Cumulative Energy Demand Analysis of Commercial and Hybrid Metal-Composite Gears at Different End-of-Life Strategies

Abstract

1. Introduction

2. Method

2.1. Case Study Design

2.1.1. Numerical Model

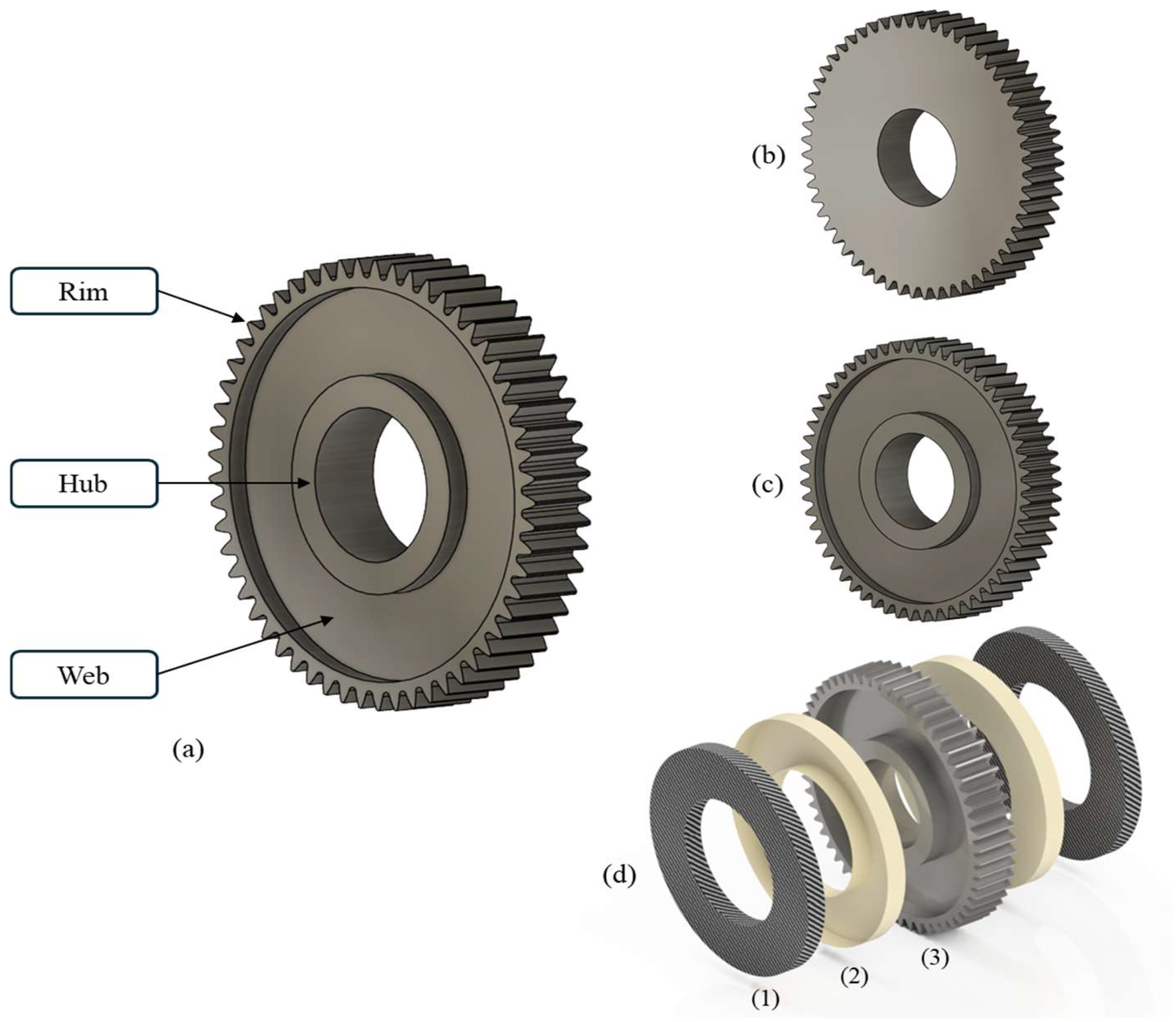

- Mass reduction is one of the key drivers of performance enhancement in automotive as well as aerospace sectors to satisfy the increasingly strict regulations on combustion engine emission and fuel efficiency [6,7,44]. Current design solutions rely either on material removal from the gear blank [11,45] or on the combination of lightweight materials with high-performance steel [22] to decrease the gear mass. In both cases, the optimal design choice must prevent the deterioration of N&V performance [12], while preserving the structural integrity of the geared transmission.

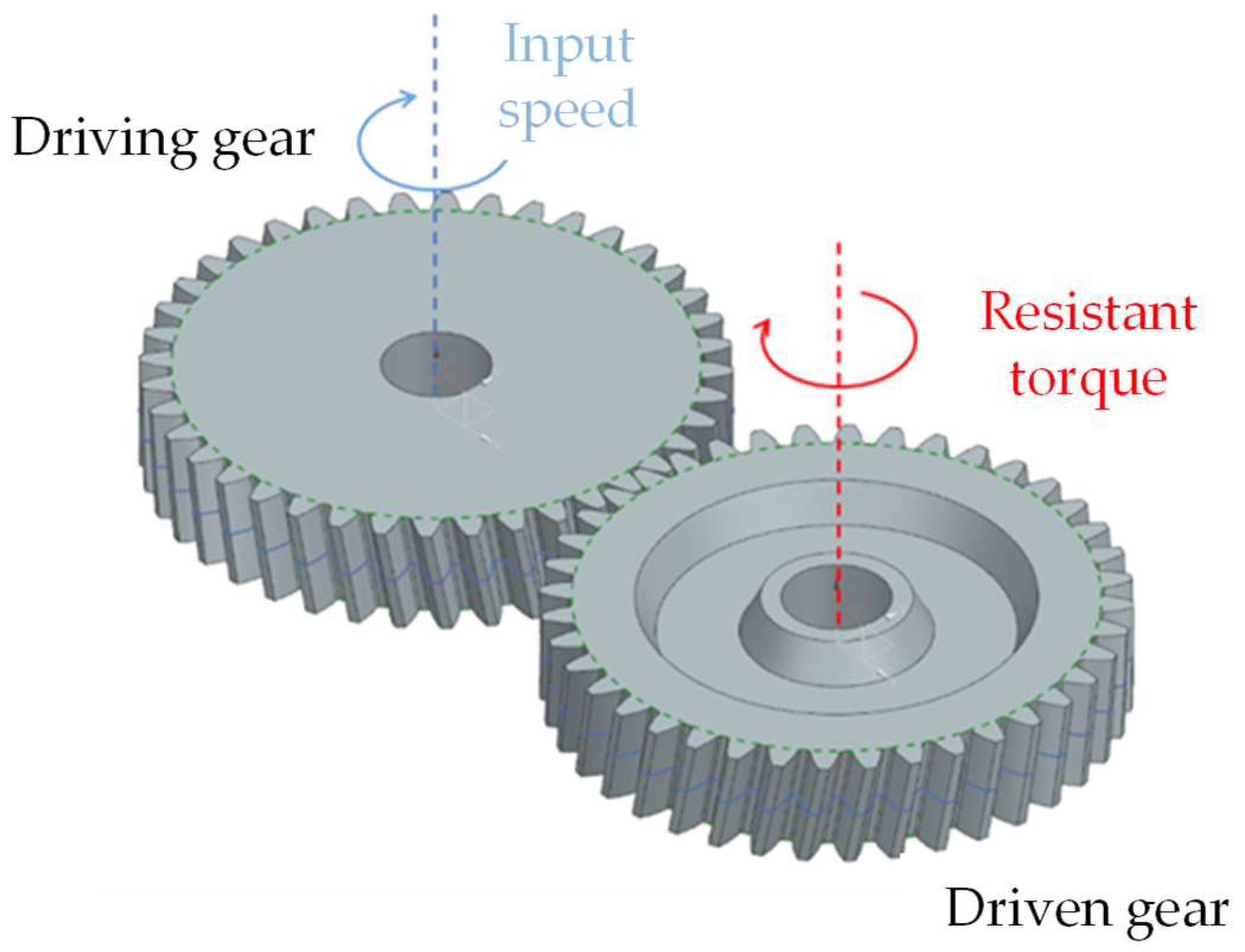

- Despite gears being designed to be perfectly conjugate, the lightweighting process introduces additional gear body flexibilities that induce deviations from the ideal kinematic conditions, producing unwanted self-induced vibrations. These are often traced back to the static transmission error (STE) of two meshing gears [12]. It is defined as the degree of offset between conjugate and actual behavior of the meshing gears:where τ is the transmission ratio of the gear pair, while Δ θ1 and Δθ2 are the rotations of the driving and driven gears, respectively. Due to the variability of the TE over the meshing cycle and the harmonic nature of the rotating gears, internal induced vibrations are generated, which highly affects the N&V performance of a geared transmission. In order to assess the severity of parametric excitation at different load and velocity levels, the pick-to-pick (PtP) value of the TE has been demonstrated in [46] to be a valuable and synthetic metric.

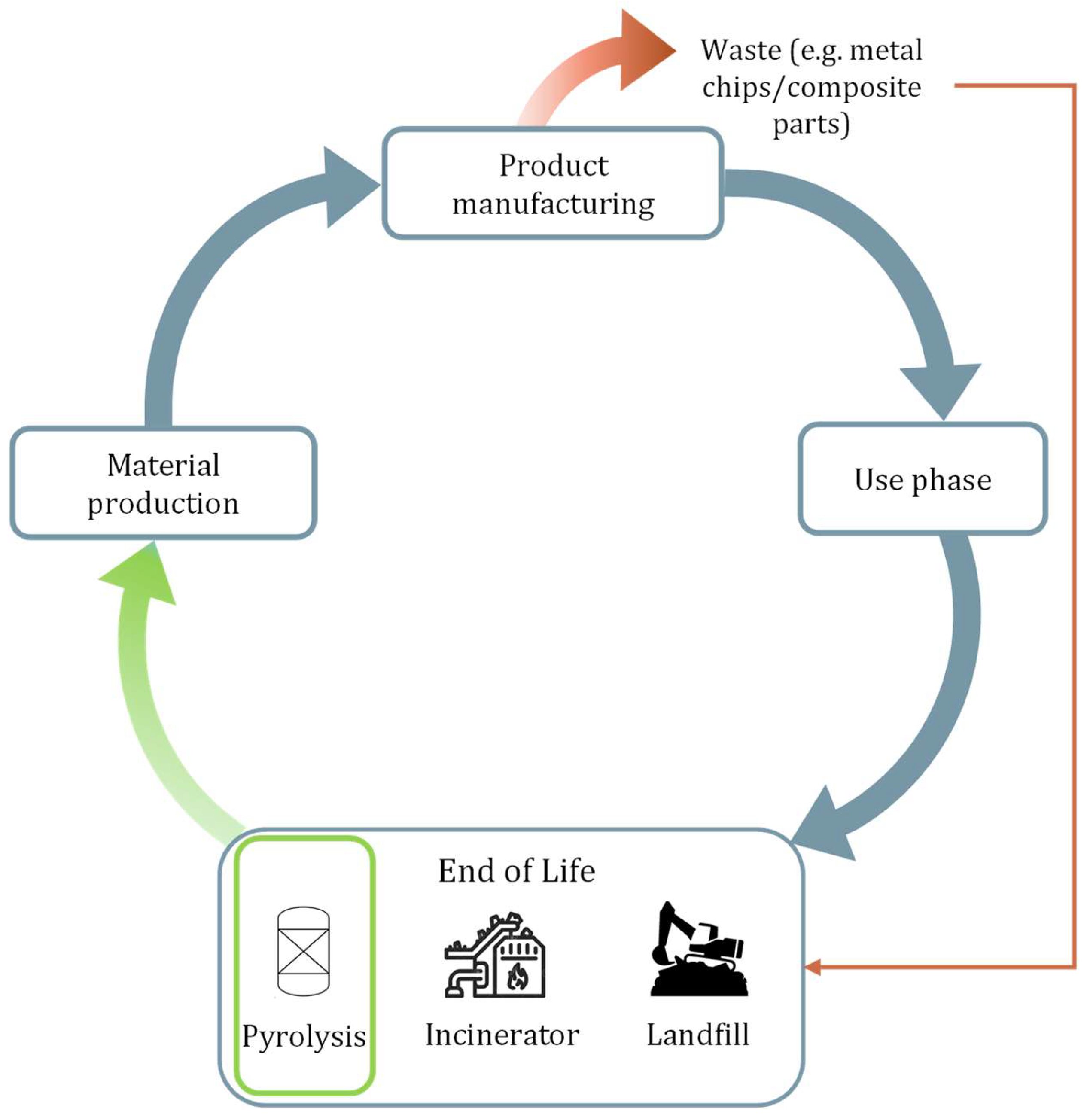

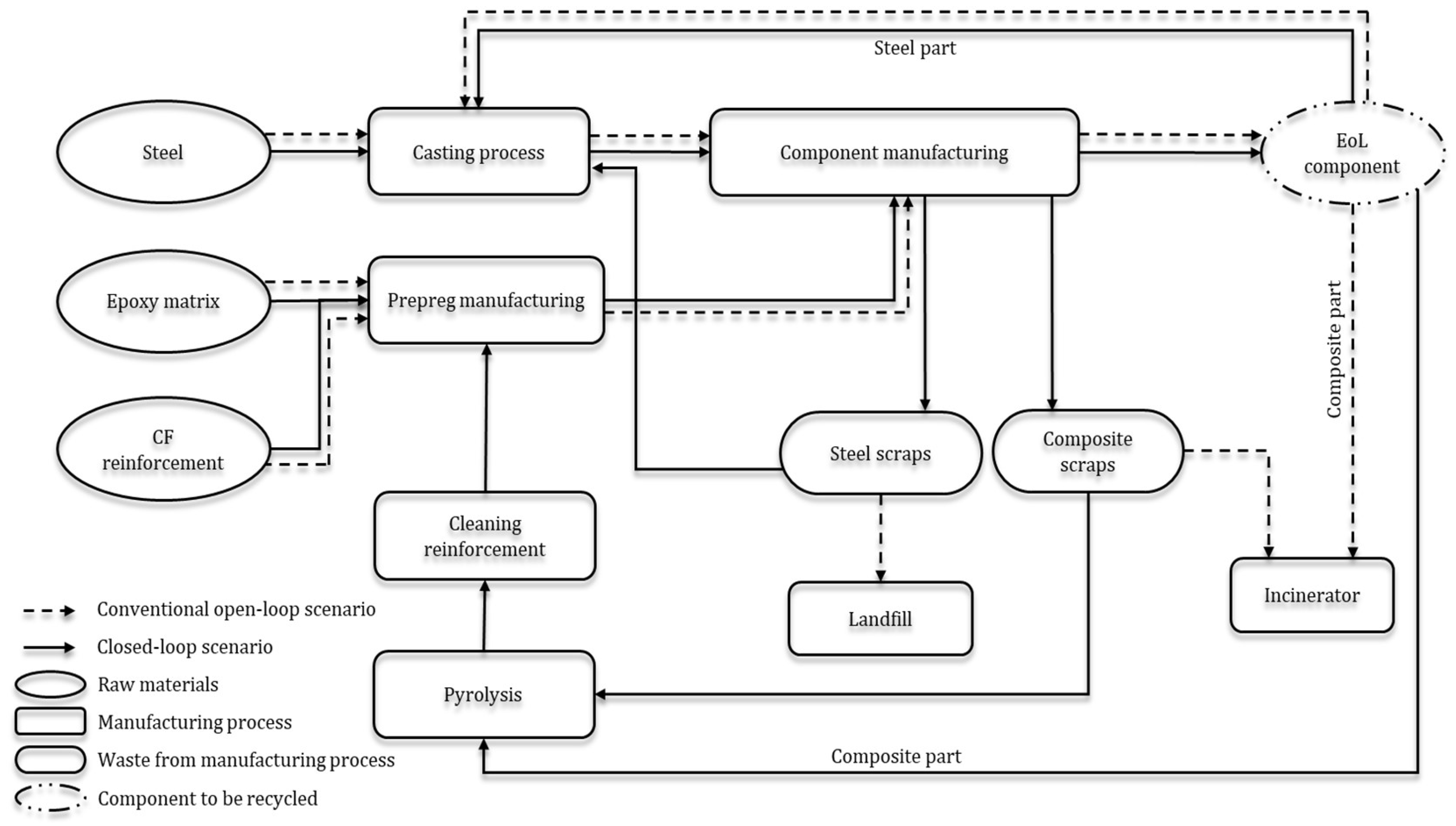

2.1.2. Goal and Scope Definition

2.1.3. Life Cycle Inventory (LCI)

2.1.4. Life Cycle Energy Demand Assessment

3. Discussion of Results

4. Conclusions

- The high environmental impact from an energy perspective, primarily attributable to the LCE associated with the CFRP laminate, prevents the hybrid gear from being considered environmentally friendly without the implementation of an appropriate EoL strategy. This is particularly evident when compared to the lightweight solution.

- The CED required for manufacturing hybrid gears could be significantly reduced with the adoption of effective recycling strategies. This would enhance the competitiveness of the hybrid solution, not only during the use phase, where its reduced weight is advantageous, but also in a comprehensive cradle-to-grave analysis.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nie, Y.; Li, F.; Wang, L.; Li, J.; Li, Y.; Sun, M.; Wang, M.; Li, G. A Novel Vibration Model for Explanation of the Frequency Features in Multistage Wind Turbine Gearboxes Considering the Effects of Inter-stage Meshing Frequency Modulation. Int. J. Precis. Eng. Manuf. Technol. 2022, 10, 151–166. [Google Scholar] [CrossRef]

- Kawasaki, K.; Tsuji, I. Manufacturing Method for Large Cylindrical Worm Gear Set of ISO Type I on Universal CNC Machine Tools. J. Manuf. Mater. Process. 2023, 7, 53. [Google Scholar] [CrossRef]

- Perdomo, I.L.F.; Quiza, R.; Haeseldonckx, D.; Rivas, M. Sustainability-Focused Multi-objective Optimization of a Turning process. Int. J. Precis. Eng. Manuf. Technol. 2019, 7, 1009–1018. [Google Scholar] [CrossRef]

- Zhu, M.; Wei, C.; Guo, W.; Zhang, Z.; Ouyang, J.; Mativenga, P.; Li, L. Significant Reduction in Energy Consumption and Carbon Emission While Improving Productivity in Laser Drilling of CFRP Sheets with a Novel Stepped Process Parameter Parallel Ring Method. J. Manuf. Mater. Process. 2022, 6, 7. [Google Scholar] [CrossRef]

- Dér, A.; Kaluza, A.; Reimer, L.; Herrmann, C.; Thiede, S. Integration of Energy Oriented Manufacturing Simulation into the Life Cycle Evaluation of Lightweight Body Parts. Int. J. Precis. Eng. Manuf. Technol. 2022, 9, 899–918. [Google Scholar] [CrossRef]

- NASA. NASA’s Revolutionary Hybrid Gear Lightens Your Load. 2016. Available online: https://www.newequipment.com/research-and-development/article/22058083/nasas-revolutionary-hybrid-gear-lightens-your-load (accessed on 3 September 2024).

- Dobrzański, L.; Tański, T.; Čížek, L.; Brytan, Z. Structure and properties of magnesium cast alloys. J. Mech. Work. Technol. 2007, 192–193, 567–574. [Google Scholar] [CrossRef]

- Pavlović, A.; Sintoni, D.; Minak, G.; Fragassa, C. On the modal behaviour of ultralight composite sandwich automotive panels. Compos. Struct. 2020, 248, 112523. [Google Scholar] [CrossRef]

- Suski, C.A.; Filho, J.F.S.; Cortez, A.; Gonçalves, F.E.; Ferreira, R.R. The environmental impact of lightweight body in white structures in vehicle manufacturing. J. Clean. Prod. 2024, 449, 141833. [Google Scholar] [CrossRef]

- Ullah, A.S. Machining Forces Due to Turning of Bimetallic Objects Made of Aluminum, Titanium, Cast Iron, and Mild/Stainless Steel. J. Manuf. Mater. Process. 2018, 2, 68. [Google Scholar] [CrossRef]

- Silva, F.J.G.; Martinho, R.P.; Magalhães, L.L.; Fernandes, F.; Sales-Contini, R.C.M.; Durão, L.M.; Casais, R.C.B.; Sousa, V.F.C. A Comparative Study of Different Milling Strategies on Productivity, Tool Wear, Surface Roughness, and Vibration. J. Manuf. Mater. Process. 2024, 8, 115. [Google Scholar] [CrossRef]

- Shweiki, S.; Palermo, A.; Mundo, D. A Study on the Dynamic Behaviour of Lightweight Gears. Shock. Vib. 2017, 2017, 7982170. [Google Scholar] [CrossRef]

- Handschuh, R.F.; Roberts, G.D.; Sinnamon, R.R.; Stringer, D.B.; Dykas, B.D.; Kohlman, L.W. Hybrid Gear Preliminary Results-Application of Composites to Dynamic Mechanical Components. 2012. Available online: https://ntrs.nasa.gov/citations/20120005332 (accessed on 10 November 2024).

- Qi, L.; Li, C.; Yu, X.; Min, W.; Shi, H.; Tao, L.; Wang, H.; Yu, M.; Ni, L.; Sun, Z. Effect of reinforced fibers on the vibration characteristics of fibers reinforced composite shaft tubes with metal flanges. Compos. Struct. 2021, 275, 114460. [Google Scholar] [CrossRef]

- Sauer, K.; Dix, M.; Putz, M. Process Forces Analysis and a New Feed Control Strategy for Drilling of Unidirectional Carbon Fiber Reinforced Plastics (UD-CFRP). J. Manuf. Mater. Process. 2018, 2, 46. [Google Scholar] [CrossRef]

- Laberge, K.E.; Thorp, S. Performance Investigation of a Full-Scale Hybrid Composite Bull Gear. In Proceedings of the Vertical Flight Society 72nd Annual Forum & Technology Display, West Palm Beach, FL, USA, 16–19 May 2015. [Google Scholar]

- Laberge, K.E.; Johnston, J.P.; Handschuh, R.F. Evaluation of a Variable Thickness Hybrid Composite Bull Gear. In Proceedings of the Vertical Flight Society 74th Annual Forum & Technology Display, Phoenix, AZ, USA, 14–17 May 2018. [Google Scholar]

- Catera, P.G.; Mundo, D.; Treviso, A.; Gagliardi, F.; Visrolia, A. On the Design and Simulation of Hybrid Metal-Composite Gears. Appl. Compos. Mater. 2018, 26, 817–833. [Google Scholar] [CrossRef]

- Isaac, C.W.; Ezekwem, C. A review of the crashworthiness performance of energy absorbing composite structure within the context of materials, manufacturing and maintenance for sustainability. Compos. Struct. 2020, 257, 113081. [Google Scholar] [CrossRef]

- Zheng, C.; Duan, F.; Liang, S. Manufacturing and mechanical performance of novel epoxy resin matrix carbon fiber reinforced damping composites. Compos. Struct. 2020, 256, 113099. [Google Scholar] [CrossRef]

- Catera, P.G.; Gagliardi, F.; Mundo, D.; De Napoli, L.; Matveeva, A.; Farkas, L. Multi-scale modeling of triaxial braided composites for FE-based modal analysis of hybrid metal-composite gears. Compos. Struct. 2017, 182, 116–123. [Google Scholar] [CrossRef]

- Catera, P.G.; Mundo, D.; Gagliardi, F.; Treviso, A. A comparative analysis of adhesive bonding and interference fitting as joining technologies for hybrid metal-composite gear manufacturing. Int. J. Interact. Des. Manuf. 2020, 14, 535–550. [Google Scholar] [CrossRef]

- Rezayat, A.; Catera, P.G.; Capalbo, C.; Cosco, F.; Mundo, D. Numerical and experimental analysis of the transmission error in hybrid metal-composite gears. Compos. Struct. 2022, 298, 116012. [Google Scholar] [CrossRef]

- Yılmaz, T.G.; Doğan, O.; Karpat, F. A numerical investigation on the hybrid spur gears: Stress and dynamic analysis. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 236, 354–369. [Google Scholar] [CrossRef]

- Gauntt, S.M.; Campbell, R.L. Characterization of a Hybrid (Steel-Composite) Gear with Various Composite Materials and Layups. In Proceedings of the AIAA Scitech 2019 Forum, Reston, Virginia: American Institute of Aeronautics and Astronautics, San Diego, CA, USA, 7–11 January 2018. [Google Scholar] [CrossRef]

- Jiang, S.; Li, W.; Xin, G.; Sheng, L.; Wang, Y. Study on dynamic reliability of permanent magnet gear transmission system with wear and failure correlation. Eng. Fail. Anal. 2021, 131, 105802. [Google Scholar] [CrossRef]

- Skulić, A.; Bukvić, M.; Gajević, S.; Miladinović, S.; Stojanović, B. The influence of worm gear material and lubricant on the efficiency and coefficient of friction. Tribol. Mater. 2024, 3, 15–23. [Google Scholar] [CrossRef]

- Czakó, A.; Řehák, K.; Prokop, A.; Rekem, J.; Láštic, D.; Trochta, M. Static transmission error measurement of various gear-shaft systems by finite element analysis. J. Meas. Eng. 2023, 12, 183–198. [Google Scholar] [CrossRef]

- European Council. Industrial Emissions. 2024. Available online: https://www.consilium.europa.eu/en/press/press-releases/2024/04/12/industrial-emissions-council-signs-off-on-updated-rules-to-better-protect-the-environment/ (accessed on 9 December 2024).

- International Energy Agency. Energy System of EUROPE. 2023. Available online: https://www.iea.org/energy-system (accessed on 9 December 2024).

- Campos-Romero, H.; Rodil-Marzábal, Ó.; Gómez Pérez, A.L. Environmental asymmetries in global value chains: The case of the European automotive sector. J. Clean. Prod. 2024, 449, 141606. [Google Scholar] [CrossRef]

- International Energy Agency. Industry Energy System. 2023. Available online: https://www.iea.org/energy-system/industry (accessed on 9 December 2024).

- Gagliardi, F.; La Rosa, A.D.; Filice, L.; Ambrogio, G. Environmental impact of material selection in a car body component—The side door intrusion beam. J. Clean. Prod. 2021, 318, 128528. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J. Life Cycle Assessment of Vehicle Lightweighting: A Physics-Based Model to Estimate Use-Phase Fuel Consumption of Electrified Vehicles. Environ. Sci. Technol. 2016, 50, 11226–11233. [Google Scholar] [CrossRef]

- Luk, J.M.; Kim, H.C.; De Kleine, R.D.; Wallington, T.J.; MacLean, H.L. Greenhouse gas emission benefits of vehicle lightweighting: Monte Carlo probabalistic analysis of the multi material lightweight vehicle glider. Transp. Res. Part D Transp. Environ. 2018, 62, 1–10. [Google Scholar] [CrossRef]

- Choi, J.Y.; Jeon, J.H.; Lyu, J.H.; Park, J.; Kim, G.Y.; Chey, S.Y.; Quan, Y.-J.; Bhandari, B.; Prusty, B.G.; Ahn, S.-H. Current Applications and Development of Composite Manufacturing Processes for Future Mobility. Int. J. Precis. Eng. Manuf. Technol. 2022, 10, 269–291. [Google Scholar] [CrossRef]

- Kirchain, R.E., Jr.; Gregory, J.R.; Olivetti, E.A. Environmental life-cycle assessment. Nat. Mater. 2017, 16, 693–697. [Google Scholar] [CrossRef]

- Rödger, J.-M.; Beier, J.; Schönemann, M.; Schulze, C.; Thiede, S.; Bey, N.; Herrmann, C.; Hauschild, M.Z. Combining Life Cycle Assessment and Manufacturing System Simulation: Evaluating Dynamic Impacts from Renewable Energy Supply on Product-Specific Environmental Footprints. Int. J. Precis. Eng. Manuf. Technol. 2020, 8, 1007–1026. [Google Scholar] [CrossRef]

- Galve, J.E.; Elduque, D.; Pina, C.; Javierre, C. Life Cycle Assessment of a Plastic Part Injected with Recycled Polypropylene: A Comparison with Alternative Virgin Materials. Int. J. Precis. Eng. Manuf. Technol. 2021, 9, 919–932. [Google Scholar] [CrossRef]

- Borda, F.; La Rosa, A.D.; Filice, L.; Gagliardi, F. Environmental impact of process constrained topology optimization design on automotive component’ life. Int. J. Mater. Form. 2023, 16, 48. [Google Scholar] [CrossRef]

- Zhu, Y.; Kang, Z. A topology optimization framework for 3D phononic crystals via the method of successive iteration of analysis and design. Compos. Struct. 2023, 326, 117641. [Google Scholar] [CrossRef]

- Borda, F.; Ingarao, G.; Ambrogio, G.; Gagliardi, F. Cumulative energy demand analysis in the current manufacturing and end-of-life strategies for a polymeric composite at different fibre-matrix combinations. J. Clean. Prod. 2024, 69, 141775. [Google Scholar] [CrossRef]

- Bhong, M.; Khan, T.K.; Devade, K.; Krishna, B.V.; Sura, S.; Eftikhaar, H.; Thethi, H.P.; Gupta, N. Review of composite materials and applications. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Ohrn, K.E. Aircraft Energy Use. In Encyclopedia of Energy Engineering and Technology, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 32–38. [Google Scholar] [CrossRef]

- Benaïcha, Y.; Mélot, A.; Rigaud, E.; Beley, J.-D.; Thouverez, F.; Perret-Liaudet, J. A decomposition method for the fast computation of the transmission error of gears with holes. J. Sound Vib. 2022, 532, 116927. [Google Scholar] [CrossRef]

- Palermo, A.; Britte, L.; Janssens, K.; Mundo, D.; Desmet, W. The measurement of Gear Transmission Error as an NVH indicator: Theoretical discussion and industrial application via low-cost digital encoders to an all-electric vehicle gearbox. Mech. Syst. Signal Process. 2018, 110, 368–389. [Google Scholar] [CrossRef]

- Siemens PLM Software. Boosting Productivity in Gearbox Engineering; Siemens PLM Software: Plano, TX, USA, 2019; Available online: https://www.plm.automation.siemens.com/media/global/it/CE-37062-Siemens%20SW%20Boosting%20productivity%20in%20gearbox%20engineering%20wp_tcm56-71442.pdf (accessed on 4 January 2025).

- Cosco, F.; Adduci, R.; Muzzi, L.; Rezayat, A.; Mundo, D. Multiobjective Design Optimization of Lightweight Gears. Machines 2022, 10, 779. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Pimenta, S.; Pinho, S.T. The effect of recycling on the mechanical response of carbon fibres and their composites. Compos. Struct. 2012, 94, 3669–3684. [Google Scholar] [CrossRef]

- Abdou, T.R.; Espinosa, D.C.R.; Tenório, J.A.S. Recovering of Carbon Fiber Present in an Industrial Polymeric Composite Waste Through Pyrolysis Method while Studying the Influence of Resin Impregnation Process: Prepreg. In REWAS 2016; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 313–318. [Google Scholar] [CrossRef]

- Giorgini, L.; Benelli, T.; Mazzocchetti, L.; Leonardi, C.; Zattini, G.; Minak, G.; Dolcini, E.; Cavazzoni, M.; Montanari, I.; Tosi, C. Recovery of carbon fibers from cured and uncured carbon fiber reinforced composites wastes and their use as feedstock for a new composite production. Polym. Compos. 2015, 36, 1084–1095. [Google Scholar] [CrossRef]

- Meyer, L.; Schulte, K.; Grove-Nielsen, E. CFRP-Recycling Following a Pyrolysis Route: Process Optimization and Potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Autodesk. FeatureCAM Ultimate 2024; Version 7.27; Autodesk Inc.: San Rafael, CA, USA, 2024; Available online: https://www.autodesk.com/products/featurecam/overview (accessed on 4 January 2025).

- Ingarao, G.; Priarone, P.C. A comparative assessment of energy demand and life cycle costs for additive- and subtractive-based manufacturing approaches. J. Manuf. Process. 2020, 56, 1219–1229. [Google Scholar] [CrossRef]

- Wang, J.; Dong, J. Prediction and optimization of hobbing parameters for minimizing energy consumption and gear geometric deviations. Adv. Mech. Eng. 2024, 16, 4. [Google Scholar] [CrossRef]

- Soares, L.A.P.; Firmino, A.S.; de Oliveira, J.A.; Silva, D.A.L.; Saavedra, Y.M.B.; Moris, V.A.d.S. Comparative LCA of automotive gear hobbing processes with flood lubrication and MQL. Int. J. Adv. Manuf. Technol. 2021, 119, 1071–1090. [Google Scholar] [CrossRef]

- Liu, Z.; Li, C.; Fang, X.; Guo, Y. Cumulative energy demand and environmental impact in sustainable machining of inconel superalloy. J. Clean. Prod. 2018, 181, 329–336. [Google Scholar] [CrossRef]

- Guglielmi, G.; Mitchell, B.; Song, C.; Kinsey, B.L.; Mo, W. Life Cycle Environmental and Economic Comparison of Water Droplet Machining and Traditional Abrasive Waterjet Cutting. Sustainability 2021, 13, 12275. [Google Scholar] [CrossRef]

- Candelaresi, D.; Valente, A.; Bargiacchi, E.; Spazzafumo, G. Life cycle assessment of hybrid passenger electric vehicle. In Hybrid Technologies for Power Generation; Elsevier: Amsterdam, The Netherlands, 2022; pp. 475–495. [Google Scholar] [CrossRef]

- Speight, J.G. Production, properties and environmental impact of hydrocarbon fuel conversion. In Advances in Clean Hydrocarbon Fuel Processing; Elsevier: Amsterdam, The Netherlands, 2011; pp. 54–82. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef]

- Suzuki, T.; Takahash, J. Prediction of Energy Intensity of Carbon Fiber Reinforced Plastics for Mass-Produced Passenger CARS. In Proceedings of the Ninth Japan International SAMPE Symposium, Tokyo, Japan, 29 November 2005. [Google Scholar]

- EuRIC—European Recycling Industries’ Confederation. Metal Recycling Factsheet; EuRIC: Brussels, Belgium, 2020; Available online: https://circulareconomy.europa.eu/platform/sites/default/files/euric_metal_recycling_factsheet.pdf (accessed on 4 January 2025).

| Parameter | Value |

|---|---|

| Teeth number | 59 |

| Module | 2.5 mm |

| Pressure angle | 20° |

| Face width | 24 mm |

| Tip diameter | 154 mm |

| Root diameter | 142.75 mm |

| Theoretical pitch diameter | 147.50 mm |

| Base diameter | 138.60 mm |

| Property | Fiber | Matrix |

|---|---|---|

| Material type | Carbon M40J | Epoxy |

| Longitudinal Modulus [GPa] | 377 | 2.7 |

| Transverse Modulus [GPa] | 15 | 2.7 |

| Shear Modulus [GPa] | 24.7 Long./5.0 Transverse | 1 |

| Poisson’s ratio [-] | 0.41 | 0.35 |

| Density [g/cm3] | 1.77 | 1.2 |

| Component | Web Thickness τ [mm] | PtP STE [µm] | PtP STE Difference [µm] | Mass [kg] |

|---|---|---|---|---|

| Hybrid gear | - | 1.963 | reference | 1.539 |

| Full gear | 23 | 1.706 | −0.257 | 2.674 |

| Lightweight gear | 15 | 1.849 | 0.114 | 2.148 |

| 12.5 | 1.907 | 0.056 | 1.954 | |

| 10 | 1.977 | 0.014 | 1.761 | |

| 7.5 | 2.072 | 0.109 | 1.567 | |

| 5 | 2.193 | 0.230 | 1.373 |

| Nomenclature | Material Energy | Energy Consumption [MJ/kg] | References |

|---|---|---|---|

| 32.00 | [49] | ||

| 4.15 | [49] | ||

| 722.39 | [42] | ||

| 117.50 | [49] | ||

| 132.63 | [42] |

| Nomenclature | Manufacturing Processes | Energy Consumption | Unit | References | ||

|---|---|---|---|---|---|---|

| full | lightweight | hybrid | ||||

| Turning | 0.31 | 3.52 | 3.73 | kWh/pc | Calculated | |

| Hobbing | 12.04 | 12.04 | 12.04 | kWh/pc | Calculated | |

| Autoclave | - | - | 152.34 | MJ/kg | [49] | |

| Adhesive | - | - | 117.50 | MJ/kg | [49] | |

| - | - | 3.46 | kWh/pc | [60] | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borda, F.; Adduci, R.; Mundo, D.; Gagliardi, F. Cumulative Energy Demand Analysis of Commercial and Hybrid Metal-Composite Gears at Different End-of-Life Strategies. J. Manuf. Mater. Process. 2025, 9, 14. https://doi.org/10.3390/jmmp9010014

Borda F, Adduci R, Mundo D, Gagliardi F. Cumulative Energy Demand Analysis of Commercial and Hybrid Metal-Composite Gears at Different End-of-Life Strategies. Journal of Manufacturing and Materials Processing. 2025; 9(1):14. https://doi.org/10.3390/jmmp9010014

Chicago/Turabian StyleBorda, Francesco, Rocco Adduci, Domenico Mundo, and Francesco Gagliardi. 2025. "Cumulative Energy Demand Analysis of Commercial and Hybrid Metal-Composite Gears at Different End-of-Life Strategies" Journal of Manufacturing and Materials Processing 9, no. 1: 14. https://doi.org/10.3390/jmmp9010014

APA StyleBorda, F., Adduci, R., Mundo, D., & Gagliardi, F. (2025). Cumulative Energy Demand Analysis of Commercial and Hybrid Metal-Composite Gears at Different End-of-Life Strategies. Journal of Manufacturing and Materials Processing, 9(1), 14. https://doi.org/10.3390/jmmp9010014