Mechanism Governing the Effect of Roller Straightening of a Pure Magnesium Strip on the Tensile Stress–Strain Curve Shape

Abstract

1. Introduction

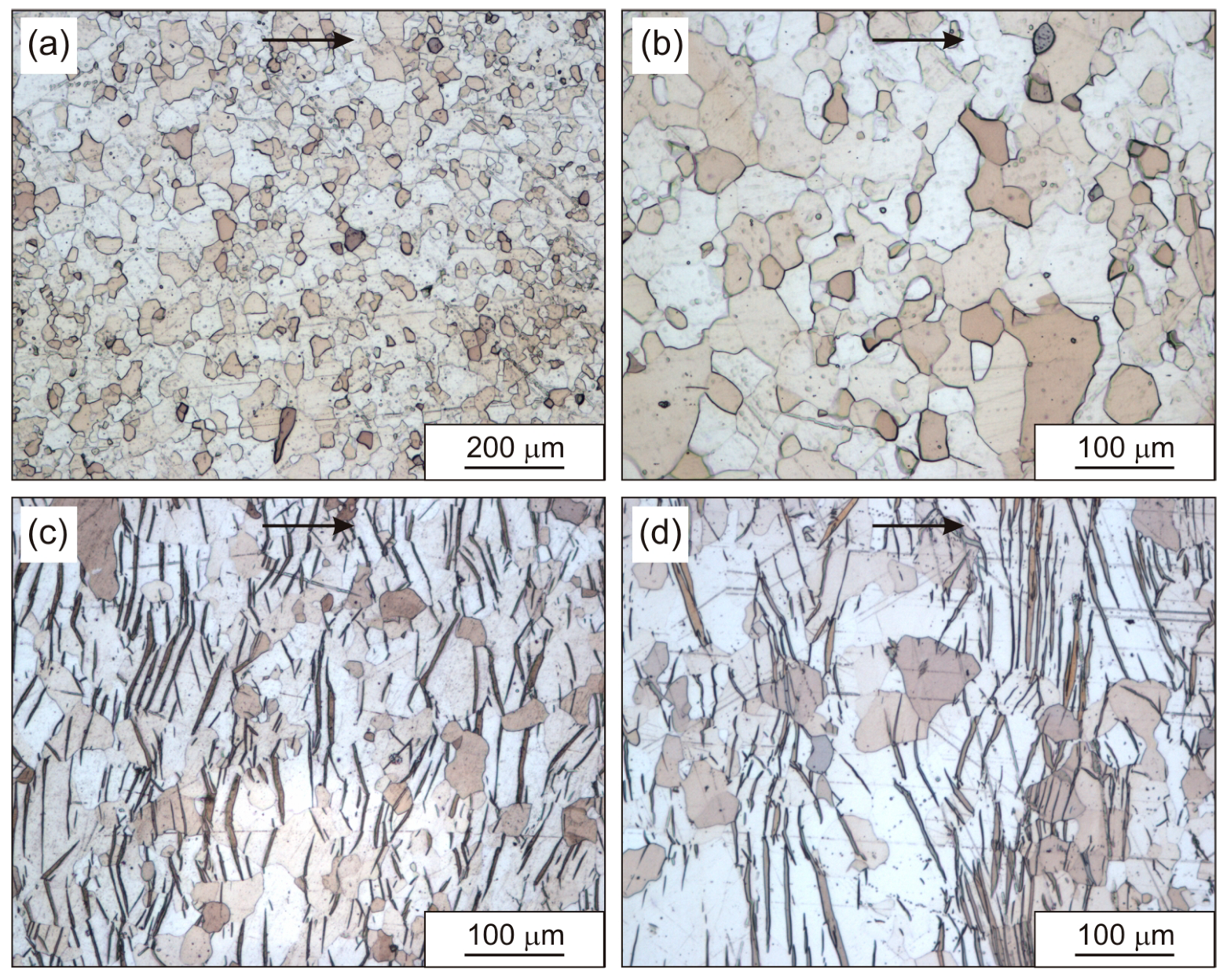

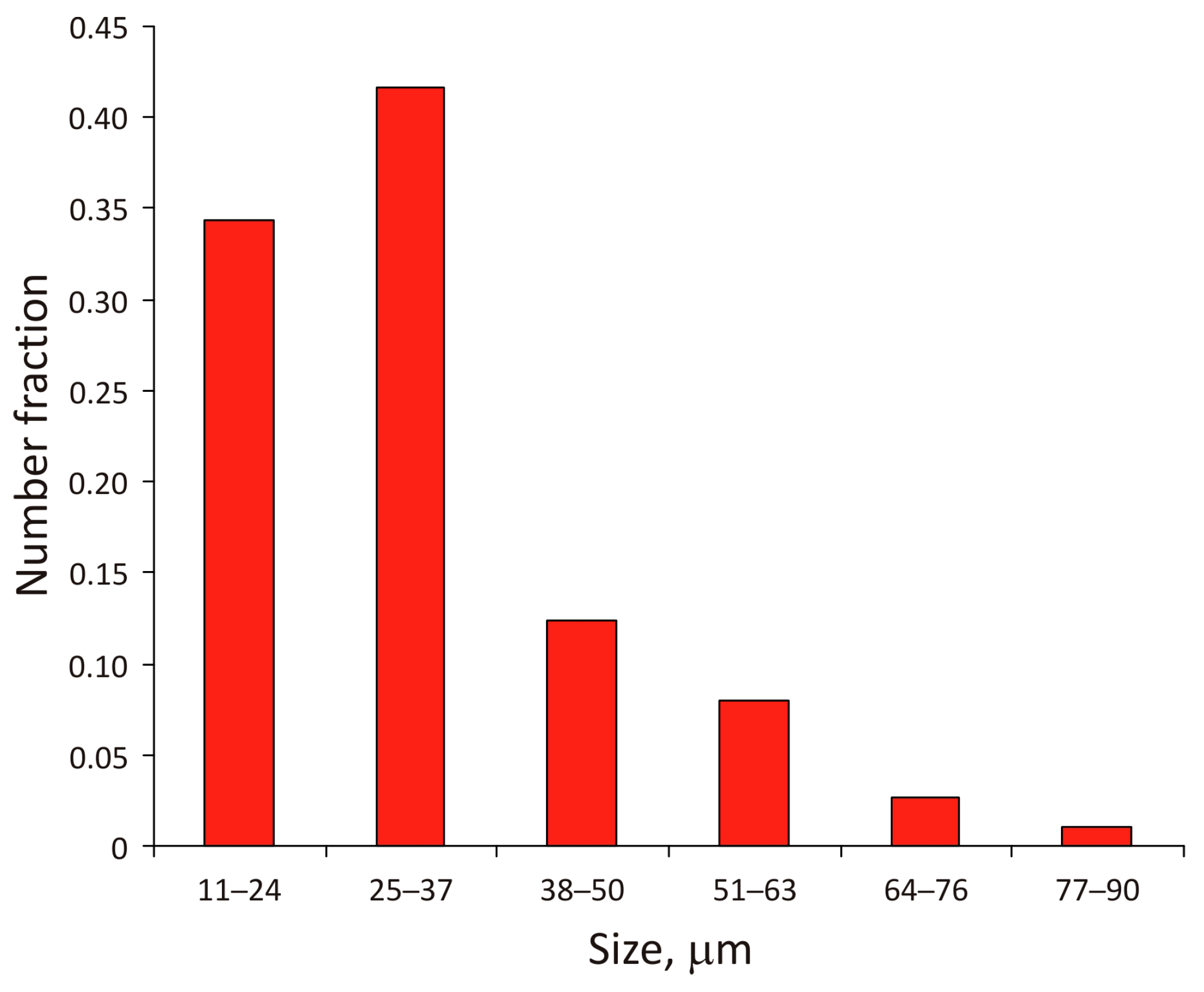

2. Materials and Methods

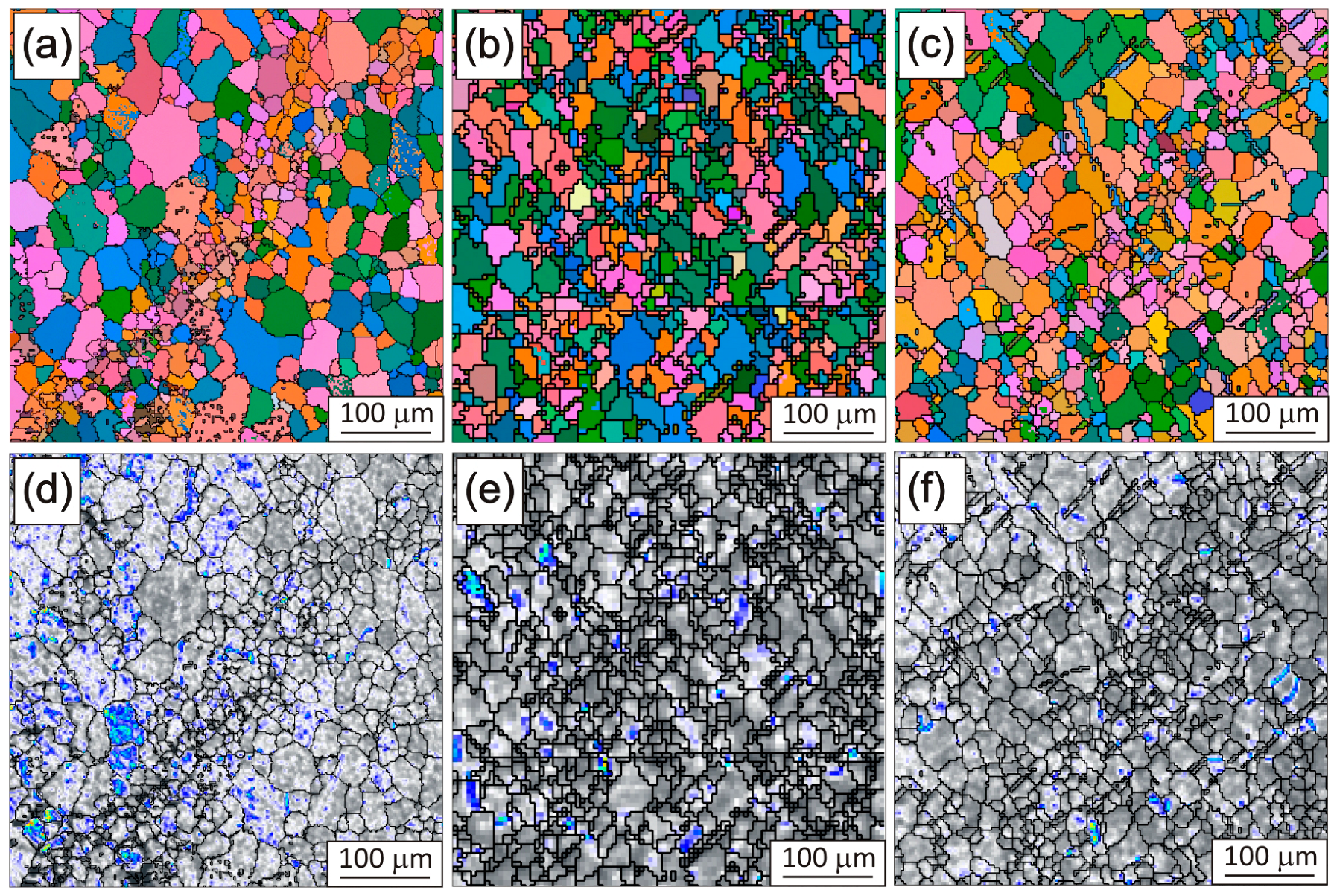

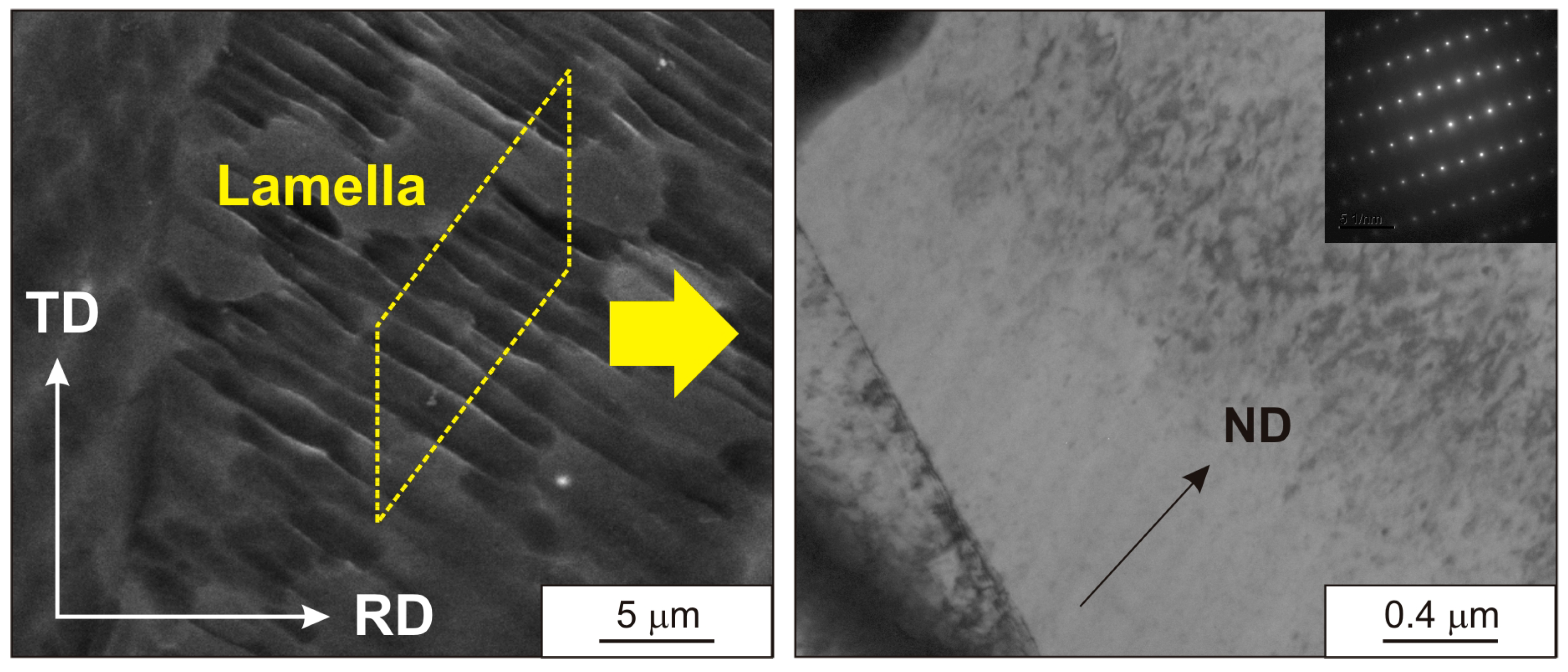

3. Results and Discussion

4. Discussion

5. Conclusions

- Roller straightening results in the appearance of an inflection point (‘yield plateau’) in the tensile stress–strain curve of longitudinal specimens, as well as a nearly twofold decrease in the yield stress from 85 to 45 MPa. This effect was observed only on longitudinal specimens, and it persists when increasing the number of passes through the roller straightening machine from one to three. The use of miniature tensile specimens, compared to full-scale ones, weakened or suppressed this effect.

- Roller straightening in 1 and 3 passes maintains a strong basal texture and does not affect the pole density.

- The hypothesis about the influence of the roller straightening-induced twins on the change in the yield strength, proposed in early works, was confirmed. High-precision microstructural studies, including EBSD analysis, established that roller straightening initiates the formation of the {} tensile twins with a proportion of about 15%, which, during subsequent tensile deformation, facilitate the detwinning process. This, along with ongoing basal slip, reduces the yield strength.

- The tensile strength and the relative elongation of the transverse specimens were significantly higher than those of longitudinal specimens, while their yield strength was identical. The lower tensile strength and relative elongation of the longitudinal specimens are due to the presence of transverse cracks formed in the original strip during hot rolling.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sunil, B.R. Repetitive corrugation and straightening of sheet metals. Mater. Manuf. Process. 2015, 30, 1262–1271. [Google Scholar] [CrossRef]

- Maksimov, E.A.; Shatalov, R.L.; Ustinovsky, E.P. Development of a method for the evaluation of the gap in the course of straightening of sheet products on roller leveling machines. Metallurgist 2021, 65, 62–71. [Google Scholar] [CrossRef]

- Kotov, K.A.; Bolobanova, N.L.; Nushtaev, D.V. Modeling the Stress State of a Steel Strip with a Roller Leveling Machine under Cyclic Alternating Deformations. Steel Transl. 2020, 50, 750–755. [Google Scholar] [CrossRef]

- Raab, G.; Utyashev, F.; Asfandiyarov, R.; Raab, A.; Aksenov, D.; Kodirov, I.; Janeček, M.; Krajňák, T. Physical and technical foundations of the use of alternating free bending for producing long-length semi-products from metals and alloys with improved mechanical properties. Metals 2020, 10, 879. [Google Scholar] [CrossRef]

- Shkatulyak, N.M.; Pravednaya, N.P. Effect of alternating bending on the texture, structure and mechanical properties of aluminum sheets. Met. Sci. Heat Treat. 2013, 54, 472–476. [Google Scholar] [CrossRef]

- Rogachev, S.O.; Andreev, V.A.; Perkas, M.M.; Yusupov, V.S.; Shelest, A.E.; Khatkevich, V.M.; Isaenkova, M.G.; Babich, Y.A. Effect of alternating bending on the structure and mechanical properties of tough-pitch copper. Met. Sci. Heat Treat. 2022, 63, 612–617. [Google Scholar] [CrossRef]

- Rogachev, S.O.; Shelest, A.E.; Perkas, M.M.; Andreev, V.A.; Tabachkova, N.Y.; Yusupov, V.S.; Ten, D.V.; Isaenkova, M.G.; Krymskaya, O.A. Effect of Alternating Bending on Structure, Texture, and Mechanical Properties of Cu–Zn Alloy. J. Mater. Eng. Perform. 2024, 33, 1241–1249. [Google Scholar] [CrossRef]

- Usov, V.V.; Shkatulyak, N.M.; Dragomeretskaya, E.A.; Savchuk, E.S.; Bargan, D.V.; Daskalytsa, G.V. Effect of Alternating Bending and Texture on Anisotropic Damage and Mechanical Properties of Stainless Steel Sheets. Mech. Mater. Sci. Eng. 2016, 6, 56–61. [Google Scholar] [CrossRef]

- Zilberg, Y.V.; Bach, F.-W.; Bormann, D.; Rodman, M.; Sharper, M.; Hepke, M. Effect of alternating bending on the structure and properties of strips from AZ31 magnesium alloy. Met. Sci. Heat Treat. 2009, 51, 170–175. [Google Scholar] [CrossRef]

- Ovechkin, B.I. Influence of straightening on the texture and mechanical of sheets of the MA2-1 alloy. Met. Sci. Heat Treat. 1966, 8, 632–634. [Google Scholar] [CrossRef]

- Chen, R.; Shen, A.; Zhang, P.; Guo, X.; Yang, N.; Zhang, G.; Chen, Q.; Su, J.; Song, H.; Dai, Q. Effect of Stretch Bending on the Microstructure and Mechanical Properties of AZ31 Magnesium Alloy. J. Mater. Eng. Perform. 2025, 34, 6199–6211. [Google Scholar] [CrossRef]

- Bryukhanov, A.A.; Stoyanov, P.P.; Zilberg, Y.V.; Shaper, M.; Rodman, M.; Hepke, M.; Rodman, D. Anisotropy of Mechanical Properties of Magnesium Alloy AZ31 Sheets as a Result of Sign-Variable Bending Deformation. Metall. Min. Ind. 2010, 2, 215–219. [Google Scholar]

- Hepke, M.; Rodman, M.; Haverkamp, H.; Zilberg, J.V.; Briukhanov, A.A.; Bormann, D.; Schaper, M.; Bach, F.-W. Investigation of the influence of low cycle alternating bending loads on the properties of thin sheets possessing different crystal lattice structures. Metall. Min. Ind. 2011, 3, 69–73. [Google Scholar]

- Rogachev, S.O.; Shelest, A.E.; Andreev, V.A.; Yusupov, V.S.; Tabachkova, N.Y.; Ten, D.V.; Isaenkova, M.G.; Krymskaya, O.A. Effect of preliminary heat treatment on the formation of structure and mechanical properties of brass during alternating bending. Russ. Metall. 2023, 2023, 1494–1500. [Google Scholar] [CrossRef]

- Nikulin, S.; Nikitin, A.; Khatkevich, V.; Rogachev, S. Deformation and fracture analysis of nitrided steels by acoustic emission measurement. Int. J. Microstruct. Mater. Prop. 2017, 12, 183–192. [Google Scholar] [CrossRef]

- Li, X.; Li, Q. Effect of pre-compression on microstructural evolution, mechanical property and strengthening mechanism of AZ31 alloy. J. Mater. Sci. 2020, 55, 11637–11649. [Google Scholar] [CrossRef]

- Tolouie, E.; Jamaati, R. Achieving Unusual Stable Textures in AZ91 Alloy by Asymmetric Hot Rolling. Met. Microstruct. Anal. 2024, 13, 307–316. [Google Scholar] [CrossRef]

- Shkatulyak, N.M.; Smirnova, S.V.; Usov, V.V. Effect of alternating bending on texture, structure, and elastic properties of sheets of magnesium lithium alloy. Int. J. Met. 2015, 2015, 349810. [Google Scholar] [CrossRef]

- Wang, R.; Zhou, Q.; Huang, Y.; Su, H.; Ma, L.; Zhang, P.; Huang, Z.; Yao, Z.; Gui, H.; Ma, L. Influence of plastic zone ratios on microstructural changes in AZ31B magnesium alloy plates after straightening. J. Alloys Compd. 2024, 981, 173649. [Google Scholar] [CrossRef]

- Shin, K.S.; Wang, L.; Bian, M.; Choi, S.; Komissarov, A.; Bazhenov, V. Effects of temperature on critical resolved shear stresses of slip and twining in Mg single crystal via experimental and crystal plasticity modeling. J. Magnes. Alloy. 2023, 11, 2027–2041. [Google Scholar] [CrossRef]

- Gautam, P.C.; Biswas, S. Anisotropic compressive deformation behavior of hot-rolled Mg-3Al-0.5Ce alloy. J. Magnes. Alloy. 2024, 12, 4646–4666. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Biswas, S.; Toth, L.S.; Gautam, P.C.; Beausir, B. Strain hardening, twinning and texture evolution in magnesium alloy using the all twin variant polycrystal modelling approach. Int. J. Plast. 2020, 128, 102660. [Google Scholar] [CrossRef]

- Hidetoshi, S.; Alok, S. Mechanical response and microstructural evolution in tension of twin-induced Mg alloy. J. Alloys Compd. 2025, 1045, 184614. [Google Scholar] [CrossRef]

- Go, J.; Park, M.-h.; Gao, S.; Matsumiya, H.; Gong, W.; Tsuji, N. Loading-direction dependence of non-basal slip activity in a pre-twinned AZ31 magnesium alloy. J. Alloys Compd. 2025, 1014, 178749. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Beer, A.G.; Atwell, D. Influence of grain size on the compressive deformation of wrought Mg–3Al–1Zn. Acta Mater. 2004, 52, 5093–5103. [Google Scholar] [CrossRef]

- Shelest, A.E.; Rogachev, S.O.; Yusupov, V.S.; Andreev, V.A.; Karelin, R.D.; Bazhenov, V.E. Features of the influence of alternating elastic-plastic deformation on the mechanical properties of metallic materials. Russ. Metall. 2025, 3, 97–103. (In Russian) [Google Scholar] [CrossRef]

- Yang, L.; Zhang, H.; Liu, G. Anisotropy evolution of wide magnesium alloy foils during continuous electroplastic rolling. J. Mech. Sci. Technol. 2023, 37, 1747–1759. [Google Scholar] [CrossRef]

| Specimen Condition | YS, MPa | TS, MPa | RE, % | |

|---|---|---|---|---|

| Before straightening | 85.0 | 143.0 | 2.3 | |

| After straightening | N = 1 | 46.0 | 170.3 | 2.9 |

| N = 3 | 44.0 | 158.2 | 3.3 | |

| Specimen Condition | Cutting Direction | YS, MPa | TS, MPa | RE, % |

|---|---|---|---|---|

| Before straightening | Longitudinal | 88.5 | 145.9 | 2.8 |

| After straightening, N = 1 | - | 160.6 | 3.0 | |

| After straightening, N = 3 | - | 158.0 | 3.5 | |

| Before straightening | Transverse | 92.7 | 203.0 | 10.8 |

| After straightening, N = 1 | 92.3 | 187.8 | 12.7 | |

| After straightening, N = 3 | 96.0 | 206.5 | 10.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogachev, S.O.; Bazhenov, V.E.; Statnik, E.S.; Andreev, V.A.; Shelest, A.E.; Ershov, N.A. Mechanism Governing the Effect of Roller Straightening of a Pure Magnesium Strip on the Tensile Stress–Strain Curve Shape. J. Manuf. Mater. Process. 2025, 9, 413. https://doi.org/10.3390/jmmp9120413

Rogachev SO, Bazhenov VE, Statnik ES, Andreev VA, Shelest AE, Ershov NA. Mechanism Governing the Effect of Roller Straightening of a Pure Magnesium Strip on the Tensile Stress–Strain Curve Shape. Journal of Manufacturing and Materials Processing. 2025; 9(12):413. https://doi.org/10.3390/jmmp9120413

Chicago/Turabian StyleRogachev, Stanislav O., Viacheslav E. Bazhenov, Eugene S. Statnik, Vladimir A. Andreev, Anatoly E. Shelest, and Nikita A. Ershov. 2025. "Mechanism Governing the Effect of Roller Straightening of a Pure Magnesium Strip on the Tensile Stress–Strain Curve Shape" Journal of Manufacturing and Materials Processing 9, no. 12: 413. https://doi.org/10.3390/jmmp9120413

APA StyleRogachev, S. O., Bazhenov, V. E., Statnik, E. S., Andreev, V. A., Shelest, A. E., & Ershov, N. A. (2025). Mechanism Governing the Effect of Roller Straightening of a Pure Magnesium Strip on the Tensile Stress–Strain Curve Shape. Journal of Manufacturing and Materials Processing, 9(12), 413. https://doi.org/10.3390/jmmp9120413