Design and Technological Aspects of Integrating Multi-Blade Machining and Surface Hardening on a Single Machine Base

Abstract

1. Introduction

- Develop a scheme for upgrading standard process equipment to the level of HMS using the methods of structural and kinematic synthesis, principles of machine tool layout, and mathematical simulation of the operating loads of the machine tool system.

- Test a metalworking machine tool complex employing hybrid processing technology at a production facility to confirm the effectiveness of its implementation in the production process.

2. Materials and Methods

2.1. Materials and Methods of Field Experiments

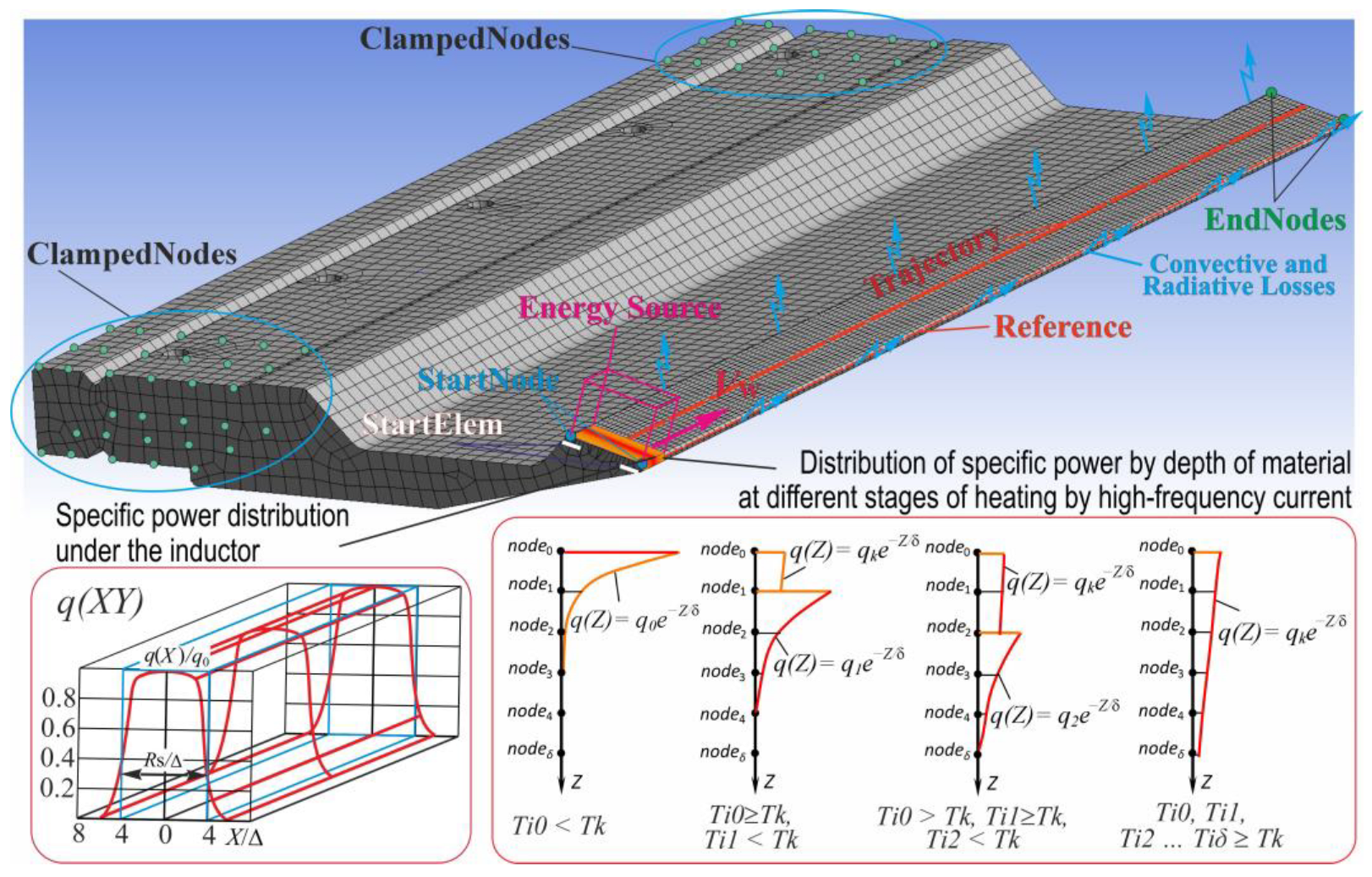

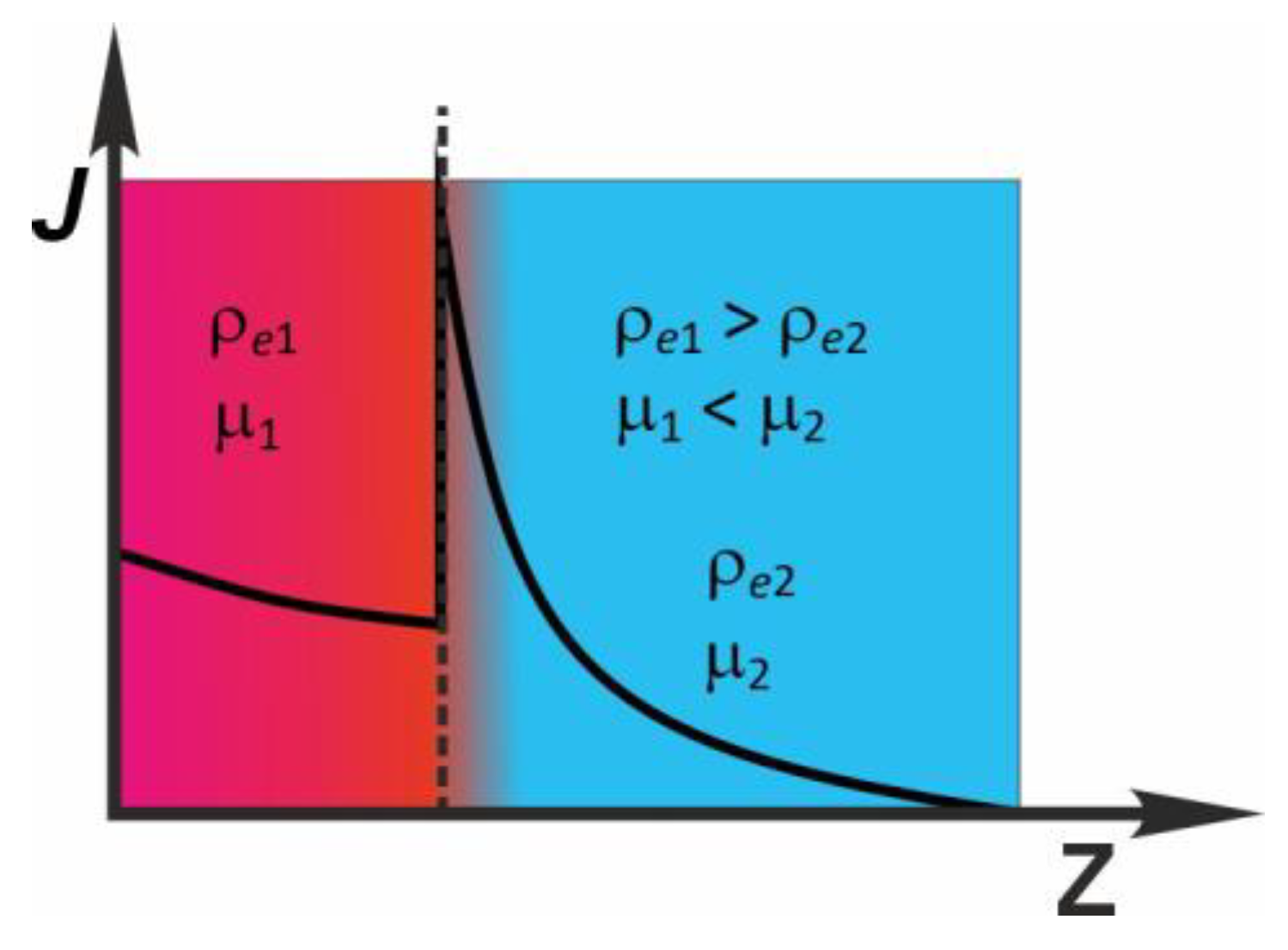

2.2. Mathematical Simulation of Thermal Fields, Structural-Phase Transformations, and the Stress–Strain State of a Material at HEH HFC

3. Results and Discussion

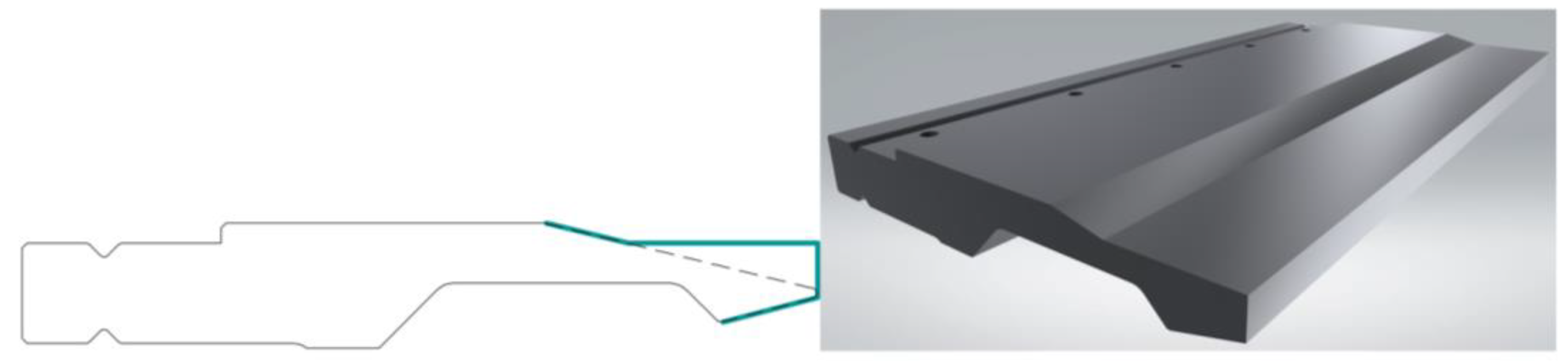

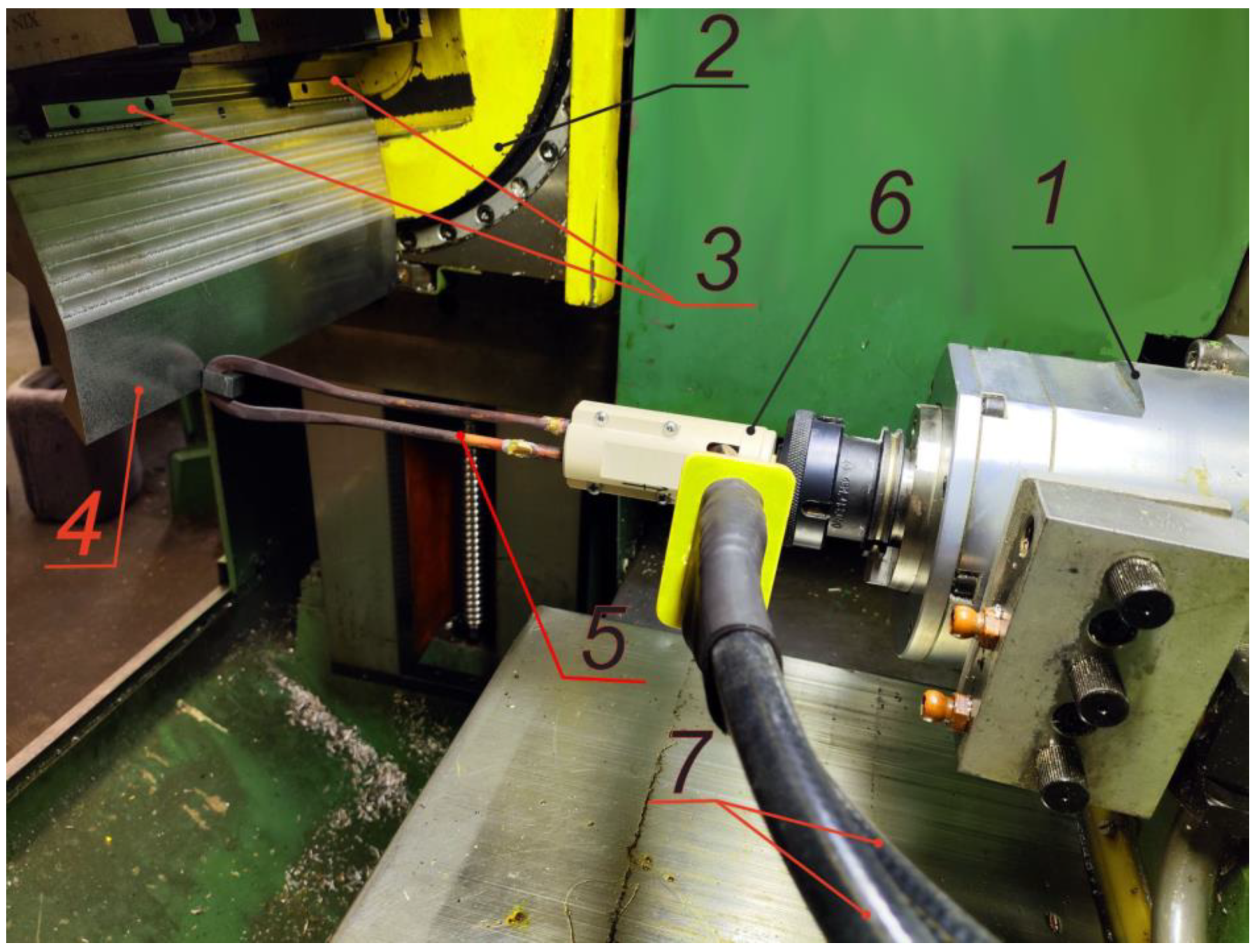

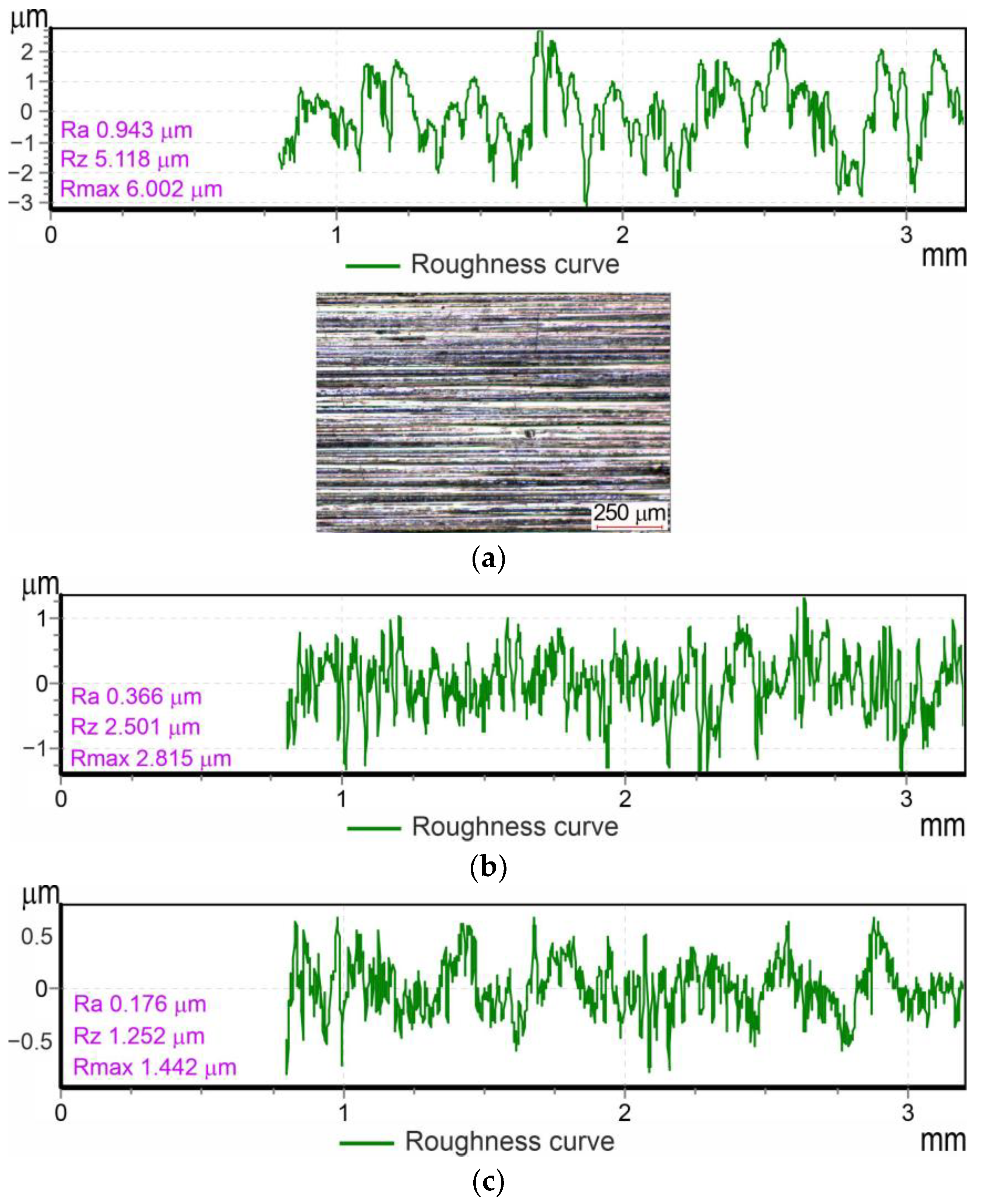

3.1. Pre-Machining (Milling)

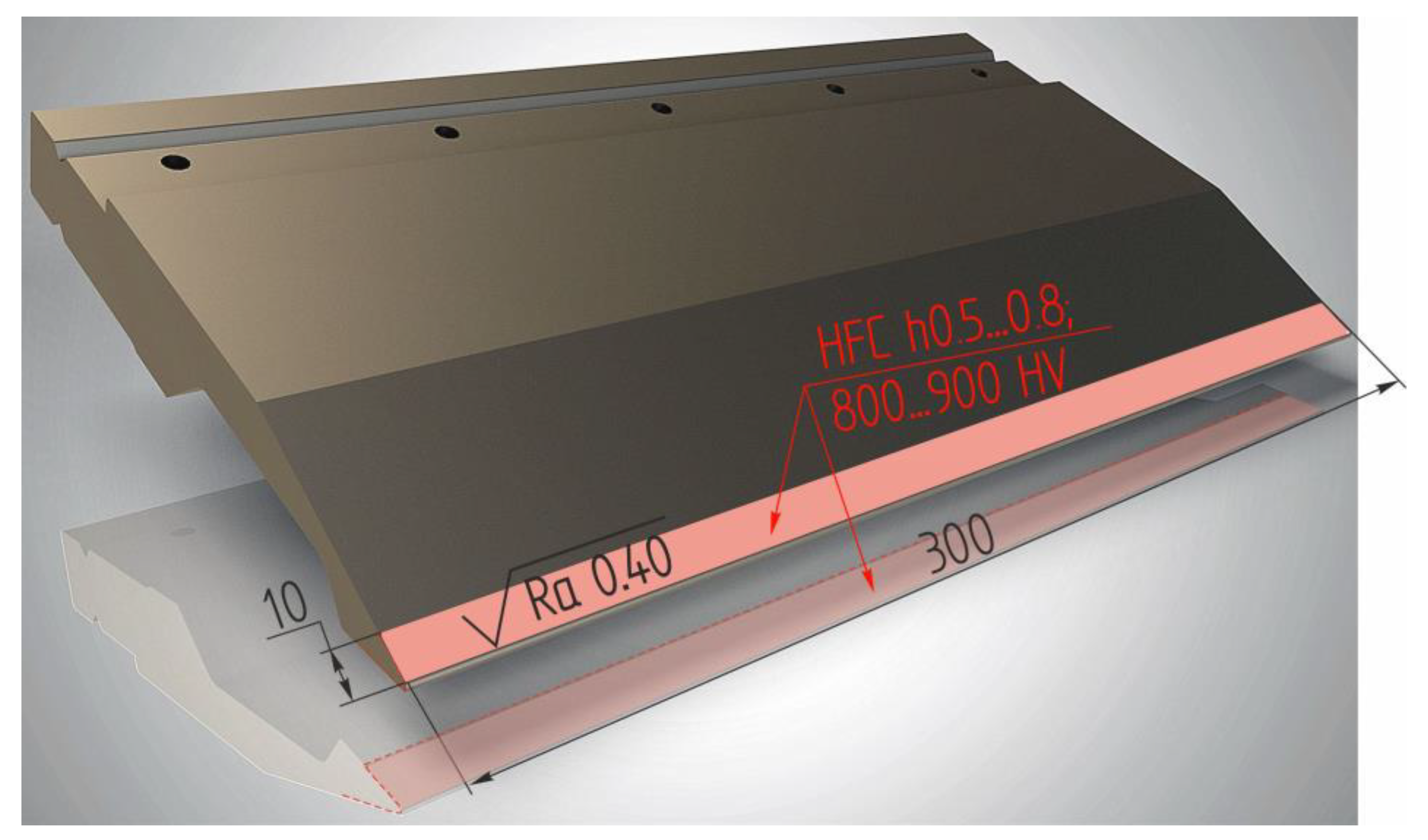

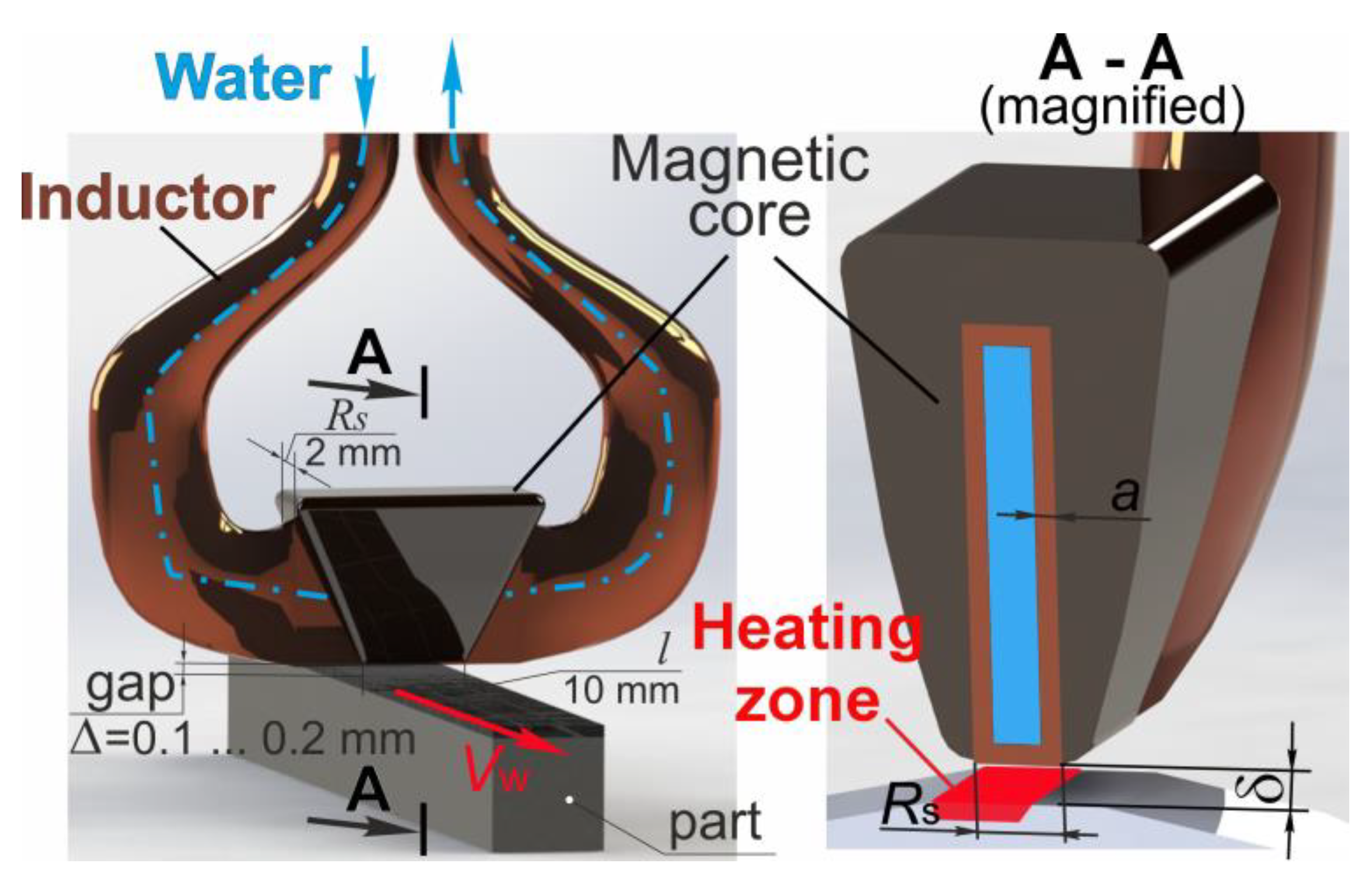

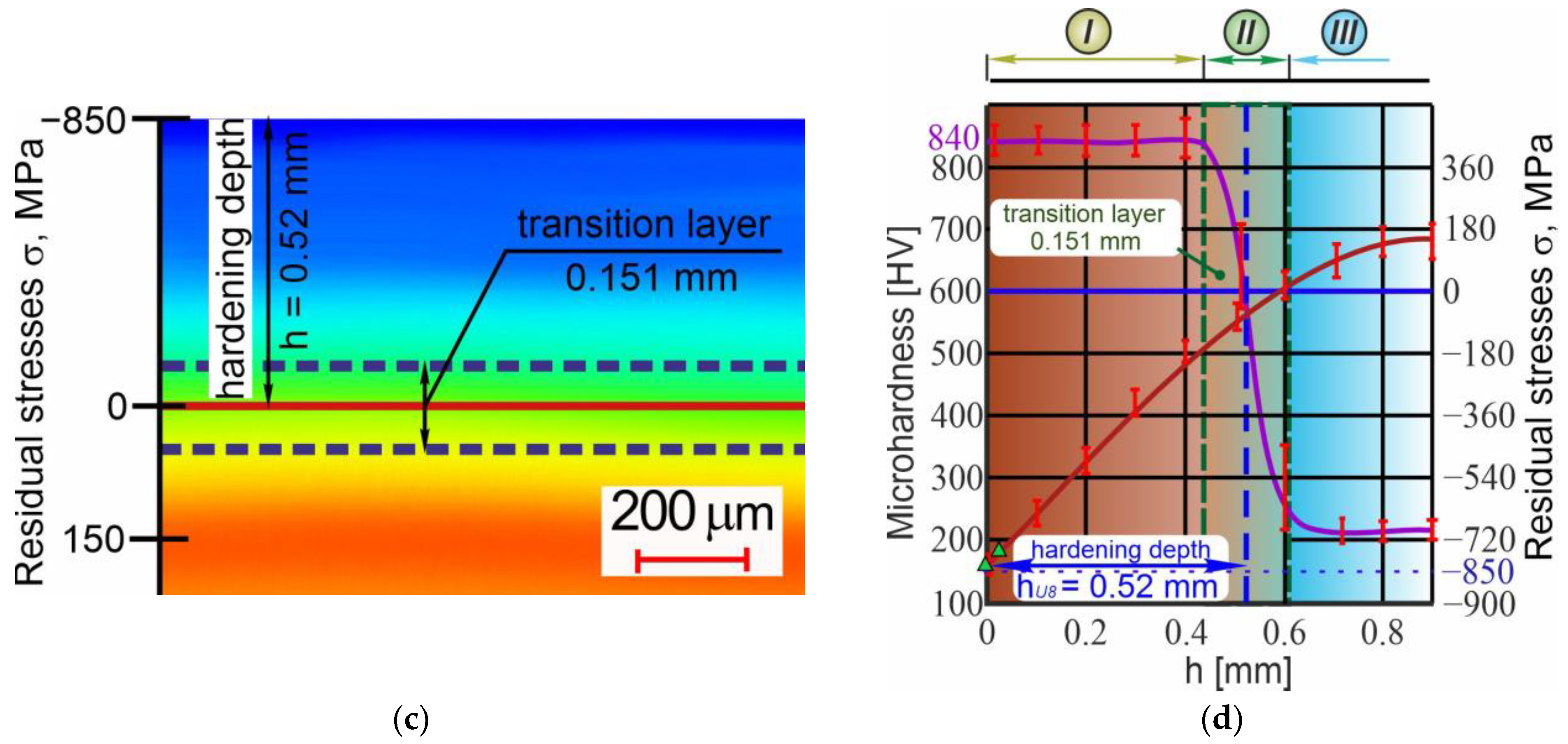

3.2. Surface Hardening by High-Energy Heating with High-Frequency Currents

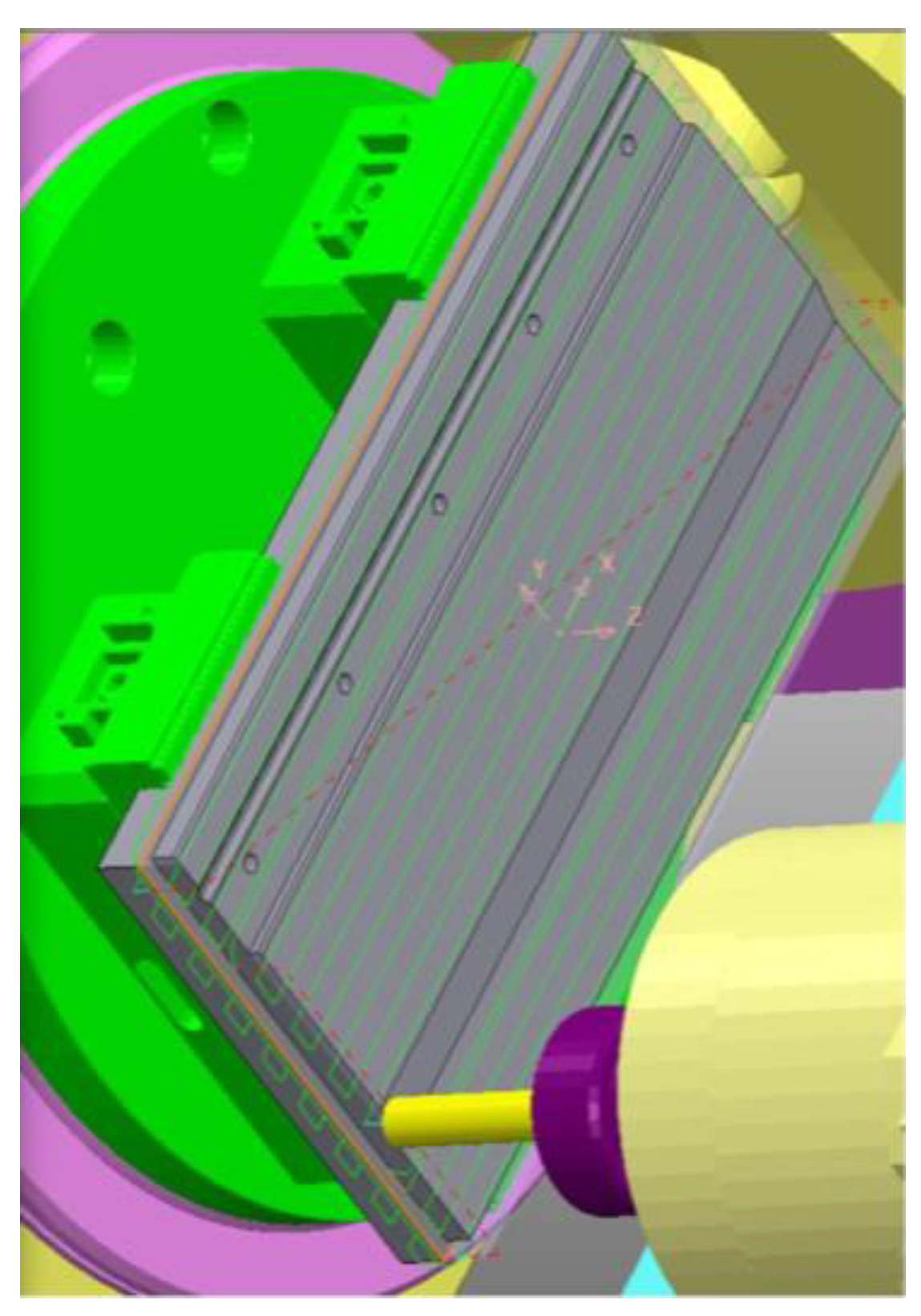

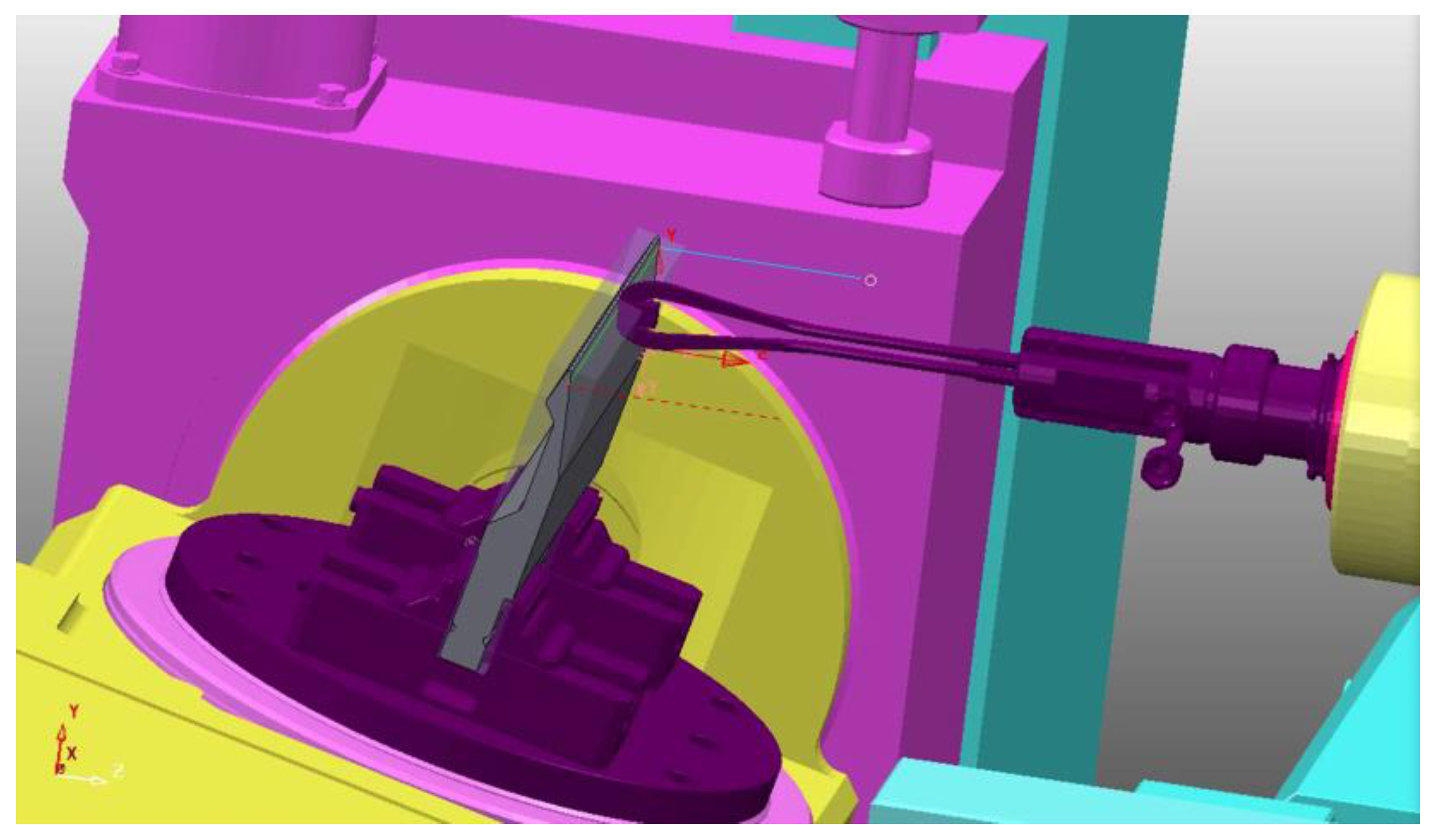

- At the first stage, all machine components were modeled with maximum accuracy of dimensional parameters in the COMPASS 3D CAD system, followed by the preparation of unit models for import into the PowerMILL CAM system in the “.stl” format.

- At the second stage, the control file of the machine kinematics was assembled, which enabled interaction with machine models and a post-processor when creating a control program, reproducing all the working movements of the process equipment inside the CAM system. In this case, the hybrid machine has one more axis in the software since the spindle has an active positioning capability and has the index “B”, and the rotary table axes have indexes “A” and “C”, respectively.

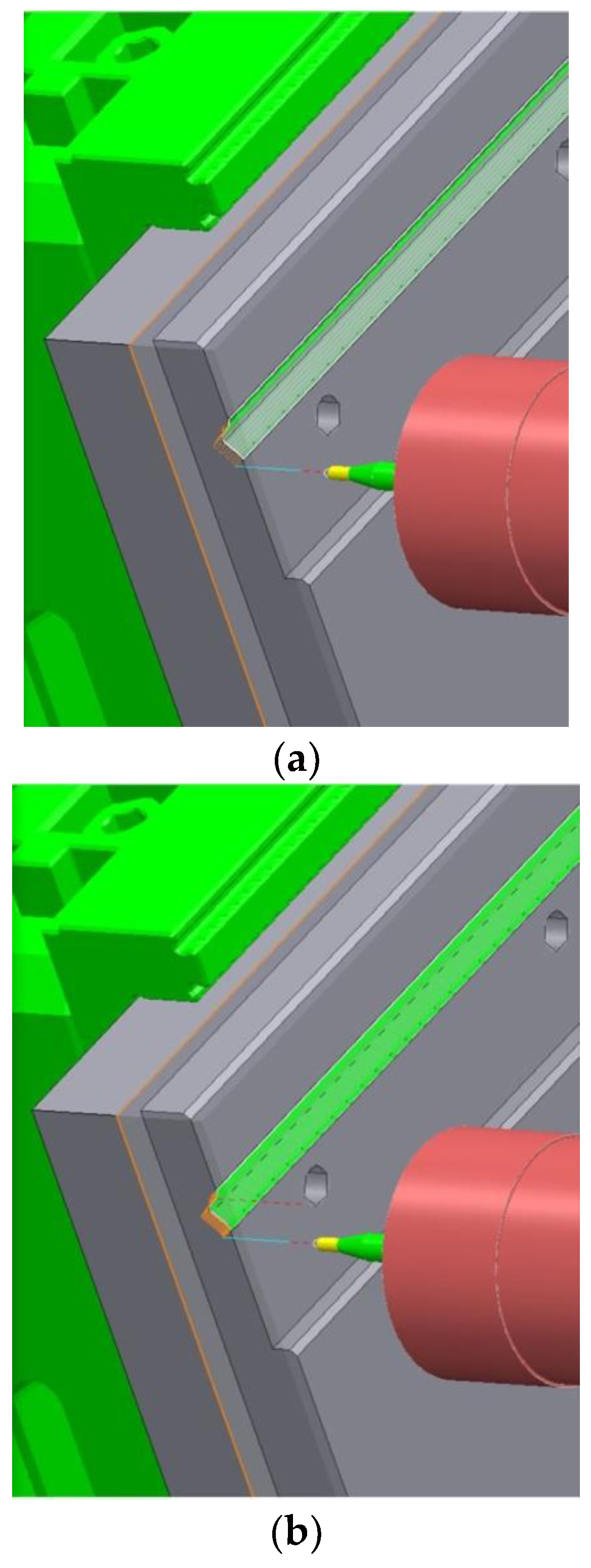

- The third, most time-consuming stage was the writing of a post-processor that includes all interdependent commands to ensure the correct operation of the system. This process was accompanied by the parallel writing of a control program to determine the correctness of the post-processor. The way the variables interact in the system is as follows: the program text contains the “code” for activating the spindle positioning in the initial position “G01 B0 F5” when choosing an inductor tool with a unique number. In this case, the address-dependent variable “B” refers to a position in the program achieved by turning the spindle axis in the desired direction at a fixed speed set as revolutions per minute through the parameter “F.” When positioning the spindle to the home position, the program uses the function G01—linear interpolation. Next, the positioning block is turned on to the first initial point at a safe height from the part, taking into account the length of the tool “G00 X0 Y0 Z161 A15 C0”. When positioning to the starting point at a safe height, the program uses the function G00—rapid positioning. This is followed by a block with the activation code of the high-frequency generator and the start of its cooling system, “M36.” Next, the program executes relative motions of the tool and the workpiece with the constant contour speed required for hardening. The program operates based on standard algorithms, but it observes the required distance of 0.15 mm between the workpiece surface and the working area of the inductor. Table 5 and Figure 19 show the kinematic structure and general view of the axis-tracking program. Upon completion of the transition “Surface Hardening by HEH HFC”, the power supply system of the high-frequency generator is switched off by the software.

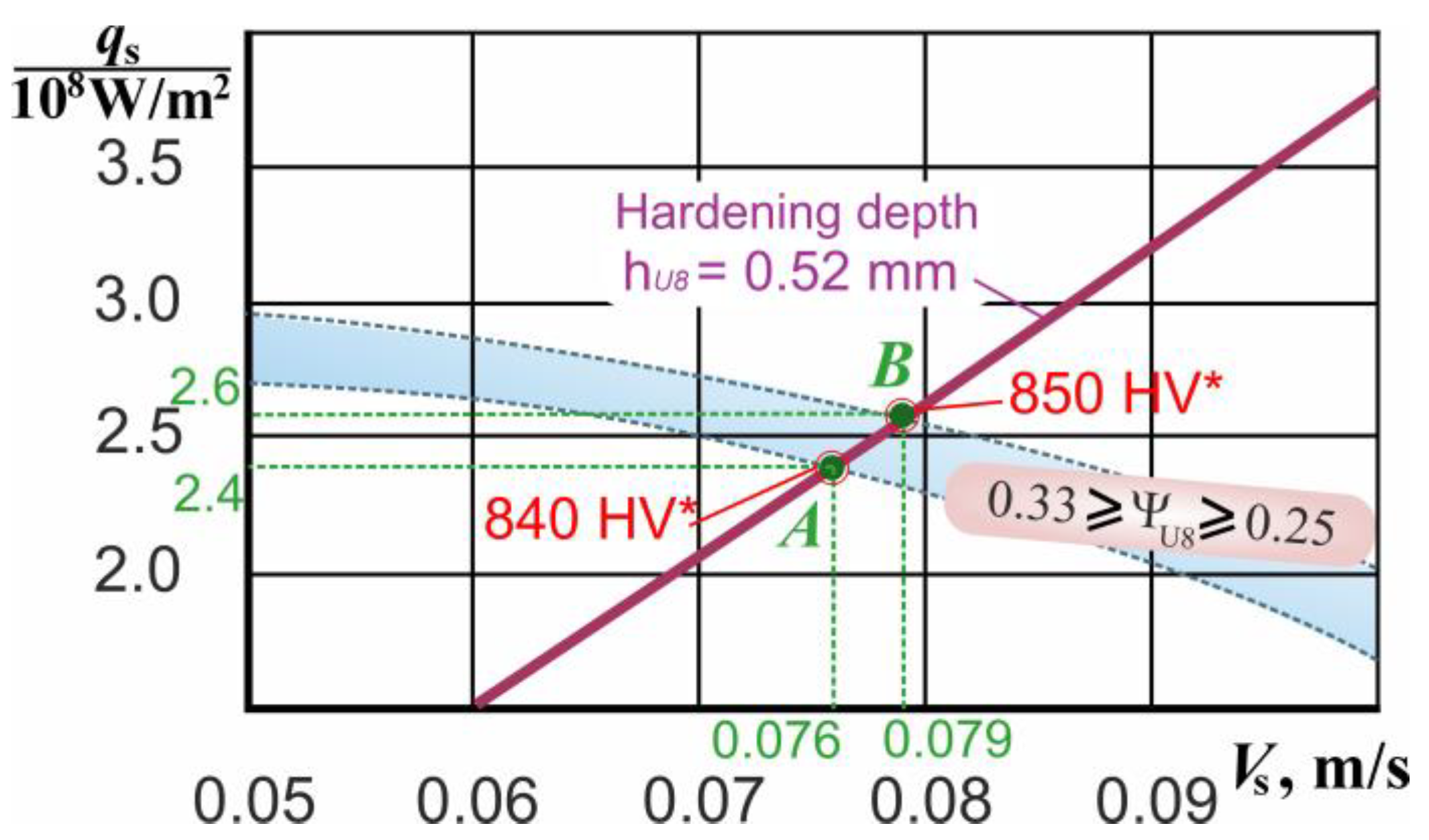

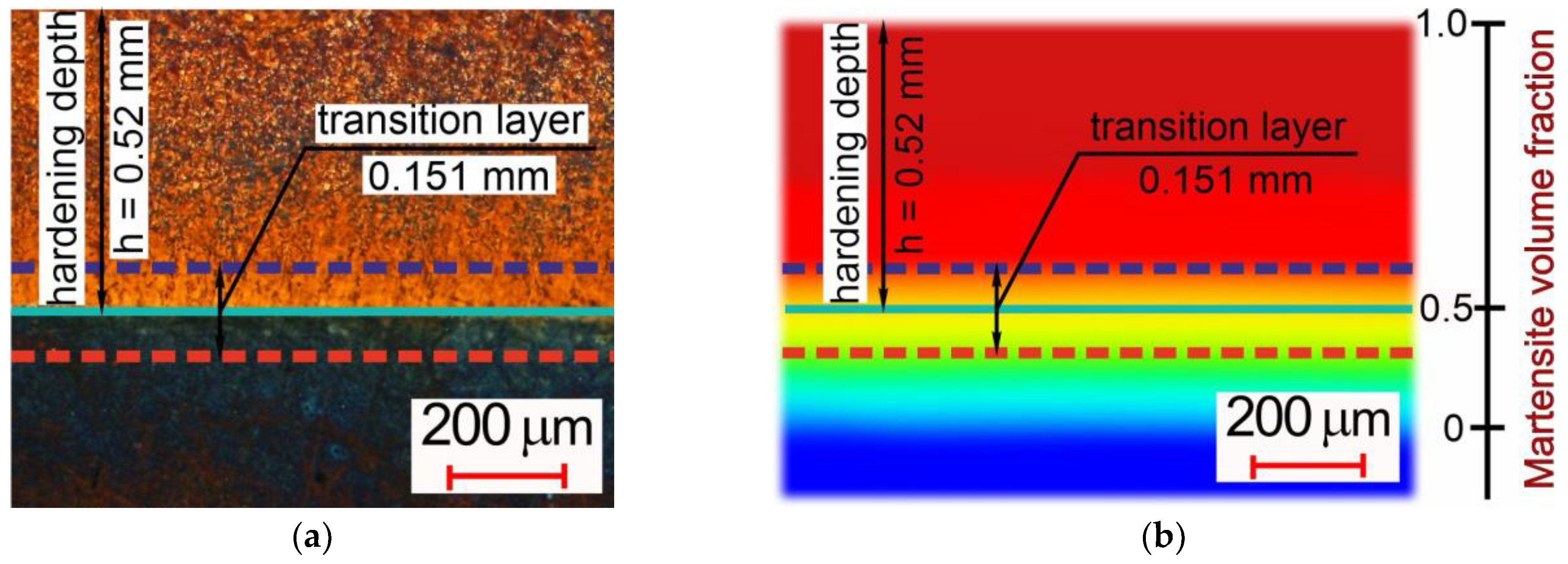

- The dependency between the hardening depth and the processing technological parameters for this steel grade (Figure 20a):

- 2.

- The dependency of the relative magnitude of the transition zone of the hardened layer Ψ on the power qs and the velocity Vs of the energy source at HEH HFC (Figure 20b):

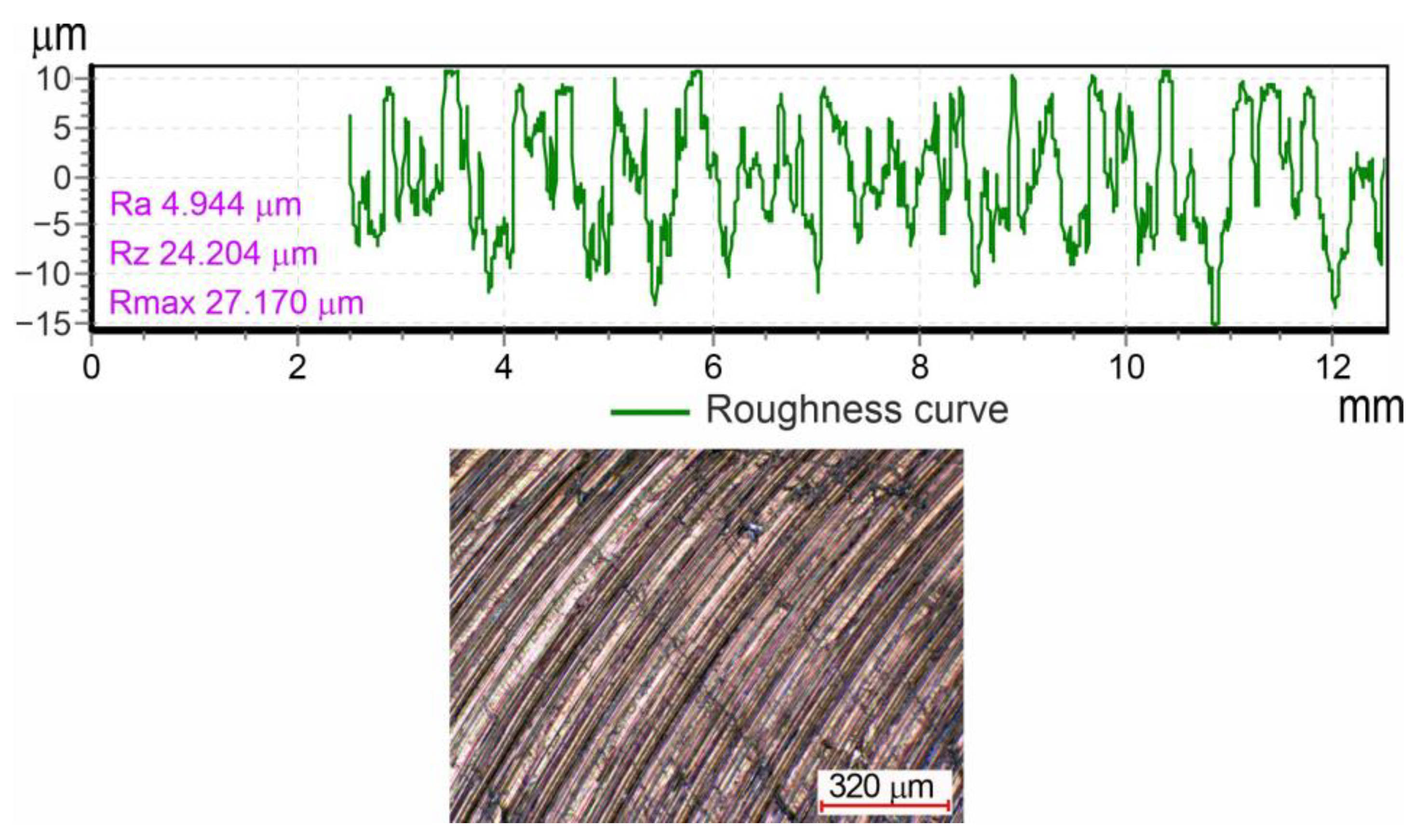

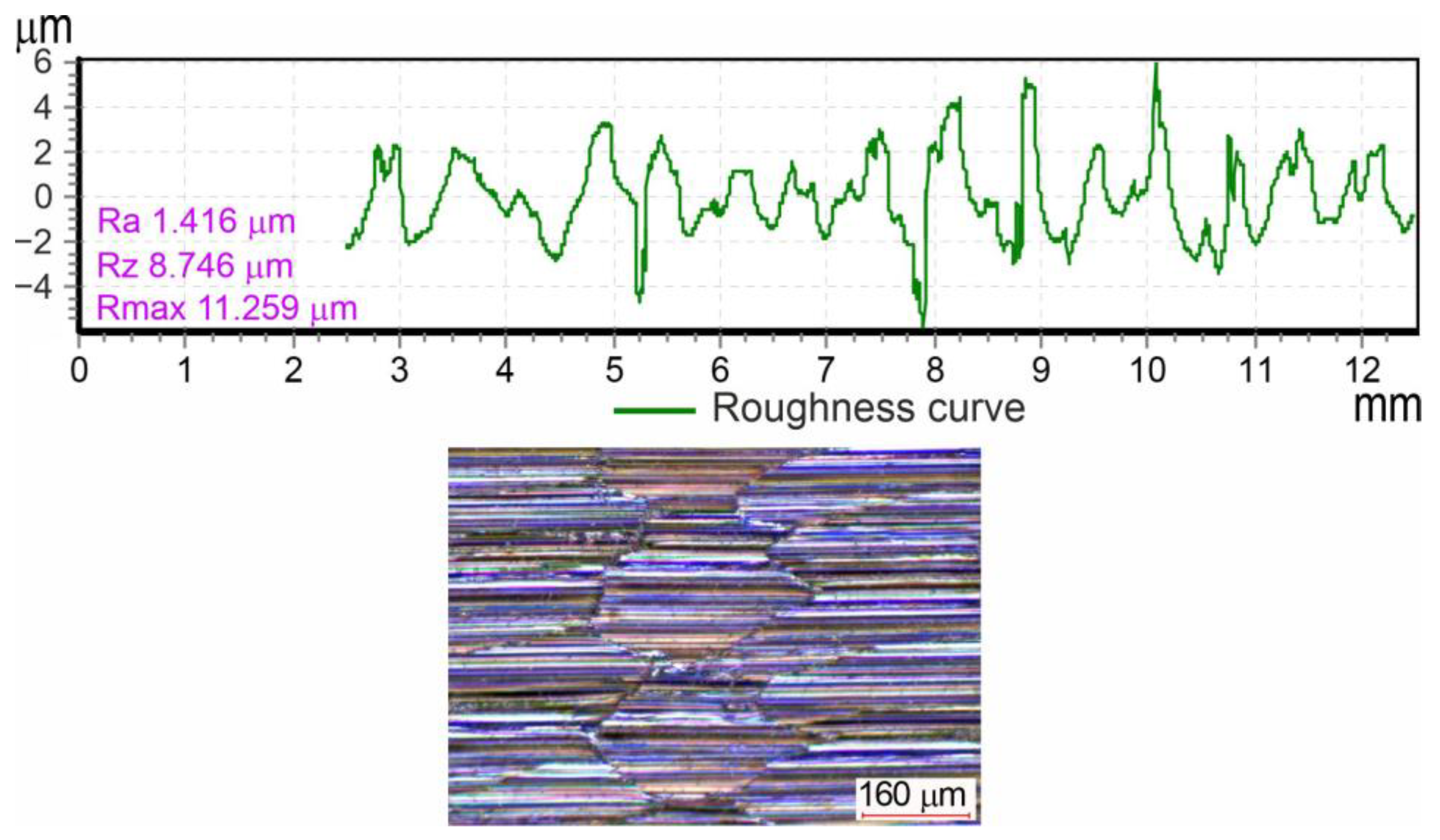

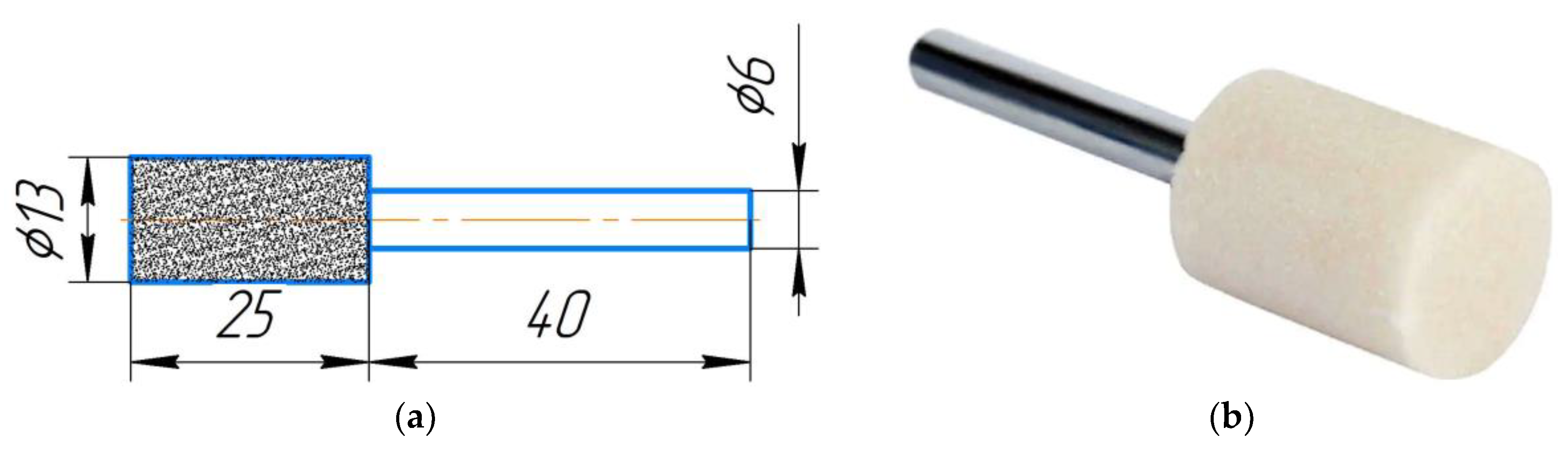

3.3. Finishing Mechanical Treatment: Grinding

4. Conclusions

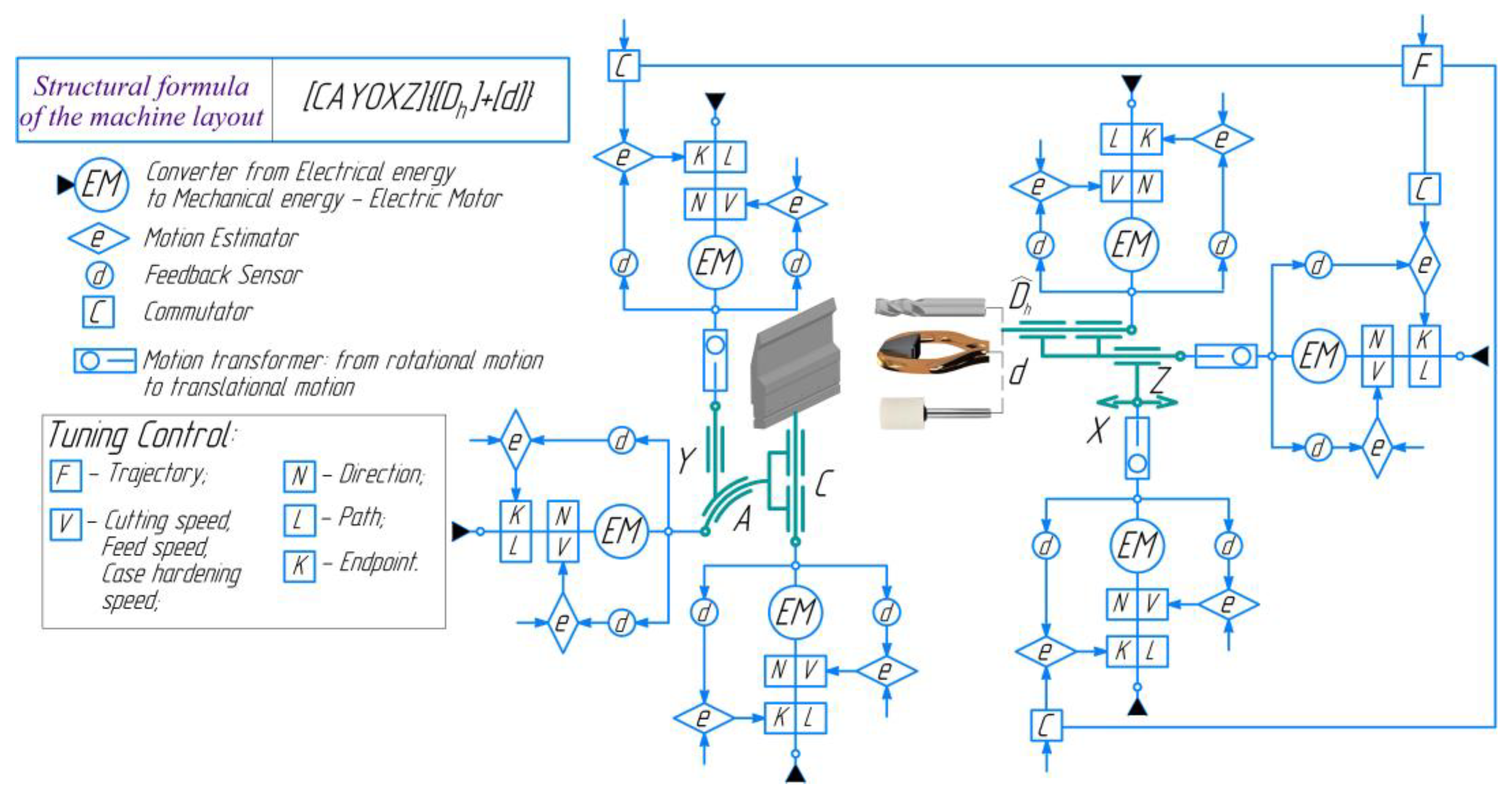

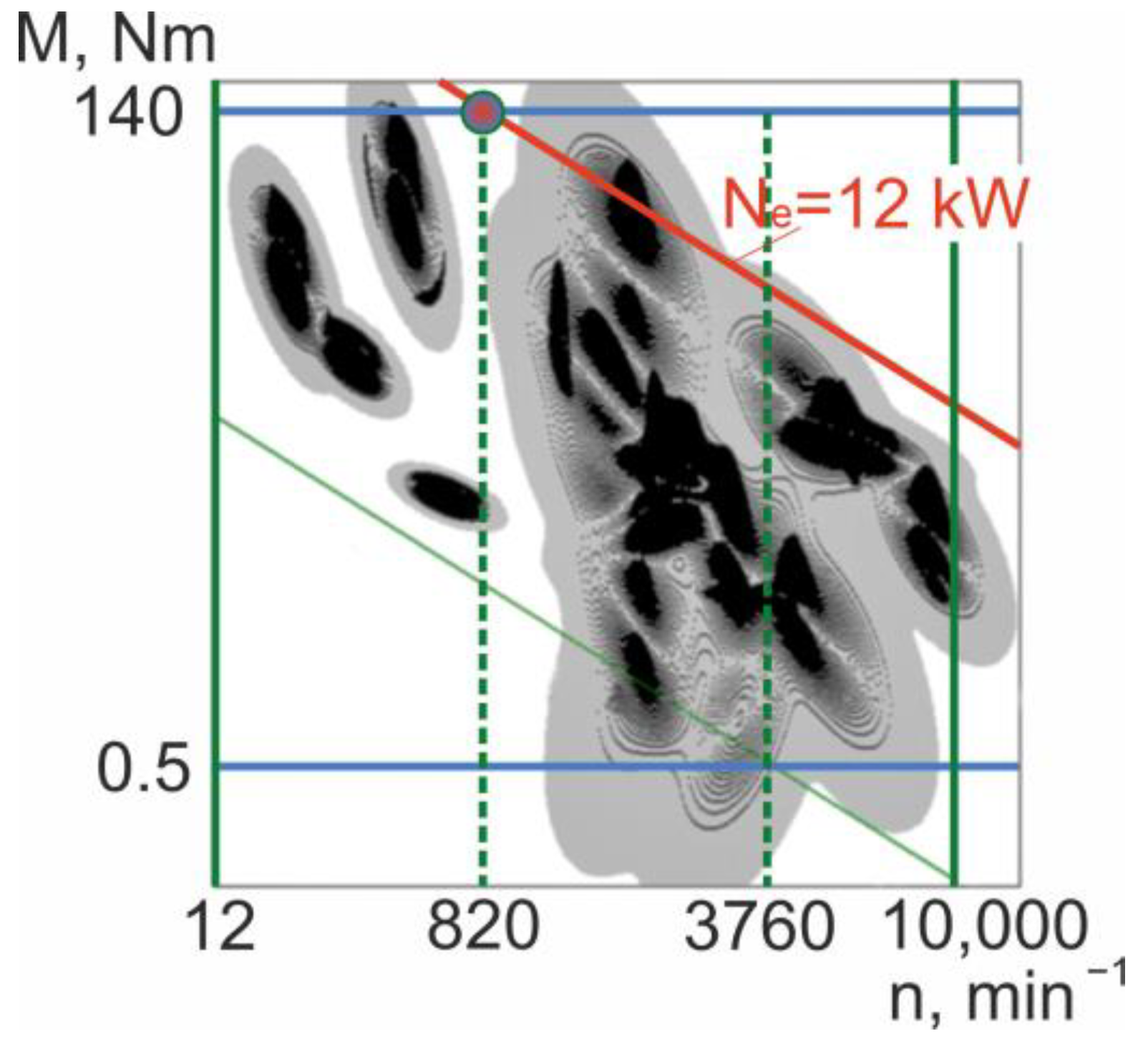

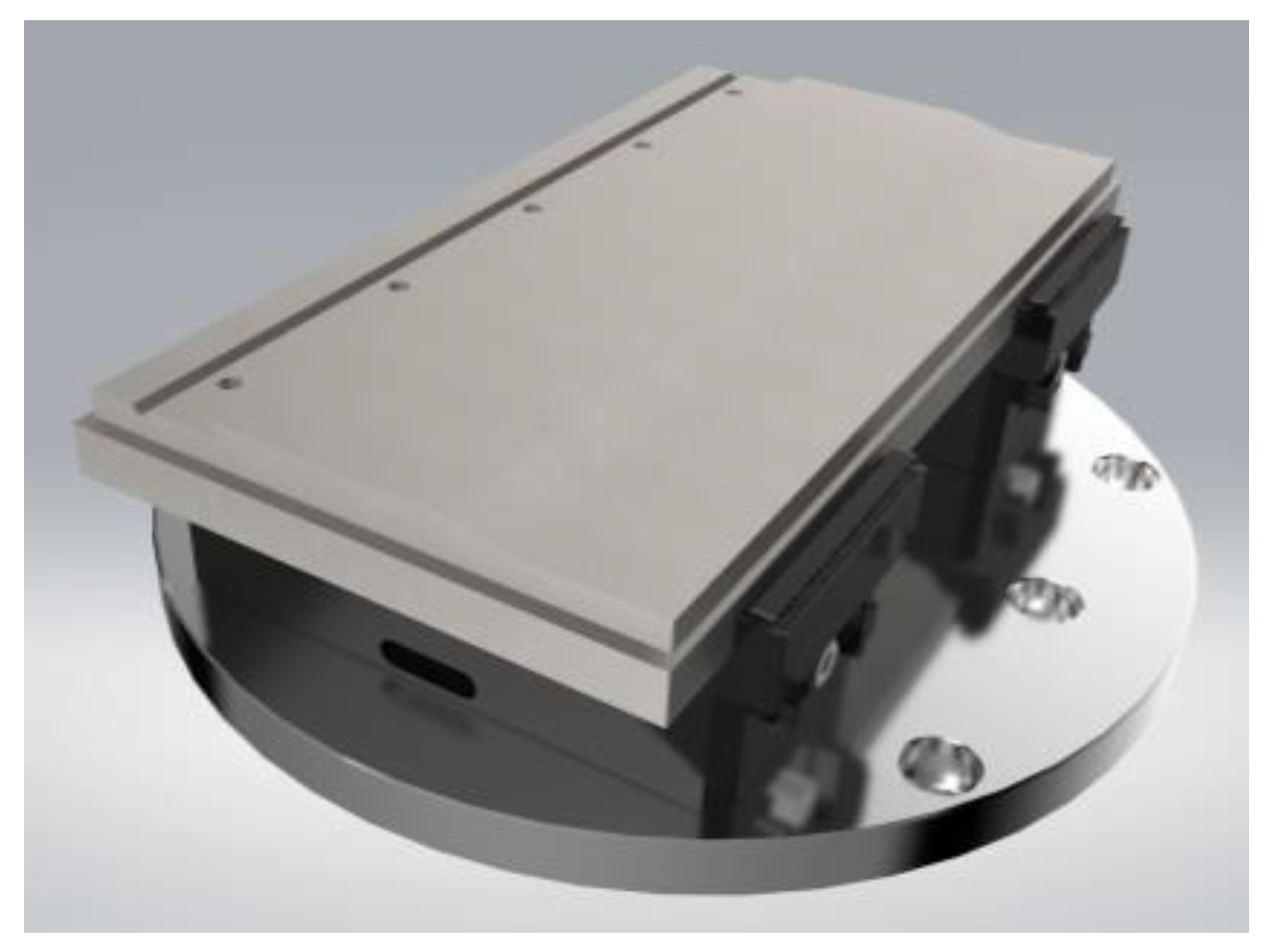

- The results of structural and kinematic analysis prove that all the transitions in integral machining require a similar set of working machine movements and a similar number of their adjustable parameters. It was found that the layout of the machine system of MS032.06 five-coordinate multi-purpose machining center is preferable for embedding an additional energy source into it, such as SVCh-10, an ultra-high-frequency thyristor generator.

- Based on the results of modeling the operational characteristics of a hybrid machine tool complex, the main drive of the machine was upgraded by replacing the existing electric drive with an asynchronous electric motor with frequency control. To ensure full-fledged 5-axis high-performance machining, as well as the possibility of integrating the SVCh-10 generator control system into the CNC machine, the standard Fanuc 6M model B CNC system was replaced with NC-400 (UEFI) CNC. The replacement of elements of DC motor control units, which control linear and circular axis drives X, Y, Z, A, and C, with modern ELL 12030 digital thyristor converters, allowed for expanding the control range of working feeds and achieving high-energy heating with high-frequency currents with the required performance.

- The range of HEH HFC modes and the rationality of the residual stresses’ redistribution in the surface-hardened material of the product are determined based on the findings of field experiments and data from finite element modeling of thermal fields, structural-phase transformations, and stress–strain states in steel under high-energy heating by high-frequency currents.

- Theoretical research revealed that grinding should be used at the last transition to ensure the required level of product-processing quality. The implementation of grinding on upgraded equipment became possible due to the use of a high-speed spindle system with an air turbine. The conducted research demonstrated that the introduction of the proposed integration principle, which ensures the processing of parts on a single technological basis, can significantly reduce the allowance for finish grinding. This ensures an increase in the quality of the surface layer of the products. In particular, during the implementation of grinding and sparking-out, the microhardness indicators achieved in the HEH HFC process and the level of compressive stresses in the surface layer of the material increase by 6–8%.

- The research team has developed a sample of hybrid metalworking equipment with numerical control and has written a unique post-processor for it, which allows for implementing all the functions of this machine tool system and the combined processing technology as a whole. They have also designed and manufactured special equipment and tools to ensure all the necessary requirements for the process of surface hardening by HEH HFC. The completed works and the approval of integrated processing technology in real conditions, when compared with traditional methods of designing the process of manufacturing parts, demonstrated a significant (1.9 times) increase in processing performance. Furthermore, the possibility of defects occurring during finishing grinding was completely eliminated, while the time required for auxiliary, preparatory, and final operations was reduced. Finally, the buffer storage was also reduced.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liao, Z.; Schoop, J.M.; Saelzer, J.; Bergmann, B.; Priarone, P.C.; Splettstößer, A.; Bedekar, V.M.; Zanger, F.; Kaynak, Y. Review of current best-practices in machinability evaluation and understanding for improving machining performance. CIRP J. Manuf. Sci. Technol. 2024, 50, 151–184. [Google Scholar] [CrossRef]

- Holmberg, J.; Berglund, J.; Wretland, A.; Klason, A.; Persson, R. Milling or grinding for manufacturing of an Alloy 718 gas turbine component?—A comparison of surface integrity and productivity. Procedia CIRP 2024, 123, 7–12. [Google Scholar] [CrossRef]

- Machado, A.R.; da Silva, L.R.R.; Pimenov, D.Y.; de Souza, F.C.R.; Kuntoğlu, M.; de Paiva, R.L. Comprehensive review of advanced methods for improving the parameters of machining steels. J. Manuf. Process. 2024, 125, 111–142. [Google Scholar] [CrossRef]

- Archenti, A.; Gao, W.; Donmez, A.; Savio, E.; Irino, N. Integrated metrology for advanced manufacturing. CIRP Ann. 2024, 73, 639–665. [Google Scholar] [CrossRef]

- Axinte, D. Portable robotised machines tools (RoboMach), for in-situ inspection and (re)manufacture: Research challenges and opportunities. Int. J. Mach. Tools Manuf. 2024, 195 Pt A, 104115. [Google Scholar] [CrossRef]

- Zhang, Y.; Du, G.; Li, H.; Yang, Y.; Zhang, H.; Xu, X.; Gong, Y. Multi-objective optimization of machining parameters based on an improved Hopfield neural network for STEP-NC manufacturing. J. Manuf. Syst. 2024, 74, 222–232. [Google Scholar] [CrossRef]

- Nguyen, T.-N.-H.; Le, D.-B.; Nguyen, D.-T. Automation for feed motion of flat grinding machine improve accuracy and productivity machine. Mater. Today. Proc. 2023, 81 Pt 2, 427–433. [Google Scholar] [CrossRef]

- Skeeba, V.Y.; Vakhrushev, N.V.; Titova, K.A.; Chernikov, A.D. Rationalization of modes of HFC hardening of working surfaces of a plug in the conditions of hybrid processing. Obrab. Met. 2023, 25, 63–86. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Jia, S.; Liu, Y. Experimental study on energy consumption of computer numerical control machine tools. J. Clean. Prod. 2016, 112, 3864–3874. [Google Scholar] [CrossRef]

- Makarov, V.M. Well integrated technological systems: Prospects and problems of implementation. Repair. Innov. Technol. Mod. 2011, 6, 20–23. [Google Scholar]

- Makarov, V.M.; Lukina, S.V. Unique synergy of hybrid machines. Repair. Innov. Technol. Mod. 2016, 8, 18–25. [Google Scholar]

- Skeeba, V.Y.; Ivancivsky, V.V. Improving the efficiency of surface thermal hardening of machine parts in conditions of combination of processing technologies, integrated on a single machine tool base. Obrab. Met. 2021, 23, 45–71. [Google Scholar] [CrossRef]

- Mitsuishi, M.; Ueda, K.; Kimura, F. Manufacturing Systems and Technologies for the New Frontier; Springer Publ.: London, UK, 2008; p. 556. ISBN 978-1-84800-267-8. [Google Scholar] [CrossRef]

- Ivancivsky, V.V.; Skeeba, V.Y. Hybrid Metal Working Equipment. Technological Aspects of Integrating the Operations of Surface Hardening and Abrasive Grinding; NSTU Publ.: Novosibirsk, Russia, 2019; p. 348. ISBN 978-5-7782-3988-3. [Google Scholar]

- Lauwers, B.; Klocke, F.; Klink, A.; Tekkaya, A.E.; Neugebauer, R.; Mcintosh, D. Hybrid processes in manufacturing. CIRP Ann. 2014, 63, 561–583. [Google Scholar] [CrossRef]

- Moriwaki, T. Multi-functional machine tool. CIRP Ann. 2008, 57, 736–749. [Google Scholar] [CrossRef]

- Brecher, C.; Özdemir, D. Integrative Production Technology: Theory and Applications; Springer International Publ.: London, UK, 2017; p. 1100. ISBN 978-3-319-47451-9/978-3-319-47452-6. [Google Scholar] [CrossRef]

- Yamazaki, T. Development of A Hybrid Multi-tasking Machine Tool: Integration of Additive Manufacturing Technology with CNC Machining. Procedia CIRP 2016, 42, 81–86. [Google Scholar] [CrossRef]

- Kushnarenko, S.V.; Fomichev, A.O.; Astakhov, Y.P.; Bogdanov, K.A.; Perepechkin, A.A.; Belov, I.I. New Science Intensive Technologies for Electrophysical and Chemical Treatment of Aerospace Parts. Proc. High. Educ. Institutions. Machine Build. 2019, 11, 46–54. [Google Scholar] [CrossRef]

- Skeeba, V.Y. Hybrid process equipment: Improving the efficiency of the integrated metalworking machines initial designing. Obrab. Met. Met. Work. Mater. Sci. 2019, 21, 62–83. [Google Scholar] [CrossRef]

- Borisov, M.A.; Lobanov, D.V.; Zvorygin, A.S.; Skeeba, V.Y. Adaptation of the CNC system of the machine to the conditions of combined processing. Obrab. Met. 2024, 26, 55–65. [Google Scholar] [CrossRef]

- You, K.; Yan, G.; Luo, X.; Gilchrist, M.D.; Fang, F. Advances in laser assisted machining of hard and brittle materials. J. Manuf. Process. 2020, 58, 677–692. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Dargusch, M.S. Thermally enhanced machining of hard-to-machine materials—A review. Int. J. Mach. Tools Manuf. 2010, 50, 663–680. [Google Scholar] [CrossRef]

- Kim, S.-G.; Lee, C.-M.; Kim, D.-H. Plasma-assisted machining characteristics of wire arc additive manufactured stainless steel with different deposition directions. J. Mater. Res. Technol. 2021, 15, 3016–3027. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Lee, C.-M. A Study on Optimal Machining Conditions and Energy Efficiency in Plasma Assisted Machining of Ti-6Al-4V. Materials 2019, 12, 2590. [Google Scholar] [CrossRef]

- Liao, Z.; Xu, D.; Luna, G.G.; Axinte, D.; Augustinavicius, G.; Sarasua, J.A.; Wretland, A. Influence of surface integrity induced by multiple machining processes upon the fatigue performance of a nickel based superalloy. J. Mater. Process. Technol. 2021, 298, 117313. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, T.; Guo, W.; Meng, X.; Ding, Z.; Liang, S.Y. Laser-assisted grinding of silicon nitride ceramics: Micro-groove preparation and removal mechanism. Ceram. Int. 2022, 48, 32366–32379. [Google Scholar] [CrossRef]

- Rao, T.B. Reliability analysis of the cutting tool in plasma-assisted turning and prediction of machining characteristics. Aust. J. Mech. Eng. 2020, 20, 1020–1034. [Google Scholar] [CrossRef]

- Skeeba, V.Y.; Ivantcivsky, V.V. Hybrid Metal Working Equipment: Improving the Effectiveness of the Details Processing under the Integration of Surface Quenching and Abrasive Grinding; NSTU Publ.: Novosibirsk, Russia, 2018; p. 312. ISBN 978-5-7782-3690-5. [Google Scholar]

- Nagesh, S.; Law, M. Machine tool design with preferentially asymmetrical structures to improve dynamics and productivity. Procedia CIRP 2019, 79, 592–595. [Google Scholar] [CrossRef]

- Costa, S.; Silva, F.J.G.; Campilho, R.D.S.G.; Pereira, T. Guidelines for Machine Tool Sensing and Smart Manufacturing Integration. Procedia Manuf. 2020, 51, 251–257. [Google Scholar] [CrossRef]

- Olsson, M.; Akujärvi, V.; Ståhl, J.-E.; Bushlya, V. Cryogenic and hybrid induction-assisted machining strategies as alternatives for conventional machining of refractory tungsten and niobium. Int. J. Refract. Met. Hard Mater. 2021, 97, 105520. [Google Scholar] [CrossRef]

- Baek, J.-T.; Woo, W.-S.; Lee, C.-M. A study on the machining characteristics of induction and laser-induction assisted machining of AISI 1045 steel and Inconel 718. J. Manuf. Process. 2018, 34, 513–522. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Chen, Y.; Zhou, Y.; Wang, S.; Yuan, Z.; Jin, Z.; Liu, X. A review of low-temperature plasma-assisted machining: From mechanism to application. Front. Mech. Eng. 2023, 18, 18. [Google Scholar] [CrossRef]

- Kim, E.-J.; Lee, C.-M. Experimental study on power consumption of laser and induction assisted machining with Inconel 718. J. Manuf. Process. 2020, 59, 411–420. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, Z.; Wang, X.; Yu, T. Effects of laser-assisted grinding on surface integrity of zirconia ceramic. Ceram. Int. 2020, 46, 921–929. [Google Scholar] [CrossRef]

- Xu, M.; Wei, R.; Li, C.; Ko, T.J. High-frequency electrical discharge assisted milling of Inconel 718 under copper-beryllium bundle electrodes. J. Manuf. Process. 2023, 85, 1116–1132. [Google Scholar] [CrossRef]

- Kim, J.; Zani, L.; Abdul-Kadir, A.; Roy, A.; Baxevanakis, K.P.; Jones, L.C.R.; Silberschmidt, V.V. Hybrid-hybrid turning of micro-SiCp/AA2124 composites: A comparative study of laser-and-ultrasonic vibration-assisted machining. J. Manuf. Process. 2023, 86, 109–125. [Google Scholar] [CrossRef]

- Skeeba, V.Y.; Ivancivsky, V.V.; Martyushev, N.V. Peculiarities of High-Energy Induction Heating during Surface Hardening in Hybrid Processing Conditions. Metals 2021, 11, 1354. [Google Scholar] [CrossRef]

- Gao, K.; Qin, X. Effect of feed path on the spot continual induction hardening for different curved surfaces of AISI 1045 steel. Int. J. Heat. Mass. Transf. 2020, 115, 104632. [Google Scholar] [CrossRef]

- Zykova, A.; Zadkov, D.; Kuzkin, A. Influence of W Addition on Microstructure and Mechanical Properties of Al-12%Si Alloys. Materials 2019, 12, 981. [Google Scholar] [CrossRef]

- Asadzadeh, M.Z.; Raninger, P.; Prevedel, P.; Ecker, W.; Mücke, M. Hybrid modeling of induction hardening processes. Appl. Eng. Sci. 2021, 5, 100030. [Google Scholar] [CrossRef]

- Isametova, M.E.; Karlina, Y.I.; Kononenko, R.V.; Absadykov, B.N. Thermal Pulse Processing of Blanks of Small-Sized Parts Made of Beryllium Bronze and 29 NK Alloy. Materials 2022, 15, 6682. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, E.-J.; Lee, C.-M. A study on the heat affected zone and machining characteristics of difficult-to-cut materials in laser and induction assisted machining. J. Manuf. Process. 2020, 57, 499–508. [Google Scholar] [CrossRef]

- Rezanov, V.A.; Kukartsev, V.V.; Tynchenko, V.S.; Kukartsev, V.A.; Grinek, A.V.; Lyosin, A.V.; Karlina, A.I. Study of Melting Methods by Electric Resistance Welding of Rails. Metals 2022, 12, 2135. [Google Scholar] [CrossRef]

- Ha, J.-H.; Lee, C.-M. A Study on the Thermal Effect by Multi Heat Sources and Machining Characteristics of Laser and Induction Assisted Milling. Materials 2019, 12, 1032. [Google Scholar] [CrossRef]

- Akzharkyn, I.; Yelemessov, K.; Baskanbayeva, D.; Konyukhov, V.Y.; Oparina, T.A. Strengthening Polymer Concrete with Carbon and Basalt Fibres. Appl. Sci. 2024, 14, 7567. [Google Scholar] [CrossRef]

- Yelemessov, K.; Baskanbayeva, D.; Gozbenko, V.E.; Karlina, A.I. Change in the Properties of Rail Steels during Operation and Reutilization of Rails. Metals 2023, 13, 1043. [Google Scholar] [CrossRef]

- Kim, E.J.; Lee, C.M. A Study on the Optimal Machining Parameters of the Induction Assisted Milling with Inconel 718. Materials 2019, 12, 233. [Google Scholar] [CrossRef]

- Skeeba, V.Y.; Pushnin, V.N.; Erokhin, I.A.; Kornev, D.Y. Analysis of the stress-strain state of the material under high-energy heating by high frequency currents. Obrab. Met. 2014, 3, 90–102. [Google Scholar]

- Efremenkov, E.A.; Grechneva, M.V.; Olisov, A.V.; Ens, A.D. Research on the Possibility of Lowering the Manufacturing Accuracy of Cycloid Transmission Wheels with Intermediate Rolling Elements and a Free Cage. Appl. Sci. 2022, 12, 5. [Google Scholar] [CrossRef]

- Ivakhnenko, A.G.; Kuts, V.V.; Erenkov, O.Y.; Ivakhnenko, E.O.; Oleinik, A.V. Effectiveness of structural–parametric synthesis of metal-cutting systems. Russ. Eng. Res. 2017, 37, 901–905. [Google Scholar] [CrossRef]

- Nakaminami, M.; Tokuma, T.; Moriwaki, M.; Nakamoto, K. Optimal Structure Design Methodology for Compound Multiaxis Machine Tools –I- Analysis of Requirements and Specifications. Int. J. Autom. Technol. 2007, 1, 78–86. [Google Scholar] [CrossRef]

- Nakaminami, M.; Tokuma, T.; Matsumoto, K.; Sakashita, S.; Moriwaki, T.; Nakamoto, K. Optimal Structure Design Methodology for Compound Multiaxis Machine Tools-II-Investigation of Basic Structure. Int. J. Autom. Technol. 2007, 1, 87–93. [Google Scholar] [CrossRef]

- Balakshin, B.S. Fundamentals of Mechanical Engineering Technology; Mashinostroenie Publ.: Moscow, Russia, 1969; p. 560. [Google Scholar]

- Ivashchenko, I.A. Technological Dimensional Calculations and Methods of their Automation; Mashinostroenie Publ.: Moscow, Russia, 1975; p. 222. [Google Scholar]

- Vander Voort, G.F. ASM Handbook. Vol. 9. Metallography and Microstructures; ASM International Publ.: Cleveland, OH, USA, 2004; p. 1184. ISBN 978-0-87170-706-2. [Google Scholar]

- Totten, G.E.; Howes, M.; Inoue, T. Handbook of Residual Stress and Deformation of Steel; ASM International: Cleveland, OH, USA, 2002; p. 499. ISBN 978-0-87170-729-1. [Google Scholar]

- Sharpe, W.N. Springer Handbook of Experimental Solid Mechanics; Springer Science and Business Media: New York, NY, USA, 2008; p. 1098. ISBN 978-0-387-26883-5. [Google Scholar]

- Avraamova, T.M.; Bushuev, V.V.; Gilova, L.Y.; Dosko, S.I.; Eremin, A.V. Metal-Cutting Machines; Mashinostroenie Publ.: Moscow, Russia, 2011; p. 608. ISBN 978-5-94275-594-2. [Google Scholar]

- Dal’skii, A.M.; Kosilova, A.G.; Mesheryakov, R.K.; Suslov, A.G. (Eds.) Handbook of a Mechanical Engineer; Mashinostroenie Publ.: Moscow, Russia, 2003; p. 912. ISBN 5-94275-014-9. [Google Scholar]

- Loskutov, V.V. Grinding of Metals; Mashinostroenie Publ.: Moscow, Russia, 1970; p. 264. [Google Scholar]

- Polevoy, S.N.; Evdokimov, V.D. Strengthening of Engineering Materials; Mashinostroenie Publ.: Moscow, Russia, 1994; p. 496. [Google Scholar]

—residual stresses obtained by X-ray determination.

—residual stresses obtained by X-ray determination.

—residual stresses obtained by X-ray determination.

—residual stresses obtained by X-ray determination.

| Elements | C | Si | Mn | S | P | Cr | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| Weight, (%) | 0.81 | 0.23 | 0.19 | 0.017 | 0.02 | 0.15 | 0.19 | 0.16 |

| For Groups P Material (Steel) | Cutting Modes | ||

|---|---|---|---|

| Cutting Speed Vc, m/min | Feed fr, mm/rev | Cutting Depth ap, mm | |

| Recommended | 80–220 | 0.1–0.4 | 1.0–3.0 |

| Accepted | 80–220 | 0.15 | 2 |

| For Groups P Material (Steel) | Cutting Modes | ||

|---|---|---|---|

| Cutting Speed Vc, m/min | Feed fm, mm/min | Cutting Depth ap, mm | |

| Recommended | 180 | 860 | 0.1 |

| For Groups P Material (Steel) | Cutting Modes | ||

|---|---|---|---|

| Cutting Speed Vc, m/min | Feed fm, mm/min | Cutting Depth ap, mm | |

| Recommended | 110 | 1260 | 0.4 |

| Order | Parameter | Direction | Origin | Orientation | Limits | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | J | K | X | Y | Z | U | V | W | Min | Initial | Max | ||

| Table | 0 | 0 | 0 | ||||||||||

| 1st Rotary (C) | Machine C | 0 | 0 | −1 | 0 | 0 | 0 | −360 | 0 | 360 | |||

| 2nd Rotary (A) | Machine A | 1 | 0 | 0 | 0 | 0 | 0 | −91 | 0 | 132 | |||

| 1st Linear (Y) | Machine Y | 0 | −1 | 0 | −400 | 0 | 200 | ||||||

| Head | 0 | 0 | 1 | 0 | 0 | 10 | 1 | 0 | 0 | ||||

| 2nd Linear (X) | Machine X | 1 | 0 | 0 | −220 | 0 | 400 | ||||||

| 3rd Linear (Z) | Machine Z | 0 | 0 | 1 | 0 | 0 | 630 | ||||||

| 3rd Rotary (B) | Machine B | 0 | 0 | −1 | 0 | 0 | 0 | −360 | 0 | 360 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skeeba, V.; Ivancivsky, V.; Chernikov, A.; Martyushev, N.; Vakhrushev, N.; Titova, K. Design and Technological Aspects of Integrating Multi-Blade Machining and Surface Hardening on a Single Machine Base. J. Manuf. Mater. Process. 2024, 8, 200. https://doi.org/10.3390/jmmp8050200

Skeeba V, Ivancivsky V, Chernikov A, Martyushev N, Vakhrushev N, Titova K. Design and Technological Aspects of Integrating Multi-Blade Machining and Surface Hardening on a Single Machine Base. Journal of Manufacturing and Materials Processing. 2024; 8(5):200. https://doi.org/10.3390/jmmp8050200

Chicago/Turabian StyleSkeeba, Vadim, Vladimir Ivancivsky, Aleksey Chernikov, Nikita Martyushev, Nikita Vakhrushev, and Kristina Titova. 2024. "Design and Technological Aspects of Integrating Multi-Blade Machining and Surface Hardening on a Single Machine Base" Journal of Manufacturing and Materials Processing 8, no. 5: 200. https://doi.org/10.3390/jmmp8050200

APA StyleSkeeba, V., Ivancivsky, V., Chernikov, A., Martyushev, N., Vakhrushev, N., & Titova, K. (2024). Design and Technological Aspects of Integrating Multi-Blade Machining and Surface Hardening on a Single Machine Base. Journal of Manufacturing and Materials Processing, 8(5), 200. https://doi.org/10.3390/jmmp8050200