Microstructure, Thermal, and Mechanical Behavior of NiTi Shape Memory Alloy Obtained by Micro Wire and Arc Direct Energy Deposition

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Raw Material and Substrate

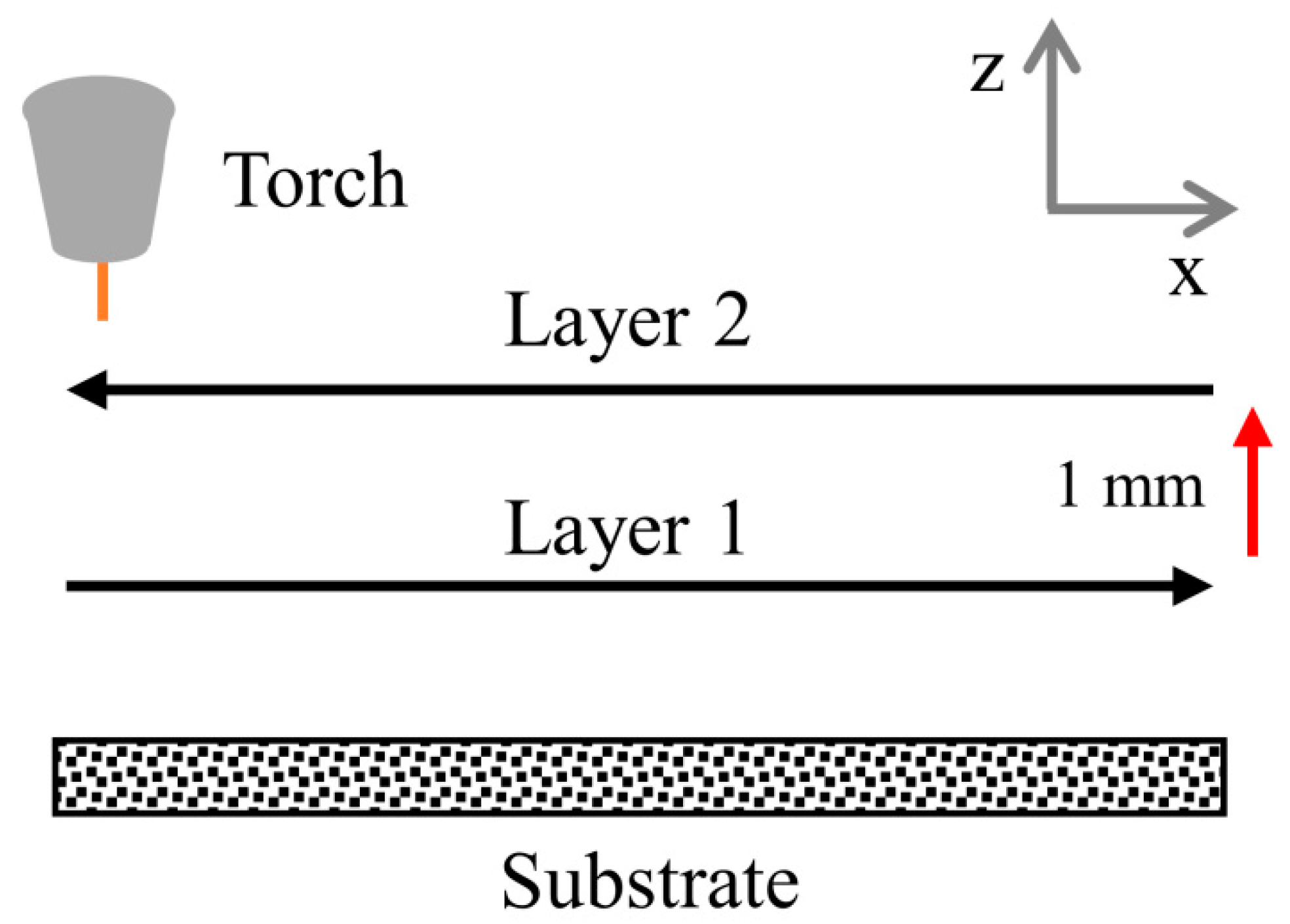

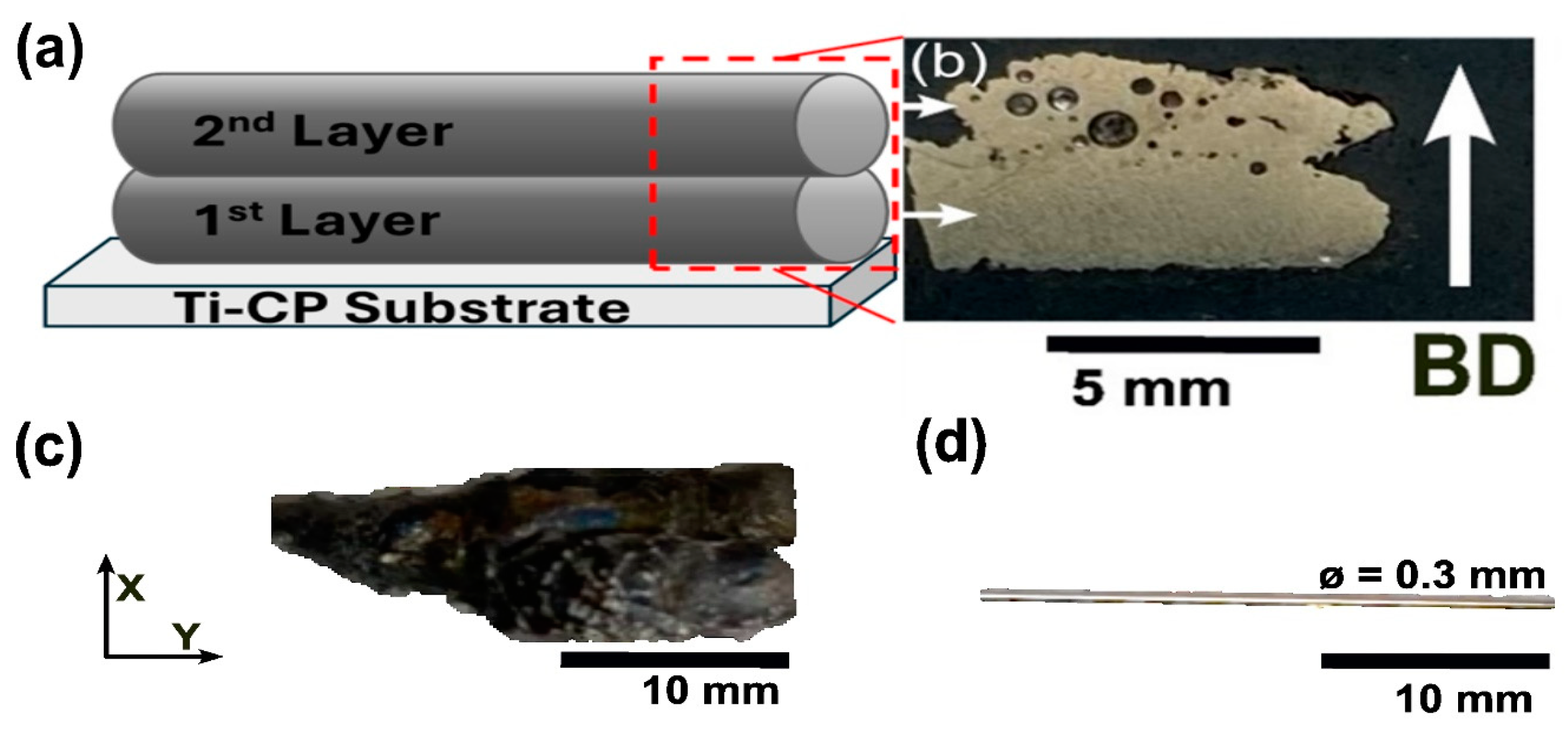

2.2. Fabrication of the NiTi Parts

2.3. Characterization of the Printed NiTi Parts

3. Results and Discussion

3.1. Metallurgical Characterization

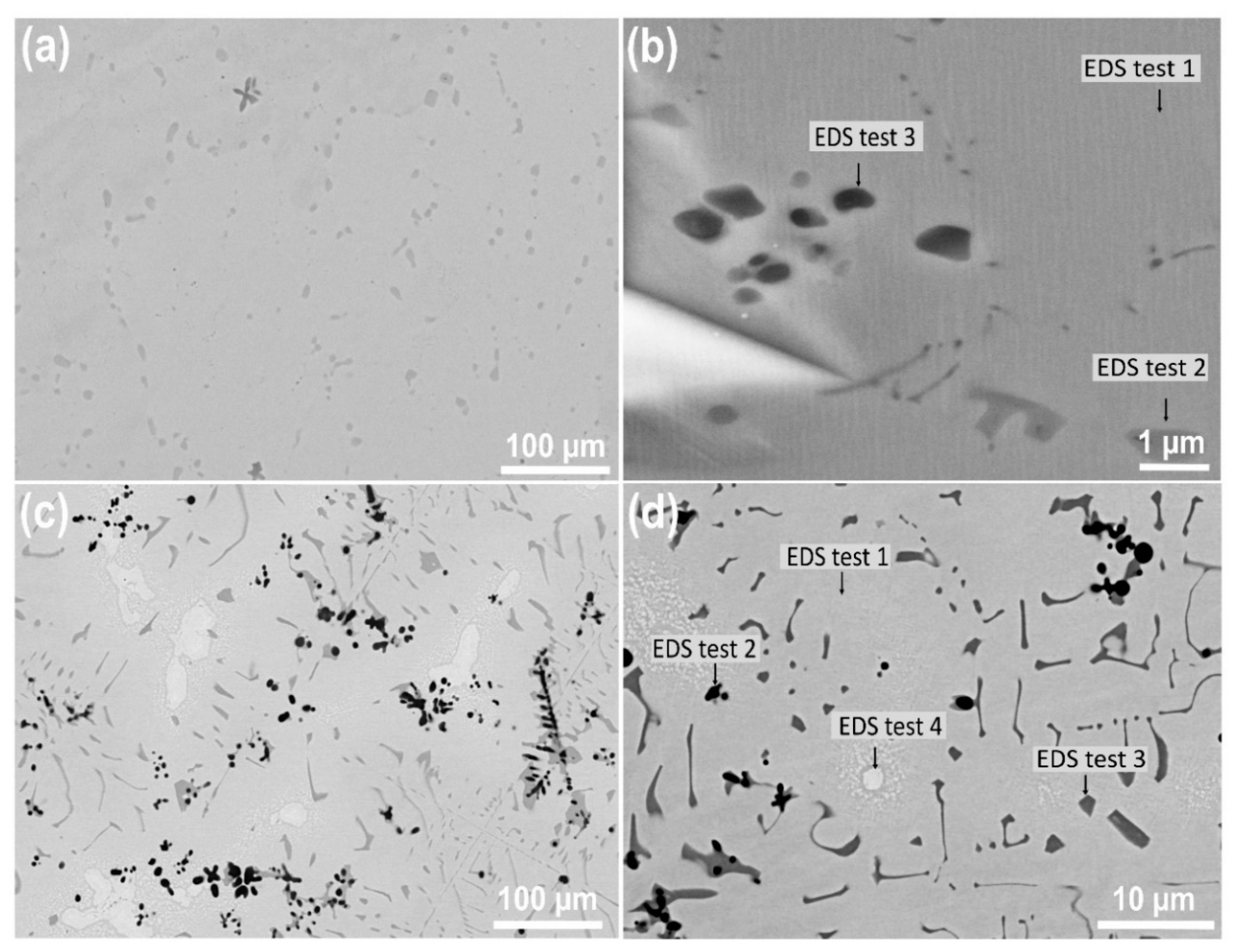

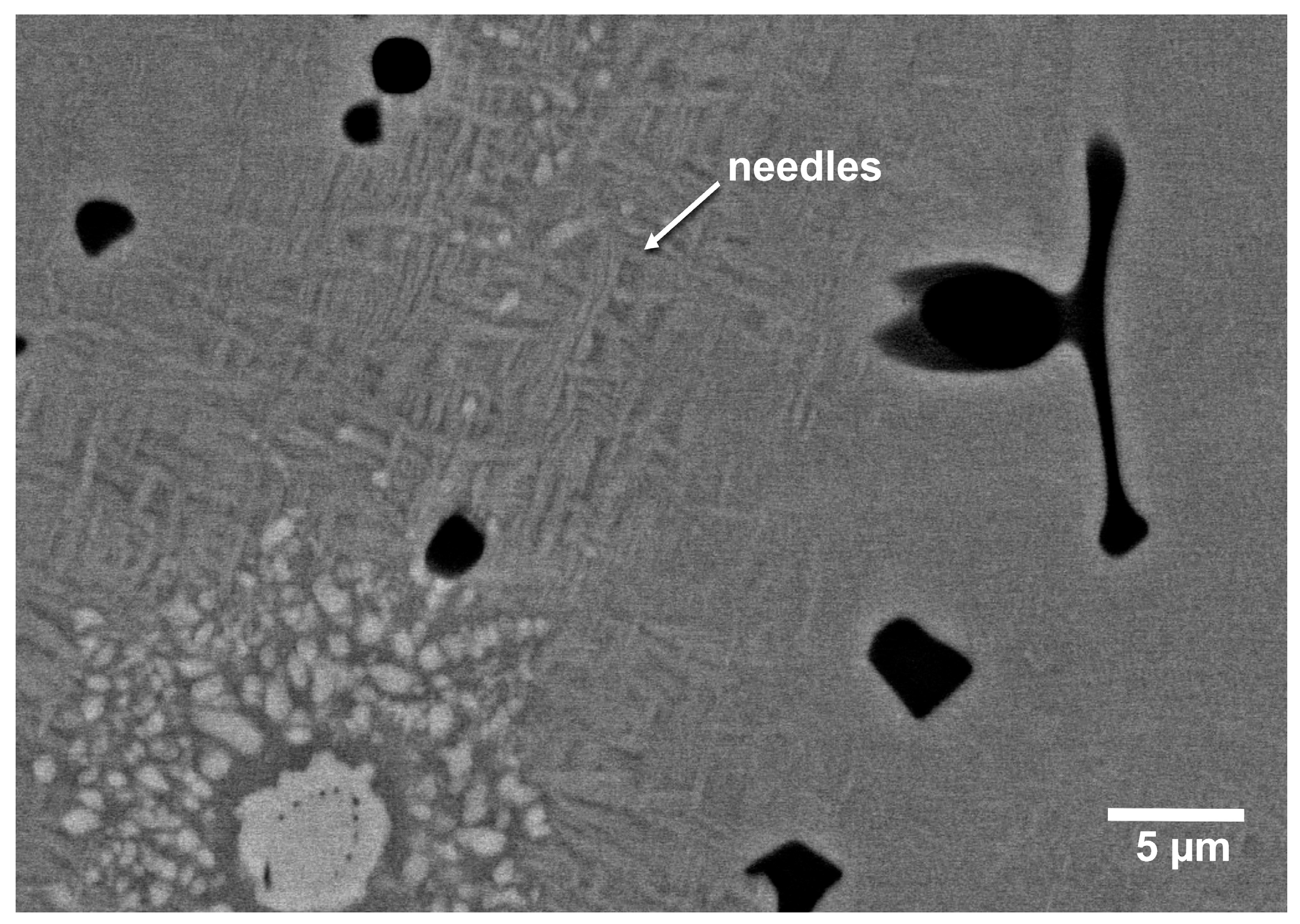

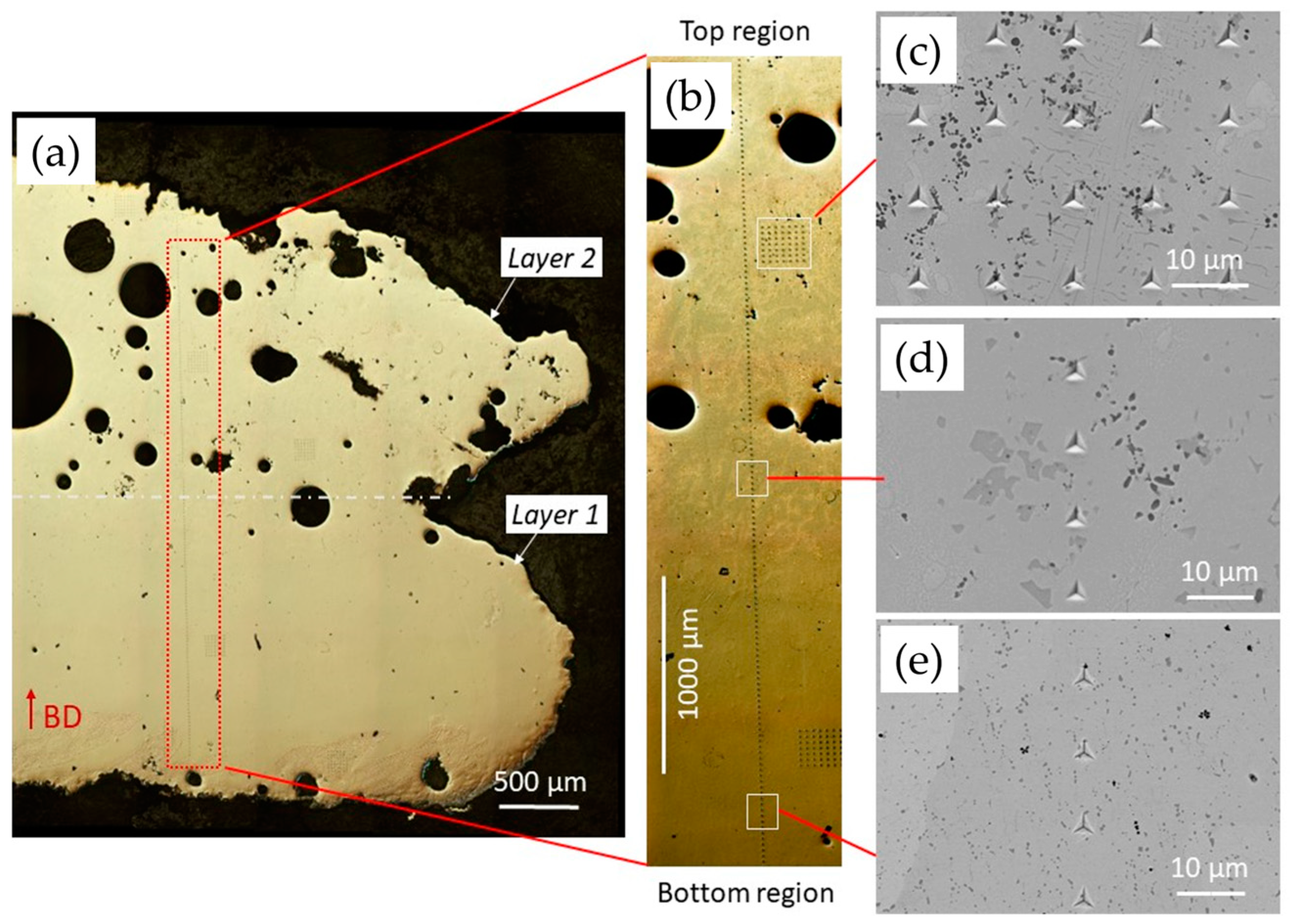

3.2. Microstructure and Chemical Characterization

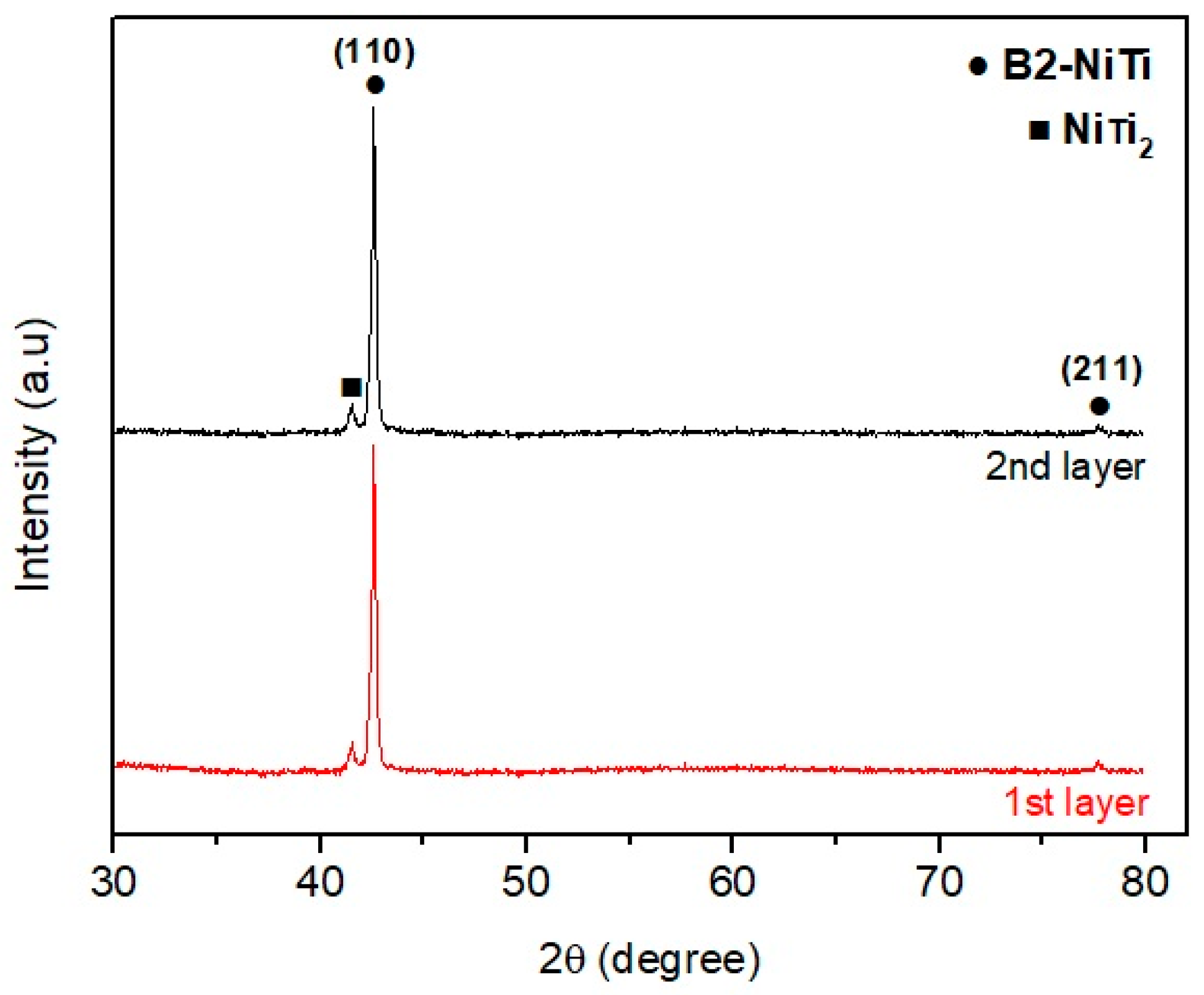

3.3. Phase Analysis

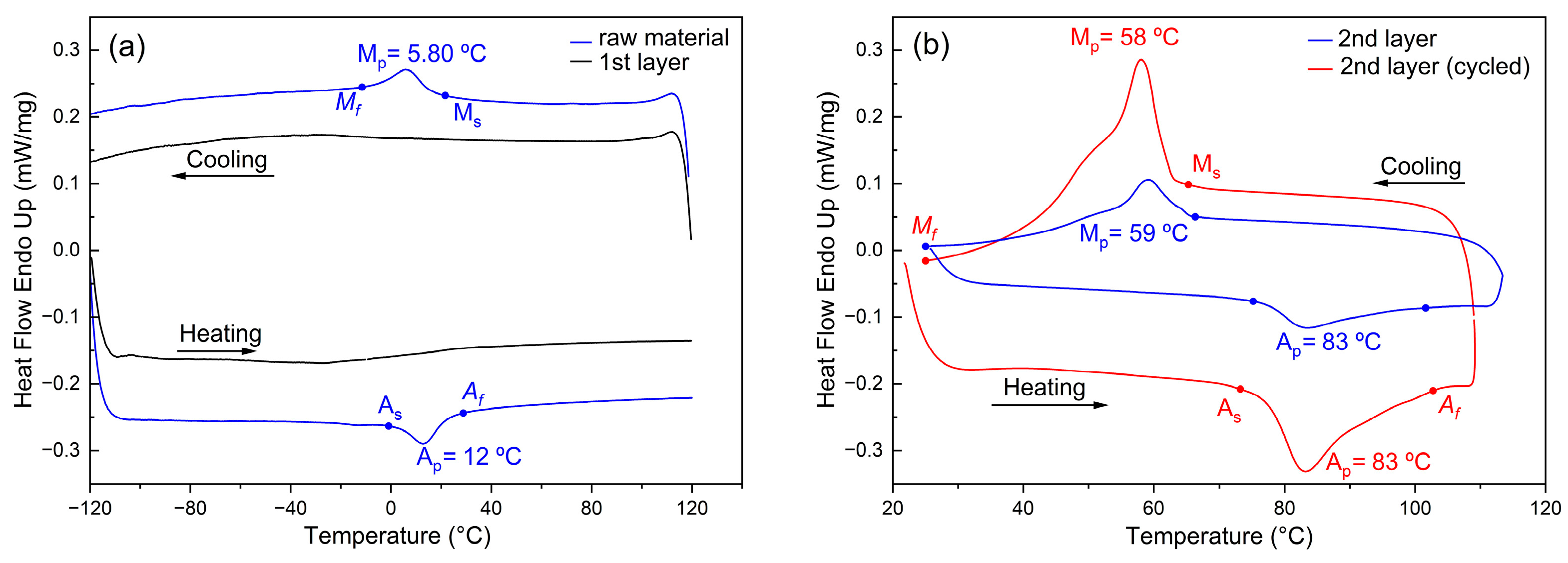

3.4. Phase-Transformation Behavior

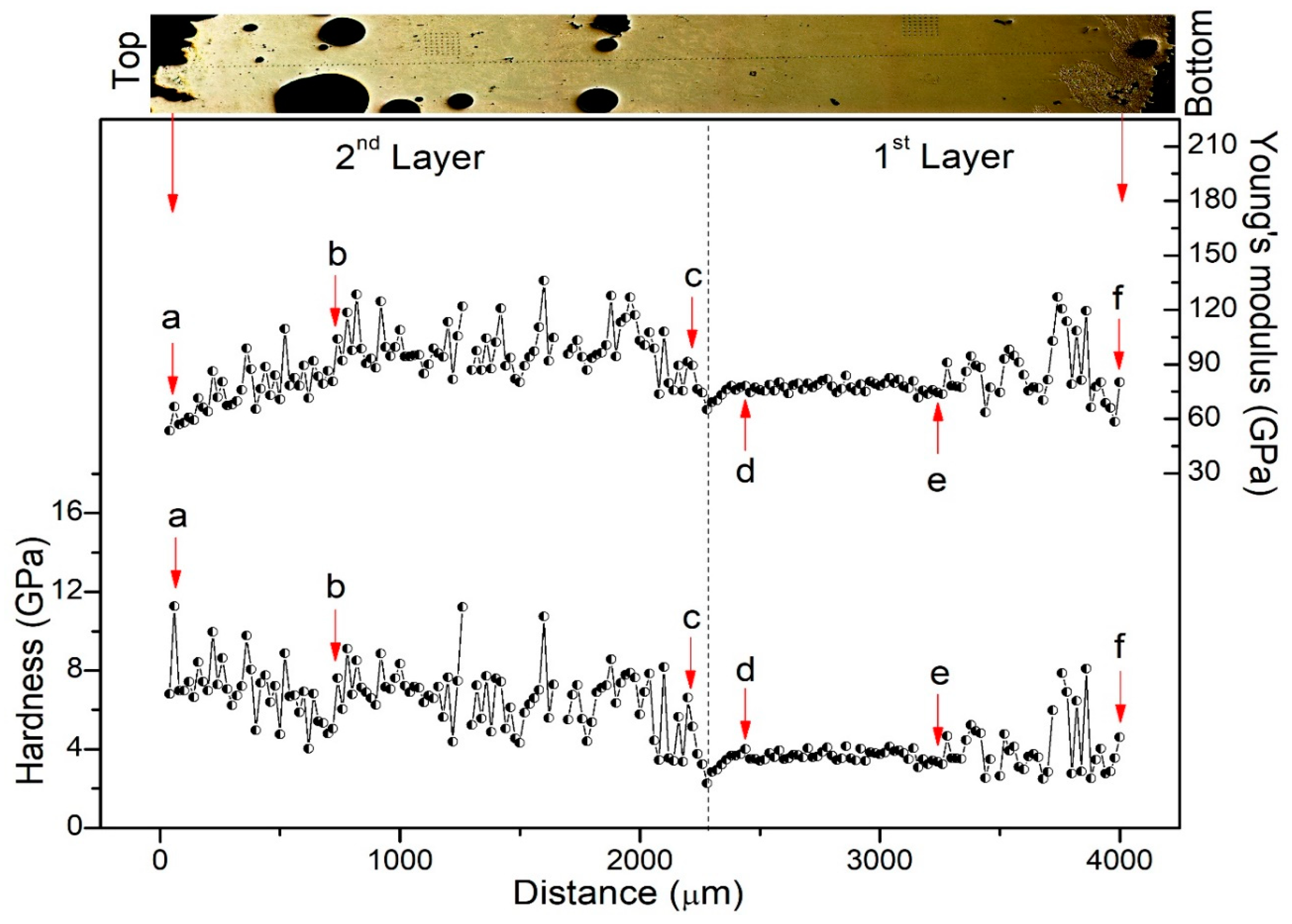

3.5. Mechanical Properties Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Patil, D.; Song, G. Shape memory alloy actuated accumulator for ultra-deepwater oil and gas exploration. Smart Mater. Struct. 2016, 25, 045012. [Google Scholar] [CrossRef]

- Özkul, İ.; Kurgun, M.A.; Kalay, E.; Canbay, C.A.; Aldaş, K. Shape memory alloys phenomena: Classification of the shape memory alloys production techniques and application fields. Eur. Phys. J. Plus 2019, 134, 585. [Google Scholar] [CrossRef]

- Manik, R.; Sahu, M.R. Biocompatibility of NiTi. Nickel-Titanium Smart Hybrid Materials; Elsevier: Amsterdam, The Netherlands, 2022; pp. 173–190. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Tadaki, T.; Otsuka, K.; Shimizu, K. Shape Memory Alloys. Annu. Rev. Mater. Sci. 1988, 18, 25–45. [Google Scholar] [CrossRef]

- Perkins, J. (Ed.) Shape Memory Effects in Alloys; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Gontijo, M.; da Silva, E.P.; de Castro, M.C.S.; dos Santos, C.T.; da Silva, T.C. Influence of deep cryogenic treatment on the pseudoelastic behavior of the Ni57Ti43 alloy. Shap. Mem. Superelasticity 2022, 8, 215–225. [Google Scholar] [CrossRef]

- Sehitoglu, H.; Wu, Y.; Patriarca, L.; Li, G.; Ojha, A.; Zhang, S.; Chumlyakov, Y.; Nishida, M. Superelasticity and shape memory behavior of NiTiHf alloys. Shape Mem. Superelasticity 2017, 3, 168–187. [Google Scholar] [CrossRef]

- Ghosh, P.; Rao, A.; Srinivasa, A.R. Design of multi-state and smart-bias components using shape memory alloy and shape memory polymer composites. Mater. Des. 2013, 44, 164–171. [Google Scholar] [CrossRef]

- Huang, W. On the selection of shape memory alloys for actuators. Mater. Des. 2002, 23, 11–19. [Google Scholar] [CrossRef]

- Kim, H.-C.; Yoo, Y.-I.; Lee, J.-J. Development of a NiTi actuator using a two-way shape memory effect induced by compressive loading cycles. Sens. Actuators A Phys. 2008, 148, 437–442. [Google Scholar] [CrossRef]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Elahinia, M.; Moghaddam, N.S.; Andani, M.T.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Van Humbeeck, J.; Kruth, J.-P. Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: From processes to potential biomedical applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef]

- Lu, H.Z.; Yang, C.; Luo, X.; Ma, H.W.; Song, B.; Li, Y.Y.; Zhang, L.C. Ultrahigh-performance TiNi shape memory alloy by 4D printing. Mater. Sci. Eng. A 2019, 763, 138177. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing: A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Resnina, N.; Palani, I.A.; Belyaev, S.; Singh, S.; Kumar, A.; Bikbaev, R.; Sahu, A. Functional Properties of the Multilayer NiTi Alloy Produced by Wire Arc Additive Manufacturing. Shap. Mem. Superelasticity 2022, 8, 5–15. [Google Scholar] [CrossRef]

- Farber, E.; Zhu, J.-N.; Popovich, A.; Popovich, V. A review of NiTi shape memory alloy as a smart material produced by additive manufacturing. Mater. Today Proc. 2020, 30, 761–767. [Google Scholar] [CrossRef]

- Yu, L.; Chen, K.; Zhang, Y.; Liu, J.; Yang, L.; Shi, Y. Microstructures and mechanical properties of NiTi shape memory alloys fabricated by wire arc additive manufacturing. J. Alloys Compd. 2022, 892, 162051. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. Powder bed fusion processes: An overview. Laser Additive Manufacturing; Woodhead Publishing: Sawston, UK, 2017; pp. 55–77. [Google Scholar]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Bayati, P.; Jahadakbar, A.; Barati, M.; Nematollahi, M.; Saint-Sulpice, L.; Haghshenas, M.; Chirani, S.A.; Mahtabi, M.J.; Elahinia, M. Toward low and high cycle fatigue behavior of SLM-fabricated NiTi: Considering the effect of build orientation and employing a self-heating approach. Int. J. Mech. Sci. 2020, 185, 105878. [Google Scholar] [CrossRef]

- Otubo, J.; Rigo, O.D.; Neto, C.M.; Mei, P.R. The effects of vacuum induction melting and electron beam melting techniques on the purity of NiTi shape memory alloys. Mater. Sci. Eng. A 2006, 438–440, 679–682. [Google Scholar] [CrossRef]

- Lu, B.; Cui, X.; Jin, G.; Dong, M.; Fang, Y.; Ma, W. Effect of La2O3 addition on mechanical properties and wear behaviour of NiTi alloy fabricated by direct metal deposition. Opt. Laser Technol. 2020, 129, 106290. [Google Scholar] [CrossRef]

- Krishna, B.V.; Bose, S.; Bandyopadhyay, A. Fabrication of porous NiTi shape memory alloy structures using laser engineered net shaping. J. Biomed. Mater. Res. B 2009, 89b, 481–490. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Ke, W.C.; Oliveira, J.P.; Cong, B.Q.; Ao, S.S.; Qi, Z.W.; Peng, B.; Zeng, Z. Multi-layer deposition mechanism in ultra-high-frequency pulsed wire arc additive manufacturing (WAAM) of NiTi shape memory alloys. Addit. Manuf. 2022, 50, 102932. [Google Scholar] [CrossRef]

- Treutler, K.; Wesling, V. The Current State of Research of Wire Arc Additive Manufacturing (WAAM): A Review. Appl. Sci. 2021, 11, 6474. [Google Scholar] [CrossRef]

- Zeng, Z.; Cong, B.Q.; Oliveira, J.P.; Ke, W.C.; Schell, N.; Peng, B.; Qi, Z.W.; Ge, F.G.; Zhang, W.; Ao, S.S. Wire and arc additive manufacturing of a Ni-rich NiTi shape memory alloy: Microstructure and mechanical properties. Addit. Manuf. 2020, 32, 101017. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Yang, G.; Han, J.; Chen, X.; Li, H. Location dependence of microstructure, phase transformation temperature and mechanical properties on Ni-rich NiTi alloy fabricated by wire arc additive manufacturing. Mater. Sci. Eng. A 2019, 749, 218–222. [Google Scholar] [CrossRef]

- Khan, M.I.; Pequegnat, A.; Zhou, Y.N. Multiple memory shape memory alloys. Adv. Eng. Mater. 2013, 15, 386–393. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Gouveia, F.M.; Santos, T.G. Micro wire and arc additive manufacturing (µ-WAAM). Addit. Manuf. Lett. 2022, 2, 100032. [Google Scholar] [CrossRef]

- Dornelas, P.H.G.; Santos, T.G.; Oliveira, J.P. Micro-metal additive manufacturing—State-of-art and perspectives. Int. J. Adv. Manuf. Technol. 2022, 122, 3547–3564. [Google Scholar] [CrossRef]

- Dornelas, P.H.G.; Oliveira, J.P.; da Silva, T.C.; Ramos, A.S.; Santos, T.G. Development of a gas metal arc-based prototype for direct energy deposition with micrometric wire. J. Mater. Res. Technol. 2024, 30, 3571–3583. [Google Scholar] [CrossRef]

- Cunningham, C.R.; Flynn, J.M.; Shokrani, A.; Dhokia, V.; Newman, S.T. Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar]

- Spears, T.G.; Gold, S.A. In-process sensing in selective laser melting (SLM) additive manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 16–40. [Google Scholar] [CrossRef]

- Dinovitzer, M.; Chen, X.; Laliberte, J.; Huang, X.; Frei, H. Effect of wire and arc additive manufacturing (WAAM) process parameters on bead geometry and microstructure. Addit. Manuf. 2019, 26, 138–146. [Google Scholar] [CrossRef]

- Jafari, D.; Vaneker, T.H.J.; Gibson, I. Wire and arc additive manufacturing: Opportunities and challenges to control the quality and accuracy of manufactured parts. Mater. Des. 2021, 202, 109471. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects, and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Kohl, M. Shape Memory Microactuators; Springer: Berlin/Heidelberg, Germany, 2004; pp. 62–95. [Google Scholar]

- ASTM F2082-03; Standard Test Method for Determination of Transformation Temperature of Nickel-Titanium Shape Memory Alloys by Bend and Free Recovery. ASTM International: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/f2082-03.html (accessed on 1 July 2023).

- ASTM F67-13; Standard Specification for Unalloyed Titanium, for Surgical Implant Applications (UNS R50250, UNS R50400, UNS R50550, UNS R50700). ASTM: West Conshohocken, PA, USA, 2017.

- Dornelas, P.H.G.; Farias, F.W.C.; da Silva, T.C.; da Cruz Payão Filho, J.; Ramos, A.S.; Oliveira, J.P.; Santos, T.G. Stainless and low-alloy steels additively manufactured by micro gas metal arc-based directed energy deposition: Microstructure and mechanical behavior. Prog. Addit. Manuf. 2024. [Google Scholar] [CrossRef]

- ASTM E407-07; Standard Practice for Microetching Metals and Alloys. ASTM: West Conshohocken, PA, USA, 2016; 7.

- ASTM-F2004-05; Standard Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis. ASTM International: West Conshohocken, PA, USA, 2010; p. 4.

- Carvalho, L.R.A.; Sallica-Leva, E.; Encinas, E.R.; Fogagnolo, J.B. Less-rigid coating in Ti obtained by laser surface alloying with Nb. Surf. Coat. Technol. 2018, 346, 19–28. [Google Scholar] [CrossRef]

- Resnina, N.; Palani, I.A.; Belyaev, S.; Singh, S.; Mani Prabu, S.S.; Bikbaev, R.; Jayachandran, S.; Kalganov, V. Peculiarities of the recoverable strain variation in the NiTi alloy produced by wire arc additive manufacturing. Mater. Lett. 2021, 298, 130004. [Google Scholar] [CrossRef]

- Du, C.; Zhao, Y.; Jiang, J.; Wang, Q.; Wang, H.; Li, N.; Sun, J. Pore defects in Laser Powder Bed Fusion: Formation mechanism, control method, and perspectives. J. Alloys Compd. 2023, 944, 169215. [Google Scholar] [CrossRef]

- Mugwagwa, L.; Yadroitsev, I.; Matope, S. Effect of process parameters on residual stresses, distortions, and porosity in selective laser melting of maraging steel 300. Metals 2019, 9, 1042. [Google Scholar] [CrossRef]

- Pellone, L.; Inamke, G.; Hong, K.M.; Shin, Y.C. Effects of interface gap and shielding gas on the quality of alloy AA6061 fiber laser lap weldings. J. Mater. Process. Technol. 2019, 268, 201–212. [Google Scholar] [CrossRef]

- Kim, C.H.; Ahn, D.C. Influence of process parameters on welding quality during lap welding of aluminum sheets using high brightness disk laser. Adv. Mater. Res. 2011, 264, 361–366. [Google Scholar] [CrossRef]

- Malukhin, K.; Ehmann, K. Material characterization of NiTi-based memory alloys fabricated by the laser direct metal deposition process. J. Manuf. Sci. Eng. 2006, 128, 691–696. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, S.; Lin, P.; Zong, X.; Chen, Z.; Zhang, Z.; Ren, L. Analysis of microstructure, mechanical properties, and wear performance of NiTi alloy fabricated by cold metal transfer-based wire arc additive manufacturing. J. Mater. Res. Technol. 2022, 20, 246–259. [Google Scholar] [CrossRef]

- Song, D.; Wang, T.; Wei, L.; Jiang, S. Microstructure evolution and functional response of NiTi shape memory alloy manufactured by dual-wire electron beam freeform fabrication. J. Manuf. Process. 2024, 119, 842–855. [Google Scholar] [CrossRef]

- Teng, J.Z.; Jiang, P.F.; Cui, X.H.; Nie, M.H.; Li, X.R.; Liu, C.Z.; Zhang, Z.H. Revealing microstructural evolutions, mechanical properties and wear performance of wire arc additive manufacturing homogeneous and heterogeneous NiTi alloy. J. Mater. Res. Technol. 2023, 27, 1593–1610. [Google Scholar] [CrossRef]

- Tadayyon, G.; Mazinani, M.; Guo, Y.; Zebarjad, S.M.; Tofail, S.A.M.; Biggs, M.J.P. Study of the microstructure evolution of heat-treated Ti-rich NiTi shape memory alloy. Mater. Charact. 2016, 112, 11–19. [Google Scholar] [CrossRef]

- Pu, Z.; Du, D.; Wang, K.; Liu, G.; Zhang, D.; Zhang, H.; Xi, R.; Wang, X.; Chang, B. Study on the NiTi shape memory alloys in-situ synthesized by dual-wire-feed electron beam additive manufacturing. Addit. Manuf. 2022, 56, 102886. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Bimber, B.A.; Palmer, T.A. Correlating microstructure and superelasticity of directed energy deposition additive manufactured Ni-rich NiTi alloys. J. Alloys Compd. 2018, 739, 712–722. [Google Scholar] [CrossRef]

- Halani, P.R.; Kaya, I.; Shin, Y.C.; Karaca, H.E. Phase transformation characteristics and mechanical characterization of nitinol synthesized by laser direct deposition. Mater. Sci. Eng. A. 2013, 559, 836–843. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Liu, Y.; An, J.; Chua, C.K.; Shen, Y.F.; Kuo, C.N. A review of selective laser melted NiTi shape memory alloy. Materials 2018, 11, 519. [Google Scholar] [CrossRef] [PubMed]

- Khalil-Allafi, J.; Dlouhy, A.; Eggeler, G. Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations. Acta Mater. 2002, 50, 4255–4274. [Google Scholar] [CrossRef]

- Chen, Z.; Qin, S.; Shang, J.; Wang, F.; Chen, Y. Size effects of NiTi nanoparticle on thermally induced martensitic phase transformation. Intermetallics 2018, 94, 47–54. [Google Scholar] [CrossRef]

- ASTM F2063-18; Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants. ASTM International: West Conshohocken, PA, USA, 2018.

- Šittner, P.; Heller, L.; Pilch, J.; Curfs, C.; Alonso, T.; Favier, D. Young’s Modulus of Austenite and Martensite Phases in Superelastic NiTi Wires. J. Mater. Eng. Perform. 2014, 23, 2303–2314. [Google Scholar] [CrossRef]

- Gall, K.; Juntunen, K.; Maier, H.J.; Sehitoglu, H.; Chumlyakov, Y.I. Instrumented micro-indentation of NiTi shape-memory alloys. Acta Mater. 2001, 49, 3205–3217. [Google Scholar] [CrossRef]

- Niklas, A.; Santos, F.; Garcia, D.; Rouco, M.; González-Martínez, R.; Pereira, J.C.; Rayón, E.; Lopez, P.; Guillonneau, G. Chemical composition effects on the microstructure and hot hardness of NiCrSiFeB self-fluxing alloys manufactured via gravity casting. J. Manuf. Mater. Process. 2023, 7, 196. [Google Scholar] [CrossRef]

- Li, Y.; Tang, S.; Gao, Y.; Ma, S.; Zheng, Q.; Cheng, Y. Mechanical and thermodynamic properties of intermetallic compounds in Ni-Ti system. Int. J. Mod. Phys. B 2017, 31, 1750161. [Google Scholar] [CrossRef]

| Composition | Ni | Ti | C | Fe | H | O | N | Others |

|---|---|---|---|---|---|---|---|---|

| Wire (wt %) | 56.03 | bal. | 0.0284 | 0.0081 | <0.005 | 0.0239 | - | <0.2485 |

| Substrate 1 (wt %) | - | bal. | ≤0.08 | ≤0.30 | ≤0.015 | ≤0.25 | ≤0.03 | - |

| Travel Speed (mm/s) | Current Peak (A) | Arc Voltage (V) | Wire Feed Speed (mm/s) | Ar Flow Rate (L/min) |

|---|---|---|---|---|

| 4 | 78 | 17.5 | 7.4 | 10 |

| Position | Elements (at%) | |

|---|---|---|

| 1st Layer | 2nd Layer | |

| 1 | 49.93 Ni + 50.07 Ti | 52.56 Ni + 47.44 Ti |

| 2 | 49.82 Ni + 50.18 Ti | 07.21 Ni + 92.79 Ti |

| 3 | 25.71 Ni + 74.29 Ti | 35.22 Ni + 64.78 Ti |

| 4 | - | 62.66 Ni + 37.34 Ti |

| Materials | Phase Transformation Temperature (°C) 1 | |||||

|---|---|---|---|---|---|---|

| Ms | Mp | Mf | As | Ap | Af | |

| Wire (raw material) | 20.40 | 5.80 | −5.40 | 2.10 | 12.00 | 23.60 |

| 2nd layer | 64.60 | 59.14 | 24.90 | 75.80 | 83.07 | 96.40 |

| 2nd layer cycled | 63.14 | 58.00 | 24.20 | 76.20 | 83.00 | 95.80 |

| Element | As-Received Wire (wt %) | NiTi Part (wt %) | ASTM F2063 (wt %) | |

|---|---|---|---|---|

| 1st Layer | 2nd Layer | |||

| Oxygen | 0.0239 ± 0.04 | 0.212 ± 0.033 | 0.262 ± 0. 038 | max. 0.040 |

| Nitrogen | 0.0004 ± 0.026 | 0.066 ± 0.008 | 0.0835 ± 0.0116 | max. 0.005 |

| Hydrogen | <0.005 ± 0.0008 | 0.0009 ± 0.0002 | 0.00114 ± 0.00004 | max. 0.005 |

| Layer | H (GPa) | E (GPa) | Phase |

|---|---|---|---|

| 1st | 3.8 | 70 | B2-NiTi |

| 2nd | 4.5 | - | NiTi2 |

| 6.7 | 85 | B2-NiTi | |

| 8 | 105 | α-Ti | |

| 15 | 135 | Ni3Ti |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, T.C.; Sallica-Leva, E.; Rayón, E.; Santos, C.T.; Filho, J.C.A.D.; Volpato, N.; Lima, D.D.; Dornelas, P.H.G.; Tavares, S.S.M.; Santos, T.G. Microstructure, Thermal, and Mechanical Behavior of NiTi Shape Memory Alloy Obtained by Micro Wire and Arc Direct Energy Deposition. J. Manuf. Mater. Process. 2025, 9, 57. https://doi.org/10.3390/jmmp9020057

da Silva TC, Sallica-Leva E, Rayón E, Santos CT, Filho JCAD, Volpato N, Lima DD, Dornelas PHG, Tavares SSM, Santos TG. Microstructure, Thermal, and Mechanical Behavior of NiTi Shape Memory Alloy Obtained by Micro Wire and Arc Direct Energy Deposition. Journal of Manufacturing and Materials Processing. 2025; 9(2):57. https://doi.org/10.3390/jmmp9020057

Chicago/Turabian Styleda Silva, Tadeu C., Edwin Sallica-Leva, Emilio Rayón, Claudio T. Santos, João C. A. D. Filho, Neri Volpato, Dalton D. Lima, Paulo H. G. Dornelas, Sergio S. M. Tavares, and Telmo G. Santos. 2025. "Microstructure, Thermal, and Mechanical Behavior of NiTi Shape Memory Alloy Obtained by Micro Wire and Arc Direct Energy Deposition" Journal of Manufacturing and Materials Processing 9, no. 2: 57. https://doi.org/10.3390/jmmp9020057

APA Styleda Silva, T. C., Sallica-Leva, E., Rayón, E., Santos, C. T., Filho, J. C. A. D., Volpato, N., Lima, D. D., Dornelas, P. H. G., Tavares, S. S. M., & Santos, T. G. (2025). Microstructure, Thermal, and Mechanical Behavior of NiTi Shape Memory Alloy Obtained by Micro Wire and Arc Direct Energy Deposition. Journal of Manufacturing and Materials Processing, 9(2), 57. https://doi.org/10.3390/jmmp9020057