1. Introduction

Wire electrical discharge machining (WEDM) is a powerful cutting and shape-forming technique. It can be used as the sole manufacturing step or as a supplementary one, such as for post-processing parts created by additive manufacturing (AM) [

1,

2]. Being non-contact, the thermal erosion process is exceptionally well-suited for addressing characteristic AM challenges, as it remains unhindered by the high hardness, residual stresses, and complex internal geometries often present in as-built components. Its capability for precision shape obtaining, enabling the machining of intricate profiles and fine features with micron-level accuracy, is highly demanded in metal AM. The primary application of WEDM lies in reliable separation of parts from the solid build platform, a fundamental step in the AM workflow that demands a stress-free cut to preserve the integrity of the final component. Beyond this, WEDM also facilitates crucial secondary operations such as creating precise starting surfaces for subsequent finishing or sectioning parts for internal analysis. This combination of capabilities makes WEDM an indispensable hybrid manufacturing strategy, bridging the gap between near-net-shape AM and the exacting dimensional and surface finish requirements of finished engineering products.

This process is based on the utilization of thermoelectric energy, where material removal from the workpiece is achieved through a series of discrete electrical discharges occurring in the narrow gap between the workpiece and the wire electrode [

3]. The removed material, or debris, is permanently flushed from the working zone by dielectric fluid. Wire Electrical Discharge Machining (WEDM) uses a thin wire as a tool electrode to remove material from an electrically conductive workpiece through a series of electrical discharges. The diameter of the wire electrode typically ranges from 0.05 mm to 0.33 mm, with sizes of 0.1–0.3 mm being commonly used [

4]. Electrode materials include copper, brass, molybdenum, tungsten, as well as coated wires (e.g., with zinc or ZnCu coating) and composite wires [

5,

6]. The choice of material and wire diameter depends on the workpiece material and processing regimes (e.g., cutting modes). Important mechanical characteristics for electrode selection include tensile strength and tensioning performance, while the optimal wire diameter can contribute to improved productivity and surface quality [

5,

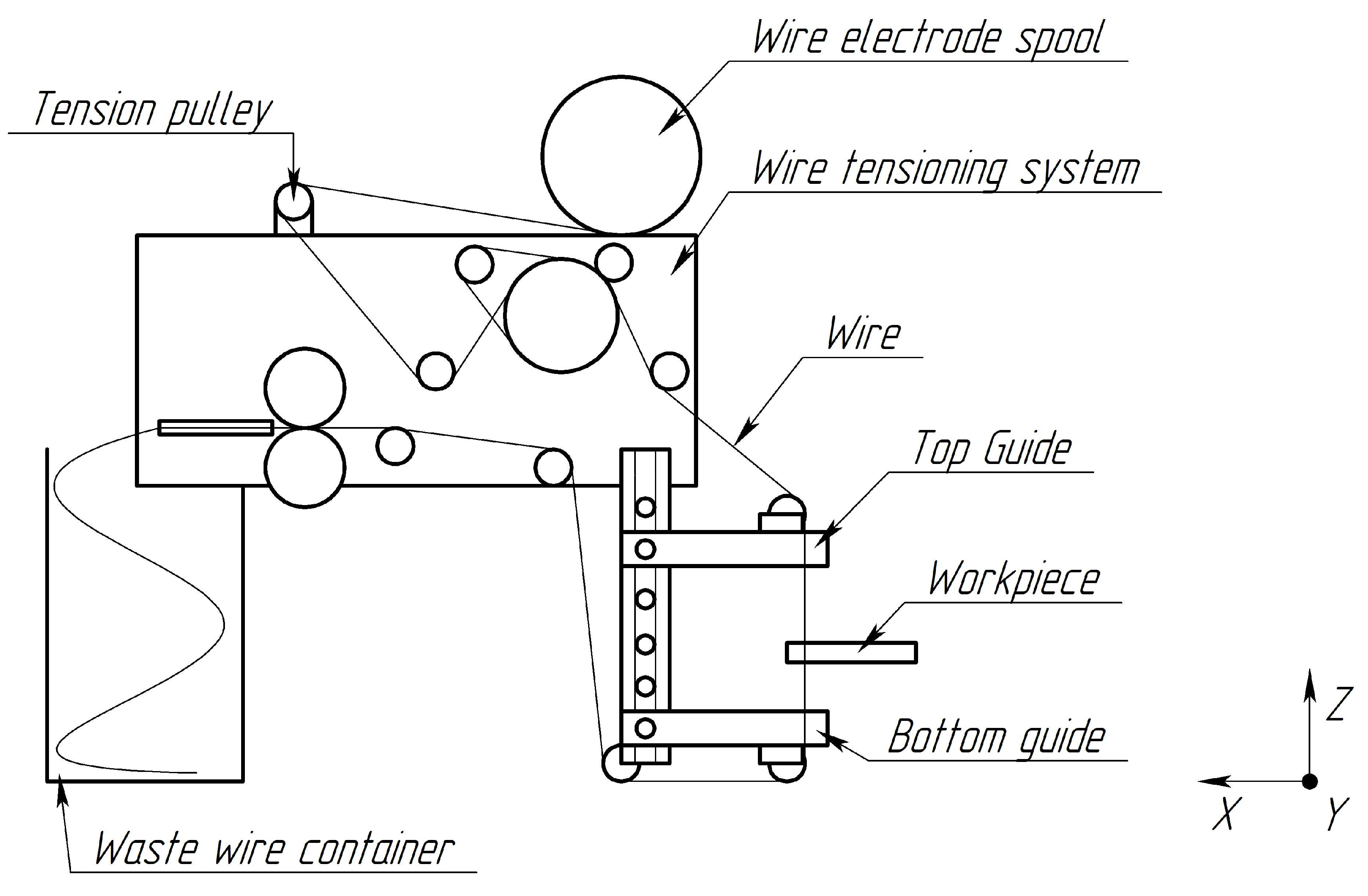

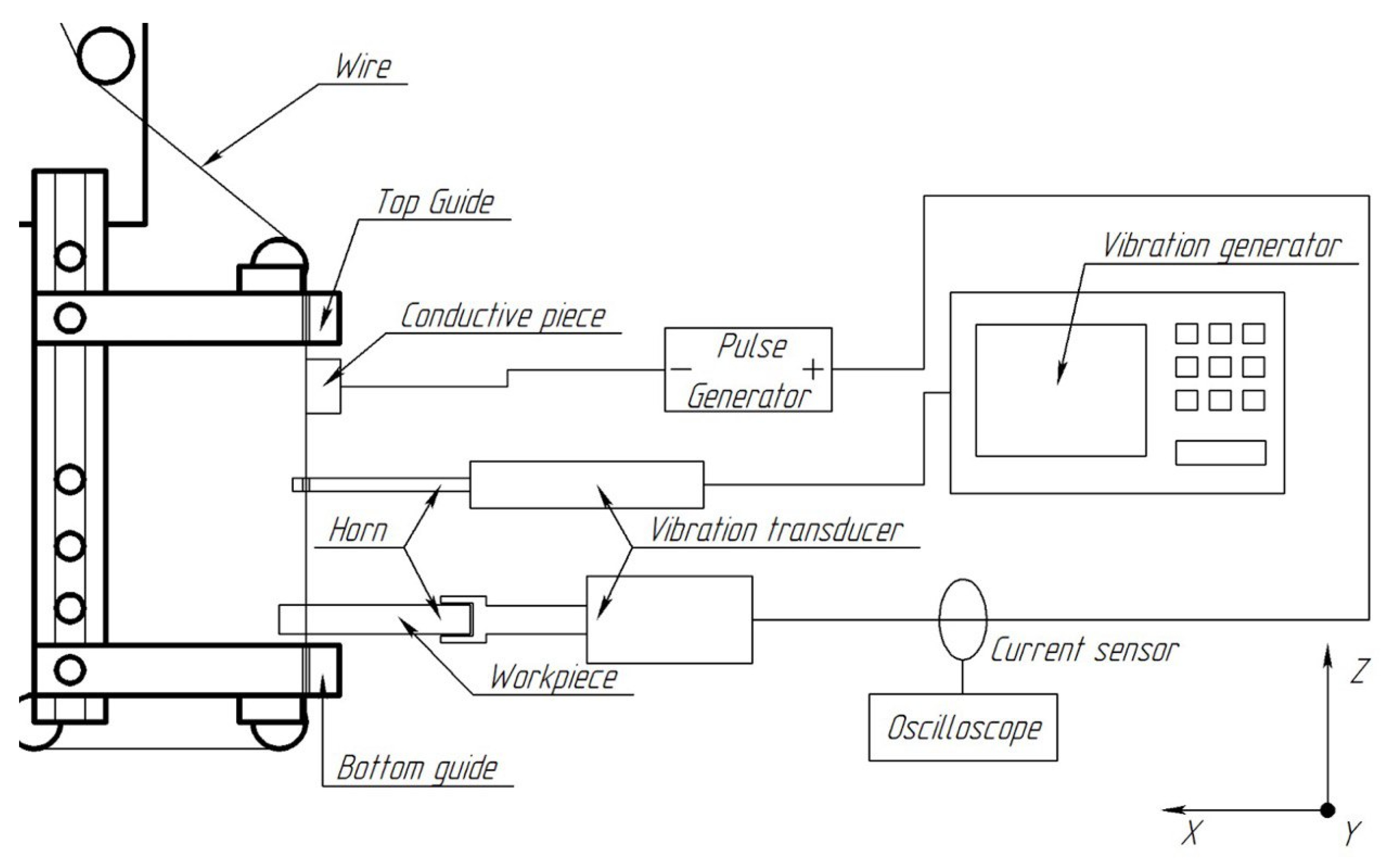

6]. The workpiece is fixed on a worktable controlled by a computer numerical control (CNC) system, enabling the cutting of complex two-dimensional shapes through precise movement along the X-Y axes (

Figure 1).

The microprocessor maintains continuous wire movement through the workpiece, sustaining a stable interelectrode gap (IEG) within the range of 0.025 to 0.05 mm, which ensures high precision when machining components with complex geometries. Notably, WEDM is suitable for processing electrically conductive materials, largely irrespective of their hardness [

7]. However, conventional WEDM suffers from inefficiencies when machining thick workpieces and encounters issues with wire electrode breakage [

8,

9]. To optimize the process, researchers are investigating various methods to enhance WEDM productivity.

For instance, the introduction of a magnetic field (MF) into the discharge zone enables enhancement and stabilization of the plasma channel within the machining area [

10]. The MF promotes more uniform distribution of spark discharges, improves dielectric fluid circulation, and enhances debris removal [

11,

12,

13]. This results in increased material removal rate (MRR) and reduced surface roughness. Studies indicate that at magnetic field intensities of approximately 0.2–0.5 T, WEDM productivity increases by 15–25%, while wire wear decreases [

14]. The combined application of MF and ultrasonic vibration (USV) has demonstrated significant improvement in discharge uniformity and debris removal from the machining zone. Furthermore, this combination enhances key quality characteristics including process efficiency, surface roughness (Ra), and density of surface cracks [

15,

16,

17].

However, despite its numerous advantages, MF implementation in electrical discharge machining presents certain drawbacks. Specifically, excessive MF intensity (e.g., 0.66 T) has been shown to degrade surface roughness (Ra), particularly when using dielectric fluid mixed with silicon carbide (SiC) powder, which is attributed to overly aggressive material removal [

18]. Moreover, electromagnetic forces in WEDM cause inevitable corner deformation of workpieces, especially pronounced in thin parts (less than 5 mm thick) [

11,

19]. The direction of this deformation depends on the workpiece material (e.g., aluminum alloy 6061 bends outward while Q235 steel bends inward), with its magnitude increasing with discharge parameters such as peak current, supply voltage, and pulse duty factor. Additionally, excessive magnetic field strength may increase workpiece thermal deformation due to excessive compression of the discharge channel and concentration of energy transfer to extremely small areas, thereby elevating thermal stresses [

20]. Furthermore, electromagnetic forces acting on the wire electrode under non-optimal or excessively high MF parameters may amplify its vibration [

19]. It should be noted that generating a uniform magnetic field requires complex systems of coils, permanent magnets, and cooling, which complicates the machine design and increases processing costs.

In addition to electromagnetic field application, the combination of WEDM with electrochemical machining (ECM) has also been investigated [

21]. In this approach, electrochemical processing occurs either simultaneously or sequentially with electrical discharge machining, significantly improving process stability and productivity while overcoming the limitations of WEDM for materials with low electrical conductivity [

22,

23].

The study [

24] describes a hybrid process called Abrasive Wire Electrodischarge Machining (AWEDM), which leverages the synergy between spark erosion and abrasive grinding. This method utilizes a metallic wire with abrasive diamond particles as the electrode. Another advanced hybrid technique, known as Electrochemical Discharge Grinding Machining (ECDGM), integrates three material removal mechanisms that, in the context of WEDM, can operate either simultaneously or sequentially with electrical discharge machining. These mechanisms are electrochemical dissolution, spark erosion, and abrasive grinding. The process employs a specialized abrasive electrode manufactured from sintered bronze and diamond particles. This technology enables highly efficient and high-quality processing of metal matrix composites (MMCs), particularly aluminum-based composites reinforced with silicon carbide particles (Al/SiC) [

25,

26].

Wang et al. [

21] proposed combining WEDM + ECM + US + MF. This combined approach demonstrated a 30% reduction in surface roughness, along with improved geometric accuracy and up to 50% increase in productivity. However, the design and implementation of such multi-process equipment is extremely complex and costly. Nevertheless, further research is required to fully understand the implications of this extensive combination of different machining methods. The stability of these discharge states is highly sensitive to the efficiency of debris removal from the interelectrode gap. Recent studies have shown that even workpiece geometry can systematically alter debris evacuation pathways, leading to predictable shifts in the distribution of normal, short-circuit, and open-circuit pulses that can be classified with high accuracy using machine learning models [

27]. This underscores the critical role of fluid dynamics in maintaining a stable process, a factor that ultrasonic vibration directly influences.

The literature also describes methods for enhancing WEDM efficiency through cryogenic technologies. According to [

28,

29], the use of cooled wire electrodes further reduces electrode wear, while the application of cryogenic media (liquid nitrogen or liquid carbon dioxide) in the machining zone ensures effective heat dissipation, minimizes thermal deformation, and reduces residual stresses in the workpiece. However, this technology presents several limitations. The primary drawbacks involve the complexity of technical implementation, the need for precise control of cryogenic exposure duration, and safety considerations during operation.

Analysis of modern WEDM intensification methods has revealed a key challenge—the accumulation of machining byproducts in the interelectrode gap, which leads to discharge instability [

30] and reduced productivity [

31,

32]. While approaches such as magnetic field application, electrochemical machining, and/or cryogenic cooling demonstrate certain effectiveness, they exhibit significant limitations in terms of universality and implementation costs.

In this context, applying vibrational oscillations on the WEDM process presents particular interest as the most versatile and technologically feasible solution. Research [

32,

33,

34,

35] has demonstrated that application of vibration on either the electrode tool or workpiece creates a unique combination of effects such as dielectric pressure pulsations, enhanced working fluid circulation, and cavitation-induced debris agglomerate disintegration. Unlike the aforementioned methods, vibration-assisted machining requires no radical equipment upgrades and proves effective for a wide range of materials. These advantages establish vibration-assisted technologies as a promising direction for further WEDM improvement, which will be examined in detail throughout this review.

The objective of this review is to systematize available information and provide a detailed analysis of the beneficial effects of vibration-assisted methods on key WEDM performance indicators, including material removal rate and workpiece surface quality. Although numerous auxiliary technologies exist for WEDM enhancement, this review specifically focuses on vibration mechanisms, as vibration-assisted methods have demonstrated significant and well-documented potential for improving process productivity, discharge stability, and surface integrity.

3. Vibration-Assisted WEDM with Wire Electrode Excitation

This section presents a systematic review of available literature on vibration-assisted WEDM with wire electrode excitation. All identified studies demonstrate the positive effect of wire electrode vibrations on WEDM process efficiency. The research primarily examines acoustic frequency vibrations (20 Hz to 20 kHz) and low-frequency ultrasonic vibrations (20 kHz to 100 kHz). However, significant variations exist across studies regarding vibration frequency parameters, excitation methods, and oscillation directions applied to the wire electrode.

Most reviewed studies employ ultrasonic vibration to analyze its effects on WEDM process efficiency and workpiece surface roughness. The observed improvements primarily arise from enhanced debris removal mechanisms, supplemented by ultrasonic energy transmission into the dielectric fluid between electrode and workpiece. This energy transfer intensifies electroerosion phenomena, thereby optimizing conditions for initiating and developing pulsed electrical discharges in the WEDM process.

In the study by Nani [

38], phenomena in the dielectric fluid accompanying electrical discharge were examined, including discharge initiation, its evolution, physicochemical effects in the gap, and material removal. The author demonstrates that ultrasonic energy transmitted into the dielectric fluid stimulates molecular collisions and locally increases temperature, thereby accelerating the formation and development of gaseous micro-regions (cavitation phenomenon) within the fluid.

The electric field between the tool electrode and workpiece electrode is enhanced after pulsed electrical discharges by electrical phenomena occurring within cavitation bubbles. This increases the proportion of material particles removed from the workpiece through forces initiated by the electrostatic field [

38,

39].

Figure 5 illustrates the temporal evolution of the electrical discharge. Phase A depicts the initial stage where the gaseous channel boundary (plasma channel) (

I) coincides with the shock wave front (

II). At this stage, electrodynamic forces (

fₛ) dominate due to the skin effect. Phase B shows the subsequent phase where the shock wave (

II) separates from the expanding gaseous channel (

I) and electrodynamic forces (

fₚ) induced by the pinch effect become active.

The skin effect occurs during discharge initiation when current intensity increases (di/dt > 0). These divergent electrodynamic forces maintain the plasma channel close to the shock wave boundaries. The pinch effect emerges during the discharge stabilization phase (di/dt = 0), causing radial constriction of the discharge column and its separation from the shock wave front [

38,

40]. Ultrasonic vibration in the dielectric fluid, particularly through cavitation, amplifies both skin and pinch effects. This promotes more efficient plasma channel formation and evolution during machining.

Nani et al. [

41] also showed that ultrasonic vibrations reduce mechanical stresses in the wire electrode, enabling higher working currents without rupture risk. Specifically, conventional processing (without ultrasound) showed a maximum current of 3.28 A, while ultrasonic activation increased this parameter to 4.42 A, achieving a 93% MRR improvement. Cavitation bubble implosion generates extreme pressures (up to 10

6 bar) and temperatures (reaching 10

4 K) [

42,

43]. These pressures can exceed material failure limits, promoting additional material removal [

38]. The ultrasonic field also enhances debris dispersion in dielectric fluid and accelerates its evacuation from the interelectrode gap. Erosion byproducts acquire high kinetic energy in the ultrasonic field, functioning as an abrasive medium that mechanically smooths discharge-created microcraters. Thus, cavitation in WEDM exerts multifactorial effects including mechanical action (pressure pulses, microjets, abrasion), improved discharge conditions, and enhanced erosion product removal. At the micro-scale, the morphology of the erosion craters that form the final surface is directly linked to the type of discharge pulse that created them. Research has established a direct correspondence between normal discharges, arcs, and the resulting crater dimensions, allowing for the development of machine learning models that predict material removal based on in-process electrical signals [

44]. Therefore, by stabilizing the process and promoting a higher percentage of effective normal discharges, ultrasonic vibration contributes directly to a more uniform crater formation, leading to improved surface finish and dimensional accuracy.

Wang et al. [

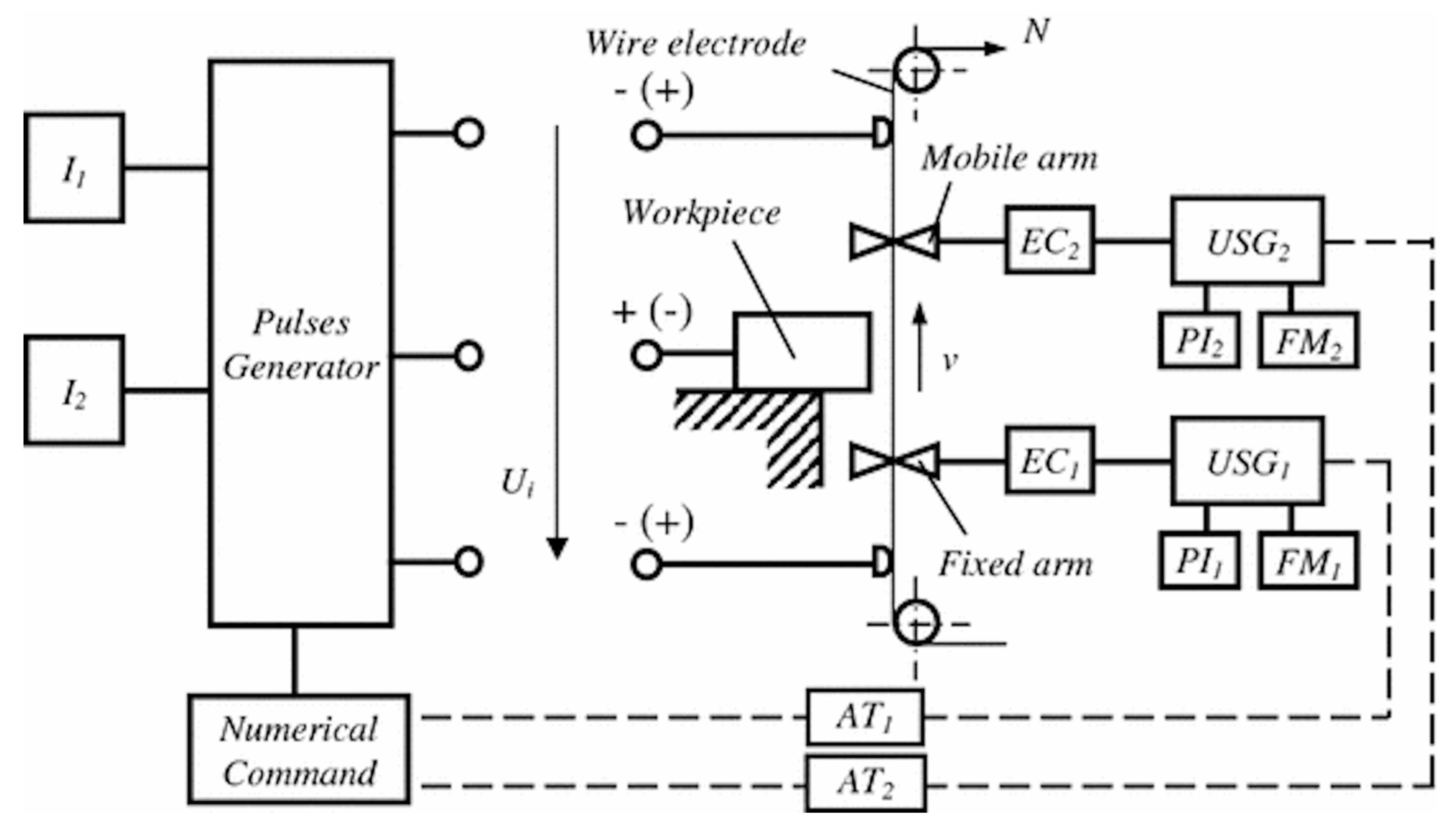

45] investigated the effect of ultrasonic wire vibration on the WEDM process, emphasizing the role of cavitation. The experiments were conducted on TiNi01 SMA (Pulse off-time (T

off) = 5 µs, Pulse on-time (T

on) = 6; 12 µs, Peak Current (PC) 6; 8; 10 A, Voltage = 30 V). The study employed the WEDM setup schematically shown in

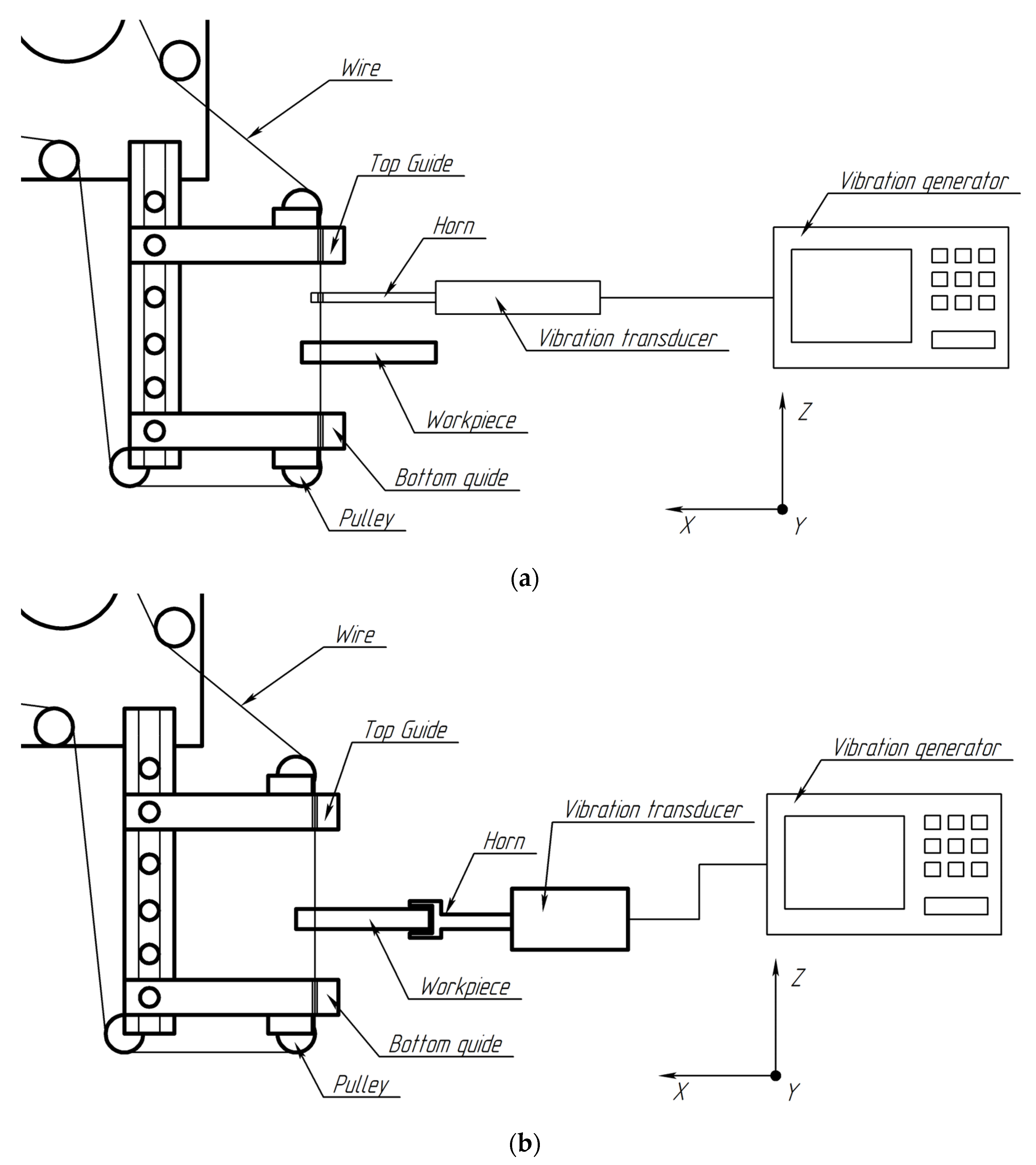

Figure 6. The results demonstrated that ultrasonic vibration (USV) improves the flow of deionized water in the interelectrode gap, facilitating more effective debris removal and accelerating dielectric deionization. These cavitation-mediated processes enhance process stability and increase the number of normal discharges between the wire and workpiece surface. The authors defined “normal” discharges as spark pulses accompanied by controlled material removal within specified limits, without transitioning into short-circuit or arc modes.

A comparative analysis revealed 48 normal discharges without USV versus 76 with USV, indicating that the MRR improvement results not only from cavitation effects but also from the increased number of effective discharges. The optimal surface finish was achieved at Toff = 5 µs, Ton = 6µs, PC = 10 A, Voltage = 30 V.

Wang and co-authors presented further research findings on US-WEDM in publications [

46,

47,

48], offering a comprehensive investigation of this process using the same experimental setup (

Figure 6). While these studies examined both isolated ultrasonic effects and their combination with magnetic fields, the current review specifically focuses on the impact of ultrasonic vibration alone, notwithstanding the mentioned combined effects in some references.

Wang et al. [

46] conducted two types of investigations—computer simulation and experimental—on the effect of ultrasonic vibration applied to the wire electrode during WEDM of TiNi01 alloy workpieces. The computational modeling was performed at ultrasonic frequencies of 20 and 30 kHz with the following parameters: T

off = 10 µs, T

on = 10 µs, PC = 9 A, Voltage = 15 V. Simulation results demonstrated that effective debris removal from the machining zone occurred only at 30 kHz. The modeling also revealed that increasing the wire vibration frequency reduces dielectric fluid temperature due to enhanced heat exchange with the surrounding environment.

Experimental studies were carried out on a WEDM setup at 20 kHz with different set of parameters Toff = 10 µs, Ton = 6; 9;12; 15 µs, PC = 4; 6; 8; 10 A, Voltage = 30 V. The investigation established a dependence of MRR on Ton, showing that beyond a certain Ton value, further increase leads to decreased MRR. A comparative analysis showed that the Material Removal Rate (MRR) increases with the growth of Ton up to 12 µs, but tends to decrease at Ton > 12 µs.

In subsequent research [

47], similar experiments were conducted with modified parameters (T

off = 10 µs, T

on = 5; 10; 20 µs, PC = 1.8; 2.0; 2.2 A, Voltage = 30 V). The maximum processing parameters yielded an MRR increase from 2.06 mm/min (conventional) to 2.80 mm/min (US-assisted) and surface roughness reduction from 1.29 Ra to 1.26 Ra. Meanwhile, under intermediate parameters (T

off = 10 µs, T

on = 10 µs, PC = 2.0 A, Voltage = 30 V), the results showed MRR improvement from 1.14 mm/min to 2.32 mm/min and surface roughness changed from 1.16 Ra to 1.19 Ra

Special attention was given to debris removal from the electrode gap in the work of Wang et al. [

48]. The authors established that ultrasonic wire vibrations enhance dielectric fluid circulation and flow characteristics. This effect was confirmed through both computational modeling and experimental studies. Modeling results showed that increasing wire vibration amplitude from 0 to 15 μm induces stronger fluid oscillations, significantly reducing debris residence time in the machining zone. Experimental verification was performed using WEDM-low speed (WEDM-LS)—a variant of unidirectional conductive machining at low speed (typically 12 m/min) [

49,

50]. With ultrasonic assistance (T

on = 6–12 μs, PC = 6–10 A, Voltage = 120 V) MRR increased by 44.4% compared to conventional WEDM-LS and surface roughness improved from 2.0517 μm to 1.7880 μm.

The experimental study in [

48] employed ultrasonic vibration amplitudes of 4, 6, and 8 μm. While the authors did not provide specific MRR dependence on amplitude variation, they reported significantly fewer abnormal discharges at 8 μm amplitude compared to conventional processing, along with more uniform distribution of discharge points across the workpiece surface. The ability to accurately classify these discharge waveforms into categories such as normal, arc, and short-circuit is fundamental for process monitoring and control. However, traditional threshold-based classification methods are often machine-specific and struggle with the complexity of modern power supplies. To overcome this, advanced data-driven pipelines using unsupervised learning have been developed to provide adaptive, threshold-free pulse classification, highlighting the importance and challenge of this task in modern WEDM research [

51]. An analysis of oscillograms in [

48] revealed that conventional WEDM-LS exhibits numerous abnormal phenomena, such as arc discharges, whereas USV-assisted WEDM-LS (at an amplitude of A = 8 μm) effectively reduces their occurrence. This improvement was attributed to the USV altering the dielectric fluid flow conditions, thereby enhancing the movement and distribution of erosion debris and mitigating their interference with subsequent pulse discharges. Furthermore, it was experimentally confirmed that USV-assisted WEDM-LS provides a more uniform distribution of discharge points across the workpiece surface. In contrast, the conventional process exhibits concentrated discharge spots, which prevents localized surface burns.

Thus, while studies [

45,

46,

47,

48] reported somewhat varying quantitative improvements in WEDM performance metrics (MRR and Ra), they unanimously confirm the benefits of ultrasonic vibration in WEDM through optimization of dielectric fluid dynamics, enhanced debris removal efficiency and discharge process stabilization.

Furthermore, Wang et al. [

52] proposed a novel approach—USC-assisted WEDM-LS (ultrasonic cavitation-supported WEDM-low speed), specifically developed to address the challenges of low machining efficiency and substantial white layer thickness when cutting thick nickel–titanium shape memory alloy (NiTi SMA) workpieces. The Recast Layer Thickness (RLT) is a resolidified layer formed when the molten material created by the instantaneous discharge heat is not ejected from the narrow gap and rapidly re-solidifies on the surface under the action of the cooling dielectric fluid. The presence of RLT negatively affects surface integrity, leading to reduced fatigue strength and part service life, as this non-resistant layer can initiate fatigue microcracks and degrade operational performance. The operational principle relies on cavitation effects in the dielectric fluid induced by ultrasonic wire electrode vibrations. During bubble collapse near the workpiece surface, high-velocity microjets form that directly eject molten material, preventing its re-solidification and, consequently, the formation of the white layer. Computational modeling confirmed these microjets’ effectiveness in material removal from the surface under processing.

The experimental results of USC-assisted WEDM-LS demonstrated significant improvements compared to conventional WEDM-LS processing. The material removal rate (MRR) showed an average increase of 31.65%, while the white layer thickness (RLT) was reduced by an average of 20.39%, with one case showing a 40.38% reduction (from 18 μm to 10.73 μm). This reduction in white layer thickness represents a key advantage of the USC-assisted method, as it prevents molten material resolidification and significantly improves surface quality. Furthermore, the surface roughness decreased by an average of 3% compared to conventional WEDM-LS and by 7.13% relative to USV-assisted WEDM-LS. The maximum height of surface profile irregularities was reduced by an average of 16.75% when compared to non-vibrated WEDM-LS processing. The study [

52] confirmed that USC-assisted WEDM-LS substantially enhances both machining performance and surface integrity, demonstrating strong potential for practical applications, particularly when processing materials prone to white layer formation.

The study by Nani [

53] examined WEDM using two ultrasonic transducers connected to the working wire above and below the workpiece, generating perpendicular vibrations both along and across the wire feed direction. Experiments were conducted on heat-treated 34 MoCrNi15 steel workpieces (54–56 HRC, 40 mm thickness) and X210CrW12 steel workpieces (60–62 HRC, 10–120 mm thickness). The author systematically investigated the effects of applying ultrasonic vibrations first separately to each end of the electrode, and then simultaneously to both transducers. The experimental setup is shown schematically in

Figure 7. When vibrations were applied at a single point either transverse or longitudinal to the cutting plane, improvements in erosion capability of 25% and 37% were achieved, respectively. With simultaneous perpendicular vibrations applied at two points, the author reported a 74% enhancement in performance.

In another study by the same author [

54], conducted using the same experimental setup (

Figure 7), the effects of single-point vibrations were investigated, demonstrating a 35–39% improvement in process efficiency. The study compared two vibration transmission methods using either a movable or fixed lever. Experimental results showed that ultrasonic activation effectiveness varied depending on the configuration. When applying vibrations parallel to the feed direction using the movable lever, productivity increased by 36.44%, while perpendicular vibrations yielded a greater improvement of 38.78%. Similarly, with the fixed-lever configuration, parallel vibrations achieved a 35.71% enhancement and perpendicular vibrations resulted in 37.03% improvement. The study concluded that perpendicular vibration relative to the feed direction provided an additional 1–2% efficiency gain due to more effective particle removal from the machining zone.

Several studies have examined the influence of vibration frequency variations on WEDM performance. In the work by Nakwong et al. [

55] involving titanium alloy machining (PC = 5 A, voltage = 12 V, brass wire 0.25 mm, wire speed 8 m/min), it was established that vibration application at 40 kHz increased MRR from 12.50 to 16.67 mm

3/min, whereas at 80 kHz the MRR reached only 13.14 mm

3/min. This reduction was attributed to decreased vibration amplitude at higher frequencies, which impairs debris removal from the cutting zone. Furthermore, surface roughness was improved at 40 kHz (1.99 μm) compared to 80 kHz (2.63 μm).

Similar conclusions were reported in the study by Muttamara et al. [

56], where ultrasonic vibration at 40 kHz applied to the wire during titanium carbide processing increased MRR by 22% and improved surface roughness (peak current 5 A, voltage 12 V, zinc-coated brass wire 0.25 mm, wire speed 8 m/min). According to [

56], these improvements resulted from enhanced cavitation-assisted debris removal, more uniform discharge distribution, and reduced short-circuit occurrences. Comparable trends were observed at lower frequencies. In the study by Chen et al. [

57], wire vibration frequencies of 1.6 and 1.8 kHz were applied during titanium carbide processing, with optimal results achieved at 1.6 kHz, where machining time was minimized. Vibration at the higher frequency (1.8 kHz) caused excessive vibration intensity that hindered erosion product removal, while lower frequencies (1.2–1.4 kHz) led to process instability. The 1.6 kHz vibration reduced machining time compared to non-vibrated conditions (0 Hz), improved discharge stability, and reduced thermal deformation risks. The authors noted that vibration had minimal effect on surface roughness (Ra), which remained primarily determined by discharge energy parameters.

Studies by Guo et al. [

58] and Kumar et al. [

59] demonstrate significant improvements in wire electrical discharge machining performance through ultrasonic wire vibration. In [

58], vibration at 35 kHz frequency (45 μm amplitude) reduced short-circuit probability from 100% to 13% through microscopic oscillations that break contact before stable current formation. This phenomenon is explained by three key effects: accelerated debris removal through enhanced dielectric circulation; uniform discharge distribution that reduces localized overheating and wire wear; and surface polishing through more frequent wire-workpiece contacts that decrease roughness. Similar conclusions were drawn in reference [

59], where vibration increased MRR by 45.88% during nickel alloy cutting, reaching 3.876 mm

3/min at optimal parameters (11 A, 110 μs pulse duration). Surface roughness was simultaneously reduced by 69.81% (to 0.106 μm at 10 A, 105 μs pulse duration). The authors attribute these improvements to enhanced particle removal and more uniform discharge energy distribution.

Another study by Guo et al. [

60] demonstrates that ultrasonic wire vibration significantly modifies the electrical discharge machining process for chromium alloy steel workpieces. The analysis of obtained results reveals a comprehensive influence of vibration parameters on WEDM technological indicators. At the resonant frequency of 35 kHz and optimal vibration amplitude of 15 μm (representing 60% of the interelectrode gap width), a 30% increase in material removal rate is observed compared to conventional processing. Maximum efficiency is achieved at 12 A current (T

off = 40 μs, Voltage = 90 V), which is attributed to improved erosion product removal through dynamic effects in the dielectric medium. The authors established that wire vibration creates pulsating pressure, enhancing particle flushing efficiency by 40–45% while simultaneously reducing the probability of ineffective discharges by 15–18%. An important aspect is USV’s influence on machined surface quality. Experimental data indicate roughness reduction from 1.95 to 1.70 μm (13% improvement), explained by two interconnected mechanisms: surface polishing effect through repeated micro-contact between wire and workpiece, and redistribution of discharge energy through multiple channel formation. The latter factor also contributes to reduced erosion crater depth and lower residual stress levels, significantly improving component operational characteristics.

Particular interest lies in the geometric accuracy investigation results. It was determined that vibration direction significantly affects machining geometric parameters: longitudinal vibration maintains kerf width within 0.25–0.28 mm range, while transverse vibrations increase it to 0.32 mm. These findings are consistent with earlier studies on ultrasonic electrode activation [

53], which also confirmed that longitudinal vibration helps maintain machining accuracy, whereas the transverse mode leads to kerf widening [

53]. Simultaneously, processing time is reduced by 14% (from 17.1 to 14.6 min) without accuracy deterioration, confirming USV effectiveness for high-productivity machining. These results indicate the promising application of ultrasonic wire vibration in WEDM, particularly for critical components requiring simultaneous high productivity (up to 30% MRR increase), improved surface quality, and minimal thermal deformations.

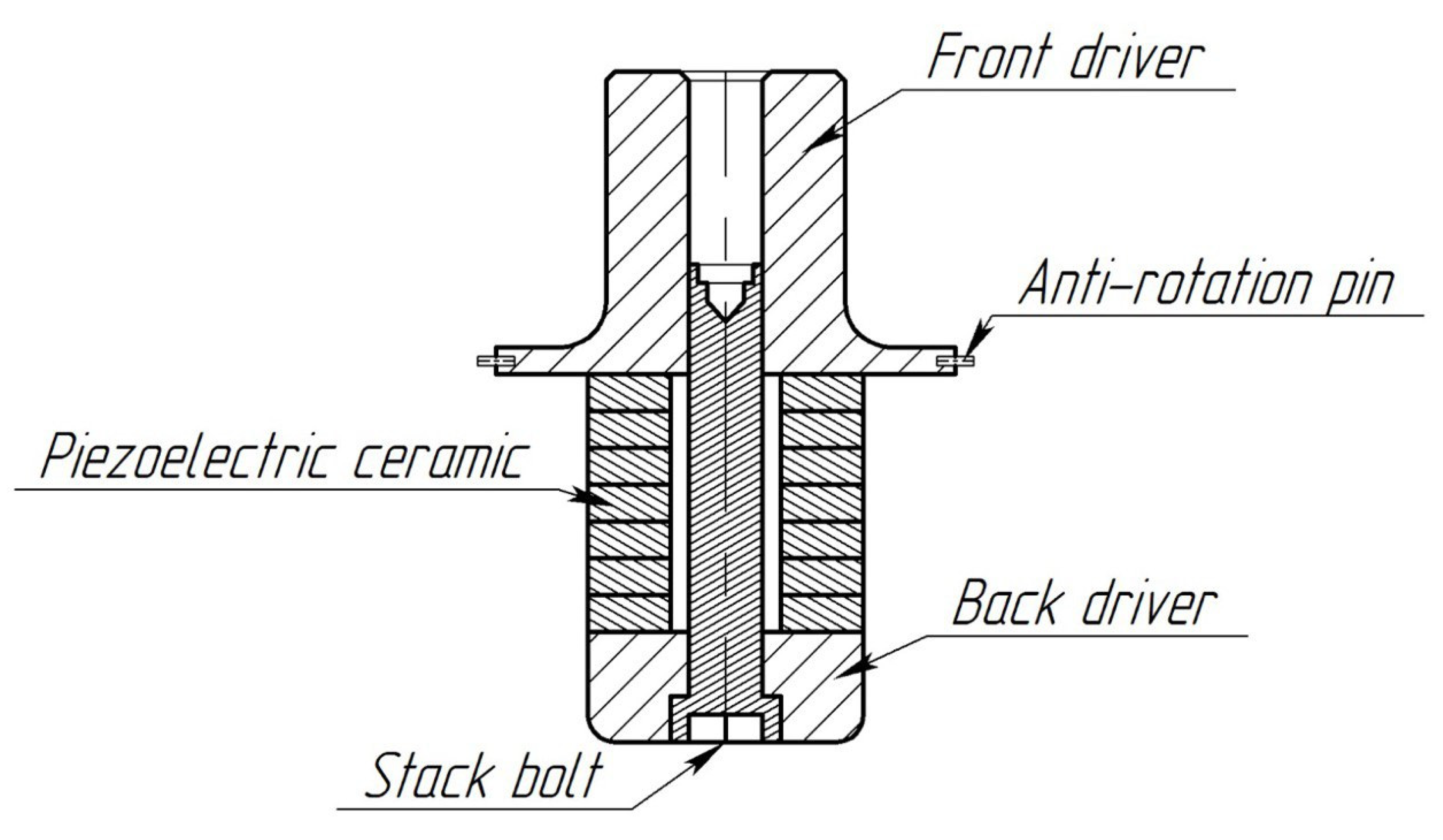

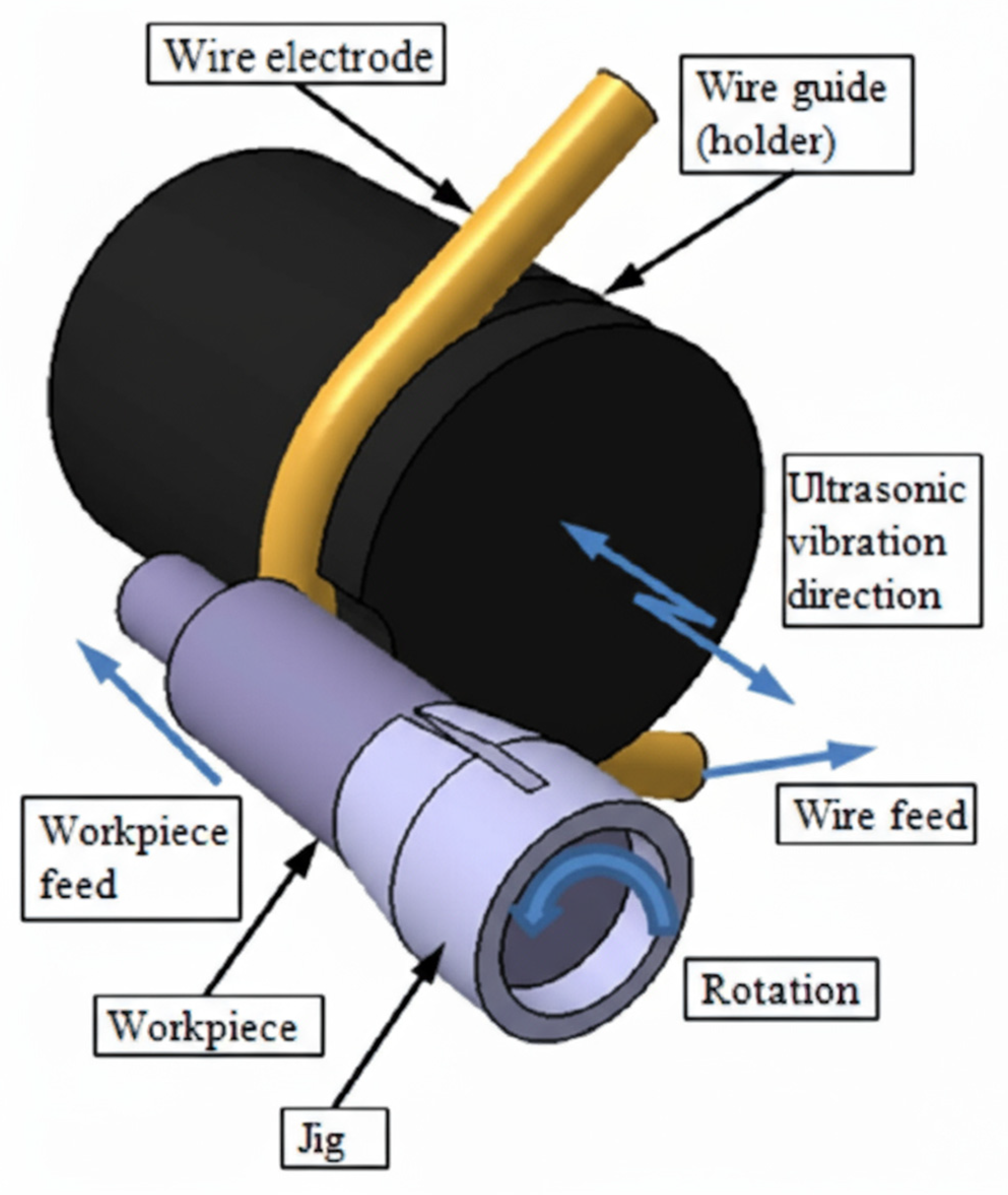

Mohammadi et al. [

61] systematically investigated the influence of ultrasonic wire vibration on wire electrical discharge turning process with particular focus on material removal rate (MRR) (

Figure 8).

The study established that vibration significantly enhances MRR through three key mechanisms: enhanced particle removal via cavitation and microflows in the dielectric medium; reduced friction between the wire and guides, decreasing breakage risk; and dynamic effects promoting efficient evacuation of molten metal from the machining zone. The authors note that ultrasonic vibration (200 W power, 10 μm amplitude) stabilizes discharge behavior and presumably improves surface roughness through more uniform energy distribution and polishing effects from micro-contacts. Thus, work [

61] confirms that ultrasonic vibration represents an effective method for optimizing wire electrical discharge turning processes, particularly in regimes characterized by intensive debris generation.

A detailed review of various studies illustrating the influence of vibration parameters on material removal rate (MRR) and surface roughness (Ra) is presented in

Table 1.

Thus, it can be concluded that the application of vibration to the wire electrode in WEDM processes leads to significant improvements in machining productivity and surface quality. This is primarily attributed to enhanced dielectric fluid flushing and deionization, often mediated through cavitation effects that promote efficient erosion product removal and prevent their resolidification. Specifically, the MRR consistently increases, while surface roughness is reduced and white layer thickness is diminished, resulting in improved surface quality. Process stability is also enhanced, with reduced short-circuit occurrences and more uniform discharge distribution.

Furthermore, research emphasizes the critical importance of optimizing vibration parameters (frequency, amplitude) to achieve optimal results. Overall, regardless of the specific application domain (micro-WEDM, WEDM-LS), the effects of ultrasonic vibration in WEDM are similar, improving both processing efficiency and quality through the same fundamental mechanisms.

4. Vibration-Assisted WEDM with Workpiece Excitation

As noted by Vilasak et al. [

65], applying vibrations directly to the workpiece rather than the wire in WEDM offers two key advantages. First, this approach is technically more feasible, as it avoids complex modifications to the WEDM machine for achieving wire resonance [

62]. Second, for thick workpieces (h >50 mm), workpiece vibration demonstrates more stable efficiency compared to wire vibration, where oscillations attenuate with increasing material thickness [

66]. Vilasak et al. [

65] demonstrated that workpiece vibrations in the frequency range of 100–900 Hz with 0.75 μm amplitude during machining of SKD11 steel (Sc = 80 V; T

on = 2 μs; T

off = 16 μs; SV = 46 V) had complex effects on WEDM performance. The maximum material removal rate increase was observed at 400–600 Hz, reaching 2.28 mm

3/min (32.6% improvement compared to non-vibrated conditions). The authors attribute this to enhanced debris removal through vibrations and increased effective discharge counts. However, further frequency increase (700–900 Hz) reduced MRR due to process destabilization.

Surface roughness (Ra) showed minimal variation (1.24–1.87 μm) but exhibited a tendency to deteriorate at medium frequencies (300–500 Hz), explained by increased crater size due to wire transverse oscillations. The frequency selection (up to 900 Hz) represented a compromise between debris removal efficiency and discharge stability: high frequencies (>600 Hz) caused discharge instability, while low frequencies (100–300 Hz) provided insufficient cavitation intensity in the dielectric.

Thus, the study confirms that optimal workpiece vibration frequencies lie within the 400–600 Hz range, where a balance between productivity and process stability is achieved.

The study by Unune et al. [

67] demonstrated that workpiece vibration within the frequency range of 0–80 Hz significantly enhances process productivity during micro-WEDM of Inconel 718 superalloy. Experimental results revealed that at 80 Hz frequency, MRR increased by an average of 66.2% compared to conventional non-vibrated processing, reaching a maximum improvement of 87% at low discharge energies (0.01 μF). The authors attribute this enhancement to two key mechanisms: first, workpiece vibration improves erosion product removal from the cutting zone through turbulent dielectric flow; second, it reduces adhesion between the wire and workpiece, minimizing short-circuit occurrences. Meanwhile, surface roughness of the machined workpiece remained largely unchanged, which is explained by the predominant influence of discharge energy (as the primary factor in micro-topography formation) over vibrational effects. The selection of the frequency range (up to 80 Hz) was determined by technical limitations of the electromagnetic vibration system and the compromise between efficiency and process stability: frequencies exceeding 80 Hz caused discharge destabilization due to excessive workpiece displacement.

These findings are consistent with conclusions from other studies [

68,

69,

70], which emphasize the role of improved debris removal and discharge process stabilization. The authors also note that for materials such as Inconel 718, which are prone to workpiece material adhesion, workpiece vibration is preferable to wire vibration as it directly affects the contact zone without requiring complex equipment modifications.

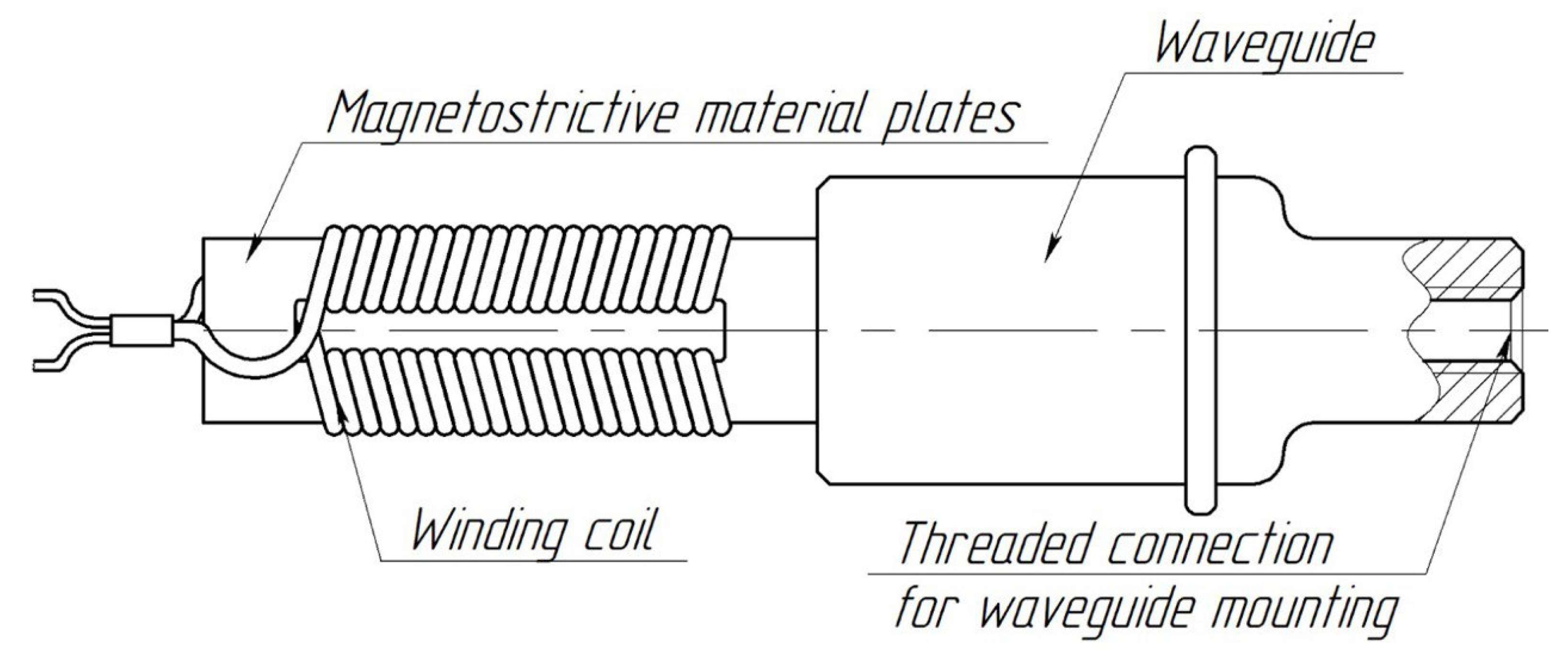

Wang et al. [

64] proposed and investigated a novel WEDM variant—WEDM-LS with vertical ultrasonic vibration (VUV) applied to the workpiece (

Figure 9)—to enhance the productivity of conventional WEDM-LS processing. The study developed a computational model simulating the interaction between dielectric fluid (deionized water) and the workpiece within the interelectrode gap. Simulations revealed that VUV approximately doubles the flow velocity of deionized water near discharge crater walls compared to wire ultrasonic vibration, significantly improving the removal efficiency of residual erosion products (debris). A multiphase fluid flow model involving debris, deionized water, and bubbles between electrodes demonstrated that workpiece vibration frequency positively correlates with bubble and debris movement intensity, promoting uniform debris evacuation across the entire machining zone. Experimental validation compared conventional WEDM-LS, wire-ultrasonic-vibration-assisted WEDM-LS (Wire USV), and VUV-assisted WEDM-LS using TiNi-01 alloy workpieces. Key findings confirmed that VUV enhances deionized water flow velocity in the interelectrode gap. Combined with cavitation effects, this improves debris and bubble removal while reducing gap temperature, thereby increasing process stability. This approach yielded 19.49% higher machining speed than conventional WEDM-LS (at T

on = 15 µs и I

p = 12 A), 8.85% higher machining speed than Wire USV, 28.57% increase in normal discharges vs. conventional WEDM-LS, and 11.7% increase in normal discharges vs. Wire USV. Surface quality improvements included 20.37% reduction in Ra compared to conventional WEDM-LS, 12.96% reduction in Ra compared to Wire USV, 24.75% decrease in maximum profile height versus conventional WEDM-LS and 14.94% decrease vs. Wire USV. These enhancements are attributed to more uniform material removal, finer crater formation, thinner white layer development, and consistent machining quality independent of cutting direction.

Hoang et al. [

62] investigated the micro-WEDM process by applying vibrations sequentially to the wire and to the workpiece (

Figure 10).

During processing, a CuZn37 wire with 70 μm diameter was employed, with wire vibration amplitudes of 1–12 μm parallel to the machining plane. The workpieces consisted of Ti6Al4V plates or discs with thicknesses of 1 mm and 5 mm. The authors established that applying vibration to the wire tool enhanced MRR by 1.7 times. MRR increased until the vibration amplitude approached 6 μm, beyond which further amplitude increases resulted in extended machining times. Processing efficiency also improved with higher vibration frequencies and greater workpiece thickness.

When vibrations were alternatively applied to the workpiece via a connecting plate under identical parameters, a maximum MRR increase of 2.5 times was observed. The authors attribute this efficiency difference to the fundamental mechanisms: wire vibration affects only the wire itself, with influence limited to localized regions where vibration amplitude is maximal. This leads to non-uniform vibration at the higher frequency (1.8 kHz) caused excessive vibration intensity that hindered erosion product removal, while lower frequencies (1.2–1.4 kHz) led to process instability. and reduced overall efficiency. In contrast, workpiece vibration generates significant alternating pressure within the interelectrode gap. As the workpiece moves toward the wire, fluid pressure increases, facilitating debris ejection. During workpiece retraction, fluid pressure decreases, allowing fresh dielectric to readily enter the gap, thereby improving conditions for subsequent discharges.

Wire vibration produces lesser fluid pressure effects due to the wire’s low mass, limiting its ability to significantly influence gap pressure dynamics. Surface roughness substantially improved with both vibration methods. However, since the wire remains stationary during workpiece vibration, achieving desired surface finish characteristics proves more straightforward with workpiece excitation.

A detailed review of various studies illustrating the influence of vibration parameters on material removal rate (MRR) and surface roughness (Ra) with vibration applied to the workpiece is presented in

Table 2.

The application of vibrations to the workpiece in WEDM provides technical, economic, and operational advantages, particularly when machining tall workpieces (h > 50 mm). This method consistently enhances material removal rate (MRR) through improved flushing conditions, more efficient removal of erosion byproducts and bubbles (e.g., vertical ultrasonic vibration (VUV) significantly increases water velocity near craters and promotes bubble disruption), and reduced adhesion between the electrode and workpiece, which stabilizes the discharge process. Although surface roughness (Ra) may exhibit varying trends depending on specific parameters, it generally improves or remains stable, contributing to enhanced surface quality and a thinner white layer. Research emphasizes the existence of optimal frequency ranges for balancing productivity and process stability.

Overall, workpiece vibration, particularly VUV, demonstrates superior effectiveness in enhancing machining productivity, quality, and stability, especially at high electrical parameters. This makes it a highly promising approach for WEDM-LS applications.

7. Conclusions

The review confirms that the application of vibrations during wire electrical discharge machining (WEDM) represents a highly effective method for substantially improving both productivity and surface quality. Research demonstrates that both direct vibration application to the wire electrode and to the workpiece yield significant advantages compared to conventional WEDM processes.

The key improvement mechanisms common to both approaches include enhanced dielectric fluid circulation within the interelectrode gap. This promotes more efficient removal of erosion byproducts (debris), preventing their resolidification on the surface and accumulation, which is critically important for maintaining discharge stability. Specifically, cavitation effects induced by ultrasonic oscillations play a central role, generating microjets that actively remove molten material and accelerate dielectric renewal.

Results from numerous studies demonstrate consistent and significant improvements in material removal rate (MRR). For wire vibration, MRR increases of up to 45.88% and 31.65% have been documented, while workpiece vibration shows enhancements reaching 87% and 2.5-fold improvements. Simultaneously, substantial improvements in machined surface quality are achieved, manifested through reduced surface roughness (Ra), decreased recast layer thickness (RLT), lower residual stresses, and prevention of workpiece burning and microcracking. These surface quality enhancements are attributed to more uniform distribution of discharge points, formation of smaller craters, and polishing effects from micro-contacts between the wire and workpiece surface. The combined action of these mechanisms ensures superior surface integrity while maintaining dimensional accuracy.

Furthermore, vibration enhances discharge process stability by reducing the incidence of short circuits. This improvement is achieved through accelerated dielectric circulation and prevention of adhesion between the electrode and workpiece. In the case of wire vibration, the risk of wire breakage is additionally reduced due to improved debris evacuation and reduced localized heating. Indirectly, ultrasonic vibration also enhances the operational reliability of the wire electrode by reducing the probability of its breakage and enabling the use of higher operating currents without compromising process stability.

Another important aspect is the necessity to optimize both vibrational parameters (frequency and amplitude) of the electrode tool and workpiece, along with electrical WEDM parameters, to achieve optimal results. Research has demonstrated that specific frequency ranges exist where the optimal balance between productivity and process stability is attained.

In summary, the integration of vibrations into the WEDM process, whether through the wire electrode (particularly via ultrasonic cavitation in USC-assisted WEDM-LS) or through the workpiece (including vertical ultrasonic vibration, VUV), represents a promising direction for advancing electrical discharge machining technologies. It was observed that vibration assistance is a highly efficient process that significantly boosts productivity and improves surface quality. Thus, vibration-assisted WEDM holds substantial potential for broad practical implementation, particularly in machining difficult-to-process materials such as nickel-titanium shape memory alloys.