Introduction of Functional Elements with Double-Sided Self-Pierce Riveting

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Selection and Equipment

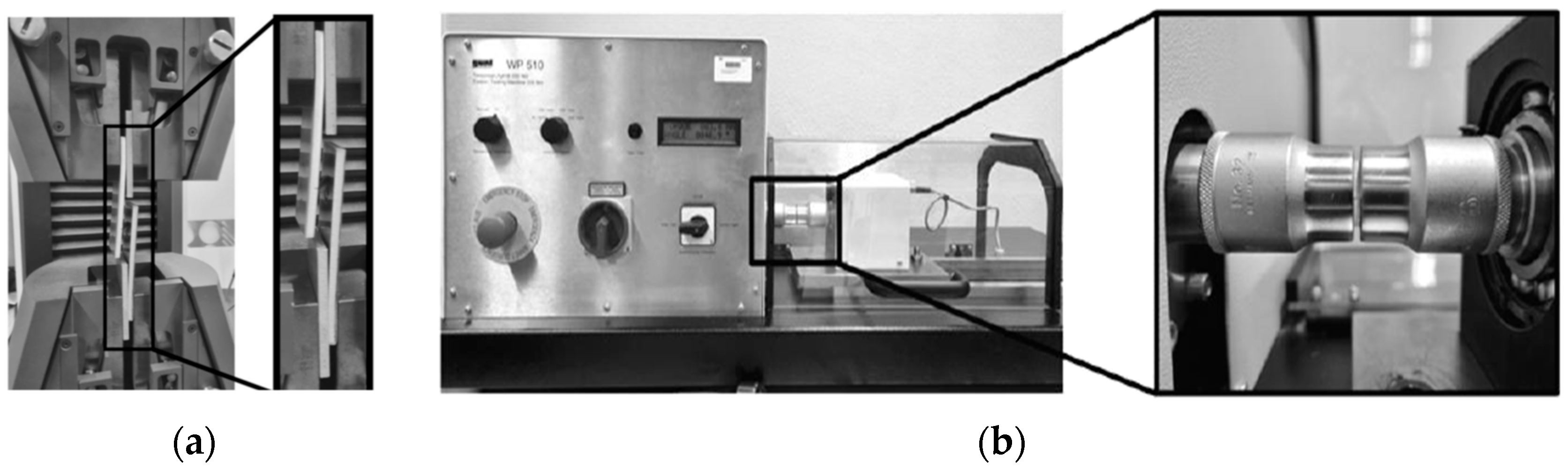

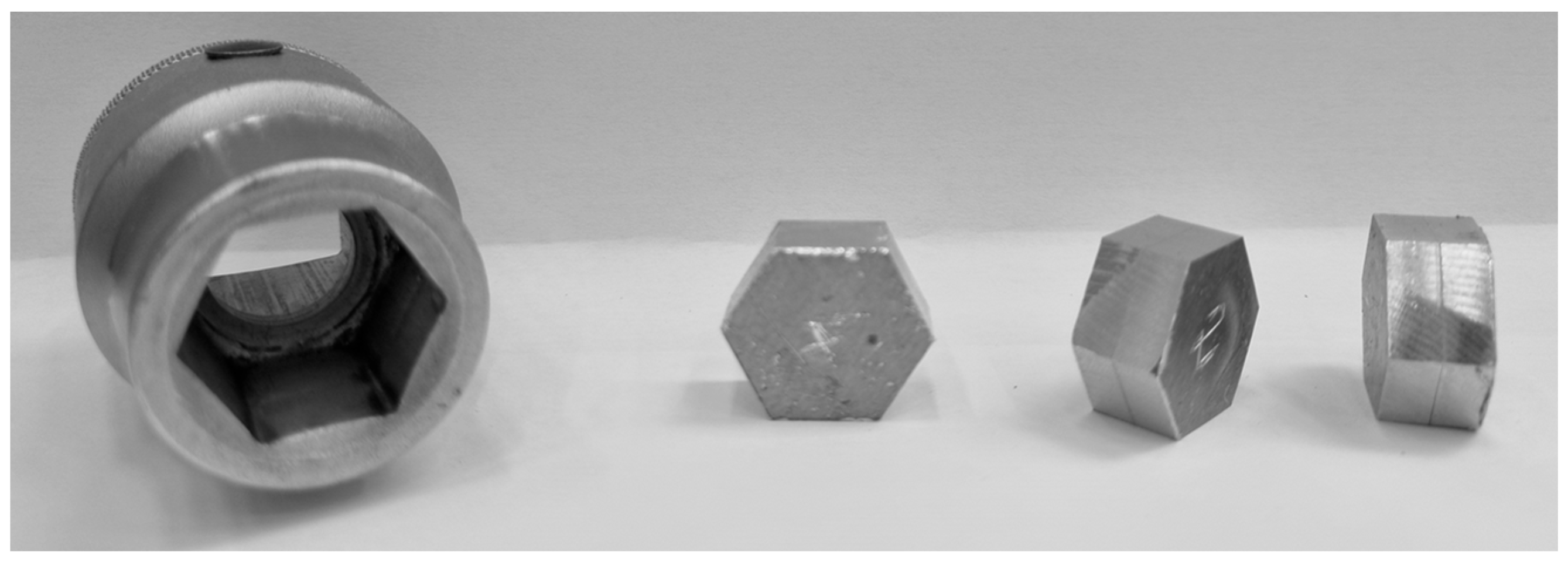

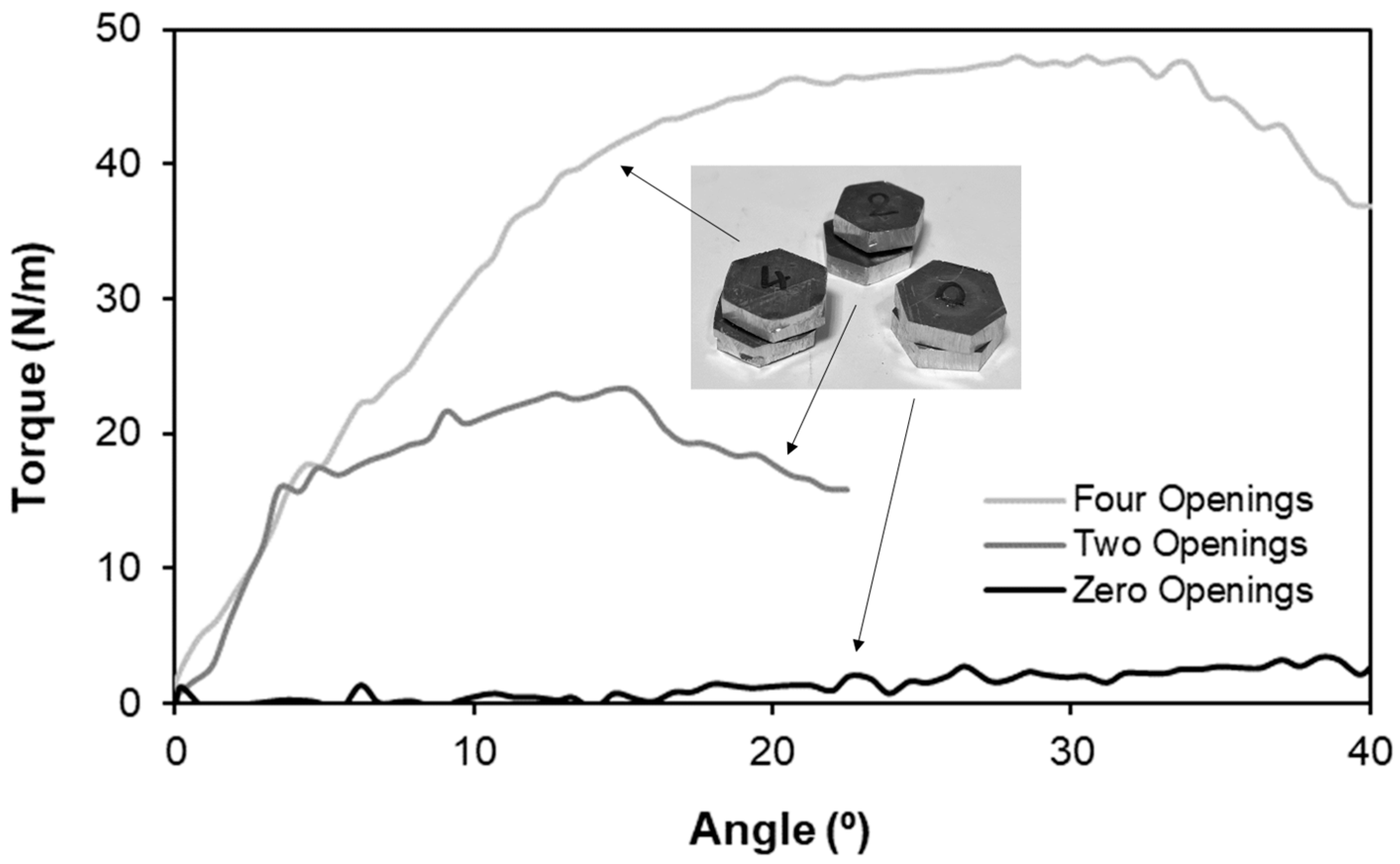

- Torsion tests followed ISO 18338:2015 [25] and were carried out on a GUNT WP510 torsion testing machine (Figure 3b) at a rotation speed of 50°/min. This machine features a stationary and a moving head, enabling the application of torsional loads to the specimen. Due to the shape of the torsion heads, specimens were machined into a hexagonal profile, as illustrated in Figure 4.

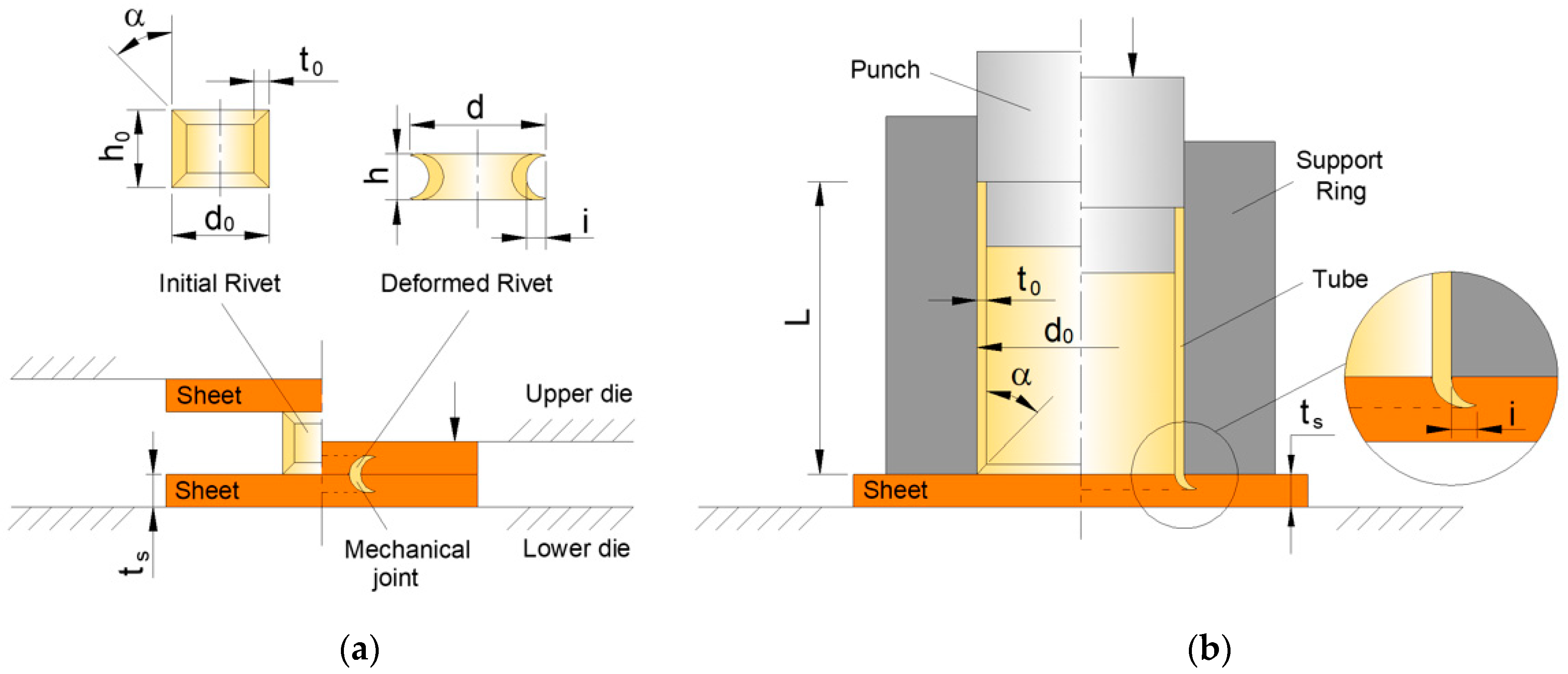

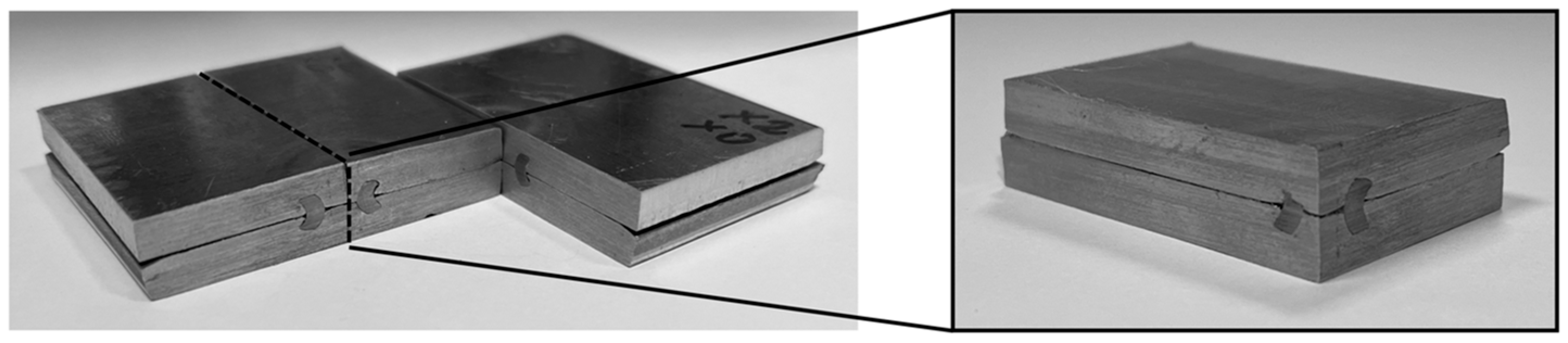

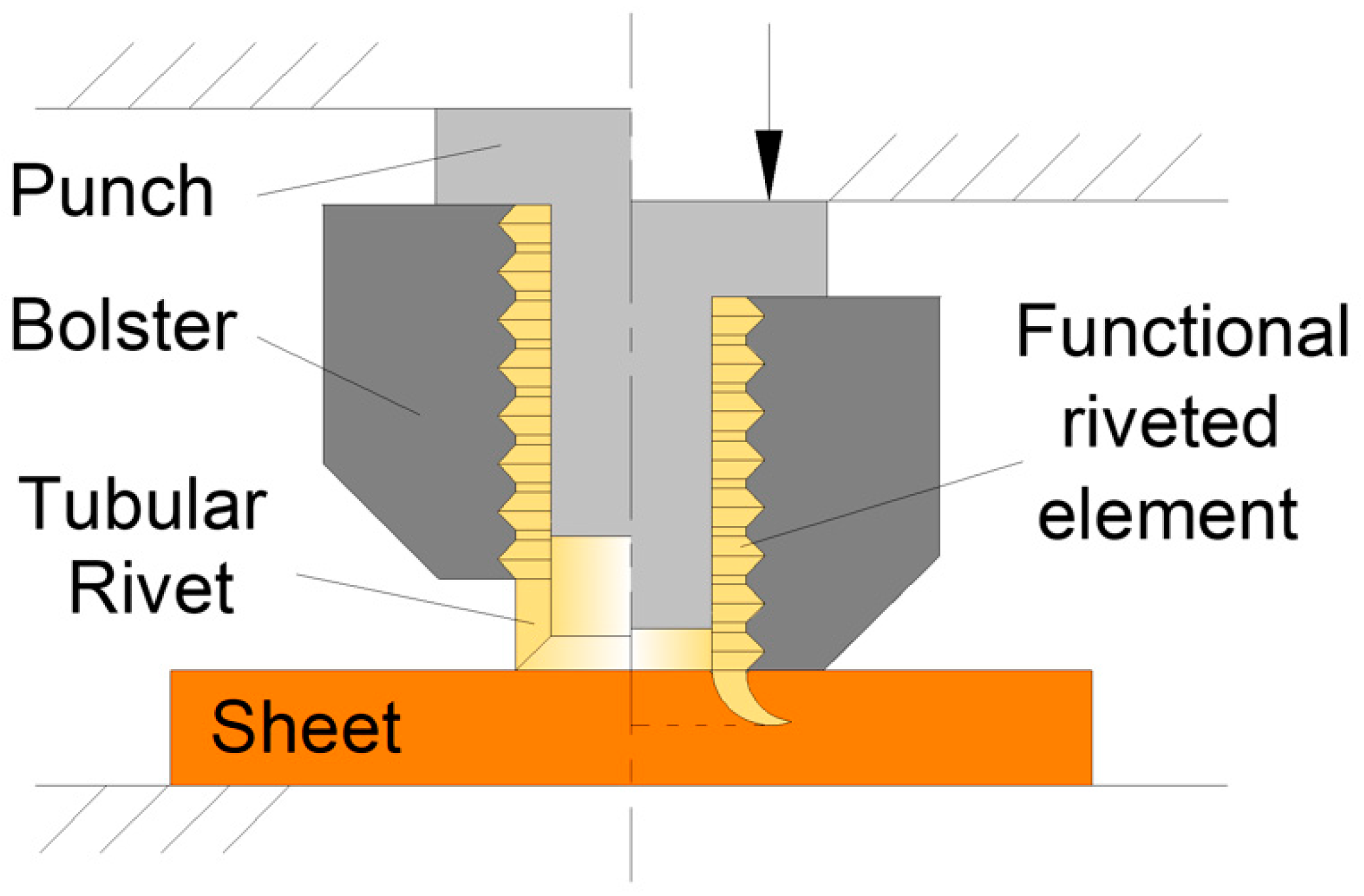

2.2. Work Development

3. Results

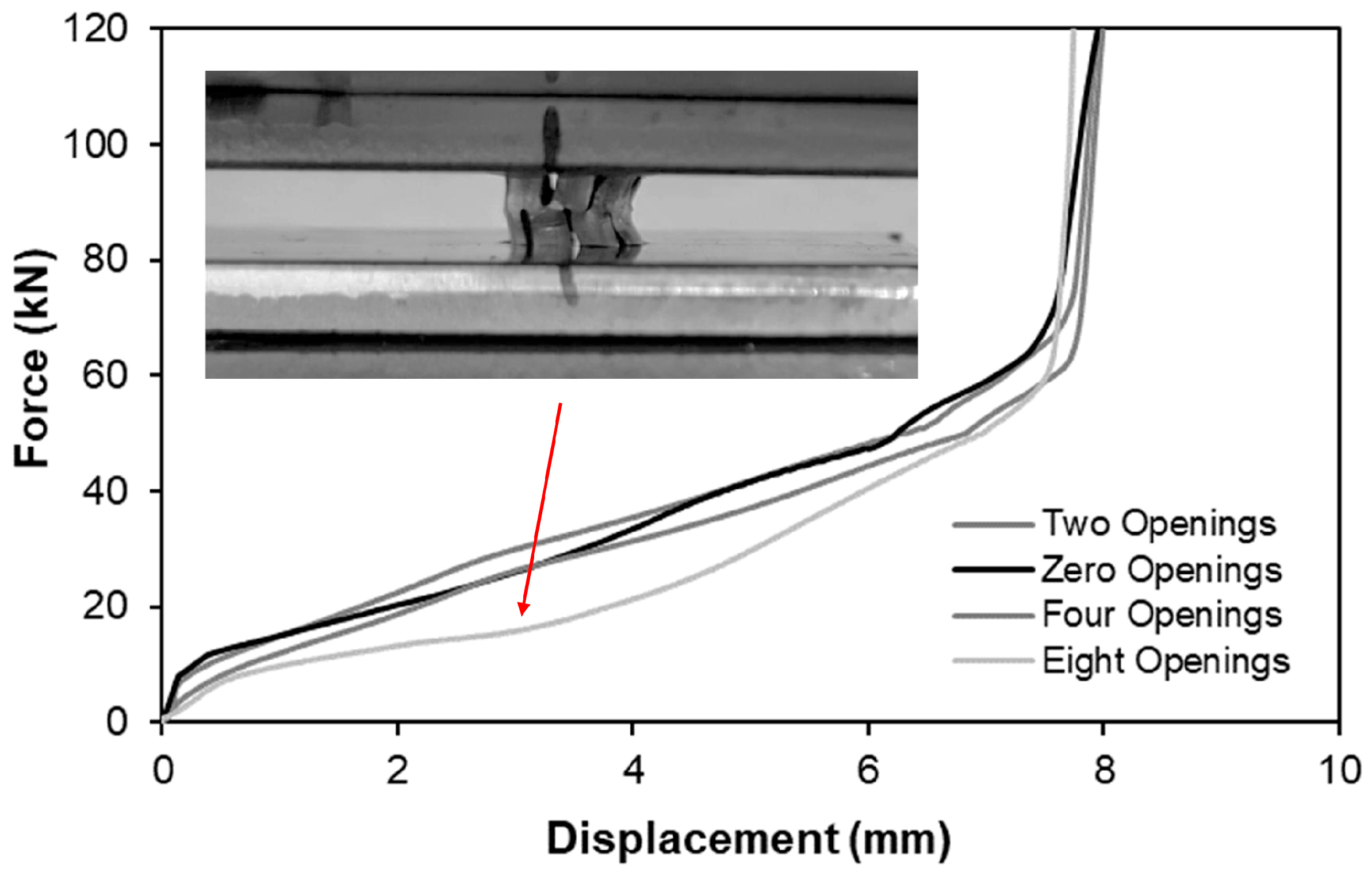

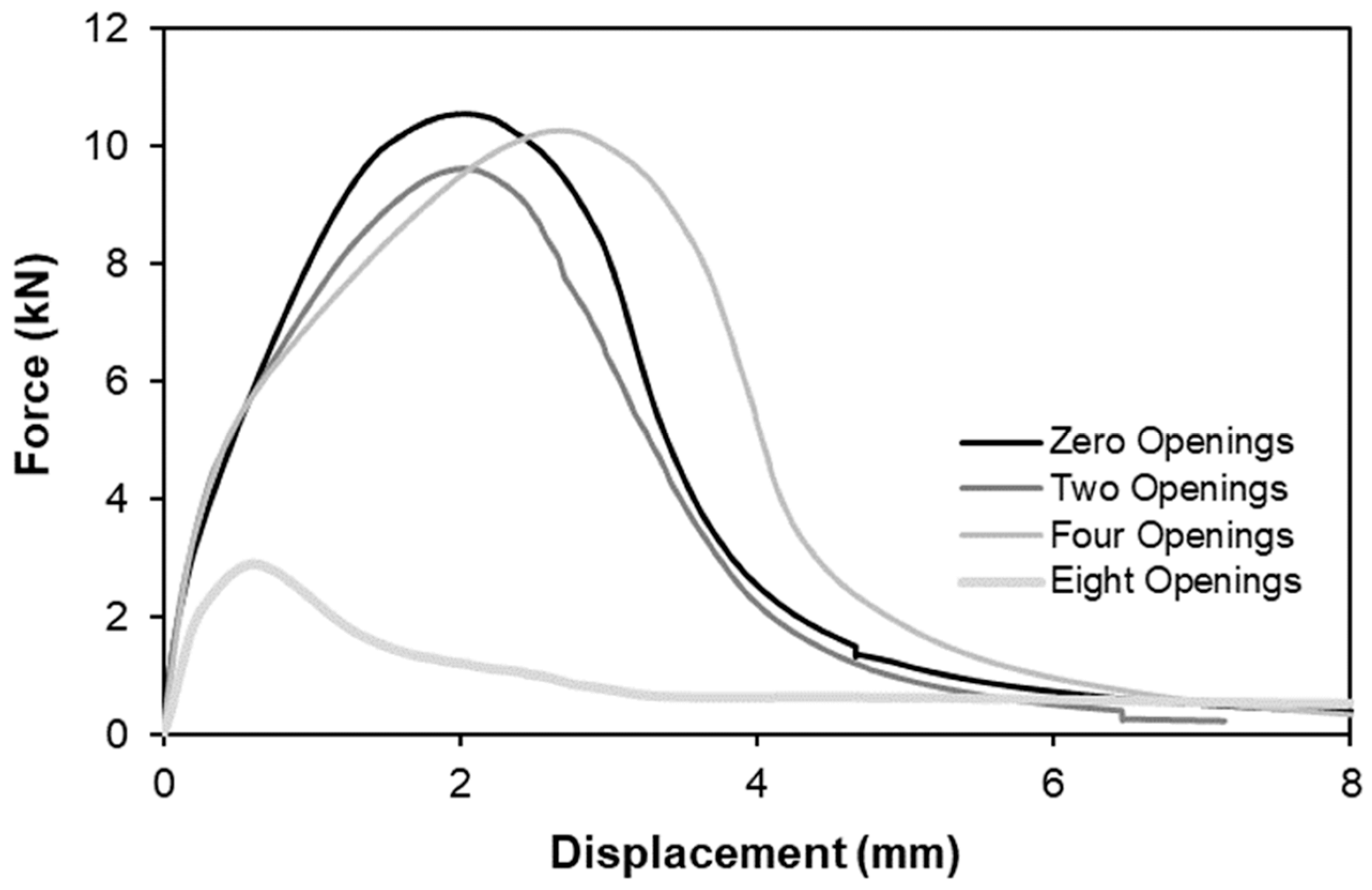

Influence of the Longitudinal Openings on the Riveting Operation

4. Discussion

4.1. Analysis of the Performance of the Riveted Joint

- 2 openings: +20 N·m compared to the original rivet;

- 4 openings: >40 N·m, more than double the original value.

4.2. Assessment of the Functional Rivet Element

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DS-SPR | Double-Sided Self-Pierce Riveting |

| SPR | Self-Pierce Riveting |

| SPR-TS | Self-Pierce Riveting of Tubes to Sheets |

| ISO | International Organization for Standardization |

References

- Alves, L.M.; Afonso, R.M.; Martins, P.A.F. Double-sided self-pierce riveting. J. Adv. Manuf. Technol. 2020, 108, 1541–1549. [Google Scholar]

- Meschut, G.; Merkein, M.; Brosius, A.; Bobbert, M. Mechanical joining in versatile process chains. Prod. Eng. 2022, 16, 187–191. [Google Scholar] [CrossRef]

- Tox Pressotechnik. Available online: https://tox.com/en-en/technologies/placing-of-functional-elements (accessed on 30 September 2025).

- Hetzel, A.; Schulte, R.; Vogel, M.; Lechner, M.; Besserer, H.-B.; Maier, H.J.; Sauer, C.; Schleich, B.; Wartzack, S.; Merklein, M. Functional Analysis of Components Manufactured by a Sheet-Bulk Metal Forming Process. J. Manuf. Mater. Process. 2021, 5, 49. [Google Scholar] [CrossRef]

- Reck, M.; Rohrmoser, A.; Jobst, A.; Pilz, F.; Merklein, M. Forming of Complex Functional Elements on Sheet Metal. In Sheet Bulk Metal Forming; Merklein, M., Tekkaya, A.E., Behrens, B.A., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Schultea, R.; Schneider, T.; Lechner, M.; Merklein, M. Interaction of various functional elements in thin-walled cups formed by a sheet-bulk metal forming process. MATEC Web Conf. 2016, 80, 07003. [Google Scholar] [CrossRef]

- Pilz, F.; Henneberg, J.; Merklein, M. Extension of the forming limits of extrusion processes in sheet-bulk metal forming for production of minute functional elements. Manuf. Rev. 2020, 7, 9. [Google Scholar] [CrossRef]

- Gröbel, D.; Koch, J.; Vierzigmann, H.U.; Engel, U.; Merklein, M. Investigations and Approaches on Material Flow of Non-uniform Arranged Cavities in Sheet Bulk Metal Forming Processes. Procedia Eng. 2014, 81, 401–406. [Google Scholar] [CrossRef]

- Schaub, A.; Ahuja, B.; Butzhammer, L.; Osterziel, J.; Schmidt, M.; Merklein, M. Additive Manufacturing of Functional Elements on Sheet Metal. Phys. Procedia 2016, 83, 797–807. [Google Scholar] [CrossRef]

- DIN 8593-5:2003-09; Manufacturing Processes Joining—Part 5: Joining by Forming Processes; Classification, Subdivision, Terms and Definitions. DIN—German Institute for Standardization: Berlin, Germany, 2003.

- Buffa, G.; Fratini, L.; La Commare, U.; Römisch, D.; Wiesenmayer, S.; Wituschek, S.; Merklein, M. Joining by forming technologies: Current solutions and future trends. Int. J. Mater. Form. 2022, 15, 27. [Google Scholar] [CrossRef]

- Li, D.; Chrysanthou, A.; Patel, I.; Williams, G. Self-piercing riveting—A review. J. Adv. Manuf. Technol. 2017, 92, 1777–1824. [Google Scholar] [CrossRef]

- He, X.; Zhao, W.; Wang, Y.; Lin, J.; Liu, Y.; Wang, C. On the utilization of auxiliary sleeves for joining dissimilar material structures using a versatile self-piercing riveting process. Prod. Eng. 2023, 17, 65–79. [Google Scholar]

- Kappe, F.; Wituschek, S.; Bobbert, M.; Lechner, M.; Meschut, G. Joining of multi-material structures using a versatile self-piercing riveting process. Prod. Eng. 2023, 17, 65–79. [Google Scholar] [CrossRef]

- Alves, L.M.; Afonso, R.M.; Pereira, P.T.; Martins, P.A.F. Double-sided self-pierce riveting of dissimilar materials. J. Adv. Manuf. Technol. 2021, 115, 3679–3687. [Google Scholar] [CrossRef]

- Alves, L.M.; Moghadam, M.; Afonso, R.M.; Nielsen, C.V.; Martins, P.A.F. On the applicability limits of double-sided self-pierce riveting. Proc. Inst. Mech. Eng. 2022, 236, 2027–2036. [Google Scholar] [CrossRef]

- Pengyi, W.; Zuo, P.; Jin, J.; Afonso, R.M.; Zhang, X.; Zhao, X. A novel combined rivet and its effect on mechanical properties and failure behavior in double-sided self-pierce riveting. Thin-Walled Struct. 2024, 199, 111788. [Google Scholar]

- Alves, L.M.; Afonso, R.M.; Martins, P.A.F. Self-pierce riveting of tubes to sheets. J. Adv. Manuf. Technol. 2020, 111, 3351–3360. [Google Scholar] [CrossRef]

- Afonso, R.M.; Alves, L.M. Joining Strategies for Double-Sided Self-Pierce Riveting. Materials 2023, 16, 1191. [Google Scholar] [CrossRef] [PubMed]

- Afonso, R.M.; Alves, L.M. Double-Sided Self-Pierce Riveting: Electro-Mechanical Analysis of Dissimilar Al-Cu Half-Lap Butt Joints. Metals 2023, 13, 1472. [Google Scholar] [CrossRef]

- Li, D.; Slater, C.; Cai, H.; Hou, X.; Li, Y.; Wang, Q. Joining Technologies for Aluminium Castings—A Review. Coatings 2023, 13, 958. [Google Scholar] [CrossRef]

- Barakat, A.A.; Ahmed, A.A.; Darras, B.M.; Nazzal, M.A. Towards Sustainable Metal-to-Polymer Joining: A Comparative Study on Friction Stir Welding, Self-Piercing Riveting, and Adhesive Bonding. Sustainability 2024, 16, 3664. [Google Scholar] [CrossRef]

- Merklein, M.; Kuppert, A. A method for the layer compression test considering the anisotropic material behavior. Int. J. Mater. Form. 2009, 2, 483. [Google Scholar] [CrossRef]

- ISO 12996:2013; Mechanical Joining—Destructive Testing of Joints—Specimen Dimensions and Test Procedure for Tensile Shear Testing of Single Joints. ISO—International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 18338; Metallic Materials—Torsion Test at Ambient Temperature. ISO—International Organization for Standardization: Geneva, Switzerland, 2015.

| Material | Equation |

|---|---|

| Stainless steel AISI 304 | |

| Aluminum AA5754-H111 |

| Determination of the Optimal Number of Semi-Longitudinal Rectangular Openings | |

|---|---|

| Item | Quantity |

| Openings | 0; 2; 4; 8 |

| Sheets | 2 |

| Rivets | |

| Performance assessment of the optimal functional rivet element | |

| Item | Quantity |

| Openings | 4 |

| Sheets | 1 |

| Rivets | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afonso, R.M.; Alves, L.M. Introduction of Functional Elements with Double-Sided Self-Pierce Riveting. J. Manuf. Mater. Process. 2025, 9, 344. https://doi.org/10.3390/jmmp9100344

Afonso RM, Alves LM. Introduction of Functional Elements with Double-Sided Self-Pierce Riveting. Journal of Manufacturing and Materials Processing. 2025; 9(10):344. https://doi.org/10.3390/jmmp9100344

Chicago/Turabian StyleAfonso, Rafael M., and Luís M. Alves. 2025. "Introduction of Functional Elements with Double-Sided Self-Pierce Riveting" Journal of Manufacturing and Materials Processing 9, no. 10: 344. https://doi.org/10.3390/jmmp9100344

APA StyleAfonso, R. M., & Alves, L. M. (2025). Introduction of Functional Elements with Double-Sided Self-Pierce Riveting. Journal of Manufacturing and Materials Processing, 9(10), 344. https://doi.org/10.3390/jmmp9100344