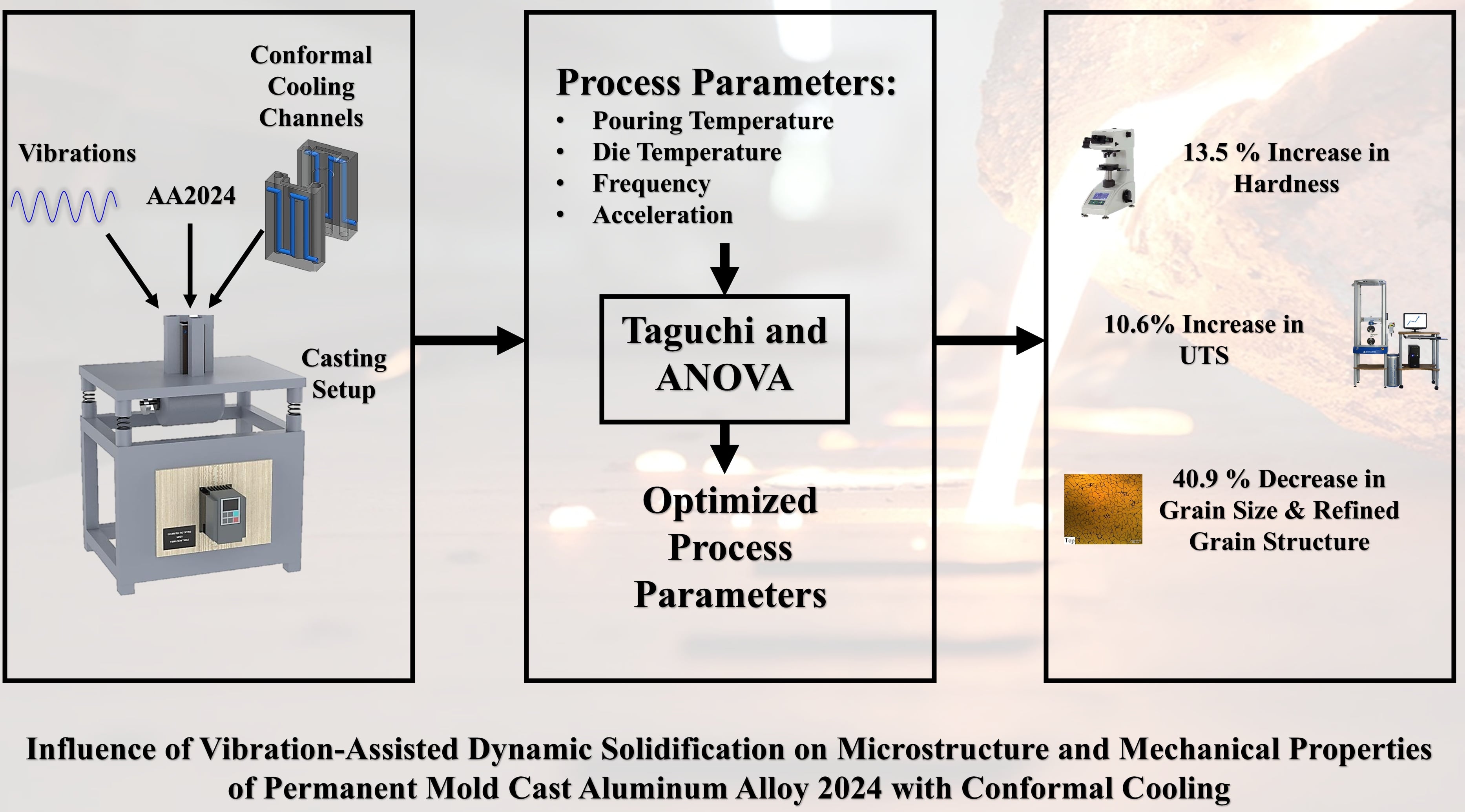

Influence of Vibration-Assisted Dynamic Solidification on Microstructure and Mechanical Properties of Permanent Mold Cast Aluminum Alloy 2024 with Conformal Cooling

Abstract

Share and Cite

Khan, M.W.A.; Ahmad, R.; Bukhari, S.M.A.; Sultan, M.; Husnain, N.; Anwar, M.T.; Bin Nooman, U.; Raza, H.; Latif, A.; Ahmad, S.; et al. Influence of Vibration-Assisted Dynamic Solidification on Microstructure and Mechanical Properties of Permanent Mold Cast Aluminum Alloy 2024 with Conformal Cooling. J. Manuf. Mater. Process. 2025, 9, 416. https://doi.org/10.3390/jmmp9120416

Khan MWA, Ahmad R, Bukhari SMA, Sultan M, Husnain N, Anwar MT, Bin Nooman U, Raza H, Latif A, Ahmad S, et al. Influence of Vibration-Assisted Dynamic Solidification on Microstructure and Mechanical Properties of Permanent Mold Cast Aluminum Alloy 2024 with Conformal Cooling. Journal of Manufacturing and Materials Processing. 2025; 9(12):416. https://doi.org/10.3390/jmmp9120416

Chicago/Turabian StyleKhan, Muhammad Waqas Ali, Rauf Ahmad, Syed Masood Arif Bukhari, Muhammad Sultan, Naveed Husnain, Muhammad Tuoqeer Anwar, Umer Bin Nooman, Hassan Raza, Abid Latif, Sajjad Ahmad, and et al. 2025. "Influence of Vibration-Assisted Dynamic Solidification on Microstructure and Mechanical Properties of Permanent Mold Cast Aluminum Alloy 2024 with Conformal Cooling" Journal of Manufacturing and Materials Processing 9, no. 12: 416. https://doi.org/10.3390/jmmp9120416

APA StyleKhan, M. W. A., Ahmad, R., Bukhari, S. M. A., Sultan, M., Husnain, N., Anwar, M. T., Bin Nooman, U., Raza, H., Latif, A., Ahmad, S., & Bukhari, K. H. (2025). Influence of Vibration-Assisted Dynamic Solidification on Microstructure and Mechanical Properties of Permanent Mold Cast Aluminum Alloy 2024 with Conformal Cooling. Journal of Manufacturing and Materials Processing, 9(12), 416. https://doi.org/10.3390/jmmp9120416