Interfacial Strength Testing of Laser Powder Bed Fusion Metal Samples Produced Using the Multi-Material Binning Method

Abstract

1. Introduction

2. Materials and Methods

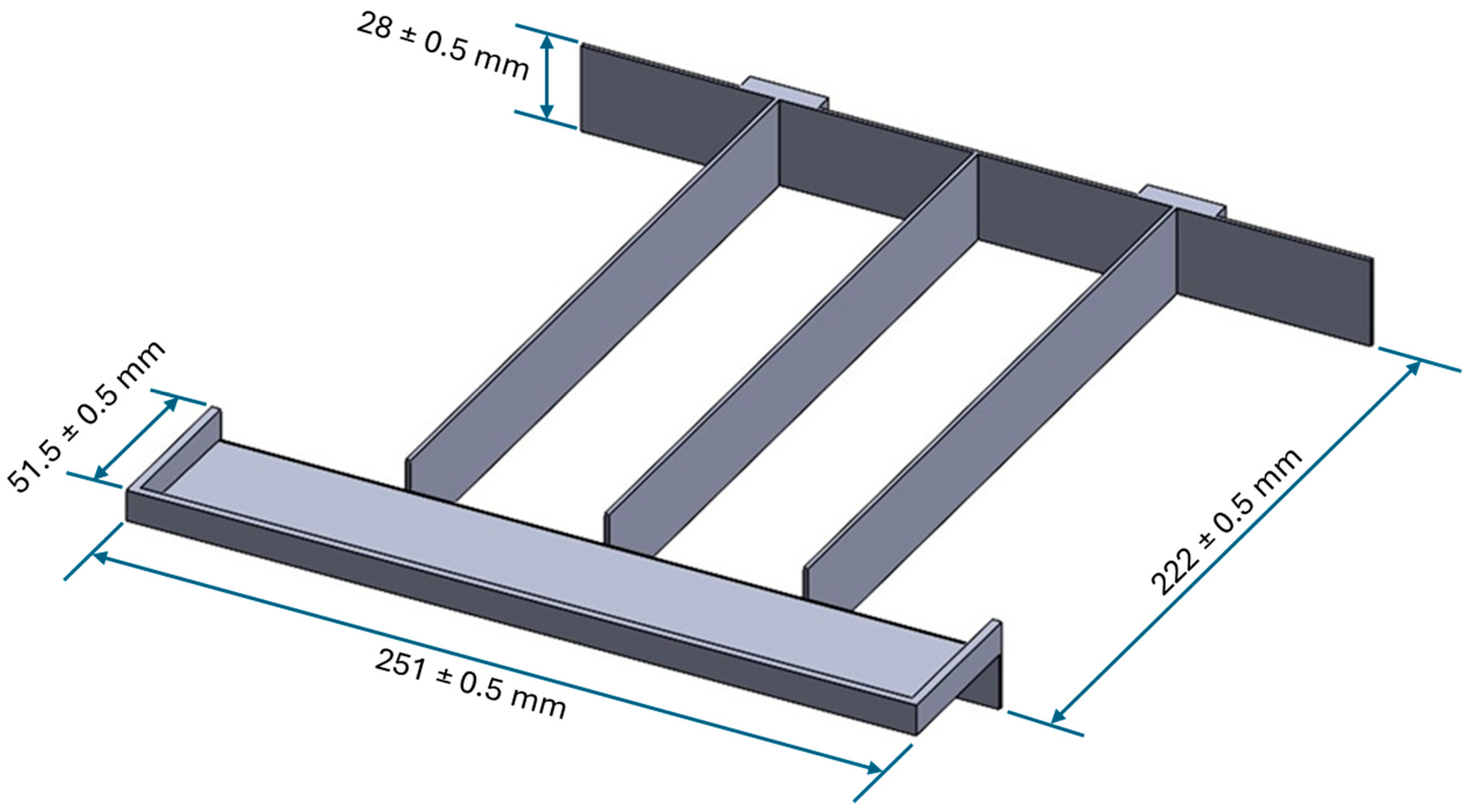

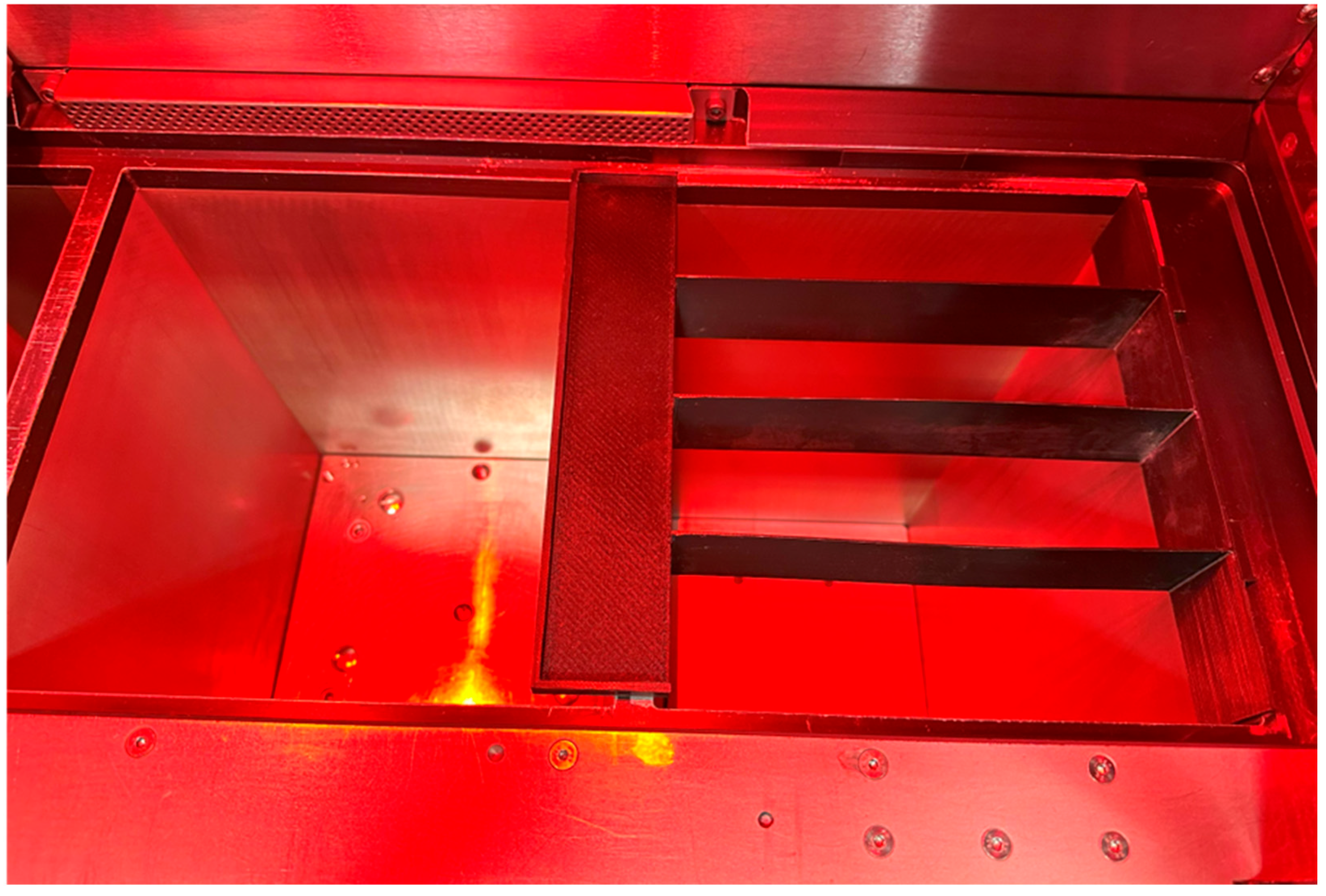

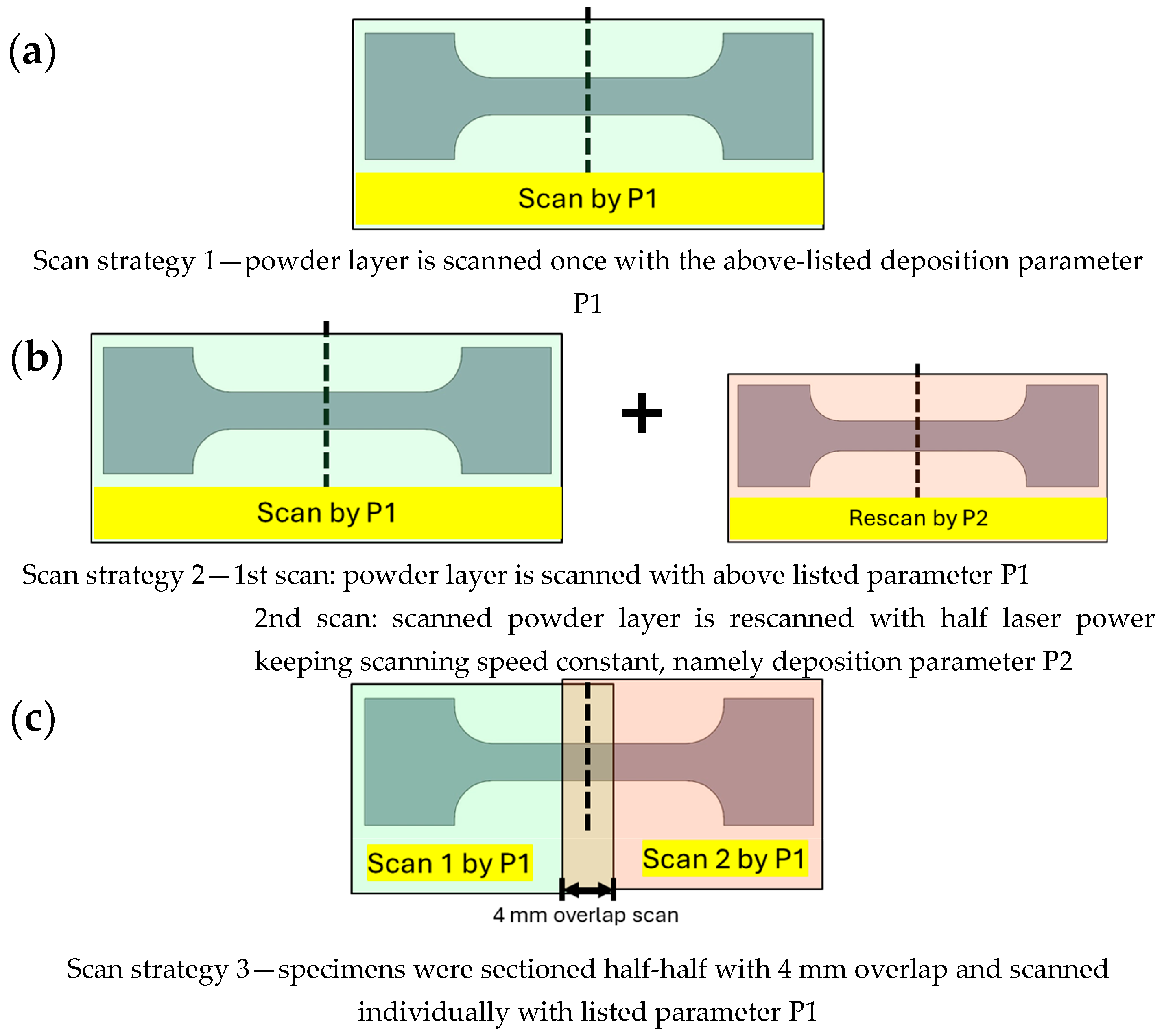

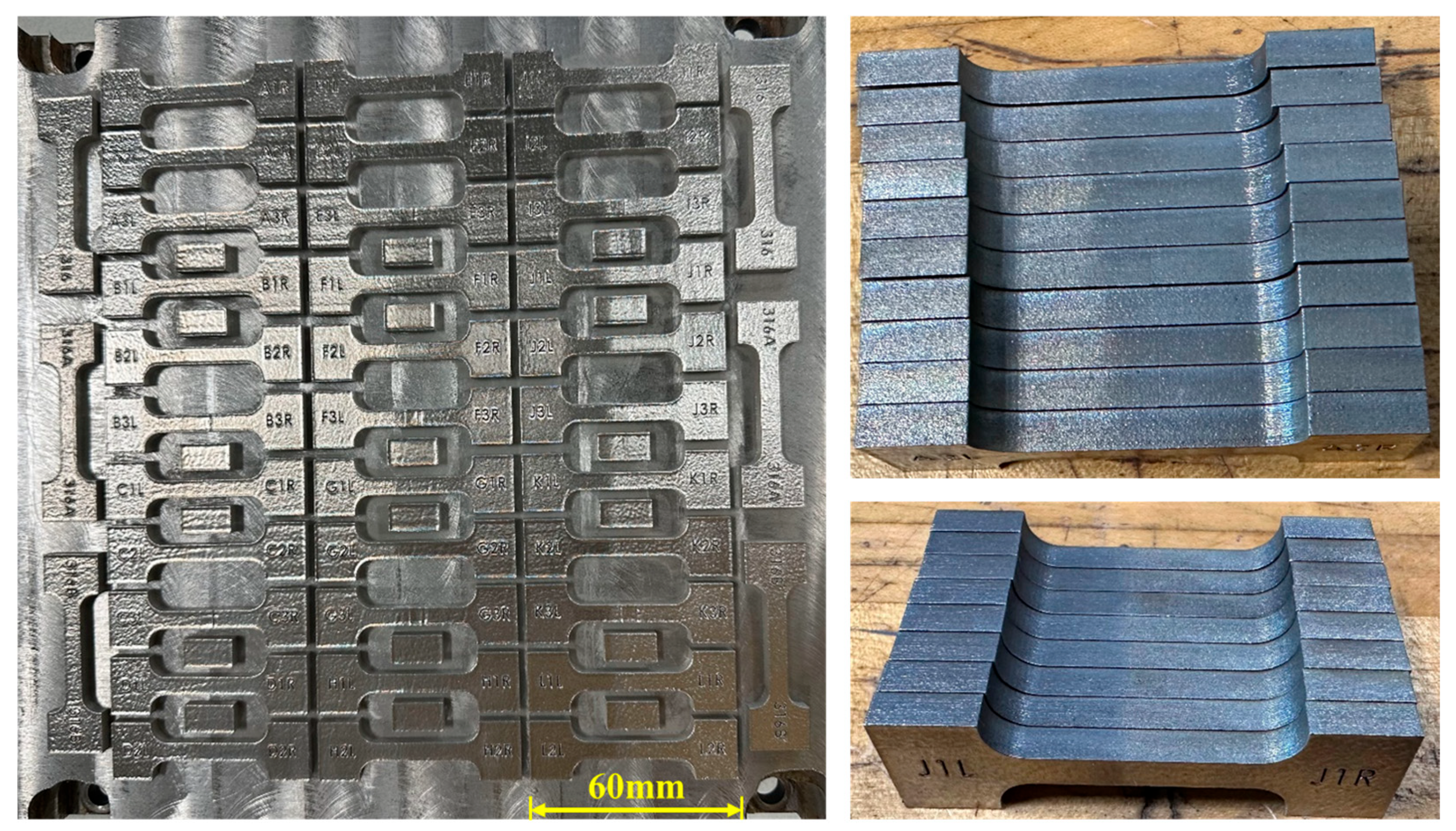

2.1. Sample Manufacturing and Preparation

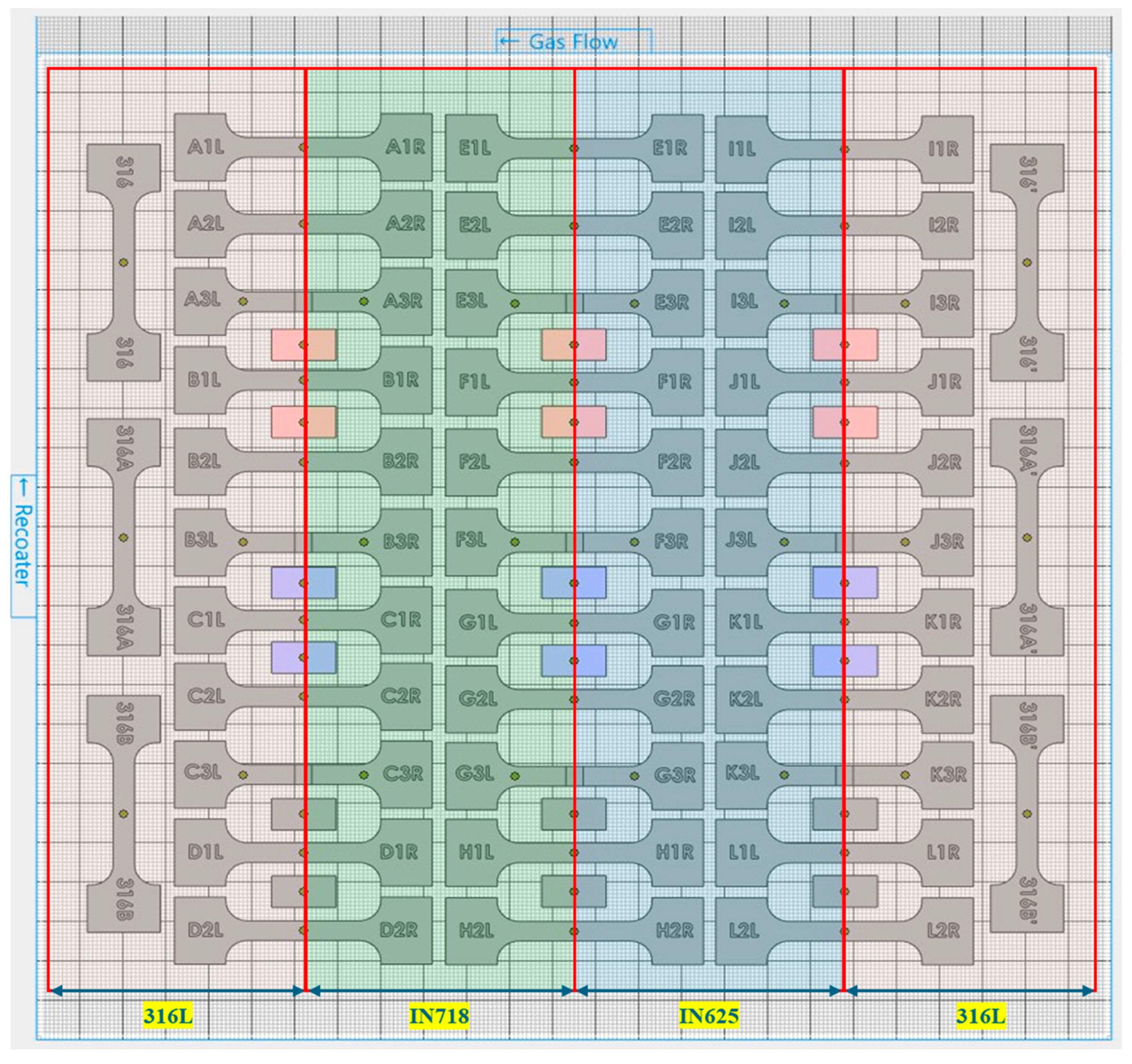

2.2. Sample Layout

2.3. Post-Processing

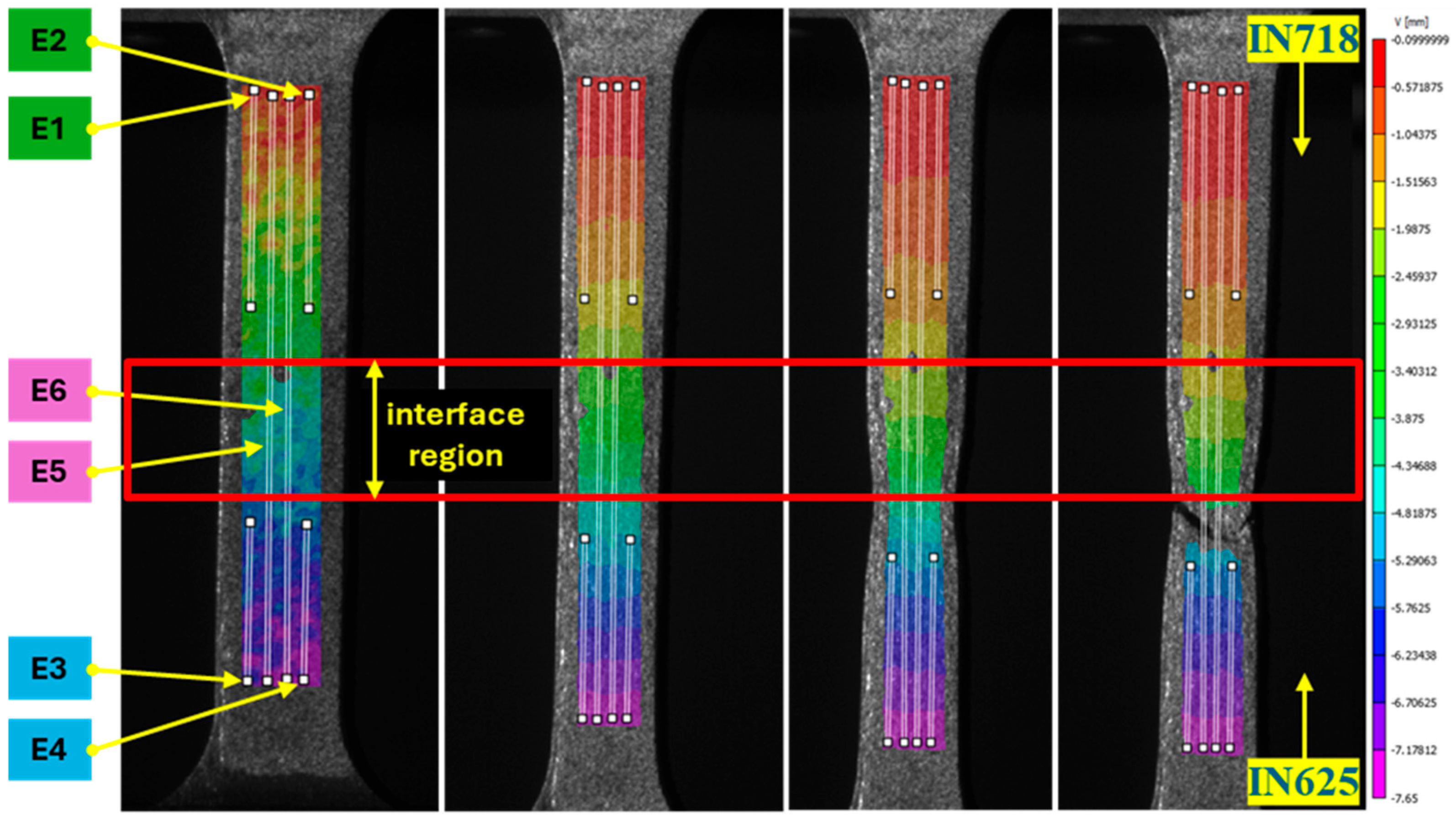

2.4. Mechanical Testing and Microstructure Characterization

3. Results and Discussion

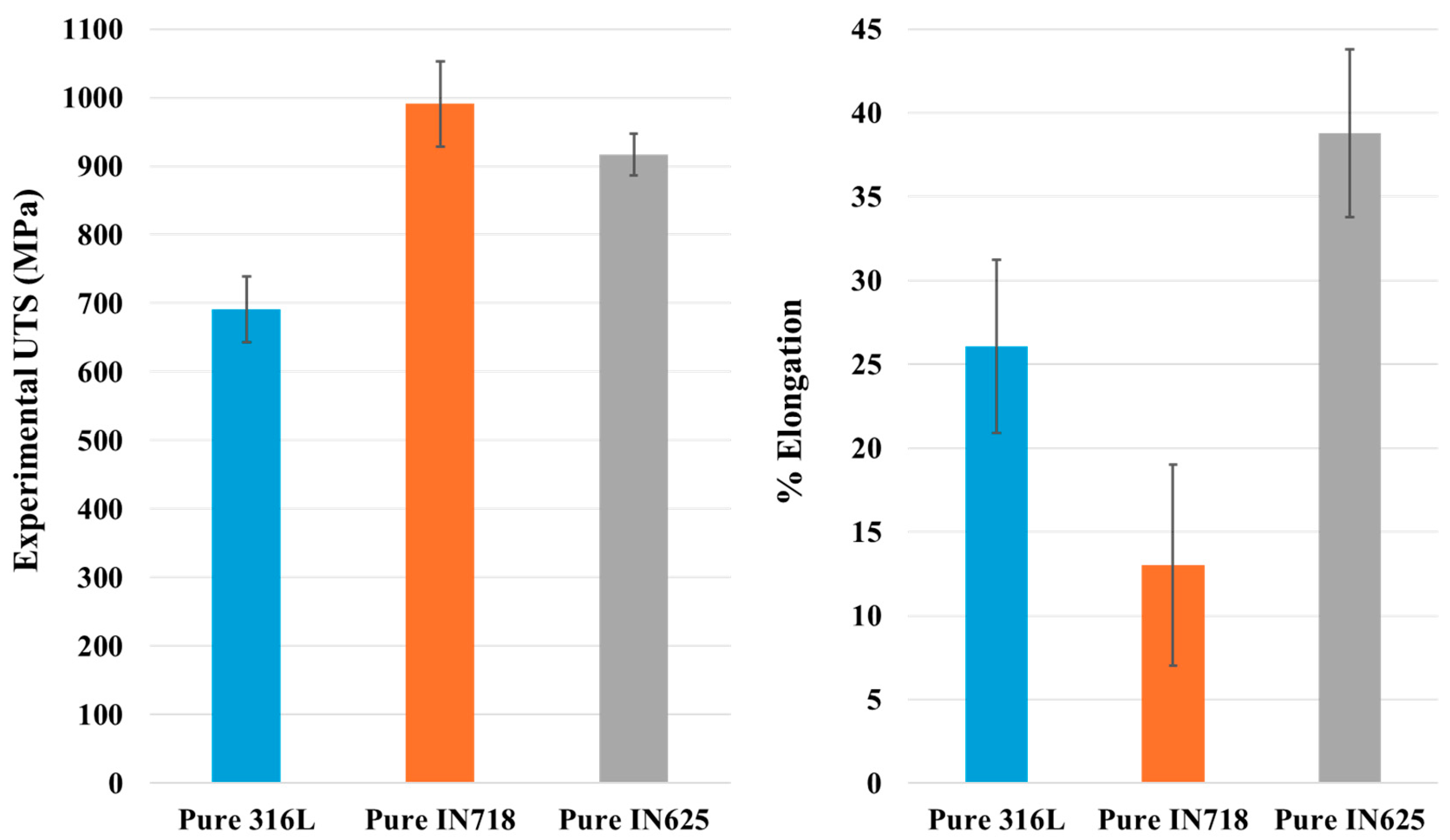

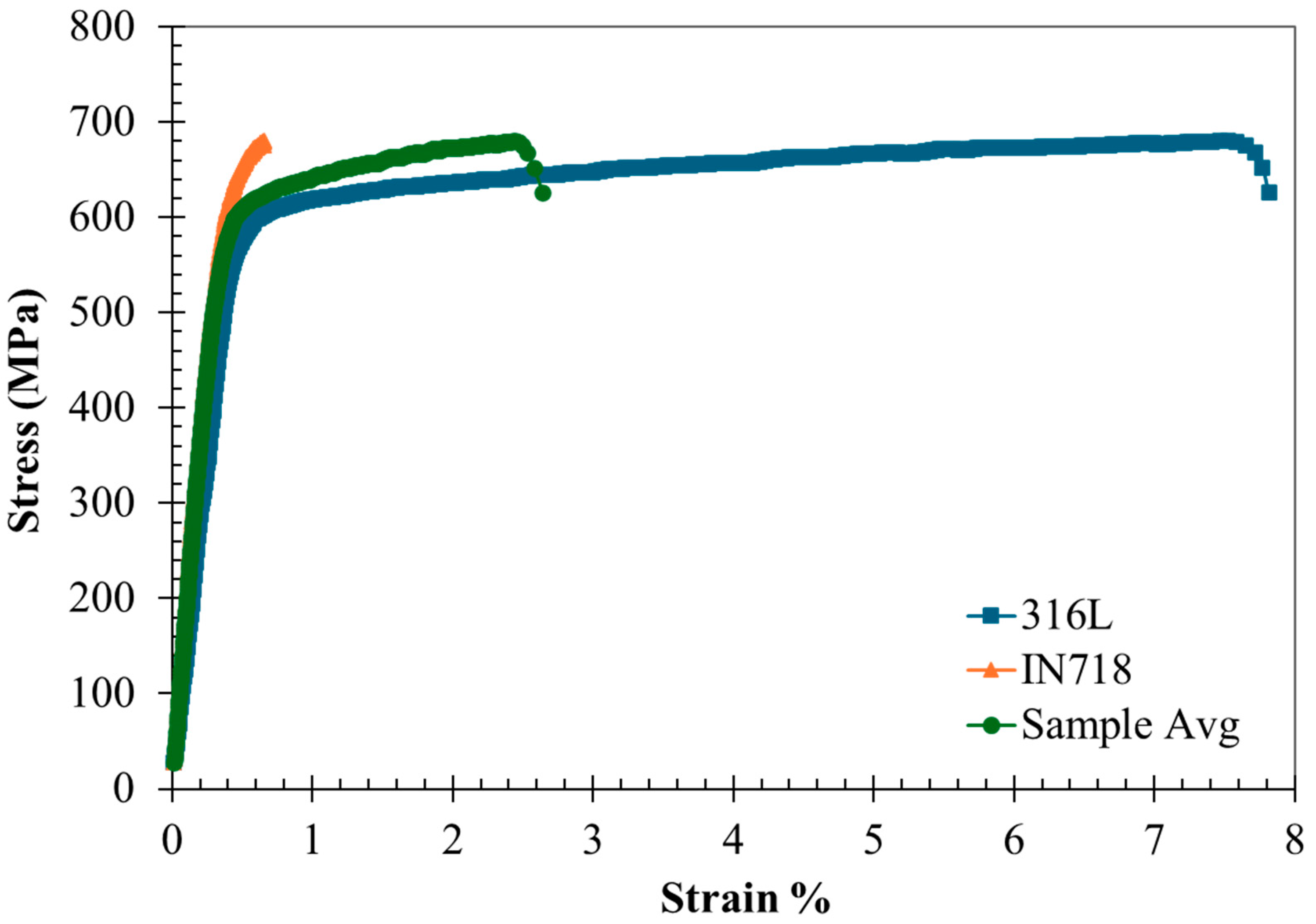

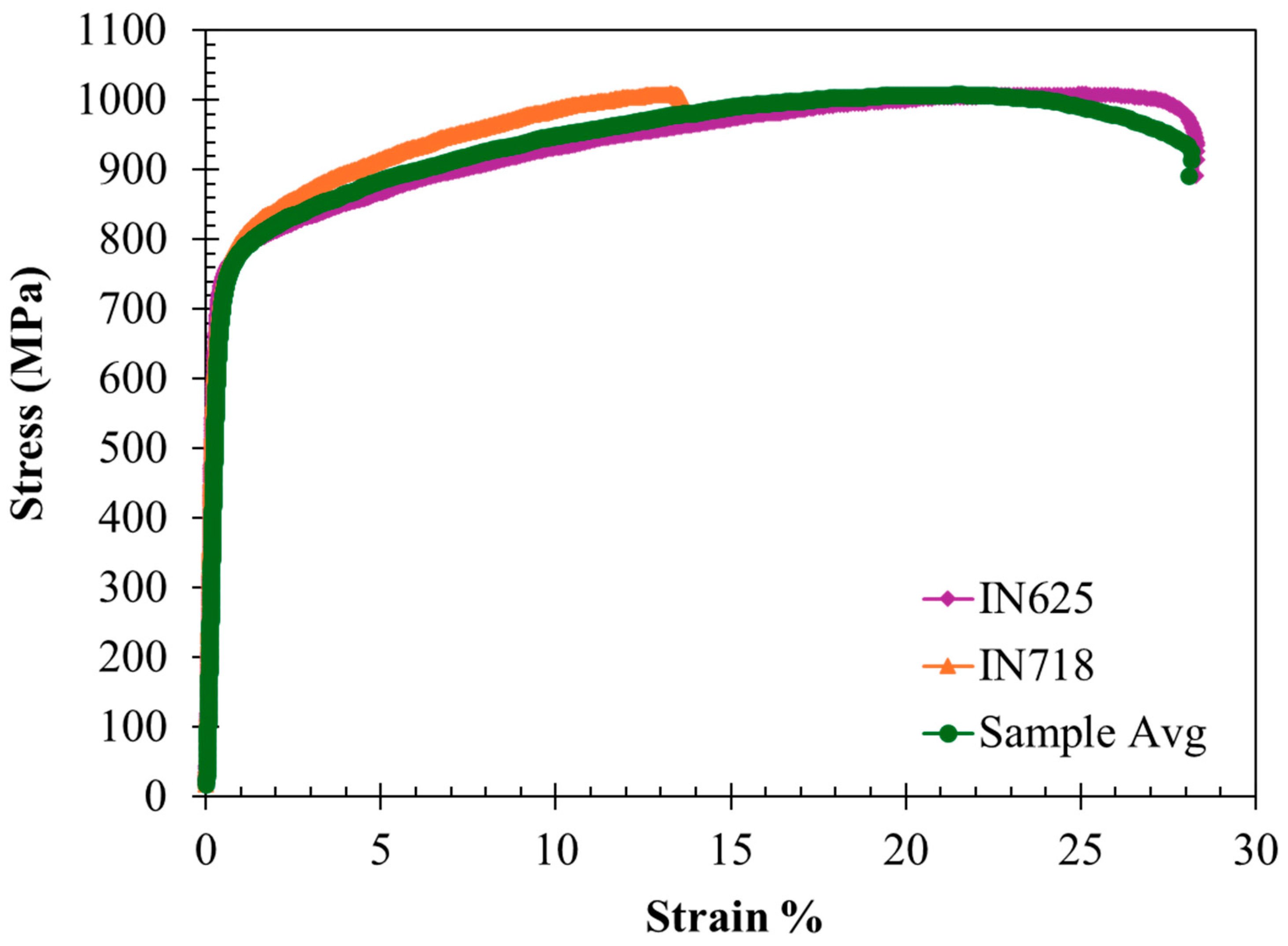

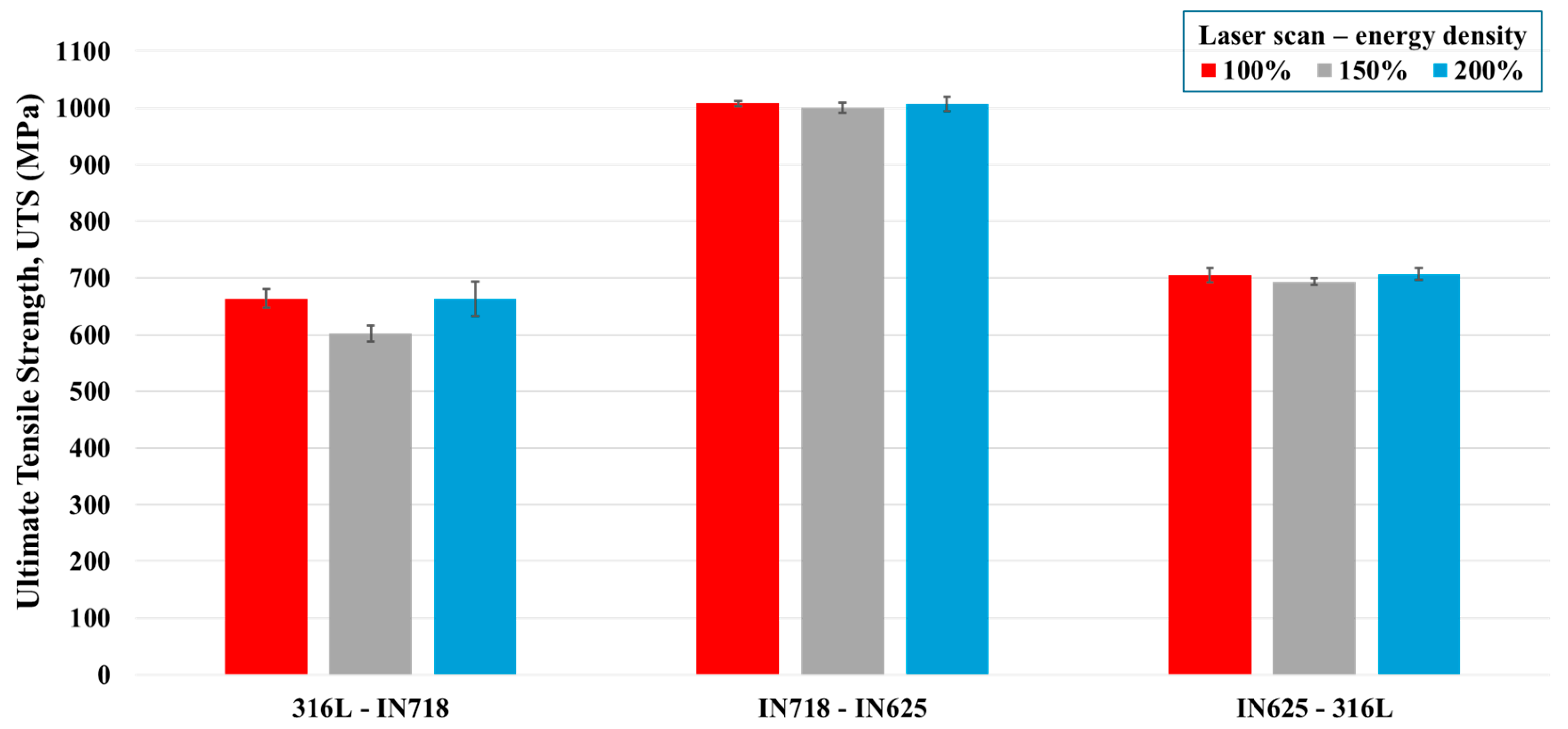

3.1. Mechanical Properties

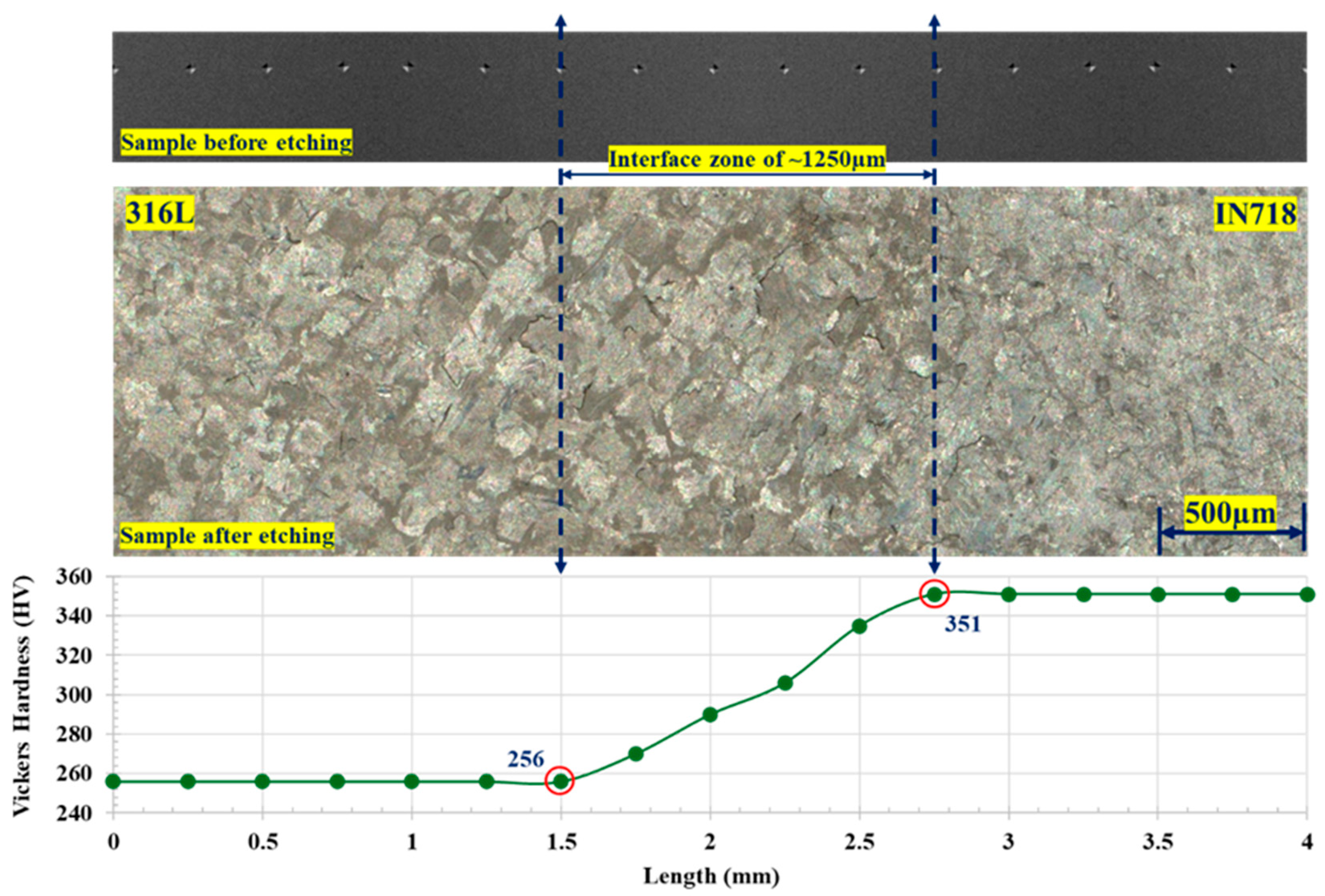

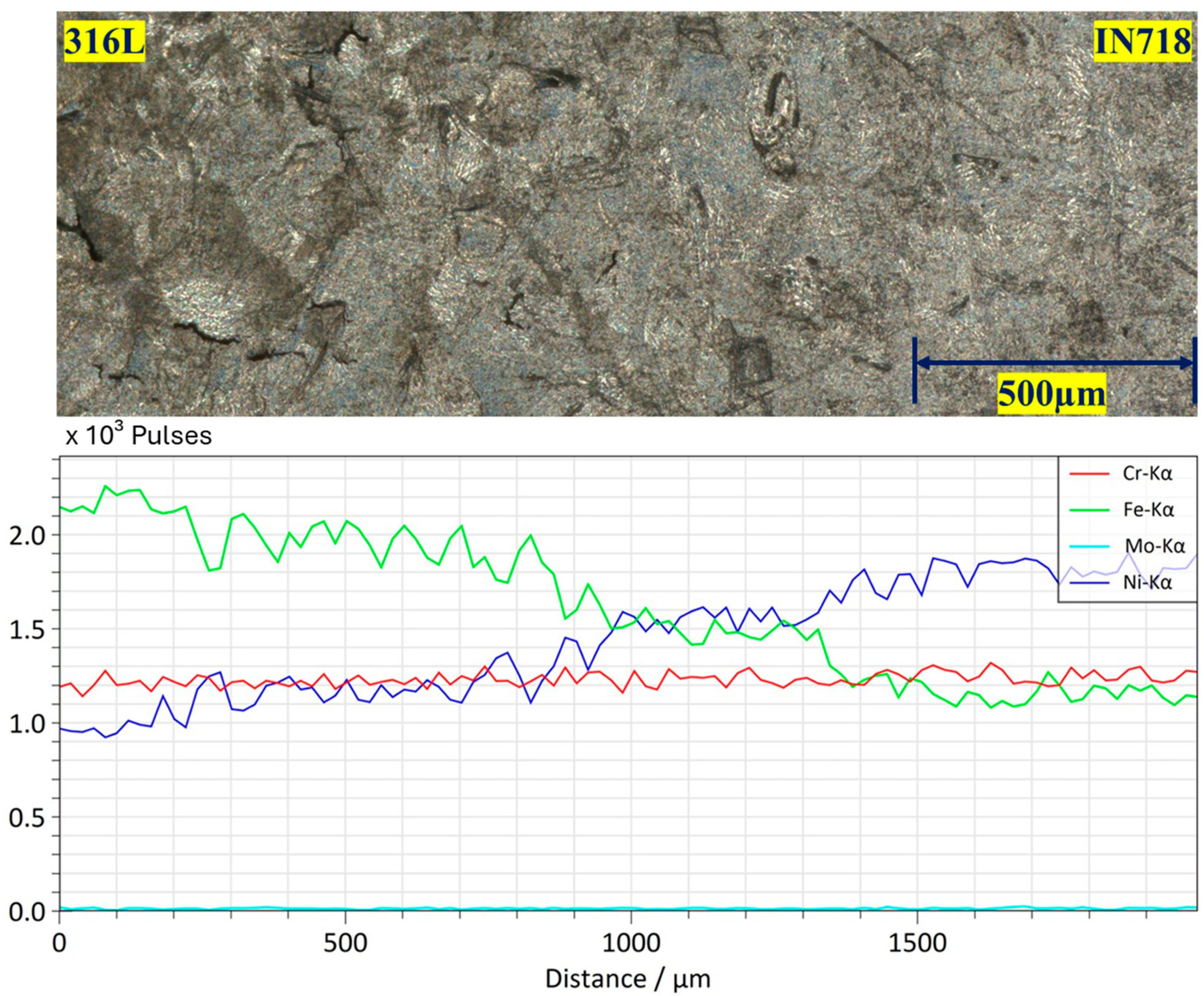

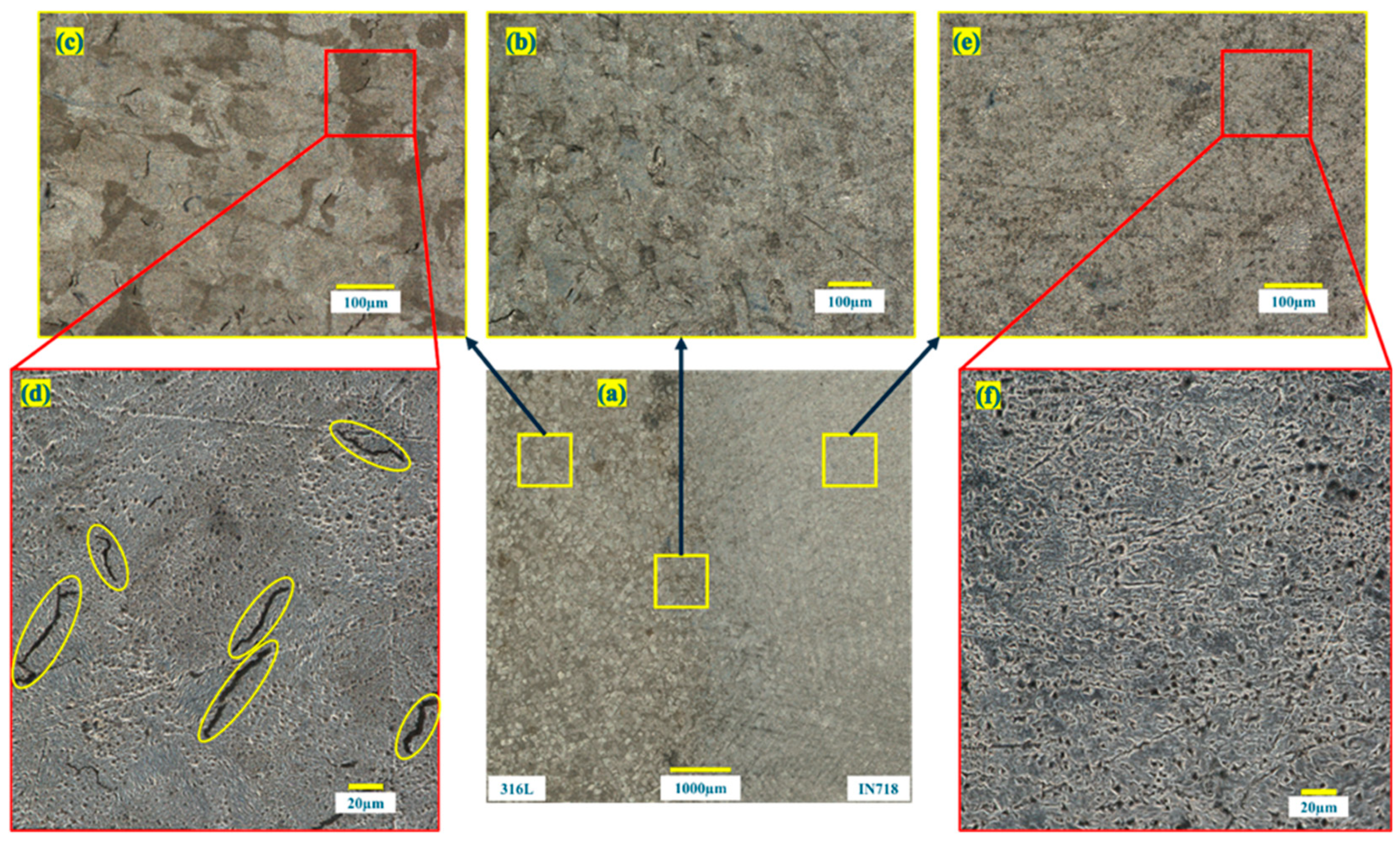

3.2. Interface Characterization

4. Conclusions

- The ultimate tensile strength (UTS) and overall mechanical performance of multi-material L-PBF samples were comparable across different scanned energy density conditions. This suggests that a strong, reliable multi-material joint can be achieved in L-PBF in a single build by adjusting laser parameters and scanning strategies, supporting the effectiveness of the binning method for producing multi-material samples.

- UTS values of the multi-material samples were found to closely match those of the lower-strength constituent material—specifically 316L in the 316L–IN718 and IN625–316L combinations. In contrast, the UTS of the IN718–IN625 sample was measured to fall between the UTS values of its individual components, exceeding the UTS of the weaker material, IN625.

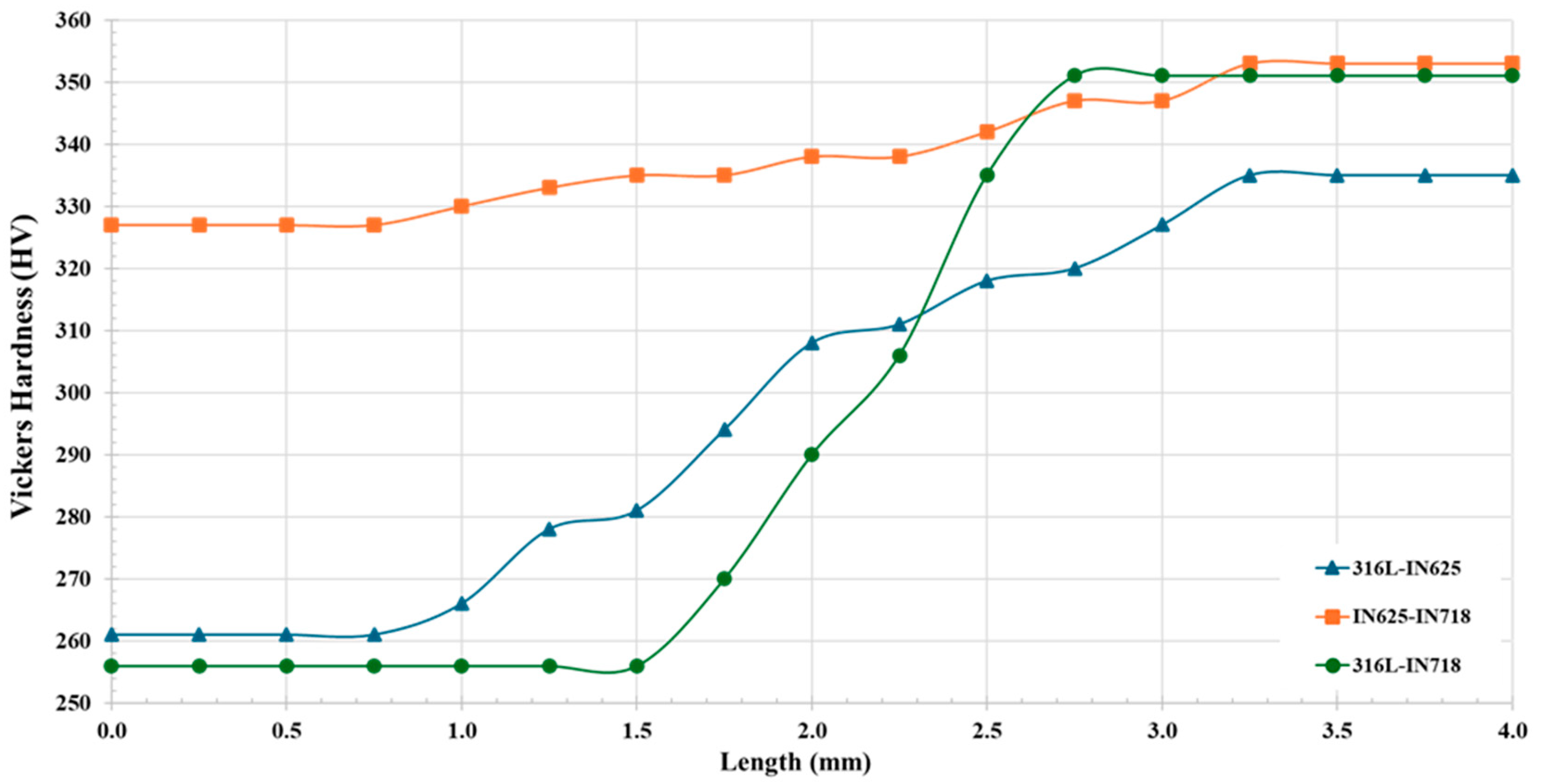

- Throughout the interface region, hardness testing results show a diffuse transition zone between materials averaging 1.5–2.0 mm in length.

- Rescanning the sample with 50% and 100% energy density did not significantly change the interface failure strength, although some small changes were noticed. Due to the overlapping processing parameter window for these specific 316L and Inconel metallic powders, a single scan using the simplified parameter set was able to reach properties closely matching those reported in the literature, eliminating the time and preparation efforts needed associated with more elaborate rescan strategies.

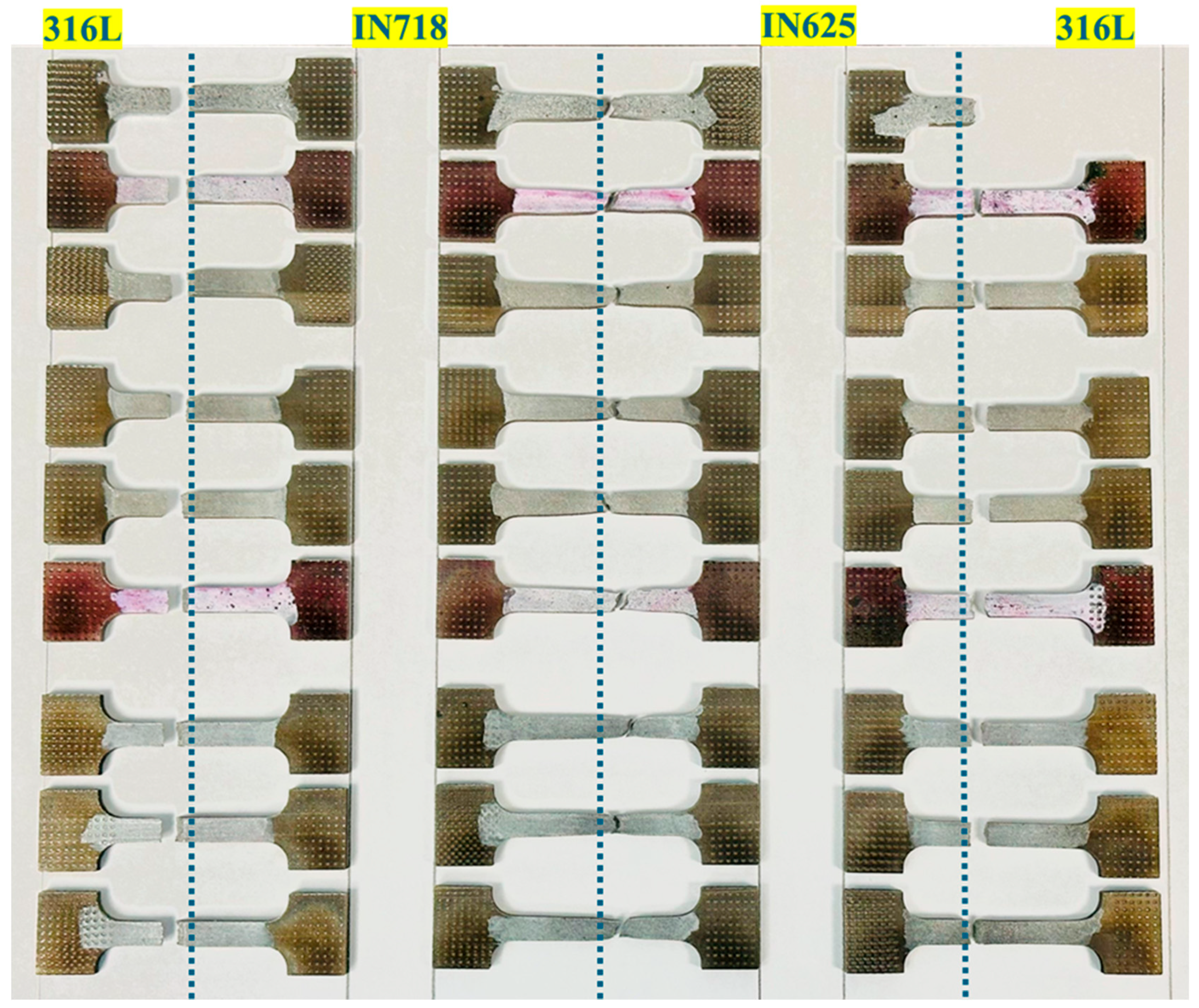

- The failure initiation location for all specimens was consistently located within the weaker material, at the beginning or before the start of the transition zone.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| L-PBF | Laser Powder Bed Fusion |

| MMAM | Multi-material Additive Manufacturing |

| DED | Direct Energy Deposition |

| VED | Volumetric Energy Density |

| 316L | Stainless steel 316 alloy |

| IN718 | Inconel 718 alloy |

| IN625 | Inconel 625 alloy |

| FRH | Hall Flow Rate |

| SEM | Scanning Electron Microscopy |

| EDX | Energy Dispersive X-Ray Spectroscopy |

References

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Wei, C.; Li, L.; Zhang, X.; Chueh, Y.-H. 3D printing of multiple metallic materials via modified selective laser melting. CIRP Ann. 2018, 67, 245–248. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Z.; Cheng, D.; Sun, Z.; Zhu, M.; Li, L. An overview of laser-based multiple metallic material additive manufacturing: From macro- to micro-scales. Int. J. Extrem. Manuf. 2021, 3, 012003. [Google Scholar] [CrossRef]

- Borisov, E.; Polozov, I.; Starikov, K.; Popovich, A.; Sufiiarov, V. Structure and Properties of Ti/Ti64 Graded Material Manufactured by Laser Powder Bed Fusion. Materials 2021, 14, 6140. [Google Scholar] [CrossRef]

- Wei, C.; Li, L. Recent progress and scientific challenges in multi-material additive manufacturing via laser-based powder bed fusion. Virtual Phys. Prototyp. 2021, 16, 347–371. [Google Scholar] [CrossRef]

- Han, D.; Lee, H. Recent advances in multi-material additive manufacturing: Methods and applications. Curr. Opin. Chem. Eng. 2020, 28, 158–166. [Google Scholar] [CrossRef]

- Walker, J.; Middendorf, J.R.; Lesko, C.C.C.; Gockel, J. Multi-material laser powder bed fusion additive manufacturing in 3-dimensions. Manuf. Lett. 2022, 31, 74–77. [Google Scholar] [CrossRef]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges. J. Manuf. Mater. Process. 2022, 6, 4. [Google Scholar] [CrossRef]

- Wu, Z.; Wilson-Heid, A.E.; Griffiths, R.J.; Elton, E.S. A review on experimentally observed mechanical and microstructural characteristics of interfaces in multi-material laser powder bed fusion. Front. Mech. Eng. 2023, 9, 1087021. [Google Scholar] [CrossRef]

- Nazir, A.; Gokcekaya, O.; Md Masum Billah, K.; Ertugrul, O.; Jiang, J.; Sun, J.; Hussain, S. Multi-material additive manufacturing: A systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Mater. Des. 2023, 226, 111661. [Google Scholar] [CrossRef]

- Razzaq, S.; Pan, Z.X.; Li, H.J.; Ringer, S.P.; Liao, X.Z. Joining dissimilar metals by additive manufacturing: A review. J. Mater. Res. Technol. 2024, 31, 2820–2845. [Google Scholar] [CrossRef]

- Verma, A.; Kapil, A.; Klobčar, D.; Sharma, A. A Review on Multiplicity in Multi-Material Additive Manufacturing: Process, Capability, Scale, and Structure. Materials 2023, 16, 5246. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Multi-material selective laser melting of Fe/Al-12Si components. Manuf. Lett. 2017, 11, 8–11. [Google Scholar] [CrossRef]

- Arivazhagan, N.; Singh, S.; Prakash, S.; Reddy, G.M. Investigation on AISI 304 austenitic stainless steel to AISI 4140 low alloy steel dissimilar joints by gas tungsten arc, electron beam and friction welding. Mater. Des. 2011, 32, 3036–3050. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Huang, C.; Xiang, T.; Ni, Y.; Wei, H. Welding process characteristics of pulse on pulse MIG arc brazing of aluminum alloy to stainless steel. Int. J. Adv. Manuf. Technol. 2017, 91, 1057–1067. [Google Scholar] [CrossRef]

- Taban, E.; Gould, J.E.; Lippold, J.C. Dissimilar friction welding of 6061-T6 aluminum and AISI 1018 steel: Properties and microstructural characterization. Mater. Des. 2010, 31, 2305–2311. [Google Scholar] [CrossRef]

- Liyanage, T.; Kilbourne, J.; Gerlich, A.P.; North, T.H. Joint formation in dissimilar Al alloy/steel and Mg alloy/steel friction stir spot welds. Sci. Technol. Weld. Join. 2009, 14, 500–508. [Google Scholar] [CrossRef]

- Pardal, G.; Meco, S.; Ganguly, S.; Williams, S.; Prangnell, P. Dissimilar metal laser spot joining of steel to aluminium in conduction mode. Int. J. Adv. Manuf. Technol. 2014, 73, 365–373. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Gisario, A.; Broggiato, G.B.; Puopolo, M.; Vesco, S.; Barletta, M. Effect of welding parameters on functionality of dissimilar laser-welded NiTi superelastic (SE) to shape memory effect (SME) wires. Int. J. Adv. Manuf. Technol. 2019, 103, 1593–1601. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Gisario, A.; Barletta, M.; Natali, S.; Veniali, F. Dissimilar Laser Welding of NiTi Wires. Lasers Manuf. Mater. Process. 2019, 6, 99–112. [Google Scholar] [CrossRef]

- Yang, J.; Chen, J.; Zhao, W.; Zhang, P.; Yu, Z.; Li, Y.; Zeng, Z.; Zhou, N. Diode Laser Welding/Brazing of Aluminum Alloy to Steel Using a Nickel Coating. Appl. Sci. 2018, 8, 922. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Grevey, D.; Sallamand, P. Dissimilar laser welding of AISI 316L stainless steel to Ti6–Al4–6V alloy via pure vanadium interlayer. Mater. Sci. Eng. A 2015, 622, 37–45. [Google Scholar] [CrossRef]

- Uhlmann, E.; Saber, Y. Mechanical properties of steel–copper multi-material samples built by laser powder bed fusion using a graded energy input. Prog. Addit. Manuf. 2025, 10, 475–489. [Google Scholar] [CrossRef]

- Rankouhi, B.; Jahani, S.; Pfefferkorn, F.E.; Thoma, D.J. Compositional grading of a 316L-Cu multi-material part using machine learning for the determination of selective laser melting process parameters. Addit. Manuf. 2021, 38, 101836. [Google Scholar] [CrossRef]

- Chen, K.; Wang, C.; Hong, Q.; Wen, S.; Zhou, Y.; Yan, C.; Shi, Y. Selective laser melting 316L/CuSn10 multi-materials: Processing optimization, interfacial characterization and mechanical property. J. Mater. Process. Technol. 2020, 283, 116701. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Song, C.; Zhang, M.; Wu, S.; Wang, D. Interfacial microstructure and mechanical properties of 316L/CuSn10 multi-material bimetallic structure fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 752, 75–85. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Wang, D.; Song, C.; Chen, J. Microstructure and mechanical properties of CuSn/18Ni300 bimetallic porous structures manufactured by selective laser melting. Mater. Des. 2019, 165, 107583. [Google Scholar] [CrossRef]

- Scaramuccia, M.G.; Demir, A.G.; Caprio, L.; Tassa, O.; Previtali, B. Development of processing strategies for multigraded selective laser melting of Ti6Al4V and IN718. Powder Technol. 2020, 367, 376–389. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Costa, M.M.; Alves, N.; Miranda, G.; Silva, F.S. Additive manufacturing of NiTi-Ti6Al4V multi-material cellular structures targeting orthopedic implants. Opt. Lasers Eng. 2020, 134, 106208. [Google Scholar] [CrossRef]

- Khaimovich, A.; Erisov, Y.; Smelov, V.; Agapovichev, A.; Petrov, I.; Razhivin, V.; Bobrovskij, I.; Kokareva, V.; Kuzin, A. Interface Quality Indices of Al–10Si–Mg Aluminum Alloy and Cr18–Ni10–Ti Stainless-Steel Bimetal Fabricated via Selective Laser Melting. Metals 2021, 11, 172. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Mazlan, N.; Musa, N.H.; Zhao, X.; Chen, Y.; Yang, S.; Nordin, N.A.; Mazlan, S.A.; Gao, N. Microstructures and Hardening Mechanisms of a 316L Stainless Steel/Inconel 718 Interface Additively Manufactured by Multi-Material Selective Laser Melting. Metals 2023, 13, 400. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Zhao, X.; Yang, S.; Gao, N. Interfacial characterisation of multi-material 316L stainless steel/Inconel 718 fabricated by laser powder bed fusion. Mater. Lett. 2021, 284, 128928. [Google Scholar] [CrossRef]

- Ureña, J.; Alvarez-Leal, M. Microstructural and hardness characterization of stainless steel 316-Inconel 718 multimaterial developed by wire-based Directed Energy Deposition. Int. J. Adv. Manuf. Technol. 2024, 135, 2975–2986. [Google Scholar] [CrossRef]

- Chen, Y.-X.; Qiu, J.-R.; Chang, W.-L.; Hwang, Y.-K.; Hwang, S.-J. Process optimization and mechanical properties analysis of Inconel 718/stainless steel 316 L multi-material via direct energy deposition. Sci. Rep. 2024, 14, 28927. [Google Scholar] [CrossRef] [PubMed]

- Carroll, B.E.; Otis, R.A.; Borgonia, J.P.; Suh, J.-O.; Dillon, R.P.; Shapiro, A.A.; Hofmann, D.C.; Liu, Z.-K.; Beese, A.M. Functionally graded material of 304L stainless steel and inconel 625 fabricated by directed energy deposition: Characterization and thermodynamic modeling. Acta Mater. 2016, 108, 46–54. [Google Scholar] [CrossRef]

- Bodner, S.C.; Hlushko, K.; van de Vorst, L.T.G.; Meindlhumer, M.; Todt, J.; Nielsen, M.A.; Hooijmans, J.W.; Saurwalt, J.J.; Mirzaei, S.; Keckes, J. Graded Inconel-stainless steel multi-material structure by inter- and intralayer variation of metal alloys. J. Mater. Res. Technol. 2022, 21, 4846–4859. [Google Scholar] [CrossRef]

- Ferro, P.; Fabrizi, A.; Elsayed, H.; Savio, G. Multi-Material Additive Manufacturing: Creating IN718-AISI 316L Bimetallic Parts by 3D Printing, Debinding, and Sintering. Sustainability 2023, 15, 11911. [Google Scholar] [CrossRef]

- Duval-Chaneac, M.S.; Gao, N.; Khan, R.H.U.; Giles, M.; Georgilas, K.; Zhao, X.; Reed, P.A.S. Fatigue crack growth in IN718/316L multi-materials layered structures fabricated by laser powder bed fusion. Int. J. Fatigue 2021, 152, 106454. [Google Scholar] [CrossRef]

- Mahmud, A.; Ayers, N.; Huynh, T.; Sohn, Y. Additive Manufacturing of SS316L/IN718 Bimetallic Structure via Laser Powder Bed Fusion. Materials 2023, 16, 6527. [Google Scholar] [CrossRef]

- Ramkumar, T.; Selvakumar, M.; Narayanasamy, P.; Begam, A.A.; Mathavan, P.; Raj, A.A. Studies on the structural property, mechanical relationships and corrosion behaviour of Inconel 718 and SS 316L dissimilar joints by TIG welding without using activated flux. J. Manuf. Process. 2017, 30, 290–298. [Google Scholar] [CrossRef]

- Hinojos, A.; Mireles, J.; Reichardt, A.; Frigola, P.; Hosemann, P.; Murr, L.E.; Wicker, R.B. Joining of Inconel 718 and 316 Stainless Steel using electron beam melting additive manufacturing technology. Mater. Des. 2016, 94, 17–27. [Google Scholar] [CrossRef]

- Pratheesh Kumar, S.; Elangovan, S.; Mohanraj, R.; Ramakrishna, J.R. A review on properties of Inconel 625 and Inconel 718 fabricated using direct energy deposition. Mater. Today Proc. 2021, 46, 7892–7906. [Google Scholar] [CrossRef]

- Shahwaz, M.; Nath, P.; Sen, I. A critical review on the microstructure and mechanical properties correlation of additively manufactured nickel-based superalloys. J. Alloys Compd. 2022, 907, 164530. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kishore Babu, N.; Talari, M.K.; Anwar, S.; Usmani, Y.; Al-Samhan, A.M. Dissimilar Rotary Friction Welding of Inconel 718 to F22 Using Inconel 625 Interlayer. Appl. Sci. 2021, 11, 10684. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Cipriano Farias, F.W.; Avila, J.A.; Maawad, E.; Schell, N.; Santos, T.G.; Oliveira, J.P. Effect of heat treatments on Inconel 625 fabricated by wire and arc additive manufacturing: An in situ synchrotron X-ray diffraction analysis. Sci. Technol. Weld. Join. 2023, 28, 534–539. [Google Scholar] [CrossRef]

- Evangeline, A.; Sathiya, P. Dissimilar Cladding of Ni–Cr–Mo Superalloy over 316L Austenitic Stainless Steel: Morphologies and Mechanical Properties. Met. Mater. Int. 2021, 27, 1155–1172. [Google Scholar] [CrossRef]

- Chen, N.; Khan, H.A.; Wan, Z.; Lippert, J.; Sun, H.; Shang, S.-L.; Liu, Z.-K.; Li, J. Microstructural characteristics and crack formation in additively manufactured bimetal material of 316L stainless steel and Inconel 625. Addit. Manuf. 2020, 32, 101037. [Google Scholar] [CrossRef]

- Kourdani, A.; Derakhshandeh-Haghighi, R. Evaluating the Properties of Dissimilar Metal Welding Between Inconel 625 and 316L Stainless Steel by Applying Different Welding Methods and Consumables. Metall. Mater. Trans. A 2018, 49, 1231–1243. [Google Scholar] [CrossRef]

- Zheng, Y.; Xiong, R.; Zhao, Z.; Zhao, C.; Wang, Z.; Niu, W.; Xue, H.; Cheng, F.; Liu, W.; Wei, S. Laser melting deposition of in-situ (TiB+TiC) hybrid reinforced TC4 composites: Preparation, microstructure and room/high-temperature corrosion behaviour. J. Mater. Sci. Technol. 2025, 228, 137–154. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Rogal, Ł.; Kalita, D.; Berent, K.; Antoszewski, B.; Danielewski, H.; Węglowski, M.S.; Łazińska, M.; Durejko, T.; Czujko, T. Microstructure and Properties of Inconel 625 Fabricated Using Two Types of Laser Metal Deposition Methods. Materials 2020, 13, 5050. [Google Scholar] [CrossRef]

- Kaščák, Ľ.; Varga, J.; Bidulská, J.; Bidulský, R.; Kvačkaj, T. A Review of Simulation Tools Utilization for the Process of Laser Powder Bed Fusion. Materials 2025, 18, 895. [Google Scholar] [CrossRef]

- Beeravolu, A.R.; Babu, N.K.; Talari, M.K.; Rehman, A.U.; Srirangam, P. Influence of Microstructure and Mechanical Properties of Dissimilar Rotary Friction Welded Inconel to Stainless Steel Joints. Materials 2023, 16, 3049. [Google Scholar] [CrossRef] [PubMed]

- Chozaki, S.P.; Piili, H.; Afkhami, S.; Amraei, M.; Salminen, A. Investigation of the microstructure and mechanical properties of dissimilar joints of PBF-LB/IN718 to AISI 316L by laser welding. Weld. World 2025, 69, 1829–1845. [Google Scholar] [CrossRef]

- Dokme, F.; Kulekci, M.K.; Esme, U. Microstructural and Mechanical Characterization of Dissimilar Metal Welding of Inconel 625 and AISI 316L. Metals 2018, 8, 797. [Google Scholar] [CrossRef]

- Tyagi, S.; Balla, S.K.; Manjaiah, M.; Aranas, C. Microstructure and mechanical properties of stainless steel 316L-Inconel 625 bimetallic structure fabricated by laser wire direct energy deposition. J. Mater. Res. Technol. 2024, 33, 8361–8371. [Google Scholar] [CrossRef]

- Paraschiv, A.; Matache, G.; Constantin, N.; Vladut, M. Investigation of Scanning Strategies and Laser Remelting Effects on Top Surface Deformation of Additively Manufactured IN 625. Materials 2022, 15, 3198. [Google Scholar] [CrossRef]

- Ravichander, B.B.; Jagdale, S.H.; Kumar, G. Interpenetrating microstructure in laser powder-bed fusion parts using selective rescanning. Addit. Manuf. Lett. 2024, 10, 100221. [Google Scholar] [CrossRef]

- Jiang, R.; Yang, Y.; Wang, H.; Liu, Z.; Liu, L.; Du, J.; Tang, T.; Ye, Z.; Li, Q.; Yan, X.; et al. Effects of remelting scan strategy on the overlapping quality of 316L stainless steel fabricated by multi-laser powder bed fusion. Mater. Sci. Eng. A 2025, 923, 147725. [Google Scholar] [CrossRef]

- Thijs, L.; Montero Sistiaga, M.L.; Wauthle, R.; Xie, Q.; Kruth, J.-P.; Van Humbeeck, J. Strong morphological and crystallographic texture and resulting yield strength anisotropy in selective laser melted tantalum. Acta Mater. 2013, 61, 4657–4668. [Google Scholar] [CrossRef]

- Brooks, N.; Porter, L.; Vaseghi, M.; Palazotto, A.; Davami, K. Mechanical, Morphological, and Microstructural Characterization of Additively Manufactured Inconel 718 After Laser Surface Remelting at Different Scan Speeds. Metall. Mater. Trans. A 2022, 53, 4471–4480. [Google Scholar] [CrossRef]

- Liang, A.; Pey, K.S.; Polcar, T.; Hamilton, A.R. Effects of rescanning parameters on densification and microstructural refinement of 316L stainless steel fabricated by laser powder bed fusion. J. Mater. Process. Technol. 2022, 302, 117493. [Google Scholar] [CrossRef]

- Hasanabadi, M.; Keshavarzkermai, A.; Asgari, H.; Azizi, N.; Gerlich, A.; Toyserkani, E. In-situ microstructure control by laser post-exposure treatment during laser powder-bed fusion. Addit. Manuf. Lett. 2023, 4, 100110. [Google Scholar] [CrossRef]

- Tan, Z.; Gao, S.; Lan, L.; He, B. Effect of Rescanning Strategy on Residual Stress and Distortion of Two Alloys Manufactured by Selective Laser Melting. J. Mater. Eng. Perform. 2021, 30, 6493–6501. [Google Scholar] [CrossRef]

- Chen, L.; Richter, B.; Zhang, X.; Bertsch, K.B.; Thoma, D.J.; Pfefferkorn, F.E. Effect of laser polishing on the microstructure and mechanical properties of stainless steel 316L fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2021, 802, 140579. [Google Scholar] [CrossRef]

- Park, J.H.; Bang, G.B.; Lee, K.-A.; Son, Y.; Kim, W.R.; Kim, H.G. Effect on microstructural and mechanical properties of Inconel 718 superalloy fabricated by selective laser melting with rescanning by low energy density. J. Mater. Res. Technol. 2021, 10, 785–796. [Google Scholar] [CrossRef]

- Carpenter Additive. PowderRange® 316L DataSheet. Available online: https://www.carpenteradditive.com/hubfs/Resources/datasheets%202023/PowderRange_316L_Datasheet.pdf (accessed on 11 August 2024).

- Linde. TruForm™ 718 Metal Powder. Available online: https://assets.linde.com/-/media/global/advanced-material-technologies/advanced-material-technologies/literature/40-4219_truform_718_amt_web.pdf (accessed on 2 October 2024).

- EOS GmbH. EOS NickelAlloy IN625. Available online: https://www.eos.info/var/assets/03_system-related-assets/material-related-contents/metal-materials-and-examples/metal-material-datasheet/nickelalloy-inconel/niall-in625-m290_material_data_sheet_06-22_en.pdf (accessed on 28 February 2025).

- ASTM B213-20; Standard Test Methods for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D1708-18; Standard Test Method for Tensile Properties of Plastics by Use of Microtensile Specimens. ASTM International: West Conshohocken, PA, USA, 2018.

- Chlebus, E.; Gruber, K.; Kuźnicka, B.; Kurzac, J.; Kurzynowski, T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A 2015, 639, 647–655. [Google Scholar] [CrossRef]

| Element | SS 316L (wt. %) [66] | IN 718 (wt. %) [67] | IN 625 (wt. %) [68] |

|---|---|---|---|

| Fe | Balance | 15.00–21.00 | 5.00 |

| Cr | 16.00–18.00 | 17.00–21.00 | 23.00 |

| Ni | 10.00–14.00 | 50.00–55.00 | Balance |

| Mo | 2.00–3.00 | 2.80–3.30 | 10.00 |

| Nb | - | 4.75–5.55 | 4.15 |

| Ti | - | 0.65–1.15 | 0.40 |

| Co | - | 1.00 | 1.00 |

| Al | - | 0.20–0.80 | 0.40 |

| Mn | 2.00 | 0.35 | 0.50 |

| Si | 1.00 | 0.35 | 0.50 |

| S | 0.03 | 0.02 | 0.02 |

| P | 0.05 | 0.02 | 0.02 |

| C | 0.03 | 0.08 | 0.10 |

| Ta | - | 0.05 | 0.05 |

| Cu | - | 0.30 | - |

| B | - | 0.01 | - |

| N | 0.10 | - | - |

| O | 0.10 | - | - |

| Laser Power (W) | Scan Speed (mm/s) | Layer Height (µm) | |

|---|---|---|---|

| Parameter P1 | 285 | 960 | 40 |

| Parameter P2 | 145 | 960 | 40 |

| VED (J/mm3) | |

|---|---|

| Parameter P1 | 114.18 |

| Parameter P2 | 58.09 |

| VED (J/mm3) | |

|---|---|

| Scan Strategy 1 | Scanned by VED of 114.18 J/mm3 |

| Scan Strategy 2 | Scanned by VED of 114.18 J/mm3 Rescanned by VED of 58.09 J/mm3 |

| Scan Strategy 3 | Half-half section scanned by VED of 114.18 J/mm3 4 mm overlap section gets double scan of 114.18 J/mm3 |

| Sample | Total % Elongation at Break | ||

|---|---|---|---|

| 100% (All P1) | 150% (P1 + P2 Rescan) | 200% (P1 Half-Half Overlap) | |

| 316L–IN718 | 3.04 | 2.15 | 3.11 |

| IN718–IN625 | 28.31 | 27.68 | 28.74 |

| IN625–316L | 12.28 | 11.94 | 14.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niraula, S.; Dodge, B.S.; Gillham, J.D.; Berfield, T.A. Interfacial Strength Testing of Laser Powder Bed Fusion Metal Samples Produced Using the Multi-Material Binning Method. J. Manuf. Mater. Process. 2025, 9, 327. https://doi.org/10.3390/jmmp9100327

Niraula S, Dodge BS, Gillham JD, Berfield TA. Interfacial Strength Testing of Laser Powder Bed Fusion Metal Samples Produced Using the Multi-Material Binning Method. Journal of Manufacturing and Materials Processing. 2025; 9(10):327. https://doi.org/10.3390/jmmp9100327

Chicago/Turabian StyleNiraula, Suyash, Brendon S. Dodge, Justin D. Gillham, and Thomas A. Berfield. 2025. "Interfacial Strength Testing of Laser Powder Bed Fusion Metal Samples Produced Using the Multi-Material Binning Method" Journal of Manufacturing and Materials Processing 9, no. 10: 327. https://doi.org/10.3390/jmmp9100327

APA StyleNiraula, S., Dodge, B. S., Gillham, J. D., & Berfield, T. A. (2025). Interfacial Strength Testing of Laser Powder Bed Fusion Metal Samples Produced Using the Multi-Material Binning Method. Journal of Manufacturing and Materials Processing, 9(10), 327. https://doi.org/10.3390/jmmp9100327