Tailoring the Functional Properties of NiTi Shape Memory Alloy by Laser Powder Bed Fusion Process Conditions for 4D Printing

Abstract

1. Introduction

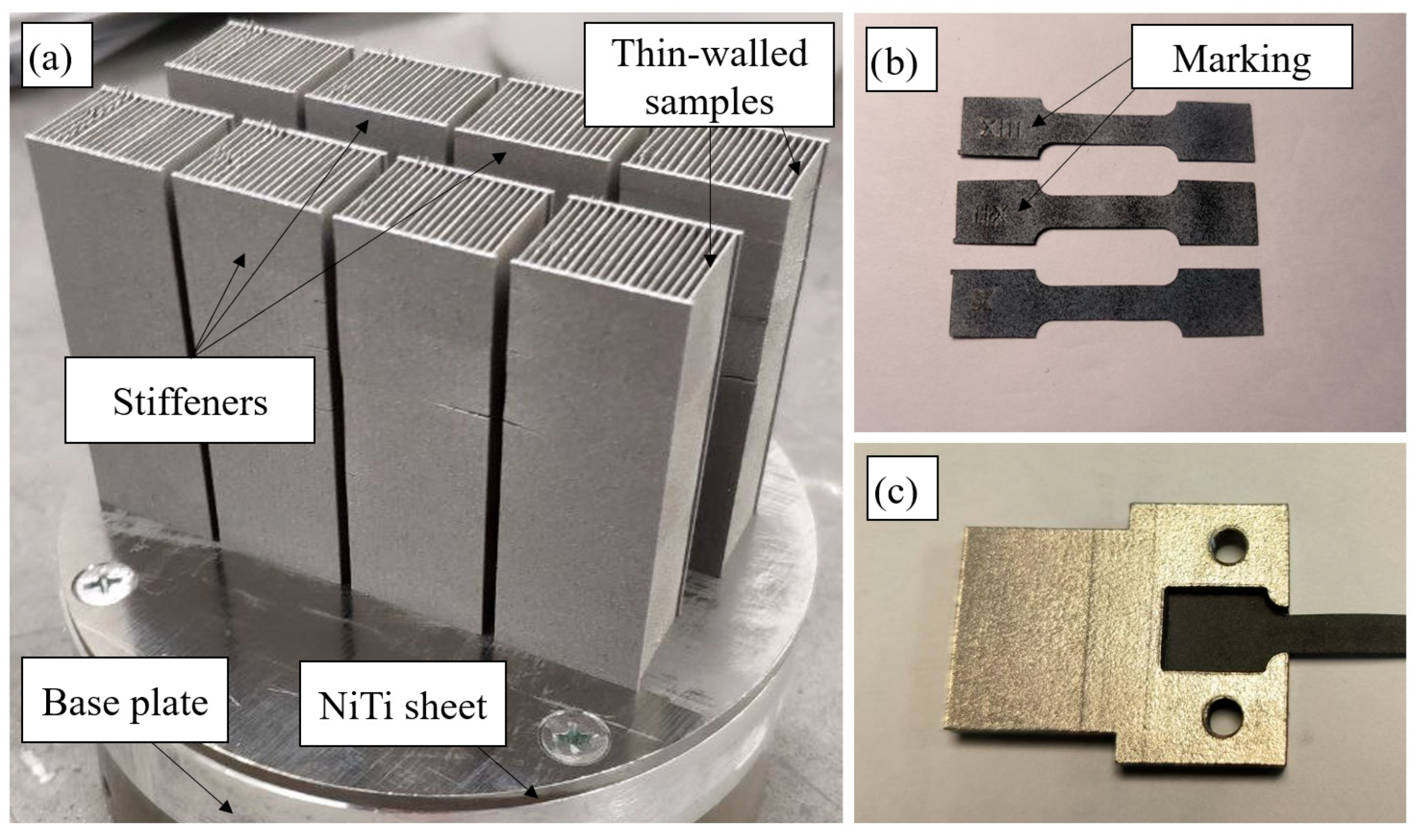

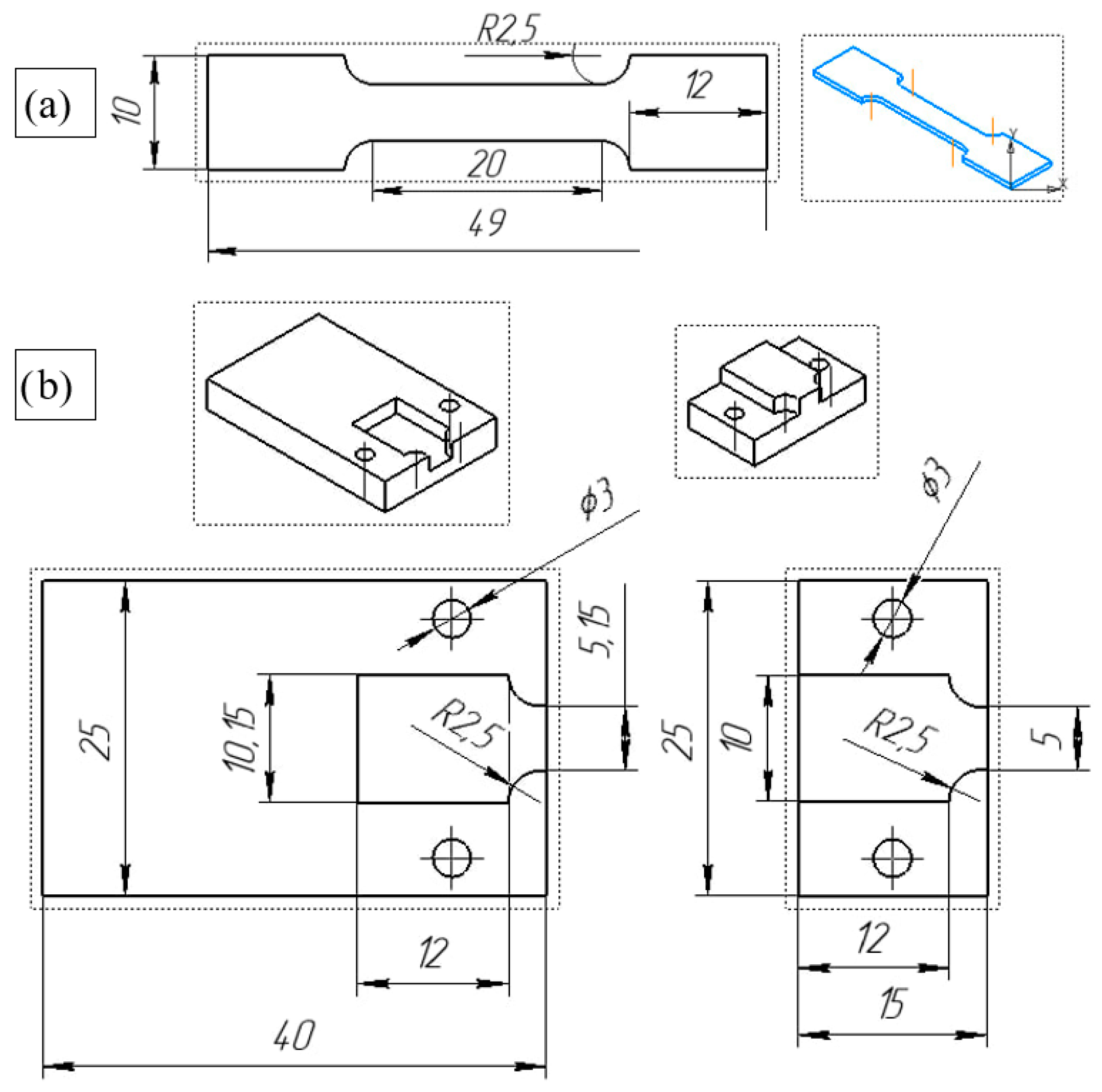

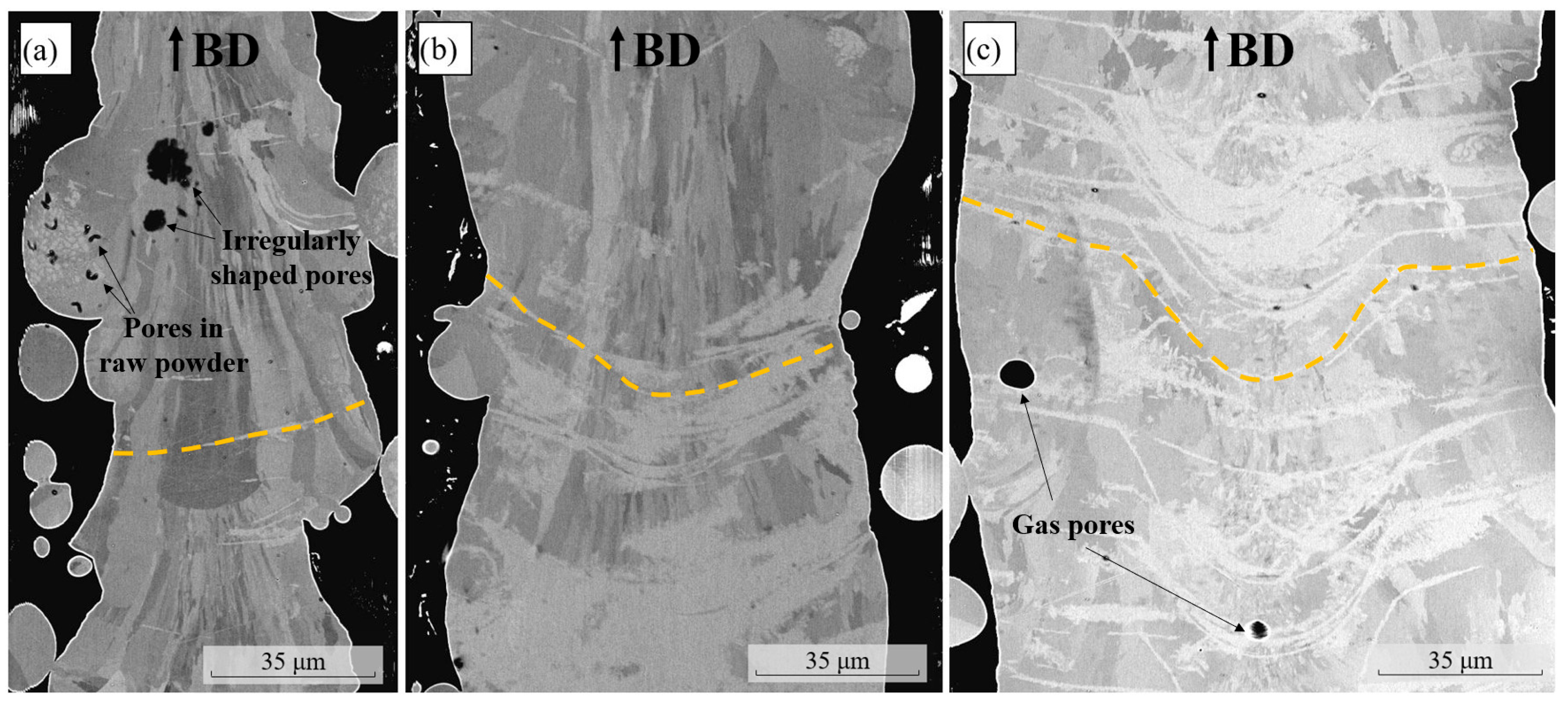

2. Materials and Methods

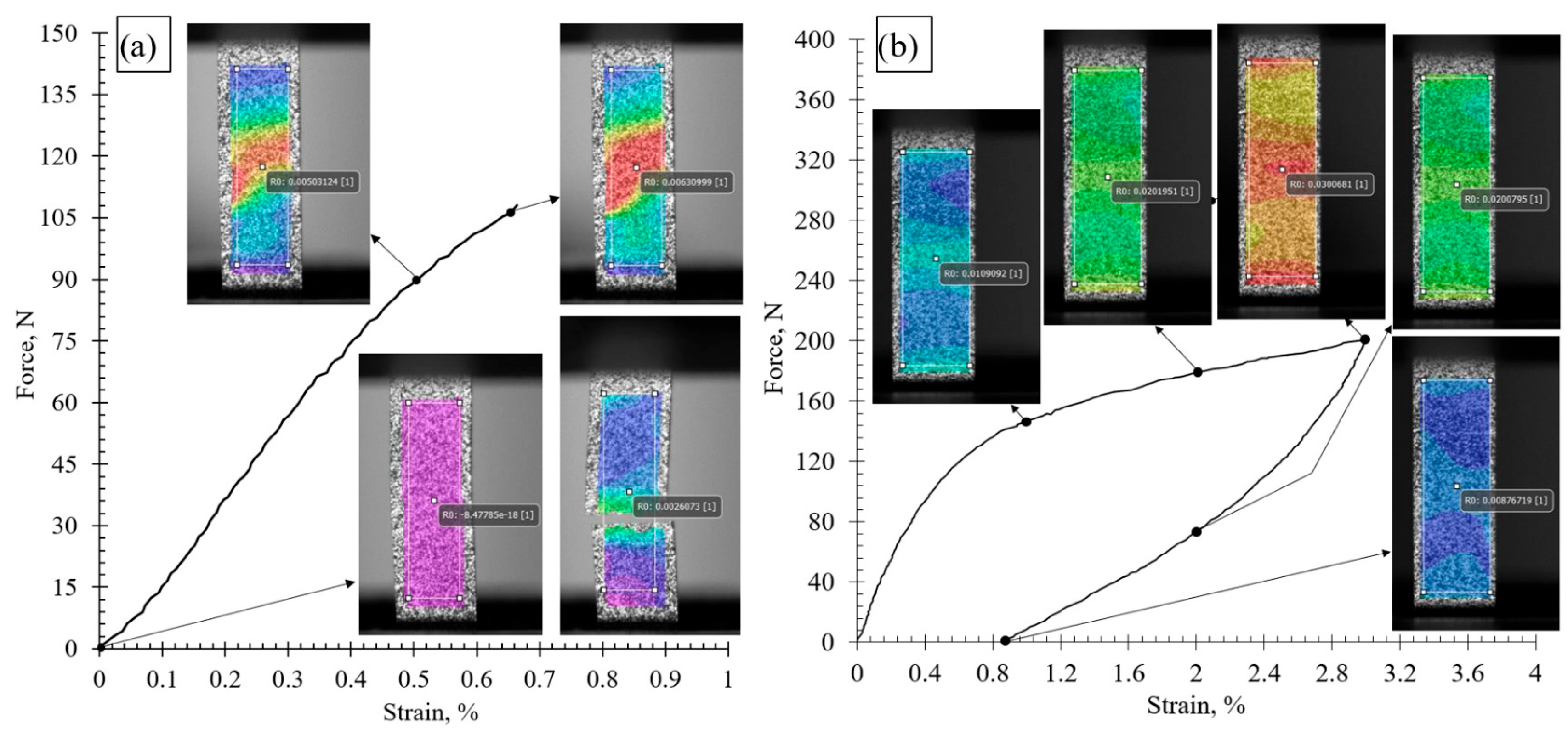

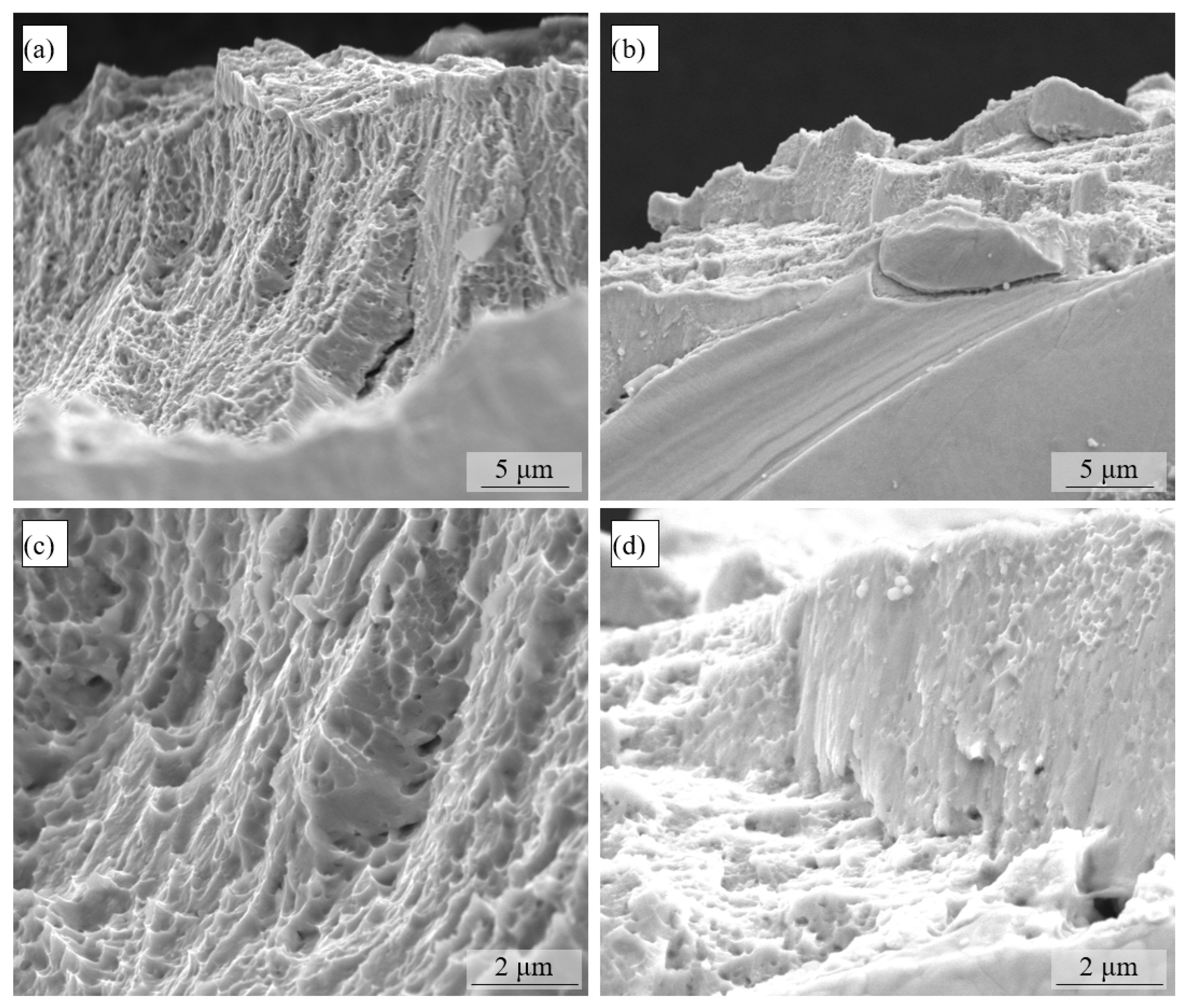

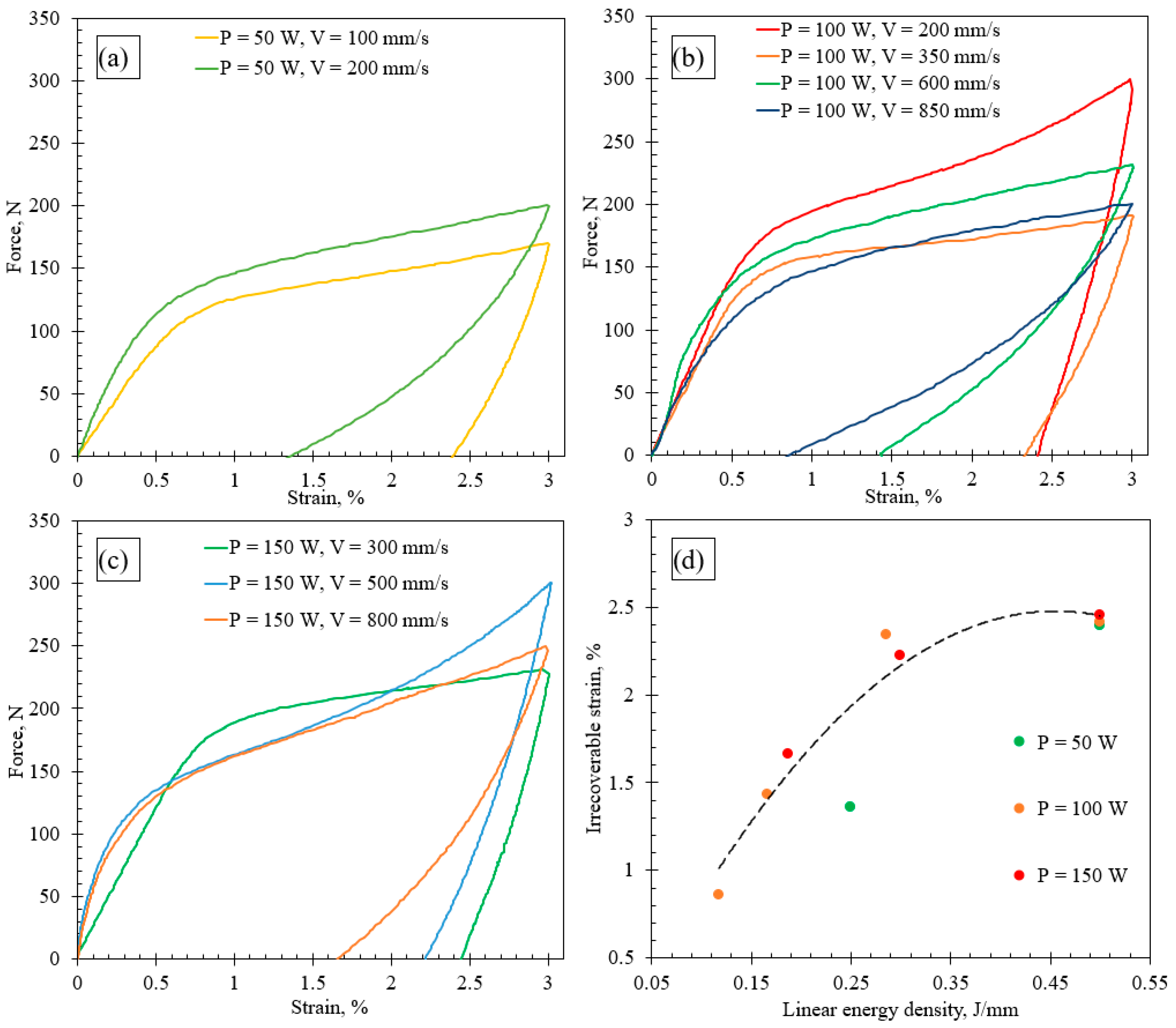

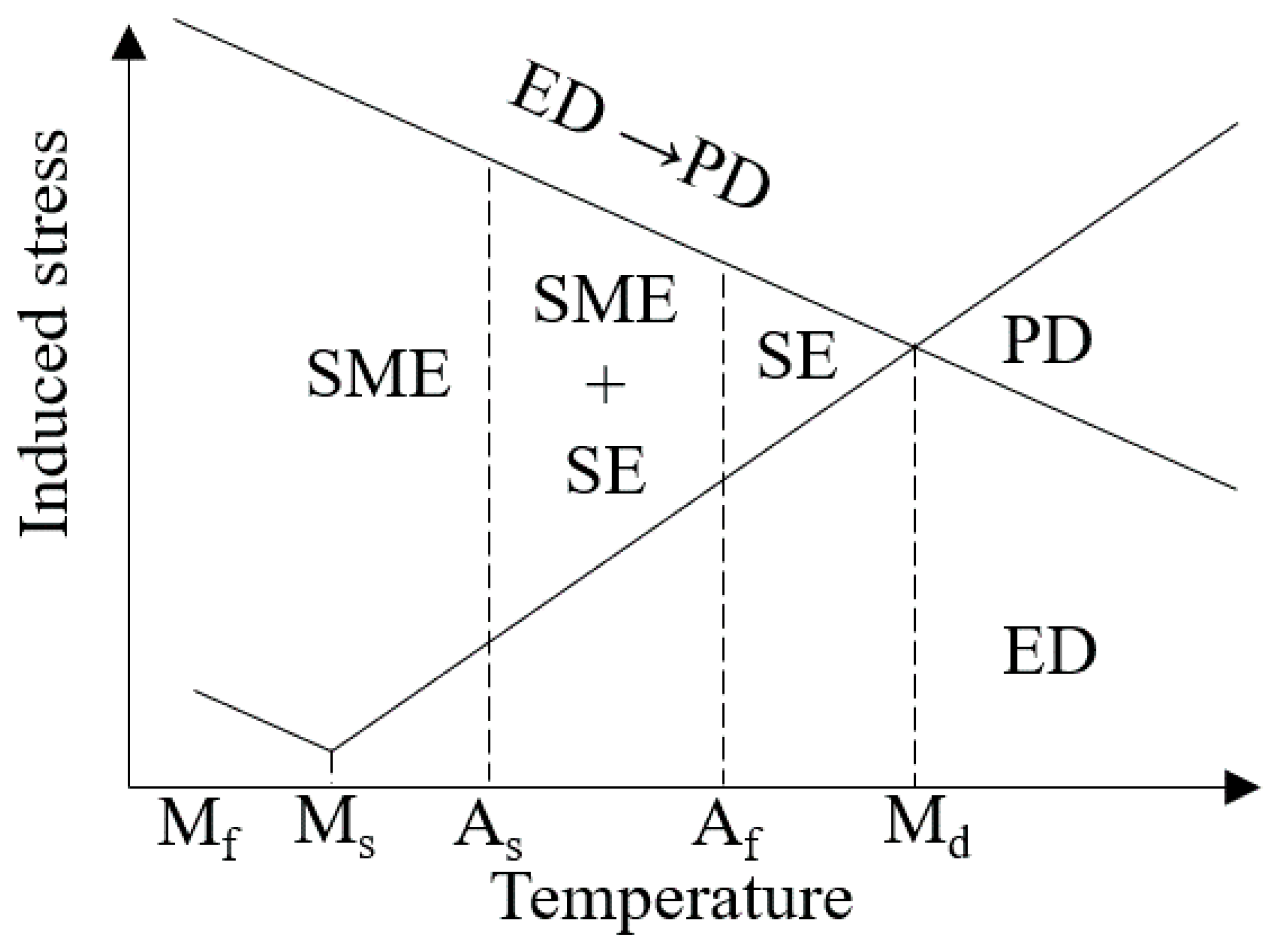

3. Results and Discussion

4. Conclusions

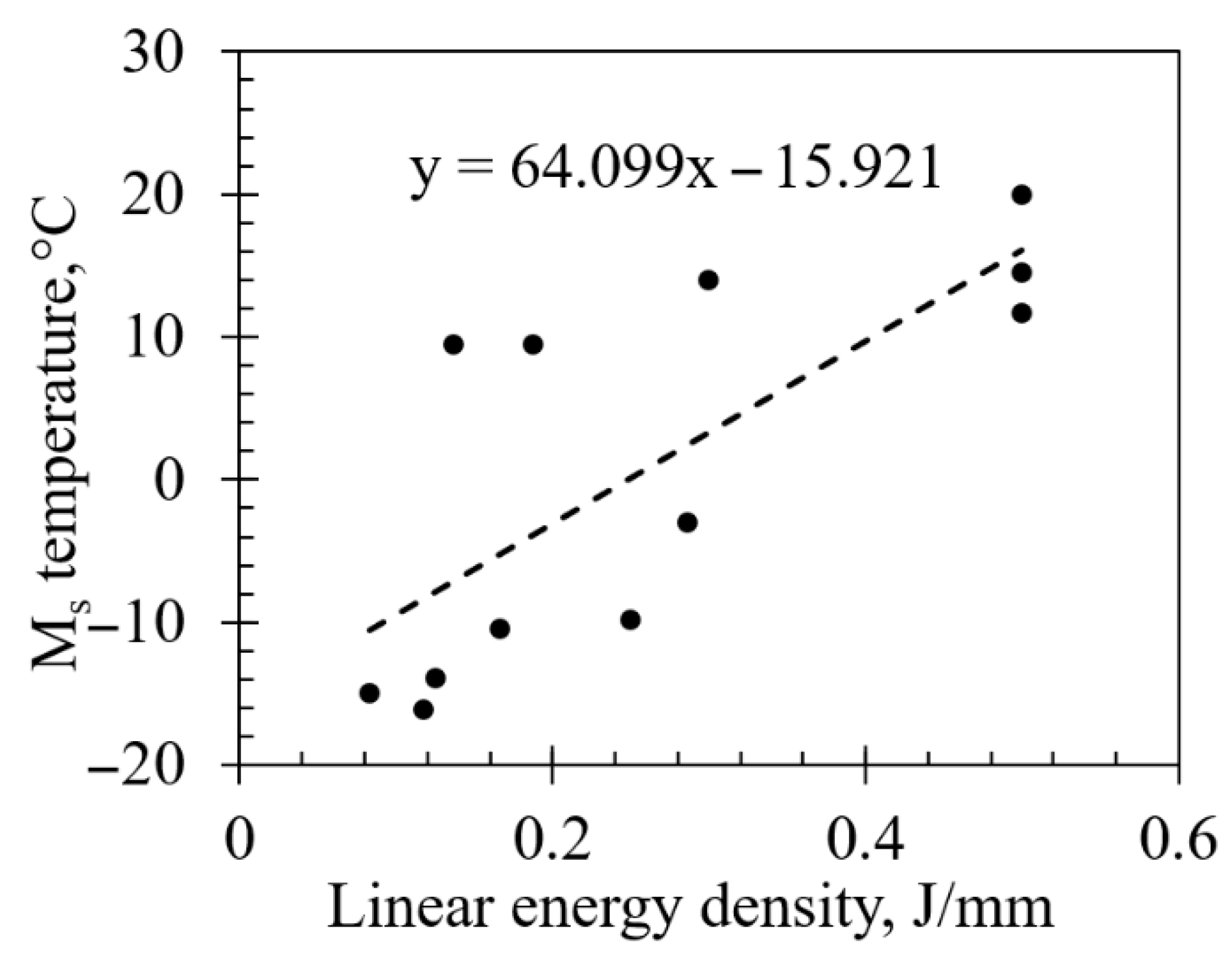

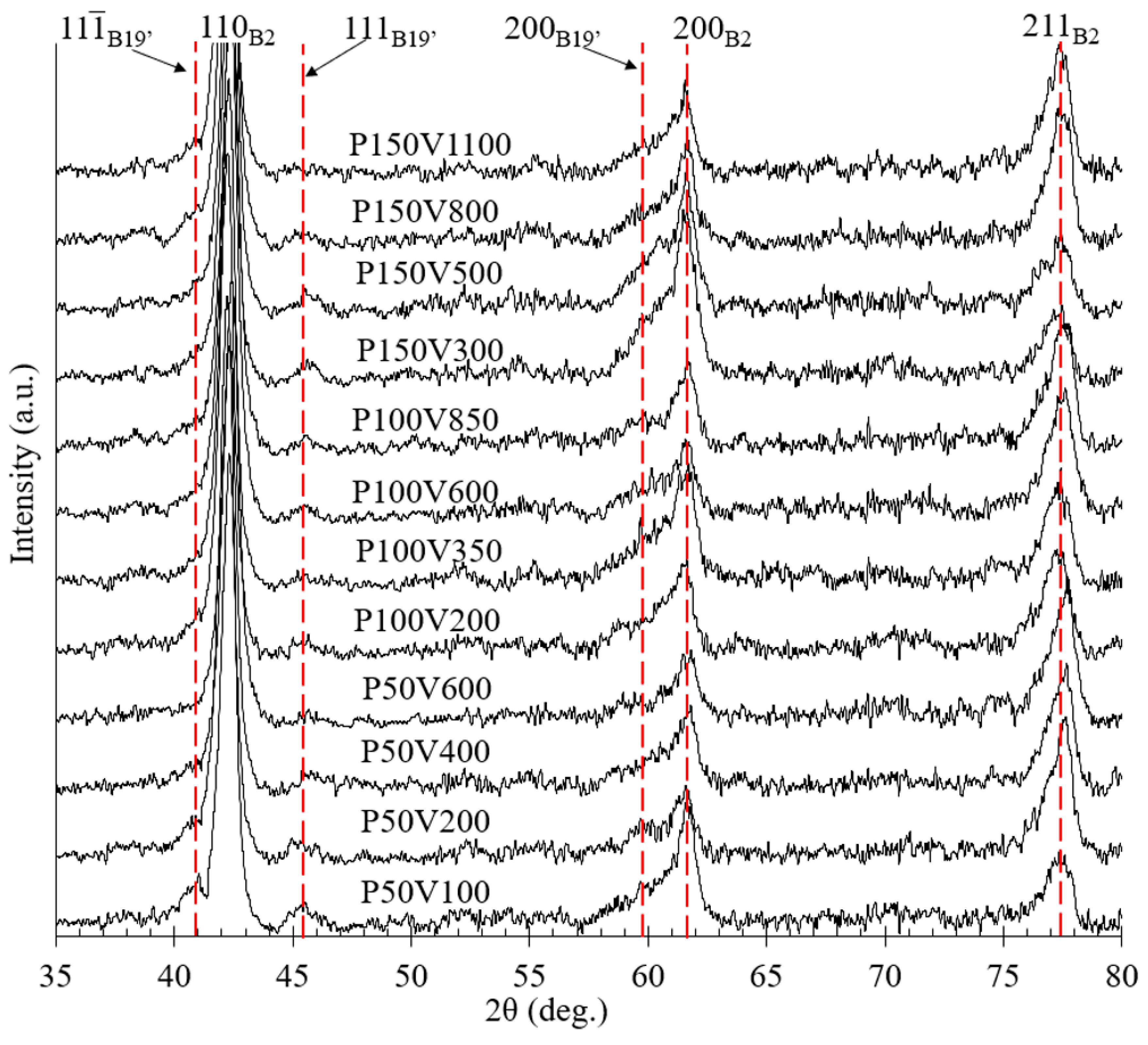

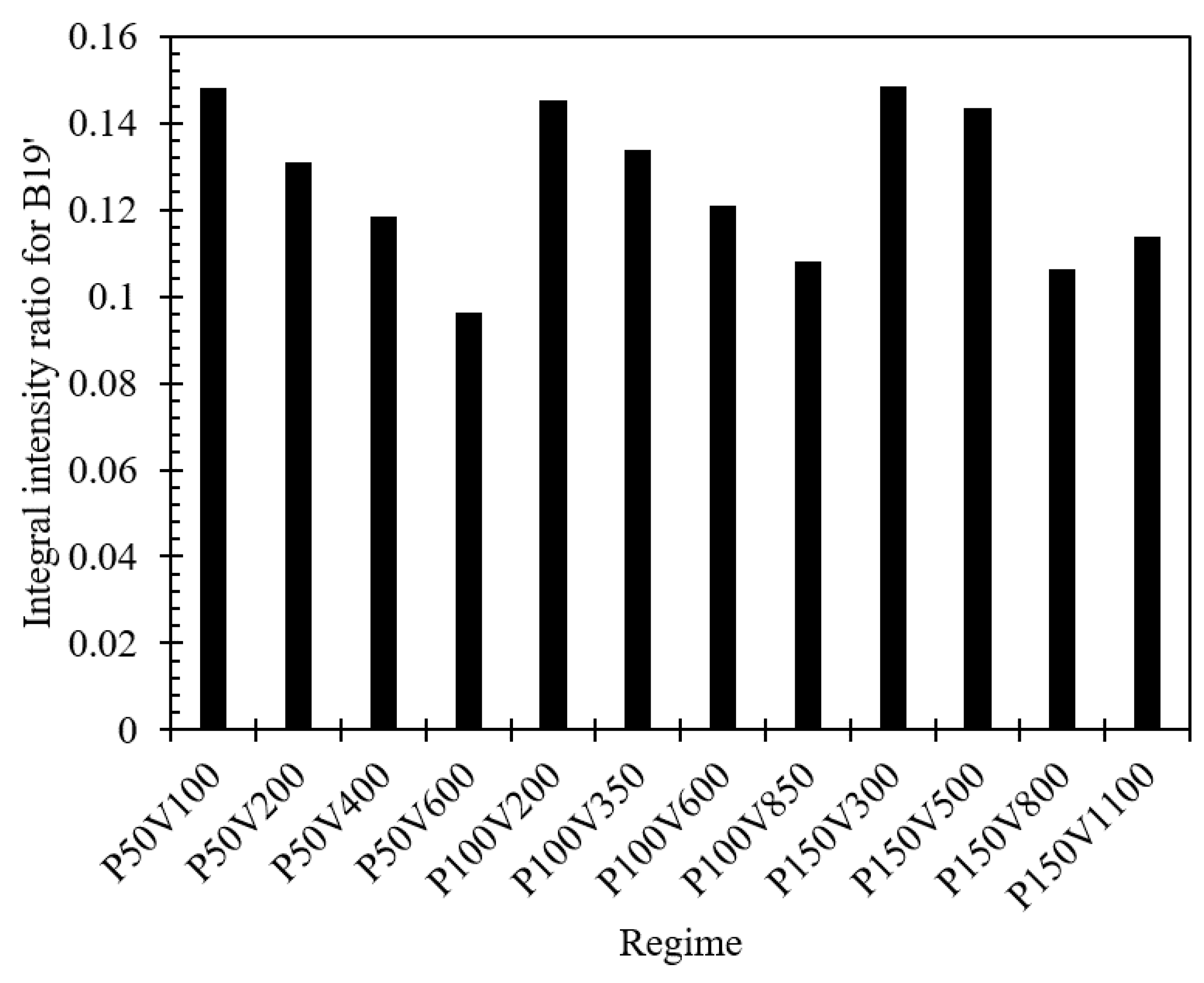

- Excluding the hatch spacing by means of single track-based thin walls consolidation allowed us to reveal the pure effect of the laser influence on the NiTi functional properties. The samples manufactured with the highest linear energy density (LED) of 0.5 J/mm and highest laser power exhibited a decrease in the characteristic transformation temperatures by 45 °C. This large temperature range provides the basis for controlling functional properties when varying the LPBF process parameters.

- It was demonstrated that the low values of LED resulted in almost no change in the transformation temperatures (TTs) in comparison with the raw powder. Thus, the process conditions with a minimal influence on the NiTi functional properties are of interest for applications requiring a superelastic (SE) response. However, it was demonstrated that after a significant decrease in LED, poor ultimate strength will limit the performance of such a consolidated part. In this regard, when the SE response of NiTi is desirable, the optimal LPBF regime presents a compromise.

- Established relationships between the NiTi properties (TTs, irreversible strain, and volume fraction of the martensitic phase) and the LPBF process conditions create a foundation for the production protocols of NiTi with SE behavior, specific SME activation temperature, or multistage SME activation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LPBF | Laser powder bed fusion |

| SMA | Shape memory alloy |

| SME | Shape memory effect |

| AM | Additive manufacturing |

| SLM | Selective laser melting |

| TTs | Transformation temperatures |

| PSD | Particle size distribution |

| EDM | Electrical discharge machining |

| DSC | Differential scanning calorimetry |

| XRD | X-ray diffraction |

| DIC | Digital image correlation |

| BD | Building direction |

| LED | Linear energy density |

| LE | Low elongation |

| HE | High elongation |

| SE | Superelasticity |

| BCC | Body-centered cubic |

References

- Lagoudas, D.C. Shape Memory Alloys; Springer: Boston, MA, USA, 2008. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Reconciling viability and cost-effective shape memory alloy options—A review of copper and iron based shape memory metallic systems. Eng. Sci. Technol. Int. J. 2016, 19, 1582–1592. [Google Scholar] [CrossRef]

- Patel, S.K.; Behera, B.; Swain, B.; Roshan, R.; Sahoo, D.; Behera, A. A review on NiTi alloys for biomedical applications and their biocompatibility. Mater. Today Proc. 2020, 33, 5548–5551. [Google Scholar] [CrossRef]

- Yoneyama, T.; Miyazaki, S. Shape Memory Alloys for Biomedical Applications; Woodhead Publishing Limited: Cambridge, UK, 2009. [Google Scholar] [CrossRef]

- Bogue, R. Shape-memory materials: A review of technology and applications. Assem. Autom. 2009, 29, 214–249. [Google Scholar] [CrossRef]

- Yahia, L. Shape Memory Implants; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar] [CrossRef]

- Piquard, R.; D’Acunto, A.; Laheurte, P.; Dudzinski, D. Micro-end milling of NiTi biomedical alloys, burr formation and phase transformation. Precis. Eng. 2014, 38, 356–364. [Google Scholar] [CrossRef]

- Kaya, E.; Kaya, İ. A review on machining of NiTi shape memory alloys: The process and post process perspective. Int. J. Adv. Manuf. Technol. 2019, 100, 2045–2087. [Google Scholar] [CrossRef]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Saha, P.; Datta, S.; Raza, M.S.; Pratihar, D.K. Effects of Heat Input on Weld-Bead Geometry, Surface Chemical Composition, Corrosion Behavior and Thermal Properties of Fiber Laser-Welded Nitinol Shape Memory Alloy. J. Mater. Eng. Perform. 2019, 28, 2754–2763. [Google Scholar] [CrossRef]

- Biermann, D.; Kahleyss, F.; Krebs, E.; Upmeier, T. A Study on Micro-Machining Technology for the Machining of NiTi: Five-Axis Micro-Milling and Micro Deep-Hole Drilling. J. Mater. Eng. Perform. 2011, 20, 745–751. [Google Scholar] [CrossRef]

- Bram, M.; Ahmad-Khanlou, A.; Heckmann, A.; Fuchs, B.; Buchkremer, H.P.; Stöver, D. Powder metallurgical fabrication processes for NiTi shape memory alloy parts. Mater. Sci. Eng. A 2002, 337, 254–263. [Google Scholar] [CrossRef]

- Alvarez, K.; Nakajima, H. Metallic scaffolds for bone regeneration. Materials 2009, 2, 790–832. [Google Scholar] [CrossRef]

- Zheng, B.; Trofimov, V.; Yang, Y.; Han, C.; Zeng, Z.; Abbas, S.F.; Li, S.; Lei, L.; Sang, J.; Zhang, J.; et al. Enhancing the dimensional accuracy and manufacturing limits of laser powder bed fusion through dual-laser hybrid additive-subtractive manufacturing. Opt. Laser Technol. 2025, 188, 112947. [Google Scholar] [CrossRef]

- Chernyshikhin, S.V.; Pelevin, I.A.; Karimi, F.; Shishkovsky, I.V. The Study on Resolution Factors of LPBF Technology for Manufacturing Superelastic NiTi Endodontic Files. Materials 2022, 15, 6556. [Google Scholar] [CrossRef]

- Safaei, K.; Abedi, H.; Nematollahi, M.; Kordizadeh, F.; Dabbaghi, H.; Bayati, P.; Javanbakht, R.; Jahadakbar, A.; Elahinia, M.; Poorganji, B. Additive Manufacturing of NiTi Shape Memory Alloy for Biomedical Applications: Review of the LPBF Process Ecosystem. JOM 2021, 73, 3771–3786. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; du Preez, W.B. Additive manufacturing of Ti-based intermetallic alloys: A review and conceptualization of a next-generation machine. Materials 2021, 14, 4317. [Google Scholar] [CrossRef]

- Caprio, L.; Demir, A.G.; Chiari, G.; Previtali, B. Defect-free laser powder bed fusion of Ti–48Al–2Cr–2Nb with a high temperature inductive preheating system. J. Phys. Photonics 2020, 2, 024002. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Sherbakof, V. Influence of laser cycling on electro-structural features of nickel-titanium SMA fabricated by LPBF process. Appl. Surf. Sci. 2020, 508, 145278. [Google Scholar] [CrossRef]

- Shinkaryov, A.S.; Ozherelkov, D.Y.; Pelevin, I.A.; Eremin, S.A.; Anikin, V.N.; Burmistrov, M.A.; Chernyshikhin, S.V.; Gromov, A.A.; Nalivaiko, A.Y. Laser fusion of aluminum powder coated with diamond particles via selective laser melting: Powder preparation and synthesis description. Coatings 2021, 11, 1219. [Google Scholar] [CrossRef]

- Nalivaiko, A.Y.; Ozherelkov, D.Y.; Pelevin, I.A.; Chernyshikhin, S.V.; Medvedev, A.E.; Korshunov, A.V.; Arnautov, A.N.; Gromov, A.A. Comprehensive Study of the 3D Printing of Single Tracks and Cubic Samples by Selective Laser Melting of AlSi10MgCu Alloy. Met. Mater. Int. 2022, 28, 787–801. [Google Scholar] [CrossRef]

- Pelevin, I.A.; Burmistrov, M.A.; Ozherelkov, D.Y.; Shinkaryov, A.S.; Chernyshikhin, S.V.; Gromov, A.A.; Nalivaiko, A.Y. Laser powder bed fusion of chromium bronze using recycled powder. Materials 2021, 14, 3644. [Google Scholar] [CrossRef]

- Forien, J.B.; Calta, N.P.; DePond, P.J.; Guss, G.M.; Roehling, T.T.; Matthews, M.J. Detecting keyhole pore defects and monitoring process signatures during laser powder bed fusion: A correlation between in situ pyrometry and ex situ X-ray radiography. Addit. Manuf. 2020, 35, 101336. [Google Scholar] [CrossRef]

- Zhu, J.N.; Borisov, E.; Liang, X.; Farber, E.; Hermans, M.J.M.; Popovich, V.A. Predictive analytical modelling and experimental validation of processing maps in additive manufacturing of nitinol alloys. Addit. Manuf. 2021, 38, 101802. [Google Scholar] [CrossRef]

- Chernyshikhin, S.V.; Firsov, D.G.; Shishkovsky, I.V. Selective Laser Melting of Pre-Alloyed NiTi Powder: Single-Track Study and FE Modeling with Heat Source Calibration. Materials 2021, 14, 7486. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.; Zhang, H.; Yin, J.; Ke, L.; Zeng, X. Selective laser melting of Al7050 powder: Melting mode transition and comparison of the characteristics between the keyhole and conduction mode. Mater. Des. 2017, 135, 257–266. [Google Scholar] [CrossRef]

- Lyu, Z.; Wang, J.; Chen, Y. 4D printing: Interdisciplinary integration of smart materials, structural design, and new functionality. Int. J. Extrem. Manuf. 2023, 5, 032011. [Google Scholar] [CrossRef]

- Shishkovsky, I.V.; Scherbakov, V.I.; Kuznetsov, M.V.; Belousova, O.V.; Morozov, Y.G. 4D Laser Printing of Functionally Graded Structures and Items from Mixtures of Powdered Polymers with Functional Micro- and Nanoparticles: An Autoreview. Int. J. Self-Propagating High-Temp. Synth. 2020, 29, 77–86. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Wu, X.; Shi, J. Nonequilibrium thermodynamic calculation and experimental investigation of an additively manufactured functionally graded material. J. Alloy Compd. 2020, 838, 155322. [Google Scholar] [CrossRef]

- Ryklina, E.P.; Polyakova, K.A.; Murygin, S.R.; Komarov, V.S.; Resnina, N.N.; Andreev, V.A. Role of Structural Heredity in Control of Functional and Mechanical Characteristics of Ni-Rich Titanium Nickelide. Phys. Met. Met. 2022, 123, 1226–1233. [Google Scholar] [CrossRef]

- Filip, P.; Mazanec, K. On precipitation kinetics in TiNi shape memory alloys. Scr. Mater. 2001, 45, 701–707. [Google Scholar] [CrossRef]

- Ma, J.; Franco, B.; Tapia, G.; Karayagiz, K.; Johnson, L.; Liu, J.; Arroyave, R.; Karaman, I.; Elwany, A. Spatial Control of Functional Response in 4D-Printed Active Metallic Structures. Sci. Rep. 2017, 7, 46707. [Google Scholar] [CrossRef] [PubMed]

- Moghaddam, S.N.; Saedi, S.; Amerinatanzi, A.; Hinojos, A.; Ramazani, A.; Kundin, J.; Mills, M.J.; Karaca, H.; Elahinia, M. Achieving superelasticity in additively manufactured NiTi in compression without post-process heat treatment. Sci. Rep. 2019, 9, 41. [Google Scholar] [CrossRef]

- Chernyshikhin, S.V.; Panov, D.V.; Van Tuan, T.; Ozherelkov, D.Y.; Sheremetyev, V.A.; Shishkovsky, I.V. Laser Polishing of Nickel-Titanium Shape Memory Alloy Produced via Laser Powder Bed Fusion. Met. Mater. Int. 2023, 29, 3024–3038. [Google Scholar] [CrossRef]

- Chernyshikhin, S.V.; Mahato, B.; Shiverskii, A.V.; Pelevin, I.A.; Dubinin, O.N.; Egorov, V.Y.; Abaimov, S.G.; Shishkovsky, I.V. In-plane measurements and computational fluid dynamics prediction of permeability for biocompatible NiTi gyroid scaffolds fabricated via laser powder bed fusion. Int. J. Bioprinting 2023, 10, 0119. [Google Scholar] [CrossRef]

- ASTM B527-20; Standard Test Method for Tap Density of Metal Powders and Compounds. ASTM International: West Conshohocken, PA, USA, 2020.

- Sitepu, H.; Schmahl, W.W.; Khalil Allafi, J.; Eggeler, G.F.; Reinecke, T.; Brokmeier, H.G.; Tovar, M.; Többens, D.M. Texture and Quantitative Phase Analysis of Aged Ni-Rich NiTi using X-Ray and Neutron Diffractions. Mater. Sci. Forum 2002, 394–395, 237–240. [Google Scholar] [CrossRef]

- Collins, P.C.; Brice, D.A.; Samimi, P.; Ghamarian, I.; Fraser, H.L. Microstructural Control of Additively Manufactured Metallic Materials. Annu. Rev. Mater. Res. 2016, 46, 63–91. [Google Scholar] [CrossRef]

- Pineau, A.; Benzerga, A.A.; Pardoen, T. Failure of metals I: Brittle and ductile fracture. Acta Mater. 2016, 107, 424–483. [Google Scholar] [CrossRef]

- Dayananda, G.N.; Rao, M.S. Effect of strain rate on properties of superelastic NiTi thin wires. Mater. Sci. Eng. A 2008, 486, 96–103. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, T.M.; Haberland, C.; Karaca, H.; Elahinia, M. The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J. Alloy Compd. 2016, 677, 204–210. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.M.; Meier, H.; Frenzel, J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23, 104002. [Google Scholar] [CrossRef]

- Prokofiev, E.A.; Burow, J.A.; Payton, E.J.; Zarnetta, R.; Frenzel, J.; Gunderov, D.V.; Valiev, R.Z.; Eggeler, G. Suppression of Ni4Ti3 Precipitation by Grain Size Refinement in Ni-Rich NiTi Shape Memory Alloys. Adv. Eng. Mater. 2010, 12, 747–753. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1987. [Google Scholar]

- Kreitcberg, A.; Sheremetyev, V.; Tsaturyants, M.; Prokoshkin, S.; Brailovski, V. Optimization of Post-processing Annealing Conditions of the Laser Powder Bed-Fused Ti–18Zr–14Nb Shape Memory Alloy: Structure and Functional Properties. Shape Mem. Superelasticity 2019, 5, 172–181. [Google Scholar] [CrossRef]

- Brailovski, V.; Kalinicheva, V.; Letenneur, M.; Lukashevich, K.; Sheremetyev, V.; Prokoshkin, S. Control of Density and Grain Structure of a Laser Powder Bed-Fused Superelastic Ti-18Zr-14Nb Alloy: Simulation-Driven Process Mapping. Metals 2020, 10, 1697. [Google Scholar] [CrossRef]

- Gunderov, D.; Kim, K.; Gunderova, S.; Churakova, A.; Lebedev, Y.; Nafikov, R.; Derkach, M.; Lukashevich, K.; Sheremetyev, V.; Prokoshkin, S. Effect of High-Pressure Torsion and Annealing on the Structure, Phase Composition, and Microhardness of the Ti-18Zr-15Nb (at. %) Alloy. Materials 2023, 16, 1754. [Google Scholar] [CrossRef] [PubMed]

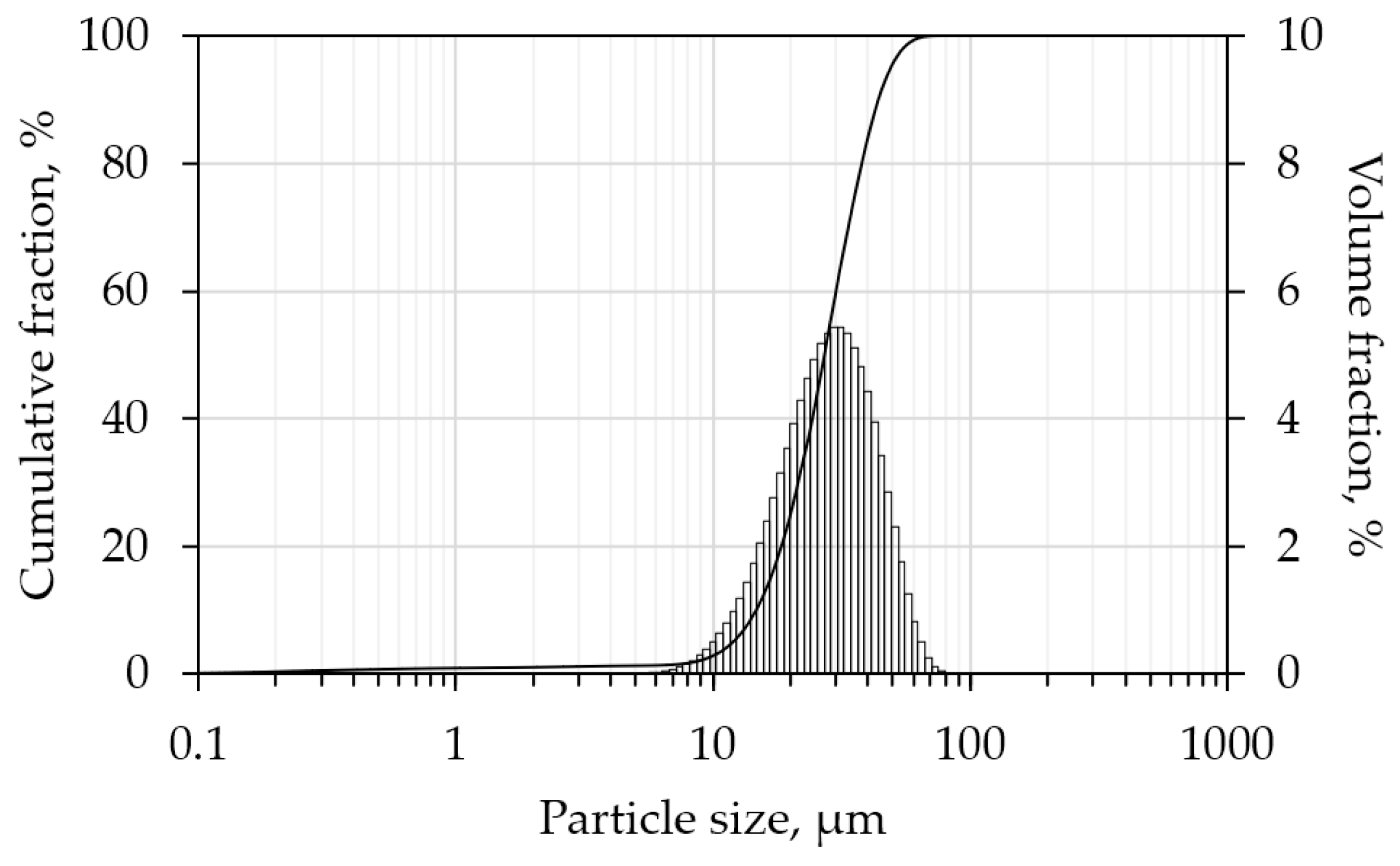

| Powder Property | Units | Value |

|---|---|---|

| Nickel content | wt.% | 55.9 |

| Oxygen content | wt.% | 0.03 |

| Hall flow | s/50 g | 18.5 |

| Tap density | g/cm3 | 3.92 |

| Relative tap density | % | 60.7 |

| d50 | μm | 27.8 |

| P, W | V, mm/s | El, J/mm |

|---|---|---|

| 50 | 100 | 0.50 |

| 50 | 200 | 0.25 |

| 100 | 200 | 0.50 |

| 100 | 350 | 0.29 |

| 100 | 600 | 0.17 |

| 100 | 850 | 0.12 |

| 150 | 300 | 0.50 |

| 150 | 500 | 0.30 |

| 150 | 800 | 0.19 |

| P, W | V, mm/s | El, J/mm | εrec, % | εirrec, % | Recovery Ratio, % |

|---|---|---|---|---|---|

| 50 | 100 | 0.50 | 0.66 | 2.34 | 22 |

| 50 | 200 | 0.25 | 1.64 | 1.36 | 55 |

| 100 | 200 | 0.50 | 0.54 | 2.46 | 18 |

| 100 | 350 | 0.29 | 0.56 | 2.44 | 19 |

| 100 | 600 | 0.17 | 1.50 | 1.50 | 50 |

| 100 | 850 | 0.12 | 2.05 | 0.95 | 68 |

| 150 | 300 | 0.50 | 0.46 | 2.54 | 15 |

| 150 | 500 | 0.30 | 0.78 | 2.22 | 26 |

| 150 | 800 | 0.19 | 1.27 | 1.73 | 42 |

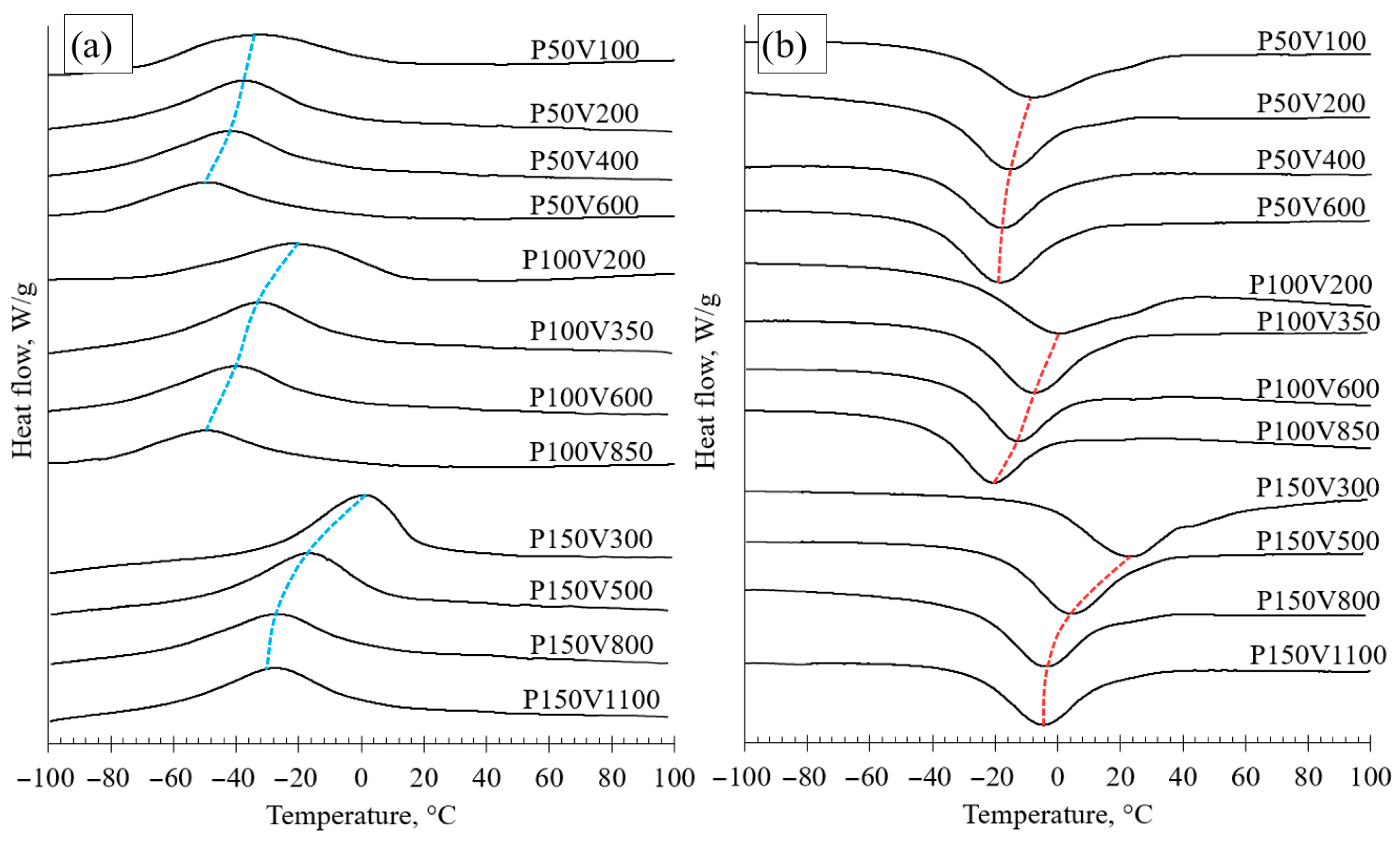

| Sample Name (LPBF Regime) | Transformation Temperatures (°C) | ||||||

|---|---|---|---|---|---|---|---|

| Ms | Mp | Mf | As | Ap | Af | ΔT | |

| P50V100 | 11.7 | −37.7 | −71.1 | −36.2 | −9.1 | 26.5 | 28.6 |

| P50V200 | −9.8 | −38.5 | −36.5 | −36.6 | −15.4 | 5.7 | 23.1 |

| P50V400 | −13.9 | −41.5 | −76 | −40.4 | −17.4 | 5.9 | 24.1 |

| P50V600 | −15 | −48.8 | −80.7 | −40.3 | −18.8 | 5.1 | 30 |

| P100V200 | 14.5 | −17.6 | −64.5 | −31.5 | −2 | 41.2 | 15.6 |

| P100V350 | −3 | −33 | −62.3 | −39.2 | −7.9 | 15.3 | 25.1 |

| P100V600 | −10.4 | −40.5 | −69.9 | −33.1 | −13 | 6.8 | 27.5 |

| P100V850 | −16.1 | −49.7 | −81.7 | −42.3 | −20.9 | −1.8 | 28.8 |

| P150V300 | 20 | 1 | −31 | −4.5 | 23 | 43 | 22 |

| P150V500 | 14 | −17 | −58 | −19.5 | 4 | 29.5 | 21 |

| P150V800 | 9.5 | −27 | −76 | −29.5 | −4 | 20 | 23 |

| P150V1100 | 9.5 | −27.5 | −71 | −28.9 | −5.5 | 17.1 | 22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chernyshikhin, S.V.; Zherebtsov, D.D.; Fedorenko, L.V.; Egorov, V.Y.; Filinov, V.O.; Rogachev, S.O.; Urzhumtsev, A.N.; Dzidziguri, E.L.; Lyange, M.V.; Shishkovsky, I.V. Tailoring the Functional Properties of NiTi Shape Memory Alloy by Laser Powder Bed Fusion Process Conditions for 4D Printing. J. Manuf. Mater. Process. 2025, 9, 385. https://doi.org/10.3390/jmmp9120385

Chernyshikhin SV, Zherebtsov DD, Fedorenko LV, Egorov VY, Filinov VO, Rogachev SO, Urzhumtsev AN, Dzidziguri EL, Lyange MV, Shishkovsky IV. Tailoring the Functional Properties of NiTi Shape Memory Alloy by Laser Powder Bed Fusion Process Conditions for 4D Printing. Journal of Manufacturing and Materials Processing. 2025; 9(12):385. https://doi.org/10.3390/jmmp9120385

Chicago/Turabian StyleChernyshikhin, Stanislav V., Dmitry D. Zherebtsov, Leonid V. Fedorenko, Vladimir Yu. Egorov, Viktor O. Filinov, Stanislav O. Rogachev, Andrey N. Urzhumtsev, Ella L. Dzidziguri, Maria V. Lyange, and Igor V. Shishkovsky. 2025. "Tailoring the Functional Properties of NiTi Shape Memory Alloy by Laser Powder Bed Fusion Process Conditions for 4D Printing" Journal of Manufacturing and Materials Processing 9, no. 12: 385. https://doi.org/10.3390/jmmp9120385

APA StyleChernyshikhin, S. V., Zherebtsov, D. D., Fedorenko, L. V., Egorov, V. Y., Filinov, V. O., Rogachev, S. O., Urzhumtsev, A. N., Dzidziguri, E. L., Lyange, M. V., & Shishkovsky, I. V. (2025). Tailoring the Functional Properties of NiTi Shape Memory Alloy by Laser Powder Bed Fusion Process Conditions for 4D Printing. Journal of Manufacturing and Materials Processing, 9(12), 385. https://doi.org/10.3390/jmmp9120385