Evaluation of Bond Strength in Multi-Material Specimens Using a Consumer-Grade LCD 3D Printer †

Abstract

1. Introduction

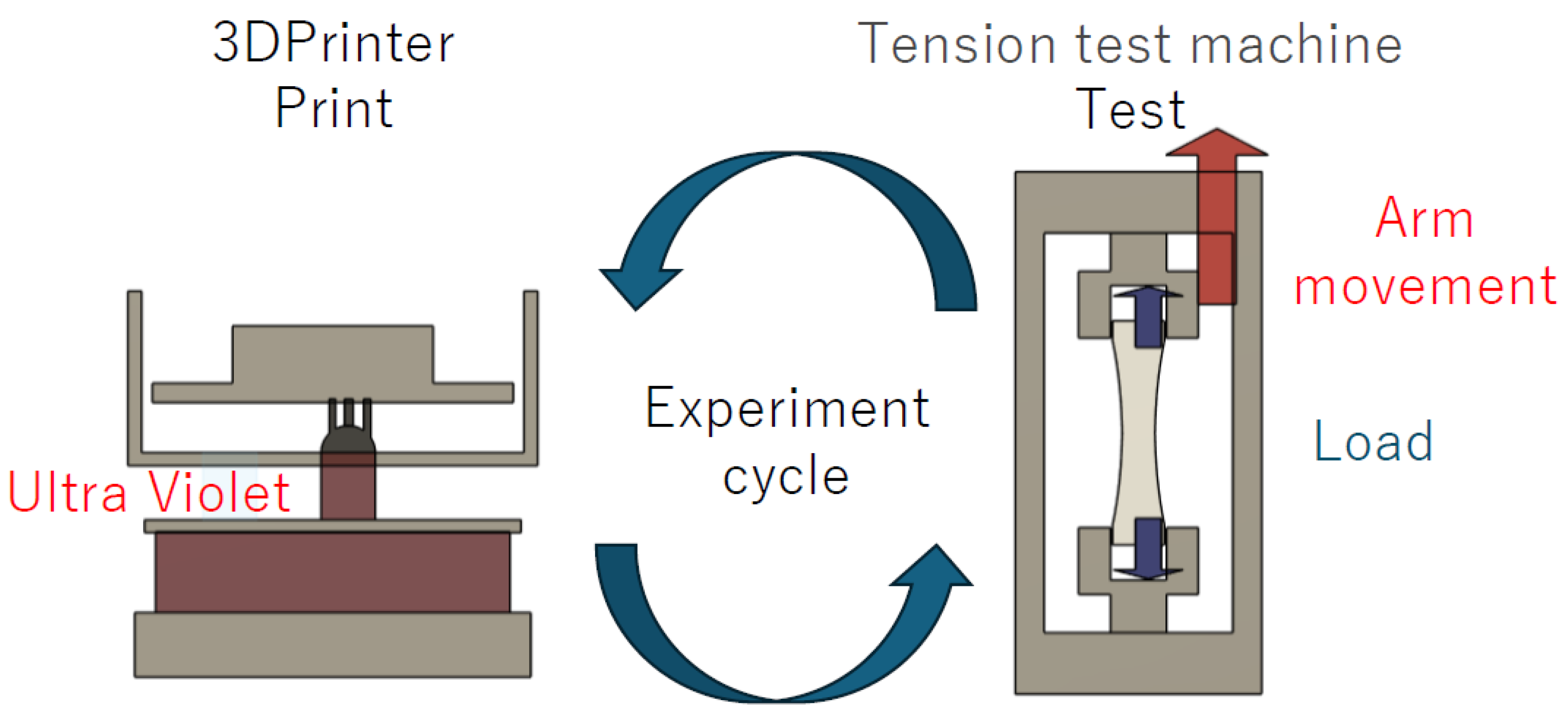

2. Materials and Methods

2.1. Equipment and Materials Used

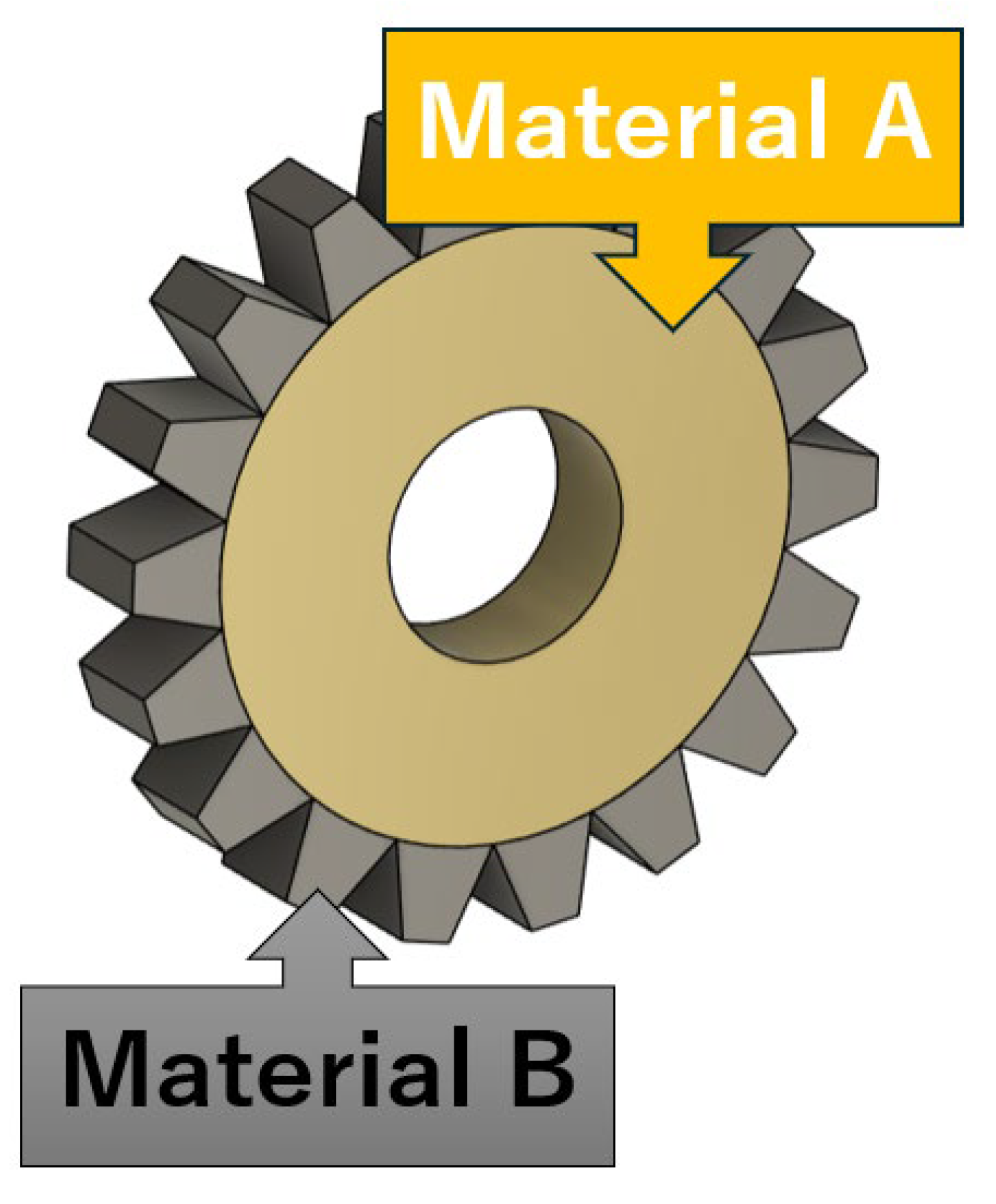

2.2. Specimen Fabrication Method and Printing Conditions

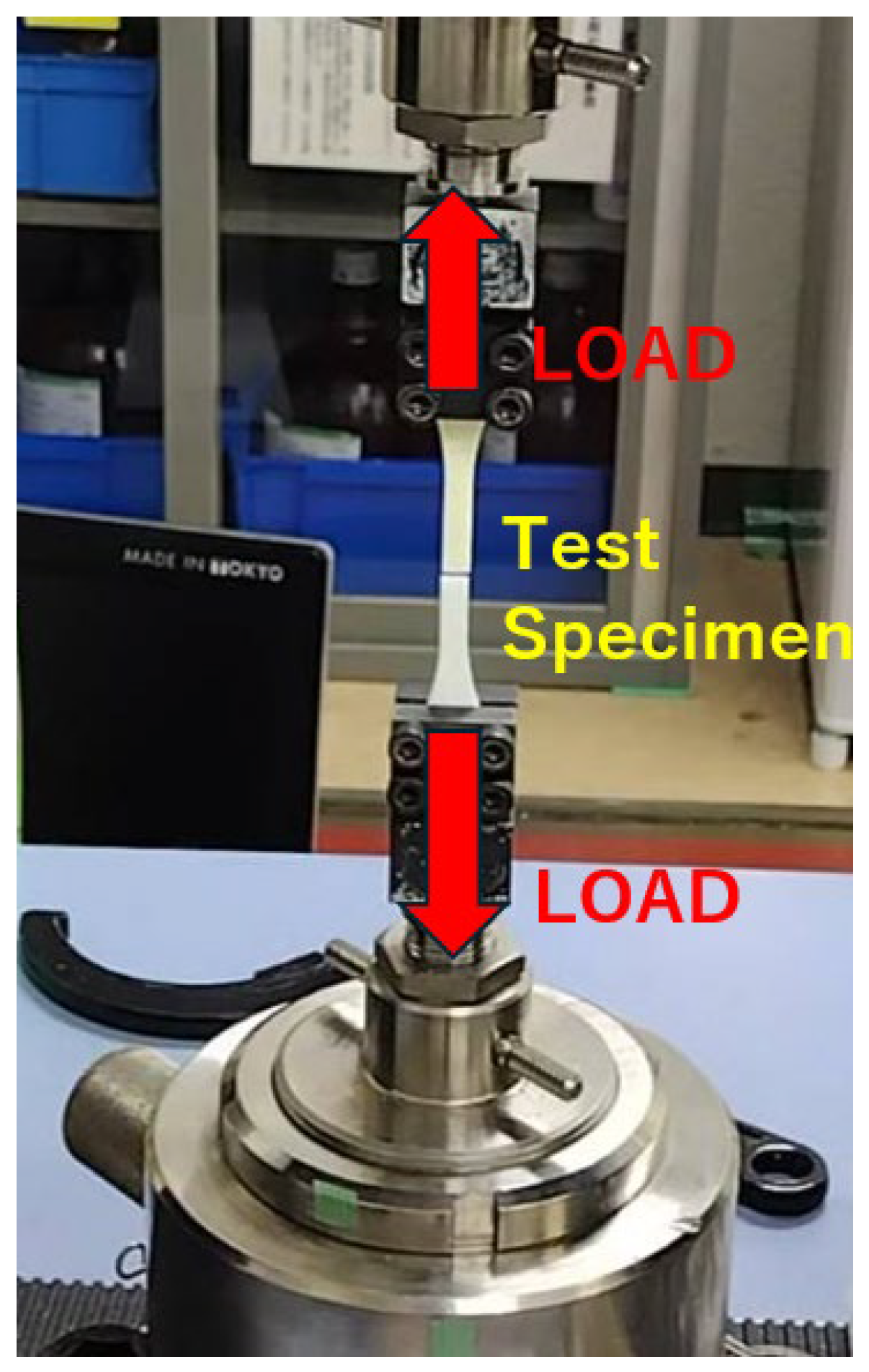

2.3. Specimen and Test Conditions

3. Results

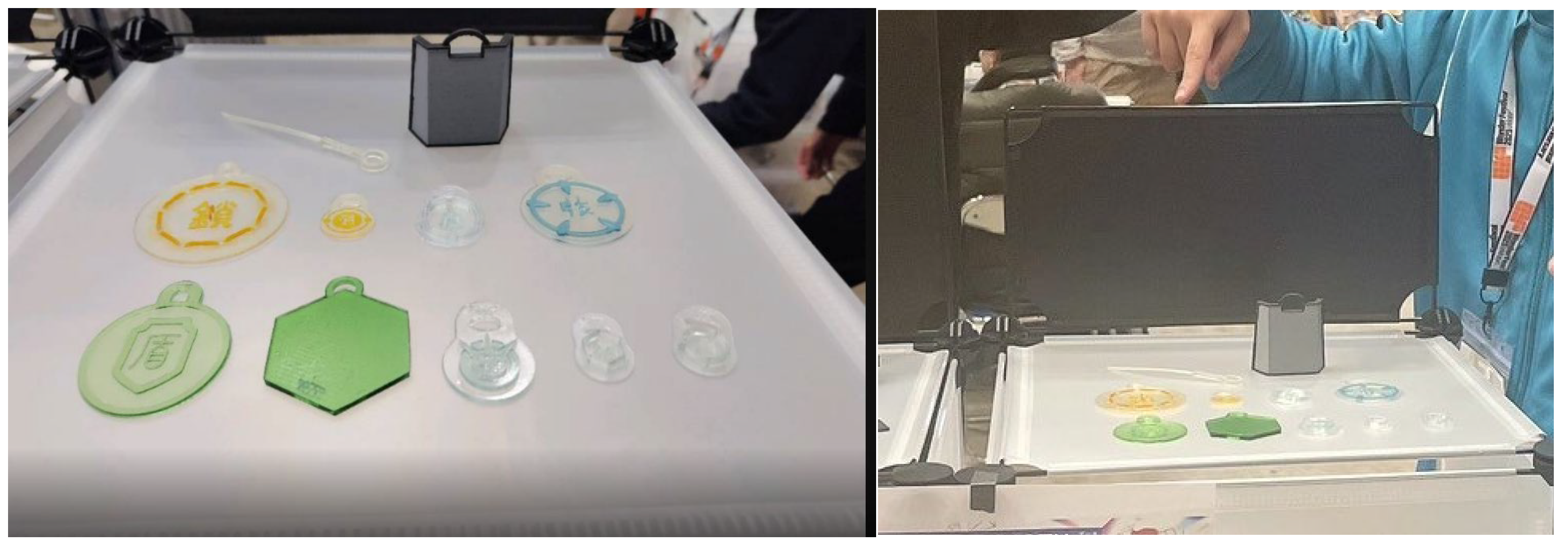

3.1. Printing Results

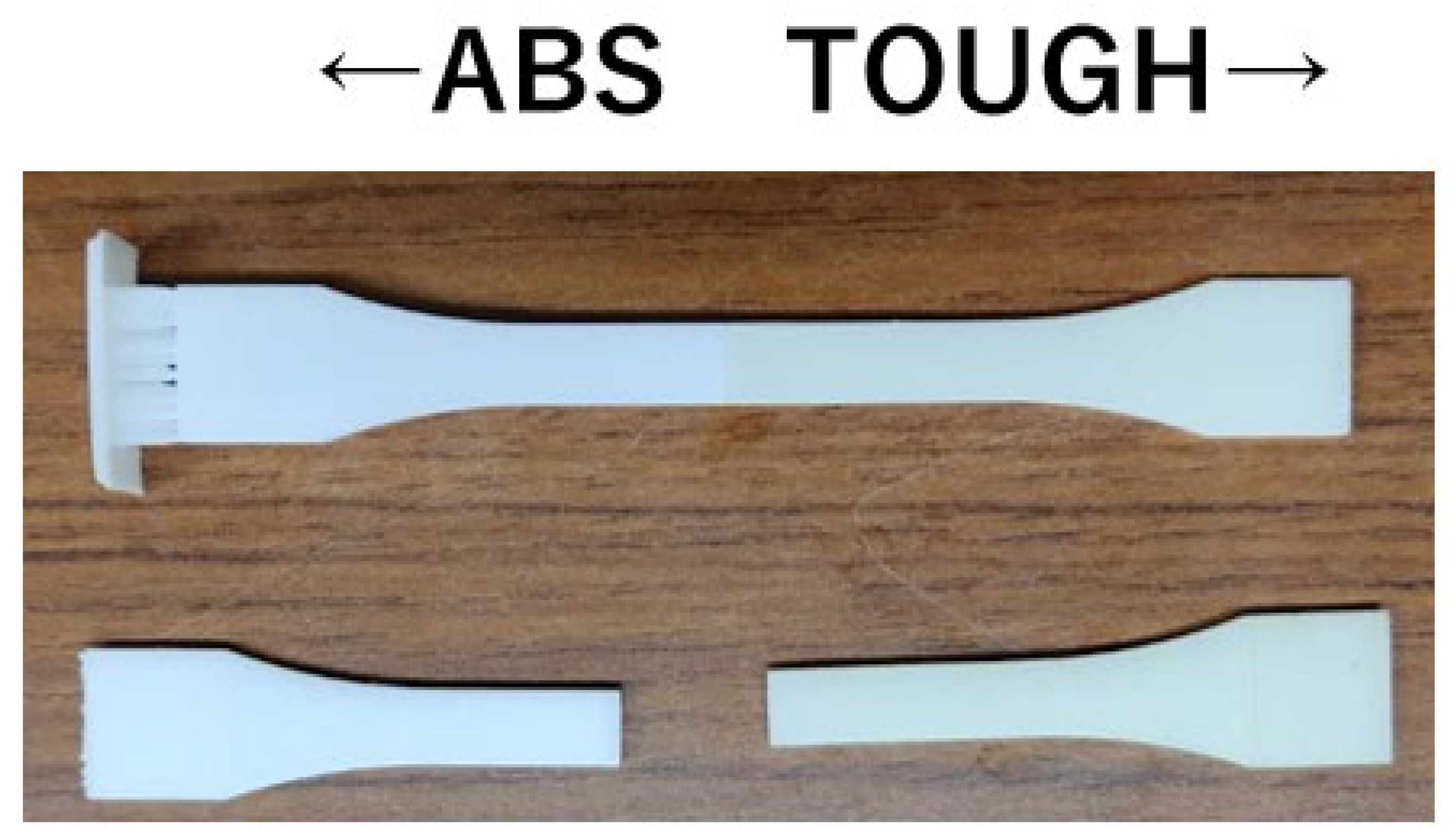

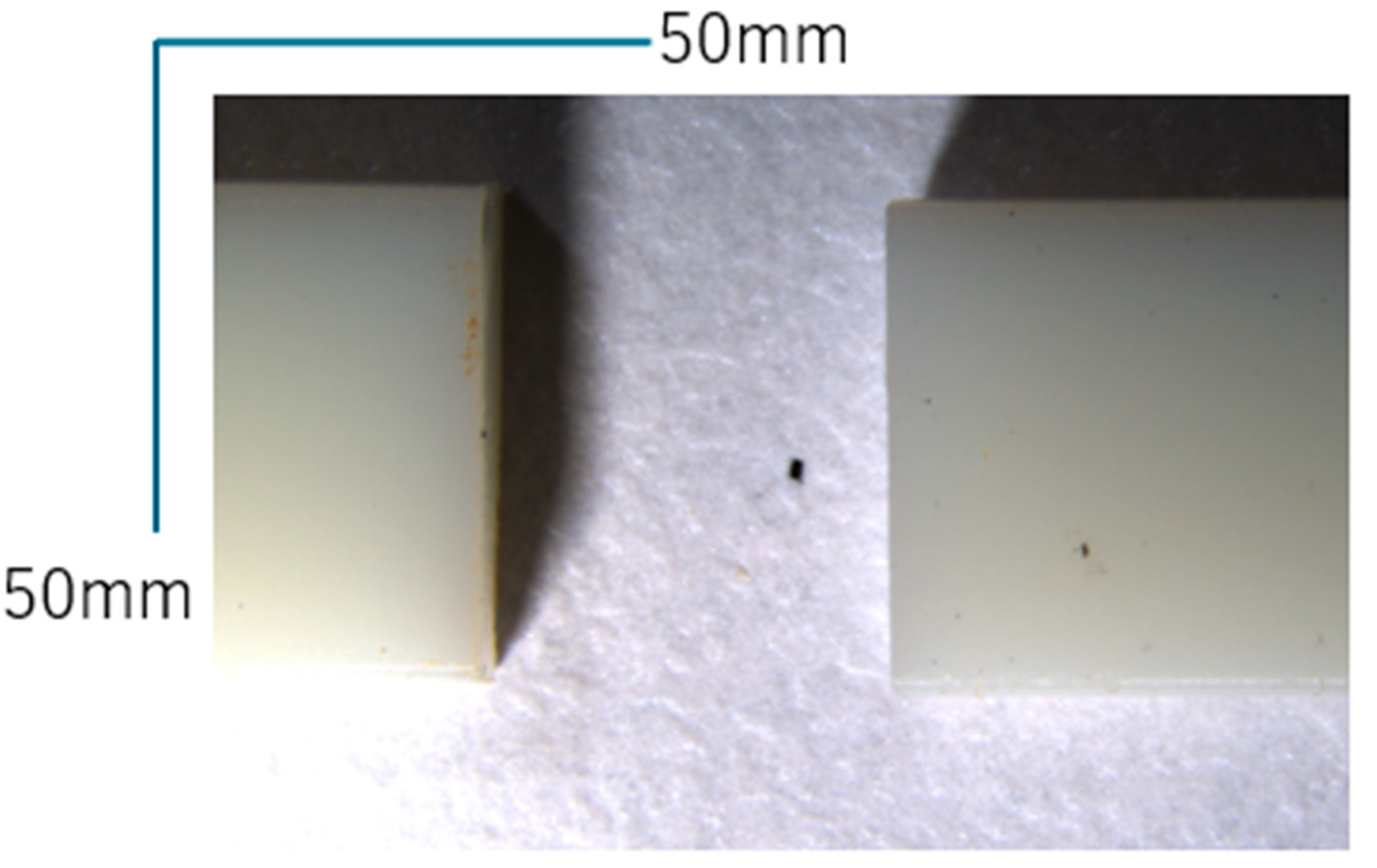

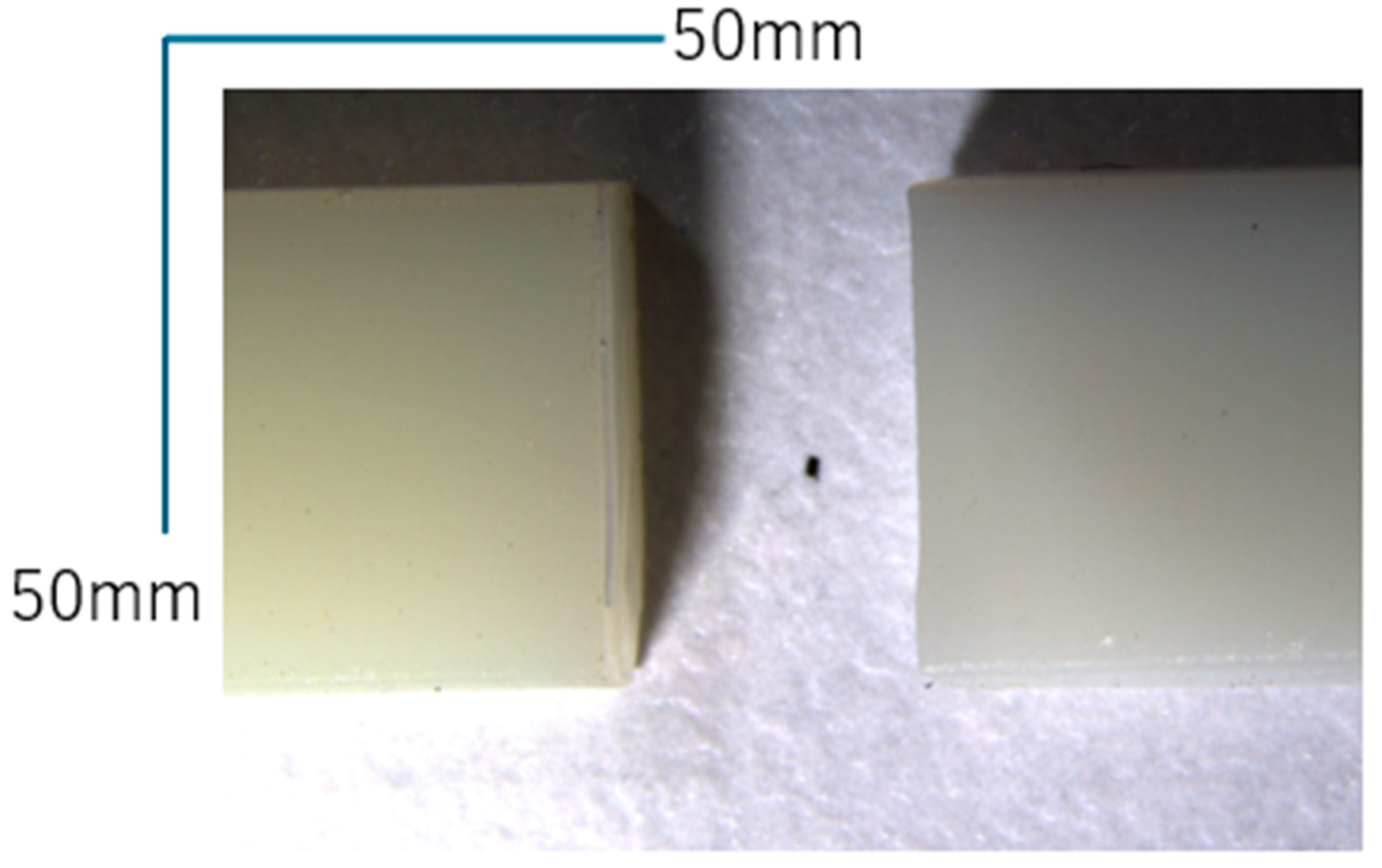

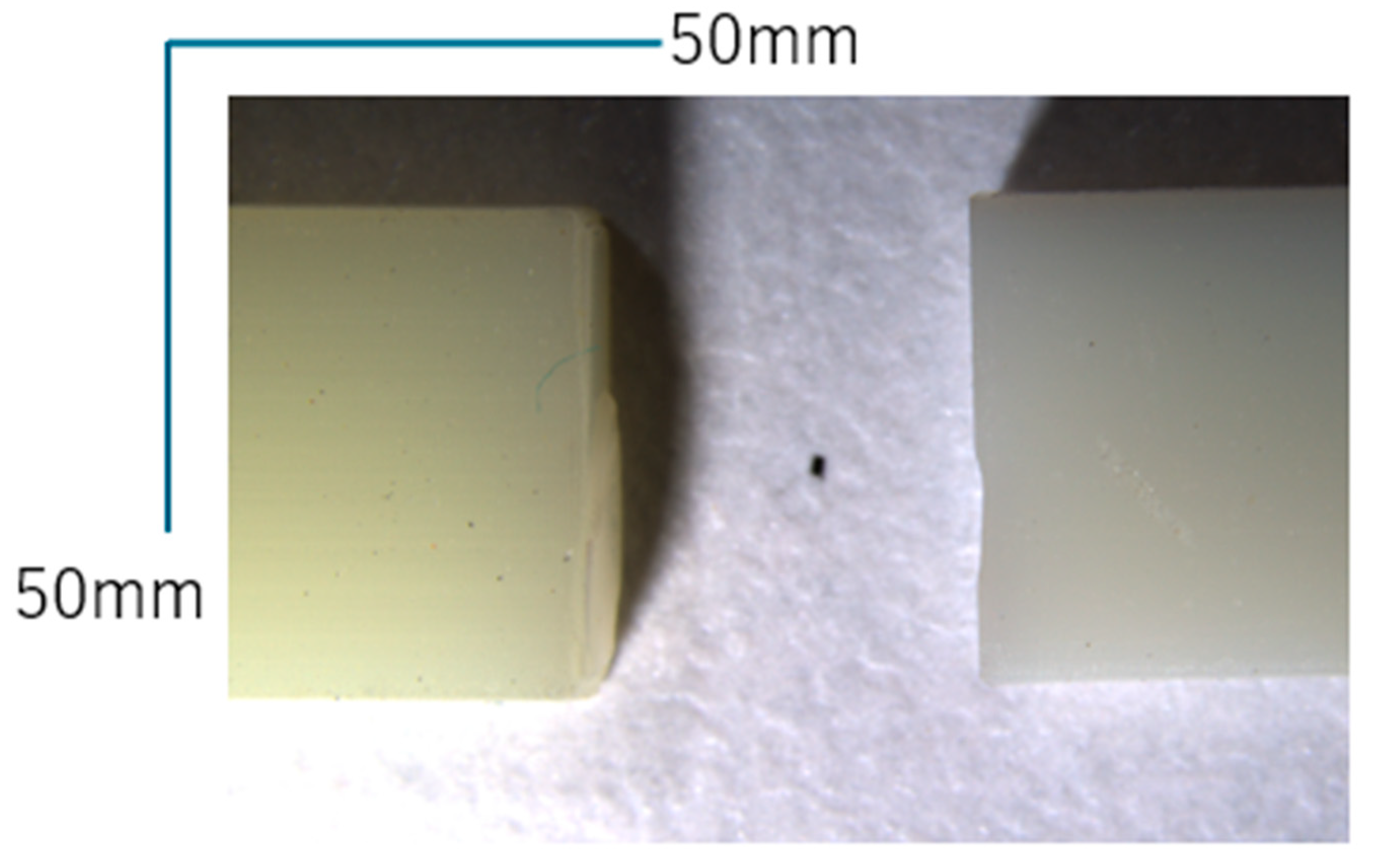

3.1.1. Output of the Test Specimen

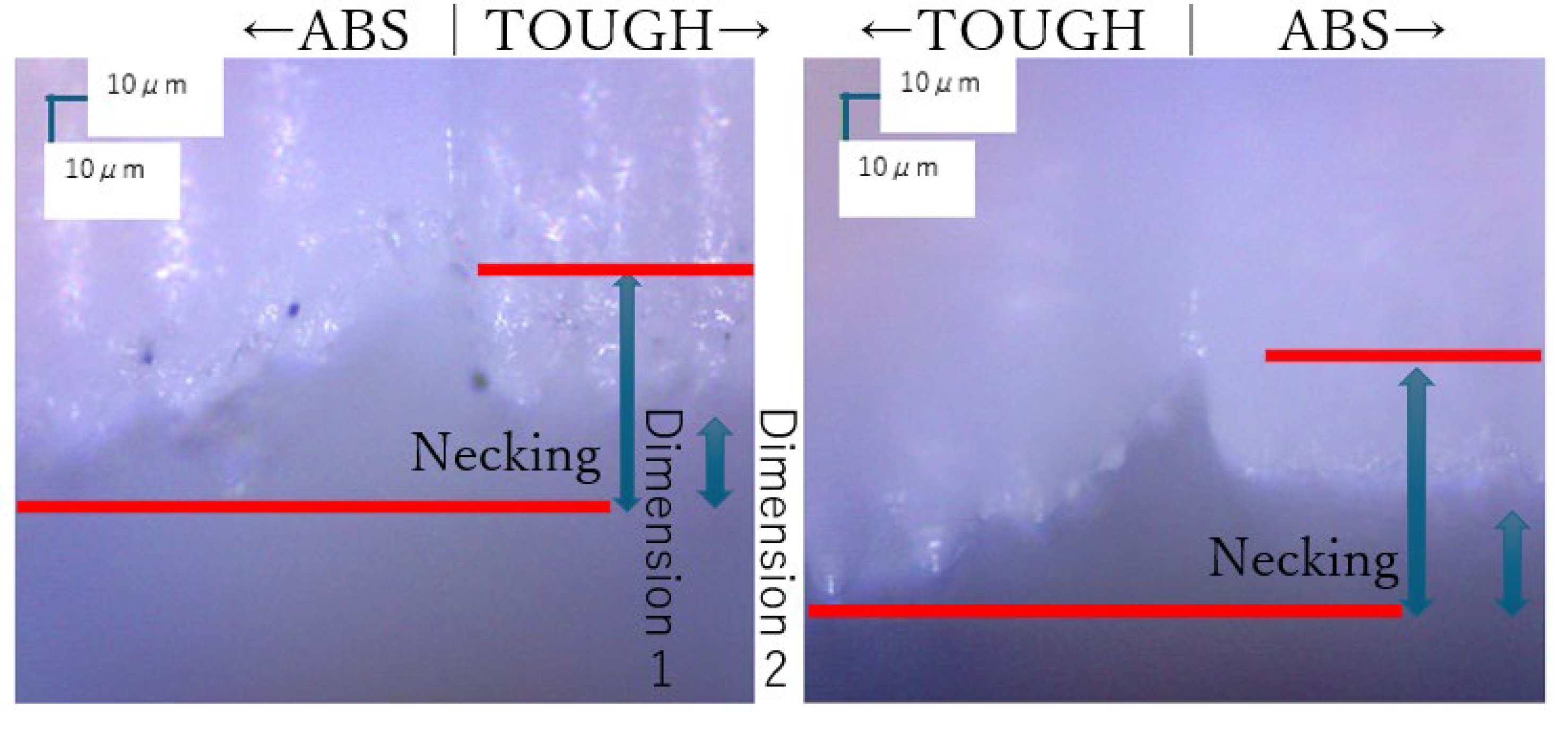

3.1.2. Fracture Mode

3.2. Comparison of Single-Material Specimens with Multi-Material and Adhesive Specimens (Result)

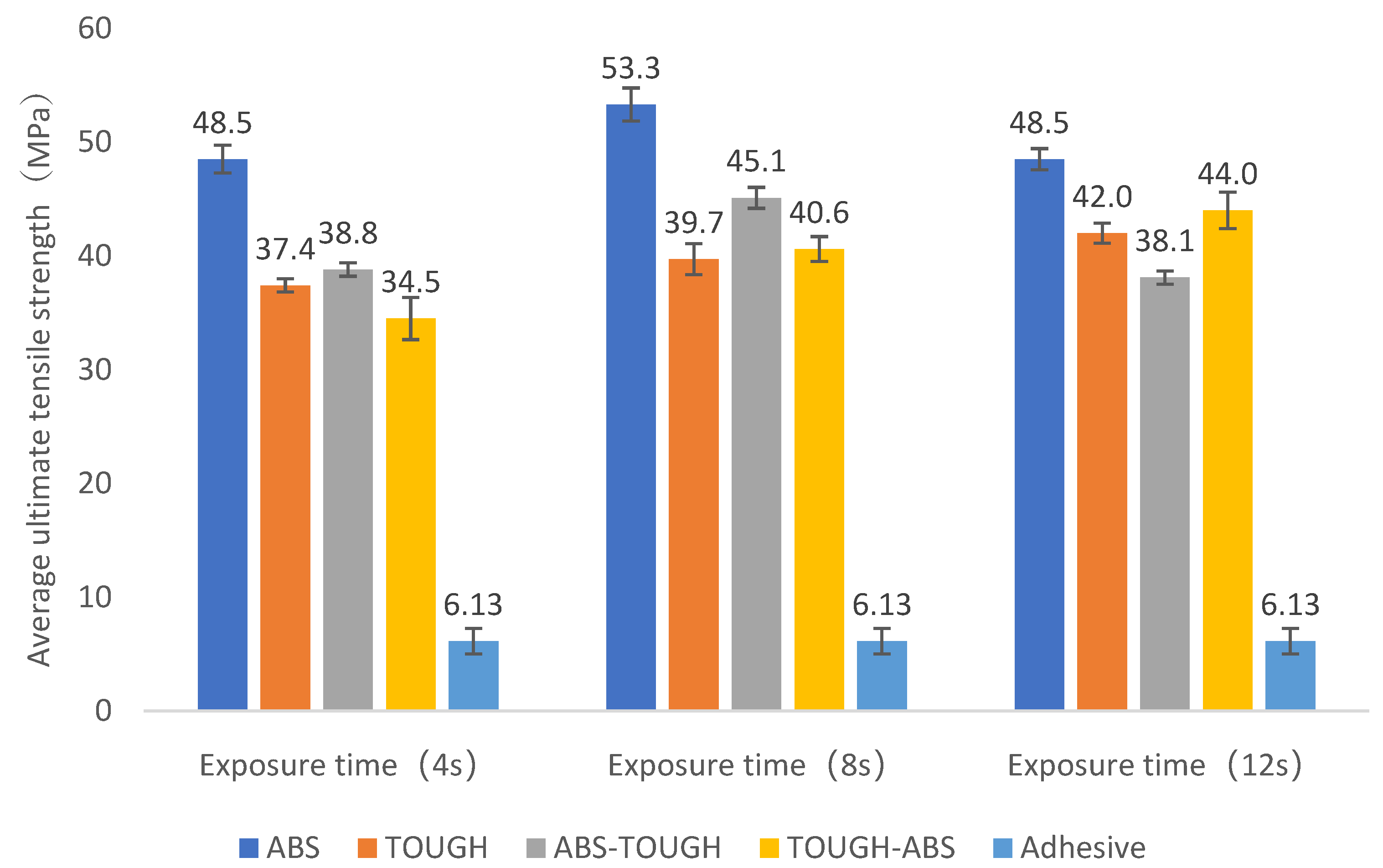

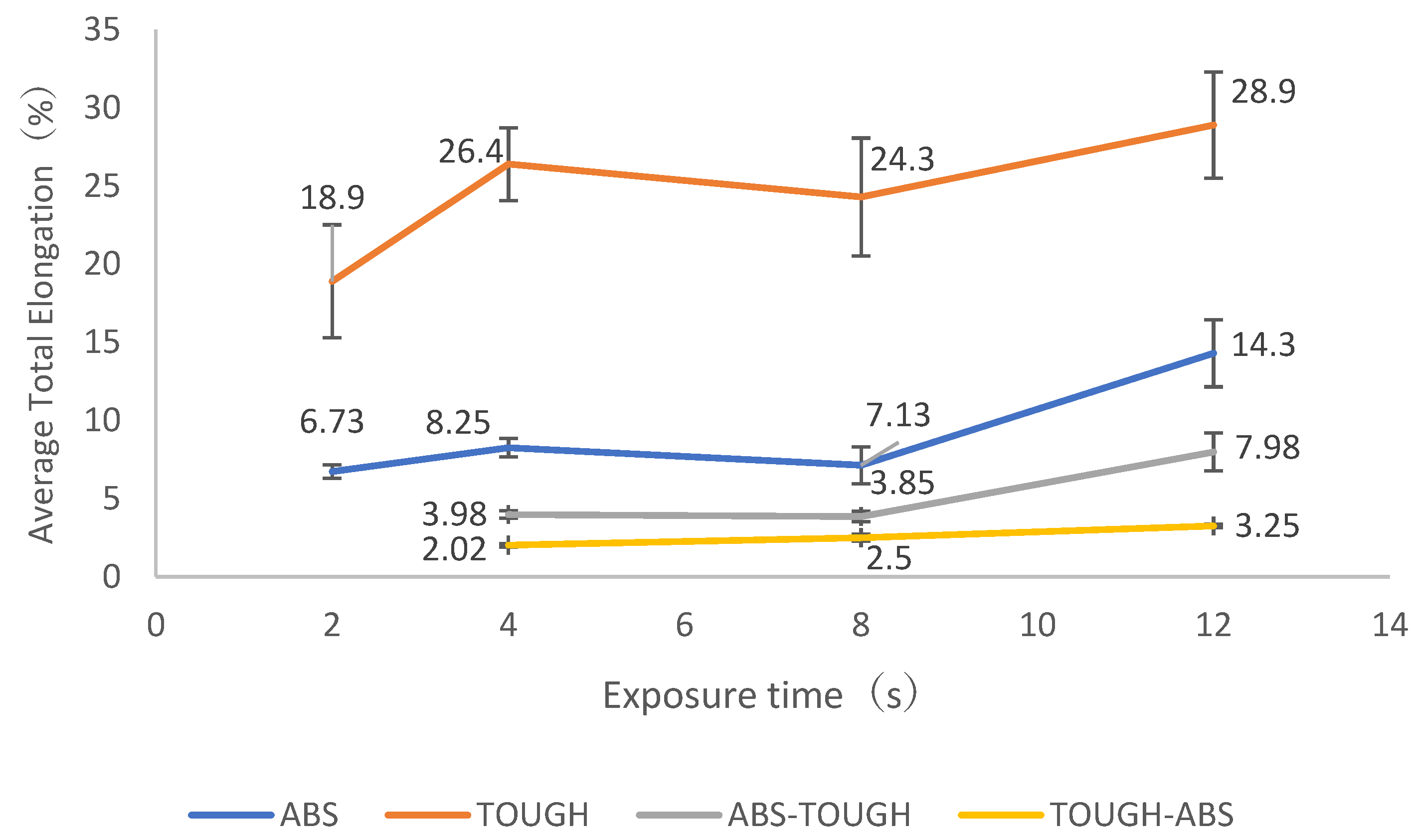

3.3. Effect of Exposure Time on Multi-Material Specimens

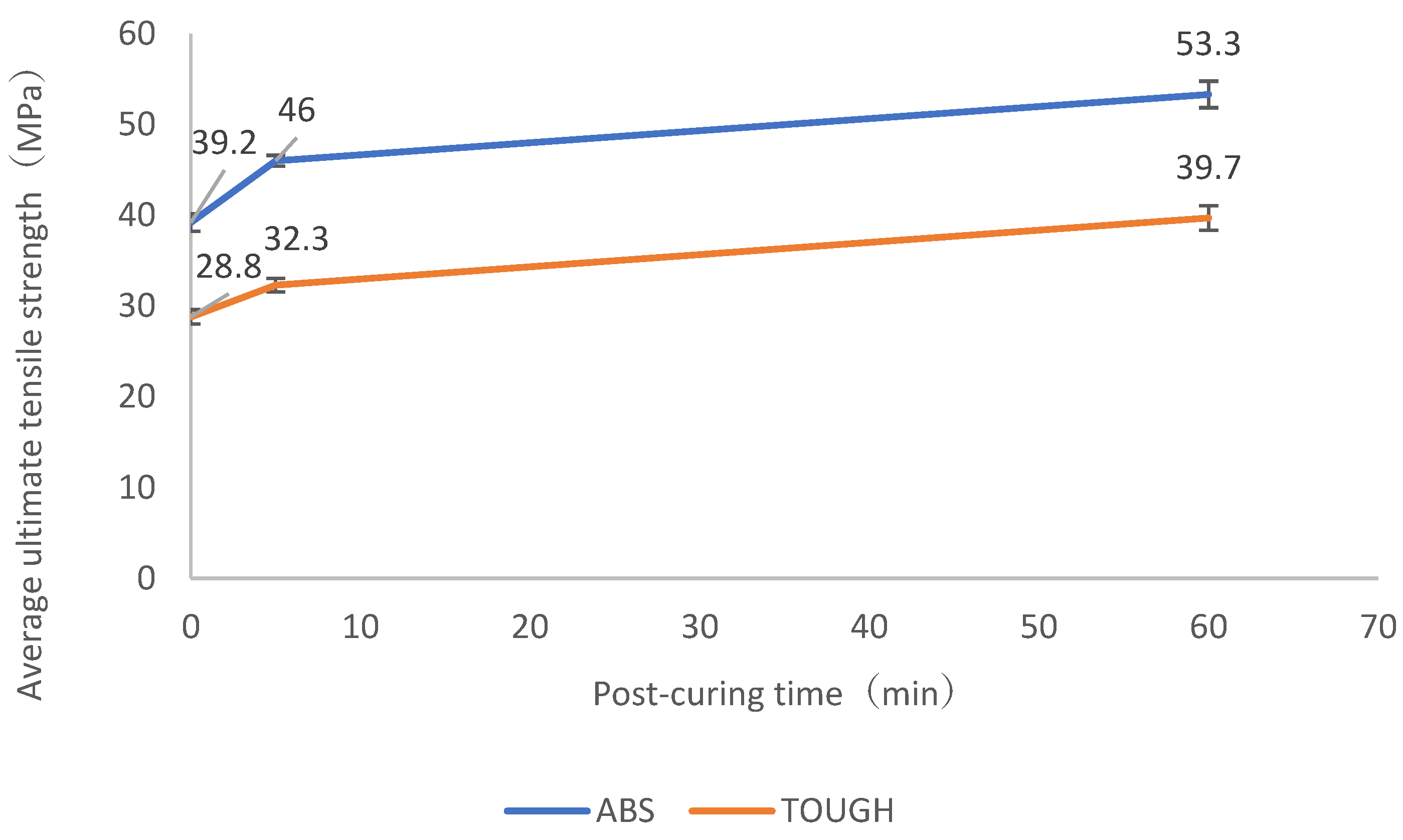

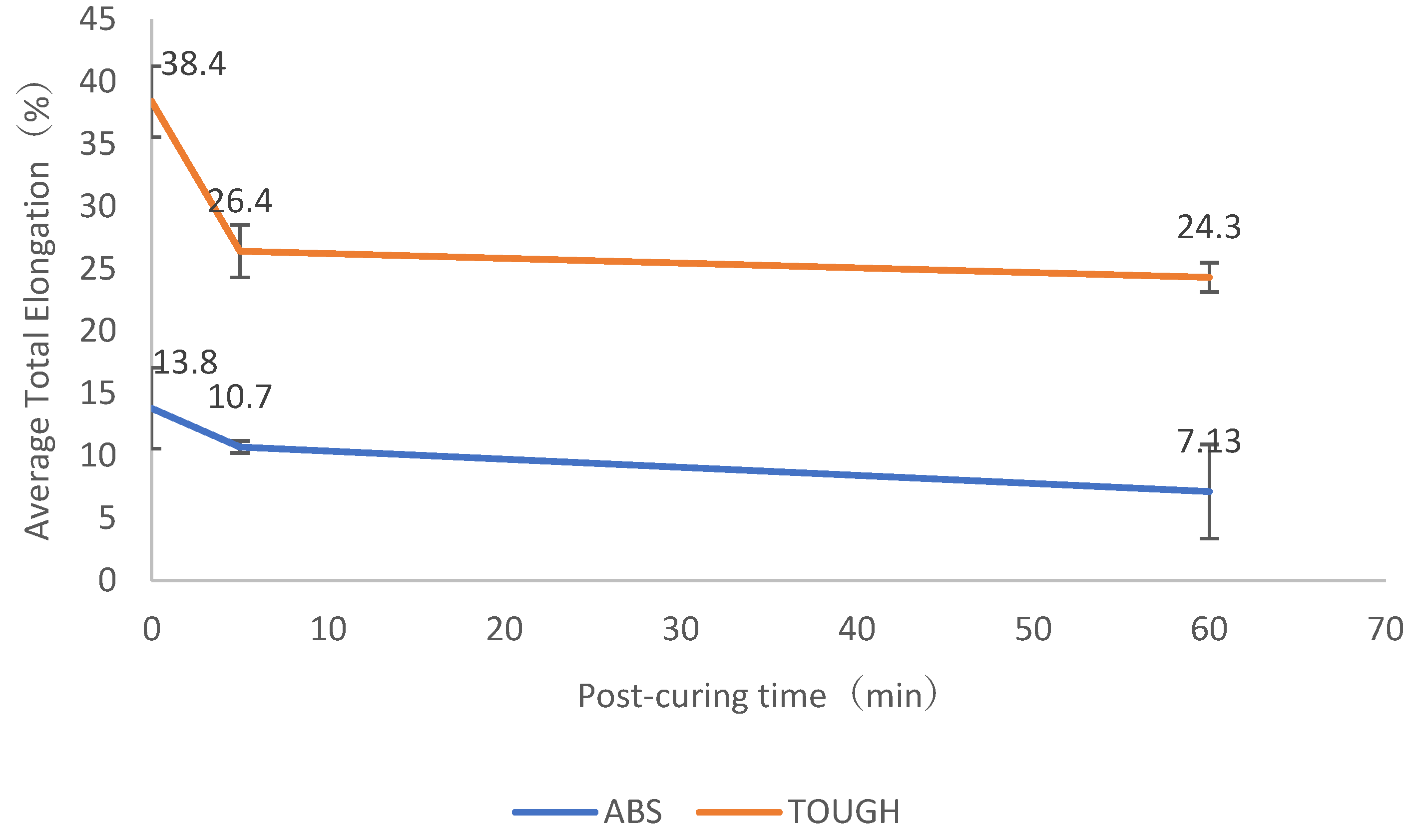

3.4. Effect of Secondary Curing Time on Multi-Material Specimens

4. Discussion

4.1. Comparison of Single-Material Specimens with Multi-Material and Adhesive Specimens

4.2. Effect of Exposure Time on Multi-Material Specimens from the Viewpoint of Single-Material Specimens

4.3. Effect of Secondary Curing Time on Multimaterial Specimens

4.4. Actual Use

5. Limitation and Future Trends

- There is a shortage of materials that can be used for combinations. In particular, for extremely soft materials, the tensile test itself could not be conducted under the current conditions, so it is necessary to reconsider the method from scratch;

- When the exposure time was 2 s, the fact that printing itself did not occur could pose a significant practical concern. Regarding dimensional shrinkage, although it may be possible to address this by adjusting the exposure time, further verification is necessary;

- Some differences from previous studies were observed regarding the behavior in response to certain exposure times and post-curing times. Additionally, for practical applications, extensive testing and accumulation beyond just tensile tests are necessary—for example, pinpoint bond surface failure. Tests that examine the distribution of elongation are also required;

- This time, we combined only two types of materials into two layers. Further multilayering and the use of multiple materials are necessary;

- It is considered that there are not enough tests to elucidate the chemical mechanism. Further testing with additional equipment is necessary.

- The material scope of this study includes all resins that cure at 405 nm. In addition to the mechanical properties of single materials, it is necessary to consider the conditions for multi-materials and the mechanical properties after output. In this regard, the introduction of machine learning [36] may prove to be effective;

- There is an increasing demand for environmental performance these days [37]. Improvements can also be considered, such as incorporating biodegradable resin, creating circuits, and enhancing the removal of support material traces using water-soluble support materials;

- This study focuses on resins, but materials other than resin can also be considered. For example, in the dental field, photopolymerization-type 3D printers are used, and sports mouthguards made from multiple materials have been reported [38]. It seems feasible to apply this approach in such fields and for models. However, when combined with metals and the like, issues such as thermal expansion are thought to arise [39]. Additionally, it is considered that digital gradient material placement and changing only part of the material in the same layer are also possible.

6. Conclusions

- The multi-material specimens required a longer exposure time (8 s in this experiment) for complete printing than the single-material specimens. In addition, all specimens showed a dimensional reduction at the bonding surface. Although the dimensional reduction is a problem, it is thought that, in the actual development of a multi-material housing, it can be handled by lengthening the exposure time for only the bonding surface;

- The single-material specimens showed a relationship between exposure time and tensile strength and elongation. Similarly, the multi-material specimens showed an increase in tensile strength followed by a decrease with increasing exposure time. However, further research on elongation is warranted;

- The tensile strength of the multi-material specimens was found to be more than 90% of the weak tensile strength of the single-material specimens. Elongation was less than 55% of that of the single-material specimen. The tensile strength of the resin exceeded the lowest official value of the resin, and it is considered that there no problem would be met when using the resin for personal use in terms of strength;

- The effect of secondary hardening was observed in the multi-material specimens, similar to that of the single-material specimens. Tensile strength and elongation have a trade-off relationship, as in the case of the single-material specimens. This suggests that the same post-treatment can be used as for the single-material specimens.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive manufacturing |

| 3DP | 3D Printer |

| FDM | Fused deposition modeling |

| FFF | Fused filament fabrication |

| SLA | Stereo lithography apparatus |

| LCD | Liquid crystal display |

| DLP | Digital light processing |

References

- Kalender, M.; Kılıç, S.E.; Ersoy, S.; Bozkurt, Y.; Salman, S. Additive Manufacturing and 3D Printer Technology in Aerospace Industry. In Proceedings of the 2019 9th International Conference on Recent Advances in Space Technologies (RAST), Istanbul, Turkey, 1–14 June 2019; pp. 689–694. [Google Scholar]

- Wohlers Admin. Wohlers Report 2013 Reveals Continued Growth in 3D Printing and Additive Manufacturing. Wohlers Assoc. 2013. Available online: https://wohlersassociates.com/press-releases/wohlers-report-2013-reveals-continued-growth/ (accessed on 3 October 2025).

- 3D Printing Trend Report 2024. Available online: https://www.protolabs.com/resources/guides-and-trend-reports/3d-printing-trend-report/ (accessed on 22 February 2025).

- ictrehab 3D Printed Assistive Device Design Contest 2024 Related Information. ICT Rehabilitation Research Association.

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Katheng, A.; Prawatvatchara, W.; Chaiamornsup, P.; Sornsuwan, T.; Lekatana, H.; Palasuk, J. Comparison of mechanical properties of different 3D printing technologies. Sci. Rep. 2025, 15, 18998. [Google Scholar] [CrossRef] [PubMed]

- Contract Signed with 3D Printer Manufacturer “Bambu Lab,” Which Is Taking the Market by Storm; Sales to Begin Domestically. Also Exhibiting at TCT Japan. Available online: https://prtimes.jp/main/html/rd/p/000000095.000030909.html (accessed on 22 February 2025).

- Elegoo Mars 5 Ultra—Best Beginner’s Dream Resin 3D Printer. Available online: https://us.elegoo.com/products/mars-5-ultra-9k-7inch-monochrome-lcd-resin-3d-printer (accessed on 23 March 2025).

- Hwang, S.; Lee, J.; Lee, S.; Hong, D.; Park, M. Development of DLP 3D Printer with Multiple Composite Materials. J. Korean Soc. Precis. Eng. 2020, 37, 381–388. [Google Scholar] [CrossRef]

- Park, S.-W.; Jung, M.-W.; Son, Y.-U.; Kang, T.-Y.; Lee, C. Development of Multi-Material DLP 3D Printer. J. Korean Soc. Manuf. Technol. Eng. 2017, 26, 100–107. [Google Scholar] [CrossRef]

- Multi-Material Microstereolithography Using a Palette with Multicolor Photocurable Resins. Available online: https://opg-optica-org.utokyo.idm.oclc.org/ome/fulltext.cfm?uri=ome-10-10-2522&id=439721 (accessed on 22 February 2025).

- Quero, R.F.; de Jesus, D.P.; Silva, J.A.F. da Simple modification to allow high-efficiency and high-resolution multi-material 3D-printing fabrication of microfluidic devices. Lab. Chip 2023, 23, 3694–3703. [Google Scholar] [CrossRef]

- Multi-Material Stereolithography—ScienceDirect. Available online: https://www-sciencedirect-com.utokyo.idm.oclc.org/science/article/pii/S0924013610003043 (accessed on 22 February 2025).

- Tsolakis, I.A.; Papaioannou, W.; Papadopoulou, E.; Dalampira, M.; Tsolakis, A.I. Comparison in Terms of Accuracy between DLP and LCD Printing Technology for Dental Model Printing. Dent. J. 2022, 10, 181. [Google Scholar] [CrossRef]

- Hyeonwoo, H.; Jeon, S.J. Digital light processing 3D printing of multi-materials with improved adhesion using resins containing low functional acrylates. Korean J. Chem. Eng. 2022, 39, 451–459. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Q.; Wang, F.; Jian, L.; Wang, Q.; Xiao, J.; Wu, T.; Li, D. Research on the Morphology and Mechanical Property of Bonding Interfaces Fabricated by Multimaterial Digital Light Processing. Addit. Manuf. Front. 2025, 4, 200200. [Google Scholar] [CrossRef]

- Salih, R.M.; Kadauw, A.; Zeidler, H.; Aliyev, R. Investigation of LCD 3D Printing of Carbon Fiber Composites by Utilising Central Composite Design. J. Manuf. Mater. Process. 2023, 7, 58. [Google Scholar] [CrossRef]

- Bergoglio, M.; Rossegger, E.; Schlögl, S.; Griesser, T.; Waly, C.; Arbeiter, F.; Sangermano, M. Multi-Material 3D Printing of Biobased Epoxy Resins. Polymers 2024, 16, 1510. [Google Scholar] [CrossRef]

- Palavicini, J.; Quin, S.L.; Zakkour, W.; Zakkour, K.; Manafi Varkiani, S.; Xu, X.; Lawson, N.C.; Nejat, A.H. Bond Strength of Reline Materials to 3D-Printed Provisional Crown Resins. Polymers 2023, 15, 3745. [Google Scholar] [CrossRef]

- Anycubic Flexible Tough Resin: Durable Flexibility for Robust 3D Prints. Available online: https://store.anycubic.com/products/uv-tough-resin (accessed on 11 January 2025).

- Anycubic Resin User Manual & MSDS|ANYCUBIC 3D Printing. Available online: https://store.anycubic.com/pages/resin-user-manual (accessed on 11 January 2025).

- Elegoo Resin MSDS. Available online: https://jp.elegoo.com/blogs/3d-printing/elegoo-resin-sds (accessed on 11 January 2025).

- Hozdić, E. Characterization and Comparative Analysis of Mechanical Parameters of FDM- and SLA-Printed ABS Materials. Appl. Sci. 2024, 14, 649. [Google Scholar] [CrossRef]

- Japanese Standards Association JSA GROUP Webdesk. Available online: https://webdesk.jsa.or.jp (accessed on 23 March 2025).

- Shimizu, S.; Aoba, T.; Inada, M.; Orita, S. Bond strength measurement of composite materials using an optical 3D printer (LCD type). Proc. Conf. Kanto Branch 2024, 2024.30, 14C03. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, S.; Zhao, X.G.; Lee, D.; Kim, T.; Jung, H.; Kim, N. Impact of UV curing process on mechanical properties and dimensional accuracies of digital light processing 3D printed objects. Smart Struct. Syst. 2018, 22, 161–166. [Google Scholar] [CrossRef]

- Deng, X.; Zhang, G.; Mo, Y.; Huang, Z.; Zhou, D.; Qiao, J.; Li, L. Simultaneously improving fabrication accuracy and interfacial bonding strength of multi-material projection stereolithography by multi-step exposure. Int. J. Smart Nano Mater. 2024, 15, 387–404. [Google Scholar] [CrossRef]

- Kowsari, K.; Akbari, S.; Wang, D.; Fang, N.X.; Ge, Q. High-Efficiency High-Resolution Multimaterial Fabrication for Digital Light Processing-Based Three-Dimensional Printing. 3D Print. Addit. Manuf. 2018, 5, 185–193. [Google Scholar] [CrossRef]

- Pazhamannil, R.V.; Rajeev, A.; Govindan, P.; Edacherian, A. Experimental Investigations into the Effects of Process Parameters and UV Curing on the Tensile Strength of Projection Based Stereolithography. Strength Mater. 2022, 54, 483–492. [Google Scholar] [CrossRef]

- Temiz, A. The Effects of Process Parameters on Tensile Characteristics and Printing Time for Masked Stereolithography Components, Analyzed Using the Response Surface Method. J. Mater. Eng. Perform. 2024, 33, 9356–9365. [Google Scholar] [CrossRef]

- Bazyar, M.M.; Tabary, S.A.A.B.; Rahmatabdi, D.; Mohammadi, K.; Hashemi, R. A novel practical method for the production of Functionally Graded Materials by varying exposure time via photo-curing 3D printing. J. Manuf. Process. 2023, 103, 136–143. [Google Scholar] [CrossRef]

- Sukindar, N.A.; Khata, M.T.A.H.M.; Yasir, A.S.H.M.; Zawawi, M.F.; Kamaruddin, S.; Aziz, A.A. Effect of the Printing Parameters on the Tensile Strength and Surface Roughness of a Photopolymer Resin Using DLP 3D Printing. Malays. J. Microsc. 2024, 20, 189–200. [Google Scholar]

- List of Specially-Made Resin Exposure Times by Printer—SK Honpo. Available online: https://skhonpo.com/pages/exposuretime (accessed on 4 March 2025).

- How Mechanical Properties of Stereolithography 3D Prints are Affected by UV Curing. Available online: https://www.google.com/search?q=How+Mechanical+Properties+of+Stereolithography+3D+Prints+are+Affected+by+UV+Curing&oq=How+Mechanical+Properties+of+Stereolithography+3D+Prints+are+Affected+by+UV+Curing&gs_lcrp=EgZjaHJvbWUqBggAEEUYOzIGCAAQRRg70gEHNTQ5ajBqN6gCALACAA&sourceid=chrome&ie=UTF-8#vhid=zephyr:0&vssid=atritem-https://www.dynamism.com/download/2016/UV%2520Postcure%2520white%2520paper.pdf?srsltid%3DAfmBOoorKXvX6HO1Te_ANDPXrQaW-6hO3e8WP4NqHmIjEl4mbNuDj2HA (accessed on 13 June 2025).

- Štaffová, M.; Ondreáš, F.; Svatík, J.; Zbončák, M.; Jančář, J.; Lepcio, P. 3D printing and post-curing optimization of photopolymerized structures: Basic concepts and effective tools for improved thermomechanical properties. Polym. Test. 2022, 108, 107499. [Google Scholar] [CrossRef]

- Integration of Machine Learning and Digital Twin in Additive Manufacturing of Polymeric-Based Materials and Products|Progress in Additive Manufacturing. Available online: https://link-springer-com.utokyo.idm.oclc.org/article/10.1007/s40964-025-01257-4 (accessed on 16 September 2025).

- State-of-the-Art Review on Fused Deposition Modeling (FDM) for 3D Printing of Polymer Blends and Composites: Innovations, Challenges, and Applications|The International Journal of Advanced Manufacturing Technology. Available online: https://link-springer-com.utokyo.idm.oclc.org/article/10.1007/s00170-024-14820-0 (accessed on 16 September 2025).

- Unkovskiy, A.; Huettig, F.; Kraemer-Fernandez, P.; Spintzyk, S. Multi-Material 3D Printing of a Customized Sports Mouth Guard: Proof-of-Concept Clinical Case. Int. J. Environ. Res. Public. Health 2021, 18, 12762. [Google Scholar] [CrossRef] [PubMed]

- Ogasawara, T.; Arai, N.; Fukumoto, R.; Ogawa, T.; Yokozeki, T.; Yoshimura, A. Titanium alloy foil-inserted carbon fiber/epoxy composites for cryogenic propellant tank application. Adv. Compos. Mater. 2014, 23, 129–149. [Google Scholar] [CrossRef]

| Resin Name | Manufacture | Published Tensile Strength (MPa) | Abbreviation Used in This Study | Exposure Time (s) |

|---|---|---|---|---|

| ABS-Like Resin | Elegoo (Shenzhen, China) | 39.39 ± 10% | ABS | 2, 4, 8, 12 |

| Tough Resin | Anycubic (Shenzhen, China) | 35~45 | TOUGH | 2, 4, 8, 12 |

| Item | Value |

|---|---|

| Layer height (mm) | 0.050 |

| Number of bottom layers | 6 |

| Exposure time (s) | 2, 4, 8, 12 |

| Bottom layer exposure time (s) | 60 |

| Lifting speed of the bottom layers(mm/min) | 60, 0 |

| Lifting distance (mm) | 9 |

| Retraction speed (s) | 6.390 |

| Bottom light-off delay (s) | 0.000 |

| Standard light-off delay (s) | 0.000 |

| Bottom lift acceleration (mm/s2) | 0.000 |

| Standard lift acceleration (mm/s2) | 0.000 |

| Bottom retraction acceleration (mm/s2) | 0.000 |

| Standard retraction acceleration (mm/s2) | 0.000 |

| Bottom lift speed (mm/min) | 2.500 ± 2.500 |

| Standard lift speed (mm/min) | 3.500 ± 3.500 |

| Bottom retract speed (mm/min) | 3.500 ± 3.500 |

| Standard retract speed (mm/min) | 7.000 ± 23.000 |

| Lift speed (mm/min) | 73.000 ± 23.000 |

| Retract speed (mm/min) | 73.000 ± 23.000 |

| Bottom lift height (mm) | 2.500 ± 2.500 |

| Dimension 1 (μm) | Dimension 2 (μm) | |

|---|---|---|

| ABS-TOUGH | 34.6 | 10.6 |

| TOUGH-ABS | 52.8 | 25.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shimizu, S.; Inada, M.; Aoba, T.; Tamagawa, H.; Aoki, Y.; Sekine, M.; Orita, S. Evaluation of Bond Strength in Multi-Material Specimens Using a Consumer-Grade LCD 3D Printer. J. Manuf. Mater. Process. 2025, 9, 332. https://doi.org/10.3390/jmmp9100332

Shimizu S, Inada M, Aoba T, Tamagawa H, Aoki Y, Sekine M, Orita S. Evaluation of Bond Strength in Multi-Material Specimens Using a Consumer-Grade LCD 3D Printer. Journal of Manufacturing and Materials Processing. 2025; 9(10):332. https://doi.org/10.3390/jmmp9100332

Chicago/Turabian StyleShimizu, Shunpei, Masaya Inada, Tomoya Aoba, Haruka Tamagawa, Yuichiro Aoki, Masashi Sekine, and Sumihisa Orita. 2025. "Evaluation of Bond Strength in Multi-Material Specimens Using a Consumer-Grade LCD 3D Printer" Journal of Manufacturing and Materials Processing 9, no. 10: 332. https://doi.org/10.3390/jmmp9100332

APA StyleShimizu, S., Inada, M., Aoba, T., Tamagawa, H., Aoki, Y., Sekine, M., & Orita, S. (2025). Evaluation of Bond Strength in Multi-Material Specimens Using a Consumer-Grade LCD 3D Printer. Journal of Manufacturing and Materials Processing, 9(10), 332. https://doi.org/10.3390/jmmp9100332