Effect of Strain Rate on Aluminum–Polymer Friction Stir Joints Mechanical Performance

Abstract

1. Introduction

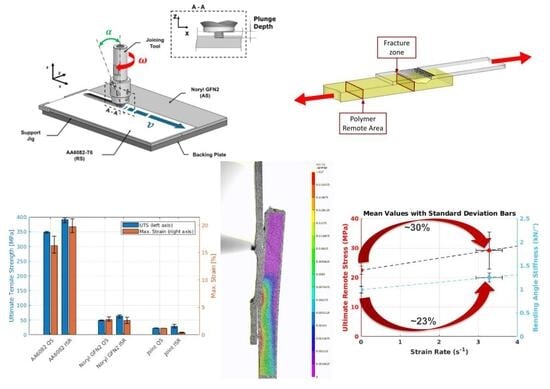

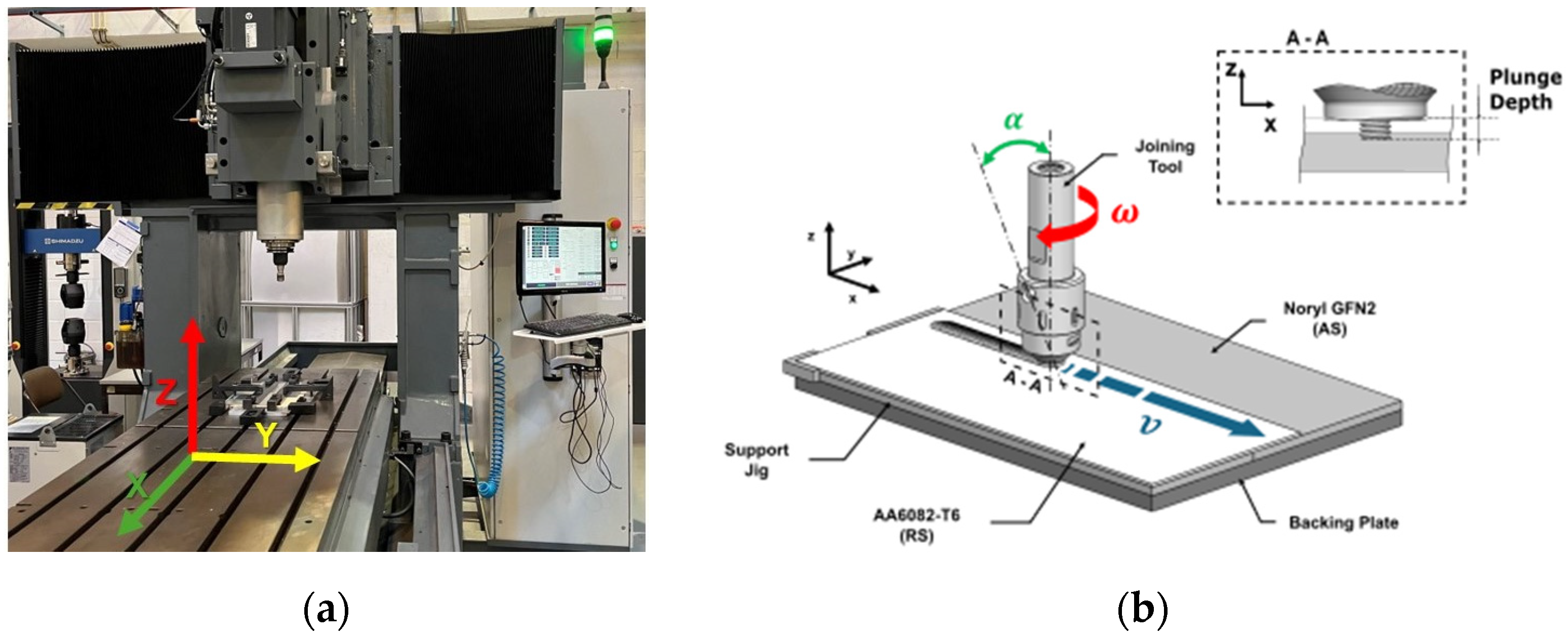

2. Materials and Methods

3. Results and Discussion

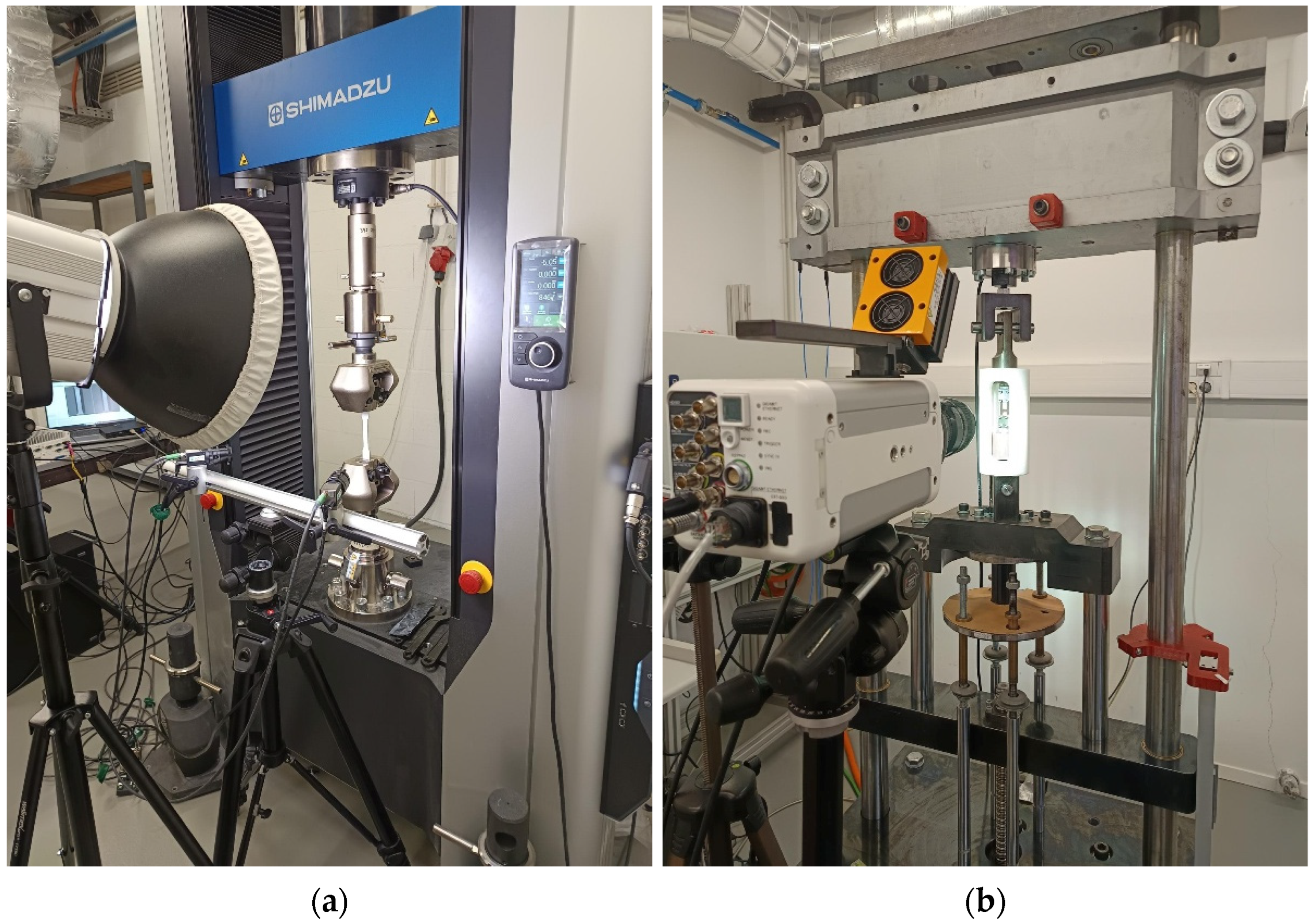

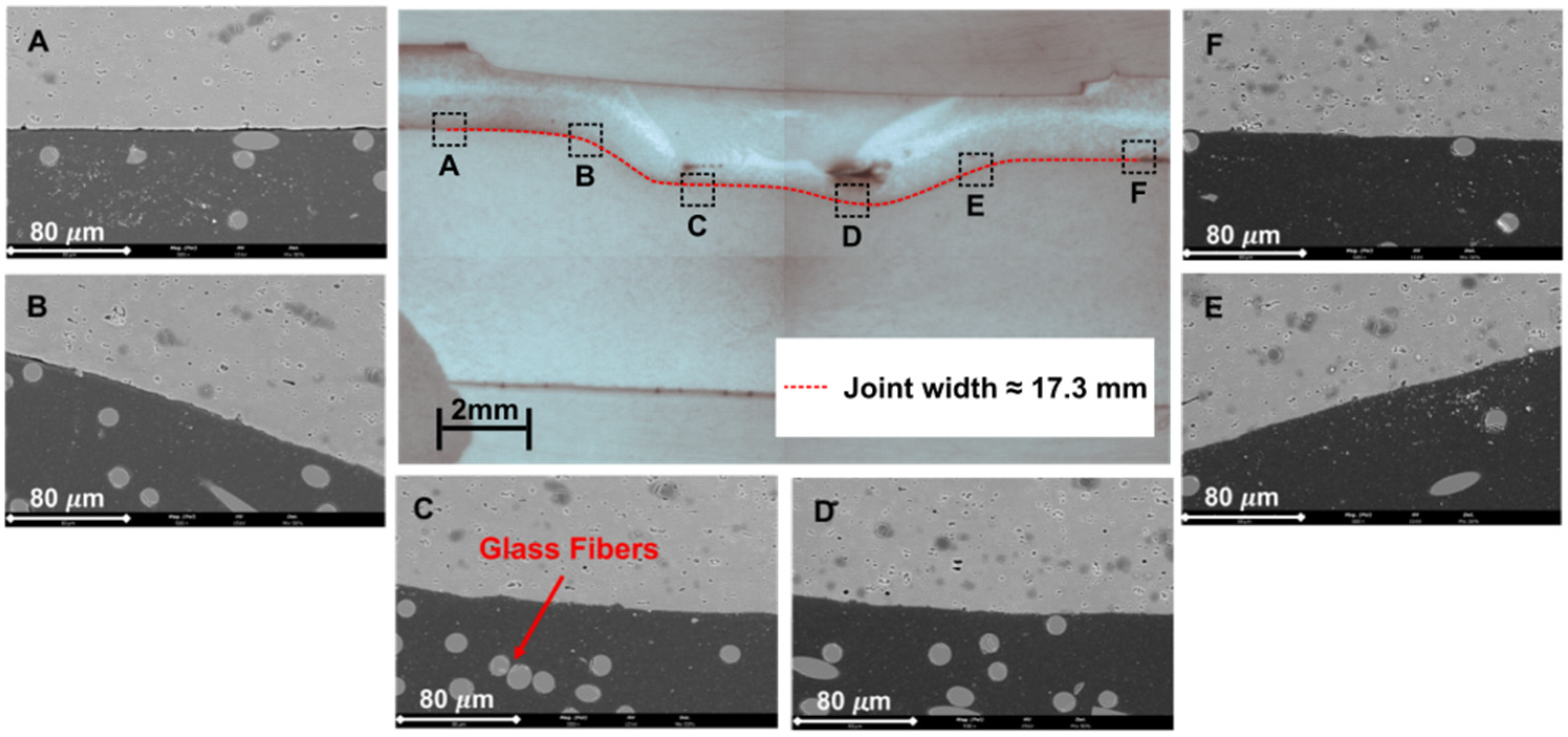

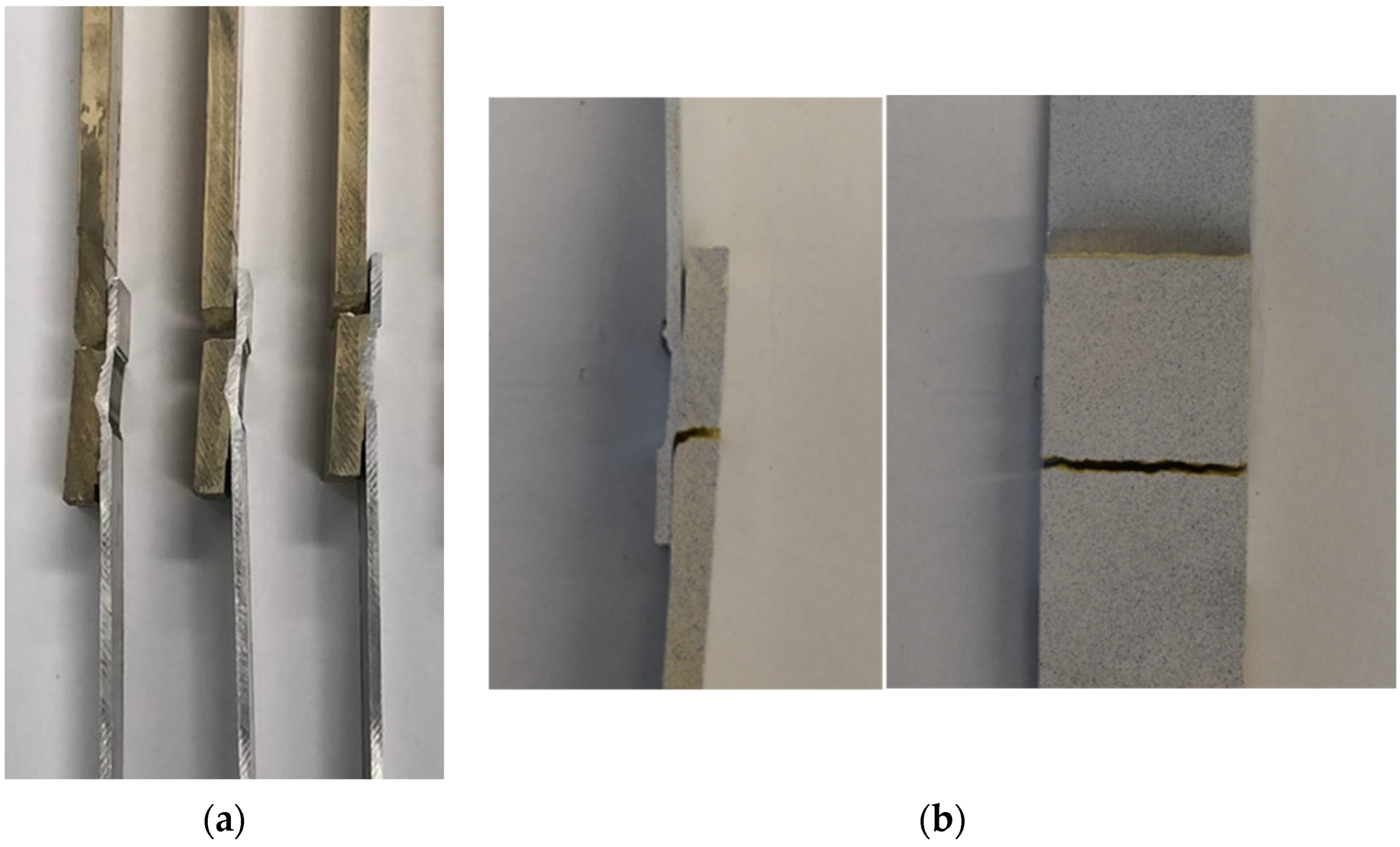

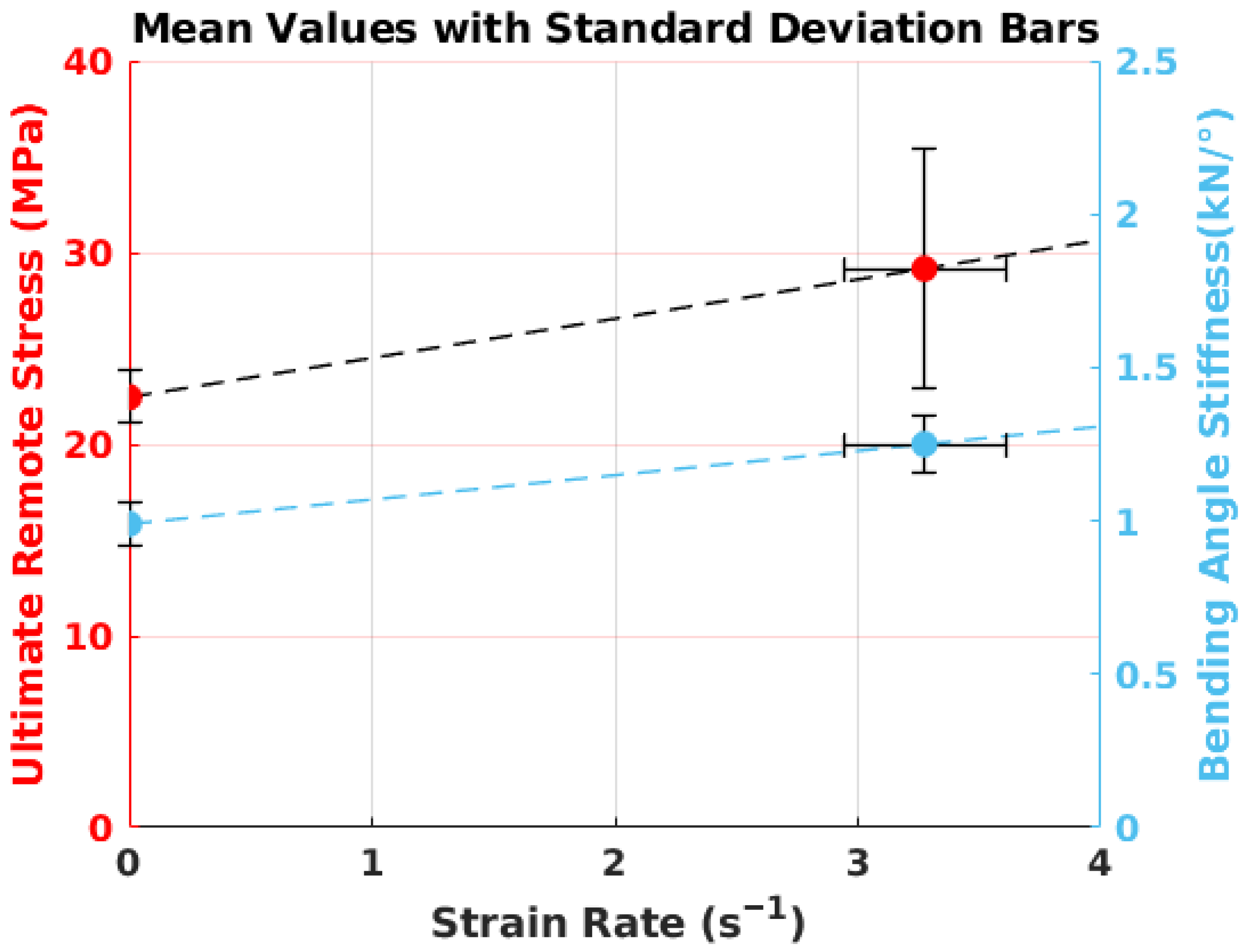

3.1. Joint and Base Material Characterization with Strain Rate

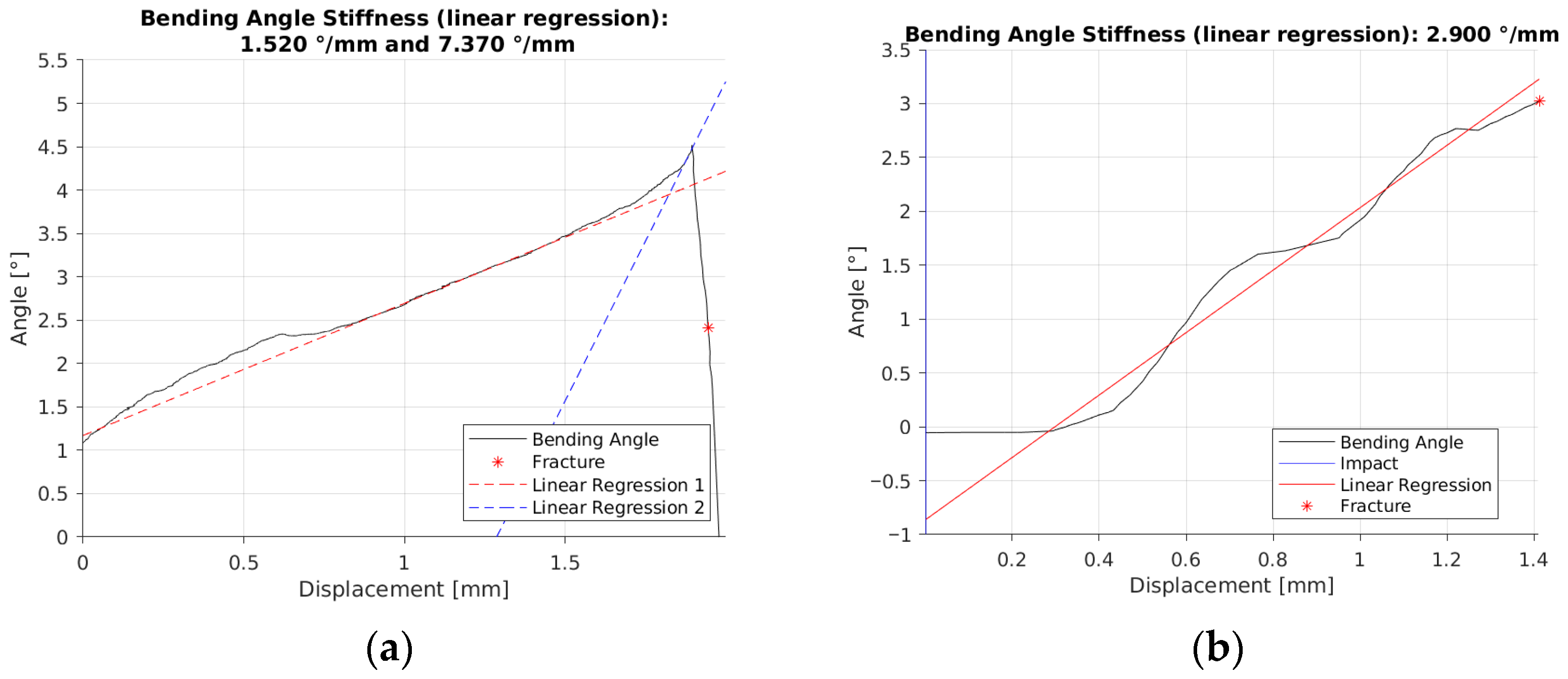

3.2. Out-of-Plane Assessment with Strain Rate

4. Conclusions

- Dissimilar polymer—aluminum friction stir lap joints have a positive strength strain rate sensitivity. This increase in strength is accompanied by an increase in joint stiffness and decrease in ductility. The average remote stress increased by ≈30% and stiffness ≈23%;

- The glass-fiber-reinforced polymer has a higher strain rate sensitivity than the aluminum alloy, but the dissimilar joints have an even higher strain rate sensitivity;

- Failure remains polymer-controlled at both rates, occurring in the Noryl™ adhered near the processed zone edge; higher rates shift the load mix toward more shear/less peel, consistent with reduced out-of-plane rotation and a more brittle polymer response; the nonplanar bending of the joints differed from quasi-static to intermediate strain rate. A higher bending angle stiffness was found for higher strain rates, requiring higher values of joint load or joint displacement to achieve similar values of out-of-plane bending angle;

- The bending angle increased linearly with joint loading at an intermediate strain rate, while in quasi-static loading, a rapid increase was found when approaching joint failure;

- As design implication for friction stir metal–polymer lap joints, increased rate can raise strength/stiffness but narrows the deformation margin; joint performance envelopes are therefore governed by the polymer constituent and by secondary-bending kinematics.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| QS | Quasi-static |

| ISR | Intermediate Strain Rate |

| DIC | Digital Image Correlation |

| FS | Friction Stir |

| FSW | Friction Stir Welding |

| FSJ | Friction Stir Joining |

References

- Li, J.; Chai, X.; Gu, Y.; Zhang, P.; Yang, X.; Wen, Y.; Xu, Z.; Jiang, B.; Wang, J.; Jin, G.; et al. Small-Scale High-Pressure Hydrogen Storage Vessels: A Review. Materials 2024, 17, 721. [Google Scholar] [CrossRef]

- Khan, S.; Kumar, A. Buckling Behaviour for Advance Cylindrical Shells (COPV) Subjected to Extreme Pressure Conditions: A Comprehensive Review. Polym. Compos. 2025, 46, 7785–7818. [Google Scholar] [CrossRef]

- Magliano, A.; Perez Carrera, C.; Pappalardo, C.M.; Guida, D.; Berardi, V.P. A Comprehensive Literature Review on Hydrogen Tanks: Storage, Safety, and Structural Integrity. Appl. Sci. 2024, 14, 9348. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, Y.; Bui, T.Q.; Curiel-Sosa, J.L. Crushing Performance and Energy Absorption Characteristics of Aluminum/CFRP Hybrid Thin-Walled Tubes: Experimental and Numerical Investigations. Compos. Commun. 2024, 51, 102089. [Google Scholar] [CrossRef]

- El-baky, M.A.A.; Allah, M.M.A.; Kamel, M.; Abd-Elaziem, W. Lightweight Cost-Effective Hybrid Materials for Energy Absorption Applications. Sci. Rep. 2022, 12, 21101. [Google Scholar] [CrossRef]

- Barakat, A.A.; Darras, B.M.; Nazzal, M.A.; Ahmed, A.A. A Comprehensive Technical Review of the Friction Stir Welding of Metal-to-Polymer Hybrid Structures. Polymers 2023, 15, 220. [Google Scholar] [CrossRef]

- Melaku, L.E.; Tomków, J. Dissimilar Friction Stir Welding of Aluminum to Polymer: A Review. Int. J. Adv. Manuf. Technol. 2025, 140, 2377–2396. [Google Scholar] [CrossRef]

- Correia, A.N.; Coelho, R.J.; Braga, D.F.O.; Guedes, M.; Baptista, R.; Infante, V. Effect of Service Temperature on the Mechanical and Fatigue Behaviour of Metal–Polymer Friction Stir Composite Joints. Polymers 2025, 17, 1366. [Google Scholar] [CrossRef]

- Correia, A.N.; Braga, D.F.O.; Baptista, R.; Infante, V. Experimental and Numerical Investigation on Failure Behaviour of Aluminum-Polymer Friction Stir Composite Joints. Eng. Fail. Anal. 2024, 165, 108805. [Google Scholar] [CrossRef]

- Wetta, M.; Kopp, J.-B.; Le Barbenchon, L.; Viot, P. Strain Rate Effect on the Compressive Behaviour of a Thick Cellular Structural Adhesive. Mater. Lett. 2024, 356, 135573. [Google Scholar] [CrossRef]

- Alrayyes, S.Y.A.; Apalak, M.K. Strain Rate Effect on the Dynamic Mechanical Behaviour of Microparticle Reinforced Adhesives in Tension. Int. J. Adhes. Adhes. 2025, 142, 104129. [Google Scholar] [CrossRef]

- André, N.M.; dos Santos, J.F.; Amancio-Filho, S.T. Impact Resistance of Metal-Composite Hybrid Joints Produced by Frictional Heat. Compos. Struct. 2020, 233, 111754. [Google Scholar] [CrossRef]

- Siviour, C.R.; Jordan, J.L. High Strain Rate Mechanics of Polymers: A Review. J. Dyn. Behav. Mater. 2016, 2, 15–32. [Google Scholar] [CrossRef]

- Yin, J.; Miao, Y.; Wu, Z.; Zhang, C.; Sun, R.; He, H.; Liu, J.; Tang, Z.; Li, Y. A Novel Hopkinson Tension Bar System for Testing Polymers under Intermediate Strain Rate and Large Deformation. Int. J. Impact Eng. 2025, 198, 105197. [Google Scholar] [CrossRef]

- Baumann, G.; Czibula, C.; Hirn, U.; Feist, F. A Digital-Twin Driven Split Hopkinson Bar Layout for the Tensile Characterization of Thin, Low Impedance, Sheet-like Materials. Int. J. Impact Eng. 2024, 194, 105098. [Google Scholar] [CrossRef]

- Bieler, S.; Weinberg, K. Signal Correction for the Split-Hopkinson Bar Testing of Soft Materials. Dynamics 2025, 5, 5. [Google Scholar] [CrossRef]

- Bhujangrao, T.; Froustey, C.; Iriondo, E.; Veiga, F.; Darnis, P.; Mata, F.G. Review of Intermediate Strain Rate Testing Devices. Metals 2020, 10, 894. [Google Scholar] [CrossRef]

- Ying, P.; Chen, W.; Ge, Y.; Zhou, Q.; Xia, Y. Loading Measurement for Intermediate Strain Rate Material Test Based on Dynamic Oscillation. Int. J. Impact Eng. 2023, 173, 104436. [Google Scholar] [CrossRef]

- Wei, Y.; Jin, X.; Luo, Q.; Li, Q.; Sun, G. Adhesively Bonded Joints—A Review on Design, Manufacturing, Experiments, Modeling and Challenges. Compos. B Eng. 2024, 276, 111225. [Google Scholar] [CrossRef]

- Dang, Z.; Zhou, J.; Cao, J.; Xia, R.; Zhang, C. Rate-Dependent Fracture Behavior of Composite-Metal Adhesively Bonded Structure under Symmetric Separation Loading. Eng. Fract. Mech. 2025, 326, 111428. [Google Scholar] [CrossRef]

- Correia, A.N.; Gaspar, B.M.; Cipriano, G.; Braga, D.F.O.; Baptista, R.; Infante, V. Thermo-Mechanical Characterization of Metal–Polymer Friction Stir Composite Joints—A Full Factorial Design of Experiments. Polymers 2024, 16, 602. [Google Scholar] [CrossRef]

- Rüthnick, P.; Ledford, N.; Imbert, M.; May, M. Mechanical Behavior of Multi-Material Single-Lap Joints under High Rates of Loading Using a Split Hopkinson Tension Bar. Metals 2022, 12, 1082. [Google Scholar] [CrossRef]

- Pereira, M.A.R.; Galvão, I.; Costa, J.D.M.; Amaro, A.M.; Leal, R.M. Metal-Polymer Friction Stir Spot Welding Enhanced by Meso-Mechanical Interlocking. Int. J. Adv. Manuf. Technol. 2025, 136, 4581–4593. [Google Scholar] [CrossRef]

- Khadka, P.; Varglund, S.; Akinwamide, S.; Vilaça, P. Characterization of Friction Stir-Based Linear Continuous Joining of Aluminium Alloy to Structural Polymer. Weld. World 2024, 68, 71–90. [Google Scholar] [CrossRef]

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Correia, A.N.; Santos, P.A.M.; Braga, D.F.O.; Cipriano, G.P.; Moreira, P.M.G.P.; Infante, V. Effects of Processing Temperature on Failure Mechanisms of Dissimilar Aluminum-to-Polymer Joints Produced by Friction Stir Welding. Eng. Fail. Anal. 2023, 146, 107155. [Google Scholar] [CrossRef]

- Chen, X.; Peng, Y.; Peng, S.; Yao, S.; Chen, C.; Xu, P. Flow and Fracture Behavior of Aluminum Alloy 6082-T6 at Different Tensile Strain Rates and Triaxialities. PLoS ONE 2017, 12, e0181983. [Google Scholar] [CrossRef] [PubMed]

- Lypchanskyi, O.; Janus, K.; Irmer, D.; Wójcik, A.; Korpała, G.; Prahl, U. Advancement of Microstructural Evolution and Deformation Mechanisms in AA6082 Aluminum Alloy under Elevated-Temperature Tensile Loading. Int. J. Plast. 2024, 176, 103969. [Google Scholar] [CrossRef]

- Sasso, M.; Mancini, E.; Chiappini, G.; Simoncini, M.; Forcellese, A. Adapted Nakazima Test to Evaluate Dynamic Effect on Strain Distribution and Dome Height in Balanced Biaxial Stretching Condition. Int. J. Mech. Sci. 2018, 148, 50–63. [Google Scholar] [CrossRef]

- Papanikolaou, S.; Shanthraj, P.; Thibault, J.; Woodward, C.; Roters, F. Brittle to Quasi-Brittle Transition and Crack Initiation Precursors in Crystals with Structural Inhomogeneities. Mater. Theory 2019, 3, 5. [Google Scholar] [CrossRef]

- Patel, Z.S.; Alrashed, A.O.; Dwivedi, K.; Salviato, M.; Meza, L.R. Rethinking Ductility—A Study into the Size-Affected Fracture of Additively Manufactured Polymers. Addit. Manuf. 2024, 84, 104113. [Google Scholar] [CrossRef]

| Dwell Time (s) | (RPM) | v (mm/s) | (°) | Pin Length (mm) | Plunge Depth (mm) |

|---|---|---|---|---|---|

| 15 | 1000 | 2.33 | 2 | 2 | 2.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coelho, R.J.; Silva, B.; Correia, A.N.; Batista, R.; Moreira, P.M.G.P.; Infante, V.; Braga, D.F.O. Effect of Strain Rate on Aluminum–Polymer Friction Stir Joints Mechanical Performance. J. Manuf. Mater. Process. 2025, 9, 362. https://doi.org/10.3390/jmmp9110362

Coelho RJ, Silva B, Correia AN, Batista R, Moreira PMGP, Infante V, Braga DFO. Effect of Strain Rate on Aluminum–Polymer Friction Stir Joints Mechanical Performance. Journal of Manufacturing and Materials Processing. 2025; 9(11):362. https://doi.org/10.3390/jmmp9110362

Chicago/Turabian StyleCoelho, Rodrigo J., Beatriz Silva, Arménio N. Correia, Ricardo Batista, Pedro M. G. P. Moreira, Virgínia Infante, and Daniel F. O. Braga. 2025. "Effect of Strain Rate on Aluminum–Polymer Friction Stir Joints Mechanical Performance" Journal of Manufacturing and Materials Processing 9, no. 11: 362. https://doi.org/10.3390/jmmp9110362

APA StyleCoelho, R. J., Silva, B., Correia, A. N., Batista, R., Moreira, P. M. G. P., Infante, V., & Braga, D. F. O. (2025). Effect of Strain Rate on Aluminum–Polymer Friction Stir Joints Mechanical Performance. Journal of Manufacturing and Materials Processing, 9(11), 362. https://doi.org/10.3390/jmmp9110362