Smart Drilling: Integrating AI for Process Optimisation and Quality Enhancement in Manufacturing

Abstract

1. Introduction

2. Fundamentals of Drilling in Manufacturing

2.1. From Conventional to Advanced Drilling Processes

2.2. Key Quality Indicators (Thrust Force, Torque, Burr, Delamination, Tool Wear)

- Thrust force is one of the primary indicators of drilling performance. An increase in thrust force during the production of multiple holes is typically indicative of a growing tool wear state, with the predictable consequences on hole dimensional inaccuracies [5]. Several studies have shown that lowering thrust force through optimised tool geometry or advanced strategies effectively reduces the risk of delamination damage in composites and burr height in metals, thereby improving hole quality [23,38].

- Torque provides complementary information by quantifying the resistance encountered by the cutting edges during the drilling process. High torque values are often associated with increased friction, adhesion phenomena in ductile alloys (e.g., Al and Ti), or the excessive wear of the cutting lips [40]. In composite/metal stacks, torque fluctuations have been identified as a key feature for detecting the transition between layers and for developing adaptive control strategies [13]. However, torque is generally more difficult to interpret and less straightforward compared to thrust force.

- The use of data such as thrust force and torque typically requires load cells, which are costly, require maintenance, and may complicate process monitoring in assemblies with complex geometry or when drilling is performed in semi-automatic conditions. A valid alternative is to use devices for monitoring active power during drilling. Although several studies and applications have already demonstrated the use of thrust force and torque for predicting hole quality and tool wear [41], active power has recently emerged as an effective indicator for both process monitoring and hole quality assessment. Since spindle power is directly related to the product of torque and rotational speed, it provides a global measure that incorporates the combined effects of thrust and torque in a single parameter. An important advantage is that spindle active power can be directly acquired from modern CNC machine tools and robots without the need for external sensors, thus offering a cost-effective and non-invasive monitoring solution [15].

- Acoustic emission (AE) has become a widely used signal for tool condition monitoring in drilling, particularly for composite/metal stacks. These hybrid structures are extensively applied in aerospace components, like fuselage panels, where mechanical fastening requires high-quality holes. However, due to the very different machining properties of metals and composites, drilling is associated with rapid tool wear, delamination in composites, and burr formation in metals. Since tool life is short and quality risks are high, online process monitoring is essential [42]. AE sensors detect high-frequency elastic waves generated by chip formation, fibre breakage, matrix cracking, and interactions between the tool and the workpiece, and are therefore sensitive to tool wear progression. In the drilling of CFRP/Ti stacks, AE has been successfully applied to distinguish different drilling phases (entry, interlaminar transition, exit) and to correlate changes in frequency bands with flank wear and tool fracture. This makes AE a powerful in-process monitoring technique for predicting tool wear, reducing premature tool replacement, and improving hole quality in aerospace drilling operations [43]. Furthermore, integrating AE with other signals such as thrust force or spindle power has been shown to enhance the robustness of monitoring systems, reducing false detections and improving predictive accuracy [44].

- Burr formation is a persistent issue in the drilling of metallic alloys such as aluminium, stainless steel, and titanium. Burrs not only require costly post processing operations (deburring, reaming) but can also compromise fatigue life and assembly tolerances [22], considering that burr height and morphology depend on tool wear state, feed rate, and exit support conditions. In this regard, both innovative tool designs and drilling strategies have been developed over the years to minimise burr formation [30]. An example of burr formation is shown in Figure 1.

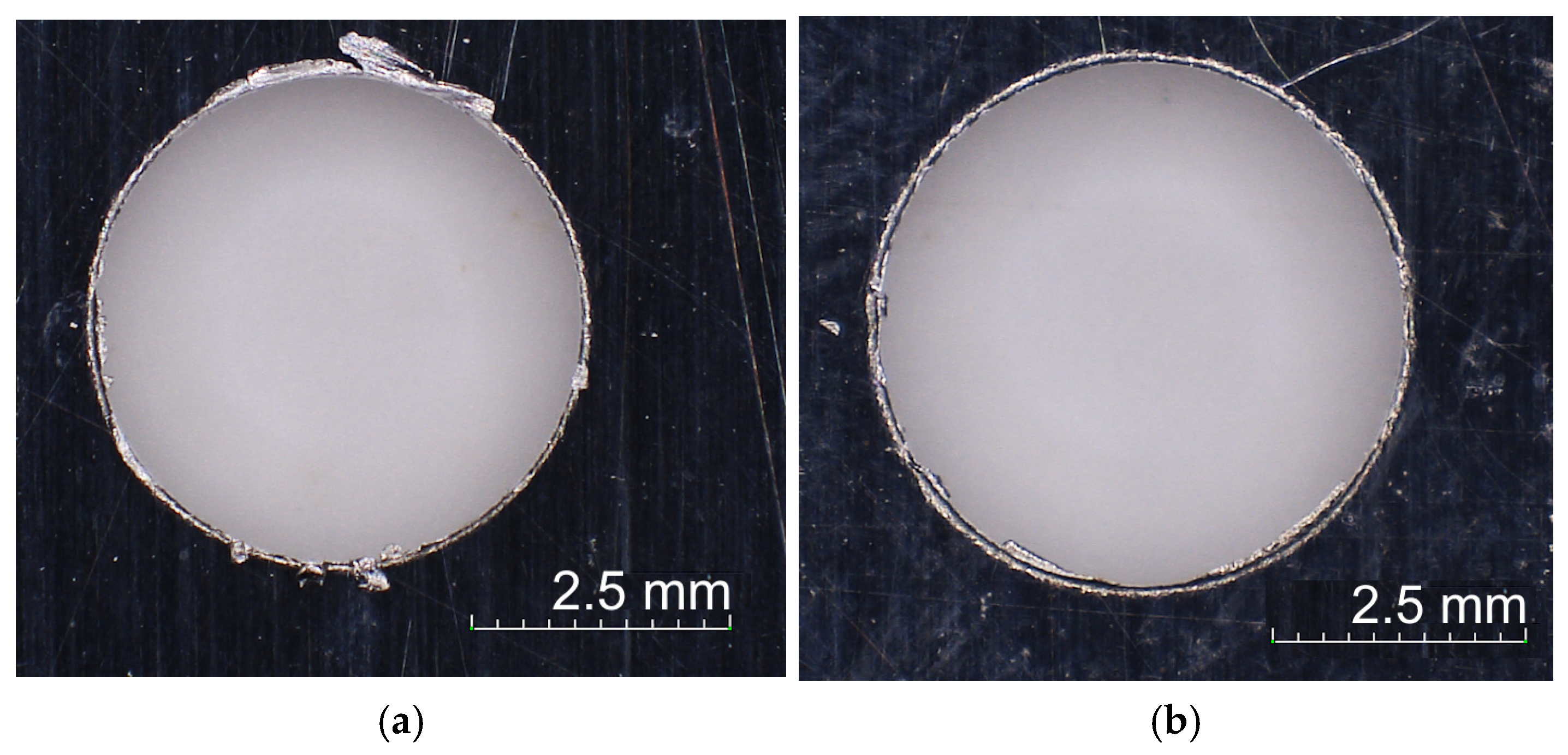

- Delamination is the most common and severe defect in composite drilling, arising from interlaminar stresses that exceed the resin–fibre bonding strength [6]. Entry delamination occurs when the cutting edge pushes fibres downward at hole initiation, while exit delamination is primarily caused by excessive thrust during tool breakthrough. Both phenomena lead to reduced load bearing capacity and the early onset of fatigue failure in aerospace structures. Strategies to mitigate delamination include optimised drill geometries [45], circular and orbital drilling strategies [2] (see Figure 2), and parameter adaptation when transitioning across hybrid stacks.

- Roundness, cylindricity and coaxiality are important geometric accuracy indicators [46], as they directly influence the ability of a hole to accommodate fasteners or load bearing inserts, which is essential in aerospace and automotive assemblies. Deviations from ideal geometry often result from tool deflection, uneven wear, or vibrations during drilling. For example, the loss of roundness and cylindricity compromises interference fit and load transfer efficiency in riveted joints, while poor coaxiality between successive stacked layers can induce misalignment and stress concentrations [4,47]. Advanced drilling methods such as orbital drilling and robotic drilling, combined with real-time sensor feedback, have been shown to significantly improve hole geometry, achieving tighter tolerances and reduced variability across large batch productions.

- Tool wear represents both a quality indicator and a limiting factor for productivity. In drilling, wear typically manifests as flank wear, chisel edge rounding, and edge chipping, which progressively increase thrust force and torque, thereby accelerating delamination and burr formation [43]. CFRPs, due to their abrasive fibres, cause rapid edge degradation, while Ti alloys promote adhesion and diffusion wear at elevated temperatures. Tool coatings such as TiAlN, AlCrN, and diamond-like carbon have been widely investigated to extend tool life, while in-process monitoring using acoustic emission, thrust force, or spindle power signals is increasingly adopted to detect wear progression in real time [39,40].

3. Applications of AI in Drilling

3.1. Process Monitoring

3.1.1. Force and Torque Measurements

3.1.2. Vibration Monitoring

3.1.3. Acoustic Emission (AE) Monitoring

3.1.4. Spindle Current and Power Monitoring

3.1.5. Thermal and Vision-Based Monitoring

3.1.6. Multi-Sensor Integration and Monitoring Architecture

3.2. Tool Condition Monitoring and Wear Prediction

3.2.1. Signal Acquisition in Drilling

- Cutting forces: highly sensitive to wear, but difficult to implement industrially with bench dynamometers.

- Vibrations: acquired with piezoelectric accelerometers or micro-electromechanical systems (MEMSs), correlated with roughness and instabilities but difficult to filter.

- Acoustic Emission (AE): wide frequency range (100 kHz–1 MHz), excellent for detecting wear, chipping and fractures; also provides early warning in case of unstable cracks.

- Motor current/spindle power: easily accessible in modern CNCs, already used in commercial TCMs, though less sensitive to high-frequency fluctuations.

- Thermal signals: useful in difficult-to-cut materials (e.g., Ti and Inconel) but limited by thermal inertia and integration hurdles.

3.2.2. AI Models and Representative Studies

3.2.3. Guidelines and Design Principles

- Feature extraction: prefer physically interpretable features (e.g., AE band 150–250 kHz linked to flank friction) over blind statistics to improve transferability [71].

- Model selection: choose according to data and constraints: (a) SVM/LS-SVM (preferably APSO-optimised), RF/ET/GBM excel with curated features and medium datasets; (b) MLP are excellent for slow CNC signals (power/current) [15]; (c) LSTM/GRU are needed when the sequence is informative (AE/vibration) [72,77].

3.3. Process Optimisation

3.3.1. Offline Parameters Optimisation (AI-Based Algorithms)

3.3.2. Online Parameters Optimisation

3.4. Predictive Quality Modelling

3.4.1. Predictive Models for Delamination in CFRP and Hybrid Stacks

3.4.2. Predictive Modelling of Burr Formation (Metallic Alloys)

3.4.3. Predictive Modelling of Other Hole Quality Indices

4. Challenges and Research Gap

5. Conclusions and Future Overlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 1D CNN | One-dimensional convolutional neural network |

| ACO | Ant colony optimisation |

| AE | Acoustic emission |

| AI | Artificial intelligence |

| ANNs | Artificial neural networks |

| ANFISs | Adaptive neuro fuzzy inference systems |

| AOA | Arithmetic optimisation algorithm |

| APSO | Adaptive particle swarm optimisation |

| Bi-GRU | Bidirectional gated recurrent unit |

| Bi-LSTM | Bidirectional long short-term memory |

| BI | Bayesian interference |

| BLSTMN | Bidirectional long short-term memory network |

| CG | Conjugate gradient |

| CID | Control internal data |

| CNN | Convolutional neural network |

| CNN-LSTM | Convolutional neural networks—long short-term memory |

| CNC | Computer numerical control |

| DIC | Digital image correlation |

| DLC | Diamond-like carbon |

| DE | Differential evolution |

| ETs | Extra trees |

| Fd | Delamination factor |

| Fed | Equivalent delamination factor |

| FFT | Fast Fourier transform |

| FPA | Flower pollination algorithm |

| Fz | Thrust force |

| GA | Genetic algorithms |

| GBMs | Gradient boosting machines |

| GBR | Gradient boosting regressor |

| GPR | Gaussian process regression |

| GRNNs | Generalised regression neural networks |

| HMI | Human–machine interface |

| HSS | High-speed steel |

| LEPs | Local exponential patterns |

| LFVAD | Low-frequency vibration-assisted drilling |

| LM | Levenberg–Marquardt |

| LS-SVM | Least squares support vector machine |

| MAD | Mean absolute deviation |

| MAPE | Mean absolute percentage error |

| MEMS | Micro-electromechanical systems |

| ML | Machine learning |

| MLP | Multi-layer perception |

| MQL | Minimum quantity lubrication |

| MRA | Multiple regression analysis |

| MRR | Material removal rate |

| MSE | Mean squared error |

| Mz | Cutting torque |

| NSGA-II | Non-dominated sorting genetic algorithm |

| PCA | Principal component analysis |

| PLS | Partial least squares |

| PSO | Particle swarm optimisation |

| QNR | Quadratic nonlinear regression |

| Ra | Average arithmetic roughness |

| RAD | Rotary assisted drilling |

| RANSAC | Random sample consensus |

| RF | Random forest |

| RMS | Root mean square |

| RMSE | Root mean square error |

| RNNs | Recurrent neural networks |

| Rq | Root mean square roughness |

| RSM | Response surface methodology |

| Rt | Total height of the roughness profile |

| SHAP | Shapley additive explanations |

| SSA | Singular spectrum analysis |

| STFT | Short-time Fourier transform |

| SVR | Support vector regression |

| SVM | Support vector machine |

| TCM | Tool condition monitoring |

| TLBO | Teaching–learning-based optimisation |

| UAD | Ultrasonic assisted drilling |

| VSG | Virtual sample generation |

| WPT | Wavelet packet transform |

| XAI | Explainable artificial intelligence |

References

- Melhem, G.N. Aerospace Fasteners: Use in Structural Applications. In Encyclopedia of Aluminum and Its Alloys; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Durante, M.; Boccarusso, L.; De Fazio, D.; Langella, A. Circular Cutting Strategy for Drilling of Carbon Fiber-Reinforced Plastics (CFRPs). Mater. Manuf. Process. 2019, 34, 554–566. [Google Scholar] [CrossRef]

- Rey, P.-A.; Senatore, J.; Landon, Y. Effect of Cutting Tool Geometry on Hole Quality in Orbital Drilling. Int. J. Adv. Manuf. Technol. 2024, 131, 827–841. [Google Scholar] [CrossRef]

- Yu, L.; Bi, Q.; Ji, Y.; Fan, Y.; Huang, N.; Wang, Y. Vision Based In-Process Inspection for Countersink in Automated Drilling and Riveting. Precis. Eng. 2019, 58, 35–46. [Google Scholar] [CrossRef]

- Byrne, G.; O’Donnell, G.E. An Integrated Force Sensor Solution for Process Monitoring of Drilling Operations. CIRP Ann. 2007, 56, 89–92. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Chen, M.; El Mansori, M.; Paulo Davim, J. On the Analysis of Temperatures, Surface Morphologies and Tool Wear in Drilling CFRP/Ti6Al4V Stacks under Different Cutting Sequence Strategies. Compos. Struct. 2020, 234, 111708. [Google Scholar] [CrossRef]

- Yan, M.; Lai, Y.; Zhang, Y.; Yang, L.; Zheng, Y.; Wen, T.; Pan, C. Drilling Surface Quality Analysis of Carbon Fiber-Reinforced Polymers Based on Acoustic Emission Characteristics. Polymers 2025, 17, 2628. [Google Scholar] [CrossRef]

- Araujo, A.C.; Landon, Y.; Lagarrigue, P. Smart Drilling for Aerospace Industry: State of Art in Research and Education. Procedia CIRP 2021, 99, 387–391. [Google Scholar] [CrossRef]

- Ge, J.; Zhang, J.; Xu, M.; Wu, M.; Yao, Z.; Fu, G.; Zhang, W.; Falzon, B.G.; Catalanotti, G.; Xu, J.; et al. Data-Driven CFRP Machining Performance Prediction and Optimization: Advances, Challenges and Future Prospects. Thin-Walled Struct. 2025, 216, 113721. [Google Scholar] [CrossRef]

- Panico, M.; Langella, A.; Boccarusso, L. On the Influence of Clamping Conditions and Cutting Edge Geometry on Drilling of Thin Aluminium Stacks. CIRP J. Manuf. Sci. Technol. 2025, 61, 572–587. [Google Scholar] [CrossRef]

- Panico, M.; Begemann, E.; Gebhardt, A.; Hartmann, F.; Herrmann, T.; Langella, A.; Boccarusso, L. Evaluating the Impact of Boundary Conditions and Clamping Force in Robotic One-up Drilling of Hybrid Stacks. CIRP J. Manuf. Sci. Technol. 2025, 60, 1–14. [Google Scholar] [CrossRef]

- Cao, S.; Li, Y.; Zhang, K.; Hou, G.; Luo, B.; Liu, S.; Long, T.; Liu, P. Investigation of CFRP Damages Induced by the Interface High Temperature and Mixed Tool Wear Mechanism in Drilling of Thin-Walled CFRP/Ti Stacks. Compos. Struct. 2023, 323, 117438. [Google Scholar] [CrossRef]

- Panico, M.; Begemann, E.; Gebhardt, A.; Hartmann, F.; Herrmann, T.; Langella, A.; Boccarusso, L. Process Parameter Auto-Adaptation Strategy for One-up Drilling of CFRP/Aluminium Hybrid Stack. Int. J. Adv. Manuf. Technol. 2024, 135, 4169–4187. [Google Scholar] [CrossRef]

- Shokrani, A.; Dogan, H.; Burian, D.; Nwabueze, T.D.; Kolar, P.; Liao, Z.; Sadek, A.; Teti, R.; Wang, P.; Pavel, R.; et al. Sensors for In-Process and on-Machine Monitoring of Machining Operations. CIRP J. Manuf. Sci. Technol. 2024, 51, 263–292. [Google Scholar] [CrossRef]

- Corne, R.; Nath, C.; El Mansori, M.; Kurfess, T. Study of Spindle Power Data with Neural Network for Predicting Real-Time Tool Wear/Breakage during Inconel Drilling. J. Manuf. Syst. 2017, 43, 287–295. [Google Scholar] [CrossRef]

- Domínguez-Monferrer, C.; Fernández-Pérez, J.; Santos, R.D.; Miguélez, M.H.; Cantero, J.L. CFRP Drilling Process Control Based on Spindle Power Consumption from Real Production Data in the Aircraft Industry. Procedia CIRP 2022, 107, 1533–1538. [Google Scholar] [CrossRef]

- Mypati, O.; Mukherjee, A.; Mishra, D.; Pal, S.K.; Chakrabarti, P.P.; Pal, A. A Critical Review on Applications of Artificial Intelligence in Manufacturing. Artif. Intell. Rev. 2023, 56, 661–768. [Google Scholar] [CrossRef]

- Mohamed, A.; Hassan, M.; M’Saoubi, R.; Attia, H. Tool Condition Monitoring for High-Performance Machining Systems—A Review. Sensors 2022, 22, 2206. [Google Scholar] [CrossRef]

- Boukredera, F.S.; Hadjadj, A.; Youcefi, M.R.; Ouadi, H. AI-Driven Optimization of Drilling Performance Through Torque Management Using Machine Learning and Differential Evolution. Processes 2025, 13, 1472. [Google Scholar] [CrossRef]

- Sarhan, A.A.D. AI-Driven ANFIS Modeling for Smart Drilling to Maximize the Utilization of the Cutting Tools—I4.0 Application. Arab. J. Sci. Eng. 2025. [Google Scholar] [CrossRef]

- Lee, S.K.H.; Simeth, A.; Hinchy, E.P.; Plapper, P.; O’Dowd, N.P.; McCarthy, C.T. A Vision-Based Hole Quality Assessment Technique for Robotic Drilling of Composite Materials Using a Hybrid Classification Model. Int. J. Adv. Manuf. Technol. 2023, 129, 1249–1258. [Google Scholar] [CrossRef]

- Kimmelmann, M.; Duntschew, J.; Schluchter, I.; Möhring, H.-C. Analysis of Burr Formation Mechanisms When Drilling CFRP-Aluminium Stacks Using Acoustic Emission. Procedia Manuf. 2019, 40, 64–69. [Google Scholar] [CrossRef]

- Xu, J.; Mkaddem, A.; El Mansori, M. Recent Advances in Drilling Hybrid FRP/Ti Composite: A State-of-the-Art Review. Compos. Struct. 2016, 135, 316–338. [Google Scholar] [CrossRef]

- Zhu, F.; Zhang, H.; Hu, K.; Duan, L.; Zhang, K.; Xu, X. A Comparative Investigation on Surface Quality of CFRP Laminates between Rotary Drilling and Rotary Ultrasonic-Assisted Drilling. Compos. Struct. 2025, 358, 118964. [Google Scholar] [CrossRef]

- Liu, F.; Chen, T.; Duan, Z.; Suo, Y.; Zhang, C. Ultrasonic Assisted Pecking Drilling Process for CFRP/Ti Laminated Materials. J. Manuf. Process. 2023, 108, 834–851. [Google Scholar] [CrossRef]

- Bertolini, R.; Alagan, N.T.; Gustafsson, A.; Savio, E.; Ghiotti, A.; Bruschi, S. Ultrasonic Vibration and Cryogenic Assisted Drilling of Aluminum-CFRP Composite Stack—An Innovative Approach. Procedia CIRP 2022, 108, 94–99. [Google Scholar] [CrossRef]

- Chu, N.-H.; Nguyen, V.-D.; Ngo, Q.-H. Machinability Enhancements of Ultrasonic-Assisted Deep Drilling of Aluminum Alloys. Mach. Sci. Technol. 2020, 24, 112–135. [Google Scholar] [CrossRef]

- Wei, L.; Wang, D. Comparative Study on Drilling Effect between Conventional Drilling and Ultrasonic-Assisted Drilling of Ti-6Al-4V/Al2024-T351 Laminated Material. Int. J. Adv. Manuf. Technol. 2019, 103, 141–152. [Google Scholar] [CrossRef]

- Pecat, O.; Brinksmeier, E. Tool Wear Analyses in Low Frequency Vibration Assisted Drilling of CFRP/Ti6Al4V Stack Material. Procedia CIRP 2014, 14, 142–147. [Google Scholar] [CrossRef]

- Liu, S.; Meng, Z.; Liang, S.; Wang, T.; Niu, H.; Luo, B.; Zhang, K. Effect of Cooling Temperature on Machinability and Hole Quality in Cryogenic Drilling of CFRP/Ti Stacks. J. Mater. Res. Technol. 2025, 36, 10383–10394. [Google Scholar] [CrossRef]

- Gajrani, K.K. Assessment of Cryo-MQL Environment for Machining of Ti-6Al-4V. J. Manuf. Process. 2020, 60, 494–502. [Google Scholar] [CrossRef]

- Del Bianco, E.; Rollo, F.; Roveri, M.; Tsagarakis, N.G. Smart Drill: An Autonomous Drilling End-Effector with Embedded Sensing and Intelligence for Mobile and Collaborative Robots. In Proceedings of the 2024 IEEE 20th International Conference on Automation Science and Engineering (CASE), Bari, Italy, 28 August–1 September 2024; pp. 508–513. [Google Scholar]

- Farhadi, A.; Lee, S.K.H.; Hinchy, E.P.; O’Dowd, N.P.; McCarthy, C.T. The Development of a Digital Twin Framework for an Industrial Robotic Drilling Process. Sensors 2022, 22, 7232. [Google Scholar] [CrossRef]

- Shi, Z.; Yuan, P.; Wang, Q.; Chen, D.; Wang, T. New Design of a Compact Aero-Robotic Drilling End Effector: An Experimental Analysis. Chin. J. Aeronaut. 2016, 29, 1132–1141. [Google Scholar] [CrossRef]

- Frommknecht, A.; Kuehnle, J.; Effenberger, I.; Pidan, S. Multi-Sensor Measurement System for Robotic Drilling. Robot. Comput. Integr. Manuf. 2017, 47, 4–10. [Google Scholar] [CrossRef]

- Zhang, L.; Tian, W.; Li, D.; Hong, P.; Li, Z.; Zhou, W.; Liao, W. Design of Drilling and Riveting Multi-Functional End Effector for CFRP and Aluminum Components in Robotic Aircraft Assembly. Trans. Nanjing Univ. Aeronaut. Astronaut. 2018, 35, 529–538. [Google Scholar] [CrossRef]

- Yuan, C.G.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S. Drilling of Titanium Alloy (Ti6Al4V)—A Review. Mach. Sci. Technol. 2021, 25, 637–702. [Google Scholar] [CrossRef]

- Liu, D.; Tang, Y.; Cong, W.L. A Review of Mechanical Drilling for Composite Laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Zhao, M.; Wang, F.; Fu, R.; Sun, K.; Du, C.; Cui, J. Drilling Study on CFRP/Al Stack with Different CFRP Thickness Using Chip-Breaking Step Drill Bit. J. Manuf. Process. 2023, 90, 300–309. [Google Scholar] [CrossRef]

- Pelikán, L.; Slaný, M.; Stránský, O.; Beránek, L.; Pitrmuc, Z.; Čepová, L.; Dvořáčková, Š. Novel Drill Geometries for Dry Drilling of Stainless Steel. J. Manuf. Process. 2023, 92, 500–520. [Google Scholar] [CrossRef]

- Duo, A.; Basagoiti, R.; Arrazola, P.J.; Cuesta, M. Sensor Signal Selection for Tool Wear Curve Estimation and Subsequent Tool Breakage Prediction in a Drilling Operation. Int. J. Comput. Integr. Manuf. 2022, 35, 203–227. [Google Scholar] [CrossRef]

- Shu, S.; He, Y.; Chen, L.; He, W.; Zhou, L.; Pan, X.; Xuan, S.; Rong, Y.; Li, W. High-Quality Drilling Method for CFRP Blind Holes Guided by Acoustic Emission Signals. Mech. Syst. Signal Process. 2025, 224, 112029. [Google Scholar] [CrossRef]

- Leng, S.; Wang, Z.; Min, T.; Dai, Z.; Chen, G. Detection of Tool Wear in Drilling CFRP/TC4 Stacks by Acoustic Emission. J. Vib. Eng. Technol. 2020, 8, 463–470. [Google Scholar] [CrossRef]

- Ramme, J.; Reeber, T.; Rapp, M.; Möhring, H.-C. Process Stability Monitoring—Potential of Internal Control Data for Drilling Processes in the Aerospace Industry. In Proceedings of the Machining Innovations Conference for Aerospace Industry (MIC 2023), Hanover, Germany, 22–23 November 2023; pp. 57–64. [Google Scholar] [CrossRef]

- Patel, P.; Chaudhary, V. Delamination Evaluation in Drilling of Composite Materials—A Review. Mater. Today Proc. 2022, 56, 2690–2695. [Google Scholar] [CrossRef]

- Mustari, A.; Chakma, P.; Sobhan, R.; Dhar, N.R. Investigation on Roundness and Taper of Holes in Drilling GFRP Composites with Variable Weight Percentages of Glass Fiber. Mater. Today Proc. 2021, 38, 2578–2583. [Google Scholar] [CrossRef]

- Lee, S.K.H.; Mongan, P.G.; Farhadi, A.; Hinchy, E.P.; O’Dowd, N.P.; McCarthy, C.T. In-Situ Evaluation of Hole Quality and Cutting Tool Condition in Robotic Drilling of Composite Materials Using Machine Learning. J. Intell. Manuf. 2025. [Google Scholar] [CrossRef]

- Totis, G.; Adams, O.; Sortino, M.; Veselovac, D.; Klocke, F. Development of an Innovative Plate Dynamometer for Advanced Milling and Drilling Applications. Measurement 2014, 49, 164–181. [Google Scholar] [CrossRef]

- Rezvani, S.; Kim, C.-J.; Park, S.S.; Lee, J. Simultaneous Clamping and Cutting Force Measurements with Built-in Sensors. Sensors 2020, 20, 3736. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Sun, C.; Li, A.; Guan, Q.; Shu, L. An Integrated Smart Tool Holder with Six-Axis Cutting Force Sensors for Milling and Drilling Operations. Int. J. Adv. Manuf. Technol. 2025. [Google Scholar] [CrossRef]

- Vogl, G.W.; Qu, Y.; Eischens, R.; Corson, G.; Schmitz, T.; Honeycutt, A.; Karandikar, J.; Smith, S. Cutting Force Estimation from Machine Learning and Physics-Inspired Data-Driven Models Utilizing Accelerometer Measurements. Procedia CIRP 2024, 126, 318–323. [Google Scholar] [CrossRef]

- Uekita, M.; Takaya, Y. Tool Condition Monitoring Technique for Deep-Hole Drilling of Large Components Based on Chatter Identification in Time–Frequency Domain. Measurement 2017, 103, 199–207. [Google Scholar] [CrossRef]

- Messaoud, A.; Weihs, C.; Hering, F. Detection of Chatter Vibration in a Drilling Process Using Multivariate Control Charts. Comput. Stat. Data Anal. 2008, 52, 3208–3219. [Google Scholar] [CrossRef]

- Gerken, J.F.; Biermann, D. Concept of a Mechatronic System for Targeted Drill Head Direction and Angular Alignment Control in BTA Deep Hole Drilling. In Proceedings of the 10th Congress of the German Academic Association for Production Technology (WGP), Dresden, Germany, 23–24 September 2020; pp. 215–224. [Google Scholar]

- Bombiński, S.; Kossakowska, J.; Nejman, M.; Haber, R.E.; Castaño, F.; Fularski, R. Needs, Requirements and a Concept of a Tool Condition Monitoring System for the Aerospace Industry. Sensors 2021, 21, 5086. [Google Scholar] [CrossRef] [PubMed]

- Mathiyazhagan, V.; Meena, A. Predictive Modelling of Tool Wear in CFRP Drilling Using Acoustic Emission Sensors under Dry and Cryogenic Conditions. Wear 2025, 570, 205930. [Google Scholar] [CrossRef]

- Kim, H.Y.; Ahn, J.H.; Kim, S.H.; Takata, S. Real-Time Drill Wear Estimation Based on Spindle Motor Power. J. Mater. Process. Technol. 2002, 124, 267–273. [Google Scholar] [CrossRef]

- Haoua, A.A.; Rey, P.-A.; Cherif, M.; Abisset-Chavanne, E.; Yousfi, W. Material Recognition Method to Enable Adaptive Drilling of Multi-Material Aerospace Stacks. Int. J. Adv. Manuf. Technol. 2024, 131, 779–796. [Google Scholar] [CrossRef]

- Panico, M.; Durante, M.; Langella, A.; Boccarusso, L. One-Shot Drilling Process for Thin CFRP/Aluminium Alloys Stacks. Mater. Manuf. Process. 2024, 39, 1187–1202. [Google Scholar] [CrossRef]

- Zhu, Z.; Sun, X.; Guo, K.; Sun, J.; Li, J. Recent Advances in Drilling Tool Temperature: A State-of-the-Art Review. Chin. J. Mech. Eng. 2022, 35, 148. [Google Scholar] [CrossRef]

- Moghaddas, M.A.; Yi, A.Y.; Graff, K.F. Temperature Measurement in the Ultrasonic-Assisted Drilling Process. Int. J. Adv. Manuf. Technol. 2019, 103, 187–199. [Google Scholar] [CrossRef]

- Xu, J.; Lin, T.; Davim, J.P. On the Machining Temperature and Hole Quality of CFRP Laminates When Using Diamond-Coated Special Drills. J. Compos. Sci. 2022, 6, 45. [Google Scholar] [CrossRef]

- Fu, R.; Jia, Z.; Wang, F.; Jin, Y.; Sun, D.; Yang, L.; Cheng, D. Drill-Exit Temperature Characteristics in Drilling of UD and MD CFRP Composites Based on Infrared Thermography. Int. J. Mach. Tools Manuf. 2018, 135, 24–37. [Google Scholar] [CrossRef]

- Panico, M.; Durante, M.; Langella, A.; Boccarusso, L. Preliminary Numerical and Experimental Investigation of Clamping Effects on One-up Drilling of Stacked Aluminium Aerospace Components. In Proceedings of the XVII AiTeM (Italian Manufacturing Association) Conference, Bari, Italy, 10–12 September 2025; pp. 655–664. [Google Scholar]

- Panico, M.; Durante, M.; Langella, A.; Boccarusso, L. Numerical and Theoretical Approach to Evaluate the Clamping Force and the Interlayer Gap Extent during Drilling of Stacked Materials. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2024, 239, 484–496. [Google Scholar] [CrossRef]

- Li, G.; Yang, S.; Cao, S.; Zhu, W.; Ke, Y. A Semi-Supervised Deep Learning Approach for Circular Hole Detection on Composite Parts. Vis. Comput. 2021, 37, 433–445. [Google Scholar] [CrossRef]

- Munaro, R.; Attanasio, A.; Del Prete, A. Tool Wear Monitoring with Artificial Intelligence Methods: A Review. J. Manuf. Mater. Process. 2023, 7, 129. [Google Scholar] [CrossRef]

- Nordmann Tool Monitoring. Available online: https://www.toolmonitoring.com/ (accessed on 23 October 2025).

- Desoutter Industrial Tools—Drilling and Assembly Tools. Available online: https://www.desouttertools.com/en-us/industries/aerospace (accessed on 23 October 2025).

- Spike®—Sensory Tool Holder Made in Germany. Available online: https://www.pro-micron.de/en/neuigkeit/spike-sensory-tool-holder-made-in-germany/ (accessed on 23 October 2025).

- Klocke, F.; Döbbeler, B.; Pullen, T.; Bergs, T. Acoustic Emission Signal Source Separation for a Flank Wear Estimation of Drilling Tools. Procedia CIRP 2019, 79, 57–62. [Google Scholar] [CrossRef]

- Mahmood, J.; Luo, M.; Rehman, M. An Accurate Detection of Tool Wear Type in Drilling Process by Applying PCA and One-Hot Encoding to SSA-BLSTM Model. Int. J. Adv. Manuf. Technol. 2022, 118, 3897–3916. [Google Scholar] [CrossRef]

- Dheeraj Simon, G.; Deivanathan, R. Early Detection of Drilling Tool Wear by Vibration Data Acquisition and Classification. Manuf. Lett. 2019, 21, 60–65. [Google Scholar] [CrossRef]

- Chen, N.; Hao, B.; Guo, Y.; Li, L.; Khan, M.A.; He, N. Research on Tool Wear Monitoring in Drilling Process Based on APSO-LS-SVM Approach. Int. J. Adv. Manuf. Technol. 2020, 108, 2091–2101. [Google Scholar] [CrossRef]

- Dayam, S.; Desai, K.A. Smart Tool Wear State and Chatter Onset Identification System for Legacy Manual Drilling Machine Operators. Int. J. Adv. Manuf. Technol. 2025, 136, 675–692. [Google Scholar] [CrossRef]

- ISO 8688-2:1989; Tool Life Testing in Milling—Part 2: End Milling. International Organization for Standardization: Geneva, Switzerland, 1989.

- Chehrehzad, M.; Kecibas, G.; Besirova, C.; Uresin, U.; Irican, M.; Lazoglu, I. Tool Wear Prediction through AI-Assisted Digital Shadow Using Industrial Edge Device. J. Manuf. Process. 2024, 113, 117–130. [Google Scholar] [CrossRef]

- Kilickap, E. Modeling and Optimization of Burr Height in Drilling of Al-7075 Using Taguchi Method and Response Surface Methodology. Int. J. Adv. Manuf. Technol. 2010, 49, 911–923. [Google Scholar] [CrossRef]

- Akdulum, A.; Kayir, Y. Modeling and Estimation of Thrust Force, Torque, and Surface Roughness in Indexable Drilling of AA6061-T651 with Taguchi, ANN, and ANFIS. Sādhanā 2023, 48, 143. [Google Scholar] [CrossRef]

- Pereira, B.; Griffiths, C.A.; Birch, B.; Rees, A. Optimization of an Autonomous Robotic Drilling System for the Machining of Aluminum Aerospace Alloys. Int. J. Adv. Manuf. Technol. 2022, 119, 2429–2444. [Google Scholar] [CrossRef]

- Bhat, R.; Mohan, N.; Sharma, S.; Pai, D.; Kulkarni, S. Multiple Response Optimisation of Process Parameters during Drilling of GFRP Composite with a Solid Carbide Twist Drill. Mater. Today Proc. 2020, 28, 2039–2046. [Google Scholar] [CrossRef]

- Erturk, A.T.; Vatansever, F.; Yarar, E.; Guven, E.A.; Sinmazcelik, T. Effects of Cutting Temperature and Process Optimization in Drilling of GFRP Composites. J. Compos. Mater. 2021, 55, 235–249. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, X. Multi-Objective Optimization of CFRP Drilling Parameters with a Hybrid Method Integrating the ANN, NSGA-II and Fuzzy C-Means. Compos. Struct. 2020, 235, 111803. [Google Scholar] [CrossRef]

- Tzotzis, A.; Antoniadis, A.; Kyratsis, P. Multivariate Modelling of AA6082-T6 Drilling Performance Using RSM, ANN and Response Optimization. Int. J. Lightweight Mater. Manuf. 2024, 7, 531–545. [Google Scholar] [CrossRef]

- Ghadai, R.K.; Baraily, A.; Logesh, K.; Sapkota, G.; Patil, S.; Das, S.; Mandal, P. Objective Optimization of Drilling of Hybrid Aluminium Metal Matrix Composites Using ANN NSGA- II Hybrid Approach. Int. J. Interact. Des. Manuf. 2025, 19, 4835–4846. [Google Scholar] [CrossRef]

- Turan, İ.; Özlü, B.; Ulaş, H.B.; Demir, H. Prediction and Modelling with Taguchi, ANN and ANFIS of Optimum Machining Parameters in Drilling of Al 6082-T6 Alloy. J. Manuf. Mater. Process. 2025, 9, 92. [Google Scholar] [CrossRef]

- Aich, U.; Behera, R.R.; Banerjee, S. Modeling of Delamination in Drilling of Glass Fiber-Reinforced Polyester Composite by Support Vector Machine Tuned by Particle Swarm Optimization. Int. J. Plast. Technol. 2019, 23, 77–91. [Google Scholar] [CrossRef]

- Kalita, K.; Mallick, P.K.; Bhoi, A.K.; Ghadai, K.R. Optimizing Drilling Induced Delamination in GFRP Composites Using Genetic Algorithm & Particle Swarm Optimisation. Adv. Compos. Lett. 2018, 27, 096369351802700101. [Google Scholar] [CrossRef]

- Mercy, J.L.; Prakash, S.; Krishnamoorthy, A.; Ramesh, S.; Anand, D.A. Experimental Investigation and Multiresponse Genetic Optimization of Drilling Parameters for Self-Healing GFRP. J. Mech. Sci. Technol. 2017, 31, 3777–3785. [Google Scholar] [CrossRef]

- Hu, L.; Zheng, P.; Liu, P.; Jia, S.; Cai, W.; Xu, K. Energy Optimisation for the Combination of Turning and Drilling Features Using Differential Evolution. Environ. Sci. Pollut. Res. 2023. [Google Scholar] [CrossRef] [PubMed]

- Hoang, V.Q.; Pham, X.D.; Nguyen, M.S. Prediction of Optimal Tool Path for Drilling Based on Ant Colony Algorithm. In Proceedings of the 3rd Annual International Conference on Material, Machines and Methods for Sustainable Development (MMMS2022), Can Tho, Vietnam, 10–13 November 2022; pp. 261–269. [Google Scholar]

- bin Rusman, M.D.I.; Abdullah, H.; Zakaria, M.S.; Talib, N.; Kiow, L.W.; Saleh, A. Optimization of Tool Path Length on Three-Dimensional Drilling Application Using Ant Colony Algorithm. J. Phys. Conf. Ser. 2021, 2129, 012060. [Google Scholar] [CrossRef]

- Sadek, A.; Hassan, M.; Attia, M.H. A New Cyber-Physical Adaptive Control System for Drilling of Hybrid Stacks. CIRP Ann. 2020, 69, 105–108. [Google Scholar] [CrossRef]

- Wegert, R.; Guski, V.; Schmauder, S.; Möhring, H.-C. In-Process Approach for Editing the Subsurface Properties during Single-Lip Deep Hole Drilling Using a Sensor-Integrated Tool. Prod. Eng. 2024, 18, 319–337. [Google Scholar] [CrossRef]

- Yan, C.; Chen, Y.; Qian, N.; Guo, N.; Wang, Y.; Yang, H.; Zhao, B. Adaptive Approaches to Identify the Interface in Low Frequency Vibration-Assisted Drilling of CFRP/Ti6Al4V Stacks. Int. J. Precis. Eng. Manuf. 2022, 23, 895–909. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, C.; Wang, S.; Yu, F.; Wang, Z. Investigation of Self-Adaptive Drilling of CFRP/Al Stacks Based on Equivalent Impedance Recognition of the Vibration-Assisted Device. Int. J. Adv. Manuf. Technol. 2022, 123, 1641–1656. [Google Scholar] [CrossRef]

- Fard, M.G.; Baseri, H.; Azami, A.; Zolfaghari, A. Prediction of Delamination Defects in Drilling of Carbon Fiber Reinforced Polymers Using a Regression-Based Approach. Machines 2024, 12, 783. [Google Scholar] [CrossRef]

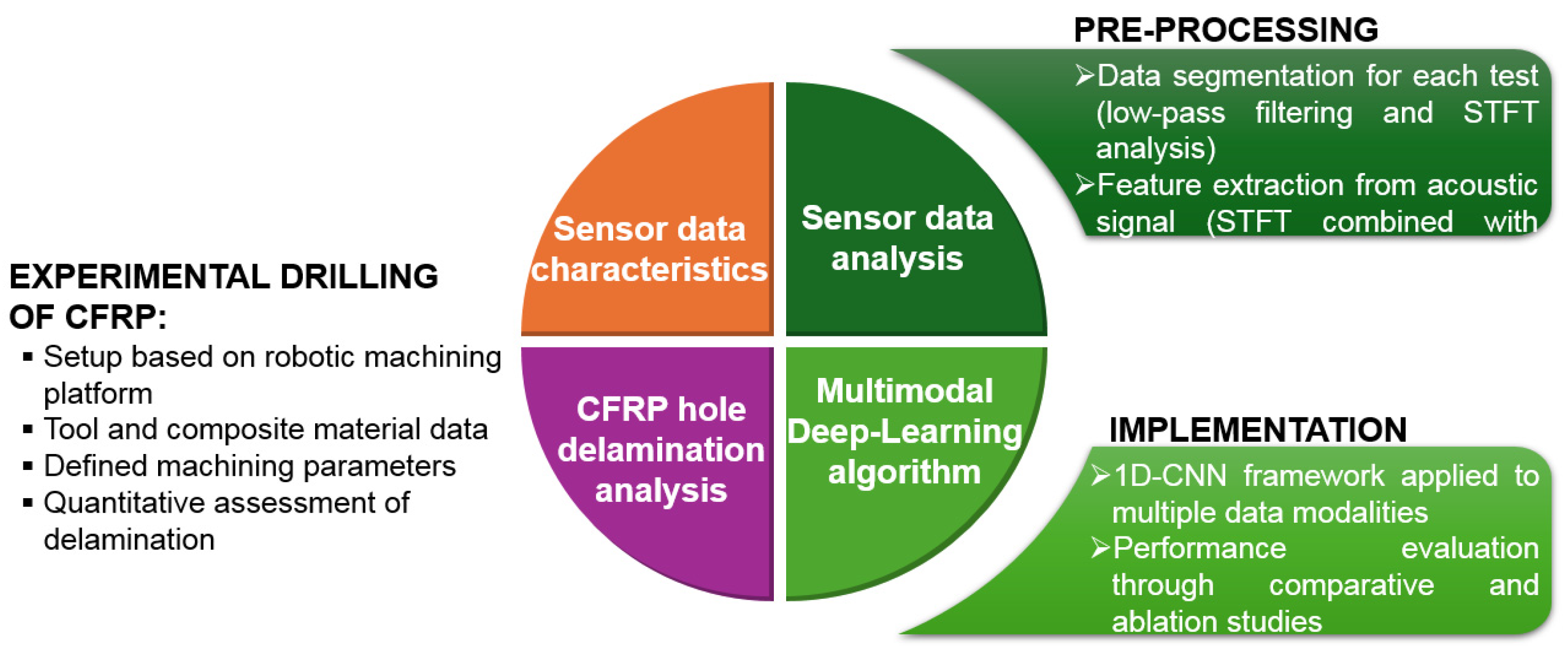

- Choi, J.G.; Kim, D.C.; Chung, M.; Lim, S.; Park, H.W. Multimodal 1D CNN for Delamination Prediction in CFRP Drilling Process with Industrial Robots. Comput. Ind. Eng. 2024, 190, 110074. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X. Predicting the Delamination Factor in Carbon Fibre Reinforced Plastic Composites during Drilling through the Gaussian Process Regression. J. Compos. Mater. 2021, 55, 2061–2068. [Google Scholar] [CrossRef]

- Yao, H.; Zhang, K.; Cheng, H.; CAO, S.; Luo, B. An Adaptive Modelling Approach Using a Novel Modified AOA/SVR for Prediction of Drilling-Induced Delamination in CFRP/Ti Stacks. J. Manuf. Process. 2023, 102, 259–274. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, J.; Xu, L.; Shen, J.; Xuan, S.; Tian, W. Analysis and Prediction of Axial Force and Exit Damage in Drilling of Composites with Delamination Damage. J. Manuf. Process. 2024, 132, 169–188. [Google Scholar] [CrossRef]

- Panico, M.; D’Agostino, E.; De Rosa, V.; Durante, M.; Messere, S.; Langella, A.; Boccarusso, L. One-Shot Drilling of Unconventional Thin Metal Hybrid Stacks for Aerospace Applications. In Proceedings of the 27th International ESAFORM Conference on Material Forming—ESAFORM 2024, Toulouse, France, 24–26 April 2024; pp. 2462–2471. [Google Scholar]

- Zai, P.; Tong, J.; Liu, Z.; Zhang, Z.; Song, C.; Zhao, B. Analytical Model of Exit Burr Height and Experimental Investigation on Ultrasonic-Assisted High-Speed Drilling Micro-Holes. J. Manuf. Process. 2021, 68, 807–817. [Google Scholar] [CrossRef]

- Hu, Y.; Song, Y.; Li, Y.; Yao, Z. An Analytical Model to Predict Interfacial Burr Height for Metal Stack Drilling. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2019, 233, 99–108. [Google Scholar] [CrossRef]

- Tao, D.; Yin, Z.; An, Q.; Yu, M.; Yu, Z.; Miao, Q.; Dai, C.; Zhang, M.; Li, H. Prediction and Suppression of Exit Burr Height in Ultrasonic Vibration-Assisted Micro-Drilling of GH4169 Superalloy. Int. J. Adv. Manuf. Technol. 2025, 140, 891–908. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S.H. Prediction of Burr Types in Drilling of Al-7075 Using Acoustic Emission and Convolution Neural Networks. IEEE Access 2022, 10, 67826–67838. [Google Scholar] [CrossRef]

- Mondal, N.; Banik, S.; Paul, S.; Sarkar, S.; Mandal, S.; Ghosh, S. ANFIS-TLBO-Based Optimization of Drilling Parameters to Minimize Burr Formation in Aluminum 6061. Multiscale Multidiscip. Model. Exp. Des. 2024, 7, 3607–3623. [Google Scholar] [CrossRef]

- Karnik, S.R.; Gaitonde, V.N.; Davim, J.P. A Comparative Study of the ANN and RSM Modeling Approaches for Predicting Burr Size in Drilling. Int. J. Adv. Manuf. Technol. 2008, 38, 868–883. [Google Scholar] [CrossRef]

- Mondal, N.; Mandal, S.; Mandal, M.C. FPA Based Optimization of Drilling Burr Using Regression Analysis and ANN Model. Measurement 2020, 152, 107327. [Google Scholar] [CrossRef]

- Prashanth, P.; Hiremath, S.S. Experimental and Predictive Modelling in Dry Micro-Drilling of Titanium Alloy Using Ti–Al–N Coated Carbide Tools. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 553–577. [Google Scholar] [CrossRef]

- Ghosh, S.; Knoblauch, R.; El Mansori, M.; Corleto, C. Towards AI Driven Surface Roughness Evaluation in Manufacturing: A Prospective Study. J. Intell. Manuf. 2025, 36, 4519–4548. [Google Scholar] [CrossRef]

- Ranjan, J.; Patra, K.; Szalay, T.; Mia, M.; Gupta, M.K.; Song, Q.; Krolczyk, G.; Chudy, R.; Pashnyov, V.A.; Pimenov, D.Y. Artificial Intelligence-Based Hole Quality Prediction in Micro-Drilling Using Multiple Sensors. Sensors 2020, 20, 885. [Google Scholar] [CrossRef]

- Dedeakayoğulları, H.; Kaçal, A.; Keser, K. Modeling and Prediction of Surface Roughness at the Drilling of SLM-Ti6Al4V Parts Manufactured with Pre-Hole with Optimized ANN and ANFIS. Measurement 2022, 203, 112029. [Google Scholar] [CrossRef]

- Tabacaru, V. Artificial Neural Networks Applied to Prediction of Surface Roughness in Dry Drilling of Some Polymers. IOP Conf. Ser. Mater. Sci. Eng. 2020, 916, 012117. [Google Scholar] [CrossRef]

- Shilpa, M.K.; Yendapalli, V. Surface Roughness Estimation Techniques for Drilled Surfaces: A Review. Mater. Today Proc. 2022, 52, 1082–1091. [Google Scholar] [CrossRef]

- Ge, J.; Yao, Z.; Wu, M.; Almeida, J.H.S., Jr.; Jin, Y.; Sun, D. Tackling Data Scarcity in Machine Learning-Based CFRP Drilling Performance Prediction through a Broad Learning System with Virtual Sample Generation (BLS-VSG). Compos. B Eng. 2025, 305, 112701. [Google Scholar] [CrossRef]

- Zhong, R.; Salehi, C.; Johnson, R. Machine Learning for Drilling Applications: A Review. J. Nat. Gas Sci. Eng. 2022, 108, 104807. [Google Scholar] [CrossRef]

- Eche, T.; Schwartz, L.H.; Mokrane, F.-Z.; Dercle, L. Toward Generalizability in the Deployment of Artificial Intelligence in Radiology: Role of Computation Stress Testing to Overcome Underspecification. Radiol. Artif. Intell. 2021, 3, e210097. [Google Scholar] [CrossRef] [PubMed]

- Johnson, M.V.; Garanger, K.; Hardin, J.O.; Berrigan, J.D.; Feron, E.; Kalidindi, S.R. A Generalizable Artificial Intelligence Tool for Identification and Correction of Self-Supporting Structures in Additive Manufacturing Processes. Addit. Manuf. 2021, 46, 102191. [Google Scholar] [CrossRef]

- Wang, P.; Qi, J.; Xu, X.; Yang, S. Machining Quality Prediction of Multi-Feature Parts Using Integrated Multi-Source Domain Dynamic Adaptive Transfer Learning. Robot. Comput. Integr. Manuf. 2024, 90, 102815. [Google Scholar] [CrossRef]

- Tóth, M.; Brown, A.; Cross, E.; Rogers, T.; Sims, N.D. Resource-Efficient Machining through Physics-Informed Machine Learning. Procedia CIRP 2023, 117, 347–352. [Google Scholar] [CrossRef]

- Brusa, E.; Cibrario, L.; Delprete, C.; Di Maggio, L.G. Explainable AI for Machine Fault Diagnosis: Understanding Features’ Contribution in Machine Learning Models for Industrial Condition Monitoring. Appl. Sci. 2023, 13, 2038. [Google Scholar] [CrossRef]

| Phase | Key Technological Innovation | Main Benefits/Motivations |

|---|---|---|

| Conventional drilling | Standard twist drill (HSS, uncoated carbide) | Simple, cost-effective, mature technology, but limited for advanced materials |

| Enhanced mechanical kinematics | Orbital/helical drilling, circular drilling | Reduced thrust forces, improved chip evacuation, lower delamination |

| Assisted drilling techniques | Ultrasonic-assisted drilling (UAD), rotary-assisted drilling (RAD), peck drilling | Lower friction and heat, longer tool life, improved surface finish |

| Advanced cooling and lubrication | Cryogenic drilling (LN2), MQL, hybrid cryo–MQL | Lower cutting temperatures, tool wear reduction, eco-efficiency |

| Self-adaptive parameter control | One-up/auto-adaptive drilling with real-time spindle power monitoring | On-the-fly feed/speed adjustment, defect reduction, interface damage control |

| Robotic and sensor-integrated drilling | Robotic drilling systems, multi-sensor end-effectors, real-time alignment and pose correction | Autonomous positioning, process flexibility, digital twin connectivity |

| Intelligent and AI-driven drilling | Data fusion, AI-based monitoring, predictive quality control | Closed-loop control, zero-defect production, energy-aware optimisation |

| Monitoring Method | Typical Sensors | Main Features Extracted | Correlated Process Indicators | Representative References |

|---|---|---|---|---|

| Force and torque monitoring | Piezoelectric dynamometers, spindle-integrated sensors, instrumented toolholders, hybrid vise sensors | Thrust force, torque, slope of load curve, breakthrough signature | Delamination (CFRP), burr height, surface roughness, roundness, tool wear | [5,48,49,50] |

| Vibration monitoring | Accelerometers (spindle-mounted, tri-axial), mechatronics systems, CNC internal data (CID) | RMS values, frequency spectra, time–frequency wavelet features | Chatter detection, tool wear progression, process stability | [44,51,52,53,54,55] |

| Acoustic emission (AE) | Piezoelectric AE transducers, broadband sensors (kHz–MHz) | RMS, amplitude, burst vs. continuous signals, frequency bands, wavelet packet energy | Tool wear, matrix fracture, delamination onset, burr initiation in metallic layers, surface roughness | [7,22,43,56] |

| Spindle current and power | Hall-effect current probes, machine load metres, SEM-Modul-e, eADU drivers (spindle + feed currents) | Active power, dynamic component, power surges, segmented signal features | Tool wear, breakage detection, material transition recognition, energy efficiency | [13,15,16,57,58] |

| Thermal monitoring | Tool/work thermocouples, embedded drill-channel thermocouples, IR pyrometers, IR cameras | Peak temperature, spatial distribution, drill-exit hot spots | Matrix softening, delamination growth, burr formation, tool wear acceleration | [61,62,63] |

| Vision-based monitoring | High-speed cameras, digital image correlation (DIC) coaxial CCD with telecentric lens, industrial cameras integrated in robotic MFEEs | Interlayer gap evolution, displacement fields, hole geometry, delamination factor, countersink depth | Structural instabilities, burr/delamination onset, dimensional accuracy, defect classification | [4,21,64,65,67] |

| Algorithm | Main Application in Drilling | Advantages | Limitations | Representative Studies |

|---|---|---|---|---|

| Genetic Algorithm (GA) | Optimisation of cutting parameters (speed, feed, geometry) to minimise thrust force, torque, burrs, delamination, or maximise productivity | Robust global search; effective for both discrete and continuous variables; well-established in manufacturing | Risk of premature convergence; relatively high computational cost | [88,89] |

| Particle Swarm Optimisation (PSO) | Optimisation of process parameters for defect reduction (delamination, roughness) and surrogate model tuning | Fast convergence; simple implementation with few parameters: efficient in continuous domains | Can stagnate in local minima; performance sensitive to swarm size and coefficient | [87,88] |

| Differential Evolution (DE) | Optimisation of drilling energy efficiency, torque/thrust management, vibration reduction | Strong exploration capability; robust for continuous optimisation; fewer control parameters than GA | Sensitive to scaling (F, CR) and population size; fewer drilling applications compared to GA/PSO | [19,90] |

| Ant Colony Optimisation (ACO) | Optimisation of drilling sequences and tool paths to reduce total path length and machining time in multi-hole components | Highly effective for combinatorial optimisation; scalable to complex geometries; significant machining time reduction | Computational effort grows with number of holes; not suitable for continuous process responses | [91,92] |

| Hybrid frameworks (e.g., ANN + NSGA-II; SVM + PSO; ANFIS + GA) | Multi-response optimisation combining parametric tuning with surrogate-based prediction (forces, roughness, delamination, MRR) | Combine predictive accuracy of surrogates with global search of evolutionary algorithms; yield Pareto-efficient solutions | Require large training datasets; computationally more sensitive; interpretability can be limited | [83,85] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panico, M.; Boccarusso, L. Smart Drilling: Integrating AI for Process Optimisation and Quality Enhancement in Manufacturing. J. Manuf. Mater. Process. 2025, 9, 386. https://doi.org/10.3390/jmmp9120386

Panico M, Boccarusso L. Smart Drilling: Integrating AI for Process Optimisation and Quality Enhancement in Manufacturing. Journal of Manufacturing and Materials Processing. 2025; 9(12):386. https://doi.org/10.3390/jmmp9120386

Chicago/Turabian StylePanico, Martina, and Luca Boccarusso. 2025. "Smart Drilling: Integrating AI for Process Optimisation and Quality Enhancement in Manufacturing" Journal of Manufacturing and Materials Processing 9, no. 12: 386. https://doi.org/10.3390/jmmp9120386

APA StylePanico, M., & Boccarusso, L. (2025). Smart Drilling: Integrating AI for Process Optimisation and Quality Enhancement in Manufacturing. Journal of Manufacturing and Materials Processing, 9(12), 386. https://doi.org/10.3390/jmmp9120386