Enhancement of Additively Manufactured Bagasse Fiber-Reinforced Composite Material Properties Utilizing a Novel Fiber Extraction Process Used for 3D SLA Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. FTIR Spectroscopy

2.3. Fiber Diameter Measurement

2.4. 3D Printer

2.5. Resin

2.6. Composite Fabrication Method

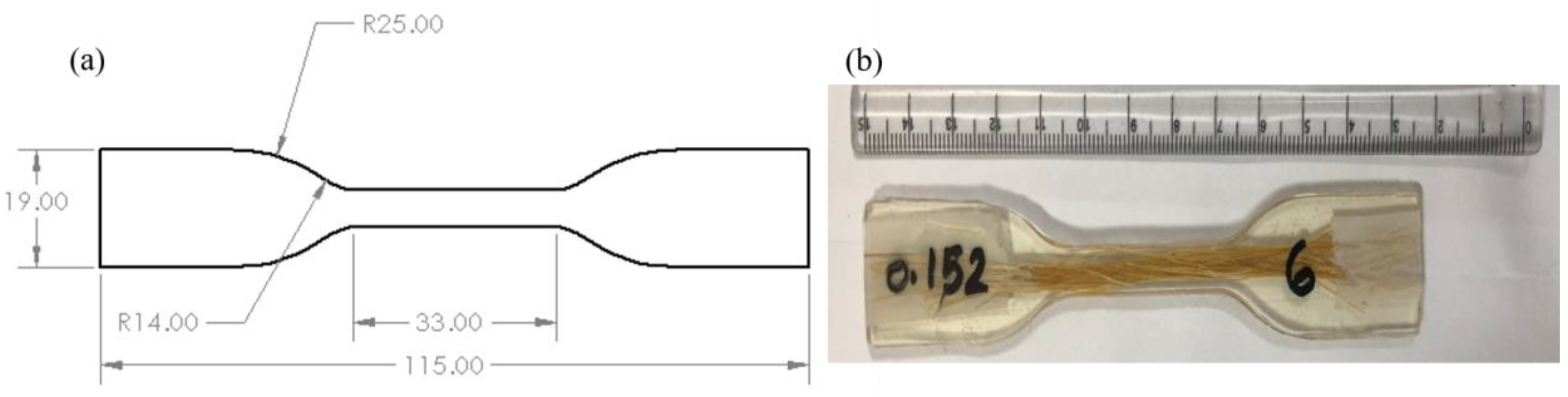

2.7. Tensile Test

2.8. SEM

3. Results

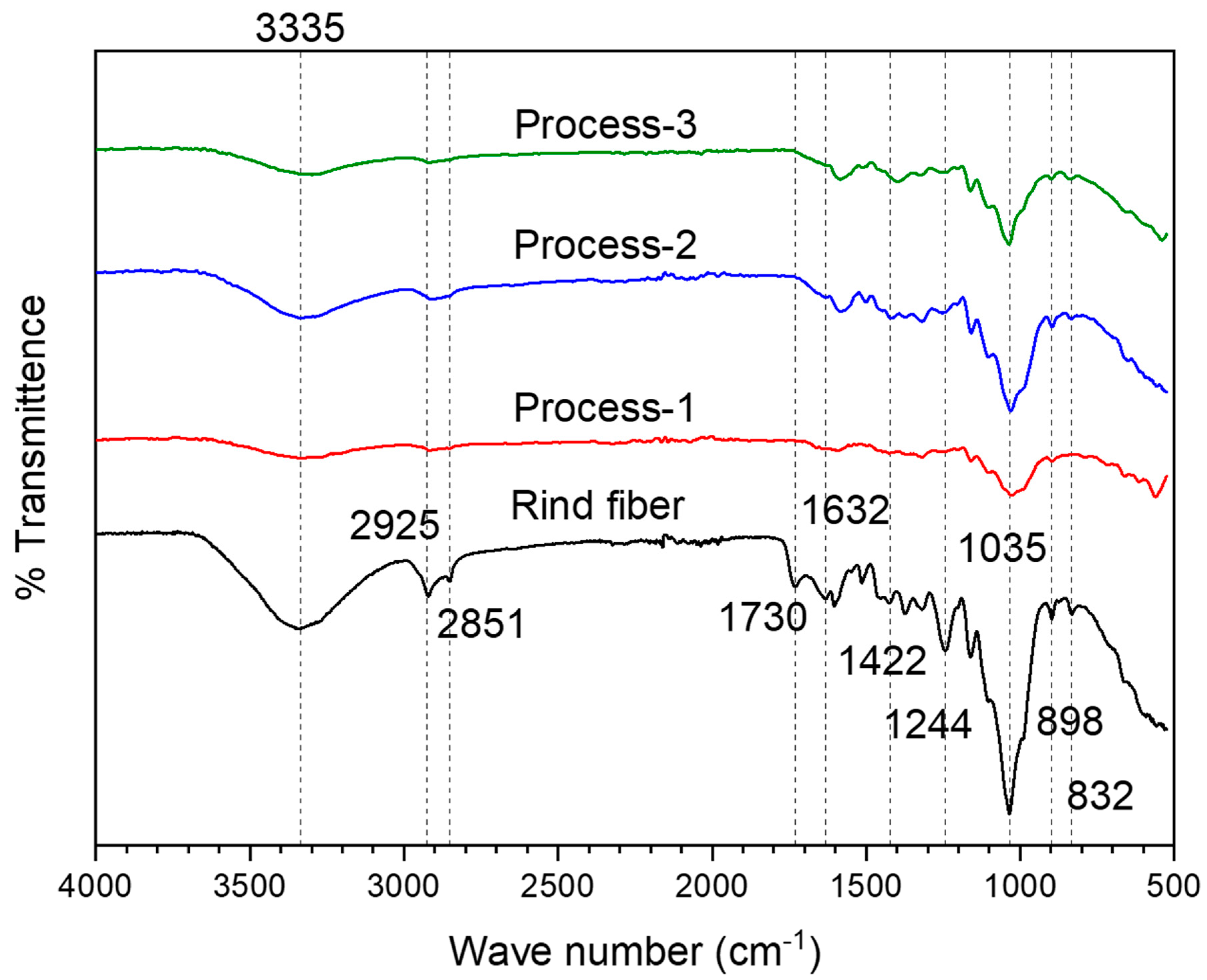

3.1. FTIR Analysis

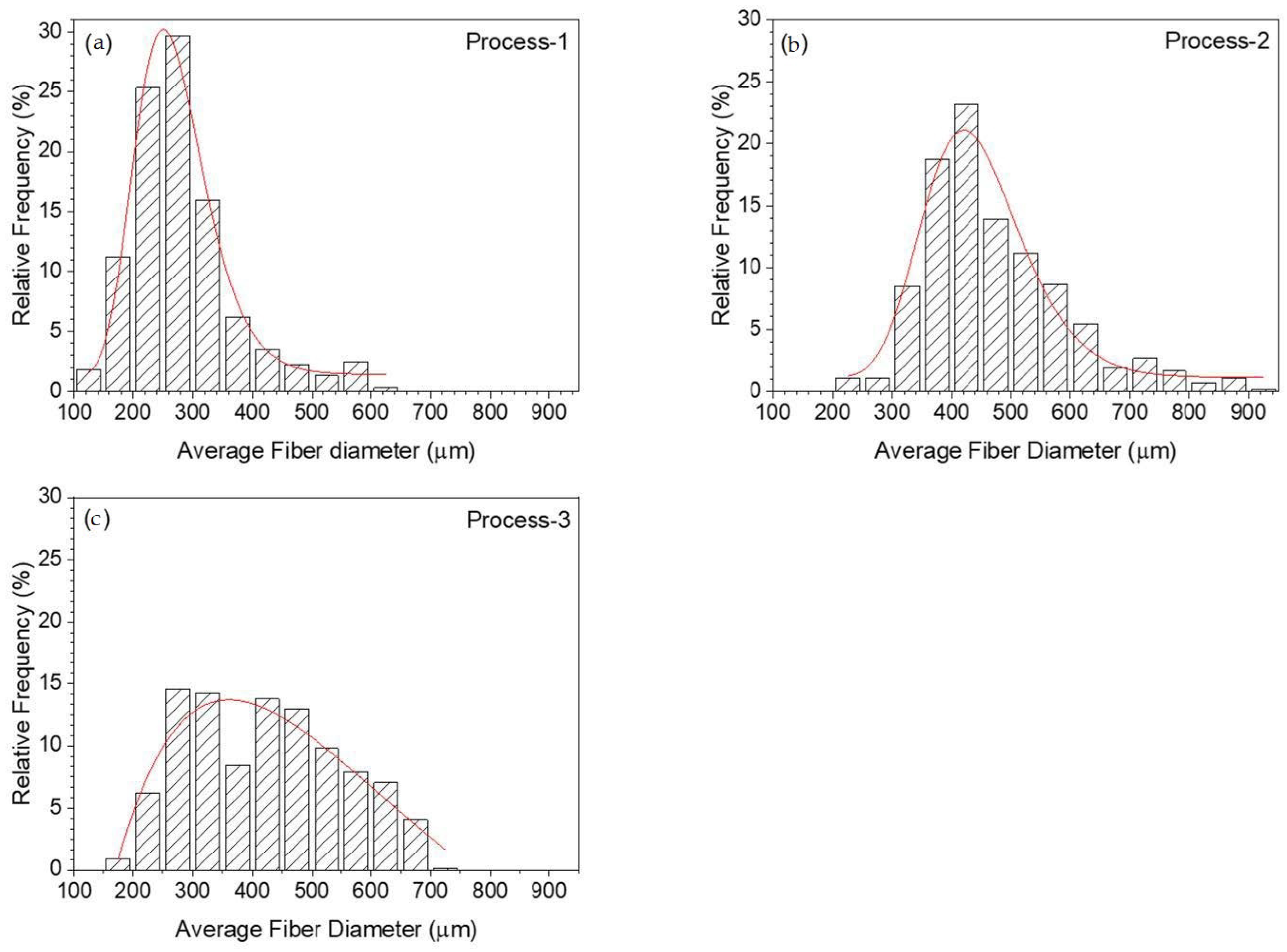

3.2. Fiber Diameter

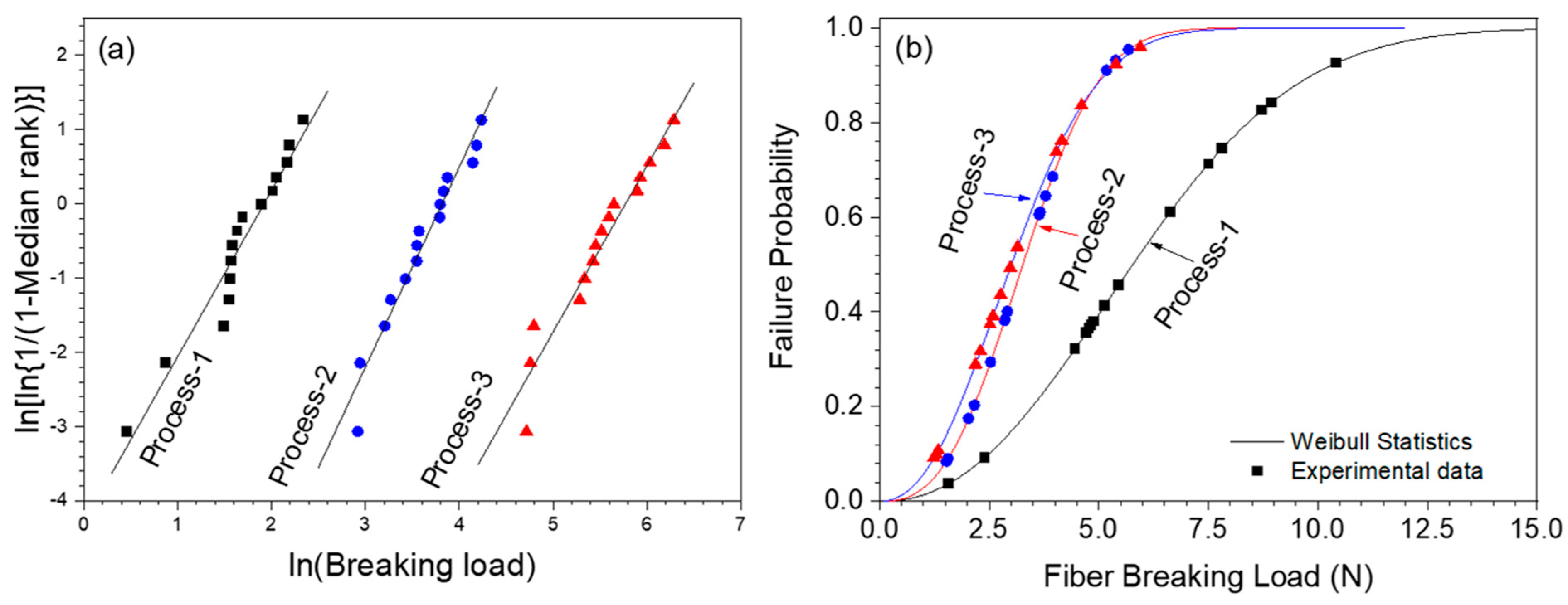

3.3. Fiber Strength

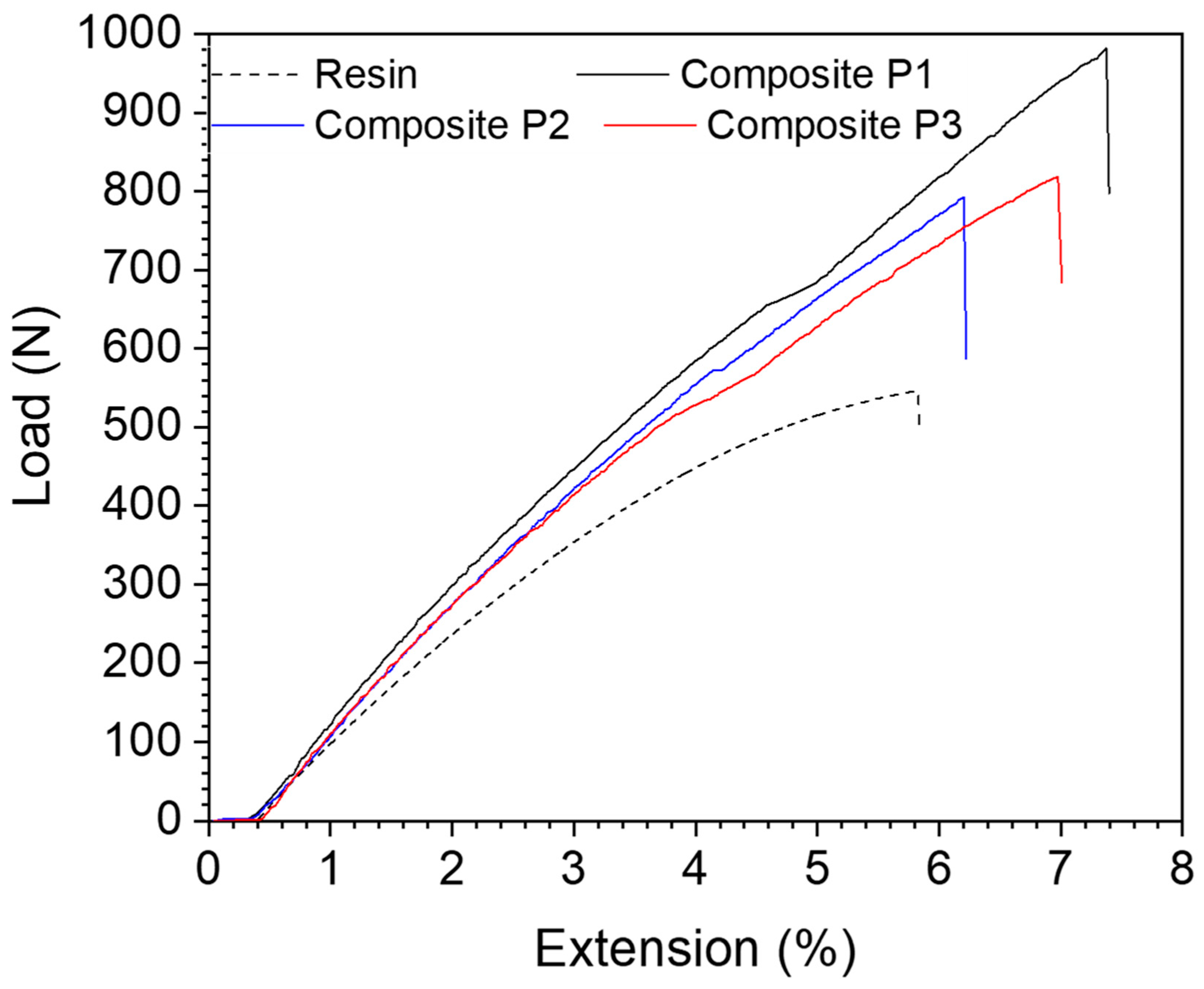

3.4. Composite Tensile Strength

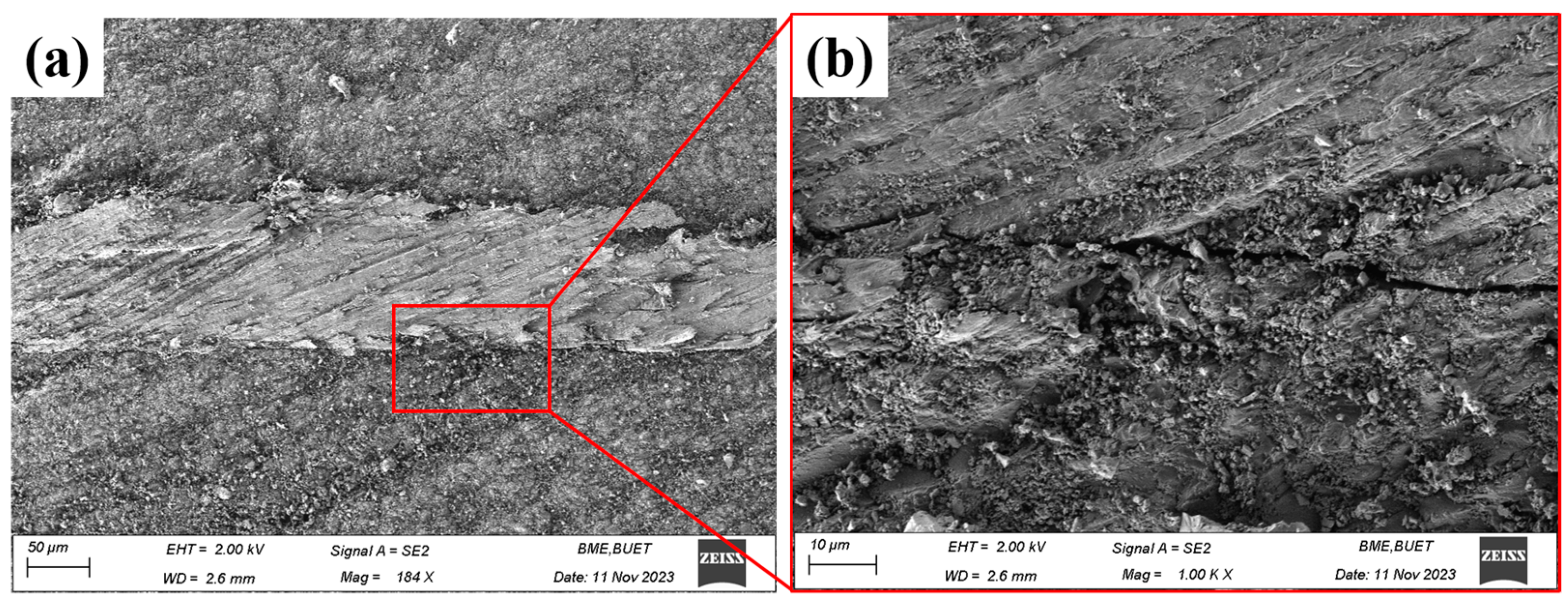

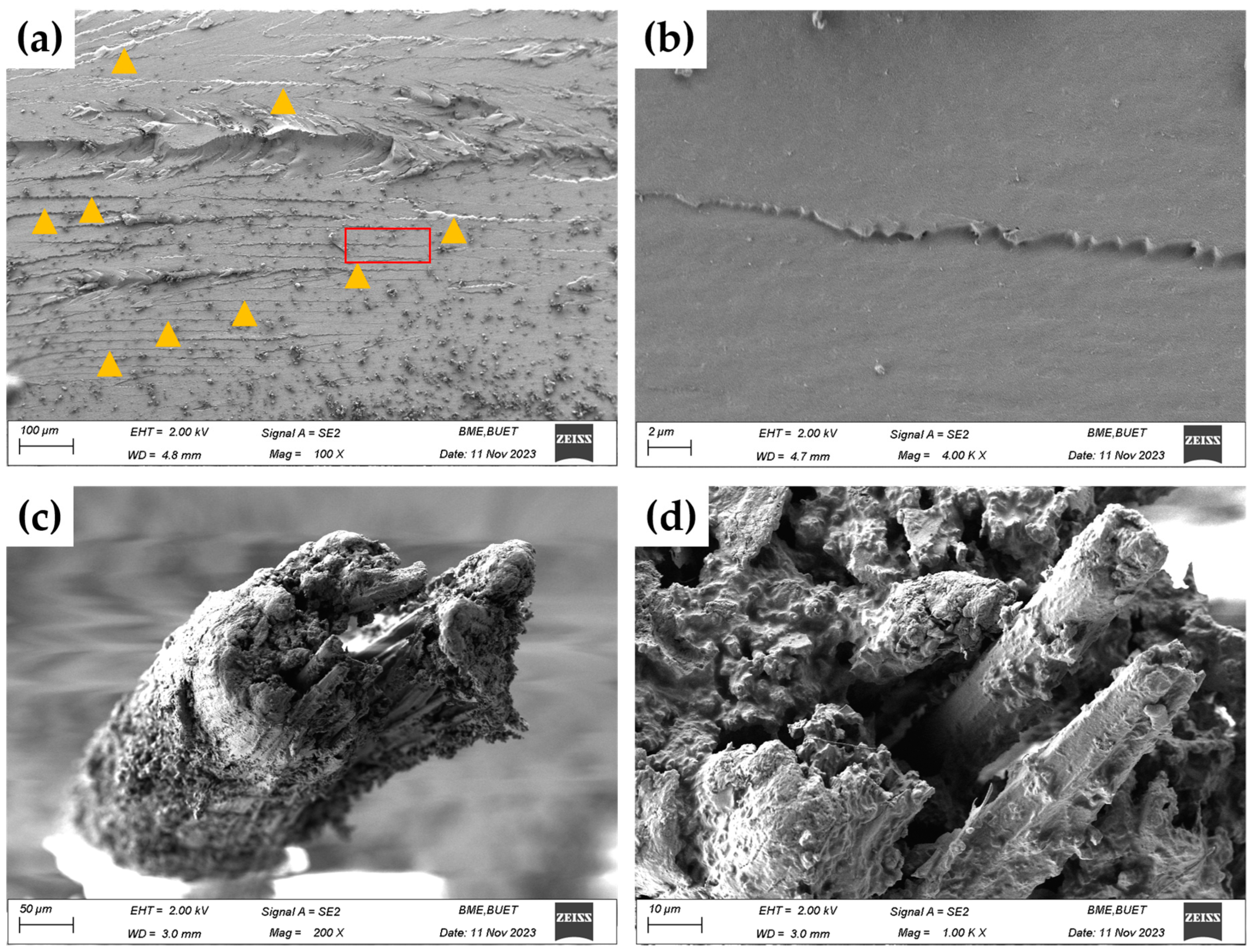

3.5. SEM

3.6. Comparative Study

4. Discussion

5. Conclusions

- The outcome of the FTIR spectra illustrates that due to the soaking of the rind fibers in NaOH solution, the binding components such as hemicellulose, lignin, and amorphous cellulose were partially or completely dissolved, indicating that the cellulose portion was increased.

- The bagasse fibers extracted through Process-1 showed the highest average tensile load, approximately 78% higher than those from Process-2 and 90% greater than those obtained using Process-3. It is speculated that the synergistic interaction of thin bagasse fibers, along with the fiber fracture mechanism and elevated cellulose content, creates localized conditions for fracture and improved tensile load.

- 3D-printed composites reinforced with bagasse fibers extracted through Process-1 showed the highest improvement in tensile strength (approximately 70%) compared to specimens made from pure resin. The lack of pores in the composite and the observable fiber fracture phenomena clearly indicate that 3D printing technology effectively enhances the quality of fiber–matrix interfacial bonding, consequently resulting in improved tensile properties of the composites.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, H.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, G.; Wu, G.; Yang, X.; Huang, Y.; Ma, L. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Part B 2022, 233, 109639. [Google Scholar] [CrossRef]

- Olszewski, A.; Kosmela, P.; Mielewczyk-Gryń, A.; Piszczyk, Ł. Bio-Based Polyurethane Composites and Hybrid Composites Containing a New Type of Bio-Polyol and Addition of Natural and Synthetic Fibers. Materials 2020, 13, 2028. [Google Scholar] [CrossRef] [PubMed]

- Kirmasha, Y.K.; Sharba, M.J.; Leman, Z.; Sultan, M.T.H. Mechanical Performance of Unstitched and Silk Fiber-Stitched Woven Kenaf Fiber-Reinforced Epoxy Composites. Materials 2020, 13, 4801. [Google Scholar] [CrossRef]

- Singh, T.; Gangil, B.; Patnaik, A.; Biswas, D.; Fekete, G. Agriculture waste reinforced cornstarch-based biocomposites: Effect of rice husk/walnut shell on physicomechanical, biodegradable and thermal properties. Mater. Res. Express 2019, 6, 045702. [Google Scholar] [CrossRef]

- Prasad, V.; Vijayyakumar, A.A.; Jose, T.; George, S.C. A comprehensive Review of Sustainability in Natural-Fiber Reinforced Polymers. Sustainability 2024, 16, 1223. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Guimaraes, J.L.; Wypych, F. Studies on Lignocellulosic fibers of Brazil. Part 1: Source, production morphology, properties and applications. Compos. A Appl. Sci. Manuf. 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, M.; Trada, M. A review on the tensile properties of Natural fiber reinforced polymer composites. Compos. B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Mushtaq, B.; Ahmad, S.; Ahmad, F.; Nawab, Y. Alternative natural fibers for biocomposites. In Natural Fibers to Composites: Process, Properties, Structures; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–18. [Google Scholar]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Shaker, K.; Nawab, Y.; Jabbar, M. Bio-Composites: Eco-Friendly Substitute of Glass Fiber Composites. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Springer: Cham, Switzerland, 2020; pp. 1–25. [Google Scholar]

- Verma, D.; Gope, P.C.; Maheshwari, M.K.; Sharma, R.K. Bagasse Fiber Composites—A Review. J. Mater. Environ. Sci. 2012, 3, 1079–1092. [Google Scholar]

- Pandey, A.; Soccol, C.R.; Nigam, P.; Soccol, V.T. Biotechnological potential of agro-industrial residues. I: Sugarcane bagasse. Bioresour. Technol. 2000, 74, 69–80. [Google Scholar] [CrossRef]

- Bilba, K.; Arsène, M. Silane treatment of bagasse fibre for reinforcement of cementitious composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1488–1495. [Google Scholar] [CrossRef]

- Candido, R.G.; Godoy, G.G.; Gonsalves, A.R. Study of sugarcane bagasse pretreatment with sulfuric acid as a step of cellulose obtaining. Int. J. Nutr. 2012, 6, 6–10. [Google Scholar]

- Lopez, R.; Poblano, V.M.; Licea-Clavere, A.; Avalos, M.; Alvarez-Castillo, A.; Castano, V.M. Alkaline surface modification of sugarcane bagasse. Adv. Compos. Mater. 2012, 9, 99–108. [Google Scholar] [CrossRef]

- Wirawan, R.; Sapuan, S.M.; Yunus, R.; Abdan, K. Properties of sugarcane bagasse poly (vinyl chloride) composites after various treatments. J. Compos. Mater. 2011, 45, 1667–1674. [Google Scholar] [CrossRef]

- Sathish, S.; Karthi, N.; Prabhu, L.; Gokulkumar, S.; Balaji, D.; Vigneshkumar, N.; Dinesh, V.P. A review of natural fiber composites: Extraction methods, chemical treatments and applications. Mater. Today Proc. 2021, 45, 8017–8023. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Devadiga, D.G.; Subrahmanya Bhat, K.; Mahesha, G.T. Sugarcane bagasse fiber reinforced composites: Recent advances and applications. Cogent Eng. 2020, 7, 1823159. [Google Scholar] [CrossRef]

- Rajendran Royan, N.R.; Leong, J.S.; Chan, W.N.; Tan, J.R.; Shamsuddin, Z.S.B. Current State and Challenges of Natural Fibre-Reinforced Polymer Composites as Feeder in FDM-Based 3D Printing. Polymers 2021, 13, 2289. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimization for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed]

- Moran, J.; Alvarez, V.; Petrucci, R.; Kenny, J.; Vazquez, A. Mechanical properties of polypropylene composites based on natural fibers subjected to multiple extrusion cycles. J. Appl. Polym. Sci. 2007, 103, 228–237. [Google Scholar] [CrossRef]

- Van den Oever, M.J.A.; Beck, B.; Müssig, J. Agrofibre reinforced poly (lactic acid) composites: Effect of moisture on degradation and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1628–1635. [Google Scholar] [CrossRef]

- Sano, Y.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of discontinuous and continuous fiber composites using stereolithography. Addit. Manuf. 2018, 24, 521–527. [Google Scholar]

- Zhang, S.; Li, M.; Hao, N.; Ragauska, A.J. Stereolithography 3D printing of Lignin Reinforced Composites with Enhanced Mechanical Properties. ACS Omega 2019, 4, 20197–20204. [Google Scholar] [CrossRef]

- Bhuiyan, M.S.; Rahman, M.A.; Farabi, M.S.; Hasan, M.M. Tensile behavior of geometrically irregular bagasse fiber. Appl. Mech. 2021, 2, 274–288. [Google Scholar] [CrossRef]

- Corrales, R.C.N.R.; Mendes, F.M.T.; Perrone, C.C.; Anna, C.S.; de Souza, W.; Abud, Y.; Bon, E.P.S.; Ferreira-Leitão, V. Structural evaluation of sugarcane bagasse steam pretreated in the presence of CO2 and SO2. Biotechnol. Biofuels 2012, 5, 36. [Google Scholar] [CrossRef]

- Anggono, J.; Sugondo, S.; Sewucipto, S.; Purwaningsih, H.; Henrico, S. The use of sugarcane bagasse in PP matrix composites: A comparative study of Bagasse treatment using Calcium Hydroxide and Sodium Hydroxide on composite strength. AIP Conf. Proc. 2017, 1788, 030055. [Google Scholar]

- Biagiotti, J.; Puglia, D.; Torre, L.; Kenny, M.J.; Arbelaiz, A.; Cantero, G.; Marieta, C.; Llano-Ponte, R.; Mondragon, I. A systematic investigation on the influence of the chemical treatment of natural fibers on the properties of their polymer matrix composites. Polym. Compos. 2004, 25, 470–479. [Google Scholar] [CrossRef]

- Liu, W.; Mohanty, A.K.; Drzal, L.T.; Askel, P.; Misra, M. Effect of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer matrix composites. J. Mater. Sci. 2004, 39, 1051–1054. [Google Scholar] [CrossRef]

- Costa, L.A.S.; Assis, D.J.; Gomes, G.V.P.; Silva, J.B.; Fonsêca, A.F.; Druzian, J.I. Extraction and characterization of nanocellulose from corn stover. Mater. Today Proc. 2015, 2, 287–294. [Google Scholar] [CrossRef]

- Bian, J.; Peng, F.; Peng, X.P.; Xiao, X.; Peng, P.; Xu, F.; Sun, R.C. Effect of [Emim]Ac pretreatment on the structure and enzymatic hydrolysis of sugarcane bagasse cellulose. Carbohydr. Polym. 2014, 100, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Fu, S.Y.; Lauke, B. Effects of fibre length and orientation distributions on the tensile strength of short-fibre-reinforced polymers. Compos. Sci. Technol. 1996, 56, 1179–1190. [Google Scholar] [CrossRef]

- Jiang, B.; Liu, C.; Zhang, C.; Wang, B.; Wang, Z. The effect of non-symmetric distribution of fiber orientation and aspect ratio on elastic properties of composites. Compos. B Eng. 2007, 38, 24–34. [Google Scholar] [CrossRef]

- Le Moigne, N.; van den Oever, M.; Budtova, T. A statistical analysis of fiber size and shape distribution after compounding in composites reinforced by natural fibers. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1542–1550. [Google Scholar] [CrossRef]

- Trujillo, E.; Moesen, M.; Osorio, L.; Van Vuure, A.W.; Ivens, J.; Verpoest, I. Bamboo fibers for reinforcement in composite materials: Strength Weibull analysis. Compos. Part A Appl. Sci. Manuf. 2014, 61, 115–125. [Google Scholar] [CrossRef]

- Weibull, W. A statistical function of wide applicability. J. Appl. Mech. 1951, 18, 293–307. [Google Scholar] [CrossRef]

- Barbero, E.; Fernández-Sáez, J.; Navarro, C. Statistical analysis of the mechanical properties of composite materials. Compos. B Eng. 2000, 31, 375–381. [Google Scholar] [CrossRef]

- Swolfs, Y.; Morton, H.; Scott, A.E.; Gorbatikh, L.; Reed, P.A.S.; Sinclair, I.; Spearing, S.M.; Verpoest, I. Synchrotron radiation computed tomography for experimental validation of a tensile strength model for unidirectional fibre-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2015, 77, 106–111. [Google Scholar] [CrossRef]

- Huang, Y.; Talreja, R. Statistical analysis of oblique crack evolution in composite laminates. Compos. B Eng. 2014, 65, 34–39. [Google Scholar] [CrossRef]

- Xia, Z.P.; Yu, J.Y.; Cheng, L.D.; Liu, L.F.; Wang, W.M. Study on the breaking strength of jute fibres using modified Weibull distribution. Compos. Part A Appl. Sci. Manuf. 2009, 40, 54–59. [Google Scholar] [CrossRef]

- Sia, C.V.; Nakai, Y.; Shiozawa, D.; Ohtani, H. Statistical analysis of the tensile strength of treated oil palm fiber by utilisation of Weibull distribution model. Open J. Compos. Mater. 2014, 4, 72–77. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.T.; Abdan, K.; Ibrahim, N.A. Fabrication of epoxy nanocomposites from oil palm nano filler: Mechanical and morphological properties. BioResources 2016, 11, 7721–7736. [Google Scholar] [CrossRef]

- Balaji, A.; Karthikeyan, B.; Raj, C.S. Morphological and mechanical behavior of sugarcane bagasse fibers reinforced polyester eco-friendly biocomposites. J. Chem. Pharm. Res. 2015, 7, 573–577. [Google Scholar]

- Arrakhiz, F.Z.; Malha, M.; Bouhfid, R.; Benmoussa, K.; Qaiss, A. Tensile, flexural and torsional properties of chemically treated alfa, coir, and bagasse reinforced polypropylene. Compos. B Eng. 2013, 47, 35–41. [Google Scholar] [CrossRef]

- Cerqueira, E.F.; Baptista, C.A.R.P.; Mulinari, D.R. Mechanical behavior of polypropylene reinforced sugarcane bagasse fibers composites. Procedia Eng. 2011, 10, 2046–2051. [Google Scholar] [CrossRef]

- Vilay, V.; Mariatti, M.; Taib, R.M.; Todo, M. Effect of fiber surface treatment and fiber loading on the properties of bagasse fiber-reinforced unsaturated polyester composites. Compos. Sci. Technol. 2008, 68, 631–638. [Google Scholar] [CrossRef]

- Marques, M.F.; Melo, R.P.; Araujo, R.S.; Lunz, J.N.; Aguiar, V.O. Improvement of mechanical properties of natural fiber–polypropylene composites using successive alkaline treatments. J. Appl. Polym. Sci. 2015, 12, 132. [Google Scholar] [CrossRef]

- Inacio, W.P.; Lopes, F.P.D.; Monterio, S.N. Diameter dependence of tensile strength by Weibull analysis: Part III sisal fiber. Rev. Mater. 2010, 15, 124–130. [Google Scholar] [CrossRef]

- Bevitori, A.B.; Da Silva, I.L.A.; Lopes, F.P.D.; Monterio, S.N. Diameter dependence of tensile strength by Weibull analysis: Part II jute fiber. Rev. Mater. 2010, 15, 117–123. [Google Scholar] [CrossRef]

- Monterio, S.N.; Lopes, L.P.D.; Ferreira, A.S.; Nascimento, D.C.O. Natural fiber polymer matrix composites: Cheaper, tougher and environmentally friendly. JOM 2009, 61, 17–22. [Google Scholar] [CrossRef]

- Siti Alwani, M.; Abdul Khalil, H.P.S.; Islam, M.N.; Sulaiman, O.; Zaidon, A.; Dungani, R. Microstructural Study, Tensile Properties, and Scanning Electron Microscopy Fractography Failure Analysis of Various Agricultural Residue Fibers. J. Nat. Fibers 2015, 12, 154–168. [Google Scholar] [CrossRef]

- Defoirdt, N.; Biswas, S.; Vriese, L.; Tran, L.Q.N.; Acker, J.V.; Ahsan, Q.; Gorbatikh, L.; Vuure, A.V.; Verpoesta, I. Assessment of the tensile properties of coir, bamboo and jute fiber. Compos. Part A Appl. Sci. Manuf. 2010, 41, 588–595. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Compos. A Appl. Sci. Manuf. 2011, 42, 888–895. [Google Scholar] [CrossRef]

- de Farias, J.G.; Cavalcante, R.C.; Canabarro, B.R.; Viana, H.M.; Scholz, S.; Simão, R.A. Surface lignin removal on coir fibers by plasma treatment for improved adhesion in thermoplastic starch composites. Carbohydr. Polym. 2017, 165, 429–436. [Google Scholar] [CrossRef] [PubMed]

- Faludi, G.; Dora, G.; Imre, B.; Renner, K.; Móczó, J.; Pukánszky, B. PLA/lignocellulosic fiber composites: Particle characteristics, interfacial adhesion, and failure mechanism. J. Appl. Polym. Sci. 2014, 131, 39902. [Google Scholar] [CrossRef]

- Renner, K.; Kenyo, C.; Móczó, J.; Pukánszky, B. Micromechanical deformation processes in PP/wood composites: Particle characteristics, adhesion, mechanisms. Compos. A Appl. Sci. Manuf. 2010, 41, 1653–1661. [Google Scholar] [CrossRef]

| Material | Average Breaking Load (N) |

|---|---|

| Process-1 | 5.9 ± 2.4 |

| Process-2 | 3.3 ± 1.3 |

| Process-3 | 3.1 ± 1.4 |

| Material | Weibull Modulus | Constant Term | Scale Parameter | |

|---|---|---|---|---|

| Process-1 | 2.24 | −4.3 | 6.80 | 0.94 |

| Process-2 | 2.7 | −3.56 | 3.74 | 0.96 |

| Process-3 | 2.24 | −2.83 | 3.53 | 0.94 |

| Material | Ultimate Tensile Strength (MPa) | % Improvement |

|---|---|---|

| Resin | 20.4 ± 1.7 | |

| Composite P1 | 34.5 ± 2.9 | 69.3% |

| Composite P2 | 31.6 ± 3.2 | 55% |

| Composite P3 | 32.8 ± 2.9 | 61% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhuiyan, M.S.; Fardin, A.; Rahman, M.A.; Mohiv, A.; Islam, R.; Kharshiduzzaman, M.; Khan, M.E.; Haque, M.R. Enhancement of Additively Manufactured Bagasse Fiber-Reinforced Composite Material Properties Utilizing a Novel Fiber Extraction Process Used for 3D SLA Printing. J. Manuf. Mater. Process. 2024, 8, 185. https://doi.org/10.3390/jmmp8050185

Bhuiyan MS, Fardin A, Rahman MA, Mohiv A, Islam R, Kharshiduzzaman M, Khan ME, Haque MR. Enhancement of Additively Manufactured Bagasse Fiber-Reinforced Composite Material Properties Utilizing a Novel Fiber Extraction Process Used for 3D SLA Printing. Journal of Manufacturing and Materials Processing. 2024; 8(5):185. https://doi.org/10.3390/jmmp8050185

Chicago/Turabian StyleBhuiyan, Md. Shahnewaz, Ahmed Fardin, M. Azizur Rahman, Arafath Mohiv, Rashedul Islam, Md. Kharshiduzzaman, Md. Ershad Khan, and Mohammad Rejaul Haque. 2024. "Enhancement of Additively Manufactured Bagasse Fiber-Reinforced Composite Material Properties Utilizing a Novel Fiber Extraction Process Used for 3D SLA Printing" Journal of Manufacturing and Materials Processing 8, no. 5: 185. https://doi.org/10.3390/jmmp8050185

APA StyleBhuiyan, M. S., Fardin, A., Rahman, M. A., Mohiv, A., Islam, R., Kharshiduzzaman, M., Khan, M. E., & Haque, M. R. (2024). Enhancement of Additively Manufactured Bagasse Fiber-Reinforced Composite Material Properties Utilizing a Novel Fiber Extraction Process Used for 3D SLA Printing. Journal of Manufacturing and Materials Processing, 8(5), 185. https://doi.org/10.3390/jmmp8050185