Process Optimization, Microstructure and Mechanical Properties of SiC + TiB2/AlSi10Mg Composites Fabricated by Laser-Directed Energy Deposition

Abstract

1. Introduction

2. Materials and Methods

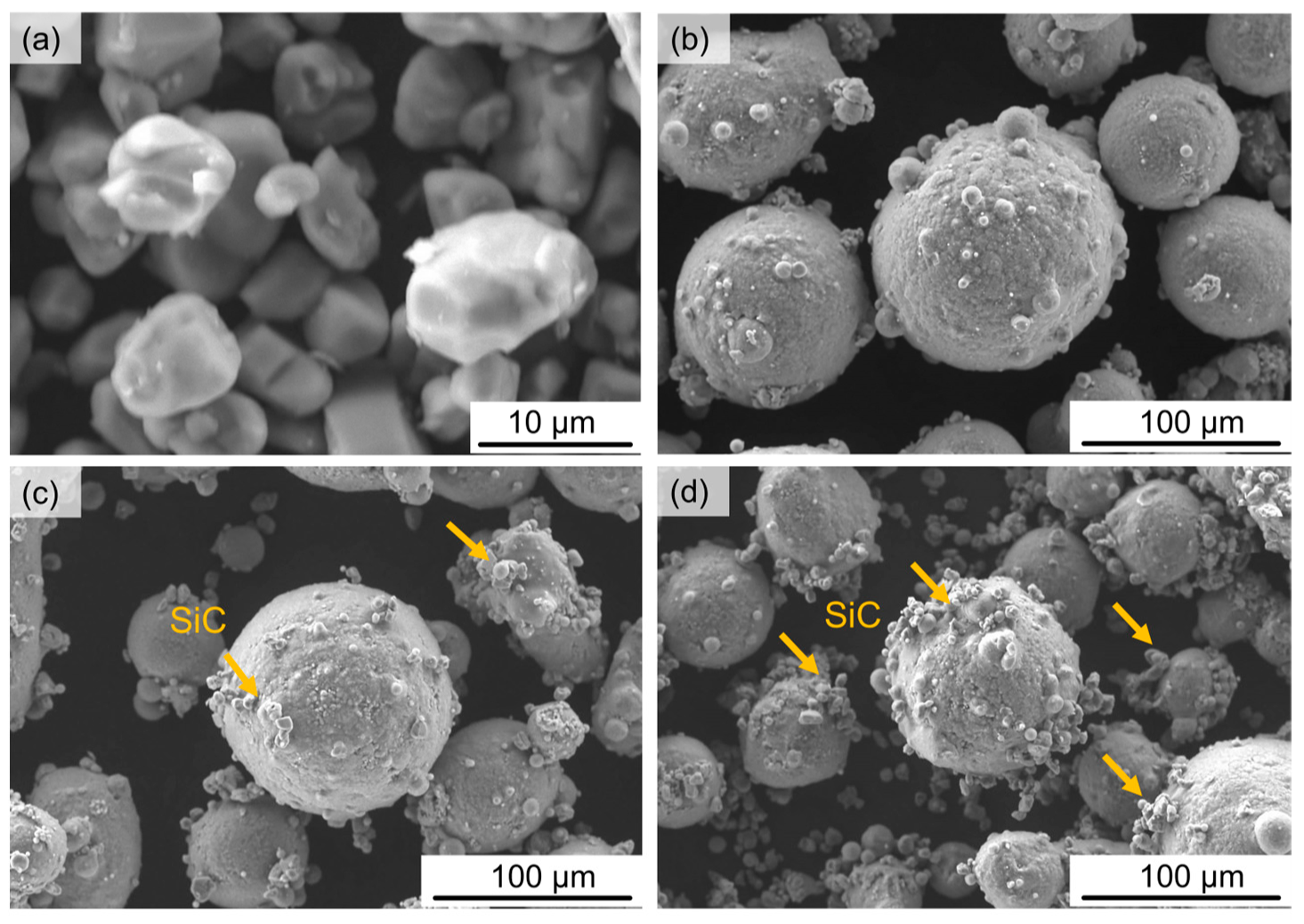

2.1. Experimental Materials

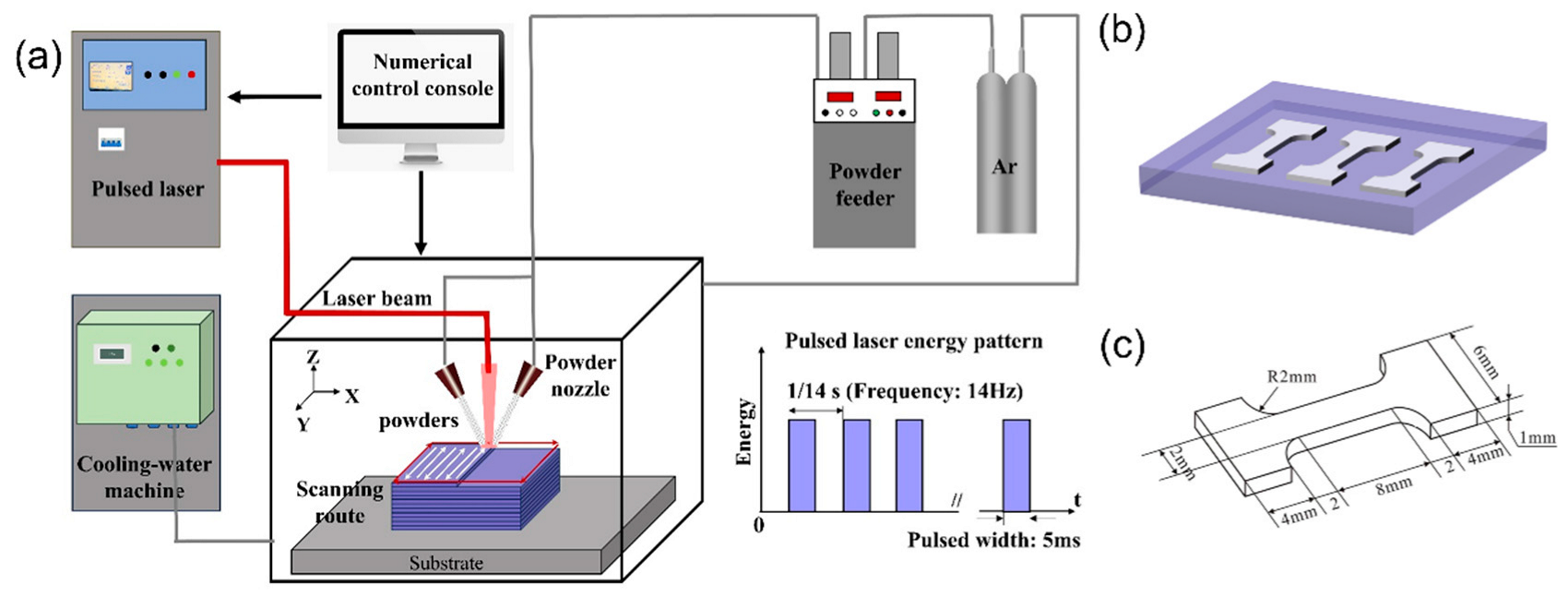

2.2. Experimental System

2.3. Material Characterization and Performance Testing

2.3.1. Powder Particle Size Analysis

2.3.2. Metallurgical Quality Characterization

2.3.3. Microstructural Characterization

2.3.4. Mechanical Property Testing

3. Results

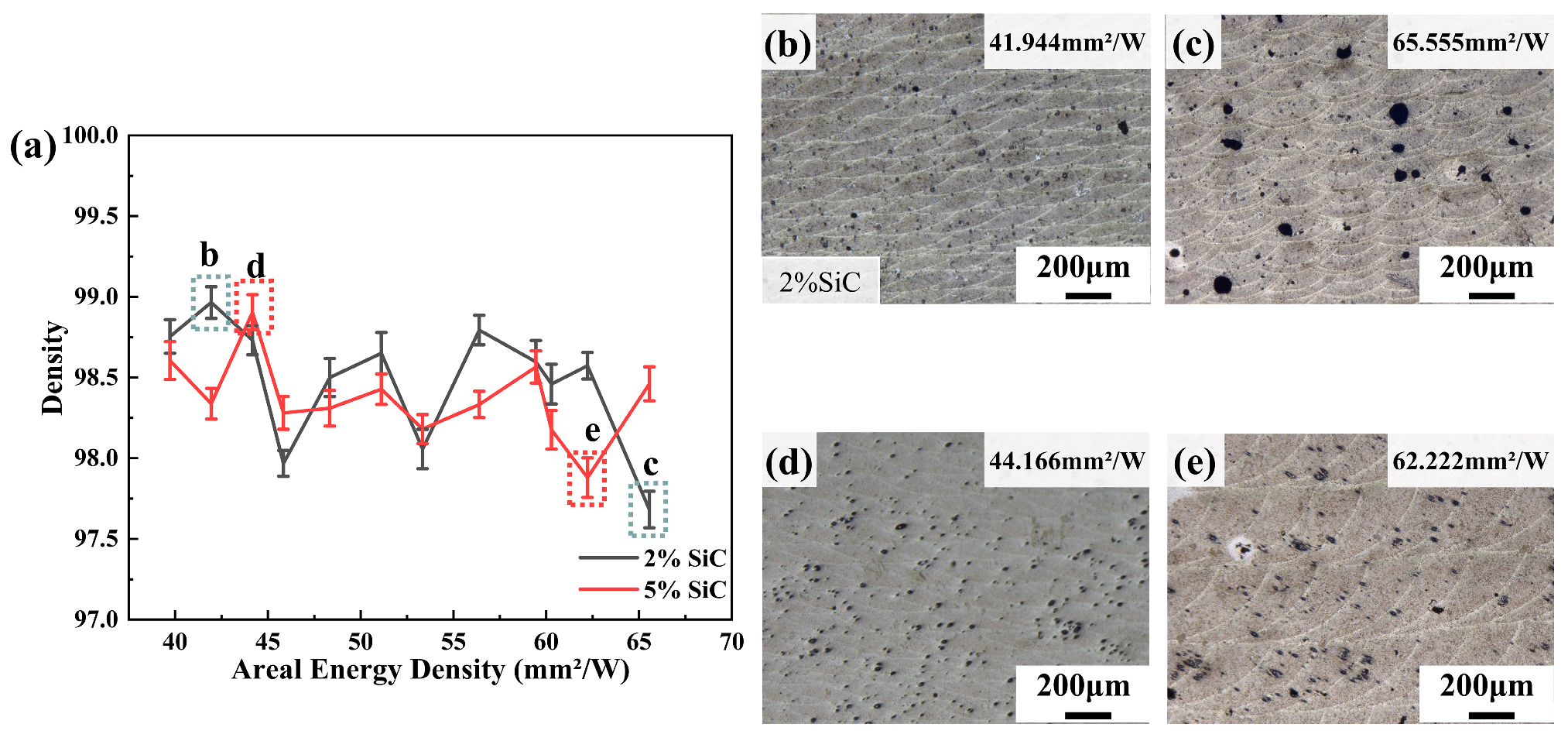

3.1. Process Characteristics of SiC + TiB2/AlSi10Mg Composites

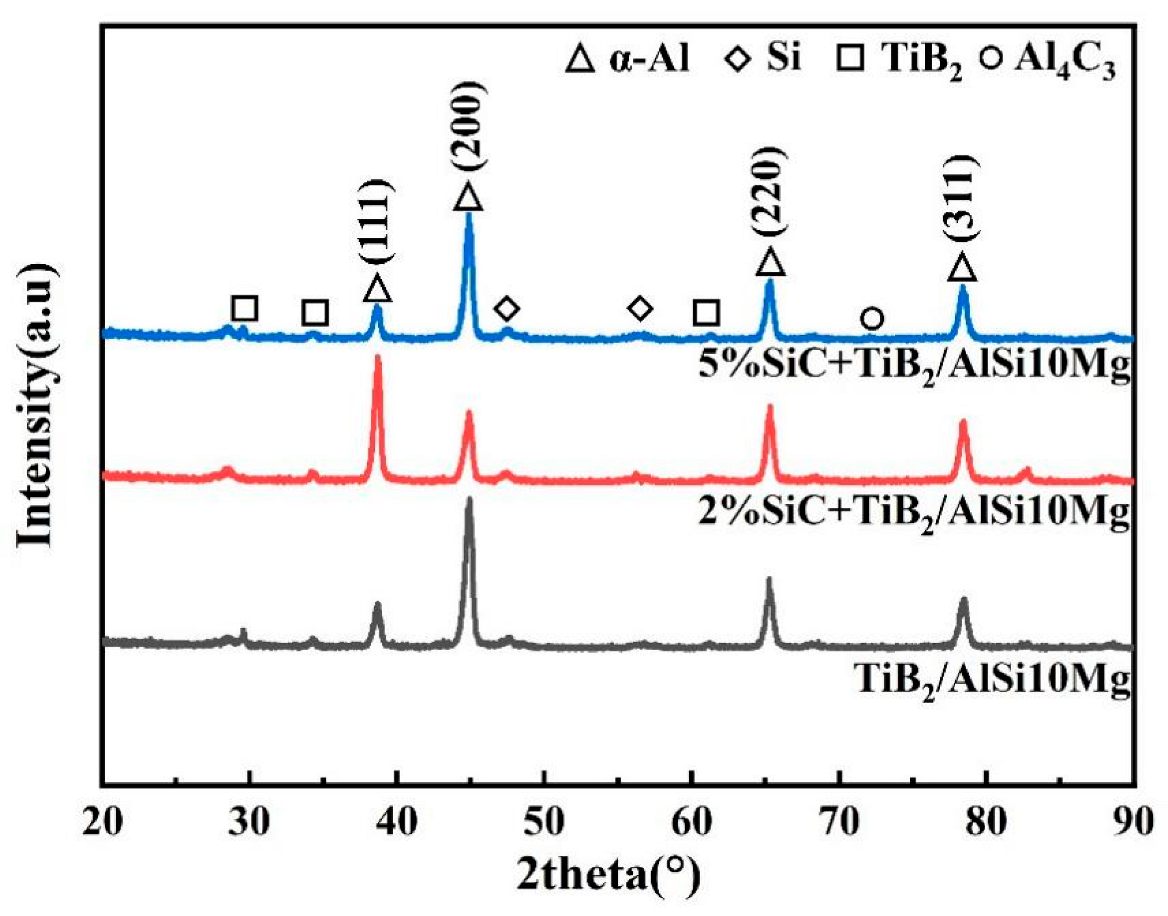

3.2. Microstructural Evolution of SiC + TiB2/AlSi10Mg Composites

3.2.1. Grain Morphology and Orientation Relationship of SiC + TiB2/AlSi10Mg Composites

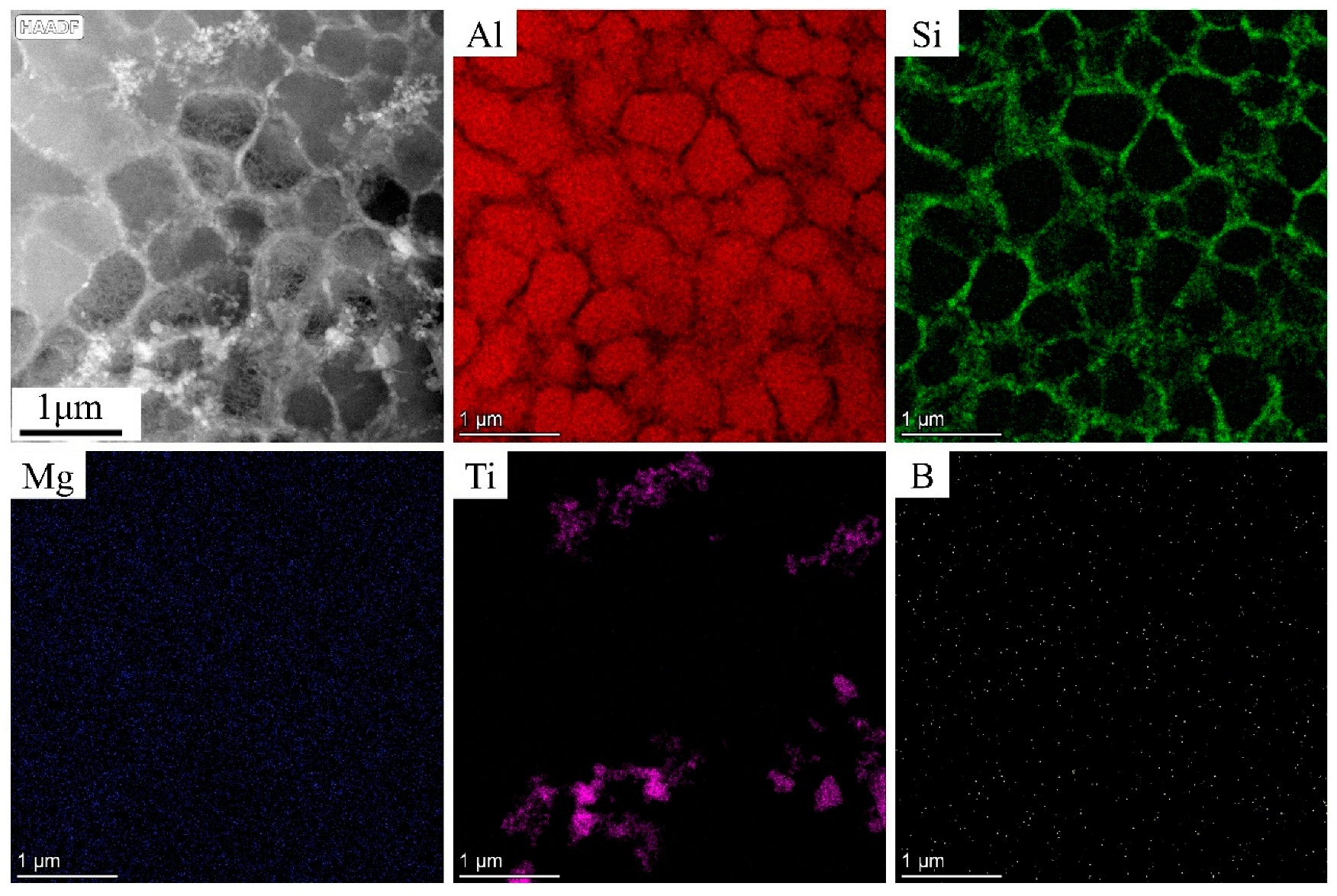

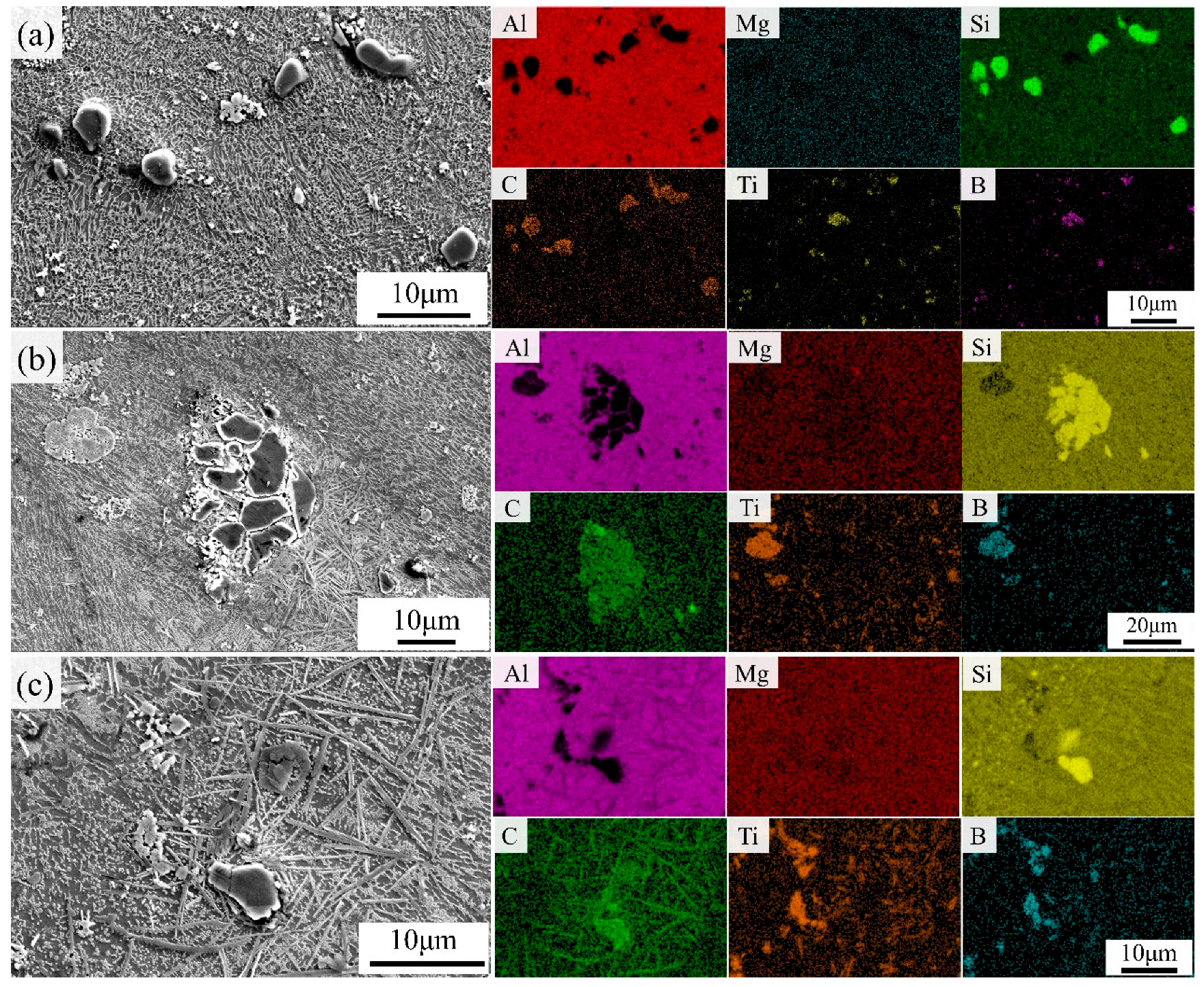

3.2.2. Solidification Microstructure and Particle Distribution Behavior of SiC + TiB2/AlSi10Mg Composites

3.3. Mechanical Properties of SiC + TiB2/AlSi10Mg Composites

3.3.1. Microhardness and Elastic Modulus of SiC + TiB2/AlSi10Mg Composites

3.3.2. Room-Temperature Tensile Properties of SiC + TiB2/AlSi10Mg Composites

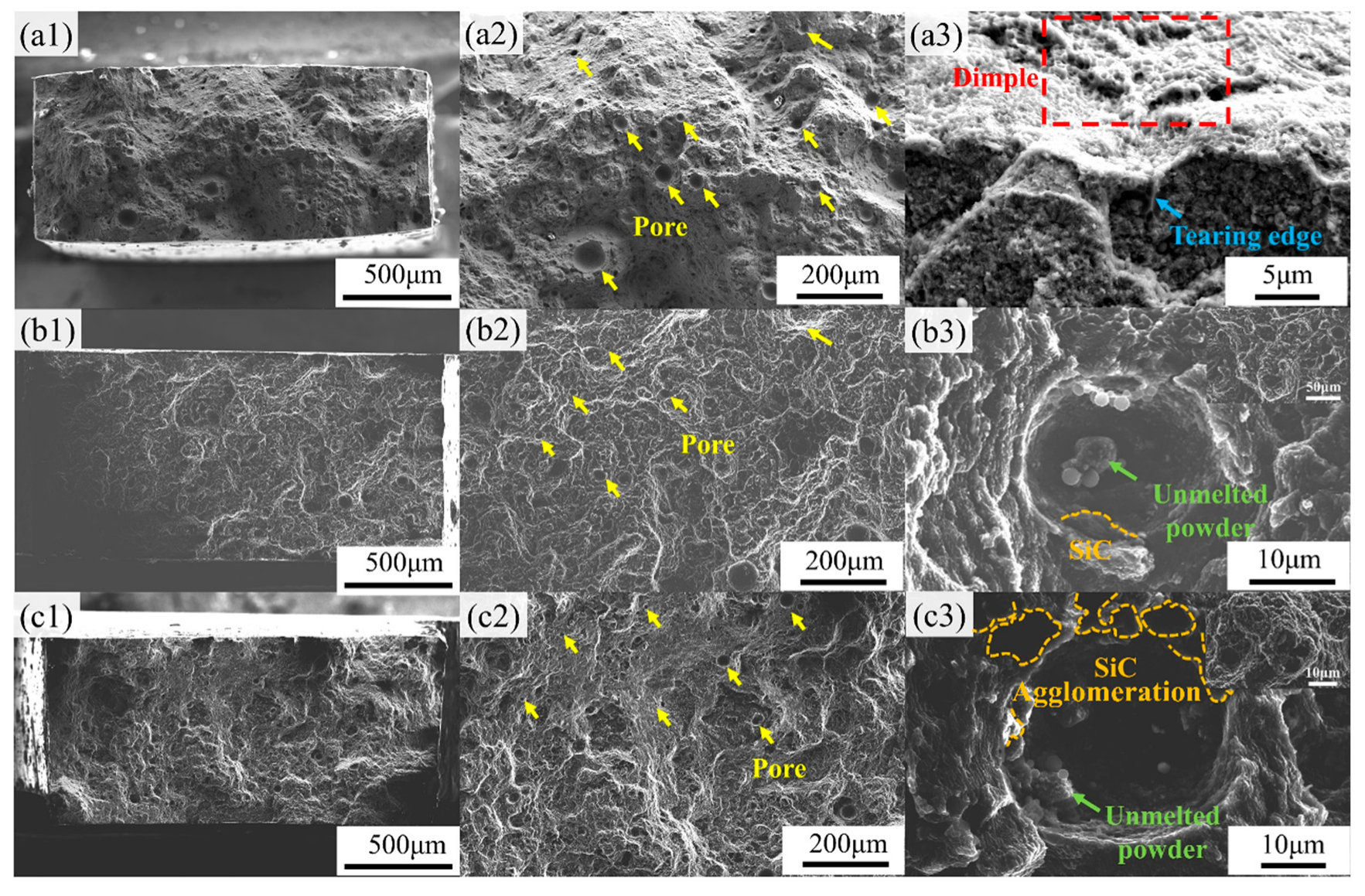

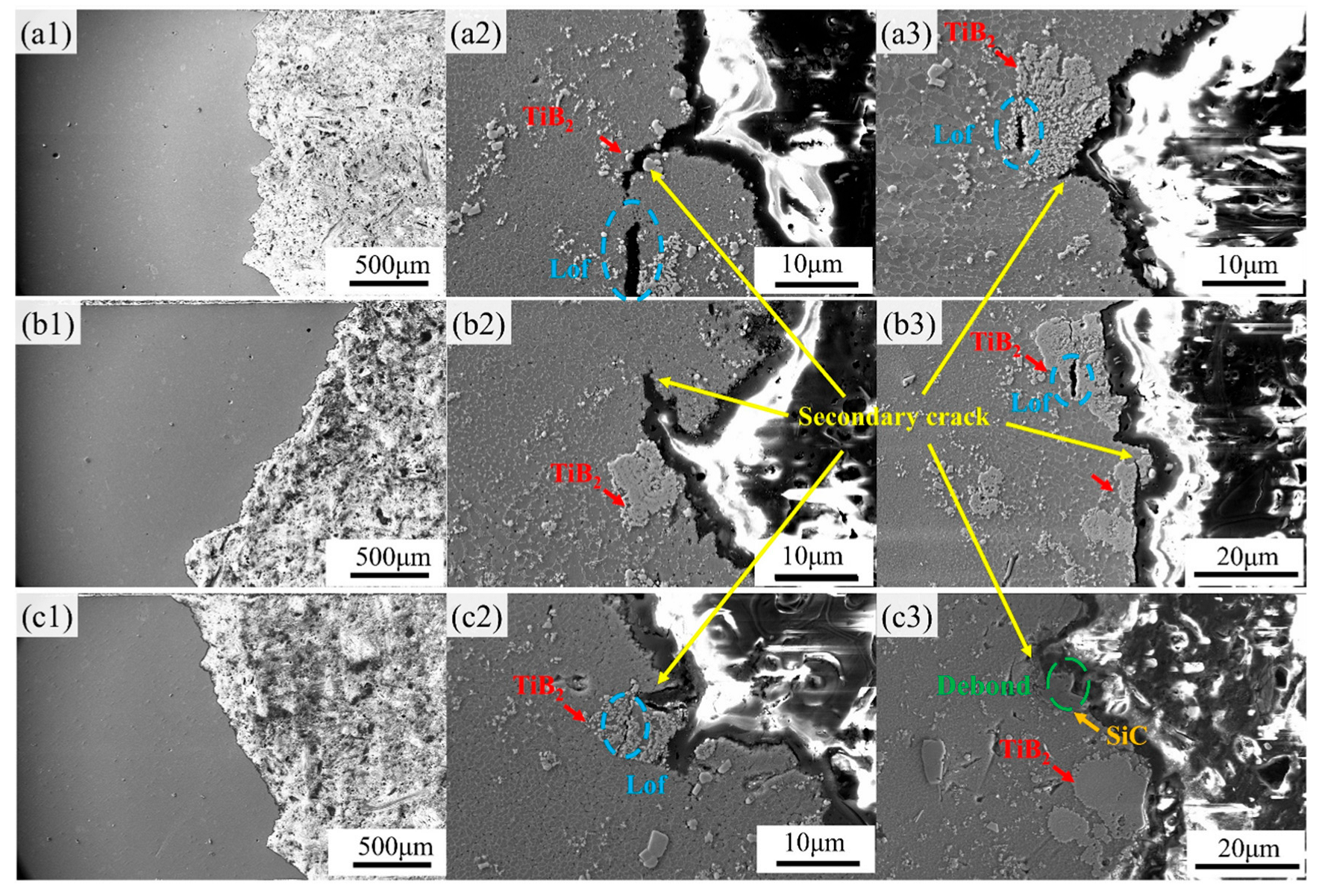

3.3.3. Fracture and Failure Behavior of SiC + TiB2/AlSi10Mg Composites

4. Discussion

4.1. Interaction Between Different Reinforcement Phases

4.2. Exploration of Strengthening Mechanisms

4.3. Failure Behavior Analysis

5. Conclusions

- The addition of SiC particles slightly reduced the metallurgical quality of the LDED-fabricated TiB2/AlSi10Mg composites. Within the tested process parameter range, the 2 wt.% SiC + TiB2/AlSi10Mg and 5 wt.% SiC + TiB2/AlSi10Mg composites both achieved a maximum relative density of 98.9%.

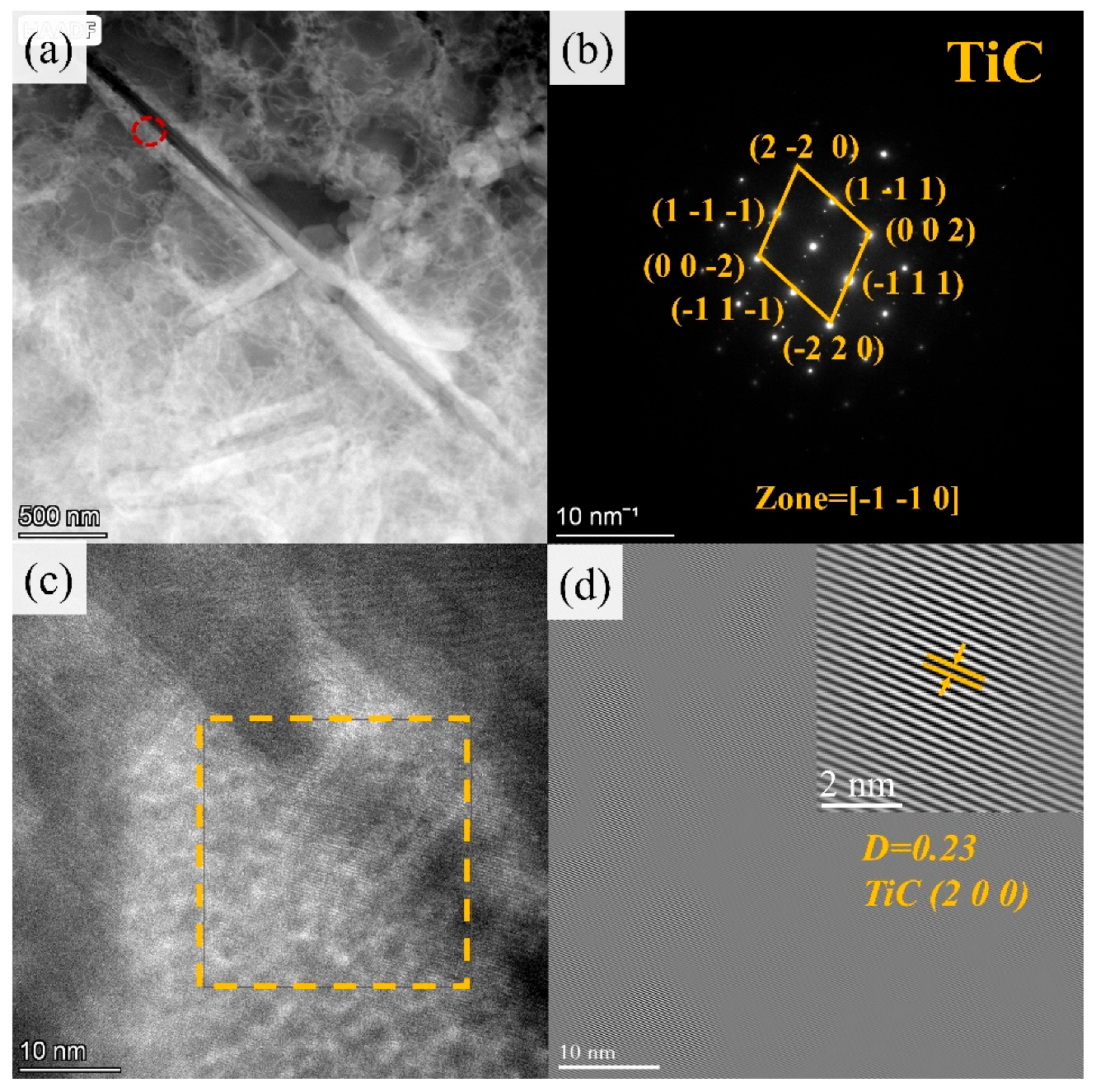

- The incorporation of SiC did not alter the solidification morphology or particle distribution of the LDED-fabricated composites. The melt pool center still exhibited a bright, fibrous Al–Si eutectic network. Additionally, in the 5 wt.% SiC + TiB2/AlSi10Mg composite, needle-like phases were observed around SiC agglomerations, where the dark-contrast phase was identified as Al4C3, and the bright-contrast phase as TiC.

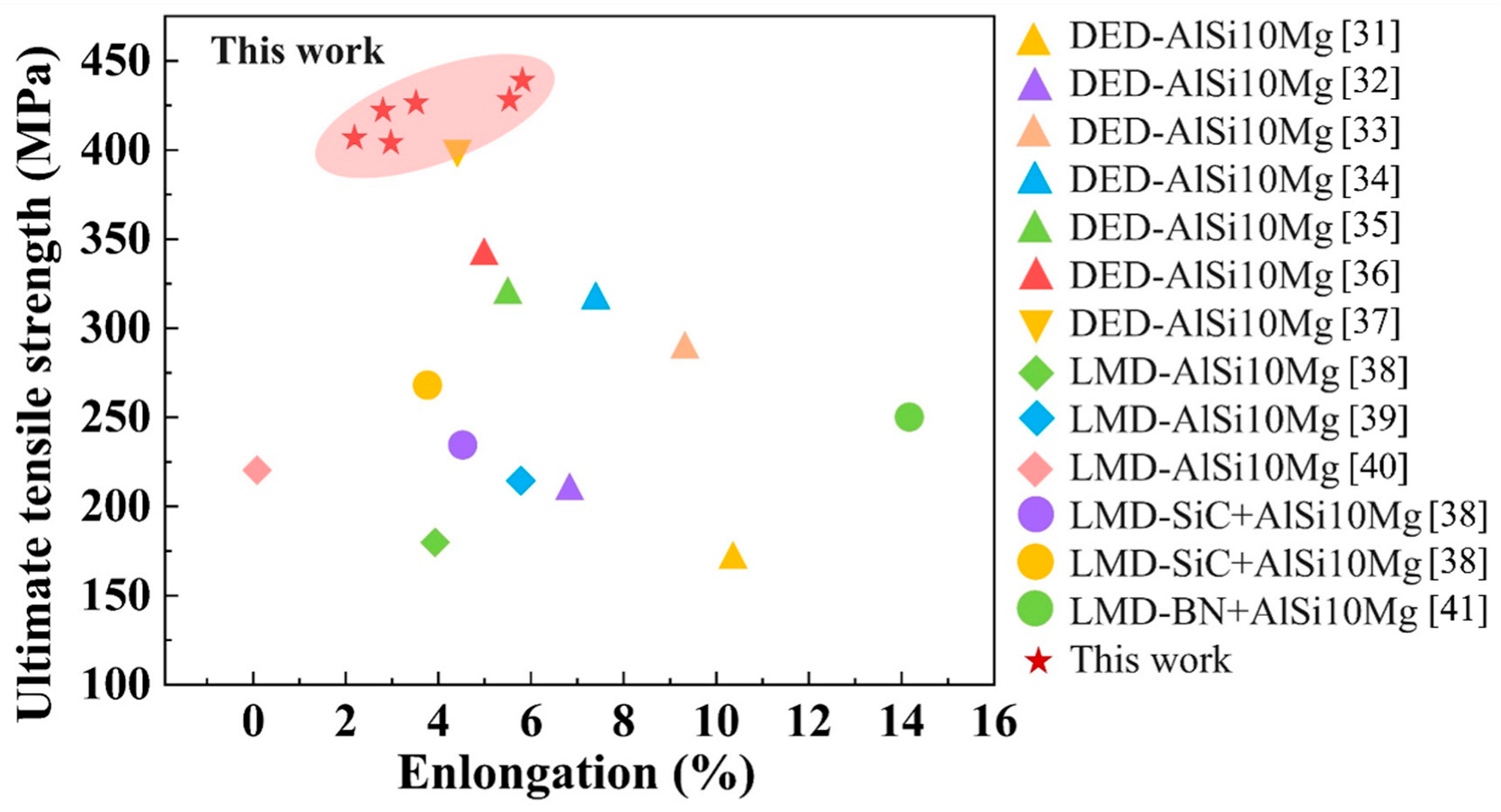

- Compared with the LDED-fabricated AlSi10Mg alloy, the tensile strength of the TiB2/AlSi10Mg composite reached 438.00 MPa, representing an increase of 39.5%. In contrast, the 2 wt.% SiC + TiB2/AlSi10Mg and 5 wt.% SiC + TiB2/AlSi10Mg composites exhibited lower tensile strengths of 421.71 MPa and 426.74 MPa, respectively. The decrease in tensile strength after adding SiC is primarily attributed to SiC particle agglomeration and the consumption of TiB2 particles due to TiC formation.

- The addition of SiC particles significantly enhanced the elastic modulus of the composites. With 2 wt.% SiC, the elastic modulus increased to 85.38 GPa, representing a 9% improvement over the TiB2/AlSi10Mg composite. When 5 wt.% SiC was added, the elastic modulus further increased to 91.06 GPa, corresponding to a 16.3% improvement.

- The composites primarily exhibited a mixed ductile–brittle fracture mode. However, pore defects (>10 μm) and SiC/TiB2 clusters acted as crack initiation sites, causing stress concentration and promoting the propagation of secondary cracks. Significant interfacial debonding between SiC particles and the matrix was observed, and in the 5 wt.% SiC composite, cracks were more likely to initiate along particle cluster interfaces, leading to further degradation of ductility.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Svetlizky, D.; Zheng, B.; Vyatskikh, A.; Das, M.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Laser-based directed energy deposition (DED-LB) of advanced materials. Mater. Sci. Eng. A 2022, 840, 142967. [Google Scholar] [CrossRef]

- Ahn, D.-G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Singh, A.; Kapil, S.; Das, M. A comprehensive review of the methods and mechanisms for powder feedstock handling in directed energy deposition. Addit. Manuf. 2020, 35, 101388. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Parvez, M.M.; Liou, F. A Review on Metallic Alloys Fabrication Using Elemental Powder Blends by Laser Powder Directed Energy Deposition Process. Materials 2020, 13, 3562. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Liu, G.; Su, Y.; Pi, X.; Xin, S.; Li, K.; Liu, D.; Lin, Y.C. Achieving high strength 316L stainless steel by laser directed energy deposition-ultrasonic rolling hybrid process. Mater. Sci. Eng. A 2024, 903, 146665. [Google Scholar] [CrossRef]

- Vogel, T.; Ma, S.; Liu, Y.; Guo, Q.; Zhang, D. Impact of alumina content and morphology on the mechanical properties of bulk nanolaminated Al2O3-Al composites. Compos. Commun. 2020, 22, 100462. [Google Scholar] [CrossRef]

- Zhang, T.; Feng, K.; Li, Z.; Kokawa, H. Effects of rare earth elements on the microstructure and wear properties of TiB2 reinforced aluminum matrix composite coatings: Experiments and first principles calculations. Appl. Surf. Sci. 2020, 530, 147051. [Google Scholar] [CrossRef]

- Ding, Y.; Muñiz-Lerma, J.A.; Trask, M.; Chou, S.; Walker, A.; Brochu, M. Microstructure and mechanical property considerations in additive manufacturing of aluminum alloys. MRS Bull. 2016, 41, 745–751. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, F.; Cao, Y.; Nie, J.; Zhou, H.; Yang, H.; Liu, X.; An, X.; Liao, X.; Zhao, Y.; et al. Unique defect evolution during the plastic deformation of a metal matrix composite. Scr. Mater. 2019, 162, 316–320. [Google Scholar] [CrossRef]

- Nie, J.; Lu, F.; Huang, Z.; Ma, X.; Zhou, H.; Chen, C.; Chen, X.; Yang, H.; Cao, Y.; Liu, X.; et al. Improving the high-temperature ductility of Al composites by tailoring the nanoparticle network. Materialia 2020, 9, 100523. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, H.; Zhang, X.; Qiu, F.; Jiang, Q. Enhanced elevated-temperature mechanical properties of Al-Mn-Mg containing TiC nano-particles by pre-strain and concurrent precipitation. Mater. Sci. Eng. A 2018, 718, 305–310. [Google Scholar] [CrossRef]

- Tan, H.; Hao, D.; Al-Hamdani, K.; Zhang, F.; Xu, Z.; Clare, A.T. Direct metal deposition of TiB2/AlSi10Mg composites using satellited powders. Mater. Lett. 2018, 214, 123–126. [Google Scholar] [CrossRef]

- Wang, P.; Eckert, J.; Prashanth, K.-G.; Wu, M.-W.; Kaban, I.; Xi, L.-X.; Scudino, S. A review of particulate-reinforced aluminum matrix composites fabricated by selective laser melting. Trans. Nonferrous Met. Soc. China 2020, 30, 2001–2034. [Google Scholar] [CrossRef]

- Xi, L.; Gu, D.; Guo, S.; Wang, R.; Ding, K.; Prashanth, K.G. Grain refinement in laser manufactured Al-based composites with TiB2 ceramic. J. Mater. Res. Technol. 2020, 9, 2611–2622. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, Y.; Xiao, X.; Huang, B.; Zhou, Z.; Liu, X. Microstructure and mechanical properties of a novel (TiB2 + TiC)/AlSi10Mg composite prepared by selective laser melting. Mater. Sci. Eng. A 2022, 834, 142435. [Google Scholar] [CrossRef]

- Xu, S.; Li, B.; Lv, Z.; Yan, X. Microstructures and mechanical behaviors of reinforced aluminum matrix composites with modified nano-sized TiB2/SiC fabricated by selective laser melting. Compos. Commun. 2023, 37, 101439. [Google Scholar] [CrossRef]

- Fan, Z.; Yan, X.; Fu, Z.; Niu, B.; Chen, J.; Hu, Y.; Chang, C.; Yi, J. In situ formation of D022-Al3Ti during selective laser melting of nano-TiC/AlSi10Mg alloy prepared by electrostatic self-assembly. Vacuum 2021, 188, 110179. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, R.; Peng, C.; Cai, Z.; Zhou, Z.; Li, X.; Cao, X. Microstructural evolution and mechanical performance of in-situ TiB2/AlSi10Mg composite manufactured by selective laser melting. J. Alloys Compd. 2021, 853, 157287. [Google Scholar] [CrossRef]

- Geng, L.; Wu, F.; Dang, M.; Feng, Z.; Peng, Y.; Kang, C.; Fan, W.; Wang, Y.; Tan, H.; Zhang, F.; et al. Laser powder bed fusion of SiC particle-reinforced pre-alloyed TiB2/AlSi10Mg composite with high-strength and high-stiffness. J. Mater. Process. Technol. 2024, 334, 118635. [Google Scholar] [CrossRef]

- Liu, T.-S.; Chen, P.; Qiu, F.; Yang, H.-Y.; Jin, N.T.Y.; Chew, Y.; Wang, D.; Li, R.; Jiang, Q.-C.; Tan, C. Review on laser directed energy deposited aluminum alloys. Int. J. Extrem. Manuf. 2024, 6, 022004. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Chen, B.; Xi, X.; Gu, T.; Tan, C.; Song, X. Influence of heat treatment on microstructure evolution and mechanical properties of TiB2/Al 2024 composites fabricated by directed energy deposition. J. Mater. Res. Technol. 2020, 9, 14223–14236. [Google Scholar] [CrossRef]

- Delahaye, J.; Tchuindjang, J.T.; Lecomte-Beckers, J.; Rigo, O.; Habraken, A.M.; Mertens, A. Influence of Si precipitates on fracture mechanisms of AlSi10Mg parts processed by Selective Laser Melting. Acta Mater. 2019, 175, 160–170. [Google Scholar] [CrossRef]

- Chen, Y.; Jian, Z.; Ren, Y.; Li, K.; Dang, B.; Guo, L. Influence of TiB2 volume fraction on SiCp/AlSi10Mg composites by LPBF: Microstructure, mechanical, and physical properties. J. Mater. Res. Technol. 2023, 23, 3697–3710. [Google Scholar] [CrossRef]

- Lei, Z.; Bi, J.; Chen, Y.; Chen, X.; Tian, Z.; Qin, X. Effect of TiB2 content on microstructural features and hardness of TiB2/AA7075 composites manufactured by LMD. J. Manuf. Processes 2020, 53, 283–292. [Google Scholar] [CrossRef]

- Nie, J.; Chen, Y.; Chen, X.; Liu, X.; Liu, G.; Zhao, Y.; Zhu, Y. Stiff, strong and ductile heterostructured aluminum composites reinforced with oriented nanoplatelets. Scr. Mater. 2020, 189, 140–144. [Google Scholar] [CrossRef]

- Bhowmik, A.; Sen, B.; Beemkumar, N.; Singh Chohan, J.; Bains, P.S.; Singh, G.; Kumar, A.V.; A, J.S. Development and wear resistivity performance of SiC and TiB2 particles reinforced novel aluminium matrix composites. Results Eng. 2024, 24, 102981. [Google Scholar] [CrossRef]

- Yi, J.; Zhang, X.; Liu, G.; Rao, J.H.; Liu, H. Microstructure and dynamic microhardness of additively manufactured (TiB2 + TiC)/AlSi10Mg composites with AlSi10Mg and B4C coated Ti powder. J. Alloys Compd. 2023, 939, 168718. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, H.; Feng, Z.; Zhang, F.; Shang, W.; Clare, A.T.; Lin, X. Enhanced mechanical properties of in situ synthesized TiC/Ti composites by pulsed laser directed energy deposition. Mater. Sci. Eng. A 2022, 855, 143935. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, J.; Zhao, Y.; Wang, Z.; Song, H.; Gao, M. Effect of processing parameters on solidification defects behavior of laser deposited AlSi10Mg alloy. Vacuum 2019, 167, 471–478. [Google Scholar] [CrossRef]

- Lupi, G.; de Menezes, J.T.O.; Belelli, F.; Bruzzo, F.; López, E.; Volpp, J.; Castrodeza, E.M.; Casati, R. Fracture toughness of AlSi10Mg alloy produced by direct energy deposition with different crack plane orientations. Mater. Today Commun. 2023, 37, 107460. [Google Scholar] [CrossRef]

- Gong, J.; Wei, K.; Liu, M.; Song, W.; Li, X.; Zeng, X. Microstructure and mechanical properties of AlSi10Mg alloy built by laser powder bed fusion/direct energy deposition hybrid laser additive manufacturing. Addit. Manuf. 2022, 59, 103160. [Google Scholar] [CrossRef]

- Shi, S.; Lin, X.; Wang, L.; Wang, Z.; Wei, L.; Yang, H.; Tang, Y.; Huang, W. Investigations of the processing–structure–performance relationships of an additively manufactured AlSi10Mg alloy via directed energy deposition. J. Alloys Compd. 2023, 944, 169050. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, X.; Li, H.; Hu, J.; Han, X.; Liu, S. In-situ laser shock peening for improved surface quality and mechanical properties of laser-directed energy-deposited AlSi10Mg alloy. Addit. Manuf. 2022, 60, 103177. [Google Scholar] [CrossRef]

- Kiani, P.; Dupuy, A.D.; Ma, K.; Schoenung, J.M. Directed energy deposition of AlSi10Mg: Single track nonscalability and bulk properties. Mater. Des. 2020, 194, 108847. [Google Scholar] [CrossRef]

- Wang, A.; Wei, Q.; Tang, Z.; Oliveira, J.P.; Leung, C.L.A.; Ren, P.; Zhang, X.; Wu, Y.; Wang, H.; Wang, H. Effects of hatch spacing on pore segregation and mechanical properties during blue laser directed energy deposition of AlSi10Mg. Addit. Manuf. 2024, 85, 104147. [Google Scholar] [CrossRef]

- Xi, X.; Chen, B.; Tan, C.; Song, X.; Dong, Z. Influence of micron and nano SiCp on microstructure evolution and mechanical properties of laser metal deposition AlSi10Mg alloy. J. Mater. Process. Technol. 2022, 306, 117609. [Google Scholar] [CrossRef]

- Dong, E.; Chang, T.; Zhao, L.; Xing, Y.; Chen, J.; Chen, M.; Lu, J.; Cheng, J. Laser metal deposition of AlSi10Mg for aeroengine casing repair: Microhardness, wear and corrosion behavior. Mater. Today Commun. 2024, 38, 108412. [Google Scholar] [CrossRef]

- Hermann, F.; Vogt, S.; Göbel, M.; Möller, M.; Frey, K. Laser Metal Deposition of AlSi10Mg with high build rates. Procedia CIRP 2022, 111, 210–213. [Google Scholar] [CrossRef]

- Meng, Q.; Chen, C.; Araby, S.; Cai, R.; Yang, X.; Li, P.; Wang, W. Highly ductile and mechanically strong Al-alloy/boron nitride nanosheet composites manufactured by laser additive manufacturing. J. Manuf. Processes 2023, 89, 384–396. [Google Scholar] [CrossRef]

- Xiao, Y.K.; Chen, H.; Bian, Z.Y.; Sun, T.T.; Ding, H.; Yang, Q.; Wu, Y.; Lian, Q.; Chen, Z.; Wang, H.W. Enhancing strength and ductility of AlSi10Mg fabricated by selective laser melting by TiB2 nanoparticles. J. Mater. Sci. Technol. 2022, 109, 254–266. [Google Scholar] [CrossRef]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.W.; Vleugels, J.; Van Humbeeck, J.; Kruth, J.P. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Xu, J.-Q.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.-M.; Mathaudhu, S.; Li, X.-C. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539–543. [Google Scholar] [CrossRef] [PubMed]

| TiB2/AlSi10Mg | Elements | Al | Si | Mg | Ti | B | Fe | Cu |

| Content | Bal. | 10.14 | 0.42 | 4.03 | 1.87 | 0.12 | 0.004 | |

| SiC | Elements | SiC | Fe | Cu | Pb | Cl | Ni | Ca |

| Content | ≥99.9 | 0.0512 | 0.0186 | 0.0062 | 0.0058 | 0.0043 | 0.0030 |

| Parameters | Value |

|---|---|

| pulsed current (A) | 100, 105, 110 |

| pulse width (ms) | 5, 6, 7, 8 |

| pulse frequency (Hz) | 14 |

| scanning speed (mm/s) | 3 |

| powder feed rate (g/min) | 1.12 |

| layer increment (mm) | 0.15 |

| laser spot diameter (mm) | 1.2 |

| Parameters | Pulse Width (ms) | Pulsed Current (A) | Laser Power (W) | Areal Energy Density KJ/mm2) |

|---|---|---|---|---|

| 14 | 5 | 100 | 143 | 39.722 |

| 14 | 5 | 105 | 151 | 41.944 |

| 14 | 5 | 110 | 159 | 44.166 |

| 14 | 6 | 100 | 165 | 45.833 |

| 14 | 6 | 105 | 174 | 48.333 |

| 14 | 6 | 110 | 184 | 51.111 |

| 14 | 7 | 100 | 192 | 53.333 |

| 14 | 7 | 105 | 203 | 56.388 |

| 14 | 7 | 110 | 214 | 59.444 |

| 14 | 8 | 100 | 217 | 60.277 |

| 14 | 8 | 105 | 224 | 62.222 |

| 14 | 8 | 110 | 236 | 65.555 |

| Alloys | Parameters (KJ/mm2) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| TiB2/AlSi10Mg | 39.722 | 256.00 ± 4.32 | 428.67 ± 9.67 | 5.60 ±1.56 |

| 44.166 | 254.67 ± 0.47 | 438.00 ± 12.03 | 5.83 ± 0.52 | |

| 2 wt.% SiC + TiB2/AlSi10Mg | 44.166 | 265.82 ± 4.17 | 421.71 ± 11.76 | 2.85 ± 0.2 |

| 59.444 | 250.43 ± 3.12 | 402.88 ± 6.75 | 3.03 ± 0.11 | |

| 5 wt.% SiC + TiB2/AlSi10Mg | 44.166 | 264.40 ± 1.29 | 426.74 ± 0.74 | 3.54 ± 0.12 |

| 59.444 | 267.87 ± 7.27 | 404.55 ± 10.12 | 2.19 ± 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, S.; Peng, Y.; Geng, L.; Kang, C.; Feng, Z.; Fan, W.; Tan, H.; Lin, X. Process Optimization, Microstructure and Mechanical Properties of SiC + TiB2/AlSi10Mg Composites Fabricated by Laser-Directed Energy Deposition. J. Manuf. Mater. Process. 2025, 9, 404. https://doi.org/10.3390/jmmp9120404

Zhang X, Zhang S, Peng Y, Geng L, Kang C, Feng Z, Fan W, Tan H, Lin X. Process Optimization, Microstructure and Mechanical Properties of SiC + TiB2/AlSi10Mg Composites Fabricated by Laser-Directed Energy Deposition. Journal of Manufacturing and Materials Processing. 2025; 9(12):404. https://doi.org/10.3390/jmmp9120404

Chicago/Turabian StyleZhang, Xin, Siyu Zhang, Yijie Peng, Long Geng, Chennuo Kang, Zhe Feng, Wei Fan, Hua Tan, and Xin Lin. 2025. "Process Optimization, Microstructure and Mechanical Properties of SiC + TiB2/AlSi10Mg Composites Fabricated by Laser-Directed Energy Deposition" Journal of Manufacturing and Materials Processing 9, no. 12: 404. https://doi.org/10.3390/jmmp9120404

APA StyleZhang, X., Zhang, S., Peng, Y., Geng, L., Kang, C., Feng, Z., Fan, W., Tan, H., & Lin, X. (2025). Process Optimization, Microstructure and Mechanical Properties of SiC + TiB2/AlSi10Mg Composites Fabricated by Laser-Directed Energy Deposition. Journal of Manufacturing and Materials Processing, 9(12), 404. https://doi.org/10.3390/jmmp9120404