Investigation of the Fabrication Parameters’ Influence on the Tensile Strength of 3D-Printed Copper-Filled Metal Composite Using Design of Experiments

Abstract

1. Introduction

2. Materials and Methods

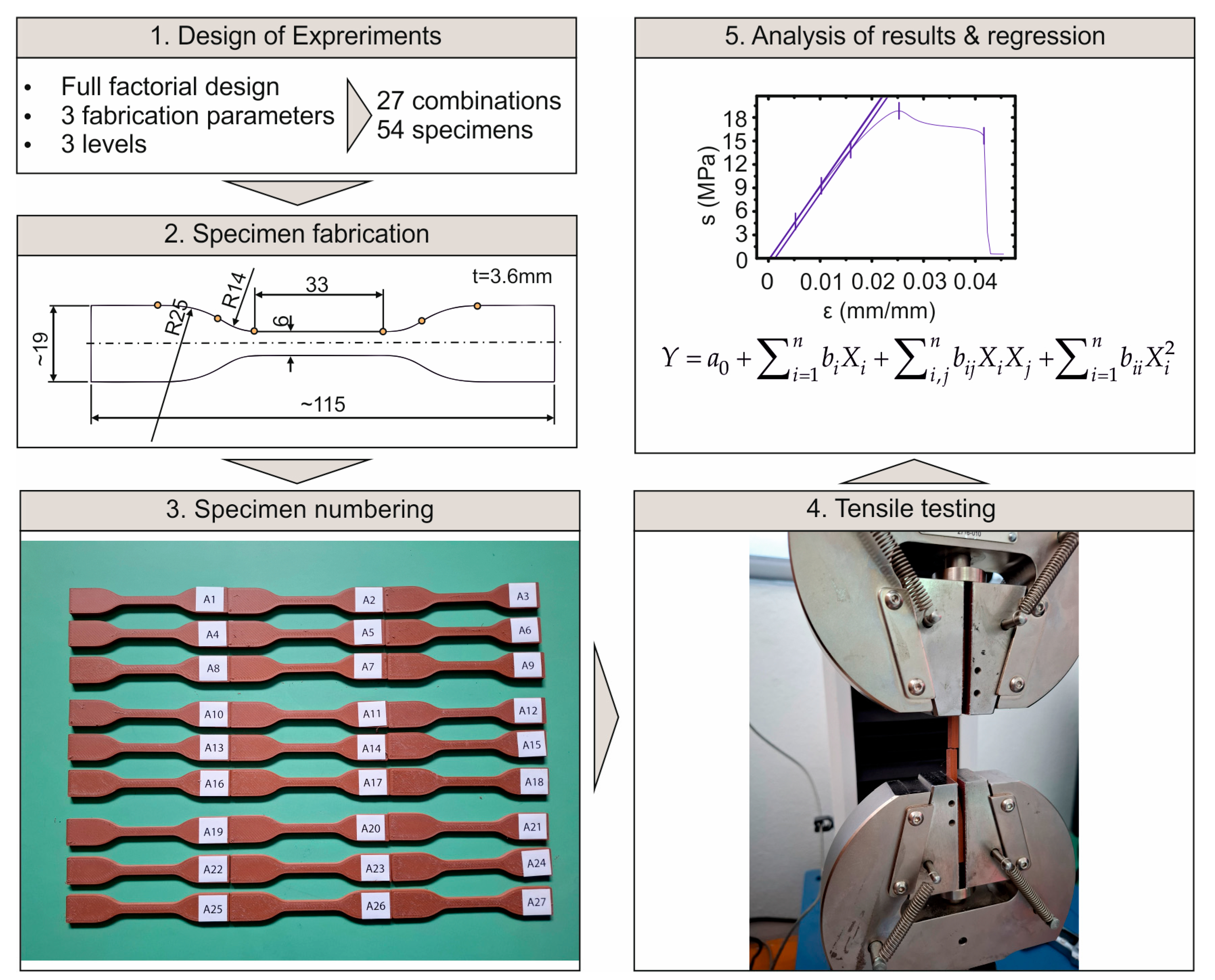

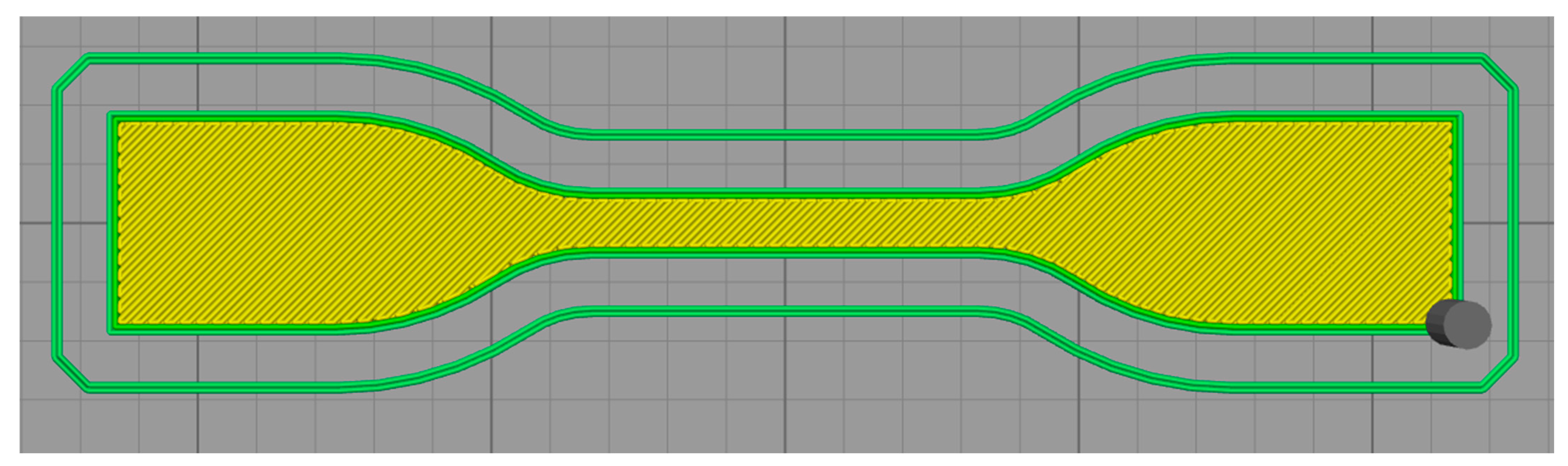

2.1. Experimental Workflow and Apparatus

2.2. Design of Experiments

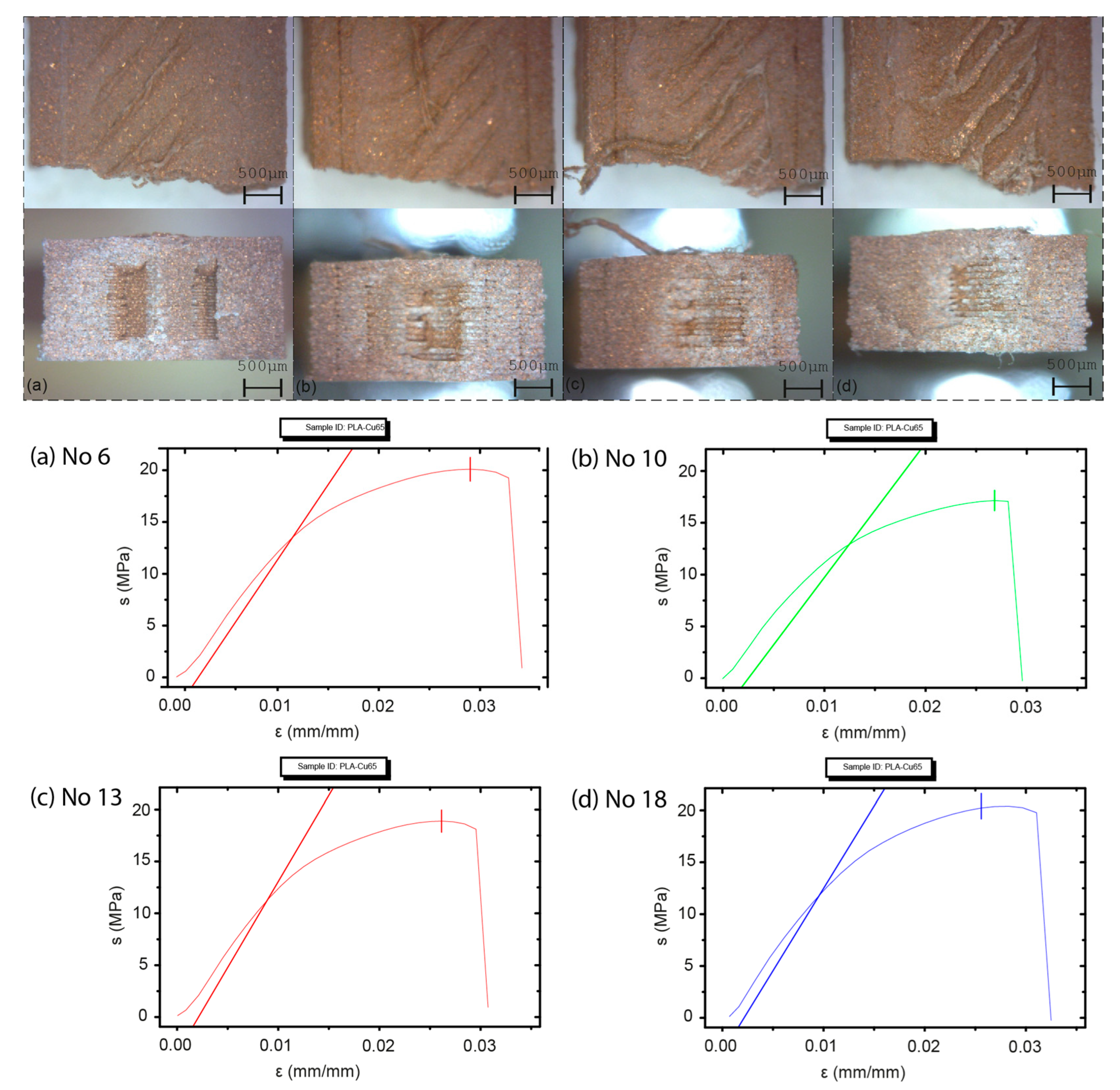

3. Results and Discussion

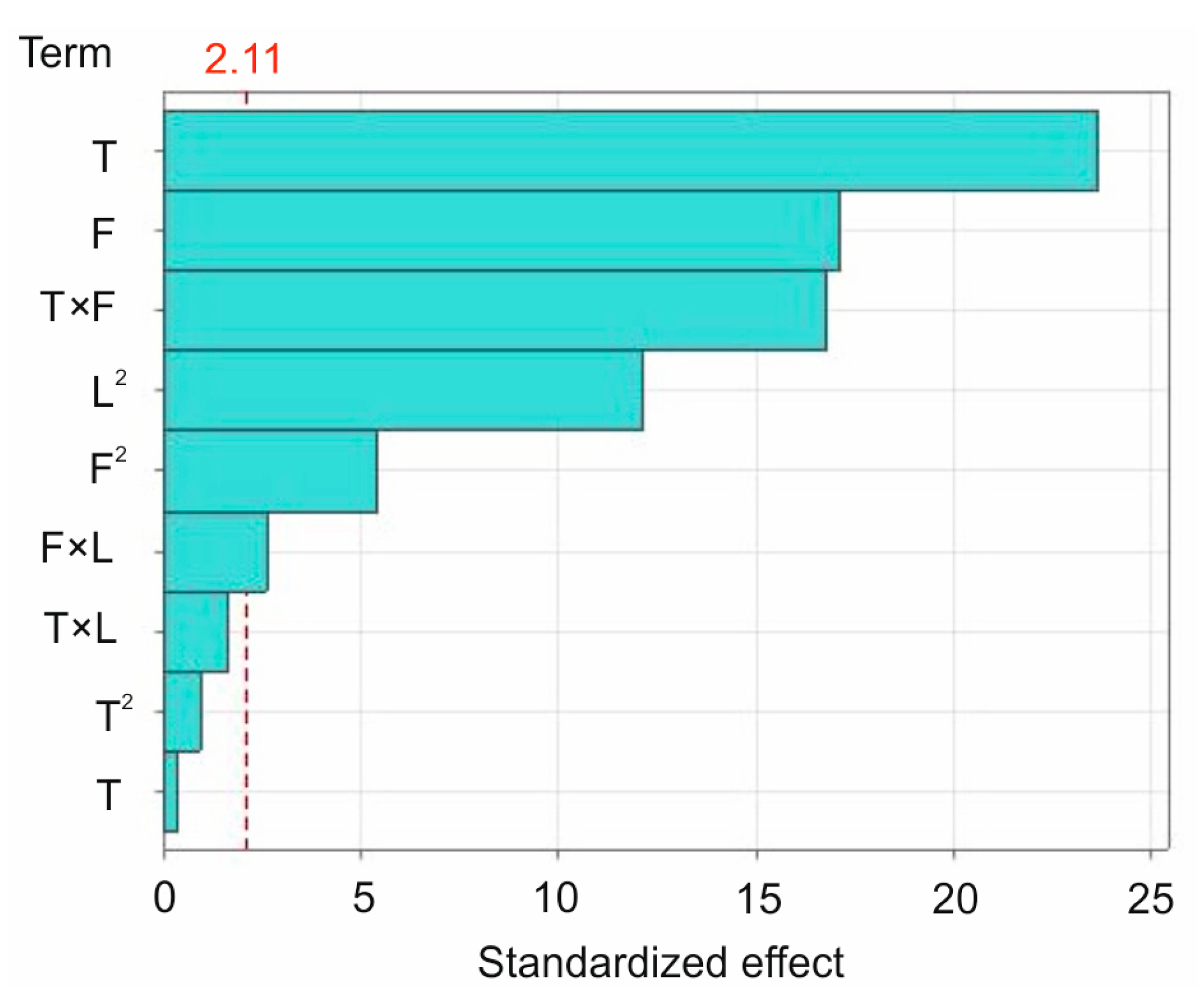

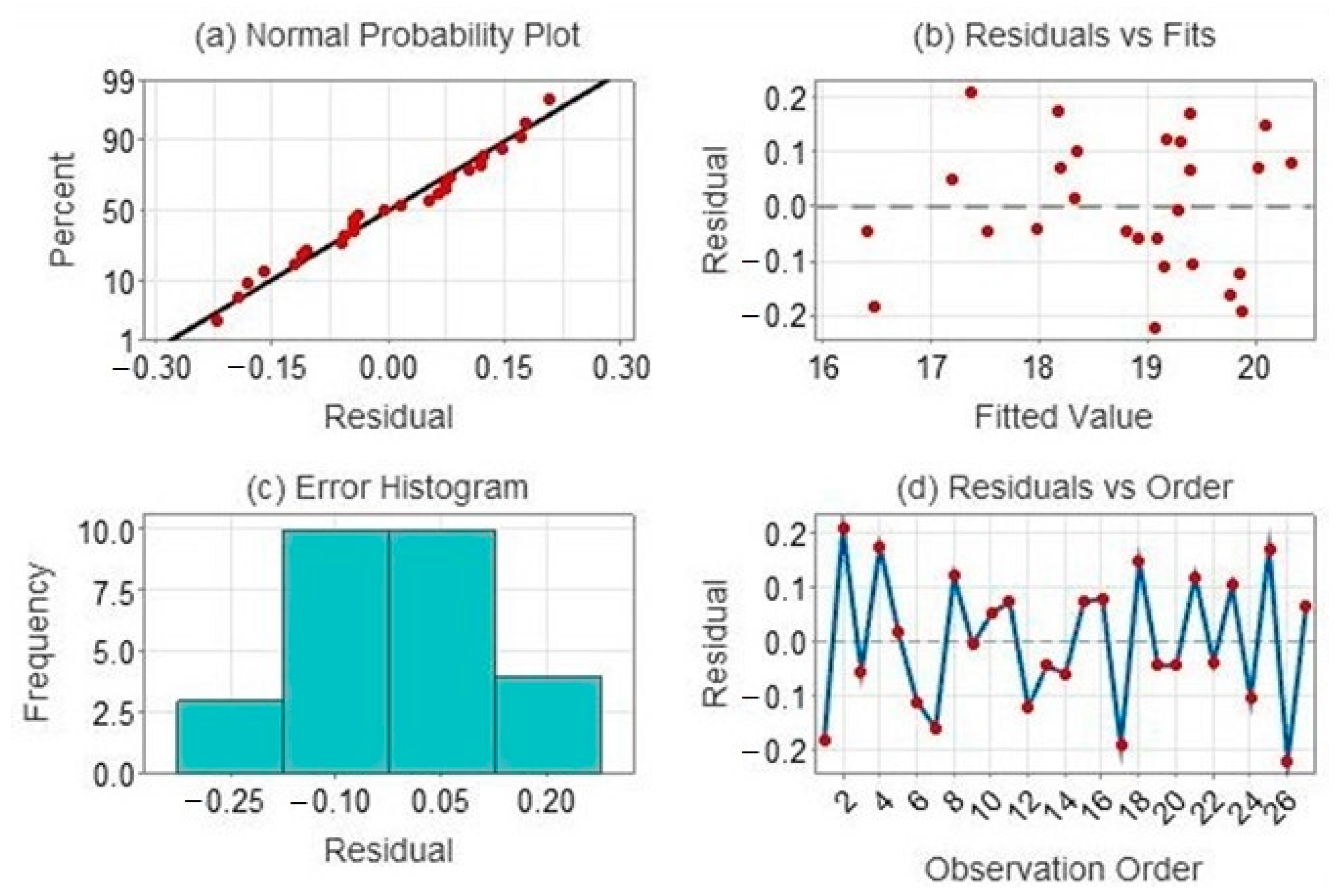

3.1. Regression Analysis

3.2. Optimization Study

4. Conclusions

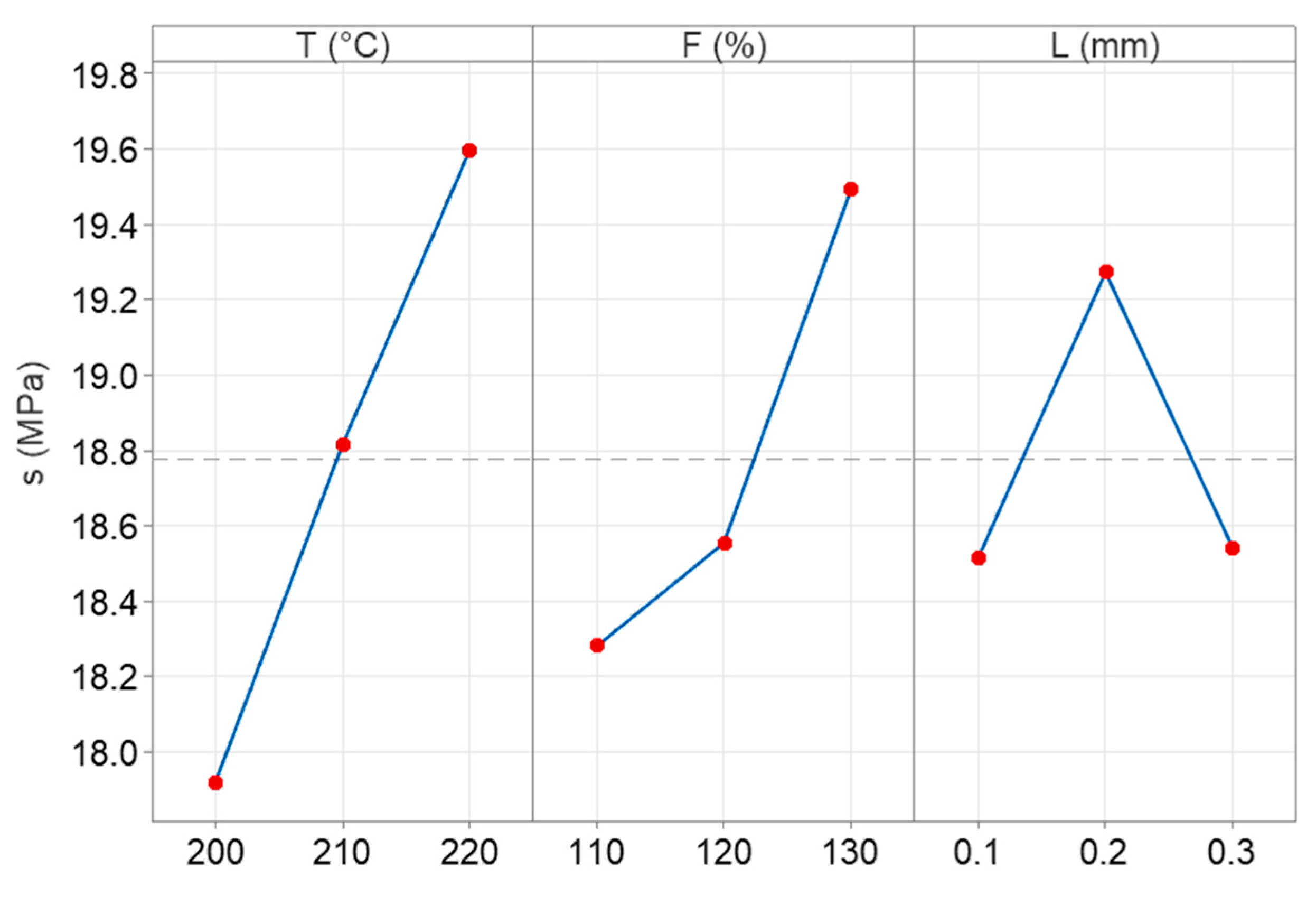

- The parameter with the most significant effect on the response is temperature, with a contribution percentage of 42.41%. It is followed by the flow rate, which contributes 22.16% to the generated response.

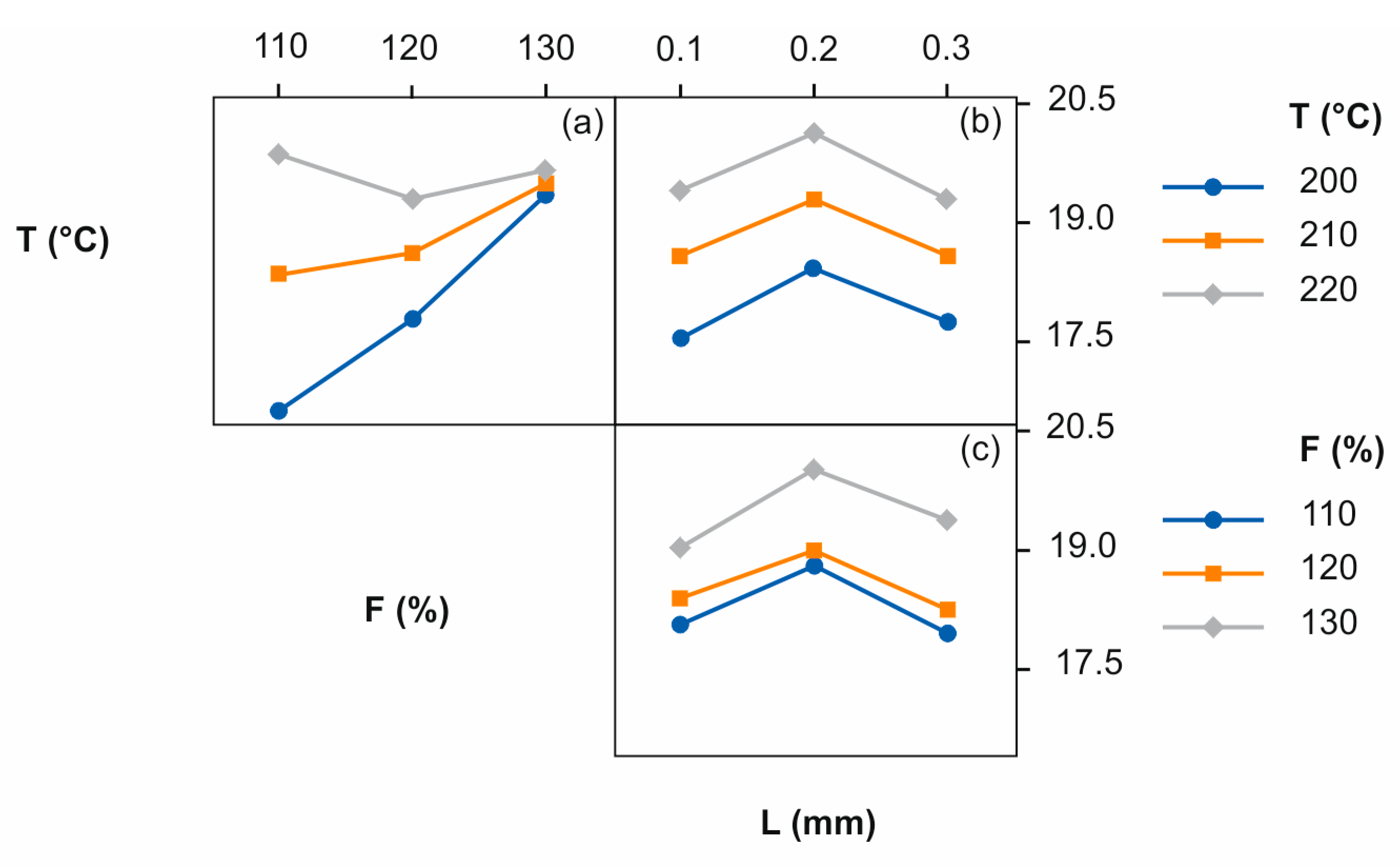

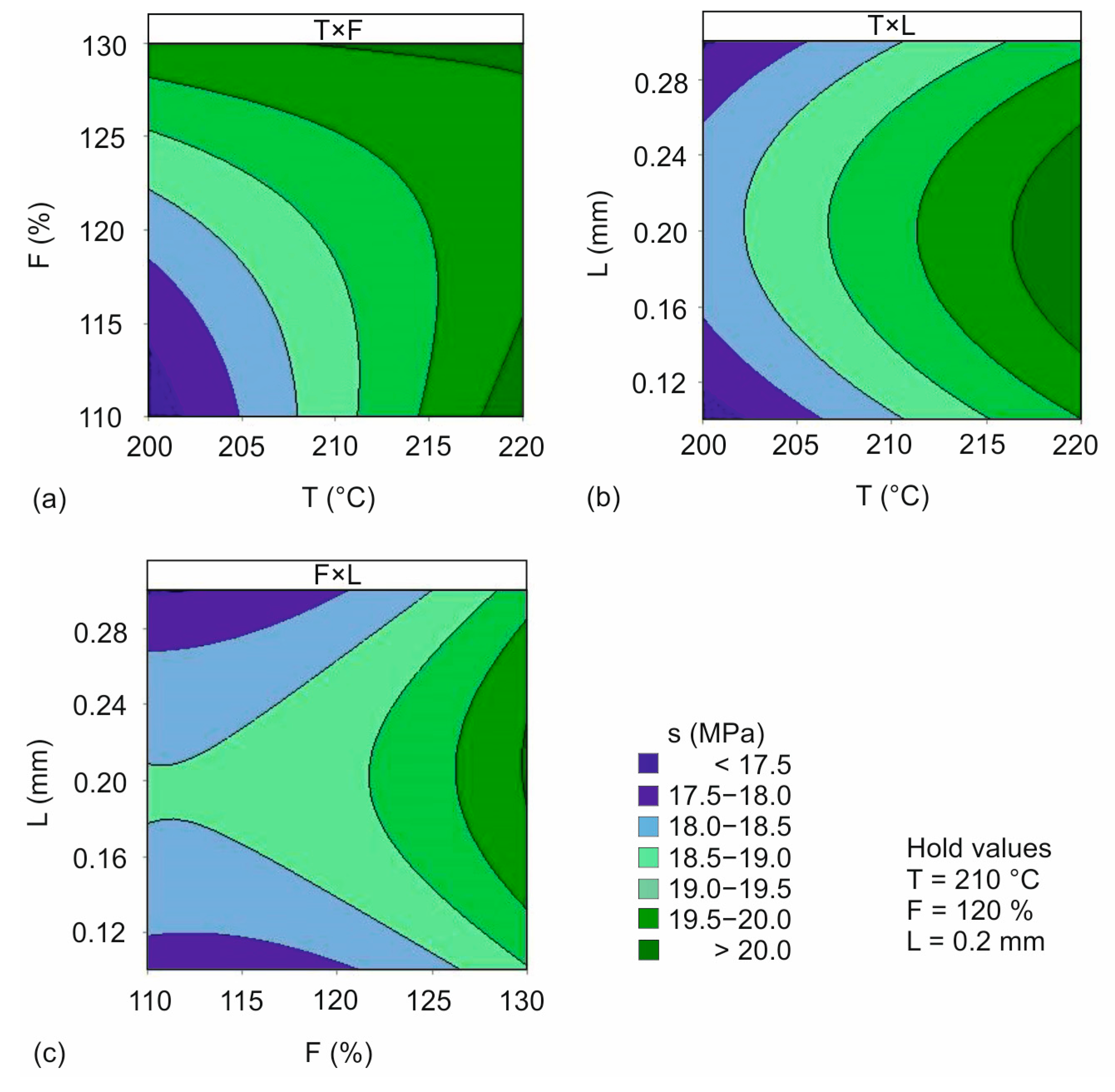

- Following the previously mentioned factors, Τ × F contributes 21.25% to the response and, L2 contributes 11.13%.

- The ANOVA results, specifically the p-values, highlighted the terms Τ × L, Τ2, and L as not statistically significant. Therefore, their contribution to the response is negligible.

- The combination of parameters that yielded the highest value of tensile strength (s = 20.40 MPa), based on the experimental testing, is T = 220 °C, F = 110%, and L = 0.2 mm.

- Both the temperature and flow rate act increasingly on the generated tensile strength. Layer thickness, however, seems to have a more complex behavior. In particular, the medium value is responsible for higher levels of tensile strength, whereas the other two layer thicknesses yield lower values for the response.

- Moreover, it was found that the combination of T = 220 °C and F = 110% generated the highest mean tensile strength compared to every other combination of temperature and flow rate.

- The developed regression model exhibits a high predicted R2 value, equal to 96.48%, supporting the reliability of the model.

- Finally, the optimal solution for maximizing the tensile strength with the regression equation is the combination of 220 °C nozzle temperature, 110% flow rate, and 0.1889 mm layer thickness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Srinivasan, R.; Pridhar, T.; Ramprasath, L.S.; Charan, N.S.; Ruban, W. Prediction of Tensile Strength in FDM Printed ABS Parts Using Response Surface Methodology (RSM). Mater. Today Proc. 2020, 27, 1827–1832. [Google Scholar] [CrossRef]

- Rezaeian, P.; Ayatollahi, M.R.; Nabavi-Kivi, A.; Razavi, N. Effect of Printing Speed on Tensile and Fracture Behavior of ABS Specimens Produced by Fused Deposition Modeling. Eng. Fract. Mech. 2022, 266, 108393. [Google Scholar] [CrossRef]

- Tzotzis, A.; Manavis, A.; Efkolidis, N. Analysis of the Influence of Structural Characteristics on the Tensile Properties of Fused Filament Fabricated ABS Polymer Using Central Composite Design. Appl. Mech. 2024, 5, 20–35. [Google Scholar] [CrossRef]

- Hikmat, M.; Rostam, S.; Ahmed, Y.M. Investigation of Tensile Property-Based Taguchi Method of PLA Parts Fabricated by FDM 3D Printing Technology. Results Eng. 2021, 11, 100264. [Google Scholar] [CrossRef]

- Atakok, G.; Kam, M.; Koc, H.B. Tensile, Three-Point Bending and Impact Strength of 3D Printed Parts Using PLA and Recycled PLA Filaments: A Statistical Investigation. J. Mater. Res. Technol. 2022, 18, 1542–1554. [Google Scholar] [CrossRef]

- Shbanah, M.; Jordanov, M.; Nyikes, Z.; Toth, L.; Kovacs, T.A. The Effect of Heat Treatment on a 3D-Printed PLA Polymer’s Mechanical Properties. Polymers 2023, 15, 1587. [Google Scholar] [CrossRef] [PubMed]

- Sanford, L.T.; Jaafar, I.H.; Seibi, A.; Gohn, A. The Effect of Infill Angle, Build Orientation, and Void Fraction on the Tensile Strength and Fracture of 3D Printed ASA via Fused Filament Fabrication. Manuf. Lett. 2022, 33, 569–573. [Google Scholar] [CrossRef]

- De Assis, C.L.F.; Rampazo, C.A. Assessment of the Mechanical Properties of PC/ABS Blends for Functional Prototyping by FFF 3D Printing. Rapid Prototyp. J. 2024, 30, 214–227. [Google Scholar] [CrossRef]

- Arifvianto, B.; Iman, T.N.; Prayoga, B.T.; Dharmastiti, R.; Salim, U.A. Tensile Properties of the FFF-Processed Thermoplastic Polyurethane (TPU) Elastomer. Int. J. Adv. Manuf. Technol. 2021, 117, 1709–1719. [Google Scholar] [CrossRef]

- Xu, T.; Shen, W.; Lin, X. Mechanical Properties of Additively Manufactured Thermoplastic Polyurethane (TPU) Material Affected by Various Processing Parameters. Polymers 2020, 12, 3010. [Google Scholar] [CrossRef] [PubMed]

- Baba, M.N.; Itu, C. The Influence of Dog-Bone Shaped Specimen Geometry on Tensile Test Results of Fused Filament Fabricated Nylon 12. J. Mech. Sci. Technol. 2023, 37, 1077–1082. [Google Scholar] [CrossRef]

- Revilla, S.R.; Valencia, D.C.; Gilmar, E.; Condori, G. Evaluation and Comparison of the Degradability and Compressive and Tensile Properties of 3D Printing Polymeric Materials: PLA, PETG, PC, and ASA Results Compressive Properties. MRS Commun. 2023, 13, 55–62. [Google Scholar] [CrossRef]

- Chen, Z.; Gong, K.; Huang, C.; Hu, S.; Xu, H.; Fuenmayor, E.; Cao, Z.; Major, I.; Major, I. Parameter Optimization for PETG/ABS Bilayer Tensile Specimens in Material Extrusion 3D Printing through Orthogonal Method. Int. J. Adv. Manuf. Technol. 2023, 127, 447–458. [Google Scholar] [CrossRef]

- Yavas, D.; Zhang, Z.; Liu, Q.; Wu, D. Fracture Behavior of 3D Printed Carbon Fiber-Reinforced Polymer Composites. Compos. Sci. Technol. 2021, 208, 108741. [Google Scholar] [CrossRef]

- Bendine, K.; Gibhardt, D.; Fiedler, B.; Backs, A. Experimental Characterization and Mechanical Behavior of 3D Printed CFRP. Eur. J. Mech. A Solids 2022, 94, 104587. [Google Scholar] [CrossRef]

- Kumar Mishra, P.; Jagadesh, T. Investigation into Tensile Behavior of 3D Printed Nylon-Based Low and High-Volume Fraction Carbon Fiber Composite. Rapid Prototyp. J. 2023, 29, 1679–1701. [Google Scholar] [CrossRef]

- Jia, X.; Luo, J.; Luo, Q.; Li, Q.; Pang, T. Experimental Study on the Effects of Temperature on Mechanical Properties of 3D Printed Continuous Carbon Fiber Reinforced Polymer (CCFRP) Composites. Thin-Walled Struct. 2024, 205, 112465. [Google Scholar] [CrossRef]

- Kumekawa, N.; Mori, Y.; Tanaka, H.; Matsuzaki, R. Experimental Evaluation of Variable Thickness 3D Printing of Continuous Carbon Fiber-Reinforced Composites. Compos. Struct. 2022, 288, 115391. [Google Scholar] [CrossRef]

- Selvam, A.; Mayilswamy, S.; Whenish, R.; Velu, R. Preparation and Evaluation of the Tensile Characteristics of Carbon Fiber Rod Reinforced 3D Printed Thermoplastic Composites. J. Compos. Sci. 2021, 5, 8. [Google Scholar] [CrossRef]

- Minaoglou, P.; Tzotzis, A.; Efkolidis, N.; Kyratsis, P. Influence of the 3D Printing Fabrication Parameters on the Tensile Properties of Carbon-Based Composite Filament. Appl. Mech. 2024, 5, 745–761. [Google Scholar] [CrossRef]

- Kesavarma, S.; Lee, E.H.; Samykano, M.; Kadirgama, K.; Rahman, M.M.; Sofiah, A.G.N. Flextural Properties of 3D Printed Copper-Filler Polylactic Acid (Cu-PLA). IOP Conf. Ser. Mater. Sci. Eng. 2020, 788, 012051. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, L.; Mulholland, T.; Osswald, T.A. Characterization of Mechanical Properties and Fracture Mode of PLA and Copper/PLA Composite Part Manufactured by Fused Deposition Modeling. SN Appl. Sci. 2019, 1, 616. [Google Scholar] [CrossRef]

- Kottasamy, A.; Samykano, M.; Kadirgama, K.; Rahman, M. Experimental Investigation and Prediction Model for Mechanical Properties of Copper-Reinforced Polylactic Acid Composites (Cu-PLA) Using FDM-Based 3D Printing Technique. Int. J. Adv. Manuf. Technol. 2022, 119, 5211–5232. [Google Scholar] [CrossRef]

- Ambruş, S.; Muntean, R.; Codrean, C.; Uţu, I.-D. Influence of Printing Conditions on the Mechanical Properties of Copper-Polylactic Acid Composites Obtained by 3D Printing Fused Deposition Modelling. Mater. Today Proc. 2023, 72, 580–585. [Google Scholar] [CrossRef]

- Adibi, H.; Hashemi, M.R. Experimental Study on Tensile Strength of Copper Microparticles Filled Polymer Composites Printed by Fused Deposition Modelling Process. Rapid Prototyp. J. 2022, 28, 21–31. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, R.; Singh Chohan, J. Multi-Objective Optimization of 3D Printing Process Using Genetic Algorithm for Fabrication of Copper Reinforced ABS Parts. Mater. Today Proc. 2022, 48, 981–988. [Google Scholar] [CrossRef]

- Ji, Q.; Wang, Z.; Yi, J.; Tang, X. Mechanical Properties and a Constitutive Model of 3D-Printed Copper Powder-Filled PLA Material. Polymers 2021, 13, 3605. [Google Scholar] [CrossRef]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical Property of FDM Printed ABS: Influence of Printing Parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Molefi, J.A.; Luyt, A.S.; Krupa, I. Comparison of the Influence of Copper Micro- and Nano-Particles on the Mechanical Properties of Polyethylene/Copper Composites. J. Mater. Sci. 2010, 45, 82–88. [Google Scholar] [CrossRef]

- Côté, R.; Demers, V.; Demarquette, N.R.; Charlon, S.; Soulestin, J. A Strategy to Eliminate Interbead Defects and Improve Dimensional Accuracy in Material Extrusion 3D Printing of Highly Filled Polymer. Addit. Manuf. 2023, 68, 103509. [Google Scholar] [CrossRef]

- Zhang, H.; Cao, S.; Yilmaz, E. Polymer Shape Effect on Damage Evolution, Internal Defects and Crack Propagation of 3D-Printed Polymer-Based Cementitious Backfill. Constr. Build. Mater. 2023, 406, 133386. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Côté, R.; Delbergue, D.; Demers, V.; Demarquette, N.R.; Charlon, S.; Soulestin, J. Influence of Process Parameters on the Occurrence of Defects and Dimensional Properties of Green Part Produced by Material Extrusion of Highly Filled Polymer. Prog. Addit. Manuf. 2024. [Google Scholar] [CrossRef]

- Tzotzis, A.; García-Hernández, C.; Huertas-Talón, J.-L.; Kyratsis, P. 3D FE Modelling of Machining Forces during AISI 4140 Hard Turning. Stroj. Vestn. J. Mech. Eng. 2020, 66, 467–478. [Google Scholar] [CrossRef]

- Kilickap, E.; Yardimeden, A.; Çelik, Y.H. Mathematical Modelling and Optimization of Cutting Force, Tool Wear and Surface Roughness by Using Artificial Neural Network and Response Surface Methodology in Milling of Ti-6242S. Appl. Sci. 2017, 7, 1064. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022. Available online: https://www.astm.org/d0638-22.html (accessed on 1 October 2024).

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015; pp. 1–17. [CrossRef]

- Kumar, R.V.; Kumar, K.R.; Soms, N. Mechanical Properties and Failure Analysis of Pla/Copper Composites Fabricated by Fused Deposition Modelling. J. Min. Metall. Sect. B Metall. 2024, 60, 33–44. [Google Scholar] [CrossRef]

- Samykano, S.K.S.K.R.M.; Kadirgama, R.R.K.K.; Mohan, R. V Investigation of Tensile Properties of PLA—Brass Composite Using FDM. Prog. Addit. Manuf. 2022, 7, 839–851. [Google Scholar] [CrossRef]

- Tzotzis, A.; García-Hernández, C.; Huertas-Talón, J.-L.; Kyratsis, P. Influence of the Nose Radius on the Machining Forces Induced during AISI-4140 Hard Turning: A CAD-Based and 3D FEM Approach. Micromachines 2020, 11, 798. [Google Scholar] [CrossRef]

- Darsin, M.; Mauludy, R.R.; Hardiatama, I.; Fachri, B.A. Analysis of the Effect 3D Printing Parameters on Tensile Strength Using Copper-PLA Filament. SINERGI 2022, 26, 99–106. [Google Scholar] [CrossRef]

- Dobrescu, T.; Pascu, N.E.; Jiga, G.; Simion, I.; Adir, V.; Enciu, G.; Tudose, D.I. Tensile Behavior of PLA and PLA Composite Materials under Different Printing Parameters. Mater. Plast. 2019, 56, 783–800. [Google Scholar] [CrossRef]

- Moradi, M.; Mehrabi, O.; Rasoul, F.A.; Mattie, A.A.; Schaber, F.; Khandan, R. Enhancing 3D Printing Copper-PLA Composite Fabrication via Fused Deposition Modeling through Statistical Process Parameter Study. Micromachines 2024, 15, 1082. [Google Scholar] [CrossRef] [PubMed]

- Radhwan, H.; Shayfull, Z.; Abdellah, A.E.-H.; Irfan, A.R.; Kamarudin, K. Optimization Parameter Effects on the Strength of 3D-Printing Process Using Taguchi Method. AIP Conf. Proc. 2019, 2129, 20154. [Google Scholar] [CrossRef]

- Ali, S.; Abdallah, S.; Devjani, D.H.; John, J.S.; Samad, W.A.; Pervaiz, S. Effect of Build Parameters and Strain Rate on Mechanical Properties of 3D Printed PLA Using DIC and Desirability Function Analysis. Rapid Prototyp. J. 2023, 29, 92–111. [Google Scholar] [CrossRef]

| Printing Parameter | Value |

|---|---|

| Nozzle temperature | Varying |

| Build plate temperature | 50 °C |

| Filament diameter | 1.75 mm |

| Nozzle diameter | 0.6 mm |

| Printing speed | 30 mm/s |

| Infill | 100% |

| Pattern | Rectilinear |

| Infill angle | 45% |

| Build orientation | Horizontal |

| Property | Value |

|---|---|

| Tensile strength | 18.69 MPa |

| Tensile elongation | 1.27% |

| Flexural strength | 17.60 MPa |

| Flexural modulus | 1.026 GPa |

| Impact strength | 49.66 J/m |

| Level | Nozzle Temperature T (°C) | Flow Rate F (%) | Layer Thickness L (mm) |

|---|---|---|---|

| +1 | 220 | 130 | 0.3 |

| 0 | 210 | 120 | 0.2 |

| −1 | 200 | 110 | 0.1 |

| Test | T (°C) | F (%) | L (mm) | s (MPa) |

|---|---|---|---|---|

| 1 | 200 | 110 | 0.1 | 16.29 |

| 2 | 200 | 120 | 0.1 | 17.57 |

| 3 | 200 | 130 | 0.1 | 18.86 |

| 4 | 210 | 110 | 0.1 | 18.35 |

| 5 | 210 | 120 | 0.1 | 18.35 |

| 6 | 210 | 130 | 0.1 | 19.04 |

| 7 | 220 | 110 | 0.1 | 19.59 |

| 8 | 220 | 120 | 0.1 | 19.31 |

| 9 | 220 | 130 | 0.1 | 19.28 |

| 10 | 200 | 110 | 0.2 | 17.24 |

| 11 | 200 | 120 | 0.2 | 18.26 |

| 12 | 200 | 130 | 0.2 | 19.74 |

| 13 | 210 | 110 | 0.2 | 18.77 |

| 14 | 210 | 120 | 0.2 | 19.03 |

| 15 | 210 | 130 | 0.2 | 20.10 |

| 16 | 220 | 110 | 0.2 | 20.40 |

| 17 | 220 | 120 | 0.2 | 19.68 |

| 18 | 220 | 130 | 0.2 | 20.23 |

| 19 | 200 | 110 | 0.3 | 16.37 |

| 20 | 200 | 120 | 0.3 | 17.49 |

| 21 | 200 | 130 | 0.3 | 19.43 |

| 22 | 210 | 110 | 0.3 | 17.93 |

| 23 | 210 | 120 | 0.3 | 18.46 |

| 24 | 210 | 130 | 0.3 | 19.30 |

| 25 | 220 | 110 | 0.3 | 19.57 |

| 26 | 220 | 120 | 0.3 | 18.84 |

| 27 | 220 | 130 | 0.3 | 19.46 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | f-Value | p-Value | Contribution % |

|---|---|---|---|---|---|---|

| Model | 9 | 29.8700 | 3.3189 | 146.63 | 0.000 | |

| Error | 17 | 0.3848 | 0.0226 | |||

| Total | 26 | 30.2548 | ||||

| R-sq = 98.73% R-sq (adj) = 98.05% R-sq (pred) = 96.48% | ||||||

| Term | ||||||

| Τ | 1 | 12.6672 | 12.6672 | 559.64 | 0.000 | 42.41 |

| F | 1 | 6.6208 | 6.6208 | 292.50 | 0.000 | 22.16 |

| L | 1 | 0.0028 | 0.0028 | 0.12 | 0.729 | 0.01 |

| Τ2 | 1 | 0.0203 | 0.0203 | 0.90 | 0.357 | 0.07 |

| F2 | 1 | 0.6650 | 0.6650 | 29.38 | 0.000 | 2.23 |

| L2 | 1 | 3.3247 | 3.3247 | 146.89 | 0.000 | 11.13 |

| Τ × F | 1 | 6.3472 | 6.3472 | 280.42 | 0.000 | 21.25 |

| Τ × L | 1 | 0.0638 | 0.0638 | 2.82 | 0.111 | 0.21 |

| F × L | 1 | 0.1582 | 0.1582 | 6.99 | 0.017 | 0.53 |

| Factor | Goal | Lower Limit | Upper Limit |

|---|---|---|---|

| T (°C) | In range | 200 | 220 |

| F (%) | In range | 110 | 130 |

| L (mm) | In range | 0.1 | 0.3 |

| s (MPa) | Maximize | 16.29 | 20.40 |

| Solution | ||

|---|---|---|

| Parameter | 1 | 2 |

| T (°C) | 220 | 220 |

| F (%) | 110 | 110 |

| L (mm) | 0.1889 | 0.2030 |

| s (MPa) Fit | 20.333 | 20.317 |

| Desirability | 0.983428 | 0.979509 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kyratsis, V.; Tzotzis, A.; Korlos, A.; Efkolidis, N. Investigation of the Fabrication Parameters’ Influence on the Tensile Strength of 3D-Printed Copper-Filled Metal Composite Using Design of Experiments. J. Manuf. Mater. Process. 2024, 8, 278. https://doi.org/10.3390/jmmp8060278

Kyratsis V, Tzotzis A, Korlos A, Efkolidis N. Investigation of the Fabrication Parameters’ Influence on the Tensile Strength of 3D-Printed Copper-Filled Metal Composite Using Design of Experiments. Journal of Manufacturing and Materials Processing. 2024; 8(6):278. https://doi.org/10.3390/jmmp8060278

Chicago/Turabian StyleKyratsis, Vasileios, Anastasios Tzotzis, Apostolos Korlos, and Nikolaos Efkolidis. 2024. "Investigation of the Fabrication Parameters’ Influence on the Tensile Strength of 3D-Printed Copper-Filled Metal Composite Using Design of Experiments" Journal of Manufacturing and Materials Processing 8, no. 6: 278. https://doi.org/10.3390/jmmp8060278

APA StyleKyratsis, V., Tzotzis, A., Korlos, A., & Efkolidis, N. (2024). Investigation of the Fabrication Parameters’ Influence on the Tensile Strength of 3D-Printed Copper-Filled Metal Composite Using Design of Experiments. Journal of Manufacturing and Materials Processing, 8(6), 278. https://doi.org/10.3390/jmmp8060278