N.; Houbertz, R.; Dommann, G.; Schulz, J.; Cronauer, C.; Fröhlich, L.; Popall, M. Femtosecond laser-induced two-photon polymerization of inorganic–organic hybrid materials for applications in photonics. Opt. Let. 2003, 28, 301–303. [Google Scholar] [CrossRef] [PubMed]

- Kotz, F.; Quick, A.S.; Risch, P.; Martin, T.; Hoose, T.; Thiel, M.; Helmer, D.; Rapp, B.E. Two-Photon Polymerization of Nanocomposites for the Fabrication of Transparent Fused Silica Glass Microstructures. Adv. Mater. 2021, 22, 2006341. [Google Scholar] [CrossRef]

- Florea, L.; Blasco, E.; Mattoli, V. New Frontiers in Materials and Technologies for 3D Two Photon Polymerization. Adv. Funct. Mater. 2023, 33, 2305697. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Ladika, D.; Yu, H.; Gailevičius, D.; Wang, H.; Pan, C.-F.; Nair, P.N.S.; Ke, Y.; Mori, T.; et al. Two-Photon Polymerization Lithography for Optics and Photonics: Fundamentals, Materials, Technologies, and Applications. Adv. Funct. Mater. 2023, 33, 2214211. [Google Scholar] [CrossRef]

- Skliutas, E.; Lebedevaite, M.; Kabouraki, E.; Baldacchini, T.; Ostrauskaite, J.; Vamvakaki, M.; Farsari, M.; Juodkazis, S.; Malinauskas, M. Polymerization mechanisms initiated by spatio-temporally confined light. Nanophotonics 2021, 10, 1211–1242. [Google Scholar] [CrossRef]

- Butkus, A.; Skliutas, E.; Gailevičius, D.; Malinauskas, M. Femtosecond-laser direct writing 3D micro/nano-lithography using VIS-light oscillator. J. Cent. South Univ. 2022, 29, 3270–3276. [Google Scholar] [CrossRef]

- Waheed, S.; Cabot, J.M.; Macdonald, N.P.; Lewis, T.; Gijit, R.M.; Paull, B.; Breadmore, M.C. 3D printed microfluidic devices: Enablers and barriers. Lab. Chip 2016, 16, 1993–2013. [Google Scholar] [CrossRef]

- Meng, H.; Chen, K.; Li, C.; Zhang, L.; He, Y.; Zhao, Z.; Wu, P.; Zhu, H.; Chi, Z.; Xu, J.; et al. Innocuous solvent-based, low-temperature curable, and highly transparent photosensitive polyimides developed using soluble polyimides containing bio-based magnolol moieties. Chem. Sci. 2025, 16, 3157–3167. [Google Scholar] [CrossRef] [PubMed]

- Vetri Buratti, V.; Sanz De Leon, A.; Maturi, M.; Sambri, L.; Molina, S.I.; Comes Franchini, M. Itaconic-acid-based sustainable poly(ester amide) resin for stereolithography. Macromolecules 2022, 55, 3087–3095. [Google Scholar] [CrossRef] [PubMed]

- Maturi, M.; Pulignani, C.; Locatelli, E.; Vetri Buratti, V.; Tortorella, S.; Sambri, L.; Comes Franchini, M. Phosphorescent bio-based resin for digital light processing (DLP) 3D-printing. Green Chem. 2020, 22, 6212–6224. [Google Scholar]

- Miao, J.-T.; Peng, S.; Ge, M.; Li, Y.; Zhong, J.; Weng, Z.; Wu, L.; Zheng, L. Three-Dimensional Printing Fully Biobased Heat-Resistant Photoactive Acrylates from Aliphatic Biomass. ACS Sustain. Chem. Eng. 2020, 8, 9415–9424. [Google Scholar] [CrossRef]

- Maturi, M.; Spanu, C.; Locatelli, E.; Sambri, L.; Comes Franchini, M. Myrcene-itaconate Diels-Alder cycloadducts in the synthesis of photocurable polyesters for the 3D printing of fully biobased resins. Addit. Manuf. 2024, 92, 104360. [Google Scholar] [CrossRef]

- Maturi, M.; Spanu, C.; Maccaferri, E.; Locatelli, E.; Benelli, T.; Mazzocchetti, L.; Sambri, L.; Giorgini, L.; Franchini, M.C. (Meth)acrylate-Free Three-Dimensional Printing of Bio-Derived Photocurable Resins with Terpene- and Itaconic Acid-Derived Poly(ester-thioether)s. ACS Sustain. Chem. Eng. 2023, 11, 17285–17298. [Google Scholar] [CrossRef] [PubMed]

- Carmenini, R.; Spanu, C.; Locatelli, E.; Sambri, L.; Comes Franchini, M.; Maturi, M. Isocyanate-free urethanediol itaconates as biobased liquid monomers in photopolymerization-based 3D printing. Prog. Addit. Manuf. 2024, 9, 2499–2510. [Google Scholar] [CrossRef]

- Pérocheau Arnaud, S.; Malitowski, N.M.; Meza Casamayor, K.; Robert, T. Itaconic Acid-Based Reactive Diluents for Renewable and Acrylate-Free UV-Curing Additive Manufacturing Materials. ACS Sustain. Chem. Eng. 2021, 9, 17142–17151. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Malitowski, N.M.; Bikiaris, D.; Robert, T. Bio-based additive manufacturing materials: An in-depth structure-property relationship study of UV-curing polyesters from itaconic acid. Eur. Polym. J. 2023, 186, 111872. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Pezzana, L.; Malitowski, N.M.; Sangermano, M.; Bikiaris, D.N.; Robert, T. UV-Curing Additive Manufacturing of Bio-Based Thermosets: Effect of Diluent Concentration on Printing and Material Properties of Itaconic Acid-Based Materials. ACS Omega 2023, 8, 31009–31020. [Google Scholar] [CrossRef] [PubMed]

- Papadopoulos, L.; Pezzana, L.; Malitowski, N.; Kladovasilakis, N.; Tzetzis, D.; Sangermano, M.; Bikiaris, D.N.; Robert, T. Itaconic acid-based 3D printed nanocomposites: An in-depth study on the effect of nanoinclusions on the physicochemical properties and the printability of formulations based on polyester itaconates. Giant 2024, 18, 100275. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Pezzana, L.; Malitowski, N.; Sangermano, M.; Bikiaris, D.N.; Robert, T. Influence of reactive diluent composition on properties and bio-based content of itaconic acid-based additive manufacturing materials. Discov. Appl. Sci. 2024, 6, 290. [Google Scholar] [CrossRef]

- Schoon, I.; Kluge, M.; Eschig, S.; Robert, T. Catalyst Influence on Undesired Side Reactions in the Polycondensation of Fully Bio-Based Polyester Itaconates. Polymers 2017, 9, 693. [Google Scholar] [CrossRef] [PubMed]

- O’Halloran, S.; Pandit, A.; Heise, A.; Kellet, A. Two-Photon Polymerization: Fundamentals, Materials, and Chemical Modification Strategies. Adv. Sci. 2023, 10, 2204072. [Google Scholar] [CrossRef]

- Wloka, T.; Gottschaldt, M.; Schubert, U.S. From Light to Structure: Photo Initiators for Radical Two-Photon Polymerization. Chem. Eur. J. 2022, 28, e202104191. [Google Scholar] [CrossRef]

- Serbin, J.; Ovsianikov, A.; Chichkov, B. Fabrication of woodpile structures by two-photon polymerization and investigation of their optical properties. Opt. Express 2004, 12, 5221. [Google Scholar] [CrossRef]

| Prepolymer | Itaconic Acid [eq] | Acid 2 [eq] | Diol 1 [eq] | Diol 2 [eq] | Diol 3 [eq] | Biobased Content [%] |

|---|---|---|---|---|---|---|

| PREPOL-01 | 0.8 | 0.2 IPA | 1.0 HDO | 0.25 NPG | - | 37 |

| PREPOL -02 | 0.7 | 0.3 SebA | 1.22 HDO | - | 0.14 Velv | 75 |

| PREPOL -03 | 0.5 | 0.5 SA | 1.05 1.3-PDO | 0.27 EDO | 0.027 Velv | 100 |

| PREPOL -04 | 0.5 | 0.5 SA | 1.05 1.3-PDO | 0.27 1.2-PDO | 0.027 Velv | 100 |

| PREPOL -05 | 0.5 | 0.5 SebA | 1.3-PDO | - | 0.15 Velv | 100 |

| PREPOL -06 | 0.8 | 0.2 IPA | 1.08 PDO | 0.27 NPG | - | 89 |

| Formulation | Prepolymer 50% | Reactive Diluent 48.95% | Photoinitiator (TPO) | Inhibitor (MeHQ) | Biobased Content (%) | ||

|---|---|---|---|---|---|---|---|

| Oligomer | Diluent | Overall | |||||

| FORM-01 | PREPOL-03 | IBOA | 1.0% | 0.05% | 100 | 71 | 85 |

| FORM-02 | PREPOL-01 | ACMO/IBOA 1:1 | 1.0% | 0.05% | 37 | 36 | 36 |

| FORM-03 | PREPOL-01 | IBOA | 1.0% | 0.05% | 37 | 71 | 53 |

| FORM-04 | PREPOL-04 | IBOA | 1.0% | 0.05% | 100 | 71 | 85 |

| FORM-05 | PREPOL-02 | IBOA | 1.0% | 0.05% | 75 | 71 | 72 |

| FORM-06 | PREPOL-05 | IBOA | 1.0% | 0.05% | 100 | 71 | 85 |

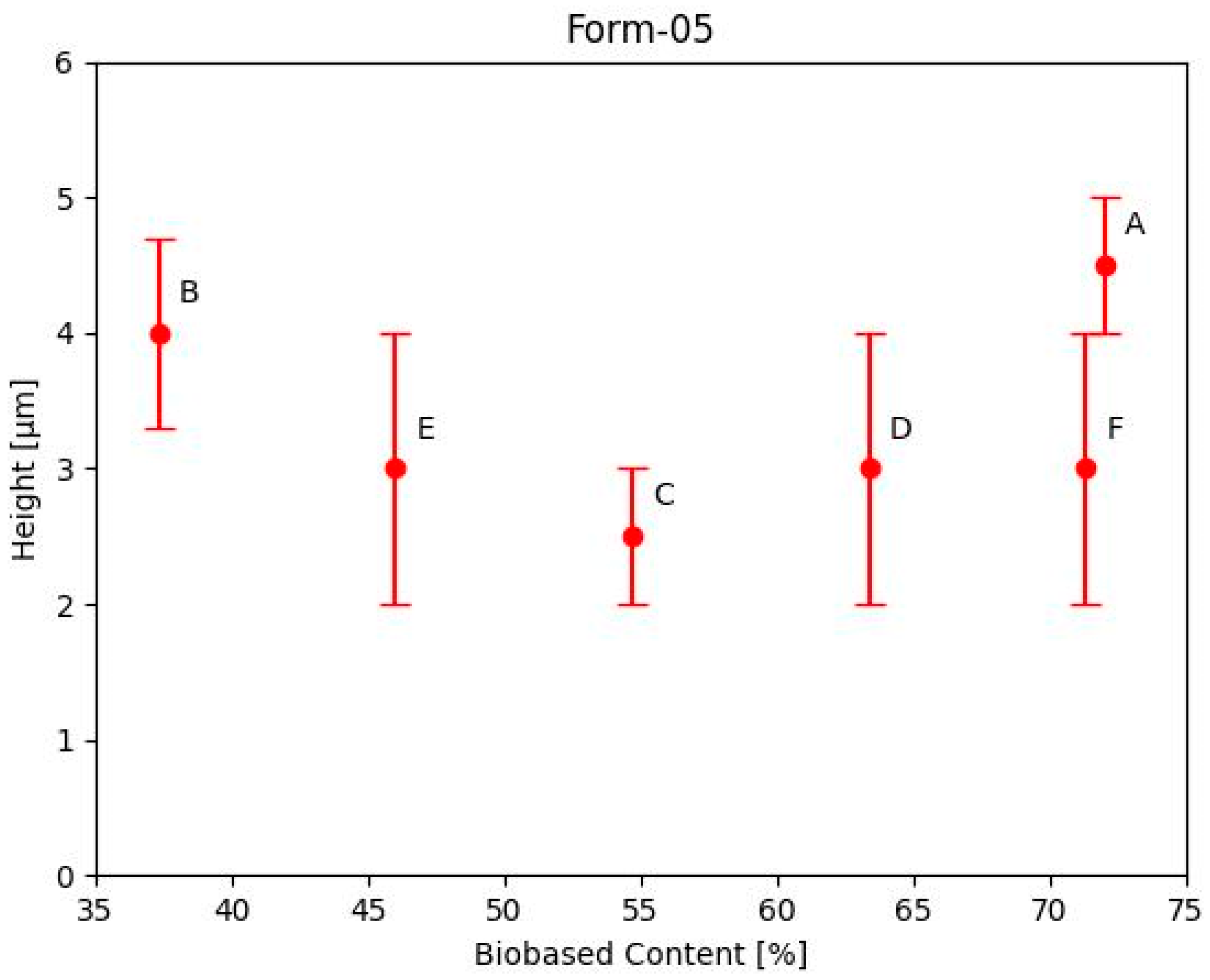

| Name | Prepolymer 50% | Reactive Diluent 48.95% | Photoinitiator (TPO) | Inhibitor (MeHQ) | Biobased Content (%) | ||

|---|---|---|---|---|---|---|---|

| Oligomer | Diluent | Overall | |||||

| FORM-05-A | PREPOL-02 | IBOA | 1.0% | 0.05 | 75 | 71 | 72 |

| FORM-05-B | PREPOL-02 | ACMO | 1.0% | 0.05 | 74.6 | 0 | 37.3 |

| FORM-05-C | PREPOL-02 | ACMO/IBOA 1:1 | 1.0% | 0.05 | 74.6 | 35.5 | 54.7 |

| FORM-05-D | PREPOL-02 | ACMO/IBOA 1:3 | 1.0% | 0.05 | 74.6 | 53.2 | 63.4 |

| FORM-05-E | PREPOL-02 | ACMO/IBOA 1:3 | 1.0% | 0.05 | 74.6 | 17.8 | 46.0 |

| FORM-05-F | PREPOL-02 | IBOA | 2.0% | 0.05 | 74.6 | 71 | 71.3 |

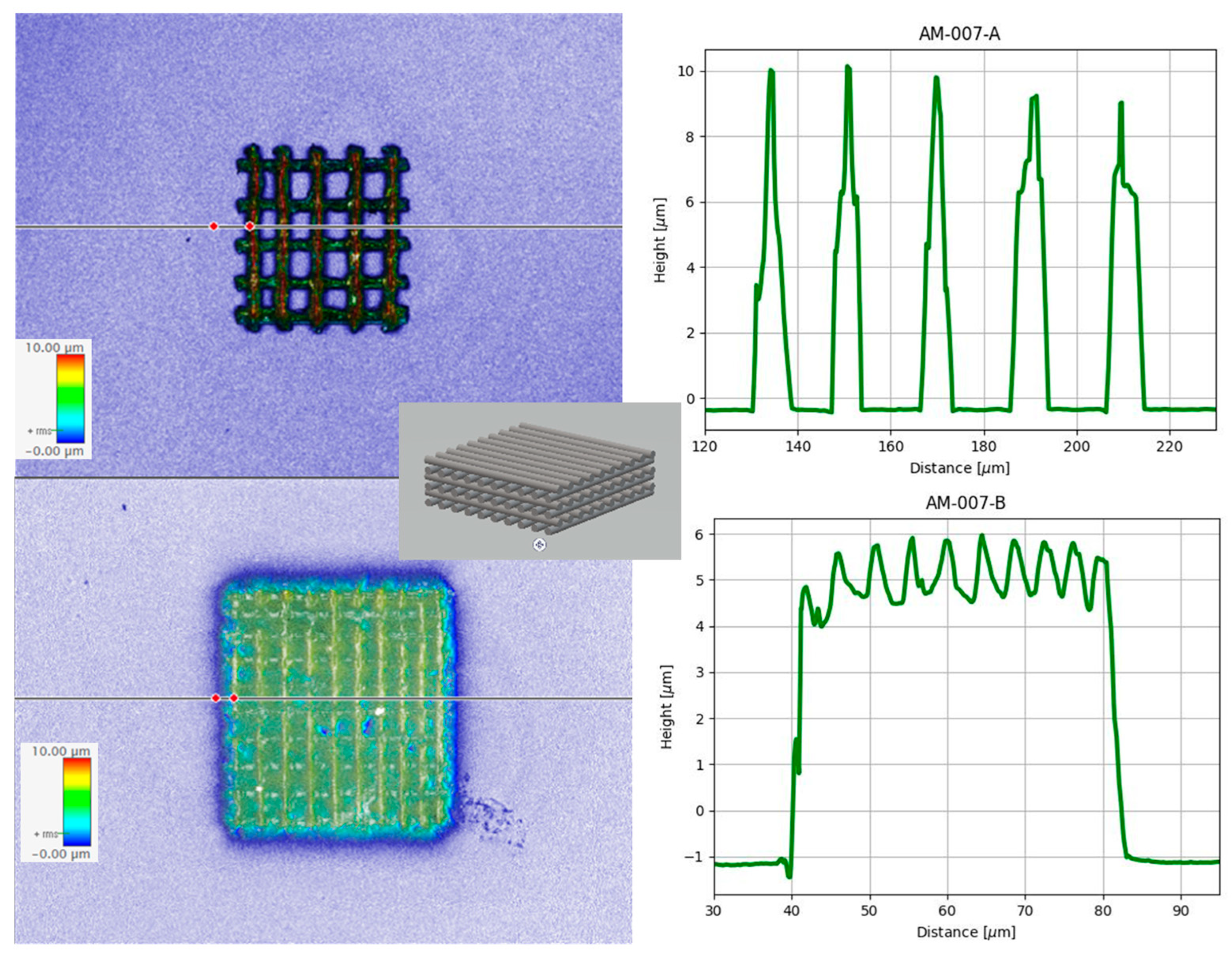

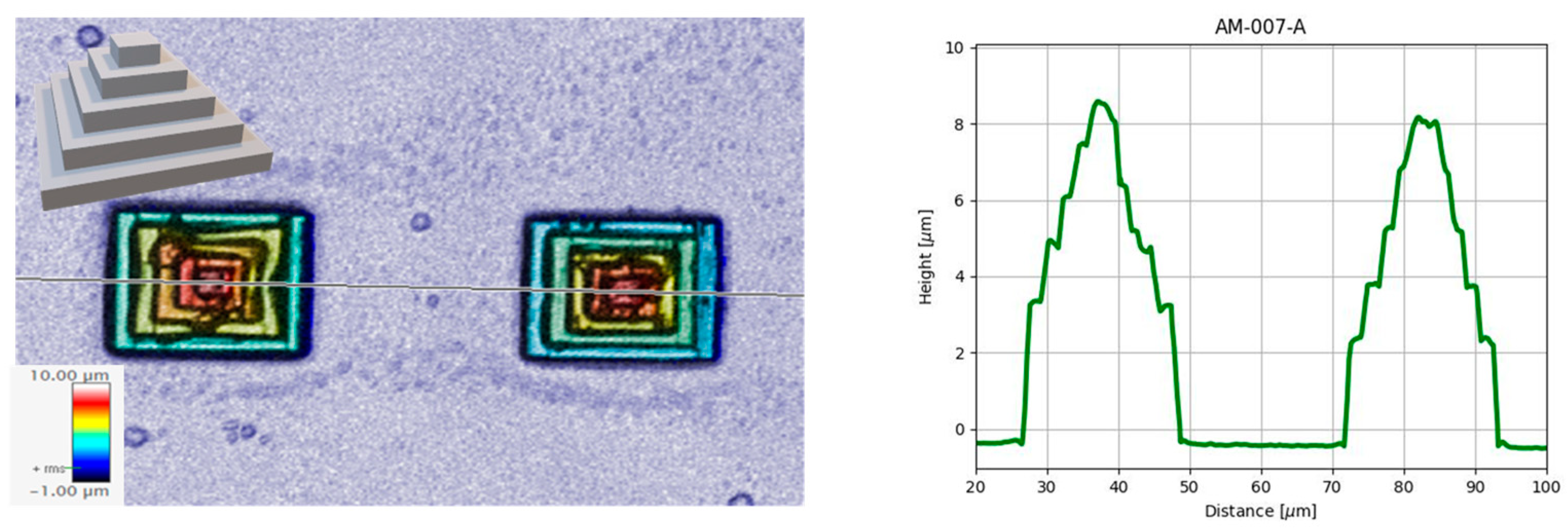

| Name | Prepolymer 50% | Reactive Diluent 48.95% | Photoinitiator (TPO) | Biobased Content (%) | ||

|---|---|---|---|---|---|---|

| Oligomer | Diluent | Overall | ||||

| FORM-07-A | PREPOL-06 | ACMO/IBOA 1:1 | 1.0% | 75 | 36 | 55 |

| FORM-07-B | PREPOL-01 | IBOA | 1.0% | 75 | 71 | 72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gontad, F.; Cuartero, J.; Vidal, S.; Otero, N.; Schulz, N.M.; Robert, T. Use of Biobased Resins Derived from Renewable Monomers for Sustainable 3D Fabrication Through Two-Photon Polymerization. J. Manuf. Mater. Process. 2025, 9, 89. https://doi.org/10.3390/jmmp9030089

Gontad F, Cuartero J, Vidal S, Otero N, Schulz NM, Robert T. Use of Biobased Resins Derived from Renewable Monomers for Sustainable 3D Fabrication Through Two-Photon Polymerization. Journal of Manufacturing and Materials Processing. 2025; 9(3):89. https://doi.org/10.3390/jmmp9030089

Chicago/Turabian StyleGontad, Francisco, Jaime Cuartero, Sara Vidal, Nerea Otero, Natalia M. Schulz, and Tobias Robert. 2025. "Use of Biobased Resins Derived from Renewable Monomers for Sustainable 3D Fabrication Through Two-Photon Polymerization" Journal of Manufacturing and Materials Processing 9, no. 3: 89. https://doi.org/10.3390/jmmp9030089

APA StyleGontad, F., Cuartero, J., Vidal, S., Otero, N., Schulz, N. M., & Robert, T. (2025). Use of Biobased Resins Derived from Renewable Monomers for Sustainable 3D Fabrication Through Two-Photon Polymerization. Journal of Manufacturing and Materials Processing, 9(3), 89. https://doi.org/10.3390/jmmp9030089