1. Introduction

Machining efficiency and performance are directly controlled by influential cutting parameters such as cutting speed, feed rate, and depth of cut. These parameters directly influence critical process outputs such as cutting forces, tool wear, surface roughness, chip morphology, and segmentation. These outputs have direct impacts on surface integrity, dimensional accuracy, tool life, energy consumption and process economics overall [

1,

2,

3]. In the quest for high-productivity, high-precision and sustainable machining, in-depth and holistic knowledge of how these variables relate to one another is no longer just a wish but a necessity. Despite much research being conducted over the decades, understanding the intricately connected and, in many cases, non-linear dependence between cutting parameters and machining responses is still a mountainous task. Variability caused by workpiece material characteristics, tool geometries, coatings and cooling/lubrication conditions also makes predictive modeling and process optimization challenging. At the same time, ongoing innovation in manufacturing, driven by digitalization, automation, and the advent of Industry 4.0 technologies, demands a rethink of traditional machining models [

4,

5,

6]. New machine tools, with force, vibration and temperature in-process measurement sensors, open up new opportunities for gathering in-process data and developing data-based techniques of adaptive control and decision-making [

7,

8,

9]. In this regard, the present research conducts a systematic and detailed experimental examination of the machining of steel alloys with the objective of clarifying the effects of variation in cutting speed, depth of cut and laser texturing of cutting tools on fundamental machining responses. Specifically, the study examines cutting force evolution, tool wear mechanisms, machined workpiece superficial roughness, chip morphology and segmentation. By examining these phenomena in controlled circumstances, this research aims to derive both quantitative and qualitative information which could be used to direct process planning and tool design. This research adds to the integrated analytical literature. Rather than analyzing output parameters individually, the research accounts for interdependencies and interactions between them. For instance, changes in chip morphology can be an indicator of hidden changes in cutting forces or wear evolution; growth in superficial roughness may signal inadequate chip evacuation or thermal degradation along the tool–workpiece interface [

10,

11,

12]. Through examining such relationships, this investigation tries to identify causal relationships that can form the foundation for predictive, high-level process models.

The inclusion of laser-textured tools is a significant aspect of this research. Cutting tool texturing has recently attracted considerable attention due to its ability to modify the tool–chip interface, enhance heat transfer, reduce friction and extend tool life [

13,

14,

15]. In particular, Özel et al. [

13] provide a comprehensive review of structured and textured cutting tool surfaces—covering their applications in turning, milling and drilling—demonstrating that micro- and nano-scale textures on rake and flank faces can improve chip flow, increase lubricant retention, reduce cutting forces and delay tool wear. These findings support the choice of laser texturing as a key experimental factor in this study. Despite these advantages, the combined effects of laser texturing and conventional cutting parameters on machining performance are still not fully understood. Therefore, the present research seeks to fill this gap in the milling of hardened steel by systematically investigating the interactions between tool surface engineering and machining variables, examining their influence on cutting forces, tool wear mechanisms, chip formation and surface integrity.

Milling of hardened or alloy steel is one of the toughest operations, as the material exhibits very high mechanical strength and generates severe forces and high temperatures during cutting, which are adverse conditions for the tool and degrade its surface quality, so process optimization is highly important [

16,

17,

18,

19]. While many studies have investigated single topics, such as tool wear under specific cutting conditions or high-speed machining influences, there are also studies addressing multiple process variables and their effects on machining outcomes. In this context, the present study aims to provide an additional contribution by systematically investigating the combined influence of three process parameters (cutting speed, depth of cut and laser tool texturing) on seven experimental responses (related to cutting force, chip morphology and surface roughness), thus extending the current understanding of multi-variable and multi-response machining analysis. By capturing real-time force data, tracking the development of wear mechanisms over time and describing the chip formation process in tandem with surface finish outcomes, this research provides an integrated view of the machining process.

The revised methodology will strengthen the scientific robustness of the study by incorporating widely recognized analytical and statistical tools used in machining research. Specifically, ANOVA is employed to quantify the statistical significance of each of the cutting factors in order to highlight the dominant effects and interactions that are necessary for distinguishing the true influence of the parameters from measurement variability [

20,

21,

22]. Furthermore, multi-objective Pareto-based analysis is applied to determine optimal trade-offs between often conflicting machining objectives, like minimizing forces while maximizing surface finish, leading to an improved decision-making process in practice. Lastly, the novelty of this study lies in its data-driven and multidimensional perspective. Through its integrated analysis of tool behavior, chip formation and surface integrity, the study aims to contribute to predictive modeling and intelligent control. Such contributions are expected to benefit the general transition to smart manufacturing systems with real-time decision-making, adaptive optimization and sustainable production. By addressing applied and basic machining science problems, this research provides beneficial information for academic researchers, industrialists and tool manufacturers alike. In this manner, it bridges existing literature gaps and supports the growing development of metal cutting operations in the Industry 4.0 era.

2. Experimental Procedure

Full-face milling tests were performed on AISI 1050 steel (

Table 1), provided as a cuboid sample W 400 × H 40 × L 380 mm, heat-treated by quenching at 840 °C followed by tempering at 320 °C to reach a final hardness of 48 HRC.

The experiments were conducted on a CNC milling center (MAZAK NEXUS 410, Oguchi, Aichi Prefecture, Japan) using a WZP 211/11/0.8/M45 insert (an indexable insert for 90° shoulder milling cutters featuring a soft-cut geometry that ensures stable machining, low vibration, and high surface quality) mounted on an A211/40/R/04/11 tool holder (both provided by Meusburger, Wolfurt, Vorarlberg, Austria), with a cutting width (ae) of 40 mm.

The original surface coating was first removed from the 8 as-received inserts. The inserts were then textured in two sets of four (two different texture configurations) using a laser, after which all inserts were recoated with a TiN layer of approximately 4 μm average thickness.

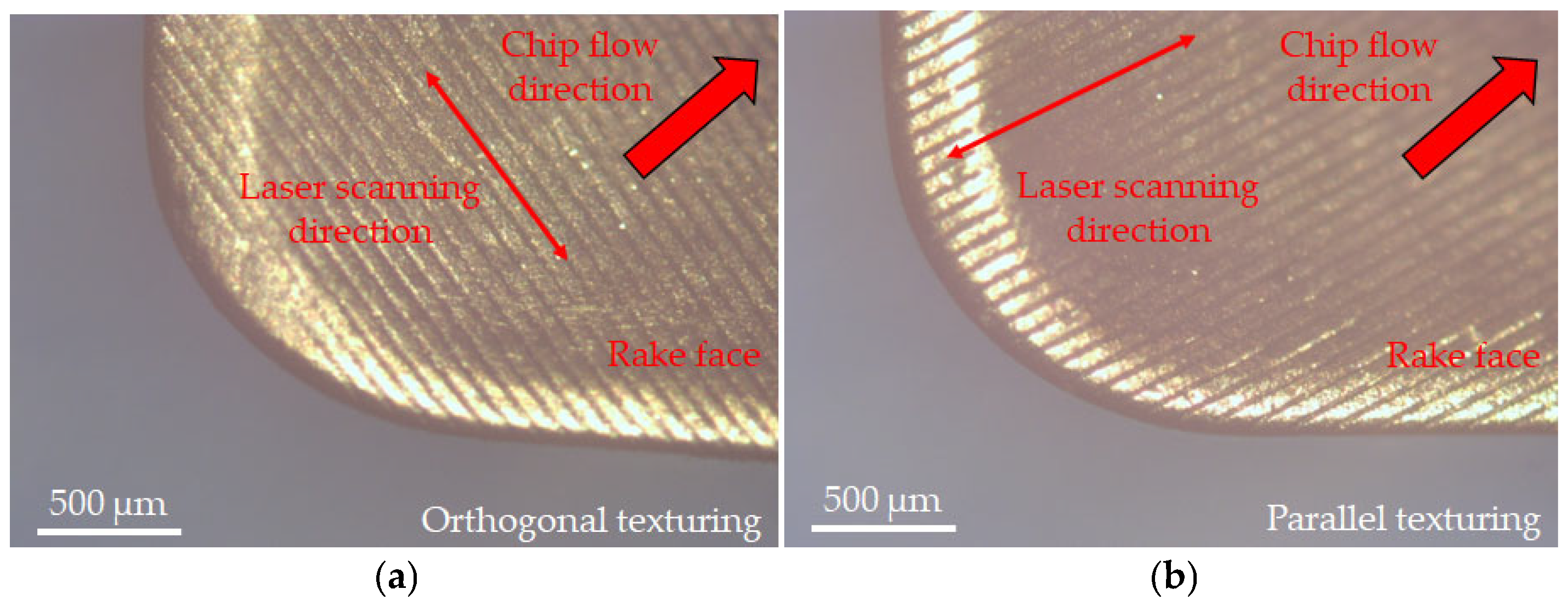

Micro-texturing of the rake face was performed using an Ekspla Atlantic 50 picosecond laser operating (Ekspla, Alytus, Lithuania) with a 10 ps pulse duration and a 1064 nm central wavelength. The laser system consists of a beam expander, a Raylase galvanometric scanning head, and an f-theta lens, producing a beam diameter of approximately 10 μm on the insert surface. The selected processing parameters were 500 kHz repetition rate, 0.95 W average power, 500 mm/s scanning speed and scanning of a 20 µm wide rectangular area to compensate for the coating thickness. An 80% overlap between adjacent scan lines and four passes at different focal heights were employed to accommodate the complex insert geometry. As shown in

Figure 1, the resulting micro-textures comprise microgrooves of 12 µm in width and 4 μm in depth, spaced 60 μm apart, produced in two configurations: grooves oriented parallel to the chip flow direction and grooves oriented perpendicular to it.

A Kistler 5167A81 piezoelectric dynamometer was used for force detection: feed force (F

x), cutting force (F

y) and thrust force (F

z). The experimental plan consisted of twelve machining parameter combinations (full factorial design), derived from three axial depth of cut (a

p) levels and two cutting speeds (V

c), replicated for both inserts, for a fixed value of feed rate (v

f) of 1000 m/min (

Table 2), defining the machining parameters in accordance with the Meusburger guideline. Experiments were carried out under wet cooling conditions applying a conventional cutting fluid through the cooling channels of the milling center at a flow rate of 120 mL/s. Three replications were performed for each test to ensure the robustness of the obtained results for a total of 36 tests. For each machining condition, 5700 mm of material were machined to evaluate the evolution of the tool wear state.

After milling, a detailed analysis of superficial roughness was conducted using a Mitutoyo SJ-410 surface roughness tester. In particular, the arithmetical mean height (Ra) and the maximum height (Rz) were evaluated along the feed direction, as these metrics are highly indicative of surface integrity and functional performance. Measurements were taken over multiple regions of the machined surface to ensure statistical robustness and to provide a representative description of the height distribution and surface morphology. Chips were mounted and processed for chip micromorphology (chip peak and pitch and spiral pitch) analysis. Furthermore, tool wear analysis was carried out on the inserts. It is worth pointing out that the analysis of tool wear and chip morphology was performed using a LEICA DFC 320 (Wetzlar, Germany) optical microscope (×1000).

3. Experimental Results and Discussion

3.1. Cutting Forces

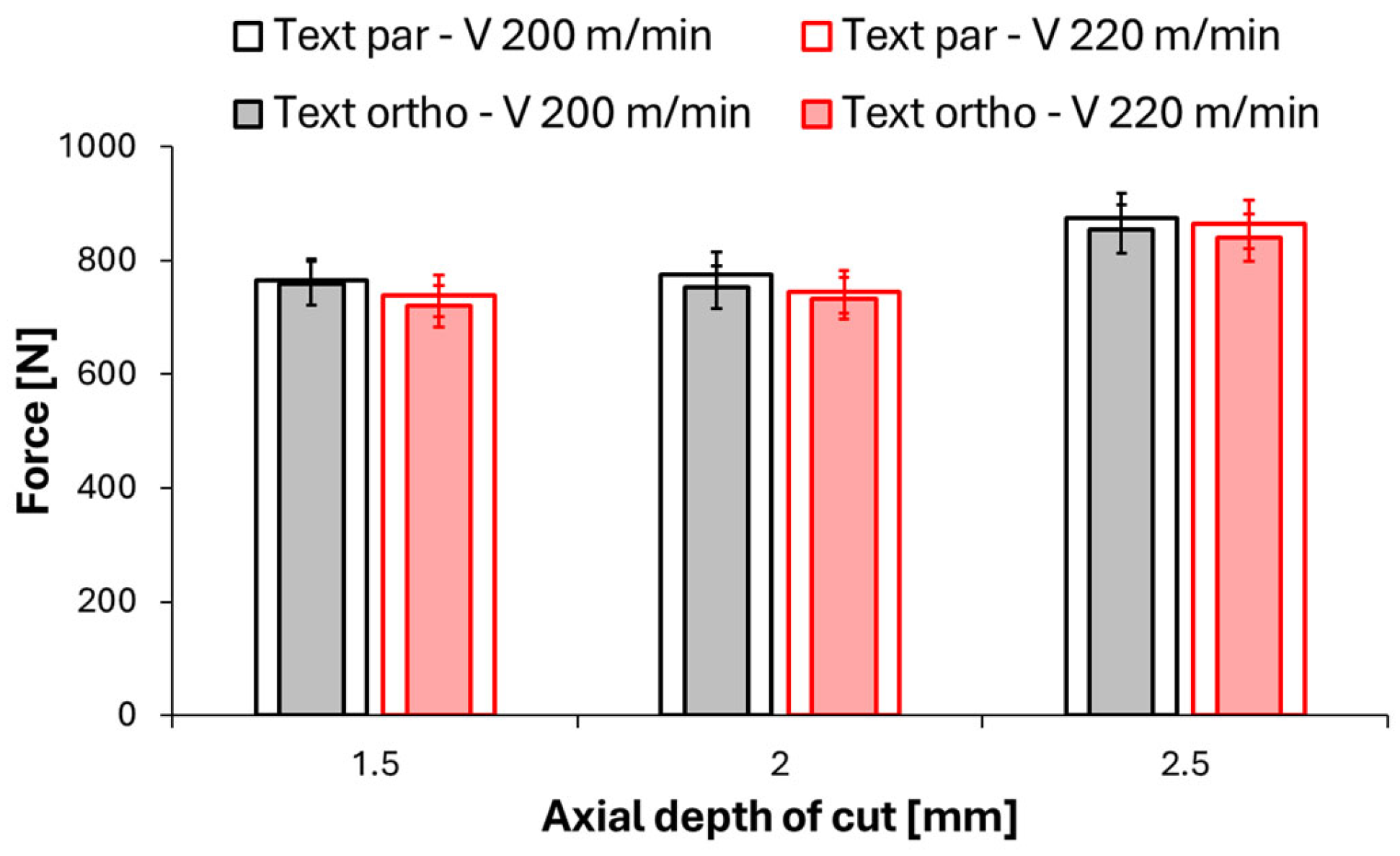

Figure 2 shows the influence of cutting parameters (axial depth of cut and cutting speed) and tool texturing on the resultant cutting force.

The results clearly reveal that the axial depth of the cut significantly affects the cutting forces. Increasing the depth of the cut from 1.5 mm to 2.5 mm leads to a significant increase in the cutting forces under all conditions. For example, at a cutting speed of 200 m/min, the average increase in the cutting forces is around 15%, regardless of the tool texturing orientation. This is expected because larger depths of cut mean more material removal along with increased tool–workpiece interaction, which requires more mechanical energy. Tool texturing orientation also has a minor effect on the cutting forces. The orthogonal texture to the chip flow direction yields slightly lower cutting forces than that of the parallel texture. The reduction is in the range of 1–3%, with the maximum difference obtained at lower cutting speeds and depths. This can be explained by the better tribological conditions at the tool–chip interface because the orthogonal texturing would disrupt the continuous chip contact, resulting in improved chip evacuation and friction reduction, which was also supported in the literature [

13]. The effect of cutting speed is present but moderate within the investigated range. Specifically, increasing the cutting speed from 200 m/min to 220 m/min results in a slight decrease in cutting forces for all textures and depths, which can be attributed to thermal softening of the work material and reduced friction in this specific speed interval. These findings altogether point to the fact that even though a higher cutting speed and orthogonal tool texturing reduce cutting forces, the increase in axial depth of the cut increases the mechanical load significantly during machining.

3.2. Tool Wear

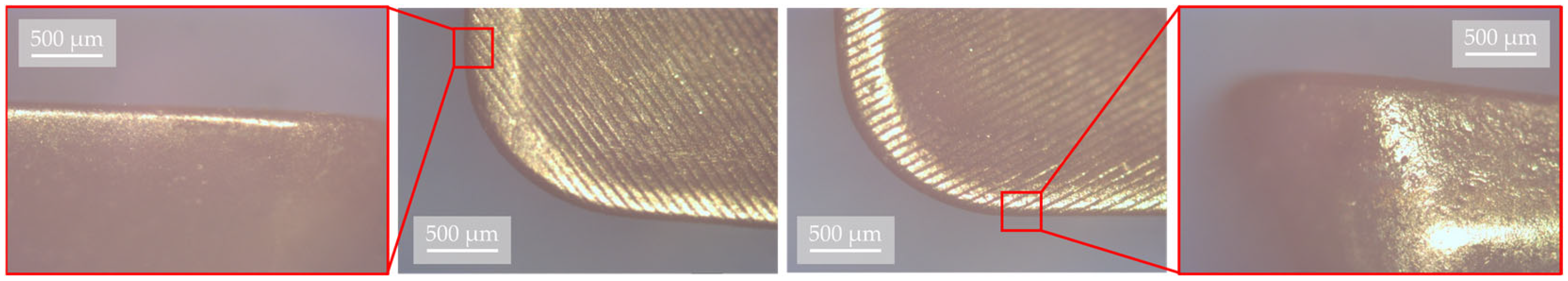

Figure 3 shows the influence of cutting parameters (axial depth of cut and cutting speed) and tool texturing on the tool wear behavior.

In this regard, neither of the two textured tools showed any evident signs of wear during the whole experimental campaign. This behavior could reasonably be related to the high quality of the coating applied on the tool surfaces, showing good adhesion and uniformity. If not, delamination or localized failure, especially in the most mechanically and thermally stressed areas, would likely have been present. This is particularly true for interrupted cutting conditions typical of face milling. The coating integrity under the applied cutting parameters witnesses not only the effectiveness of the surface engineering process but also its functionality in protecting the substrate from premature degradation. Moreover, it has to be considered that the total machined length was relatively limited. This preliminary analysis did not allow even the first stages of wear initiation to be detected. The relatively short cutting distance was adequate to establish a steady-state condition for cutting force behavior under different texturing conditions. However, it was not sufficient to develop or detect progressive wear mechanisms such as flank wear, crater formation, or coating breakdown. Although the present results are encouraging regarding tool integrity, further prolonged testing is required to draw more robust experimental conclusions on the wear evolution and tool life of textured milling tools.

3.3. Chip Morphology

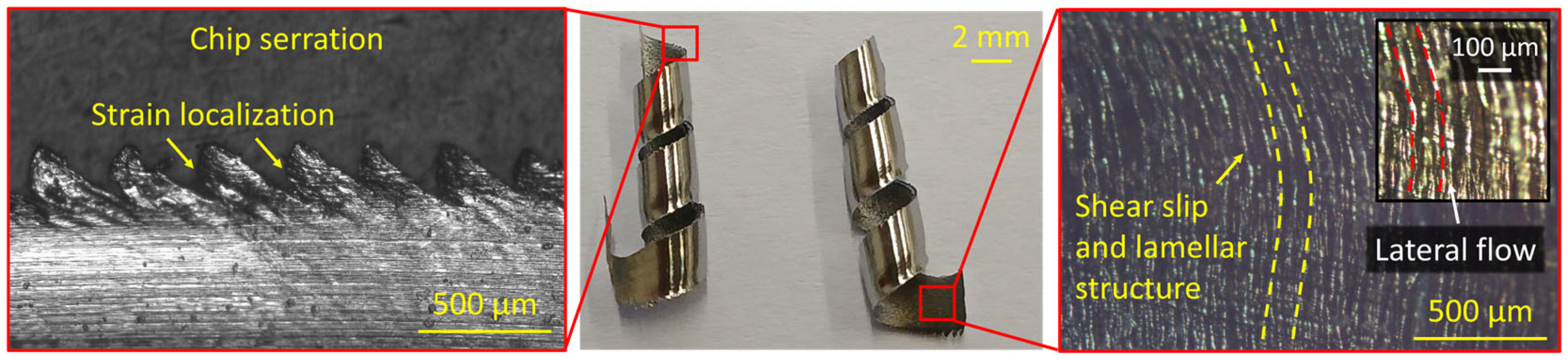

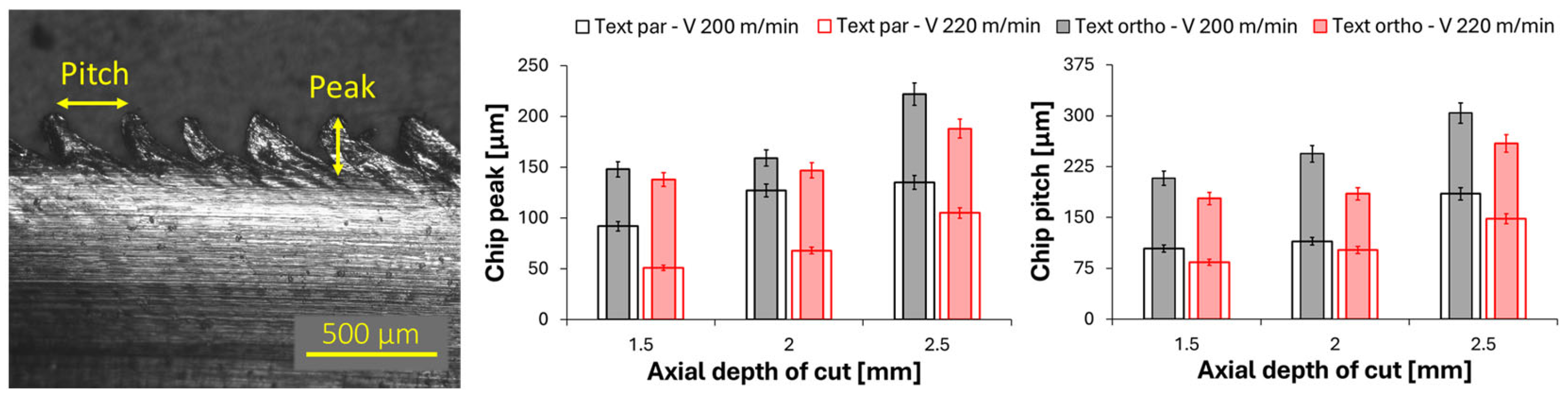

During all tests, short tubular chips were obtained, with lengths ranging between 10 and 15 mm. The chip surface not in contact with the tool exhibited the typical saw-tooth geometry that follows the shear slip pattern, as shown in

Figure 4.

Figure 5 illustrates the influence of cutting parameters (axial depth of cut and cutting speed) and tool texturing orientation on the chip peak and pitch serration measured on the chip-free surface. A clear distinction emerges between the two texturing orientations. When the tool texture is aligned parallel to the chip flow direction, both the peak and pitch values are consistently lower compared with those obtained using the orthogonal texture, which shows an average increase of approximately 70–100% over the parallel configuration. This increase, however, should not be interpreted as a deterioration in chip formation quality. As confirmed by the lower cutting forces measured for the orthogonal texture, this configuration enhances the tribological behavior at the tool–chip interface. The orthogonal grooves effectively disrupt the continuous chip–tool contact, acting as micro-reservoirs for the coolant and as channels that promote chip detachment. This mechanism reduces adhesion and friction while facilitating smoother chip evacuation. Consequently, the higher peak and pitch values observed under orthogonal texturing reflect the formation of more segmented yet better-controlled chips rather than irregular or unstable ones. Chip fragmentation occurs more readily, producing larger wavelength undulations associated with improved lubrication and a shorter contact length.

For both texturing orientations, increasing the axial depth of the cut from 1.5 mm to 2.5 mm is associated with a significant increase in both peak and pitch morphology. In the orthogonal setup, at a cutting speed of 200 m/min, the peak increases by about 50% and the pitch by around 45%. A similar but less pronounced trend is seen in the parallel configuration. Such behavior is related to the increased material removal rate, since this enhances the mechanical burden on the cutting edge and the energy involved in plastic deformation. Even under wet conditions, where frictional heat is satisfactorily dissipated by coolant, higher depths enhance the tendency for thicker and more undulated chips. Generally, an increase in cutting speed from 200 m/min to 220 m/min produces a reduction of about 10–25% in peak and pitch chip morphology values. For example, for the parallel configuration at 1.5 mm depth, the peak amplitude decreases by about 45%, while the pitch decreases by nearly 20%. This trend is mainly associated with the thermal–mechanical behavior of the cutting process. For higher cutting speeds, plastic deformation and frictional energy generation at the tool–chip interface increases, giving rise to a moderate increase in the local temperature. Thermal softening of the work material reduces its flow stress, which favors chip deformation, therefore resulting in smoother and more uniform chip surfaces with smaller serration amplitudes. Under wet cutting conditions, the coolant plays a decisive role in balancing this temperature rise. The fluid efficiently removes the heat from both the primary and secondary shear zones, avoiding steep thermal gradients that may otherwise destabilize chip formation or accelerate tool wear. Moreover, the coolant that infiltrates the micro-textured tool surface improves lubrication, in which the effective friction coefficient decreases to suppress built-up edge formation. These two contributory factors—controlled thermal softening and improved tribological behavior—bring down the cutting forces and facilitate stable, continuous chip flow even at higher cutting speeds. Within the orthogonal setup, the coolant’s infiltration into the transverse grooves increases the lubrication effect, promotes intermittent chip contact, and facilitates chip detachment. On the other hand, if the texture is parallel to the chip flow, the coolant penetration is less effective because the grooves run in the direction of the flow with fewer access channels. Thus, the cooling effect remains strong, while the lubricating effect is comparatively weaker. This complementary behavior explains the experimentally observed trend where the orthogonal texture produces lower cutting forces and larger, more easily segmented chips, and the parallel texture generates smaller and more continuous chips with slightly higher cutting forces. While the chip contact is interrupted and coolant penetration is enhanced by the orthogonal tool texture, it causes reduced friction and promotes enhanced chip evacuation that results in larger but well-controlled chip segmentation. Contrasting this, the parallel texture maintains a smoother, more continuous chip flow with smaller peaks and pitches but with slightly higher cutting loads. Chip morphology dimensions increase with increased axial depth of cut, whereas chip regularity improves with a higher cutting speed due to controlled thermal softening and efficient cooling. On the whole, orthogonal tool texturing combined with an appropriate cutting speed provides the most balanced chip formation behavior under wet machining conditions, minimizing cutting forces while maintaining effective chip segmentation and evacuation.

Figure 6 illustrates the influence of cutting parameters on the chip pitch spiral length.

In general, the pitch spiral length increases progressively with both cutting speed and axial depth of cut, following the same mechanical trend observed for chip peak and pitch morphology. When the tool texture is parallel to the chip flow direction, the pitch spiral morphology increases as the axial depth of the cut rises from 1.5 mm to 2.5 mm for both the investigated cutting speeds. This behavior directly reflects the rise in cutting forces, which increases with depth of the cut, enhancing chip thickness and the mechanical energy available for chip curling. The resulting higher cutting load produces larger and more elongated chip spirals, consistent with the development of thicker and more undulated chips. Comparing the two texture orientations, the orthogonal configuration shows systematically shorter spiral pitches, with reductions between 20% and 40% compared to the parallel texture under equivalent cutting conditions. This can be explained by the lower cutting forces measured for the orthogonal surface. The orthogonal micro-lines interrupt continuous chip contact, reducing friction and promoting localized coolant infiltration that limits the temperature rise at the tool–chip interface. The lower thermal and mechanical energy available for chip curling results in more frequent chip segmentation and consequently shorter spiral pitches. Conversely, in the parallel configuration, where friction and force levels are slightly higher and coolant penetration is less effective, the higher interface temperature enhances chip plasticity and prolongs chip curling before fracture, generating longer spiral pitches. Increasing the cutting speed from 200 to 220 m/min further promotes spiral elongation, with an average growth of 20–40%, since the additional thermal softening of the material at elevated temperature facilitates continuous chip flow and delays chip breakage. Overall, the pitch spiral morphology is governed by the combined effects of cutting forces and interface temperature: higher forces and temperatures, with greater depths of cut and parallel texturing, promote longer chip spirals, while the improved lubrication and reduced contact temperature of the orthogonal texture favor shorter, more segmented chips indicative of efficient chip control also under wet conditions.

3.4. Surface Roughness

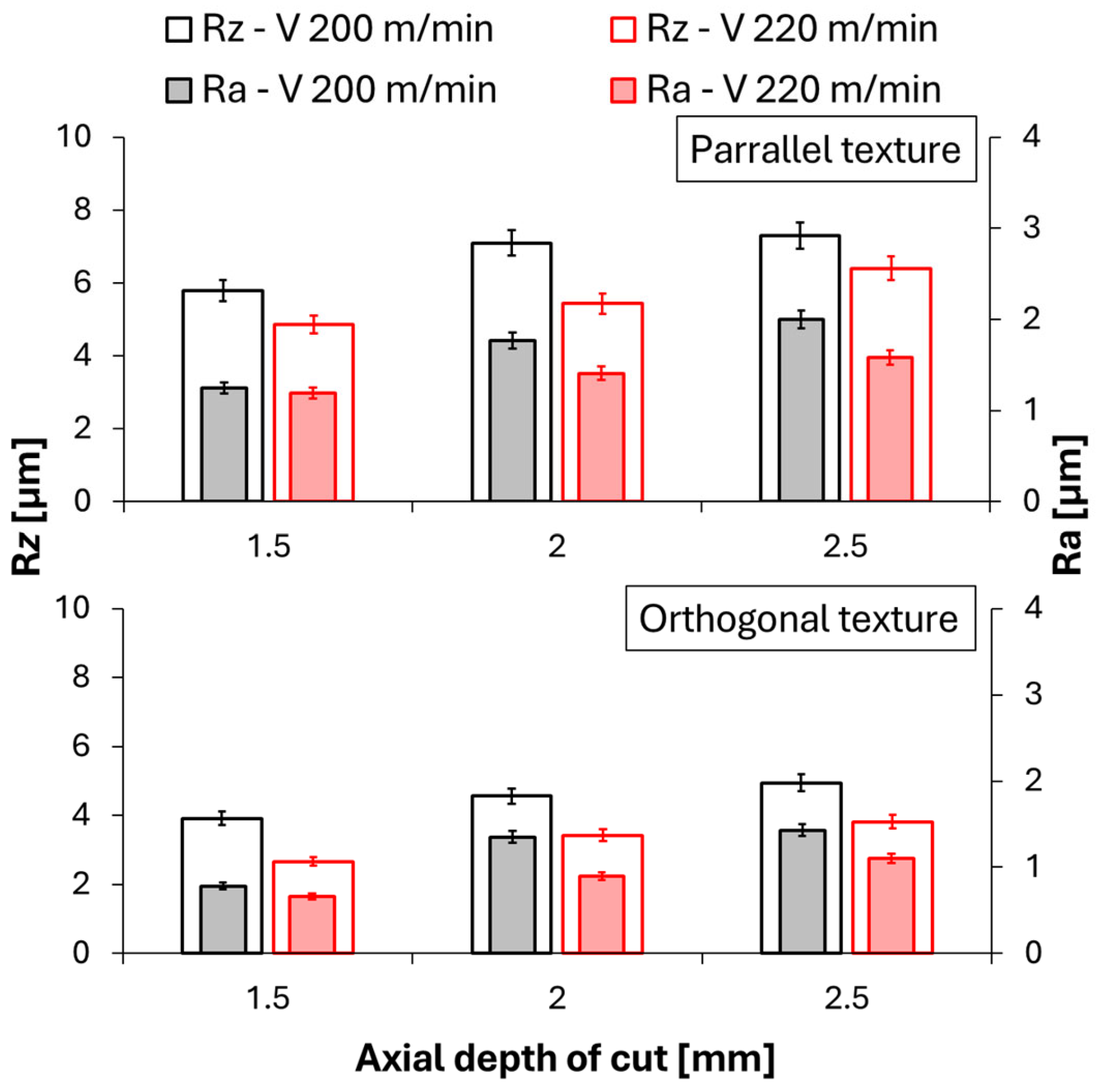

Figure 7 shows the effects of cutting parameters (axial depth of cut and cutting speed) and texturing of the tool on surface roughness parameters Ra and Rz measured in the feed direction.

This increase in the cutting speed from 200 to 220 m/min brings about a general reduction in surface roughness; the arithmetic mean roughness Ra decreases approximately by 25%, while the Rz parameter is reduced by about 20%. This trend can be attributed to the reduction in specific cutting forces at higher speeds due to thermal softening, which promotes a smoother and more regular surface profile formation.

The opposite behavior is observed when the axial depth of the cut increases from 1.5 to 2.5 mm, corresponding to a rise of about 70%. Under these conditions, the surface roughness increases significantly: Ra rises by approximately 60%, while Rz increases by about 35%. The larger chip cross-section leads to higher cutting forces and enhanced vibrations during machining, resulting in deterioration of the surface finish.

The most pronounced influence, however, is associated with the orientation of the tool texture. Under identical cutting conditions, the orthogonal texture orientation with respect to the chip flow direction yields significantly lower roughness values than the parallel configuration. The average reduction in Ra is around 40%, while Rz decreases by nearly 45%. This texture configuration appears to facilitate improved chip evacuation and reduced chip adhesion on the tool surface, consequently minimizing the formation of surface micro-irregularities. This observation is consistent with the measured cutting forces, which show a reduction likely due to the ability of the orthogonal texture to disrupt continuous chip–tool contact. Overall, the results indicate that the combination of a high cutting speed, low axial depth of cut and orthogonal tool texturing represents the most favorable condition for achieving superior surface quality. In this configuration, the Ra and Rz values are more than 50% lower than those obtained under less optimal conditions, confirming the effectiveness of orthogonally oriented texturing in enhancing surface finish in face milling operations.

4. Statistical Modeling, ANOVA Interpretation and Process Optimization

The statistical analysis was focused on modeling the main response variables by means of multiple linear regression; cutting speed, axial depth of cut, and tool micro-texturing orientation were considered as process factors. The general structure taken for all models was

where “Texture” was coded as a dummy variable (Parallel = 0, Orthogonal = 1). This formulation enabled quantification of the individual effect of the three main factors and provided an estimation of their combined influence on six response variables: cutting force, three descriptors of chip morphology (Peak, Pitch, Spiral) and two surface roughness parameters (Ra and Rz), as shown in

Table 3.

The models demonstrate a high predictive capability, with R2 spanning from 0.81 to 0.92, in good accordance with the experimental data. Coefficient interpretation reveals that the depth of cut is the dominant factor for all the variables, promoting relevant increases in cutting forces, chip dimensions and surface roughness with an increase in cutting engagement. The cutting speed has a moderate influence: it is significant for chip morphology and force variables but weakens its influence on roughness parameters. Tool micro-texturing provides a particularly relevant contribution: orthogonal configuration cuts the cutting force, improves surface roughness and gives rise to relevant changes in chip structure, highlighting a systematic tribological effect.

ANOVA confirms that the depth of cut is always highly significant (

p < 0.01), while cutting speed is significant mainly for the chip morphology and cutting force. Tool micro-texturing is significant in almost all of the models, confirming its ability to change the tribological interaction between tool and chip. Finally, the factors show a noncausal, clearly structured influence, further validating the reliability of the obtained models, as shown in

Table 4.

By combining regression models with statistical significance, it was possible to identify optimal operating configurations with respect to different process objectives. Cutting force minimization corresponds to the maximum cutting speed (220 m/min), minimum depth of cut (1.5 mm), and orthogonal texture. Optimal chip morphology control—necessary for stability and consistent evacuation—is granted by the combination of a moderate depth (2.0 mm) and high speed together with orthogonal texture. In terms of surface quality, the depth of cut still remains the most critical factor: a minimum Ra and Rz are reached for the same cutting configuration, namely, 1.5 mm depth, orthogonal texture and high speed.

The multi-objective analysis (

Table 5) highlights a highly relevant finding: the orthogonal texture appears in all optimum configurations, proving to be the most effective design factor for simultaneously improving energy efficiency, process stability, chip controllability, and surface quality. In contrast, the depth of cut requires careful balancing: lower values (1.5 mm) optimize quality and force reduction, while moderate values (2.0 mm) allow for more regular chips without compromising stability or performance. A cutting speed of 220 m/min is consistently preferred, contributing to the overall process stabilization.

5. Discussion

The obtained results establish clear trends in the effect of cutting speed, axial depth of cut and tool texturing on cutting forces, chip morphology and surface roughness parameters Ra and Rz. In general, the increase in cutting speed from 200 to 220 m/min results in the reduction in cutting force values for both tool texturing orientations; this trend is slightly more pronounced for the orthogonal texture. These phenomena can be related to thermal softening effects, which decrease the material strength, promoting chip formation. This trend is also compatible with the improved surface finish, which was represented by lower Ra and Rz values at higher speeds, especially when the tool texture was orthogonal to the chip flow direction.

On the other hand, increasing the axial depth of cut from 1.5 up to 2.5 mm results in a considerable increase in both the cutting forces and roughness parameters in all cases. This can be explained by the larger undeformed chip thickness that generates higher material removal rates, leading to increased cutting forces and more severe surface irregularities. Also, maximum chip morphology and pitch parameters increase with depth of cut, indicating that the chip formation and deformation processes are more vigorous.

Texture orientation significantly affects the machining performance, as the orthogonal texture presents lower cutting forces and better surface quality with respect to the parallel texture. This effect is in good agreement with the results of the regression analysis, which quantified the orthogonal texture as systematically reducing the cutting forces, improving surface integrity, and even modifying chip morphology. In addition, the statistical significance of texture for nearly all models, confirmed by p-values below 0.05, points to it being a key factor in influencing the tribological interaction between tool and workpiece.

The regression models further emphasized the predominant contribution of the axial depth of cut for all variables, in concert with the experimental observations, while the cutting speed demonstrated a moderate yet significant effect on chip morphology and forces but a poorer effect on surface roughness. The multi-objective optimization performed using the models indicated that the best compromise between minimum cutting forces, regulated chip morphology and improved surface finish would be achieved through a high cutting speed of 220 m/min, moderate-to-low axial depth of 1.5–2.0 mm and orthogonal texturing of the tool.

These findings confirm that tool surface engineering and process parameter selection act in concert to ensure efficient, high-quality machining, as reported in

Table 6. Orthogonal micro-texturing appears to be a comprehensive design factor that serves to simultaneously reduce energy consumption, improve chip evacuation, and enhance the quality of the machined surface while judicious selection of depth of cut can balance productivity with machining stability. An integrated analysis of experimental trends and statistical models, therefore, forms a strong basis for guiding practical parameter selection under wet lubrication conditions, considering both performance and surface quality.

6. Conclusions

This study investigated the effect of tool micro-texturing, cutting speed, and axial depth of cut on the machining performance of AISI 1050 steel during full-face milling un-der wet conditions. The experimental findings, supplemented with multiple linear regression analysis and ANOVA, highlighted the importance of tool texture orientation for modulating the nature of cutting forces, chip morphology and surface roughness. Orthogonal texturing of the tool relative to chip flow direction systematically lowered cutting forces, improved chip segmentation, and enhanced surface finish in comparison with parallel texturing.

The regression models quantified the effect of each factor. The following can be noticed: the axial depth of cut is the dominant parameter affecting all the responses, in which higher values lead to increased cutting forces, higher chip peaks and pitches and higher surface roughness; the cutting speed presents a moderate but significant effect on cutting forces and chip morphology, while its effect on surface roughness is comparably weak; orthogonal feed texture has a systematic and significant effect on almost all the responses, confirming its key role in reducing friction, improving chip evacuation and promoting stable cutting conditions. The multi-objective optimization, accordingly performed based on the identified statistical models, highlighted Pareto-optimal combinations of parameters balancing cutting force reduction, controlled chip morphology and improved surface finish. The optimal operational window is a high cutting speed of 220 m/min, and moderate-to-low axial depth of cut ranging between 1.5 and 2.0 mm with orthogonal tool texturing. The optimum operating window suggested a robust strategy toward efficient milling with high-quality standards. Overall, this investigation shows that integrating experimental observations, regression modeling and statistical analysis can provide a comprehensive understanding of the complex interactions between tool surface engineering and machining parameters. The results give some practical recommendations about how to optimize full-face milling of medium-carbon steels and perhaps other ferrous alloys, with the orthogonal micro-texturing method being highly effective at improving machinability and reducing energy consumption while maintaining good surface integrity.

Author Contributions

Conceptualization, S.C., L.O., D.U. and L.F.; methodology, S.C., M.R.S., D.U., L.O. and L.F.; validation, S.C.; formal analysis, M.R.S. and L.F.; investigation, S.C., M.R.S., V.S. and G.Z.; resources, L.F. and L.O.; data curation, S.C., D.U. and L.F.; writing—original draft preparation, S.C. and M.R.S.; writing—review and editing, S.C., M.R.S. and L.O.; visualization, S.C. and M.R.S.; supervision, L.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data and optimization code will be made available upon request to interested researchers.

Acknowledgments

The authors gratefully thank Ing. Alessandro Bertè of LAFER Coating S.p.A. and Ing. Giuseppe Romeo from Meusburger Georg GmbH & Co. KG (Austria) for their valuable technical support provided in this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rinaldi, S.; Caruso, S.; Umbrello, D.; Filice, L.; Franchi, R.; Del Prete, A. Machinability of Waspaloy under Different Cutting and Lubri-Cooling Conditions. Int. J. Adv. Manuf. Technol. 2018, 94, 3703–3712. [Google Scholar] [CrossRef]

- Alfano, M.; Ambrogio, G.; Crea, F.; Filice, L.; Furgiuele, F. Influence of Laser Surface Modification on Bonding Strength of Al/Mg Adhesive Joints. J. Adhes. Sci. Technol. 2011, 25, 1261–1276. [Google Scholar] [CrossRef]

- Tan, L.; Yao, C.; Li, X.; Fan, Y.; Cui, M. Effects of Machining Parameters on Surface Integrity when Turning Inconel 718. J. Mater. Eng. Perform. 2022, 31, 4176–4186. [Google Scholar] [CrossRef]

- Caruso, S.; Filice, L. Sustainable Manufacturing of Ultra-Fine Aluminium Alloy 6101 Wires Using Controlled High Levels of Mechanical Strain and Finite Element Modeling. Int. J. Mater. Form. 2021, 14, 1209–1219. [Google Scholar] [CrossRef]

- Kagermann, H.; Helbig, J.; Hellinger, A.; Wahlster, W. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry; Final Report of the Industrie 4.0 Working Group; Forschungsunion; Acatech—National Academy of Science and Engineering: Munich, Germany, 2013. [Google Scholar]

- Ghosh, A.K.; Ullah, A.S.; Kubo, A.; Akamatsu, T.; D’Addona, D.M. Machining Phenomenon Twin Construction for Industry 4.0: A Case of Surface Roughness. J. Manuf. Mater. Process. 2020, 4, 11. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Domroese, M.; Zsoldos, L. A Decision-Making Strategy for Machining Control. CIRP Ann. 1990, 39, 501–504. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, T.; Zuo, L. Adaptive Control Constraint of Machining Processes. Int. J. Adv. Manuf. Technol. 2001, 17, 720–726. [Google Scholar] [CrossRef]

- Gutakovskis, V.; Gerins, E.; Naginevicius, V.; Gudakovskis, V.; Styps, E.; Sertvytis, R. Adaptive Control for the Metal Cutting Process. Int. J. Eng. Res. Afr. 2020, 51, 1–7. [Google Scholar] [CrossRef]

- Ngerntong, S.; Butdee, S. Surface Roughness Prediction with Chip Morphology Using Fuzzy Logic on Milling Machine. Mater. Today Proc. 2020, 26, 2357–2362. [Google Scholar] [CrossRef]

- Thi-Hoa, P.; Thi-Bich, M.; Van-Canh, T.; Tien-Long, B.; Duc-Toan, N. A Study on the Cutting Force and Chip Shrinkage Coefficient in High-Speed Milling of A6061 Aluminum Alloy. Int. J. Adv. Manuf. Technol. 2018, 98, 177–188. [Google Scholar] [CrossRef]

- Hashmi, K.; Graham, I.D.; Mills, B. Fuzzy Logic Based Data Selection for the Drilling Process. J. Mater. Process. Technol. 2000, 108, 55–61. [Google Scholar] [CrossRef]

- Özel, T.; Biermann, D.; Enomoto, T.; Mativenga, P. Structured and Textured Cutting Tool Surfaces for Machining Applications. CIRP Ann. 2021, 70, 495–518. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Performance of Cutting Tools with Dimple Textured Surfaces: A Comparative Study of Different Texture Patterns. Precis. Eng. 2017, 49, 52–60. [Google Scholar] [CrossRef]

- Duan, R.; Deng, J.; Lei, S.; Ge, D.; Liu, Y.; Li, X. Effect of Derivative Cutting on Machining Performance of Micro Textured Tools. J. Manuf. Process. 2019, 45, 544–556. [Google Scholar] [CrossRef]

- Dewes, R.C.; Aspinwall, D.K. A Review of Ultra High Speed Milling of Hardened Steels. J. Mater. Process. Technol. 1997, 69, 1–17. [Google Scholar] [CrossRef]

- Kang, M.C.; Kim, K.H.; Shin, S.H.; Jang, S.H.; Park, J.H.; Kim, C. Effect of the Minimum Quantity Lubrication in High-Speed End-Milling of AISI D2 Cold-Worked Die Steel (62 HRC) by Coated Carbide Tools. Surf. Coat. Technol. 2008, 202, 5621–5624. [Google Scholar] [CrossRef]

- Caruso, S.; Izquierdo Rodriguez, D.; Ambrogio, G.; Gagliardi, F. Numerical and Experimental Validation of Microstructural Changes and Hardness Variation in Milling of ASTM A216 WCB Carbon Steel. J. Manuf. Process. 2024, 125, 432–441. [Google Scholar] [CrossRef]

- Caruso, S.; Umbrello, D. Numerical and experimental validation of gas metal arc welding on AISI 441 ferritic stainless steel through mechanical and microstructural analysis. Int. J. Adv. Manuf. Technol. 2022, 120, 7433–7444. [Google Scholar] [CrossRef]

- Agrawal, J.P.; Somani, N.; Gupta, N.K. Optimizing electric discharge machining parameters using Taguchi method and ANOVA: A study on AISI D2 steel machining with copper electrodes and materials science progress. Next Mater. 2026, 10, 101361. [Google Scholar] [CrossRef]

- Chaudhary, T.; Gidhi, S.G.; Sudheer, A.; Jha, A. Experimental investigation on wire electric discharge machining of Nimonic alloy miniature gear using PARETO ANOVA. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Chakrapani, P.; Suryakumari, T.S.A. Modelling and analysing the water jet machining parameters of aluminium nanocomposite by ANOVA and Taguchi. Mater. Today Proc. 2021, 47, 370–375. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).