Sustainable Drilling Strategies for Rivet Hole Formation in Nickel-Based Alloys for Aeronautical Applications

Abstract

1. Introduction

1.1. The Industrial Need for Sustainable Drilling of Inconel 625

1.2. The Limitations of Existing Studies

1.3. The Specific Research Objectives of This Work

- ▪

- Identify the most significant factors affecting surface roughness in the sustainable drilling of Inconel 625;

- ▪

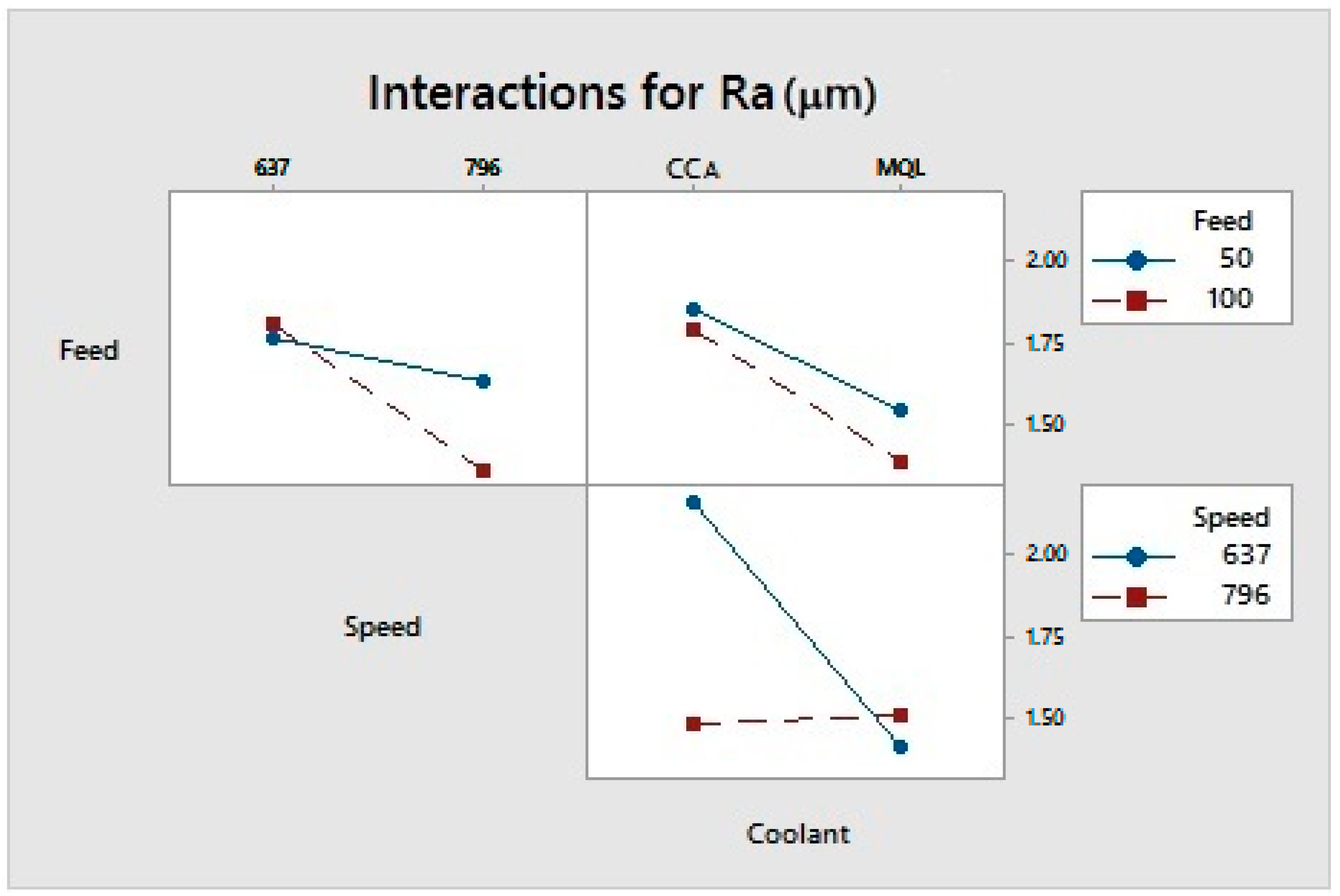

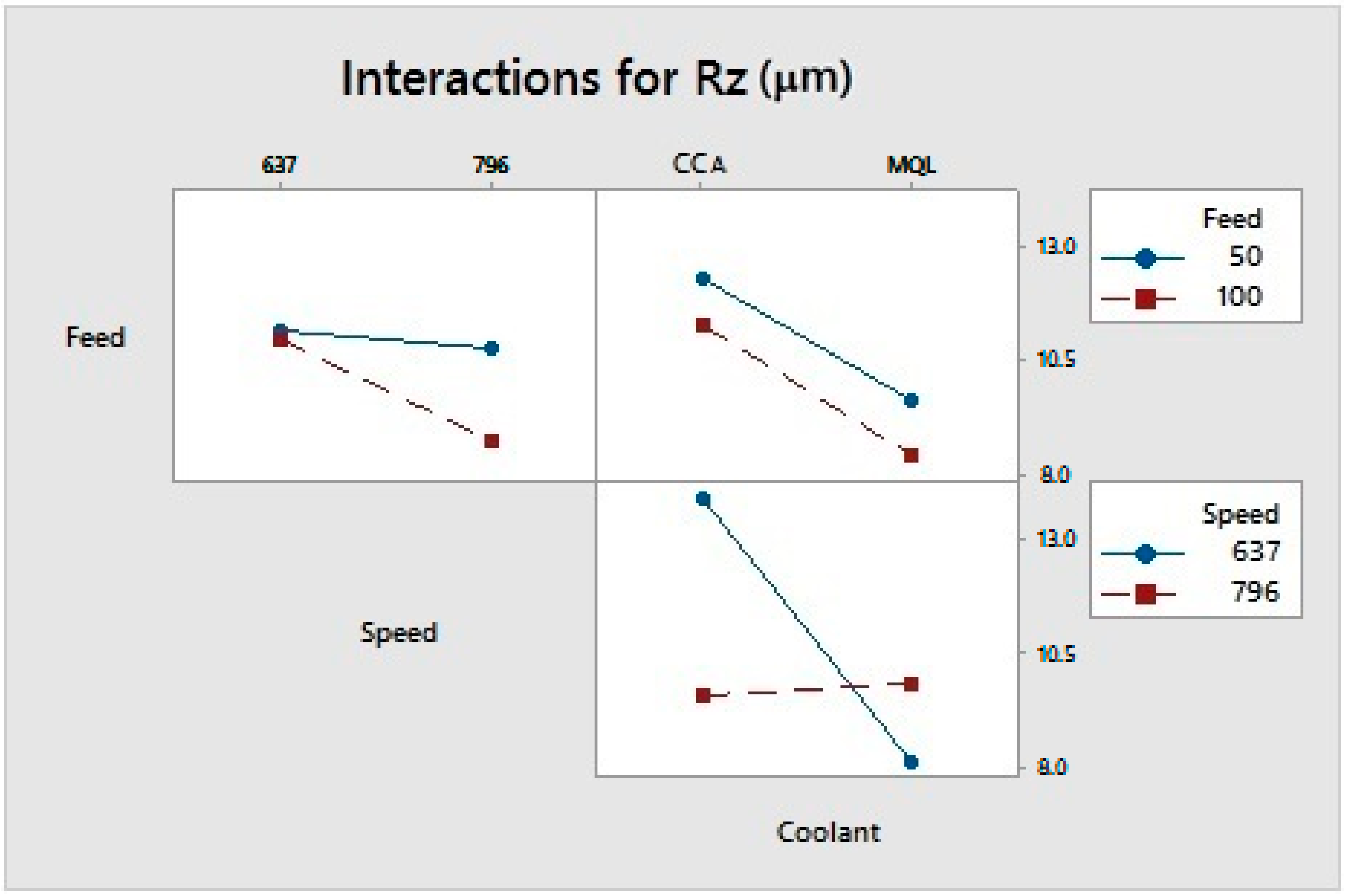

- Quantify the interaction effects between spindle speed, feed rate, and cooling strategy;

- ▪

- Determine the optimal cutting conditions that meet aeronautical surface roughness standards (Ra = 0.8–1.6 µm) while minimizing tool wear and environmental impact.

2. Methodology

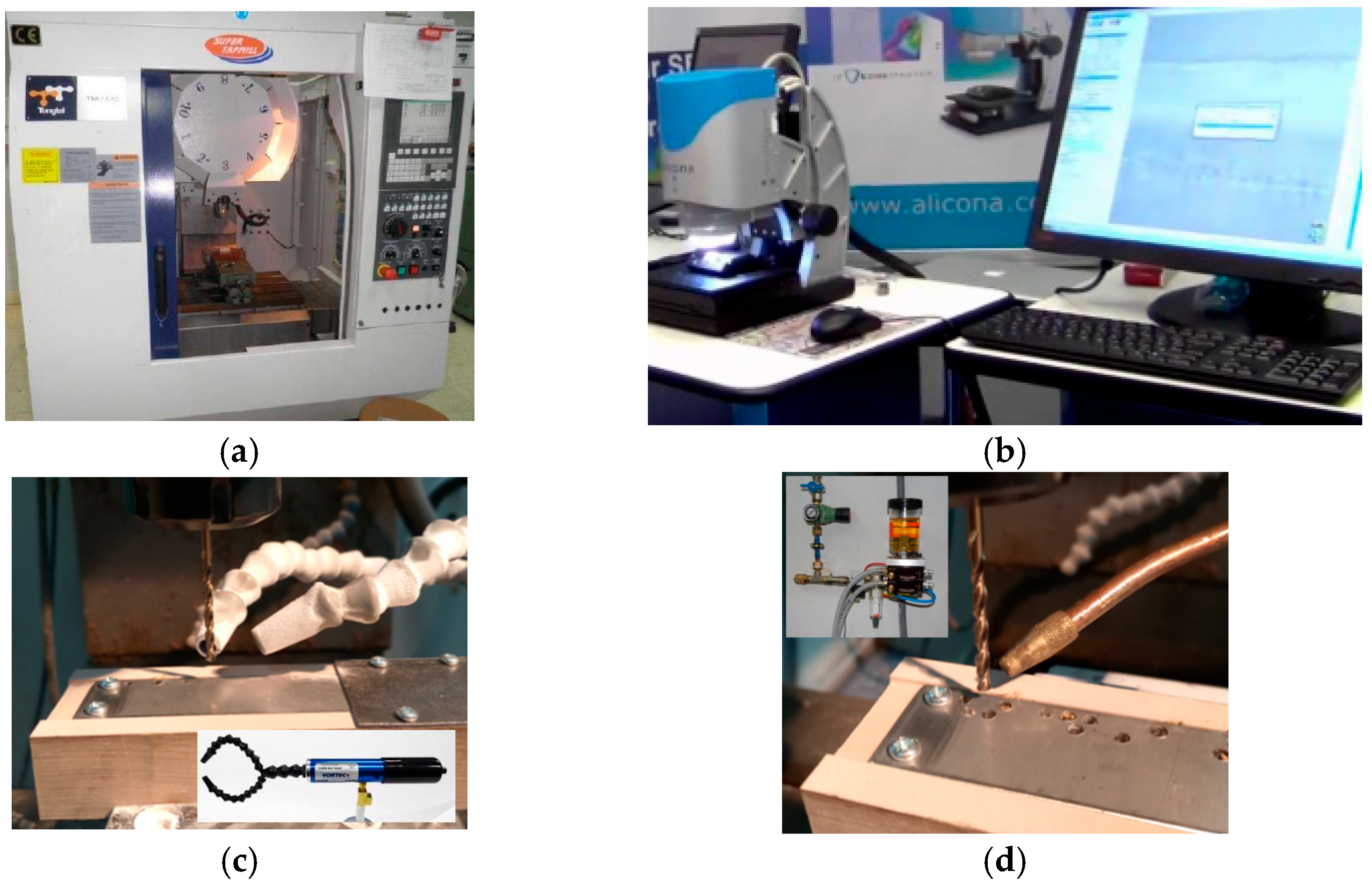

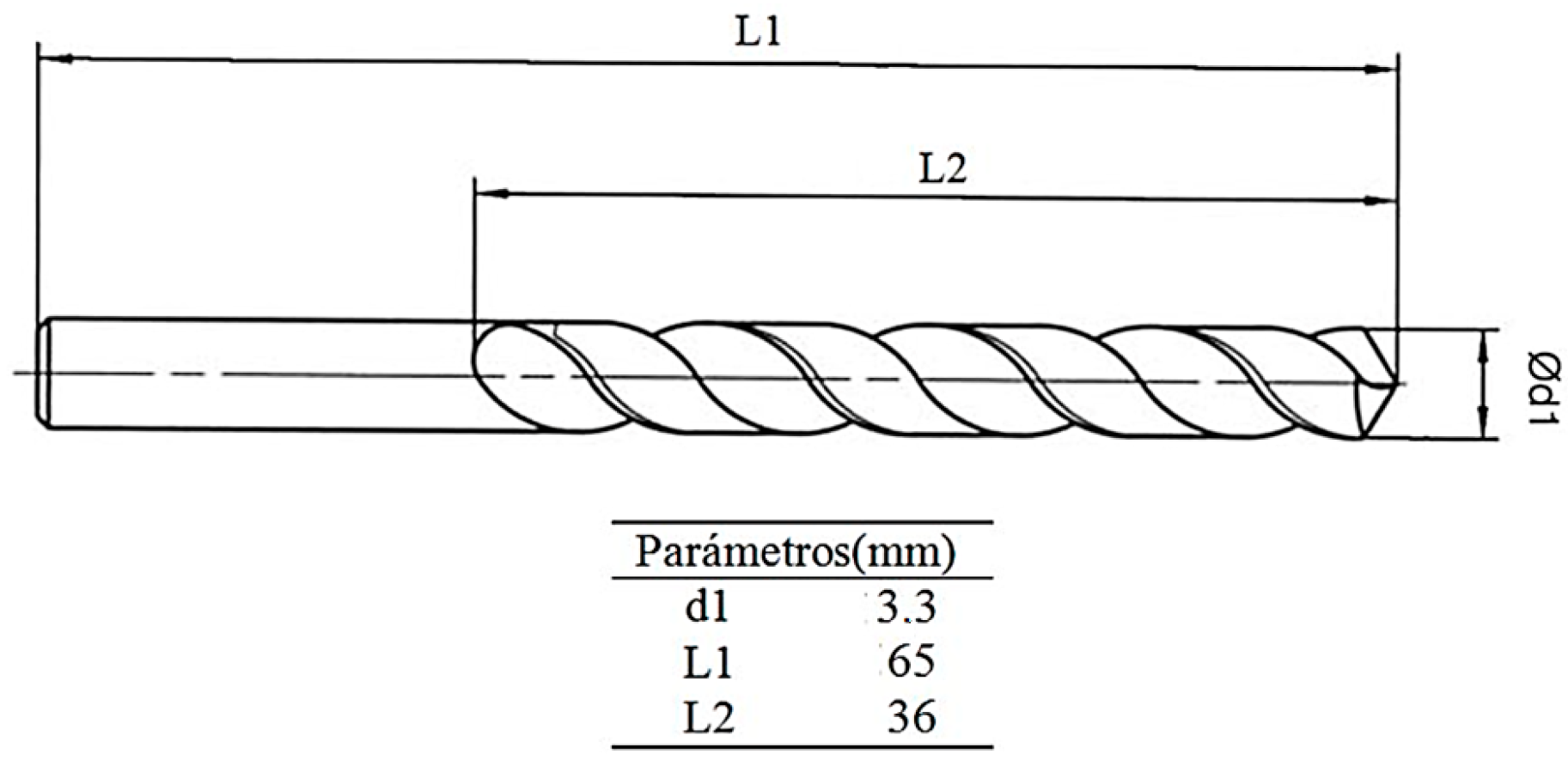

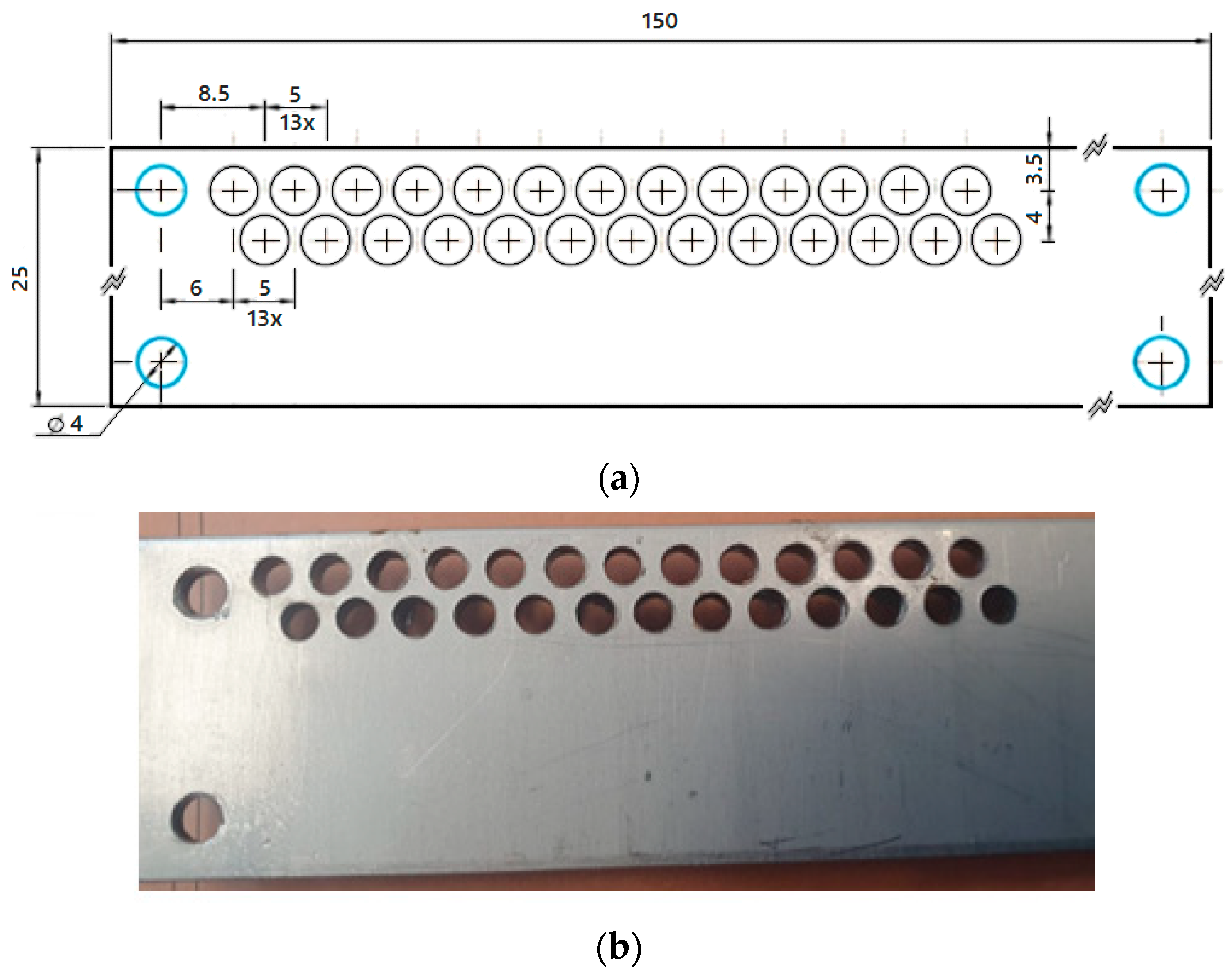

2.1. Equipment, Tools, and Materials

2.2. Experimental Campaign

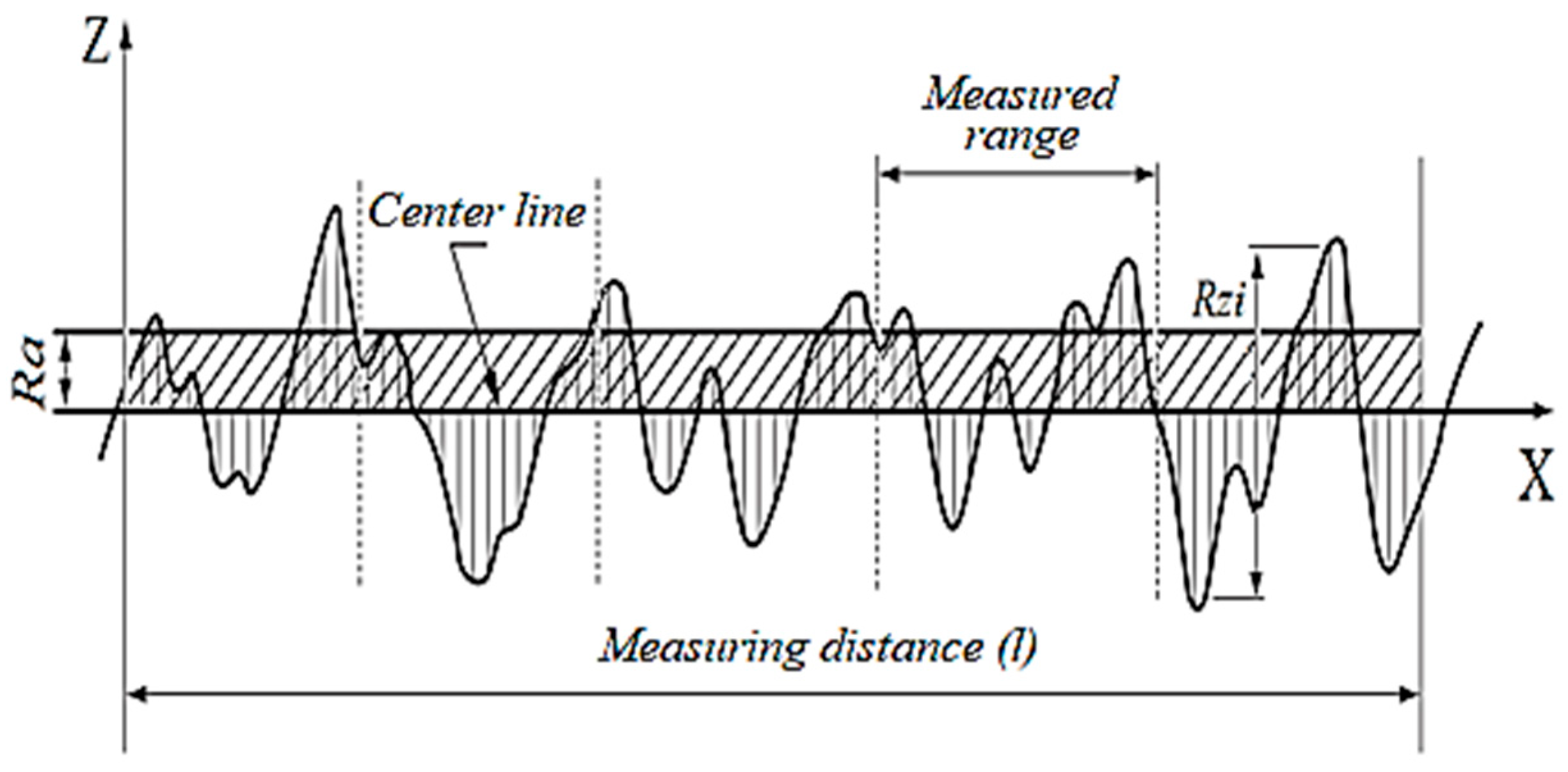

2.3. Surface Roughness Measurement and Data Analysis

3. Results and Discussion

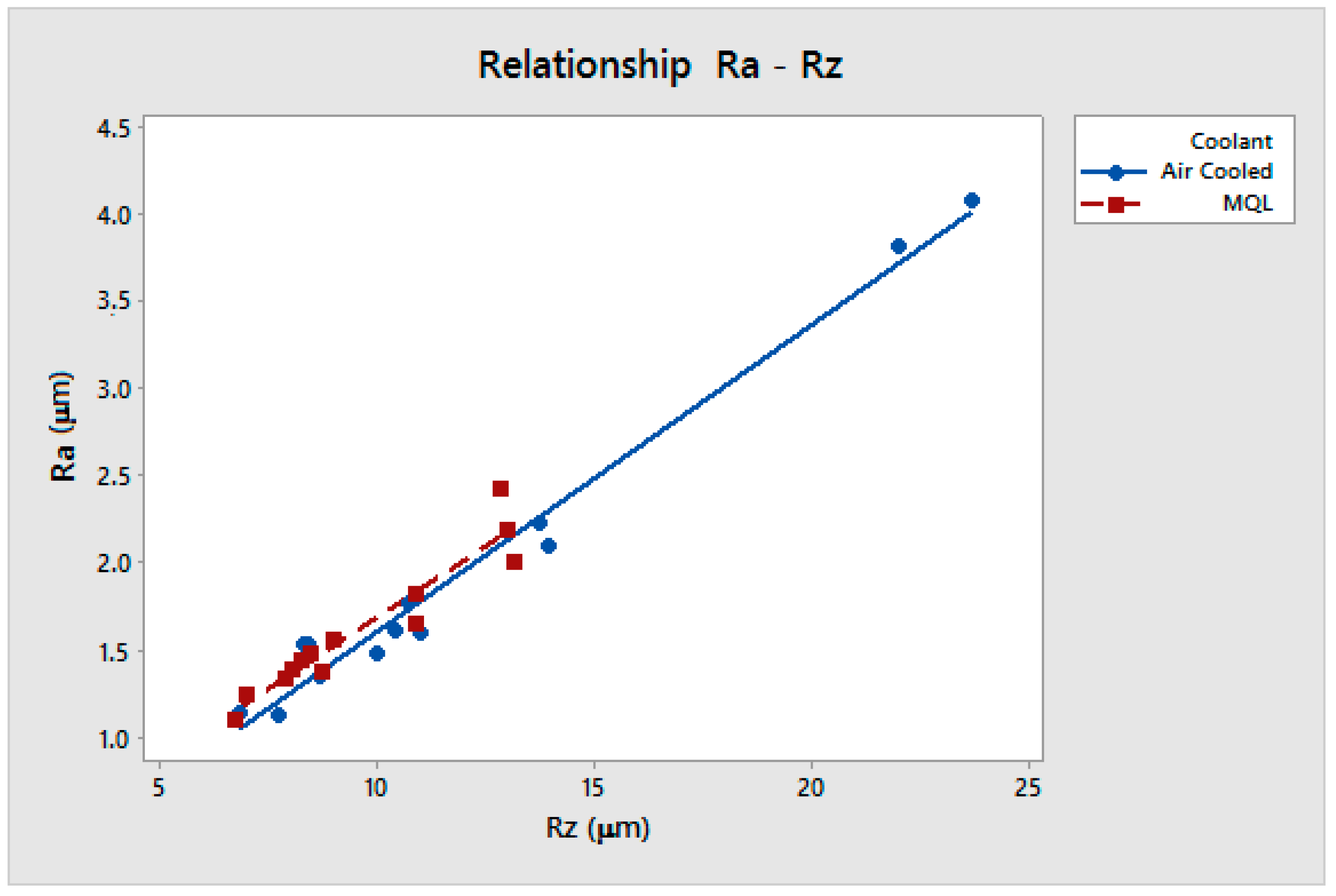

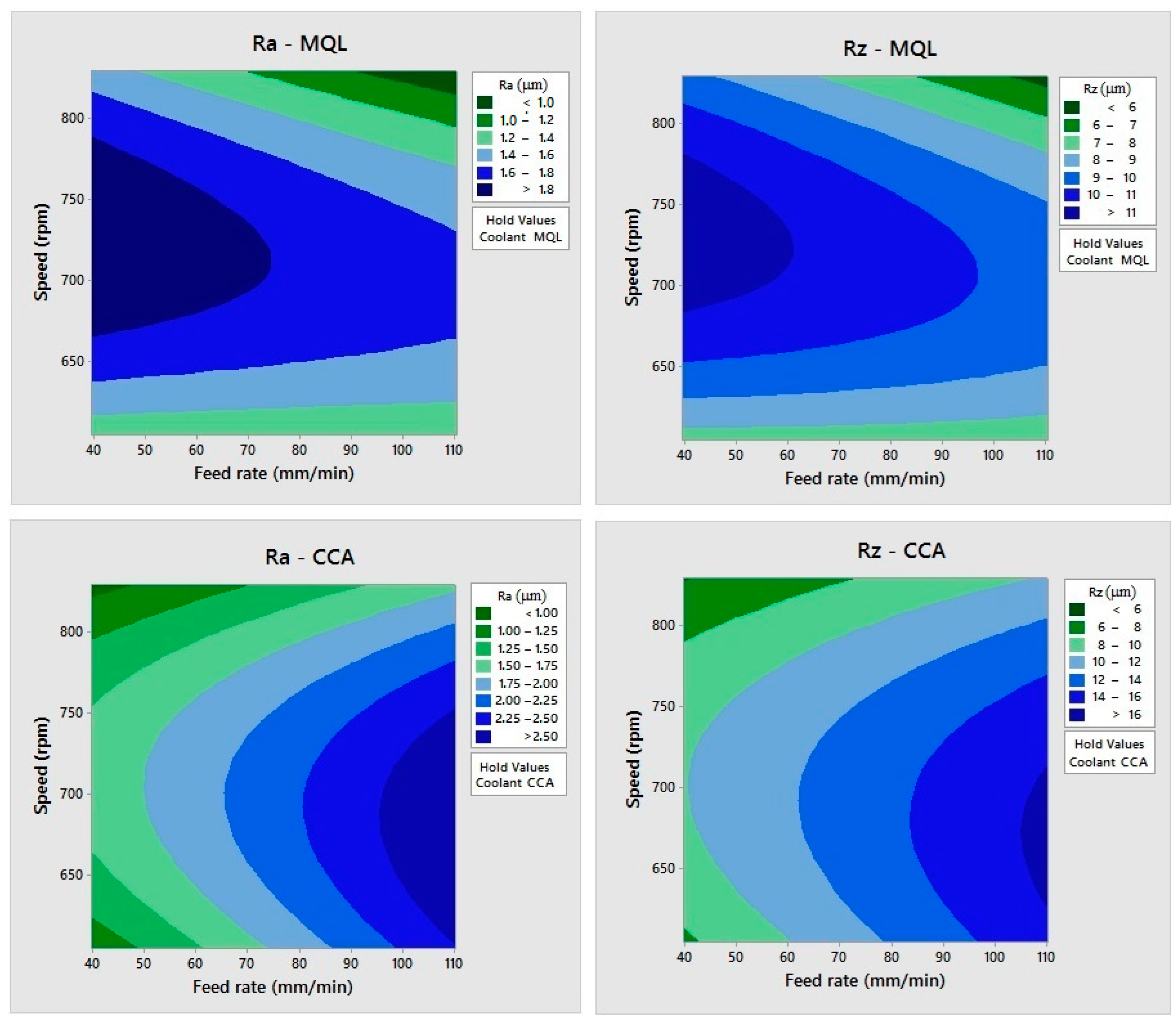

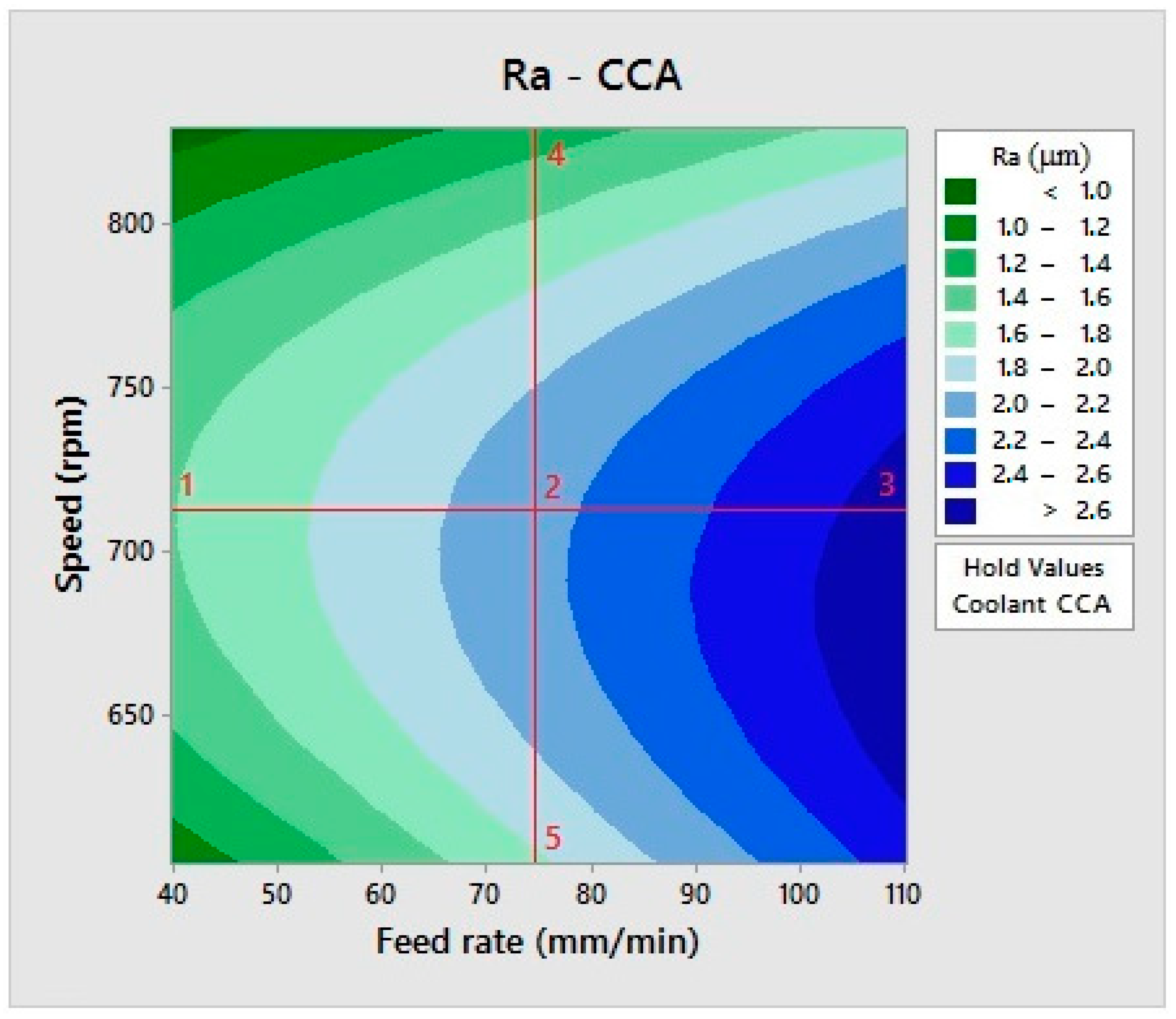

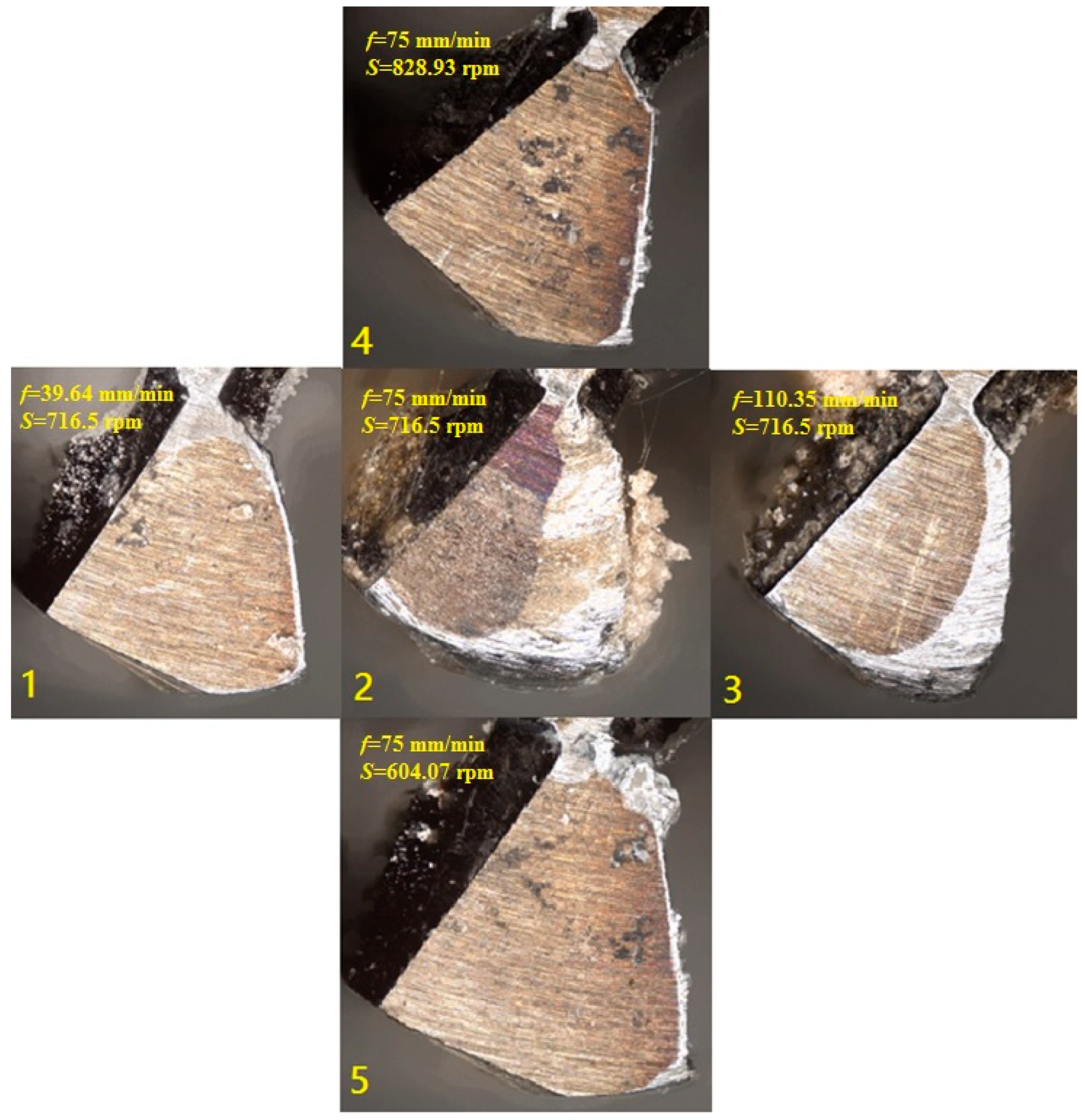

3.1. Results

3.2. Dicussion

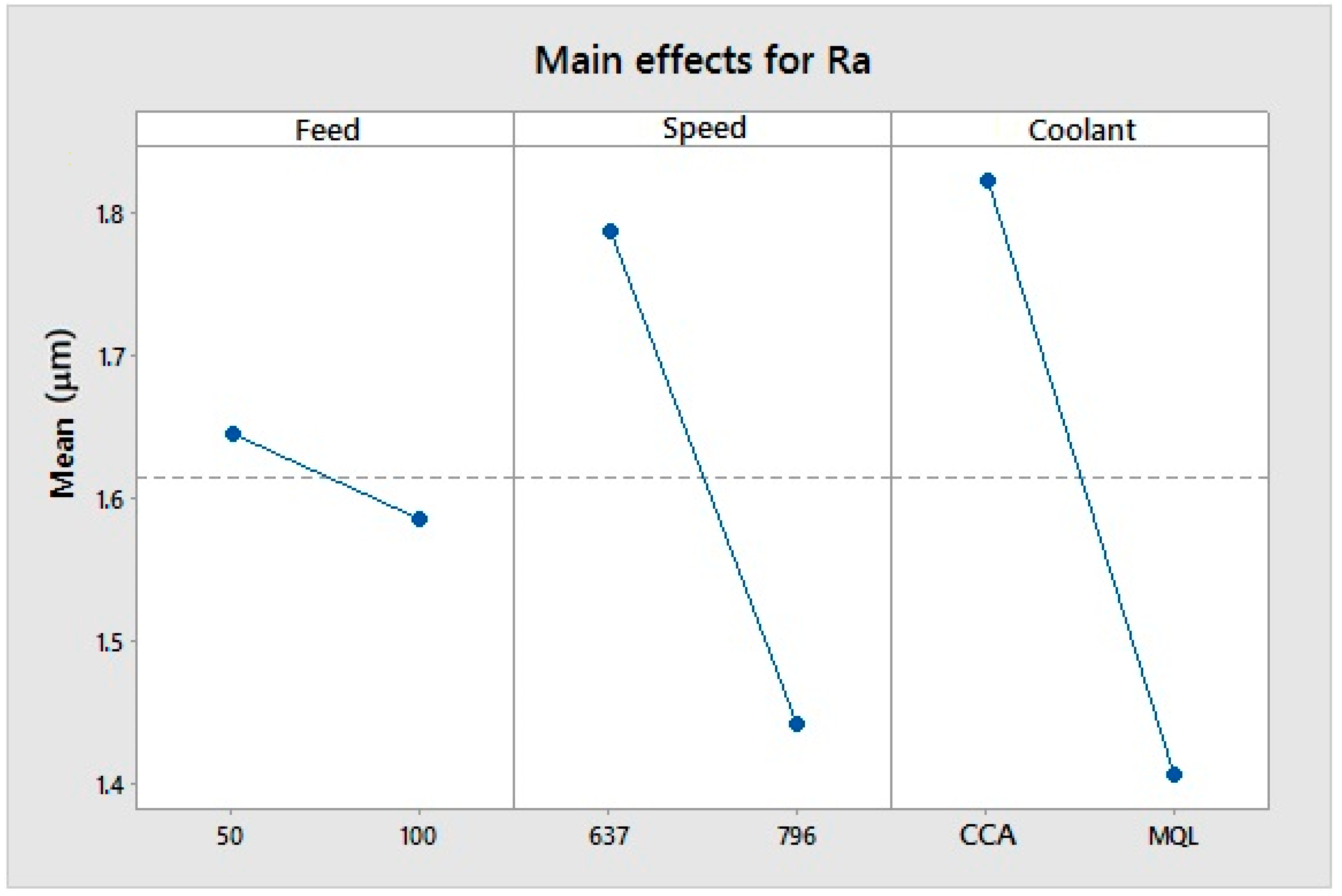

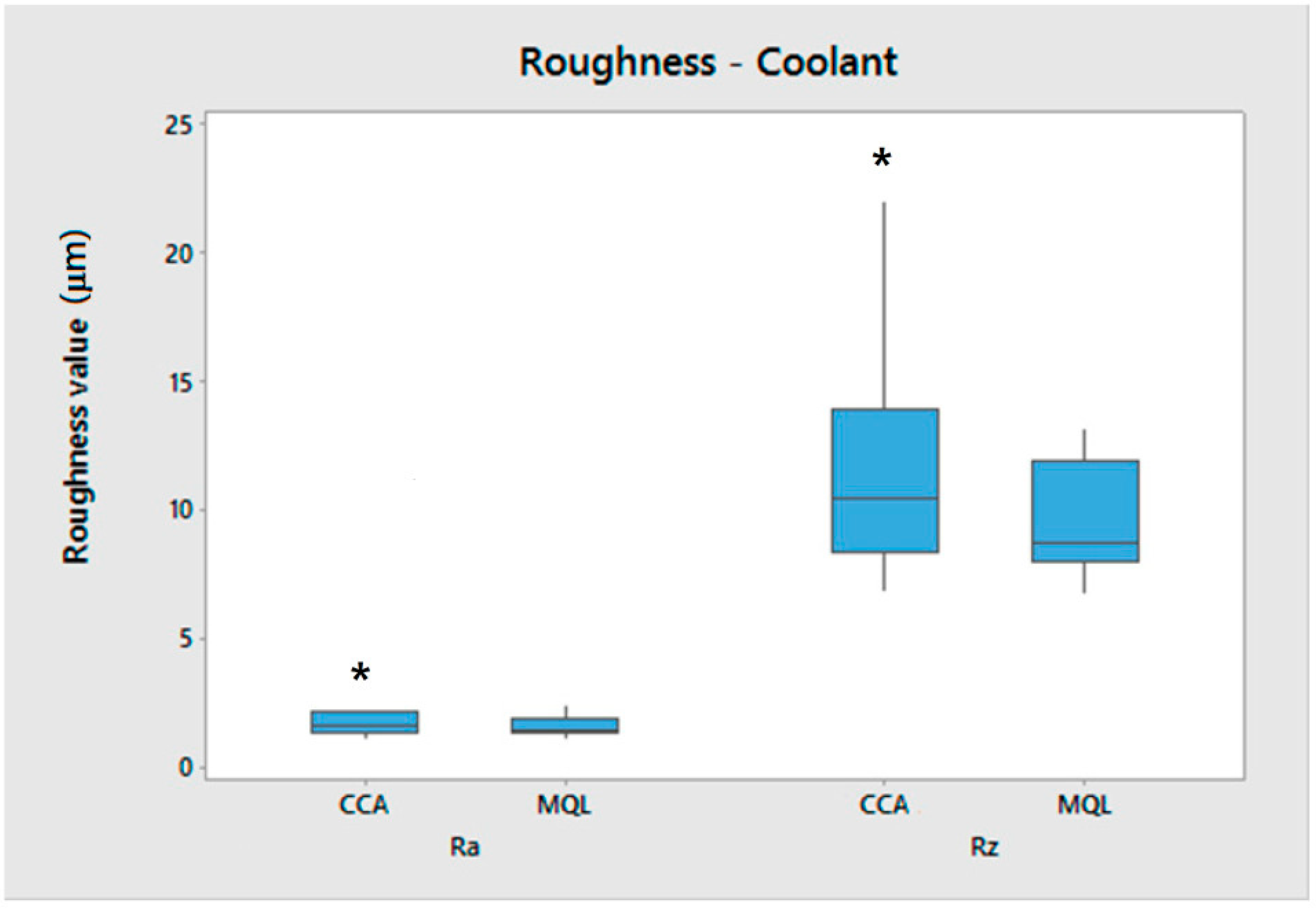

3.2.1. Influence of Cooling/Lubrication Method

3.2.2. Influence of Cutting Parameters

3.2.3. Tool Wear and Surface Integrity Correlation

3.3. Novelty and Contribution of the Study

4. Conclusions and Future Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Castro, P.M.S.T.; de Matos, P.F.P.; Moreira, P.M.G.P.; da Silva, L.F.M. An overview on fatigue analysis of aeronautical structural details: Open hole, single rivet lap-joint, and lap-joint panel. Mater. Sci. Eng. A 2007, 468–470, 144–157. [Google Scholar] [CrossRef]

- Basak, A.K.; Bajwa, D.S.; Pramanik, A. Fatigue Behaviour of Mechanical Joints: A Review. Metals 2025, 15, 25. [Google Scholar] [CrossRef]

- Deng, G.; Nagamoto, K.; Nakano, Y.; Nakanishi, T. Evaluation of the Effect of Surface Roughness on Crack Initiation Life. In Proceedings of the 12th International Conference on Fracture, Ottawa, ON, Canada, 12–17 July 2009. [Google Scholar]

- Ralph, W.C.; Johnson, W.S.; Toivonen, P.; Makeev, A.; Newman, J.C., Jr. Effect of various aircraft production drilling procedures on hole quality. Int. J. Fatigue 2006, 28, 943–950. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; De Matos, P.F.P.; Camanho, P.P.; Pastrama, S.D.; de Castro, P.M.S.T. Stress intensity factor and load transfer analysis of a cracked riveted lap joint. Mater. Des. 2007, 28, 1263–1270. [Google Scholar] [CrossRef]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Vafadar, A. A review: Drilling performance and hole quality of aluminium alloys for aerospace applications. J. Mater. Res. Technol. 2020, 9, 12484–12500. [Google Scholar] [CrossRef]

- Shishkin, S.V.; Shishkin, S.S. The application of rivets with shape memory in aeronautical engineering. J. Mach. Manuf. Reliab. 2010, 39, 179–184. [Google Scholar] [CrossRef]

- Viganò, F.; Manes, A.; Giglio, M. Effect of cold driving process on fatigue life of helicopter fuselage joints. Procedia Eng. 2010, 2, 639–647. [Google Scholar] [CrossRef]

- Olufayo, O.A.; Boulaares, M.D.; Songmene, V. Machining/machinability of Rene 65 superalloy for aerospace applications. In Proceedings of the 2020 IEEE 11th International Conference on Mechanical and Intelligent Manufacturing Technologies, Cape Town, South Africa, 20–22 January 2020. [Google Scholar] [CrossRef]

- Shahwaz, M.; Nath, P.; Sen, I. A critical review on the microstructure and mechanical properties correlation of additively manufactured nickel-based superalloys. J. Alloys Compd. 2022, 907, 164530. [Google Scholar] [CrossRef]

- Kilickap, E.; Huseyinoglu, M.; Yardimeden, A. Optimization of drilling parameters on surface roughness in drilling of AISI 1045 using response surface methodology and genetic algorithm. Int. J. Adv. Manuf. Technol. 2011, 52, 79–88. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A.; Koklu, U.; Keeble, W. Evaluation of the Surface Defects and Dimensional Tolerances in Multi-Hole Drilling of AA5083, AA6061, and AA2024. Appl. Sci. 2021, 11, 4285. [Google Scholar] [CrossRef]

- Doğan, M.A.; Yazman, Ş.; Gemi, L.; Yildiz, M.; Yapici, A. A review on drilling of FML stacks with conventional and unconventional processing methods under different conditions. Compos. Struct. 2022, 297, 115913. [Google Scholar] [CrossRef]

- Meng, G.; Gong, Y.; Zhang, J.; Ren, Q.; Zhao, J. Microstructure effect on the machinability behavior of additive and conventionally manufactured Inconel 718 alloys. J. Mater. Process. Technol. 2024, 324, 118228. [Google Scholar] [CrossRef]

- Pedroso, A.F.V.; Sebbe, N.P.V.; Costa, R.D.F.S.; Barbosa, M.L.S.; Sales-Contini, R.C.M.; Silva, F.J.G.; Campilho, R.D.S.G.; de Jesus, A.M.P. INCONEL® Alloy Machining and Tool Wear Finite Element Analysis Assessment: An Extended Review. J. Manuf. Mater. Process. 2024, 8, 37. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Gupta, M.K.; Song, Q. Tool wear and hole quality evaluation in cryogenic Drilling of Inconel 718 superalloy. Tribol. Int. 2020, 143, 106084. [Google Scholar] [CrossRef]

- Behera, B.C.; Mohamed, A.; Muduli, K. Eco-Friendly Machining of Ni-Based Superalloy with High-Velocity Mist Nozzle. Eng. Proc. 2024, 66, 33. [Google Scholar] [CrossRef]

- Fernández, D.; Sandá, A.; Bengoetxea, I. Cryogenic Milling: Study of the Effect of CO2 Cooling on Tool Wear When Machining Inconel 718, Grade EA1N Steel and Gamma TiAl. Lubricants 2019, 7, 10. [Google Scholar] [CrossRef]

- Safie, N.S.S.; Murad, M.N.; Lih, T.C.; Azmi, A.I.; Wan Hamzah, W.A.; Danish, M. Roles of Eco-Friendly Non-Edible Vegetable Oils in Drilling Inconel 718 through Minimum Quantity Lubrication. Lubricants 2022, 10, 211. [Google Scholar] [CrossRef]

- Ranjan, P.; Singh, A.K.; Mujumdar, S. Drilling performance investigation and economic analysis with minimum quantity lubrication (MQL). Manuf. Lett. 2025, 44, 1758–1764. [Google Scholar] [CrossRef]

- Khanna, N.; Patel, D.; Raval, P.; Airao, J.; Badheka, V.; Rashid, R.A.R. Comparison of sustainable cooling/lubrication strategies for drilling of wire arc additively manufactured Inconel 625. Tribol. Int. 2024, 200, 110068. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Marín, M.; de Pipaón, J.M.S. A comparative study of tool degradation in the re-drilling of magnesium-based multi-materials through sustainable cooling technologies. Procedia CIRP 2023, 118, 390–395. [Google Scholar] [CrossRef]

- Manikandan, M.; Arun, S.; Kuriachen, B.; Mathew, J. Comparative study of micro-die sink and micro-EDM drilled holes for electrode wear and surface roughness. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Gobikrishnan, U.; Suresh, P.; Kumaravel, P. Drilling investigations on Inconel alloy 625 material of material removal rate using micro electrochemical machining. Mater. Today Proc. 2021, 37, 1629–1633. [Google Scholar] [CrossRef]

- Murali, B.; Karthikeyan, S.; Mohamed, M.J.S.; Manjula, A.; Pandiarajan, P. Improvement of micro-EDM drilling efficiency on Inconel 625. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Rajesh, S.; Prabu, D.A.; Gobikrishnan, U.; Kumar, P.J.L.; Selvan, T.A.; Ramesh, A.; Madhankumar, S. Surface roughness assessments and comparative study of Inconel 625 and Inconel 718 alloys after micro electrochemical machining. Mater. Today Proc. 2022, 62, 938–943. [Google Scholar] [CrossRef]

- Szwajka, K.; Zielińska-Szwajka, J.; Żaba, K.; Trzepieciński, T. An Investigation of the Sequential Micro-Laser Drilling and Conventional Re-Drilling of Angled Holes in an Inconel 625 Ni-Based Alloy. Lubricants 2023, 11, 384. [Google Scholar] [CrossRef]

- Xiao, W.L.; Chen, H.B.; Yin, Y. Effects of Surface Roughness on the Fatigue Life of Alloy Steel. Key Eng. Mater. 2013, 525–526, 417–420. [Google Scholar] [CrossRef]

- Alang, N.A.; Razak, N.A.; Miskam, A.K. Effect of Surface Roughness on Fatigue Life of Notched Carbon Steel. Int. J. Eng. Technol. 2011, 11, 160–163. [Google Scholar]

- Rao, J.H.; Zhang, K.; Rometsch, P.; Huang, A.; Wu, X. The Influence of Surface Roughness on the Fatigue Performance of Selective Laser Melted Aluminium Alloy A357. In Proceedings of the 16th International Aluminum Alloys Conference (ICAA16) 2018, Montreal, QC, Canada, 17–21 June 2018; Canadian Institute of Mining, Metallurgy and Petroleum: Westmount, QC, Canada, 2018. [Google Scholar]

- Javadi, H.; Jomaa, W.; Texier, D.; Brochu, M.; Bocher, P. Surface Roughness Effects on the Fatigue Behavior of As-Machined Inconel718. Solid State Phenom. 2016, 258, 306–309. [Google Scholar] [CrossRef]

- Toloei, A.; Stoilov, V.; Northwood, D. Simultaneous effect of surface roughness and passivity on corrosion resistance of metals. WIT Trans. Eng. Sci. 2015, 90, 355–367. [Google Scholar] [CrossRef]

- Toloei, A.S.; Stoilov, V.; Northwood, D.O. The effect of different surface topographies on the corrosion behaviour of nickel. WIT Trans. Eng. Sci. 2013, 77, 193–204. [Google Scholar] [CrossRef]

- Tang, Y.; Dai, N.; Wu, J.; Jiang, Y.; Li, J. Investigation of Influence of Surface Roughness on Pitting Corrosion of Duplex Stainless Steel 2205 using Various Electrochemical Techniques. Int. J. Electrochem. Sci. 2019, 14, 6790–6813. [Google Scholar] [CrossRef]

- Pradhan, D.; Mahobia, G.S.; Chattopadhyay, K.; Singh, V. Effect of surface roughness on corrosion behavior of the superalloy IN718 in simulated marine environment. J. Alloys Compd. 2018, 740, 250–263. [Google Scholar] [CrossRef]

- Makhesana, M.A.; Patel, K.M.; Krolczyk, G.M.; Danish, M.; Singla, A.K.; Khanna, N. Influence of MoS2 and graphite-reinforced nanofluid-MQL on surface roughness, tool wear, cutting temperature and microhardness in machining of Inconel 625. CIRP J. Manuf. Sci. Technol. 2023, 41, 225–238. [Google Scholar] [CrossRef]

| Reference | Material/Process | Cooling/Lubrication Strategy | Main Contribution | Identified Limitation/Research Gap |

|---|---|---|---|---|

| [13,14,15,16] | Inconel 718/625—conventional drilling and turning | Conventional flood cooling | Reported severe tool wear, high cutting temperatures, and difficulty maintaining surface integrity. | Did not explore eco-friendly lubrication or combined factor effects. |

| [23,24,25,26] | Inconel 625—unconventional drilling (EDM, ECM, micro-EDM) | No external lubrication | Improved MRR and surface precision at micro-scale. | Processes unsuitable for industrial rivet-hole drilling; lack of sustainability evaluation. |

| [27] | Inconel 625—drilling | Conventional lubrication | Examined hardness variation in the heat-affected zone. | Did not link hardness changes with surface roughness or tool wear. |

| [17,18,19,20,21] | Nickel-based alloys—machining under MQL, CCA, or cryogenic conditions | MQL, cryogenic CO2, or cold air | Demonstrated lower temperatures and reduced wear compared to flood cooling. | Most studies evaluate one cooling method or a single cutting parameter. |

| [36] | Inconel 625—drilling with nanofluid MQL | MQL with nanoparticles | Reported up to 40% cost savings and improved roughness. | Focused only on economic evaluation; limited statistical modeling. |

| [6,12,22] | Aluminum and hybrid materials—multi-hole drilling | Sustainable lubrication and air cooling | Achieved good surface quality while reducing environmental impact. | Results not transferable to Ni-based alloys due to different thermal behavior. |

| [28,29,30,31,32,33,34,35] | Nickel and steel alloys—surface roughness vs. fatigue/corrosion | Various machining conditions | Demonstrated that surface roughness influences fatigue crack initiation and corrosion rate. | Did not relate roughness to machining parameters or sustainable cooling. |

| — (This work) | Inconel 625—sustainable drilling for rivet holes | MQL-Eco and CCA | Addressed the study of the combined influence, on Ra and Rz, of feed rate, spindle speed, and environmentally friendly cooling/lubrication strategies, MQL-Eco and CCA, when drilling Inconel 625; using ANOVA and RMS statistical analysis. | — |

| Diameter | 3.3 mm |

| Material | HSS–Co–TiN (twist drill) |

| Helix angle | 37° |

| Point angle | 135° |

| Equipment | Supplier | Description |

| Machining center | Tongtai Machine, Kaohsiung, Taiwan. | Tongtai TMV510. |

| Numerical control | Fanuc Iberia, Barcelona, Spain. | Fanuc series OI-MC. |

| MQL-Eco | Accu-Lube (ITW), GA, USA. | Accu-Lube with frequency generator MQL-eco system. |

| CCA | Vortec, Cincinati, OH, USA. | Cold compressed air vortex cooling system. |

| Surface 3D scan | Bruker Alicona, Graz, Austria. | Alicona Infinitive Focus S.L, optics 10×. |

| Tools | Supplier | Description |

| Drill bits | Hoffmann GmbH, Munich, Germany. | Garant HSCO; high-performance. |

| Materials | Supplier | Description |

| Inconel 625 | Böhler, Viladecans (Barcelona), Spain. | Inconel 625 sheet metal. |

| Eco-fluid | Leitat Technological Center, Terrassa, Spain. | Water-based with polyol esters. |

| Factor | Levels (Notation) | Levels (Values) | |

|---|---|---|---|

| Tool (drill bit) | T | A1 1215 | |

| Feed rate, f (mm/min) | f1, f2 | 50 | 100 |

| Spindle speed, S (rpm) | S1, S2 | 637 | 796 |

| Coolant | R1, R2 | MQL | CCA |

| Factor | Levels (Notation) | Levels (Values) |

|---|---|---|

| Tool (drill bit) | T | A1 1215 |

| Feed rate, f (mm/min) | fl, f1, fm, f2, fu | 39.64, 50, 75, 100, 110.35 |

| Spindle speed, S (rpm) | Sl, S1, Sm, S2, Su | 604.07, 637, 716.5, 796, 828.93 |

| Coolant | R1, R2 | MQL CCA |

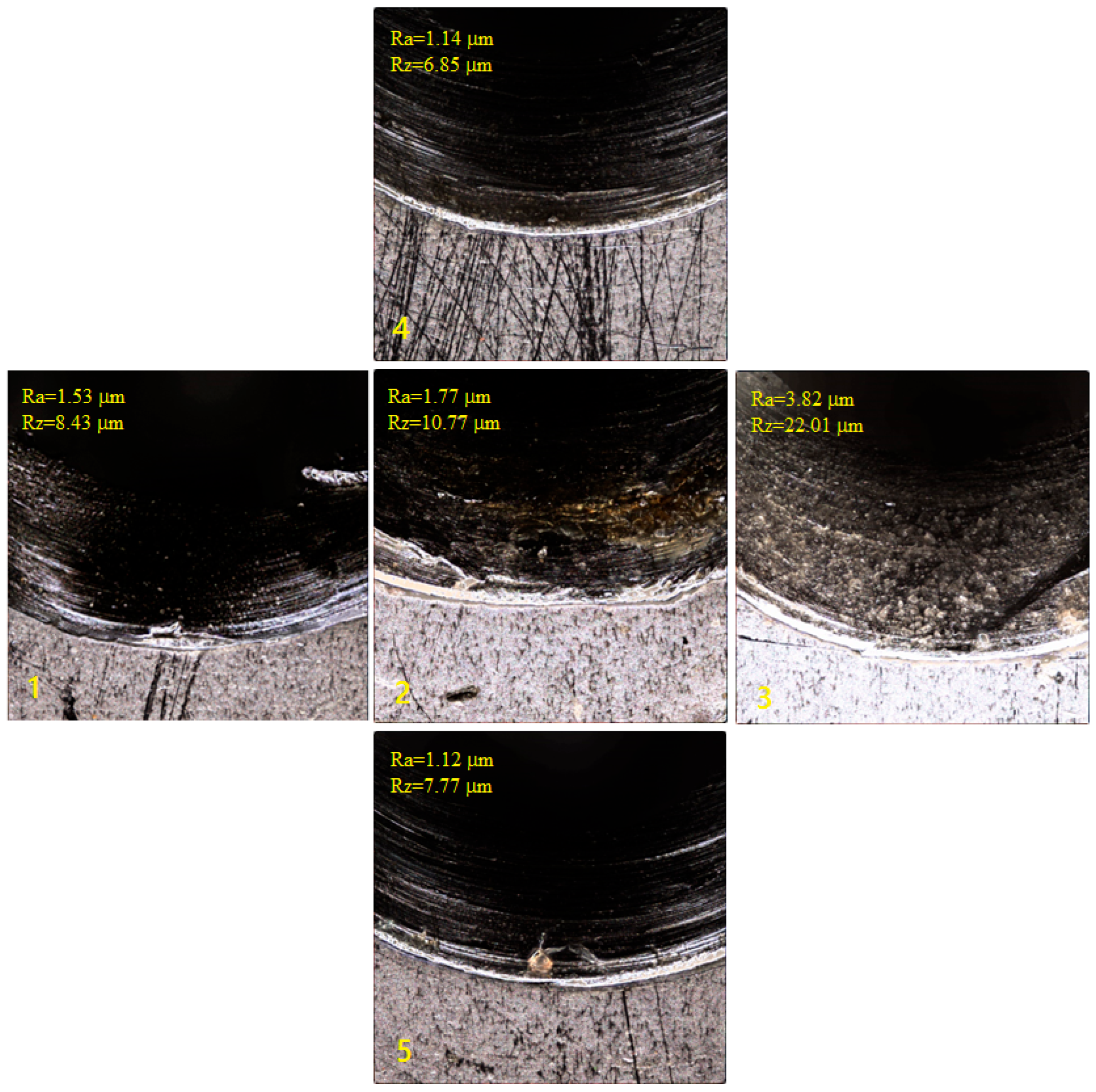

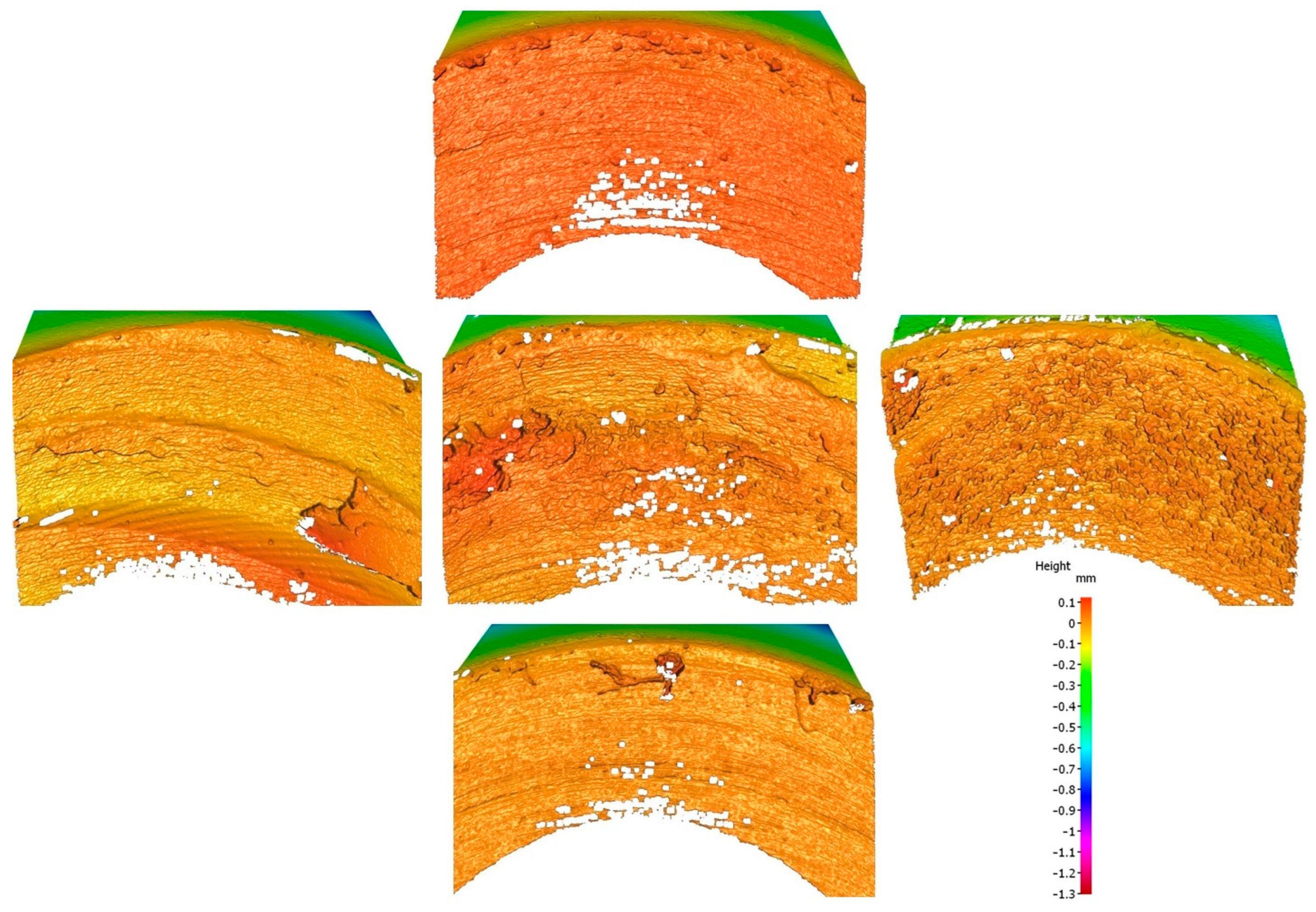

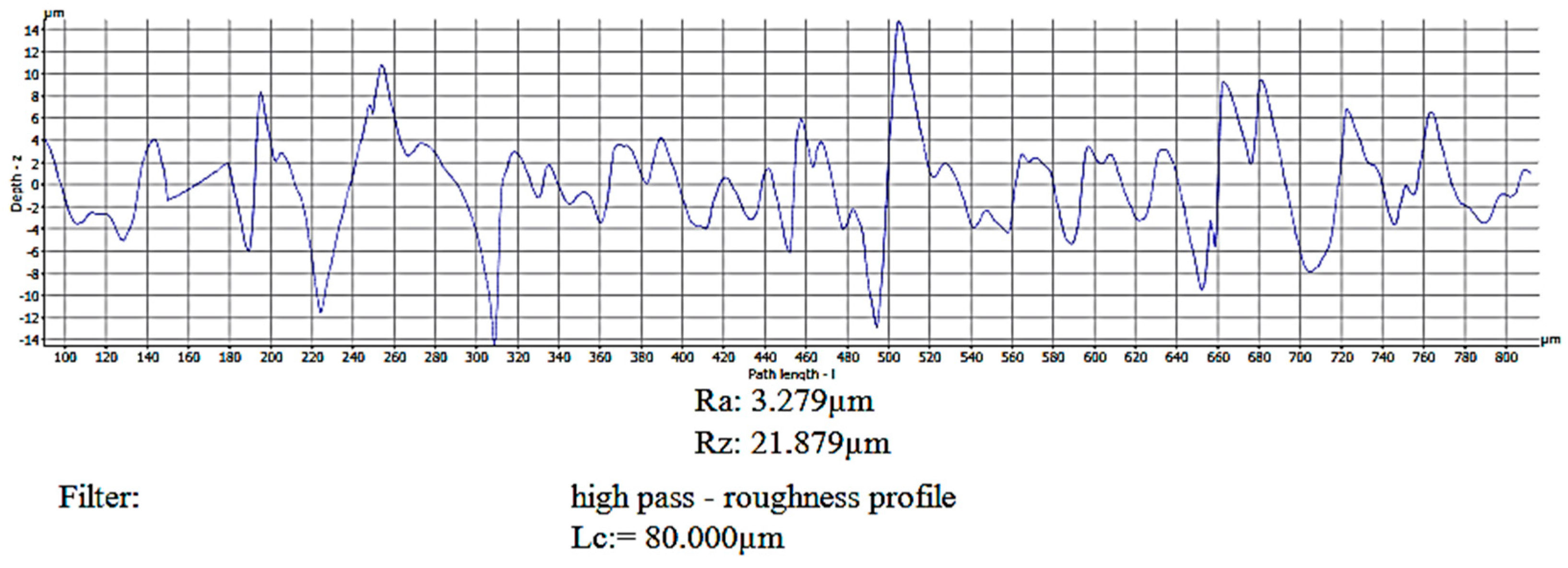

| Nº | Feed (mm/min) | Speed (rpm) | Coolant | Roughness | |

|---|---|---|---|---|---|

| Ra (µm) | Rz (µm) | ||||

| 1 | 75 | 716.5 | CCA | 1.52 | 8.32 |

| 2 | 100 | 796 | MQL | 1.37 | 8.76 |

| 3 | 75 | 716.5 | CCA | 1.77 | 10.77 |

| 4 | 50 | 796 | MQL | 1.65 | 10.95 |

| 5 | 75 | 604.07 | CCA | 1.12 | 7.77 |

| 6 | 39.64 | 716.5 | CCA | 1.53 | 8.43 |

| 7 | 100 | 637 | CCA | 2.23 | 13.76 |

| 8 | 75 | 716.5 | MQL | 2.01 | 13.19 |

| 9 | 39.64 | 716.5 | MQL | 1.56 | 9.01 |

| 10 | 50 | 637 | CCA | 2.10 | 14.00 |

| 11 | 100 | 637 | MQL | 1.39 | 8.06 |

| 12 | 50 | 637 | MQL | 1.43 | 8.28 |

| 13 | 100 | 796 | CCA | 1.35 | 8.69 |

| 14 | 75 | 828.93 | CCA | 1.14 | 6.85 |

| 15 | 75 | 716.5 | CCA | 1.59 | 11.01 |

| 16 | 75 | 716.5 | MQL | 2.19 | 13.05 |

| 17 | 75 | 716.5 | MQL | 1.24 | 7.05 |

| 18 | 110.35 | 716.5 | MQL | 1.09 | 6.75 |

| 19 | 50 | 796 | CCA | 1.61 | 10.47 |

| 20 | 75 | 716.5 | MQL | 1.33 | 7.92 |

| 21 | 75 | 716.5 | CCA | 4.08 | 23.70 |

| 22 | 75 | 716.5 | MQL | 2.43 | 12.89 |

| 23 | 75 | 828.93 | MQL | 1.47 | 8.49 |

| 24 | 75 | 604.07 | MQL | 1.82 | 10.91 |

| 25 | 75 | 716.5 | CCA | 1.47 | 10.04 |

| 26 | 110.35 | 716.5 | CCA | 3.82 | 22.01 |

| Source | Ra (µm) | Rz (µm) | ||

|---|---|---|---|---|

| p-Value | % Variability | p-Value | % Variability | |

| Coolant | 0.014 | 31.88% | 0.025 | 36.80% |

| Speed | 0.021 | 20.76% | - | |

| Speed * Coolant | 0.012 | 37.38% | 0.023 | 44.63% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sáenz de Pipaón, J.M.; García-Domínguez, A.; Claver, J.; Rubio, E.M. Sustainable Drilling Strategies for Rivet Hole Formation in Nickel-Based Alloys for Aeronautical Applications. J. Manuf. Mater. Process. 2025, 9, 389. https://doi.org/10.3390/jmmp9120389

Sáenz de Pipaón JM, García-Domínguez A, Claver J, Rubio EM. Sustainable Drilling Strategies for Rivet Hole Formation in Nickel-Based Alloys for Aeronautical Applications. Journal of Manufacturing and Materials Processing. 2025; 9(12):389. https://doi.org/10.3390/jmmp9120389

Chicago/Turabian StyleSáenz de Pipaón, José Manuel, Amabel García-Domínguez, Juan Claver, and Eva María Rubio. 2025. "Sustainable Drilling Strategies for Rivet Hole Formation in Nickel-Based Alloys for Aeronautical Applications" Journal of Manufacturing and Materials Processing 9, no. 12: 389. https://doi.org/10.3390/jmmp9120389

APA StyleSáenz de Pipaón, J. M., García-Domínguez, A., Claver, J., & Rubio, E. M. (2025). Sustainable Drilling Strategies for Rivet Hole Formation in Nickel-Based Alloys for Aeronautical Applications. Journal of Manufacturing and Materials Processing, 9(12), 389. https://doi.org/10.3390/jmmp9120389