Fabricating Three-Dimensional Metamaterials Using Additive Manufacturing: An Overview

Abstract

1. Introduction

2. Metamaterial Classification

2.1. Electromagnetic Metamaterials

2.2. Mechanical Metamaterials

2.3. Acoustic Metamaterials

2.4. Other Metamaterials

2.4.1. Optical Metamaterials

2.4.2. Thermal Metamaterials

2.4.3. Biomedical Metamaterials

2.4.4. Multifunctional Metamaterials

3. Manufacturing Methods of Metamaterials

- Performance Metrics Summary:

- Among various manufacturing techniques, multiphoton polymerization (MPP) offers the highest resolution (<1 μm), followed by traditional lithography (10 nm) and stereolithography (SLA) at around 25 μm. In terms of processing speed, binder jetting is the fastest (500 cm3/h), ahead of inkjet printing (200 cm3/h) and fused deposition modeling (FDM) (100 cm3/h). When considering cost-effectiveness, FDM stands out as the most economical method, followed by binder jetting, inkjet, and SLA. For surface quality, MPP provides the best finish, followed by traditional lithography, SLA, and inkjet printing. Lastly, in scalability, FDM ranks highest, followed by binder jetting, inkjet, and SLA.

4. Manufacturing Metamaterials Using Additive Manufacturing

4.1. Electromagnetic Metamaterials Using Additive Manufacturing

4.1.1. Microwave and Radiofrequency Metamaterials

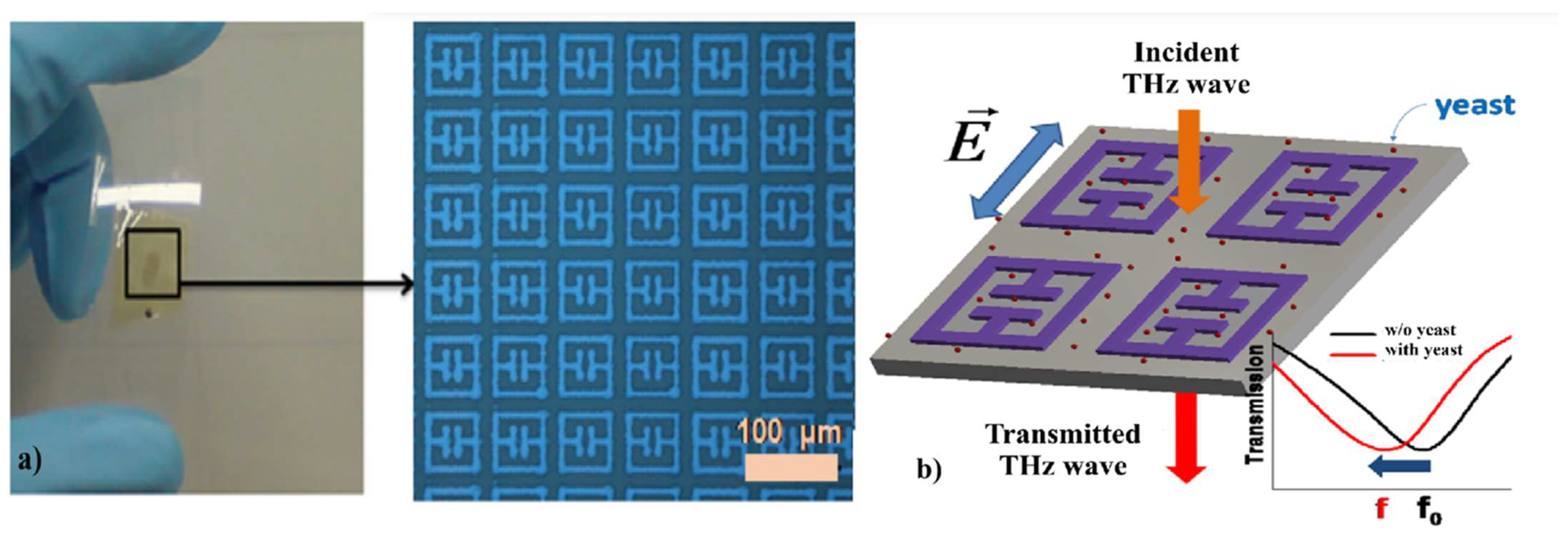

4.1.2. Terahertz Metamaterials

4.1.3. Photonic Crystals

4.1.4. Other Electromagnetic Metamaterials

4.2. Mechanical Metamaterials Using Additive Manufacturing

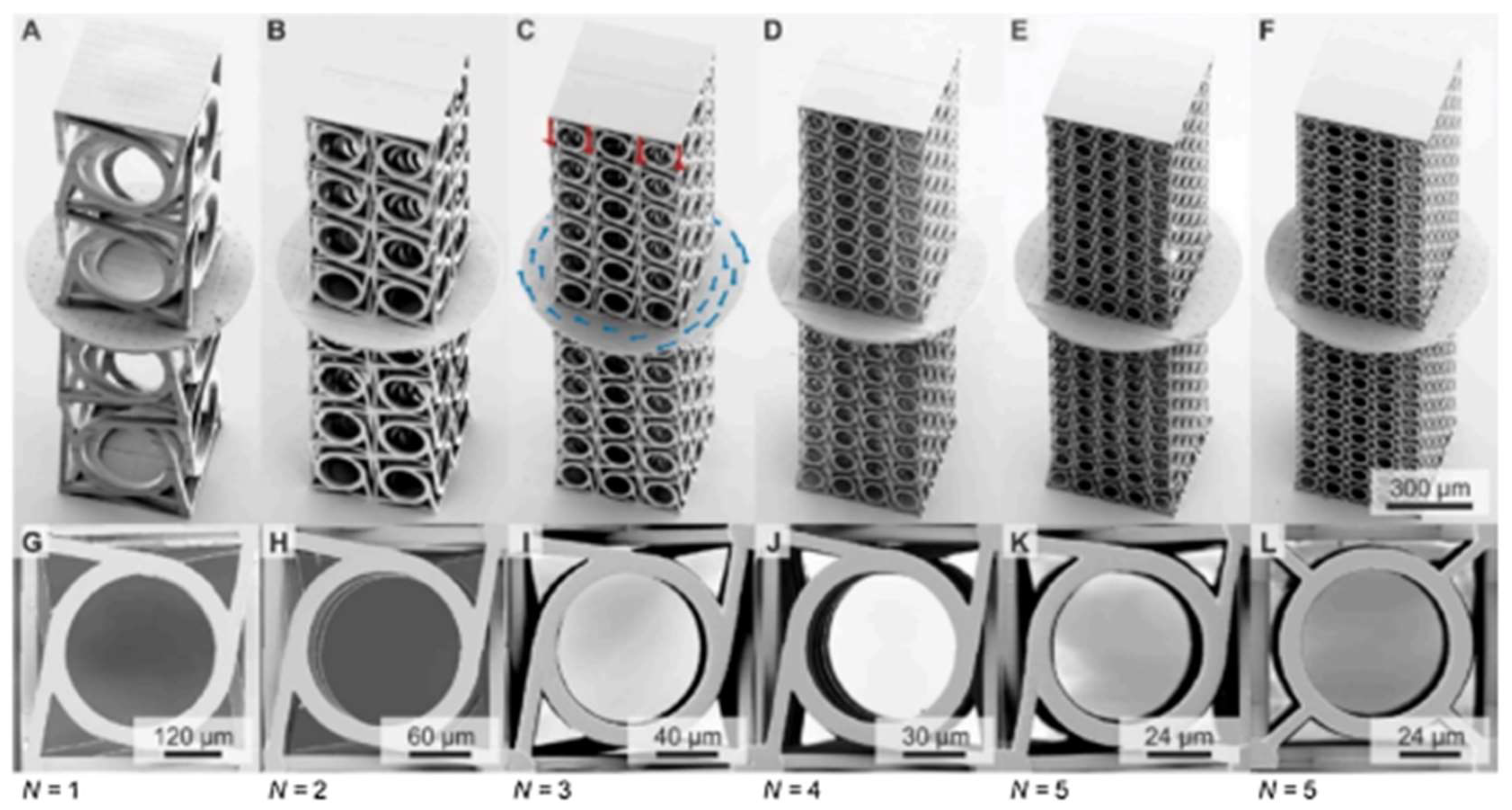

4.2.1. Auxetic Metamaterials

4.2.2. Pentamode Metamaterials

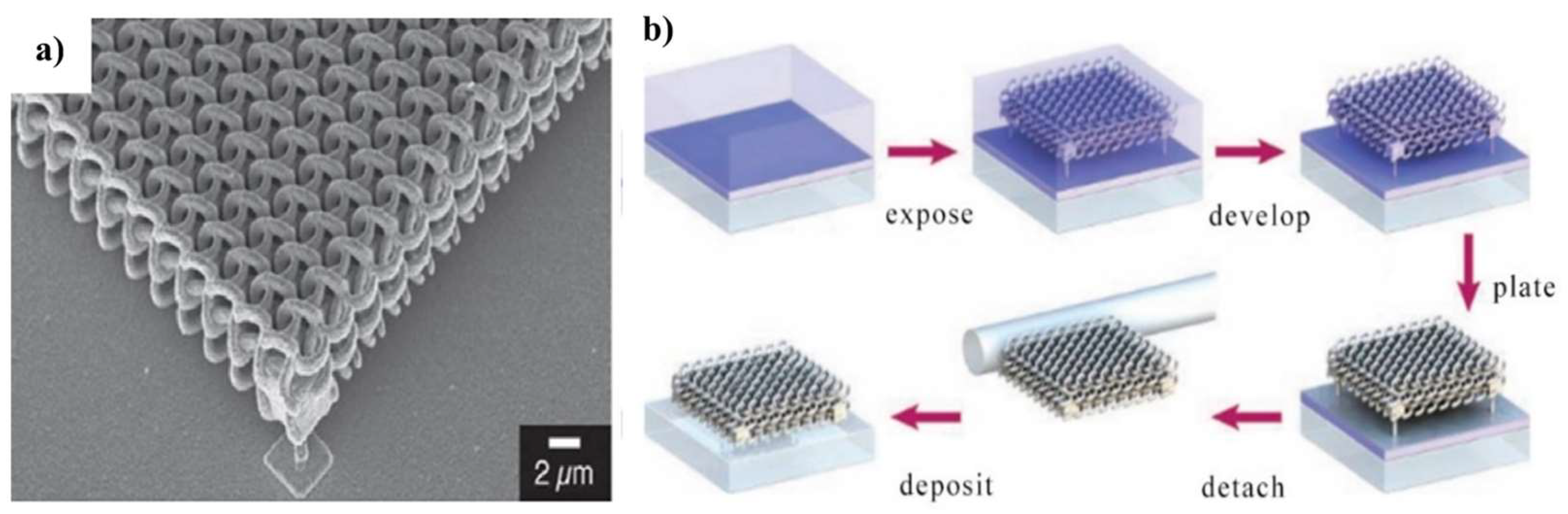

4.2.3. Other Mechanical Metamaterials

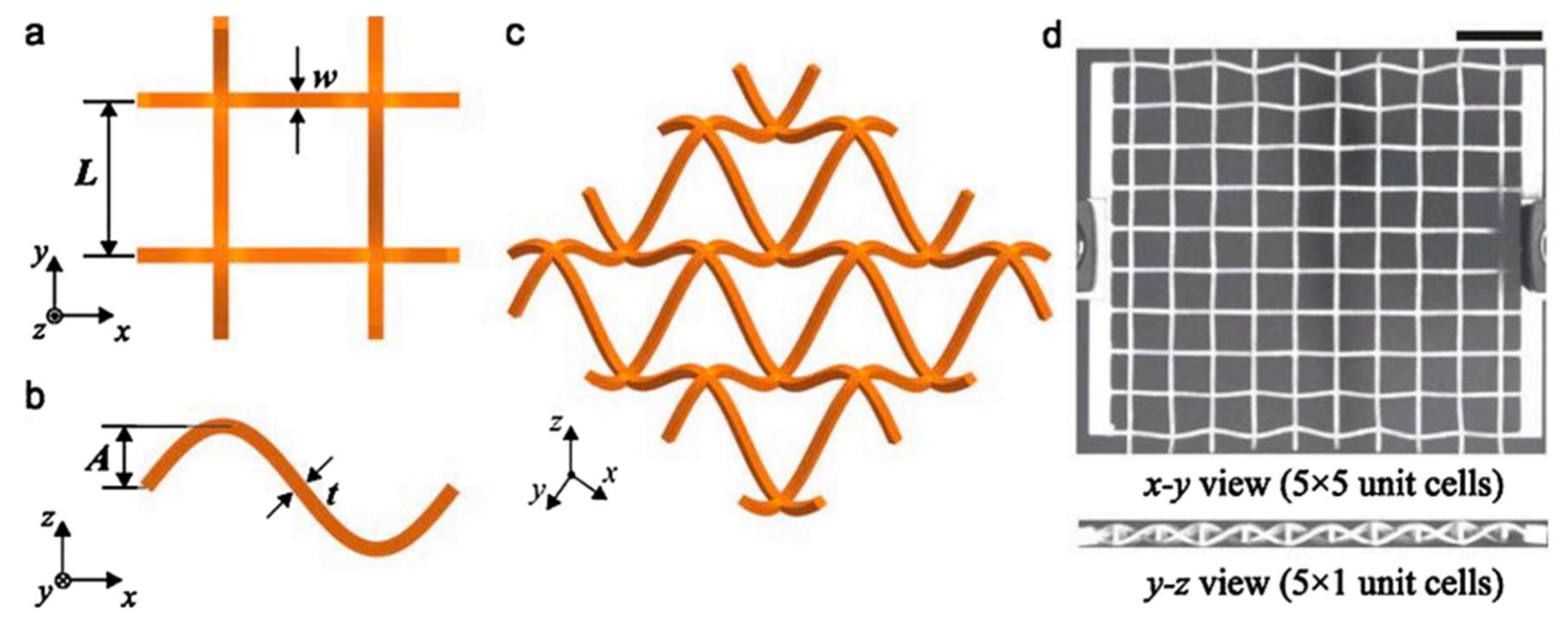

4.3. Acoustic Metamaterials Using Additive Manufacturing

4.3.1. Phononic Crystals

4.3.2. Helmholtz Resonant Acoustic Metamaterials

4.3.3. Other Acoustic Metamaterials

5. Challenges for Additively Manufactured Metamaterials

6. Developments and Future Trends of Metamaterials Using Additive Manufacturing

7. Conclusions

- Synergy Between AM and Metamaterials as an Enabling Technology: The primary conclusion is that additive manufacturing has been a transformative force, not merely an alternative fabrication method. AM provides unprecedented design freedom, enabling the physical fabrication of complex, multi-scale geometries that were previously confined to theoretical models or were impossible to produce with conventional methods [52,56]. This has accelerated the exploration of new theoretical and practical dimensions in metamaterial science, bridging the gap between computational design and tangible, functional components.

- Significant Advancements Across All Metamaterial Categories: AM has propelled the state of the art across all major domains. In electromagnetic metamaterials, it has enabled the creation of structures with negative refractive indices, gradient-index lenses, and effective absorbers from microwave to terahertz frequencies [58,96,112]. For mechanical metamaterials, techniques like Powder Bed Fusion (PBF) and Vat Photopolymerization (VP) have been instrumental in producing auxetic and pentamode structures with tailored properties like negative Poisson’s ratios and extreme anisotropy [137,178]. In acoustic metamaterials, AM has facilitated the fabrication of complex resonant structures for applications in sound cloaking, superlensing, and broadband noise attenuation [193,223].

- Persistent Challenges Requiring Further Innovation: Despite the progress, significant challenges remain that hinder the widespread adoption of AM for metamaterial production. These include limitations in fabrication resolution and precision, which are critical for performance, especially at optical frequencies [237]. The limited palette of compatible materials with desired electromagnetic, mechanical, or thermal properties remains a bottleneck. Furthermore, issues of scalability for mass production and the need for complex, often time-consuming post-processing steps must be addressed to move from laboratory-scale prototypes to industrial applications.

- Future Trends Toward Multifunctional and Intelligent Systems: The future of this field is trending towards increasingly intelligent and multifunctional systems. The emergence of 4D printing is enabling the creation of stimuli-responsive metamaterials that can change their shape or function over time in response to heat, light, or magnetic fields [239]. Multimaterial additive manufacturing is another key frontier, allowing the integration of disparate materials (e.g., conductive and dielectric, or rigid and soft) to create highly functional, monolithic components [279]. Such work demonstrates a clear pathway toward creating active 4D-printed metamaterials that can be controlled electronically. Surface roughness, often considered an undesirable artifact in AM processes like Fused Filament Fabrication (FFF), can be strategically controlled and utilized as a design feature. For instance, recent advancements in slicing software allow for the creation of a “fuzzy skin,” which intentionally introduces random oscillations in the extruder path to produce a rough, textured surface [280,281,282,283]. Looking ahead, the integration of artificial intelligence and generative design will further accelerate innovation, enabling the autonomous discovery and optimization of novel metamaterial architectures with unprecedented performance. The ability to design, simulate, and manufacture 3D structures tailored to specific needs is paving the way for exciting new developments across science, technology, and industry.

Author Contributions

Funding

Conflicts of Interest

References

- Boardman, A. Pioneers in metamaterials: John pendry and victor veselago. J. Opt. 2010, 13, 20401. [Google Scholar] [CrossRef]

- Maci, S. Electromagnetic Metamaterials and Metasurfaces: A historical journey. IEEE Antennas Propag. Mag. 2024, 66, 84–101. [Google Scholar] [CrossRef]

- Tong, X.C. Functional Metamaterials and Metadevices; Springer: Berlin/Heidelberg, Germany, 2018; Volume 262. [Google Scholar]

- Skiba, R. Advanced Materials Engineering Fundamentals; After Midnight Publishing: Melbourne, Australia, 2025. [Google Scholar]

- Liu, R.; Ji, C.; Zhao, Z.; Zhou, T. Metamaterials: Reshape and rethink. Engineering 2015, 1, 179–184. [Google Scholar] [CrossRef]

- Chen, J.; Hu, S.; Zhu, S.; Li, T. Metamaterials: From fundamental physics to intelligent design. Interdiscip. Mater. 2023, 2, 5–29. [Google Scholar] [CrossRef]

- Valipour, A.; Kargozarfard, M.H.; Rakhshi, M.; Yaghootian, A.; Sedighi, H.M. Metamaterials and their applications: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 2171–2210. [Google Scholar] [CrossRef]

- Altun, F.; Altuntas, G.; Asmatulu, E.; Asmatulu, R. Additive Manufacturing of Ti-6Al-4V: Influence of Cryogenic and Stress-Relief Heat Treatments on Electrical Conductivity. In Proceedings of the 7th International Trakya Scientific Research Congress, Edirne, Turkey, 28–29 August 2025; pp. 219–226. [Google Scholar]

- Alkunte, S.; Fidan, I.; Naikwadi, V.; Gudavasov, S.; Ali, M.A.; Mahmudov, M.; Hasanov, S.; Cheepu, M. Advancements and challenges in additively manufactured functionally graded materials: A comprehensive review. J. Manuf. Mater. Process. 2024, 8, 23. [Google Scholar] [CrossRef]

- Layher, A.-M.; Tewes, L.; Thumann, F.; Boeckh, T.; Koppka, S.; Enke, D.; Rädlein, E.; Bliedtner, J. Laser-Based Additive Manufacturing of Alkali Borosilicate Glass Powder: Influence of Laser-Beam Properties on Component Quality. J. Manuf. Mater. Process. 2025, 9, 305. [Google Scholar] [CrossRef]

- Kupfer, T.; Spano, L.; Pohl, S.; Körner, C.; Markl, M. Spot Melting Strategy for Contour Melting in Electron Beam Powder Bed Fusion. J. Manuf. Mater. Process. 2025, 9, 303. [Google Scholar] [CrossRef]

- Rajakaruna, R.A.D.N.V.; Asmatulu, E. Recent Progress in Low-Dielectric Constant Materials in the Aviation Industry: A Review. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 2365–2372. [Google Scholar] [CrossRef]

- Dubey, D.; Mirhakimi, A.S.; Elbestawi, M.A. Negative thermal expansion metamaterials: A review of design, fabrication, and applications. J. Manuf. Mater. Process. 2024, 8, 40. [Google Scholar] [CrossRef]

- Sha, W.; Xiao, M.; Wang, Y.; Huang, M.; Li, Q.; Gao, L. Topology optimization methods for thermal metamaterials: A review. Int. J. Heat Mass Transf. 2024, 227, 125588. [Google Scholar] [CrossRef]

- Ji, G.; Huber, J. Recent progress in acoustic metamaterials and active piezoelectric acoustic metamaterials—A review. Appl. Mater. Today 2022, 26, 101260. [Google Scholar] [CrossRef]

- Akbari-Farahani, F.; Ebrahimi-Nejad, S. From defect mode to topological metamaterials: A state-of-the-art review of phononic crystals & acoustic metamaterials for energy harvesting. Sens. Actuators A Phys. 2024, 365, 114871. [Google Scholar]

- Khalid, M.Y.; Arif, Z.U.; Tariq, A.; Hossain, M.; Umer, R.; Bodaghi, M. 3D printing of active mechanical metamaterials: A critical review. Mater. Des. 2024, 246, 113305. [Google Scholar] [CrossRef]

- Han, K.; Chang, C.H. Numerical modeling of sub-wavelength anti-reflective structures for solar module applications. Nanomaterials 2014, 4, 87–128. [Google Scholar] [CrossRef] [PubMed]

- Hamzat, A.K.; Murad, M.S.; Adediran, I.A.; Asmatulu, E.; Asmatulu, R. Fiber-reinforced composites for aerospace, energy, and marine applications: An insight into failure mechanisms under chemical, thermal, oxidative, and mechanical load conditions. Adv. Compos. Hybrid Mater. 2025, 8, 152. [Google Scholar] [CrossRef]

- Watts, C.M.; Liu, X.; Padilla, W.J. Metamaterial electromagnetic wave absorbers. Adv. Mater. 2012, 24, OP98–OP120. [Google Scholar] [CrossRef]

- Pendry, J.B. Negative refraction makes a perfect lens. Phys. Rev. Lett. 2000, 85, 3966–3969. [Google Scholar] [CrossRef]

- Koschny, T.; Soukoulis, C.M.; Wegener, M. Metamaterials in microwaves, optics, mechanics, thermodynamics, and transport. J. Opt. 2017, 19, 84005. [Google Scholar] [CrossRef]

- Jan Krzysztofik, W.; Nghia Cao, T. Metamaterials in Application to Improve Antenna Parameters. In Metamaterials and Metasurfaces; IOP Publishing: Bristol, UK, 2019. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Wang, J.; Ma, H.; Du, H.; Zhang, J.; Qu, S.; Xu, Z. Reconfigurable all-dielectric metamaterial frequency selective surface based on high-permittivity ceramics. Sci. Rep. 2016, 6, 24178. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.R.; Vier, D.C.; Koschny, T.; Soukoulis, C.M. Electromagnetic parameter retrieval from inhomogeneous metamaterials. Phys. Rev. E-Stat. Nonlinear Soft Matter Phys. 2005, 71, 36617. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Liu, P.; Bian, L.; Liu, H.; Liu, C.; Chen, G. Controlling enhanced absorption in graphene metamaterial. Opt. Commun. 2018, 413, 310–316. [Google Scholar] [CrossRef]

- Zhao, X.; Li, A.; Duan, G.; Chen, C.; Zhang, X. Integrating Microsystems with Metamaterials Towards Metadevices. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; Volume 5, pp. 574–577. [Google Scholar] [CrossRef]

- Kandwal, A.; Nie, Z.; Wang, L.; Liu, L.W.Y.; Das, R. Realization of low profile leaky wave antennas using the bending technique for frequency scanning and sensor applications. Sensors 2019, 19, 2265. [Google Scholar] [CrossRef] [PubMed]

- Ziolkowski, P.A.; Berchowitz, L.E.; Lambing, C.; Yelina, N.E.; Zhao, X.; Kelly, K.A.; Choi, K.; Ziolkowska, L.; June, V.; Sanchez-Moran, E.; et al. Juxtaposition of heterozygous and homozygous regions causes reciprocal crossover remodelling via interference during Arabidopsis meiosis. eLife 2015, 4, e03708. [Google Scholar] [CrossRef]

- Haxha, S.; AbdelMalek, F.; Ouerghi, F.; Charlton, M.D.B.; Aggoun, A.; Fang, X. Metamaterial Superlenses Operating at Visible Wavelength for Imaging Applications. Sci. Rep. 2018, 8, 16119. [Google Scholar] [CrossRef]

- Kim, M.; Rho, J. Metamaterials and imaging. Nano Converg. 2015, 2, 22. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Zhou, J.; Liang, H.; Jiang, Z.; Wu, L. Mechanical metamaterials associated with stiffness, rigidity and compressibility: A brief review. Prog. Mater. Sci. 2018, 94, 114–173. [Google Scholar] [CrossRef]

- Gao, S.; Liu, W.; Zhang, L.; Gain, A.K. A new polymer-based mechanical metamaterial with tailorable large negative Poisson’s ratios. Polymers 2020, 12, 1492. [Google Scholar] [CrossRef] [PubMed]

- Kelkar, P.U.; Kim, H.S.; Cho, K.H.; Kwak, J.Y.; Kang, C.Y.; Song, H.C. Cellular auxetic structures for mechanical metamaterials: A review. Sensors 2020, 20, 3132. [Google Scholar] [CrossRef]

- Surjadi, J.U.; Gao, L.; Du, H.; Li, X.; Xiong, X.; Fang, N.X.; Lu, Y. Mechanical Metamaterials and Their Engineering Applications. Adv. Eng. Mater. 2019, 21, 1800864. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, G.; You, Z. Large deformation and energy absorption of additively manufactured auxetic materials and structures: A review. Compos. Part B Eng. 2020, 201, 108340. [Google Scholar] [CrossRef]

- Kolken, H.M.A.; Zadpoor, A.A. Auxetic mechanical metamaterials. RSC Adv. 2017, 7, 5111–5129. [Google Scholar] [CrossRef]

- Adewunmi, A.A.; Mayowa, O.I.; Hamzat, A.K.; Olatunji, S.O.; Ishola, A.; Badmus, S.O.; Saleh, T.A. CO2 adsorption on polymeric amine-functionalized adsorbents by computational intelligence method. J. Taiwan Inst. Chem. Eng. 2024, 163, 105647. [Google Scholar] [CrossRef]

- Le, D.H.; Lim, S. Four-Mode Programmable Metamaterial Using Ternary Foldable Origami. ACS Appl. Mater. Interfaces 2019, 11, 28554–28561. [Google Scholar] [CrossRef] [PubMed]

- Binion, J.D.; Lier, E.; Hand, T.H.; Jiang, Z.H.; Werner, D.H. A metamaterial-enabled design enhancing decades-old short backfire antenna technology for space applications. Nat. Commun. 2019, 10, 108. [Google Scholar] [CrossRef]

- Kim, J.-H.; Yoon, H.; Viswanath, S.; Dagdeviren, C. Conformable Piezoelectric Devices and Systems for Advanced Wearable and Implantable Biomedical Applications. Annu. Rev. Biomed. Eng. 2025, 27, 255–282. [Google Scholar] [CrossRef] [PubMed]

- Sheng, P.; Zhang, X.X.; Liu, Z.; Chan, C.T. Locally resonant sonic materials. Phys. B Condens. Matter 2003, 338, 201–205. [Google Scholar] [CrossRef]

- Yao, S.; Zhou, X.; Hu, G. Investigation of the negative-mass behaviors occurring below a cut-off frequency. New J. Phys. 2010, 12, 103025. [Google Scholar] [CrossRef]

- Kumar, S.; Lee, H.P. Recent advances in acoustic metamaterials for simultaneous sound attenuation and air ventilation performances. Crystals 2020, 10, 686. [Google Scholar] [CrossRef]

- Maury, C.; Gardonio, P.; Elliott, S.J. Active control of the flow-induced noise transmitted through a panel. AIAA J. 2001, 39, 1860–1867. [Google Scholar] [CrossRef]

- Bai, H.; Zhan, Z.; Liu, J.; Ren, Z. From local structure to overall performance: An overview on the design of an acoustic coating. Materials 2019, 12, 2509. [Google Scholar] [CrossRef] [PubMed]

- Athanassiadis, A.G.; Ma, Z.; Moreno-Gomez, N.; Melde, K.; Choi, E.; Goyal, R.; Fischer, P. Ultrasound-responsive systems as components for smart materials. Chem. Rev. 2021, 122, 5165–5208. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Guo, H.; Wang, T. A review of acoustic metamaterials and phononic crystals. Crystals 2020, 10, 305. [Google Scholar] [CrossRef]

- Arshed, S.; Biswas, A.; Alzahrani, A.K.; Belic, M.R. Solitons in nonlinear directional couplers with optical metamaterials by first integral method. Optik 2020, 218, 165208. [Google Scholar] [CrossRef]

- Jibin, K.; Victor, M.; Saranya, G.; Santhakumar, H.; Murali, V.; Maiti, K.K.; Jayasree, R.S. Nanohybrids of magnetically intercalated optical metamaterials for magnetic resonance/Raman imaging and in situ chemodynamic/photothermal therapy. ACS Appl. Bio Mater. 2021, 4, 5742–5752. [Google Scholar] [CrossRef]

- Rabie, W.B.; Ahmed, H.M. Construction cubic-quartic solitons in optical metamaterials for the perturbed twin-core couplers with Kudryashov’s sextic power law using extended F-expansion method. Chaos Solitons Fractals 2022, 160, 112289. [Google Scholar] [CrossRef]

- Mathanaranjan, T. New Jacobi elliptic solutions and other solutions in optical metamaterials having higher-order dispersion and its stability analysis. Int. J. Appl. Comput. Math. 2023, 9, 66. [Google Scholar] [CrossRef]

- Ren, Z.; Chang, Y.; Ma, Y.; Shih, K.; Dong, B.; Lee, C. Leveraging of MEMS technologies for optical metamaterials applications. Adv. Opt. Mater. 2020, 8, 1900653. [Google Scholar] [CrossRef]

- Narayana, S.; Sato, Y. Heat flux manipulation with engineered thermal materials. Phys. Rev. Lett. 2012, 108, 214303. [Google Scholar] [CrossRef]

- Kadic, M.; Bückmann, T.; Schittny, R.; Wegener, M. Metamaterials beyond electromagnetism. Reports Prog. Phys. 2013, 76, 126501. [Google Scholar] [CrossRef]

- Pichanusakorn, P.; Bandaru, P.R. Minimum length scales for enhancement of the power factor in thermoelectric nanostructures. J. Appl. Phys. 2010, 107, 074304. [Google Scholar] [CrossRef]

- Vemuri, K.P.; Canbazoglu, F.M.; Bandaru, P.R. Guiding conductive heat flux through thermal metamaterials. Appl. Phys. Lett. 2014, 105, 193904. [Google Scholar] [CrossRef]

- Banerjee, S.; Dutta, P.; Jha, A.V.; Appasani, B.; Khan, M.S. A biomedical sensor for detection of cancer cells based on terahertz metamaterial absorber. IEEE Sensors Lett. 2022, 6, 6002004. [Google Scholar] [CrossRef]

- Qin, Q. Applications of piezoelectric and biomedical metamaterials: A review. AIMS Mater. Sci. 2025, 12, 562–609. [Google Scholar] [CrossRef]

- Wang, J.; Allein, F.; Boechler, N.; Friend, J.; Vazquez-Mena, O. Design and fabrication of negative-refractive-index metamaterial unit cells for near-megahertz enhanced acoustic transmission in biomedical ultrasound applications. Phys. Rev. Appl. 2021, 15, 24025. [Google Scholar] [CrossRef]

- Burrow, G.M.; Gaylord, T.K. Multi-beam interference advances and applications: Nano-electronics, photonic crystals, metamaterials, subwavelength structures, optical trapping, and biomedical structures. Micromachines 2011, 2, 221–257. [Google Scholar] [CrossRef]

- Sun, M.; Hu, X.; Tian, L.; Yang, X.; Min, L. Auxetic biomedical metamaterials for orthopedic surgery applications: A comprehensive review. Orthop. Surg. 2024, 16, 1801–1815. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Yin, G.; Xie, L.; Yin, M. Multifunctional 3D lattice metamaterials for vibration mitigation and energy absorption. Int. J. Mech. Sci. 2022, 233, 107678. [Google Scholar] [CrossRef]

- Chen, M.; Shen, X.; Chen, Z.; Lo, J.H.Y.; Liu, Y.; Xu, X.; Wu, Y.; Xu, L. Realizing the multifunctional metamaterial for fluid flow in a porous medium. Proc. Natl. Acad. Sci. USA 2022, 119, e2207630119. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Li, D.; Liao, W.; Liu, T.; Li, X.; An, Q.; Qu, Z. Multifunctional metamaterial with reconfigurable electromagnetic scattering properties for advanced stealth and adaptive applications. Adv. Mater. 2024, 36, 2408216. [Google Scholar] [CrossRef]

- Feng, J.; Qiao, J.; Xu, Q.; Zhang, G.; Li, L. Accelerated design of acoustic-mechanical multifunctional metamaterials via neural network. Int. J. Mech. Sci. 2025, 287, 109920. [Google Scholar] [CrossRef]

- Xu, X.; Wu, Q.; Pang, Y.; Cao, Y.; Fang, Y.; Huang, G.; Cao, C. Multifunctional metamaterials for energy harvesting and vibration control. Adv. Funct. Mater. 2022, 32, 2107896. [Google Scholar] [CrossRef]

- Lee, D.; Chen, W.; Wang, L.; Chan, Y.-C.; Chen, W. Data-driven design for metamaterials and multiscale systems: A review. Adv. Mater. 2024, 36, 2305254. [Google Scholar] [CrossRef] [PubMed]

- Stokes, K.; Clark, K.; Odetade, D.; Hardy, M.; Goldberg Oppenheimer, P. Advances in lithographic techniques for precision nanostructure fabrication in biomedical applications. Discov. Nano 2023, 18, 153. [Google Scholar] [CrossRef] [PubMed]

- Jaiswal, A.; Rastogi, C.K.; Rani, S.; Singh, G.P.; Saxena, S.; Shukla, S. Two decades of two-photon lithography: Materials science perspective for additive manufacturing of 2D/3D nano-microstructures. Iscience 2023, 26, 106374. [Google Scholar] [CrossRef]

- Tuli, N.T.; Khatun, S.; Rashid, A. Bin Unlocking the future of precision manufacturing: A comprehensive exploration of 3D printing with fiber-reinforced composites in aerospace, automotive, medical, and consumer industries. Heliyon 2024, 10, e27328. [Google Scholar] [CrossRef]

- Young, O.M.; Xu, X.; Sarker, S.; Sochol, R.D. Direct laser writing-enabled 3D printing strategies for microfluidic applications. Lab Chip 2024, 24, 2371–2396. [Google Scholar] [CrossRef]

- Cao, Y.; Ma, D.; Li, H.; Cui, G.; Zhang, J.; Yang, Z. Review of Industrialization Development of Nanoimprint Lithography Technology. Chips 2025, 4, 10. [Google Scholar] [CrossRef]

- Ghosheh, M.; Ehrlich, A.; Fischer, A.; Pasitka, L.; Cohen, M.; Nahmias, Y. Metamaterial-based injection molding for the cost-effective production of whole cuts. Nat. Commun. 2024, 15, 10767. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Williams, C.; Spadaccini, C.M.; Shea, K. Perspectives on multi-material additive manufacturing. J. Mater. Res. 2021, 36, 3549–3557. [Google Scholar] [CrossRef]

- Idrus, I.N.; Faruque, M.R.I.; Abdullah, S.; Khandaker, M.U.; Tamam, N.; Sulieman, A. An oval-square shaped split ring resonator based left-handed metamaterial for satellite communications and radar applications. Micromachines 2022, 13, 578. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.; Liu, X.; Peng, B.; Kan, C. Predicting the mechanical behavior of additively manufactured mechanical metamaterials using point cloud representation learning. J. Comput. Inf. Sci. Eng. 2024, 24, 1–26. [Google Scholar] [CrossRef]

- Wang, Z.; Luan, C.; Liao, G.; Liu, J.; Yao, X.; Fu, J. Progress in auxetic mechanical metamaterials: Structures, characteristics, manufacturing methods, and applications. Adv. Eng. Mater. 2020, 22, 2000312. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Picken, P.; Bodaghi, M.; Fard, M.; Rolfe, B. Additive manufacturing of composite foam metamaterial springs for vibration isolation. Adv. Eng. Mater. 2023, 25, 2300356. [Google Scholar] [CrossRef]

- Zheng, R.; Yi, B.; Liu, W.; Liu, L.; Peng, X.; Tao, Y. Topology optimization of self-supporting metamaterials for additive manufacturing: A novel framework and validation. Smart Mater. Struct. 2024, 34, 15056. [Google Scholar] [CrossRef]

- Wu, X.; Su, Y.; Shi, J. Perspective of additive manufacturing for metamaterials development. Smart Mater. Struct. 2019, 28, 93001. [Google Scholar] [CrossRef]

- Hsu, W.-L.; Chen, Y.-C.; Yeh, S.P.; Zeng, Q.-C.; Huang, Y.-W.; Wang, C.-M. Review of metasurfaces and metadevices: Advantages of different materials and fabrications. Nanomaterials 2022, 12, 1973. [Google Scholar] [CrossRef]

- Almesmari, A.; Baghous, N.; Ejeh, C.J.; Barsoum, I.; Abu Al-Rub, R.K. Review of additively manufactured polymeric metamaterials: Design, fabrication, testing and modeling. Polymers 2023, 15, 3858. [Google Scholar] [CrossRef]

- Spadaccini, C. Mechanical metamaterials: Design, fabrication, and performance. In Proceedings of the Frontiers of Engineering: Reports on Leading-Edge Engineering from the 2015 Symposium, Irvine, CA, USA, 9–11 September 2015; National Academies Press: Washington, WA, USA, 2016; pp. 85–98. [Google Scholar]

- Matei, A.T.; Vișan, A.I.; Popescu-Pelin, G.F. Design and Processing of Metamaterials. Crystals 2025, 15, 374. [Google Scholar] [CrossRef]

- Chen, Z.; Lin, Y.-T.; Salehi, H.; Che, Z.; Zhu, Y.; Ding, J.; Sheng, B.; Zhu, R.; Jiao, P. Advanced fabrication of mechanical metamaterials based on micro/nanoscale technology. Adv. Eng. Mater. 2023, 25, 2300750. [Google Scholar] [CrossRef]

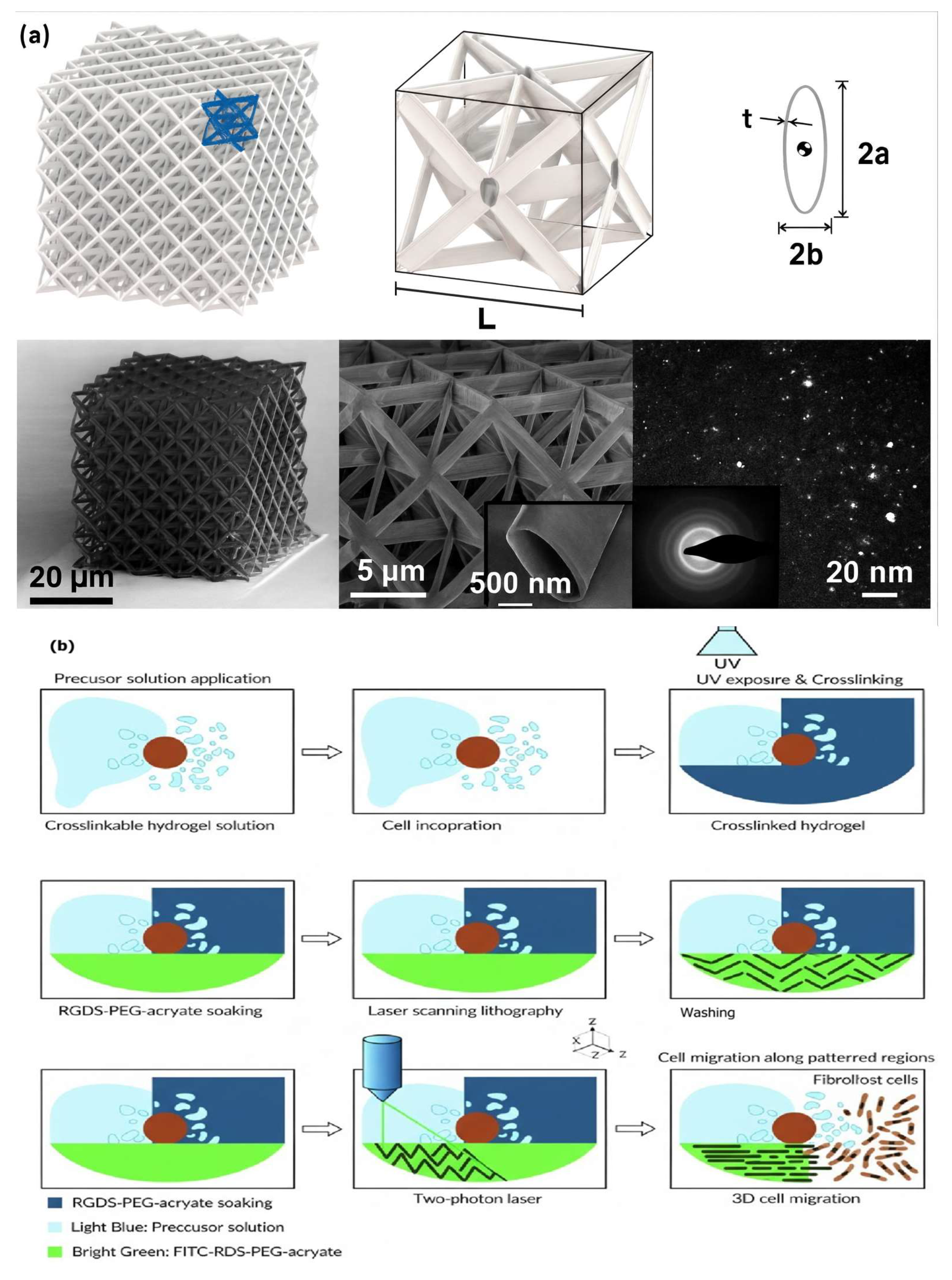

- Chen, J.; Chen, J.; Wang, H.; He, L.; Huang, B.; Dadbakhsh, S.; Bartolo, P. Fabrication and development of mechanical metamaterials via additive manufacturing for biomedical applications: A review. Int. J. Extrem. Manuf. 2024, 7, 012001. [Google Scholar] [CrossRef]

- Montazeri, A.; Bahmanpour, E.; Safarabadi, M. A Poisson’s ratio sign-switching mechanical metamaterial with tunable stiffness. Int. J. Mech. Sci. 2023, 260, 108670. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.D.M.; Domínguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 337. [Google Scholar] [CrossRef]

- Torre, M.; Giannitelli, S.M.; Mauri, E.; Trombetta, M.; Rainer, A. Additive manufacturing of biomaterials. Adv. Chem. Eng. 2021, 57, 233–260. [Google Scholar] [CrossRef]

- Dogan, E.; Bhusal, A.; Cecen, B.; Miri, A.K. 3D Printing metamaterials towards tissue engineering. Appl. Mater. Today 2020, 20, 100752. [Google Scholar] [CrossRef] [PubMed]

- Deubel, M.; Von Freymann, G.; Wegener, M.; Pereira, S.; Busch, K.; Soukoulis, C.M. Direct laser writing of three-dimensional photonic-crystal templates for telecommunications. Nat. Mater. 2004, 3, 444–447. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, J.; Liu, L.; Fan, Z.; Ma, Y. Magnetic–acoustic biphysical invisible coats for underwater objects. NPG Asia Mater. 2020, 12, 27. [Google Scholar] [CrossRef]

- Lincoln, R.L.; Scarpa, F.; Ting, V.P.; Trask, R.S. Multifunctional composites: A metamaterial perspective. Multifunct. Mater. 2019, 2, 43001. [Google Scholar] [CrossRef]

- Shelby, R.A.; Smith, D.R.; Schultz, S. Experimental verification of a negative index of refraction. Science 2001, 292, 77–79. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Guo, X.; Chen, T.; Liang, H.; Hao, X.; Hou, X.; Kou, W.; Zhao, Y.; Zhou, T.; et al. A review of THz modulators with dynamic tunable metasurfaces. Nanomaterials 2019, 9, 965. [Google Scholar] [CrossRef]

- Valentine, J.; Zhang, S.; Zentgraf, T.; Ulin-Avila, E.; Genov, D.A.; Bartal, G.; Zhang, X. Three-dimensional optical metamaterial with a negative refractive index. Nature 2008, 455, 376–379. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Jackson, J.A.; Ge, Q.; Hopkins, J.B.; Spadaccini, C.M.; Fang, N.X. Lightweight mechanical metamaterials with tunable negative thermal expansion. Phys. Rev. Lett. 2016, 117, 175901. [Google Scholar] [CrossRef]

- Camposeo, A.; Persano, L.; Farsari, M.; Pisignano, D. Additive Manufacturing: Applications and Directions in Photonics and Optoelectronics. Adv. Opt. Mater. 2019, 7, 1800419. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Lee, K.S.; Kim, R.H.; Yang, D.Y.; Park, S.H. Advances in 3D nano/microfabrication using two-photon initiated polymerization. Prog. Polym. Sci. 2008, 33, 631–681. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Bodaghi, M.; Liao, W.H. 4D printed tunable mechanical metamaterials with shape memory operations. Smart Mater. Struct. 2019, 28, 45019. [Google Scholar] [CrossRef]

- Dressler, A.D.; Jost, E.W.; Miers, J.C.; Moore, D.G.; Seepersad, C.C.; Boyce, B.L. Heterogeneities dominate mechanical performance of additively manufactured metal lattice struts. Addit. Manuf. 2019, 28, 692–703. [Google Scholar] [CrossRef]

- Sha, Y.; Jiani, L.; Haoyu, C.; Ritchie, R.O.; Jun, X. Design and strengthening mechanisms in hierarchical architected materials processed using additive manufacturing. Int. J. Mech. Sci. 2018, 149, 150–163. [Google Scholar] [CrossRef]

- Kennedy, J.; Flanagan, L.; Dowling, L.; Bennett, G.J.; Rice, H.; Trimble, D. The influence of additive manufacturing processes on the performance of a periodic acoustic metamaterial. Int. J. Polym. Sci. 2019, 2019, 7029143. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, Z.; Ragonese, A.; Zhu, T.; Khuje, S.; Li, C.; Grossman, J.C.; Zhou, C.; Nouh, M.; Ren, S. A 3D-printed molecular ferroelectric metamaterial. Proc. Natl. Acad. Sci. USA 2020, 117, 27204–27210. [Google Scholar] [CrossRef] [PubMed]

- Phuc, L.T.; Seita, M. A high-resolution and large field-of-view scanner for in-line characterization of powder bed defects during additive manufacturing. Mater. Des. 2019, 164, 107562. [Google Scholar] [CrossRef]

- Campoli, G.; Borleffs, M.S.; Amin Yavari, S.; Wauthle, R.; Weinans, H.; Zadpoor, A.A. Mechanical properties of open-cell metallic biomaterials manufactured using additive manufacturing. Mater. Des. 2013, 49, 957–965. [Google Scholar] [CrossRef]

- Singha, D.; Singh, R.; Boparaid, K.S. Investigations for surface roughness and dimensional accuracy of biomedical implants prepared by combining fused deposition modelling, vapour smoothing and investment casting. Adv. Mater. Process. Technol. 2020, 2020, 1–20. [Google Scholar] [CrossRef]

- Mak, K.F.; Ju, L.; Wang, F.; Heinz, T.F. Optical spectroscopy of graphene: From the far infrared to the ultraviolet. Solid State Commun. 2012, 152, 1341–1349. [Google Scholar] [CrossRef]

- Raut, N.C.; Al-Shamery, K. Inkjet printing metals on flexible materials for plastic and paper electronics. J. Mater. Chem. C 2018, 6, 1618–1641. [Google Scholar] [CrossRef]

- Ning, H.; Zhou, Y.; Fang, Z.; Yao, R.; Tao, R.; Chen, J.; Cai, W.; Zhu, Z.; Yang, C.; Wei, J.; et al. UV-Cured Inkjet-Printed Silver Gate Electrode with Low Electrical Resistivity. Nanoscale Res. Lett. 2017, 12, 546. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.R.; Padilla, W.J.; Vier, D.C.; Nemat-Nasser, S.C.; Schultz, S. Composite medium with simultaneously negative permeability and permittivity. Phys. Rev. Lett. 2000, 84, 4184–4187. [Google Scholar] [CrossRef] [PubMed]

- Yin, M.; Tian, X.Y.; Wu, L.L.; Li, D.C. A broadband and omnidirectional electromagnetic wave concentrator with gradient woodpile structure. Opt. Express 2013, 21, 19082–19090. [Google Scholar] [CrossRef]

- Chen, W.; Kirihara, S.; Miyamoto, Y. Fabrication and measurement of micro three-dimensional photonic crystals of SiO2 ceramic for terahertz wave applications. J. Am. Ceram. Soc. 2007, 90, 2078–2081. [Google Scholar] [CrossRef]

- Chatani, S.; Kloxin, C.J.; Bowman, C.N. The power of light in polymer science: Photochemical processes to manipulate polymer formation, structure, and properties. Polym. Chem. 2014, 5, 2187–2201. [Google Scholar] [CrossRef]

- Thiel, M.; Rill, M.S.; von Freymann, G.; Wegener, M. Three-dimensional bi-chiral photonic crystals. Adv. Mater. 2009, 21, 4680–4682. [Google Scholar] [CrossRef]

- Hou, J.; Zhou, Y.; Citrin, D.S.; Qiu, X.; Yang, C.; Chen, S. Complete two-dimensional photonic bandgap in refractive-index ratio 2.1 photonic crystals due to high-order bands. Opt. Lett. 2021, 46, 5558–5561. [Google Scholar] [CrossRef]

- Waller, E.H.; Karst, J.; von Freymann, G. Photosensitive material enabling direct fabrication of filigree 3D silver microstructures via laser-induced photoreduction. Light Adv. Manuf. 2021, 2, 228–233. [Google Scholar] [CrossRef]

- Wang, W.; Li, Z.; Su, R.; Huang, Y.; Li, Y.; He, R. Advanced 3D printing accelerates electromagnetic wave absorption from ceramic materials to structures. npj Adv. Manuf. 2025, 2, 1–21. [Google Scholar] [CrossRef]

- Xu, H.-X.; Wang, G.-M.; Tao, Z.; Cui, T.J. High-directivity emissions with flexible beam numbers and beam directions using gradient-refractive-index fractal metamaterial. Sci. Rep. 2014, 4, 5744. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wu, Z.; Zhang, Z.; Zou, Y. Ultra-broadband and wide-angle absorption based on 3D-printed pyramid. Opt. Laser Technol. 2020, 124, 105972. [Google Scholar] [CrossRef]

- Zhou, N.; Zhang, L.; Wang, W.; Zhang, X.; Zhang, K.; Chen, M.; Huang, Y.; He, R.; Fang, D. Stereolithographically 3D printed SiC metastructure for ultrabroadband and high temperature microwave absorption. Adv. Mater. Technol. 2023, 8, 2201222. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, G.; Zhou, M.; Zheng, J.; Tang, S.; Ji, G. Metamaterial electromagnetic wave absorbers and devices: Design and 3D microarchitecture. J. Mater. Sci. Technol. 2022, 108, 90–101. [Google Scholar] [CrossRef]

- Yu, S.; Wang, C.; Chen, Z.; Qiu, Z.; Chu, C.; Cheng, Y.; Zeng, T.; Sun, A. Additive manufacturing of broadband electromagnetic wave absorbing materials: Polymer-derived SiC/Si3N4 composites with triply periodic minimal surface meta-structure. Chem. Eng. J. 2024, 483, 149185. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, P.; Lu, Q.; Zhang, Y.; Lei, H.; Yu, C.; Huang, Y.; Yu, J. Functional additive manufacturing of large-size metastructure with efficient electromagnetic absorption and mechanical adaptation. Compos. Part A Appl. Sci. Manuf. 2023, 173, 107652. [Google Scholar] [CrossRef]

- Lei, H.; Shan, M.; Zhang, Y.; Zhao, P.; Yu, C.; Huang, Y. Design-manufacturing-evaluation integration of microwave absorbing metastructures based on additive manufacturing. Compos. Sci. Technol. 2023, 243, 110270. [Google Scholar] [CrossRef]

- You, J.; Ma, Q.; Zhang, L.; Liu, C.; Zhang, J.; Liu, S.; Cui, T. Electromagnetic metamaterials: From classical to quantum. Electromagn. Sci. 2023, 1, 0010051. [Google Scholar] [CrossRef]

- Kumar, P.; Ali, T.; Pai, M.M.M. Electromagnetic metamaterials: A new paradigm of antenna design. IEEE Access 2021, 9, 18722–18751. [Google Scholar] [CrossRef]

- Zhi, W.J.; Wang, L.F.; Hu, X.J. Recent advances in the effects of microwave radiation on brains. Mil. Med. Res. 2017, 4, 29. [Google Scholar] [CrossRef]

- Garcia, C.R.; Correa, J.; Espalin, D.; Barton, J.H.; Rumpf, R.C.; Wicker, R.; Gonzalez, V. 3D printing of anisotropic metamaterials. Prog. Electromagn. Res. Lett. 2012, 34, 75–82. [Google Scholar] [CrossRef]

- Driscoll, T.; Urzhumov, Y.; Landy, N.; Basov, D.; Smith, D.R. Dielectric metamaterials and composites in the age of 3D printing, and directional cloaking. In Proceedings of the 2013 7th International Congress on Advanced Electromagnetic Materials in Microwaves and Optics, Metamaterials 2013, Bordeaux, France, 16–19 September 2013; pp. 361–363. [Google Scholar]

- Lu, X.; Lee, Y.; Yang, S.; Hao, Y.; Ubic, R.; Evans, J.R.G.; Parini, C.G. Fabrication of electromagnetic crystals by extrusion freeforming. Metamaterials 2008, 2, 36–44. [Google Scholar] [CrossRef]

- Kronberger, R.; Soboll, P. New 3D printed microwave metamaterial absorbers with conductive printing materials. In Proceedings of the European Microwave Week 2016: “Microwaves Everywhere”, London, UK, 3–7 October 2016; pp. 596–599. [Google Scholar]

- Isakov, D.V.; Lei, Q.; Castles, F.; Stevens, C.J.; Grovenor, C.R.M.; Grant, P.S. 3D printed anisotropic dielectric composite with meta-material features. Mater. Des. 2016, 93, 423–430. [Google Scholar] [CrossRef]

- Cai, X.; Zhao, S.; Hu, M.; Xiao, J.; Zhang, N.; Yang, J. Water based fluidic radio frequency metamaterials. J. Appl. Phys. 2017, 122, 184101. [Google Scholar] [CrossRef]

- Yin, L.; Doyhamboure-Fouquet, J.; Tian, X.; Li, D. Design and characterization of radar absorbing structure based on gradient-refractive-index metamaterials. Compos. Part B Eng. 2018, 132, 178–187. [Google Scholar] [CrossRef]

- French, D.M.; Shiffler, D. High power microwave source with a three dimensional printed metamaterial slow-wave structure. Rev. Sci. Instrum. 2016, 87, 53308. [Google Scholar] [CrossRef]

- Tasolamprou, A.C.; Mentzaki, D.; Viskadourakis, Z.; Economou, E.N.; Kafesaki, M.; Kenanakis, G. Flexible 3D printed conductive metamaterial units for electromagnetic applications in microwaves. Materials 2020, 13, 3879. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.; Yin, J.Y. 3D-printed low-cost dielectric-resonator-based ultra-broadband microwave absorber using carbon-loaded Acrylonitrile Butadiene styrene polymer. Materials 2018, 10, 1249. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Feng, Z.; Huang, L.; Essa, K.; Bilotti, E.; Zhang, H.; Peijs, T.; Hao, L. Additive manufacturing high performance graphene-based composites: A review. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105483. [Google Scholar] [CrossRef]

- Rocha, V.G.; Saiz, E.; Tirichenko, I.S.; García-Tuñón, E. Direct ink writing advances in multi-material structures for a sustainable future. J. Mater. Chem. A 2020, 8, 15646–15657. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-material additive manufacturing of sustainable innovative materials and structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef] [PubMed]

- Tonouchi, M. Cutting-edge terahertz technology. Nat. Photonics 2007, 1, 97–105. [Google Scholar] [CrossRef]

- Kodama, C.H.; Coutu, R.A. THz Metamaterial Characterization Using THz-TDS. In Terahertz Spectroscopy—A Cutting Edge Technology; IntechOpen: London, UK, 2017. [Google Scholar]

- Secor, E.B. Principles of aerosol jet printing. Flex. Print. Electron. 2018, 3, 35002. [Google Scholar] [CrossRef]

- Santaniello, T.; Milani, P. Additive nano-manufacturing of 3D printed electronics using supersonic cluster beam deposition. In Frontiers of Nanoscience; Elsevier: Amsterdam, The Netherlands, 2020; Volume 15, pp. 313–333. [Google Scholar]

- Tenggara, A.P.; Park, S.J.; Yudistira, H.T.; Ahn, Y.H.; Byun, D. Fabrication of terahertz metamaterials using electrohydrodynamic jet printing for sensitive detection of yeast. J. Micromech. Microeng. 2017, 27, 35009. [Google Scholar] [CrossRef]

- Lee, D.; Sung, H.K.; Lim, S. Flexible subterahertz metamaterial absorber fabrication using inkjet printing technology. Appl. Phys. B Lasers Opt. 2016, 122, 206. [Google Scholar] [CrossRef]

- Murata, K.; Matsumoto, J.; Tezuka, A.; Matsuba, Y.; Yokoyama, H. Super-fine ink-jet printing: Toward the minimal manufacturing system. Microsyst. Technol. 2005, 12, 2–7. [Google Scholar] [CrossRef]

- Kashiwagi, K.; Xie, L.; Li, X.; Kageyama, T.; Miura, M.; Miyashita, H.; Kono, J.; Lee, S.-S. Inkjet-printed silver-nanoparticle THz metamaterial. In Proceedings of the 2016 41st International Conference on Infrared, Millimeter, and Terahertz waves (IRMMW-THz), Copenhagen, Denmark, 25–30 September 2016; pp. 1–2. [Google Scholar]

- Oakley, C.; Kaur, A.; Byford, J.A.; Chahal, P. Aerosol-jet printed quasi-optical terahertz filters. In Proceedings of the 2017 IEEE 67th Electronic Components and Technology Conference (ECTC), Lake Buena Vista, FL, USA, 30 May–2 June 2017; pp. 248–253. [Google Scholar]

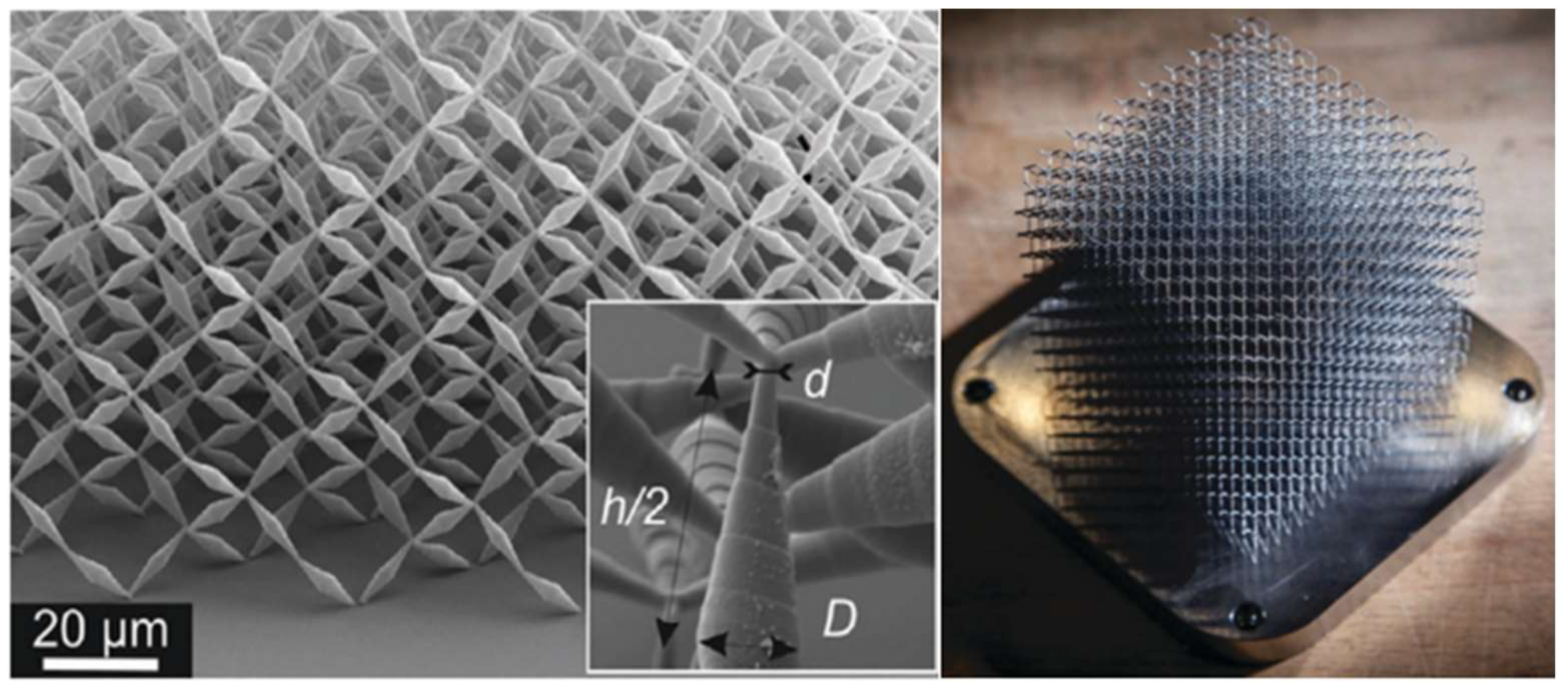

- Faraji Rad, Z.; Prewett, P.D.; Davies, G.J. High-resolution two-photon polymerization: The most versatile technique for the fabrication of microneedle arrays. Microsyst. Nanoeng. 2021, 7, 71. [Google Scholar] [CrossRef] [PubMed]

- Steinberg, C.; Papenheim, M.; Wang, S.; Scheer, H.-C. Complex 3D structures via hybrid processing of SU-8. Microelectron. Eng. 2016, 155, 14–18. [Google Scholar] [CrossRef]

- Lopez, C. Materials aspects of photonic crystals. Adv. Mater. 2003, 15, 1679–1704. [Google Scholar] [CrossRef]

- Özbay, E.; Tuttle, G.; Sigalas, M.; Soukoulis, C.M.; Ho, K.M. Defect structures in a layer-by-layer photonic band-gap crystal. Phys. Rev. B 1995, 51, 13961. [Google Scholar] [CrossRef]

- Li, J.-J.; Li, B.; Peng, Q.-M.; Zhou, J.; Li, L.-T. Fabrication and characterization of direct-written 3D TiO2 woodpile electromagnetic bandgap structures. Chin. Phys. B 2014, 23, 98104. [Google Scholar] [CrossRef]

- Kirihara, S.; Miyamoto, Y.; Kajiyama, K. Fabrication of Ceramic--Polymer Photonic Crystals by Stereolithography and Their Microwave Properties. J. Am. Ceram. Soc. 2002, 85, 1369–1371. [Google Scholar] [CrossRef]

- Kirihara, S. Stereolithography of ceramic components: Fabrication of photonic crystals with diamond structures for terahertz wave modulation. J. Ceram. Soc. Jpn. 2015, 123, 816–822. [Google Scholar] [CrossRef]

- Yin, H.; Kirihara, S.; Miyamoto, Y. Fabrication of ceramic photonic crystals with diamond structure for microwave applications. J. Am. Ceram. Soc. 2004, 87, 598–601. [Google Scholar] [CrossRef]

- Liang, Q.; Li, D.; Yang, G.; Han, H. Ultra-wide bandgap of gradient dielectric constant photonic crystal. Mater. Lett. 2012, 79, 48–50. [Google Scholar] [CrossRef]

- Wong, S.; Deubel, M.; Pérez-Willard, F.; John, S.; Ozin, G.A.; Wegener, M.; von Freymann, G. Direct laser writing of three-dimensional photonic crystals with a complete photonic bandgap in chalcogenide glasses. Adv. Mater. 2006, 18, 265–269. [Google Scholar] [CrossRef]

- Duan, X.-M.; Sun, H.-B.; Kaneko, K.; Kawata, S. Two-photon polymerization of metal ions doped acrylate monomers and oligomers for three-dimensional structure fabrication. Thin Solid Films 2004, 453, 518–521. [Google Scholar] [CrossRef]

- Xiong, Y.; Shepherd, S.; Tibbs, J.; Bacon, A.; Liu, W.; Akin, L.D.; Ayupova, T.; Bhaskar, S.; Cunningham, B.T. Photonic crystal enhanced fluorescence: A review on design strategies and applications. Micromachines 2023, 14, 668. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, R.P.; Ummethala, G.; Jaiswal, A.; Hawal, S.; Saxena, S.; Shukla, S. One-step, subwavelength patterning of plasmonic gratings in metal--polymer composites. RSC Adv. 2016, 6, 113457–113462. [Google Scholar] [CrossRef]

- Yang, L.; Wei, J.; Ma, Z.; Song, P.; Ma, J.; Zhao, Y.; Huang, Z.; Zhang, M.; Yang, F.; Wang, X. The fabrication of micro/nano structures by laser machining. Nanomaterials 2019, 9, 1789. [Google Scholar] [CrossRef]

- Kim, H.K.; Ling, K.; Kim, K.; Lim, S. Flexible inkjet-printed metamaterial absorber for coating a cylindrical object. Opt. Express 2015, 23, 5898. [Google Scholar] [CrossRef]

- Ling, K.; Yoo, M.; Su, W.; Kim, K.; Cook, B.; Tentzeris, M.M.; Lim, S. Microfluidic tunable inkjet-printed metamaterial absorber on paper. Opt. Express 2015, 23, 110–120. [Google Scholar] [CrossRef] [PubMed]

- Rudolph, S.M.; Grbic, A. A broadband three-dimensional isotropic NRI medium. In Proceedings of the 2010 IEEE Antennas and Propagation Society International Symposium, Toronto, ON, Canada, 11–17 July 2010; pp. 1–4. [Google Scholar]

- Fernandez, J.D.; De Coninck, J. Multiresolution layered manufacturing. Rapid Prototyp. J. 2019, 25, 87–94. [Google Scholar] [CrossRef]

- Takeyasu, N.; Tanaka, T.; Kawata, S. Fabrication of 3D metal/polymer microstructures by site-selective metal coating. Appl. Phys. A 2008, 90, 205–209. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, S.; Yang, J. Recent advances in graphene origami-enabled auxetic metamaterial structures. Eng. Struct. 2025, 333, 120203. [Google Scholar] [CrossRef]

- Joseph, A.; Mahesh, V.; Harursampath, D. On the application of additive manufacturing methods for auxetic structures: A review. Adv. Manuf. 2021, 9, 342–368. [Google Scholar] [CrossRef] [PubMed]

- Zadpoor, A.A. Mechanical performance of additively manufactured meta-biomaterials. Acta Biomater. 2019, 85, 41–59. [Google Scholar] [CrossRef] [PubMed]

- Mohsenizadeh, M.; Gasbarri, F.; Munther, M.; Beheshti, A.; Davami, K. Additively-manufactured lightweight Metamaterials for energy absorption. Mater. Des. 2018, 139, 521–530. [Google Scholar] [CrossRef]

- Zhang, L.; Song, B.; Liu, R.; Zhao, A.; Zhang, J.; Zhuo, L.; Tang, G.; Shi, Y. Effects of structural parameters on the Poisson’s ratio and compressive modulus of 2D pentamode structures fabricated by selective laser melting. Engineering 2020, 6, 56–67. [Google Scholar] [CrossRef]

- Hao, W.; Liu, J.; Kanwal, H. Compressive properties of cementitious composites reinforced by 3D printed PA 6 lattice. Polym. Test. 2023, 117, 107811. [Google Scholar] [CrossRef]

- Prajapati, M.J.; Kumar, A.; Lin, S.C.; Jeng, J.Y. Multi-material additive manufacturing with lightweight closed-cell foam-filled lattice structures for enhanced mechanical and functional properties. Addit. Manuf. 2022, 54, 102766. [Google Scholar] [CrossRef]

- Frenzel, T.; Kadic, M.; Wegener, M. Three-dimensional mechanical metamaterials with a twist. Science 2017, 358, 1072–1074. [Google Scholar] [CrossRef]

- Xue, Y.; Shao, Q.; Mu, J.; Ji, X.; Wang, X. Compressive mechanical behavior of additively manufactured 3D auxetic metamaterials with enhanced strength. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2023, 18, 2300226. [Google Scholar] [CrossRef]

- Li, X.; Yu, X.; Chua, J.W.; Lee, H.P.; Ding, J.; Zhai, W. Microlattice metamaterials with simultaneous superior acoustic and mechanical energy absorption. Small 2021, 17, 2100336. [Google Scholar] [CrossRef]

- Käfer, M.; Dohnal, F.; Goettgens, V.; Stajkovic, J.; Brunner, M.; Leichtfried, G. Experimental verification of additively manufactured stacked multi-wedge acoustic black holes in beams for low frequency. Mech. Syst. Signal Process. 2024, 208, 111065. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Q.; Wei, K. Additively manufactured multi-functional metamaterials: Low coefficient of thermal expansion and programmable Poisson’s ratio. Virtual Phys. Prototyp. 2024, 19, e2303714. [Google Scholar] [CrossRef]

- Tiwari, S.; Singh, A.K.; Dubey, A. Additively Manufactured Dielectric Reflectarray Antenna for Millimeter-Wave Satellite Communication. IEEE Antennas Wirel. Propag. Lett. 2024, 23, 1276–1280. [Google Scholar] [CrossRef]

- Kim, H.-G.; Hajra, S.; Lee, H.; Kim, N.; Kim, H.J. Additively Manufactured Mechanical Metamaterial-Based Pressure Sensor with Tunable Sensing Properties for Stance and Motion Analysis. Adv. Eng. Mater. 2023, 25, 2201499. [Google Scholar] [CrossRef]

- Schneider, J.; Kumar, S. Comparative performance evaluation of microarchitected lattices processed via SLS, MJ, and DLP 3D printing methods: Experimental investigation and modelling. J. Mater. Res. Technol. 2023, 26, 7182–7198. [Google Scholar] [CrossRef]

- Seng, Y.C.; Sridhar, I.; Wang, L.C.; Lim, G.K. Auxetic Composite Sandwich for Vibration Damping Through Axisymmetric Deformation. J. Compos. Sci. 2025, 9, 162. [Google Scholar] [CrossRef]

- Hmeidat, N.S.; Pack, R.C.; Talley, S.J.; Moore, R.B.; Compton, B.G. Mechanical anisotropy in polymer composites produced by material extrusion additive manufacturing. Addit. Manuf. 2020, 34, 101385. [Google Scholar] [CrossRef]

- Santos, F.A.; Rebelo, H.; Coutinho, M.; Sutherland, L.S.; Cismasiu, C.; Farina, I.; Fraternali, F. Low velocity impact response of 3D printed structures formed by cellular metamaterials and stiffening plates: PLA vs. PETg. Compos. Struct. 2021, 256, 113128. [Google Scholar] [CrossRef]

- Sa’ad, A.-W.; Ayeni, O.; Unukogbon, O.; Nwosu, O.; Imorame, I. Raising the Sleeping Giants: Restarting of Alpha & Beta Fields World-Class WRFM Collaboration. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 3–5 August 2020; SPE: Bellingham, WA, USA, 2020; p. D013S006R007. [Google Scholar]

- Ogbunude, B.; Obot, A.; Sa’ad, A.-W.; Maxwell-Amgbaduba, S.; Agbor, E.; Tafida, M.; Okereke, O.; Mude, J.; Gogo, O. Integrated Approach to Produced Water Disposal Management in a Brown Field: Safeguarding Production, Reducing Cost, Managing Deferment & Reducing HSSE Exposure. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 2–4 August 2021; SPE: Bellingham, WA, USA, 2021; p. D031S013R005. [Google Scholar]

- Sokollu, B.; Gulcan, O.; Konukseven, E.I. Mechanical properties comparison of strut-based and triply periodic minimal surface lattice structures produced by electron beam melting. Addit. Manuf. 2022, 60, 103199. [Google Scholar] [CrossRef]

- Wu, S.; Luo, Z.; Li, Z.; Liu, S.; Zhang, L.-C. Topological design of pentamode metamaterials with additive manufacturing. Comput. Methods Appl. Mech. Eng. 2021, 377, 113708. [Google Scholar] [CrossRef]

- Cheng, X.; Zhang, Y.; Ren, X.; Han, D.; Jiang, W.; Zhang, X.G.; Luo, H.C.; Xie, Y.M. Design and mechanical characteristics of auxetic metamaterial with tunable stiffness. Int. J. Mech. Sci. 2022, 223, 107286. [Google Scholar] [CrossRef]

- Acuna, D.; Gutiérrez, F.; Silva, R.; Palza, H.; Nunez, A.S.; Düring, G. A three step recipe for designing auxetic materials on demand. Commun. Phys. 2022, 5, 113. [Google Scholar] [CrossRef]

- Elipe, J.C.Á.; Lantada, A.D. Comparative study of auxetic geometries by means of computer-aided design and engineering. Smart Mater. Struct. 2012, 21, 105004. [Google Scholar] [CrossRef]

- Schwerdtfeger, J.; Schury, F.; Stingl, M.; Wein, F.; Singer, R.F.; Körner, C. Mechanical characterisation of a periodic auxetic structure produced by SEBM. Phys. Status Solidi 2012, 249, 1347–1352. [Google Scholar] [CrossRef]

- Yang, L.; Harrysson, O.; West, H.; Cormier, D. Mechanical properties of 3D re-entrant honeycomb auxetic structures realized via additive manufacturing. Int. J. Solids Struct. 2015, 69, 475–490. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Krstulović-Opara, L.; Ren, Z. Mechanical characterisation of auxetic cellular structures built from inverted tetrapods. Compos. Struct. 2018, 196, 96–107. [Google Scholar] [CrossRef]

- Li, S.; Hassanin, H.; Attallah, M.M.; Adkins, N.J.E.; Essa, K. The development of TiNi-based negative Poisson’s ratio structure using selective laser melting. Acta Mater. 2016, 105, 75–83. [Google Scholar] [CrossRef]

- Ingrole, A.; Hao, A.; Liang, R. Design and modeling of auxetic and hybrid honeycomb structures for in-plane property enhancement. Mater. Des. 2017, 117, 72–83. [Google Scholar] [CrossRef]

- Bückmann, T.; Schittny, R.; Thiel, M.; Kadic, M.; Milton, G.W.; Wegener, M. On three-dimensional dilational elastic metamaterials. New J. Phys. 2014, 16, 33032. [Google Scholar] [CrossRef]

- Xiong, X.; Xue, Z.-H.; Meng, C.; Jiang, S.-C.; Hu, Y.-H.; Peng, R.-W.; Wang, M. Polarization-dependent perfect absorbers/reflectors based on a three-dimensional metamaterial. Phys. Rev. B—Condensed Matter Mater. Phys. 2013, 88, 115105. [Google Scholar] [CrossRef]

- Ali, M.N.; Busfield, J.J.C.; Rehman, I.U. Auxetic oesophageal stents: Structure and mechanical properties. J. Mater. Sci. Mater. Med. 2014, 25, 527–553. [Google Scholar] [CrossRef]

- Li, T.; Hu, X.; Chen, Y.; Wang, L. Harnessing out-of-plane deformation to design 3D architected lattice metamaterials with tunable Poisson’s ratio. Sci. Rep. 2017, 7, 8949. [Google Scholar] [CrossRef]

- Geng, L.C.; Ruan, X.L.; Wu, W.W.; Xia, R.; Fang, D.N. Mechanical properties of selective laser sintering (SLS) additive manufactured chiral auxetic cylindrical stent. Exp. Mech. 2019, 59, 913–925. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, L.; Li, J.; Tian, S.; Zhang, M.; Fan, Y. A novel auxetic structure based bone screw design: Tensile mechanical characterization and pullout fixation strength evaluation. Mater. Des. 2020, 188, 108424. [Google Scholar] [CrossRef]

- Vijayavenkataraman, S.; Gopinath, A.; Lu, W.F. A new design of 3D-printed orthopedic bone plates with auxetic structures to mitigate stress shielding and improve intra-operative bending. Bio-Design Manuf. 2020, 3, 98–108. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, Y. 3D printed auxetic mechanical metamaterial with chiral cells and re-entrant cores. Sci. Rep. 2018, 8, 2397. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Chang, Y.H.; Chen, Y.W.; Zhang, C.; Wang, B. Designable dual-material auxetic metamaterials using three-dimensional printing. Mater. Des. 2015, 67, 159–164. [Google Scholar] [CrossRef]

- Saxena, K.K.; Das, R.; Calius, E.P. Three decades of auxetics research- materials with negative Poisson’s ratio: A review. Adv. Eng. Mater. 2016, 18, 1847–1870. [Google Scholar] [CrossRef]

- Khaghani, O.; Mostofinejad, D.; Abtahi, S.M. Auxetic structures in civil engineering applications: Experimental (by 3D printing) and numerical investigation of mechanical behavior. Results Mater. 2024, 21, 100528. [Google Scholar] [CrossRef]

- Zadpoor, A.A. Mechanical meta-materials. Mater. Horiz. 2016, 3, 371–381. [Google Scholar] [CrossRef]

- Kadic, M.; Bückmann, T.; Schittny, R.; Gumbsch, P.; Wegener, M. Pentamode metamaterials with independently tailored bulk modulus and mass density. Phys. Rev. Appl. 2014, 2, 54007. [Google Scholar] [CrossRef]

- Bückmann, T.; Thiel, M.; Kadic, M.; Schittny, R.; Wegener, M. An elasto-mechanical unfeelability cloak made of pentamode metamaterials. Nat. Commun. 2014, 5, 4130. [Google Scholar] [CrossRef]

- Amendola, A.; Smith, C.J.; Goodall, R.; Auricchio, F.; Feo, L.; Benzoni, G.; Fraternali, F. Experimental response of additively manufactured metallic pentamode materials confined between stiffening plates. Compos. Struct. 2016, 142, 254–262. [Google Scholar] [CrossRef]

- Hedayati, R.; Ahmadi, S.M.; Lietaert, K.; Pouran, B.; Li, Y.; Weinans, H.; Rans, C.D.; Zadpoor, A.A. Isolated and modulated effects of topology and material type on the mechanical properties of additively manufactured porous biomaterials. J. Mech. Behav. Biomed. Mater. 2018, 79, 254–263. [Google Scholar] [CrossRef]

- Zhang, X.A.; Dai, B.; Xu, Z.; Chang, C.-H. Sculpting asymmetric, hollow-core, three-dimensional nanostructures using colloidal particles. Small 2015, 11, 1285–1292. [Google Scholar] [CrossRef] [PubMed]

- Meza, L.R. Design, Fabrication, and Mechanical Property Analysis of 3D Nanoarchitected Materials Copyright Page; California Institute of Technology: Pasadena, CA, USA, 2016; Volume 2016. [Google Scholar]

- Zhu, C.; Han, T.Y.-J.; Duoss, E.B.; Golobic, A.M.; Kuntz, J.D.; Spadaccini, C.M.; Worsley, M.A. Highly compressible 3D periodic graphene aerogel microlattices. Nat. Commun. 2015, 6, 6962. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Moon, J.J.; West, J.L. Three-dimensional micropatterning of bioactive hydrogels via two-photon laser scanning photolithography for guided 3D cell migration. Biomaterials 2008, 29, 2962–2968. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Smith, W.; Jackson, J.; Moran, B.; Cui, H.; Chen, D.; Ye, J.; Fang, N.; Rodriguez, N.; Weisgraber, T.; et al. Multiscale metallic metamaterials. Nat. Mater. 2016, 15, 1100–1106. [Google Scholar] [CrossRef] [PubMed]

- Jacobsen, A.J.; Mahoney, S.; Carter, W.B.; Nutt, S. Vitreous carbon micro-lattice structures. Carbon N. Y. 2011, 49, 1025–1032. [Google Scholar] [CrossRef]

- Saleh, M.S.; Hu, C.; Brenneman, J.; Al Mutairi, A.M.; Panat, R. 3D printed three-dimensional metallic microlattices with controlled and tunable mechanical properties. Addit. Manuf. 2021, 39, 101856. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, Q. Highly-stretchable 3D-architected mechanical metamaterials. Sci. Rep. 2016, 6, 34147. [Google Scholar] [CrossRef] [PubMed]

- Clausen, A.; Wang, F.; Jensen, J.S.; Sigmund, O.; Lewis, J.A. Topology optimized architectures with programmable Poisson’s ratio over large deformations. Adv. Mater. 2015, 27, 5523–5527. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Guerra Silva, R. Fused filament fabrication of cellular, lattice and porous mechanical metamaterials: A review. Virtual Phys. Prototyp. 2023, 18, e2224300. [Google Scholar] [CrossRef]

- Liao, G.; Luan, C.; Wang, Z.; Liu, J.; Yao, X.; Fu, J. Acoustic metamaterials: A review of theories, structures, fabrication approaches, and applications. Adv. Mater. Technol. 2021, 6, 2000787. [Google Scholar] [CrossRef]

- Ma, G.; Sheng, P. Acoustic metamaterials: From local resonances to broad horizons. Sci. Adv. 2016, 2, e1501595. [Google Scholar] [CrossRef]

- Lee, D.; Nguyen, D.M.; Rho, J. Acoustic wave science realized by metamaterials. Nano Converg. 2017, 4, 3. [Google Scholar] [CrossRef] [PubMed]

- Ramachandran, V.P.; Rajagopal, P. Tunable acoustic superscatterer composed of magnetorheological fluid and maze-like metasurface. J. Sound Vib. 2024, 574, 118184. [Google Scholar] [CrossRef]

- Gardiner, A.; Daly, P.; Domingo-Roca, R.; Windmill, J.F.C.; Feeney, A.; Jackson-Camargo, J.C. Additive manufacture of small-scale metamaterial structures for acoustic and ultrasonic applications. Micromachines 2021, 12, 634. [Google Scholar] [CrossRef] [PubMed]

- Suárez, L.; del Mar Espinosa, M. Assessment on the use of additive manufacturing technologies for acoustic applications. Int. J. Adv. Manuf. Technol. 2020, 109, 2691–2705. [Google Scholar] [CrossRef]

- Mareze, P.H.; Silva, O.M.; Fonseca, W.D.; Brandão, E.; Godinho, L. Optimization of acoustic porous material absorbers modeled as rigid multiple microducts networks: Metamaterial design using additive manufacturing. J. Sound Vib. 2025, 596, 118739. [Google Scholar] [CrossRef]

- Li, Z.; Zhai, W.; Li, X.; Yu, X.; Guo, Z.; Wang, Z. Additively manufactured dual-functional metamaterials with customisable mechanical and sound-absorbing properties. Virtual Phys. Prototyp. 2022, 17, 864–880. [Google Scholar] [CrossRef]

- Choi, C.; Bansal, S.; Münzenrieder, N.; Subramanian, S. Fabricating and assembling acoustic metamaterials and phononic crystals. Adv. Eng. Mater. 2021, 23, 2000988. [Google Scholar] [CrossRef]

- Noronha, J.; Dash, J.; Rogers, J.; Leary, M.; Brandt, M.; Qian, M. Titanium Multi-Topology Metamaterials with Exceptional Strength. Adv. Mater. 2024, 36, 2308715. [Google Scholar] [CrossRef]

- Ross, E.P.; Figueroa-Ibrahim, K.M.; Morris, S.C.; Sutliff, D.L.; Bennett, G.J. Evaluating an Additive Manufactured Acoustic Metamaterial Using the Advanced Noise Control Fan. AIAA J. 2024, 62, 2783–2799. [Google Scholar] [CrossRef]

- Dubey, D.; Singh, S.P.; Behera, B.K. A review on recent advancements in additive manufacturing techniques. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 09544089241275860. [Google Scholar] [CrossRef]

- Monfared, V.; Bakhsheshi-Rad, H.R.; Ramakrishna, S.; Razzaghi, M.; Berto, F. A brief review on additive manufacturing of polymeric composites and nanocomposites. Micromachines 2021, 12, 704. [Google Scholar] [CrossRef] [PubMed]

- Ma, F.; Huang, Z.; Liu, C.; Wu, J.H. Acoustic focusing and imaging via phononic crystal and acoustic metamaterials. J. Appl. Phys. 2022, 131, 011103. [Google Scholar] [CrossRef]

- Li, J.; Fok, L.; Yin, X.; Bartal, G.; Zhang, X. Experimental demonstration of an acoustic magnifying hyperlens. Nat. Mater. 2009, 8, 931–934. [Google Scholar] [CrossRef]

- Zhu, J.; Christensen, J.; Jung, J.; Martin-Moreno, L.; Yin, X.; Fok, L.; Zhang, X.; Garcia-Vidal, F.J. A holey-structured metamaterial for acoustic deep-subwavelength imaging. Nat. Phys. 2011, 7, 52–55. [Google Scholar] [CrossRef]

- Gorshkov, V.N.; Bereznykov, O.V.; Boiger, G.K.; Sareh, P.; Fallah, A.S. Acoustic metamaterials with controllable bandgap gates based on magnetorheological elastomers. Int. J. Mech. Sci. 2023, 238, 107829. [Google Scholar] [CrossRef]

- Krushynska, A.O.; Torrent, D.; Aragón, A.M.; Ardito, R.; Bilal, O.R.; Bonello, B.; Bosia, F.; Chen, Y.; Christensen, J.; Colombi, A.; et al. Emerging topics in nanophononics and elastic, acoustic, and mechanical metamaterials: An overview. Nanophotonics 2023, 12, 659–686. [Google Scholar] [CrossRef]

- Omrani, E.M.; Nazari, F. Magnetically adjustable AND/XOR logic gates using Terfenol-D in phononic crystal. Sci. Rep. 2025, 15, 12169. [Google Scholar] [CrossRef] [PubMed]

- Suresh, P.; Sreedhar, I.; Vaidhiswaran, R.; Venugopal, A. A comprehensive review on process and engineering aspects of pharmaceutical wet granulation. Chem. Eng. J. 2017, 328, 785–815. [Google Scholar] [CrossRef]

- Ramos-Grez, J.; Sen, M.; Ramos-Cahis, M. Theoretical study of the interactions between vibrations of large numbers of FDM 3D printers. Prog. Addit. Manuf. 2024, 9, 135–149. [Google Scholar] [CrossRef]

- Yang, W.; Bai, X.; Zhu, W.; Kiran, R.; An, J.; Chua, C.K.; Zhou, K. 3D printing of polymeric multi-layer micro-perforated panels for tunable wideband sound absorption. Polymers 2020, 12, 360. [Google Scholar] [CrossRef]

- D’Alessandro, L.; Belloni, E.; Ardito, R.; Corigliano, A.; Braghin, F. Modeling and experimental verification of an ultra-wide bandgap in 3D phononic crystal. Appl. Phys. Lett. 2016, 109, 221907. [Google Scholar] [CrossRef]

- Zhang, Z. A review on additive manufacturing of wave controlling metamaterial. Int. J. Adv. Manuf. Technol. 2023, 124, 647–680. [Google Scholar] [CrossRef]

- Laureti, S.; Hutchins, D.A.; Davis, L.A.J.; Leigh, S.J.; Ricci, M. High-resolution acoustic imaging at low frequencies using 3D-printed metamaterials. AIP Adv. 2016, 6, 121701. [Google Scholar] [CrossRef]

- Wormser, M.; Warmuth, F.; Körner, C. Evolution of full phononic band gaps in periodic cellular structures. Appl. Phys. A 2017, 123, 661. [Google Scholar] [CrossRef]

- Wormser, M.; Wein, F.; Stingl, M.; Körner, C. Design and additive manufacturing of 3D phononic band gap structures based on gradient based optimization. Materials 2017, 10, 1125. [Google Scholar] [CrossRef]

- Mahesh, K.; Mini, R.S. Helmholtz resonator based metamaterials for sound manipulation. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; Volume 1355, p. 12031. [Google Scholar]

- Domingo-Roca, R.; Feeney, A.; Windmill, J.F.C.; Jackson-Camargo, J.C. On the directionality of membrane coupled Helmholtz resonators under open air conditions. Sci. Rep. 2024, 14, 27771. [Google Scholar] [CrossRef] [PubMed]

- Mir, F.; Mandal, D.; Banerjee, S. Metamaterials for acoustic noise filtering and energy harvesting. Sensors 2023, 23, 4227. [Google Scholar] [CrossRef] [PubMed]

- Reynolds, B.W.; Fee, C.J.; Morison, K.R.; Holland, D.J. Characterisation of heat transfer within 3D printed TPMS heat exchangers. Int. J. Heat Mass Transf. 2023, 212, 124264. [Google Scholar] [CrossRef]

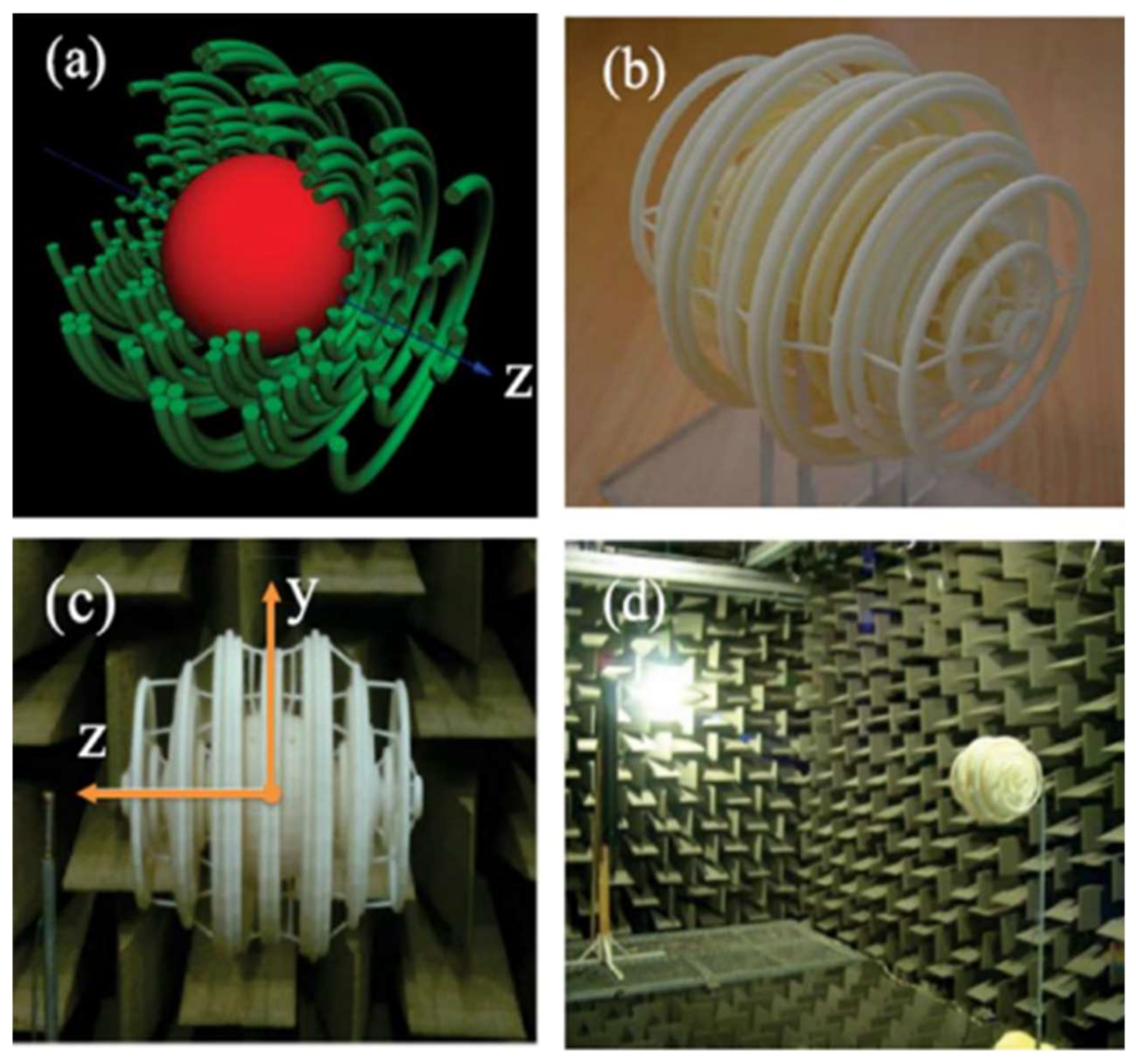

- Sanchis, L.; García-Chocano, V.M.; Llopis-Pontiveros, R.; Climente, A.; Martínez-Pastor, J.; Cervera, F.; Sánchez-Dehesa, J. Three-Dimensional Axisymmetric Cloak Based on the Cancellation of Acoustic Scattering from a Sphere. Phys. Rev. Lett. 2013, 110, 124301. [Google Scholar] [CrossRef] [PubMed]

- Casarini, C.; Tiller, B.; Mineo, C.; MacLeod, C.N.; Windmill, J.F.C.; Jackson, J.C. Enhancing the sound absorption of small-scale 3-D printed acoustic metamaterials based on Helmholtz resonators. IEEE Sens. J. 2018, 18, 7949–7955. [Google Scholar] [CrossRef]

- Oudich, M.; Gerard, N.J.R.K.; Deng, Y.; Jing, Y. Tailoring structure-borne sound through bandgap engineering in phononic crystals and metamaterials: A comprehensive review. Adv. Funct. Mater. 2023, 33, 2206309. [Google Scholar] [CrossRef]

- Ba, A.; Lavie, A.; Leblanc, A. Soft 3d printed membrane type-acoustic metamaterials. In Proceedings of the 23rd International Congress on Sound and Vibration, Athens, Greece, 10–14 July 2016. [Google Scholar]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Reeves, J.B.; Jayne, R.K.; Barrett, L.; White, A.E.; Bishop, D.J. Fabrication of multi-material 3D structures by the integration of direct laser writing and MEMS stencil patterning. Nanoscale 2019, 11, 3261–3267. [Google Scholar] [CrossRef]

- Wang, X.; Sun, P.; Gu, X.; Xu, S.; Luo, X.; Huang, Z. Industrial-scale manufactured acoustic metamaterials for multi-bandgap sound reduction. Int. J. Mech. Sci. 2025, 293, 110184. [Google Scholar] [CrossRef]

- Matlack, K.H.; Krödel, S.; Bauhofer, A.; Daraio, C. Advanced structured composites as novel phononic crystals and acoustic metamaterials. In Mechanics of Composite and Multi-Functional Materials, Volume 7, Proceedings of the 2015 Annual Conference on Experimental and Applied Mechanics, Costa Mesa, CA, USA, 8–11 June 2016; Springer: Cham, Switzerland; pp. 155–162.

- Qureshi, A.; Li, B.; Tan, K.T. Numerical investigation of band gaps in 3D printed cantilever-in-mass metamaterials. Sci. Rep. 2016, 6, 28314. [Google Scholar] [CrossRef]

- Raza, I.M.; Iannucci, L.; Curtis, P.T. Additive Manufacturing of Locally Resonant Composite Metamaterials; Imperial College London: London, UK, 2016. [Google Scholar]

- Yu, K.; Fang, N.X.; Huang, G.; Wang, Q. Magnetoactive acoustic metamaterials. Adv. Mater. 2018, 30, 1706348. [Google Scholar] [CrossRef] [PubMed]

- Pillarisetti, L.S.S.; Giraldo Guzman, D.; Keirn, J.; Sridhar, S.; Lissenden, C.; Frecker, M.; Shokouhi, P. Frequency bandgap enhancement in locally resonant metasurfaces for S0 Lamb wave mode using topology-optimized resonators. J. Appl. Phys. 2025, 137, 043104. [Google Scholar] [CrossRef]

- Fu, X.F.; Li, G.Y.; Lu, M.H.; Lu, G.; Huang, X. A 3D space coiling metamaterial with isotropic negative acoustic properties. Appl. Phys. Lett. 2017, 111, 251904. [Google Scholar] [CrossRef]

- Xie, Y.; Fu, Y.; Jia, Z.; Li, J.; Shen, C.; Xu, Y.; Chen, H.; Cummer, S.A. Acoustic imaging with metamaterial Luneburg lenses. Sci. Rep. 2018, 8, 16188. [Google Scholar] [CrossRef] [PubMed]

- Esfandiari, M.; Zhu, J.; Yang, Y. Additively manufactured metasurfaces and metamaterials: Designs, fabrications, and applications from microwave to photonics. APL Photonics 2025, 10, 041101. [Google Scholar] [CrossRef]

- Feng, Y.; Liang, M.; Zhao, X.; You, R. Fabrication and modulation of flexible electromagnetic metamaterials. Microsystems Nanoeng. 2025, 11, 14. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, A.; Akram, T.; Shenggui, C.; Chen, H. Revolutionizing manufacturing: A review of 4D printing materials, stimuli, and cutting-edge applications. Compos. Part B Eng. 2023, 266, 110952. [Google Scholar] [CrossRef]

- Kshirsagar, M.; Ambike, S.D.; Prakash, N.J.; Kandasubramanian, B.; Deshpande, P. Origami engineering: Creating dynamic functional materials through folded structures. Hybrid Adv. 2023, 4, 100092. [Google Scholar] [CrossRef]

- Antezana, P.E.; Municoy, S.; Ostapchuk, G.; Catalano, P.N.; Hardy, J.G.; Evelson, P.A.; Orive, G.; Desimone, M.F. 4D printing: The development of responsive materials using 3D-printing technology. Pharmaceutics 2023, 15, 2743. [Google Scholar] [CrossRef]

- Salvi, D.; Ucciardello, N.; Vesco, S. Multi-Head MEX 3D Printing of Self-Recoverable Joule-Heating-Based Shape Memory Polymeric Components. Arab. J. Sci. Eng. 2025, 1–15. [Google Scholar] [CrossRef]

- Basar, G.; Der, O.; Guvenc, M.A. AI-powered hybrid metaheuristic optimization for predicting surface roughness and kerf width in CO2 laser cutting of 3D-printed PLA-CF composites. J. Thermoplast. Compos. Mater. 2025, 38(7), 2688–2717. [Google Scholar] [CrossRef]

- Sood, A.K. Study on Parametric Optimization of Fused Deposition Modelling (FDM) Process. Ph.D. Thesis, National Institute of Technology, Rourkela, Odisha, India, 2011. [Google Scholar]

- Saad, M.S.; Mohd Nor, A.; Abd Rahim, I.; Syahruddin, M.A.; Mat Darus, I.Z. Optimization of FDM process parameters to minimize surface roughness with integrated artificial neural network model and symbiotic organism search. Neural Comput. Appl. 2022, 34, 17423–17439. [Google Scholar] [CrossRef]

- Vesco, S.; Salvi, D. Fuzzy skin in fused filament fabrication: Enhancing morphology, wettability, and friction through a full-factorial experimental plan. Prog. Addit. Manuf. 2025, 1–25. [Google Scholar] [CrossRef]

| Manufacturing Method | Resolution Range | Material Compatibility | Processing Speed | Cost Level | Scalability | Typical Applications | Key Advantages | Primary Limitations |

|---|---|---|---|---|---|---|---|---|

| Traditional Lithography | 10 nm–1 μm | Photoresists, limited metals | Very Slow (hours/cm2) | Very High | Very Poor | Research prototypes, 2D structures | Ultra-high precision, established process | 2D limitation, expensive equipment |

| Material Extrusion (FDM/FFF) | 100–300 μm | Thermoplastics, composites, metals | Fast (10–100 cm3/h) | Low | Excellent | Large components, rapid prototyping | Cost-effective, wide materials, scalable | Lower resolution, layer adhesion |

| Vat Photopolymerization (SLA/DLP) | 25–100 μm | Photopolymers, ceramics (limited) | Medium (5–50 cm3/h) | Medium | Good | Complex geometries, detailed parts | High accuracy, smooth surfaces | Material limitations, post-processing |

| Powder Bed Fusion (SLM/DMLS) | 20–100 μm | Metals, alloys, ceramics | Medium (2–30 cm3/h) | High | Good | Aerospace, medical implants | Strong materials, design freedom | High cost, support structures |

| Multiphoton Polymerization (MPP) | 50–200 μm | Specialized photoresists | Very Slow (μm3/h) | Very High | Very Poor | Nano-applications, research | Ultra-high resolution, 3D capability | Very slow, expensive, limited materials |

| Inkjet 3D Printing | 50–200 μm | Polymers, metals, ceramics | Fast (20–200 cm3/h) | Medium | Excellent | Multimaterial parts, electronics | Multimaterial capability, speed | Material viscosity limits, resolution |

| Aerosol Jet Printing | 10–300 μm | Conductive inks, polymers | Fast (7 cm2/min) | Medium | Good | Electronics, sensors, THz devices | Conformal printing, fine features | Material compatibility, equipment |

| Electron Beam Melting (EBM) | 50–200 μm | Reactive metals, alloys | Medium (5–40 cm3/h) | Very High | Good | Biomedical, aerospace | Vacuum processing, reactive materials | Very high cost, limited materials |

| Binder Jetting | 100–400 μm | Metals, ceramics, sand | Fast (50–500 cm3/h) | Medium | Excellent | Large parts, casting patterns | High speed, large builds | Post-processing required, limited strength |

| Direct Energy Deposition (DED) | 200–2000 μm | Metals, alloys | Medium (10–100 cm3/h) | High | Good | Repair, large components | Material flexibility, repair capability | Lower resolution, rough surfaces |

| Material | Functionality | AM Processes/Production Method | Performance | Targeted Application | Ref. |

|---|---|---|---|---|---|

| Acrylonitrile butadiene styrene (ABS) | Multimeter-wave waveguide | Fused deposition modeling (FDM) | Impressive antenna aperture efficiency | Satellite communication | [123] |

| Copper–graphene composite | Electromagnetic shielding | Stereolithography (SLA) | Improved electrical conductivity | Aerospace, automotive | [124] |

| Silicon carbide (SiC) | Dielectric properties | Powder bed fusion (PBF) | High dielectric constant | Antennas, radar systems | [125] |

| Aluminum-doped zinc oxide | Transparent conductive coating | Atomic layer deposition (ALD) | High optical transmittance and conductivity | Optical sensors | [126] |

| Ferrite-based composites | Magnetic wave absorption | Selective laser melting (SLM) | Strong magnetic/electromagnetic response | Waveguides, stealth technology | [127] |

| TiO2-doped polymers | High refractive index | 3D printing | Improve light manipulation | Lens fabrication | [126] |

| Graphene | Plasmonic waveguides | Chemical Vapor deposition (CVD) | Enhanced plasmonic resonance | Optical communication | [128] |

| Silver nanowires | Flexible electronics | Inkjet printing | Excellent conductivity and flexibility | Wearable device | [129] |

| Iron oxide nanoparticles | Magnetic resonance imaging (MRI) | 3D printing | Enhanced imaging quality | Biomedical Imagine | [130] |

| Material | Functionality | AM Process/Production Method | Performance | Targeted Application | Ref. |

|---|---|---|---|---|---|

| Epoxy resin | Energy absorption | Stereolithography (SLA) | Lightweight, excellent recovery after 70% strain | Airplanes, trucks, battery electrodes | [176] |

| Low-melting-point alloy (LMPA) | Tunable energy absorption | 3D-printed with PVA | Dynamic performance | Reusable energy absorption | [177] |

| Epoxy resin | Negative Poisson’s ratio | Multimaterial 3D printing | Enhanced mechanical properties | Flexible armor, actuators | [178] |

| Ti-6Al-4V | Vanishing shear modulus | Selective laser melting (SLM) | Improved load bearing | Elastic absorbers, cloaking | [179] |

| Polyamide 6 (PA6) | Property tuning | Multijet fusion (MJF) | Improved mechanical properties | Energy conservation | [180] |

| Polyurethane (PU) | Enhanced mechanics | Fused filament fabrication (FFF) | Higher stiffness, energy dissipation | Protective equipment | [181] |

| PEGDA | Twistable compression | 3D laser micro printer | >2% twist per axial strain | Cloaking Structure | [182] |

| Polylactide (PLA) | Enhanced strength | Selective laser melting (SLM) | Better mechanical properties | Biomedical | [183] |

| Carbon nanotube (CNT) composites | Energy absorption | Selective laser sintering (SLS) | Superior mechanical properties | Aerospace, military | [184] |

| Nickle–titanium (Ni-Ti) alloy | Shape memory | Selective laser melting (SLM) | Reversible deformation | Smart devices | [185] |

| Titanium grade 5 allow (Ti-6Al-4V) | Dynamic behavior | Selective laser melting (SLM) | Higher failure strain and toughness | Energy production, aerospace | [186] |

| Thermoplastic polyurethane (TPU) | Tunable sensing | Fused deposition modeling (FDM) | Wide sensing range and higher sensitivity | Wearable applications | [187] |

| Material | Functionality | AM Processes/Production Method | Performance | Targeted Application | Ref. |

|---|---|---|---|---|---|

| Magnetorheological fluid (MRF) | Modulated acoustic super scatterer | Numerical representation in COMSOL | Superscatterer performs tunability at low frequency | Autonomous underwater vehicles (AUVs), submersible vehicles | [232] |

| Silicon-based gel | Customized acoustic impedance | Multimaterials 3D printing | Tunable sound reflection and absorption | Biomedical ultrasound devices | [233] |

| Kevlar | Impact sound dampening | Resin infusion | High resistance to sound transmission | Ballistic shields | [234] |

| Nylon composite | Soundproofing panels | Fused deposition modeling (FDM) | Durable with effective noise cancelation | Industrial equipment | [235] |

| Thermoplastic polyurethane (TPU) | Acoustic energy absorption | Selective laser sintering (SLS) | Excellent sound absorption | Protective headgear | [236] |

| Polypropylene | Broadband noise attenuation | Fused deposition modeling (FDM) | High noise suppression | HVAC systems | [237] |

| Titanium alloy | Sound wave scattering | Laser Powder bed fusion (LPBF) | Improved acoustic cloaking | Military submarines | [238] |

| Silicon rubber | Tunable acoustic impedance | Multimaterials 3D printing | Adjustable sound reflection | Architectural acoustic | [239] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subeshan, B.; Hamzat, A.K.; Asmatulu, E. Fabricating Three-Dimensional Metamaterials Using Additive Manufacturing: An Overview. J. Manuf. Mater. Process. 2025, 9, 343. https://doi.org/10.3390/jmmp9100343

Subeshan B, Hamzat AK, Asmatulu E. Fabricating Three-Dimensional Metamaterials Using Additive Manufacturing: An Overview. Journal of Manufacturing and Materials Processing. 2025; 9(10):343. https://doi.org/10.3390/jmmp9100343

Chicago/Turabian StyleSubeshan, Balakrishnan, Abdulhammed K. Hamzat, and Eylem Asmatulu. 2025. "Fabricating Three-Dimensional Metamaterials Using Additive Manufacturing: An Overview" Journal of Manufacturing and Materials Processing 9, no. 10: 343. https://doi.org/10.3390/jmmp9100343

APA StyleSubeshan, B., Hamzat, A. K., & Asmatulu, E. (2025). Fabricating Three-Dimensional Metamaterials Using Additive Manufacturing: An Overview. Journal of Manufacturing and Materials Processing, 9(10), 343. https://doi.org/10.3390/jmmp9100343