Application of 3D and 4D Printing in Electronics

Abstract

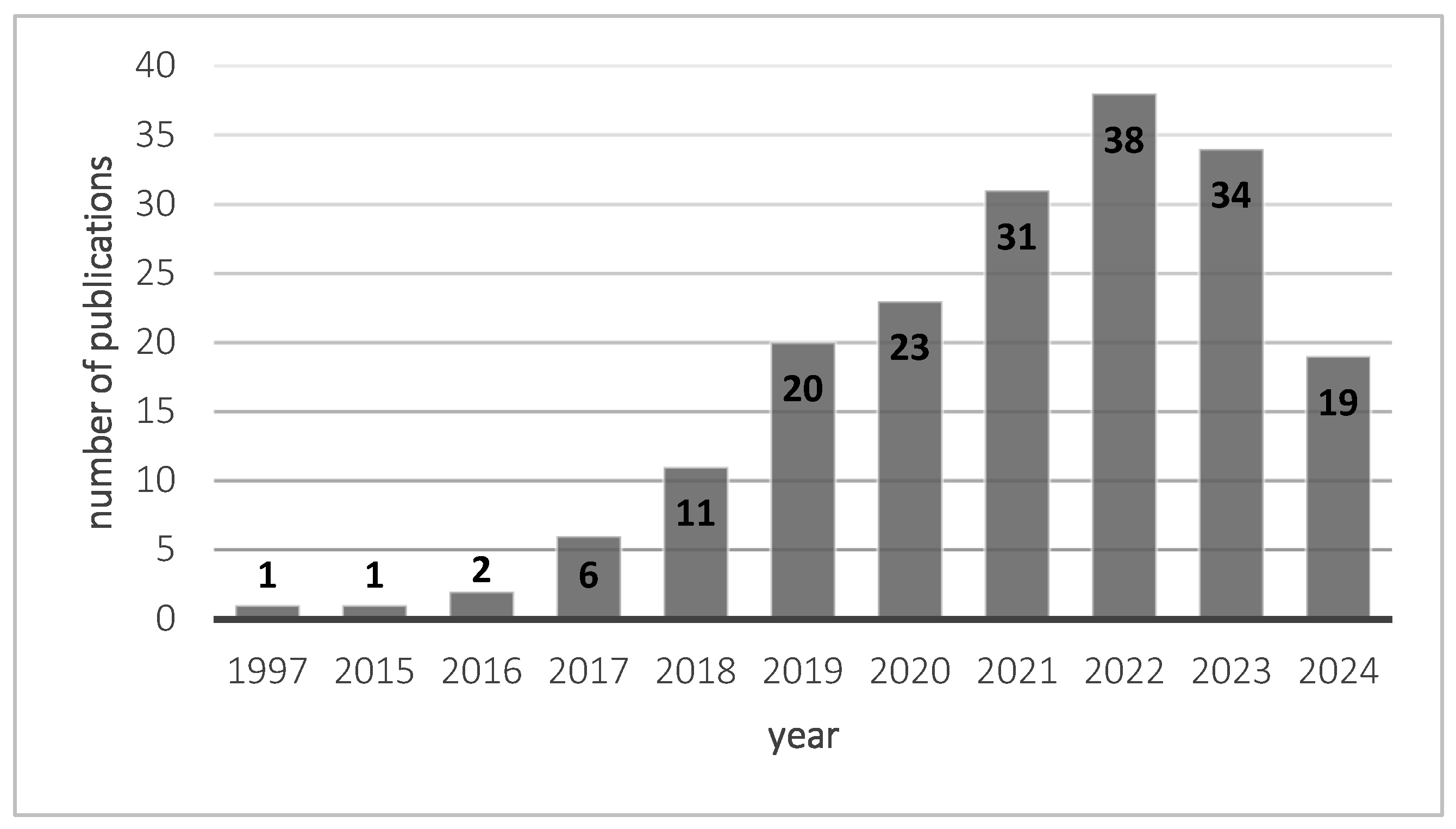

1. Introduction

2. Printing Technologies

2.1. Vat Photopolymerization-Based 4D Printing

- Functional electronics

2.2. Material Extrusion-Based 4D Printing

- Antennas

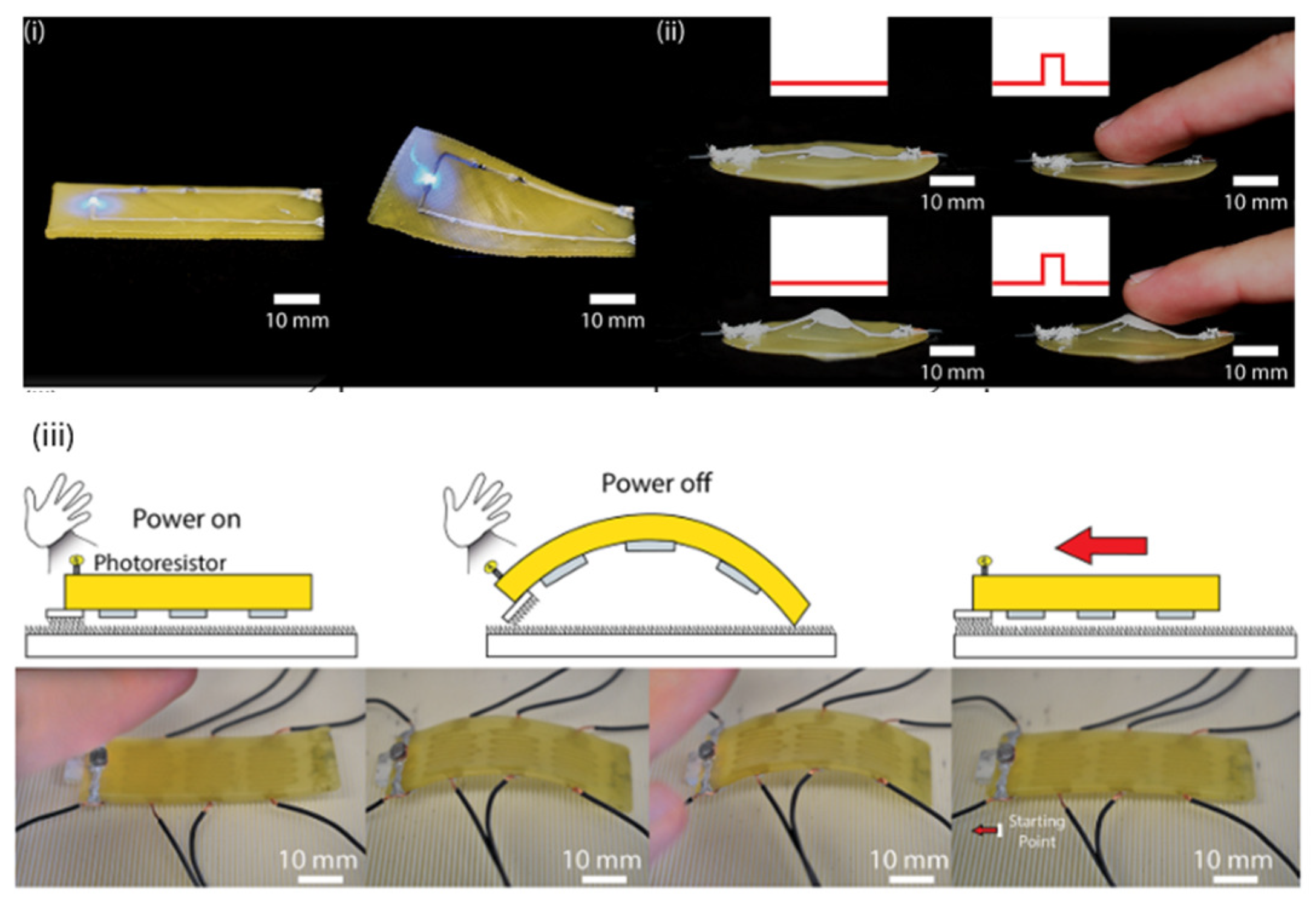

- Self-morphing circuits

- Sensors

2.3. Multi-Method Fabrication Solutions

3. Smart Materials

3.1. Polymers and Composites

3.2. Metal Alloys and Ceramics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tong, C. Advanced Materials for Printed Flexible Electronics, 1st ed.; Springer Cham: Bolingbrook, IL, USA, 2022; Volume 317. [Google Scholar] [CrossRef]

- Subramanian, V.; Chang, J.B.; de la Fuente Vornbrock, A.; Huang, D.C.; Jagannathan, L.; Liao, F.; Mattis, B.; Molesa, S.; Redinger, D.R.; Soltman, D.; et al. Printed Electronics for Low-Cost Electronic Systems: Technology Status and Application Development. In Proceedings of the ESSDERC 2008—38th European Solid-State Device Research Conference, Edinburgh, UK, 15–19 September 2008; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Bonnassieux, Y.; Brabec, C.J.; Cao, Y.; Carmichael, T.B.; Chabinyc, M.L.; Cheng, K.T.; Cho, G.; Chung, A.; Cobb, C.L.; Distler, A.; et al. The 2021 Flexible and Printed Electronics Roadmap. Flex. Print. Electron. 2021, 6, 023001. [Google Scholar] [CrossRef]

- ISO/TC 261; ASTM Committee F42; Technical Committee CEN/TC 438. ISO/ASTM 52900:2021(en) Additive manufacturing—General principles—Fundamentals and vocabulary. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 30 May 2024).

- Khorasani, M.; Loy, J.; Ghasemi, A.H.; Sharabian, E.; Leary, M.; Mirafzal, H.; Cochrane, P.; Rolfe, B.; Gibson, I. A Review of Industry 4.0 and Additive Manufacturing Synergy. Rapid Prototyp. J. 2022, 28, 1462–1475. [Google Scholar] [CrossRef]

- Praveena, B.A.; Lokesh, N.; Buradi, A.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A Comprehensive Review of Emerging Additive Manufacturing (3D Printing Technology): Methods, Materials, Applications, Challenges, Trends and Future Potential. Mater. Today Proc. 2022, 52, 1309–1313. [Google Scholar] [CrossRef]

- Alammar, A.; Kois, J.C.; Revilla-León, M.; Att, W. Additive Manufacturing Technologies: Current Status and Future Perspectives. J. Prosthodont. 2022, 31, 4–12. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, A.; Arya, S.; Gupta, V.; Furukawa, H.; Khosla, A. 4D Printing: Fundamentals, Materials, Applications and Challenges. Polymer 2021, 228, 123926. [Google Scholar] [CrossRef]

- Momeni, F.; Hassani, M.; Liu, X.; Ni, J. A Review of 4D Printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Chen, A.; Yin, R.; Cao, L.; Yuan, C.; Ding, H.K.; Zhang, W.J. Soft Robotics: Definition and Research Issues. In Proceedings of the 2017 24th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 21–23 November 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An Integrated Design and Fabrication Strategy for Entirely Soft, Autonomous Robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef] [PubMed]

- Truxova, V.; Safka, J.; Seidl, M.; Kovalenko, I.; Volesky, L.; Ackermann, M. Ceramic 3d Printing: Comparison of SLA and DLP Technologies. MM Sci. J. 2020, 2, 3905–3911. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-Curing 3D Printing Technique and Its Challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Guo, R.; Zhen, Y.; Huang, X.; Liu, J. Spatially Selective Adhesion Enabled Transfer Printing of Liquid Metal for 3D Electronic Circuits. Appl. Mater. Today 2021, 25, 101236. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Extrusion-Based Additive Manufacturing Technologies: State of the Art and Future Perspectives. J. Manuf. Process. 2022, 83, 607–636. [Google Scholar] [CrossRef]

- Gülcan, O.; Günaydın, K.; Tamer, A. The State of the Art of Material Jetting—A Critical Review. Polymers 2021, 13, 2829. [Google Scholar] [CrossRef] [PubMed]

- Marasso, S.L.; Cocuzza, M. (Eds.) High Resolution Manufacturing from 2D to 3D/4D Printing; Springer International Publishing: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Le, T.; Tuan, C.C.; Bahr, R.A.; Wong, C.P.; Tentzeris, M.M. A Novel Approach to Integrating 3D/4D Printing and Stretchable Conductive Adhesive Technologies for High Frequency Packaging Applications. In Proceedings of the Proceedings—Electronic Components and Technology Conference, Las Vegas, NV, USA, 31 May–3 June 2016; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2016. [Google Scholar] [CrossRef]

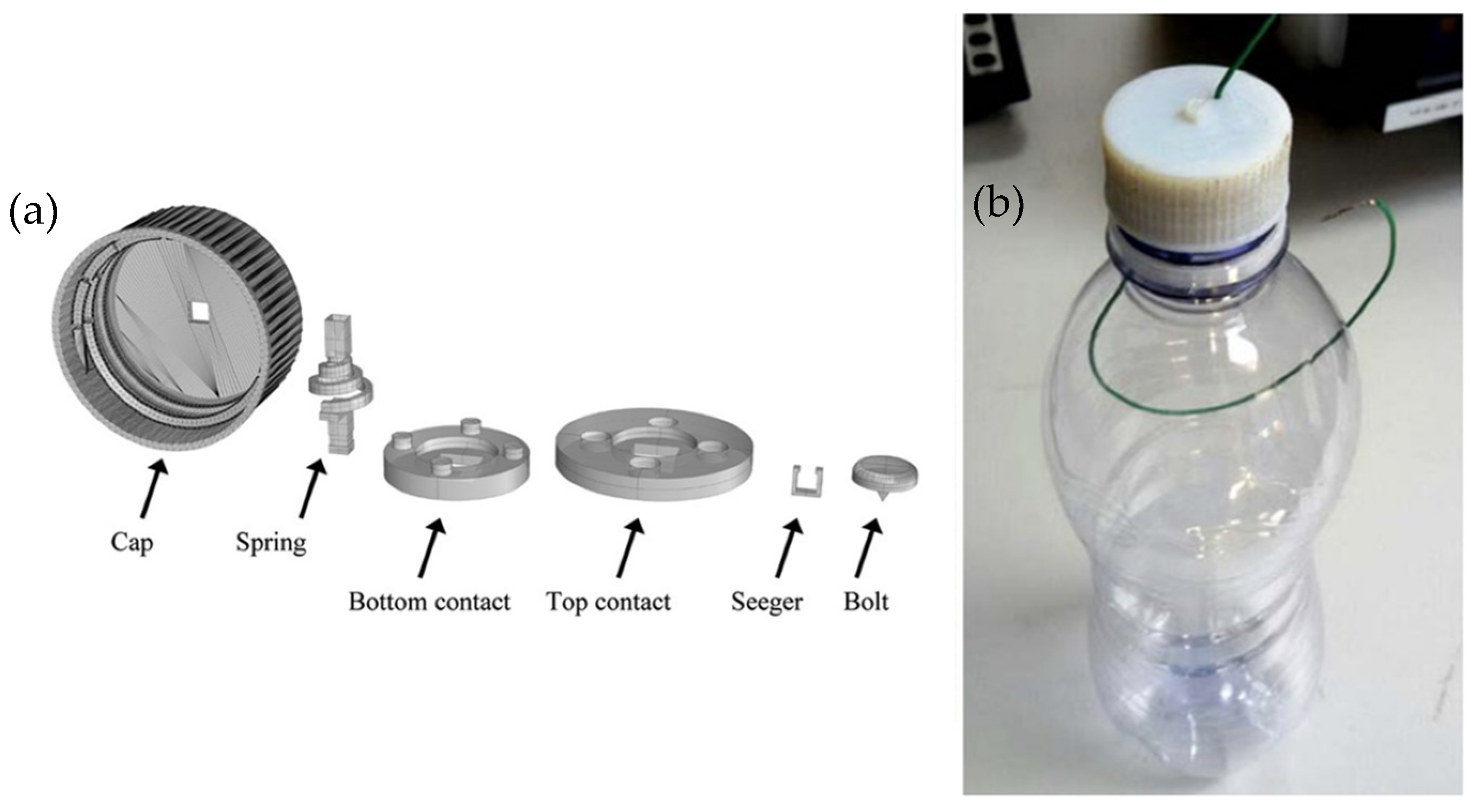

- Cuevas, M.; Pizarro, F.; Leiva, A.; Hermosilla, G.; Yunge, D. Parametric Study of a Fully 3D-Printed Dielectric Resonator Antenna Loaded with a Metallic Cap. IEEE Access 2021, 9, 73771–73779. [Google Scholar] [CrossRef]

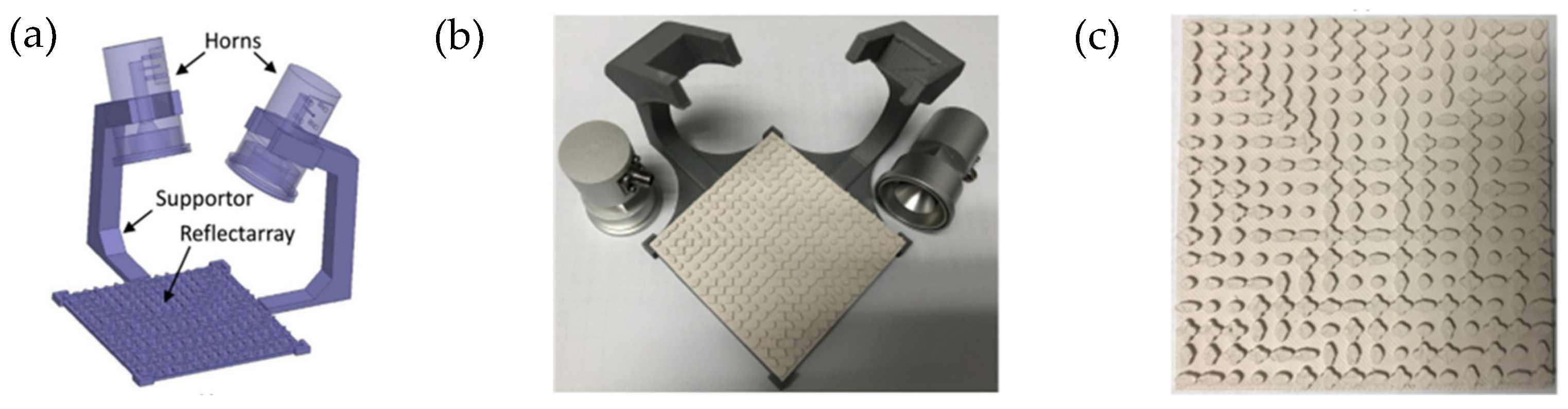

- Sun, Y.X.; Wu, D.; Ren, J. Millimeter-Wave Dual-Polarized Dielectric Resonator Reflectarray Fabricated by 3D Printing with High Relative Permittivity Material. IEEE Access 2021, 9, 103795–103803. [Google Scholar] [CrossRef]

- Tokan, F.; Demir, S.; Çalışkan, A. Influence of 3D Printing Process Parameters on the Radiation Characteristics of Dense Dielectric Lens Antennas. Prog. Electromagn. Res. C 2021, 116, 113–128. [Google Scholar] [CrossRef]

- Wang, G.; Qin, F.; Liu, H.; Tao, Y.; Zhang, Y.; Zhang, Y.J.; Yao, L. Morphingcircuit: An Integrated Design, Simulation, and Fabrication Workflow for Self-Morphing Electronics. In Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies; 2020; Volume 4. Available online: https://dl.acm.org/doi/10.1145/3432232 (accessed on 17 July 2024). [CrossRef]

- Pei, E.; Loh, G.H. Technological Considerations for 4D Printing: An Overview. Prog. Addit. Manuf. 2018, 3, 95–107. [Google Scholar] [CrossRef]

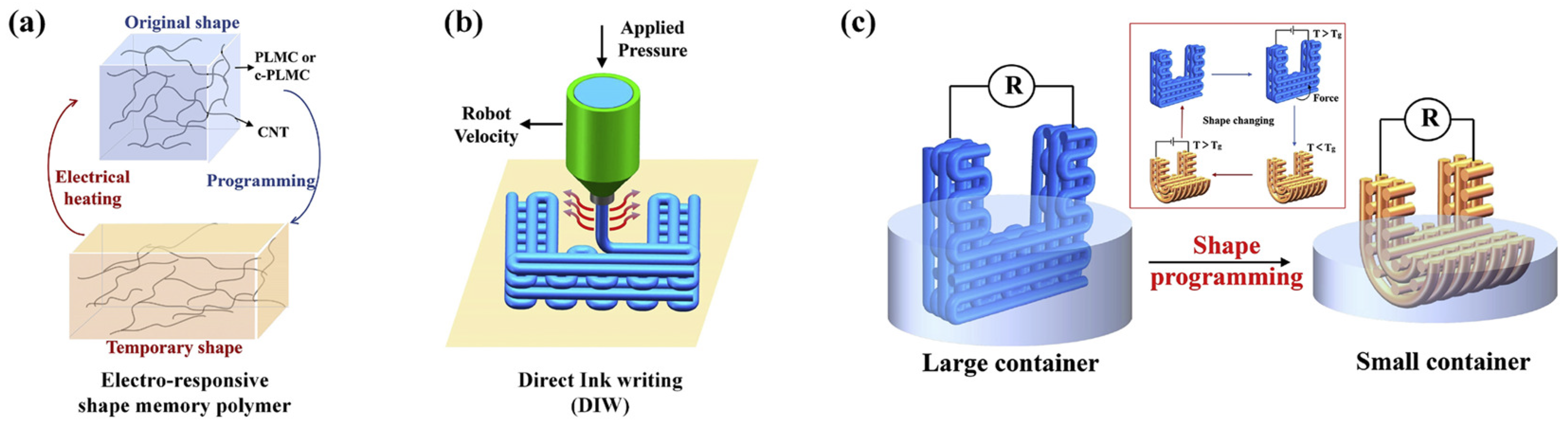

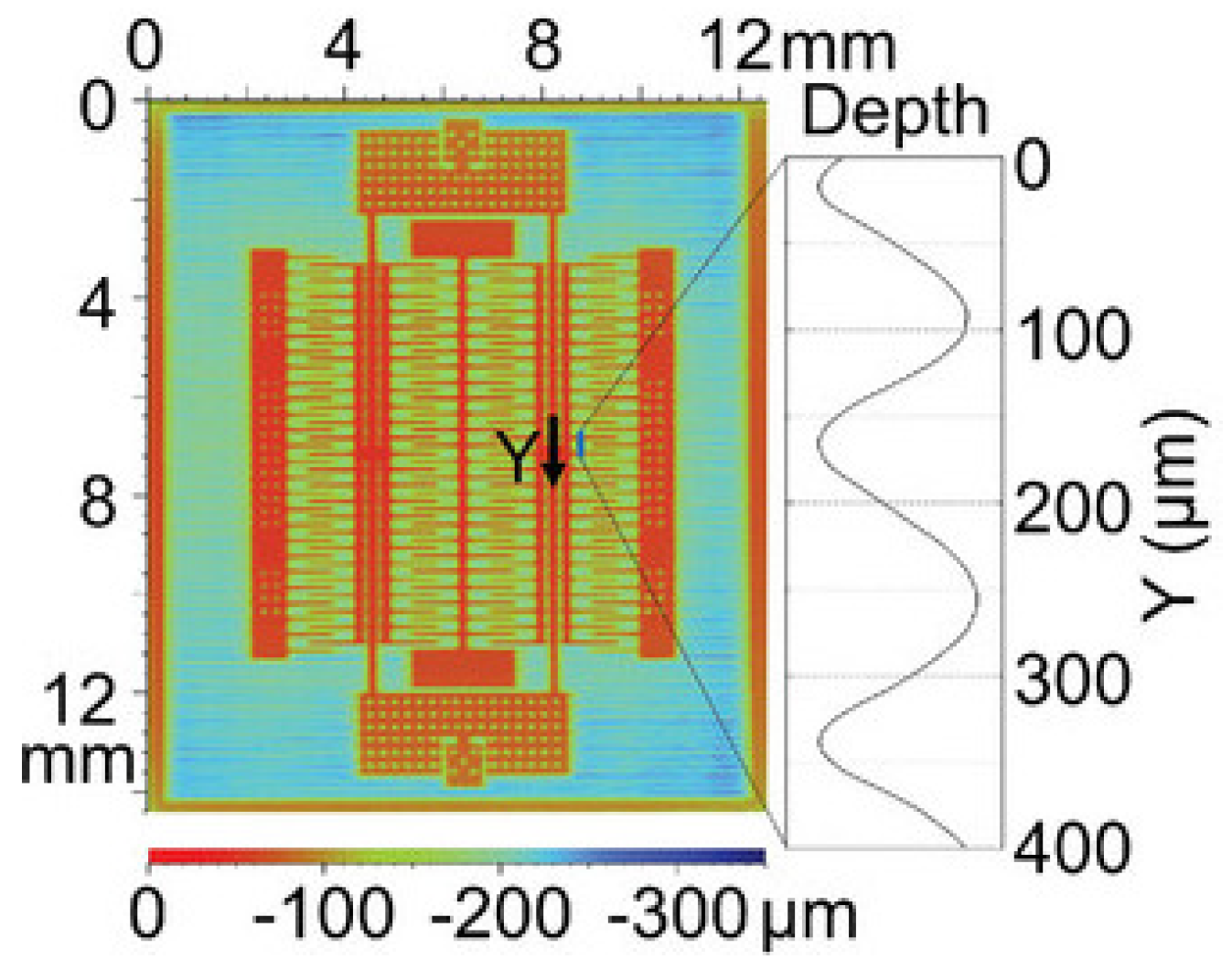

- Wan, X.; Zhang, F.; Liu, Y.; Leng, J. CNT-Based Electro-Responsive Shape Memory Functionalized 3D Printed Nanocomposites for Liquid Sensors. Carbon 2019, 155, 77–87. [Google Scholar] [CrossRef]

- Ahmad, S.; Shakeel, M.; Iqbal, N.; Amin, M.; Rahman, K. Printing of Low Cost Sensors by Additive Manufacturing. In Proceedings of the 18th International Bhurban Conference on Applied Sciences and Technologies, IBCAST 2021, Islamabad, Pakistan, 12–16 January 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Mkhize, N.; Bhaskaran, H. Electrohydrodynamic Jet Printing: Introductory Concepts and Considerations. Small Sci. 2022, 2, 2100073. [Google Scholar] [CrossRef]

- Roach, D.J.; Hamel, C.M.; Dunn, C.K.; Johnson, M.V.; Kuang, X.; Qi, H.J. The M4 3D Printer: A Multi-Material Multi-Method Additive Manufacturing Platform for Future 3D Printed Structures. Addit. Manuf. 2019, 29, 100819. [Google Scholar] [CrossRef]

- Guo, Y.; Patanwala, H.S.; Bognet, B.; Ma, A.W.K. Inkjet and Inkjet-Based 3D Printing: Connecting Fluid Properties and Printing Performance. Rapid Prototyp. J. 2017, 23, 562–576. [Google Scholar] [CrossRef]

- Agarwala, S.; Goh, G.L.; Goh, G.D.; Dikshit, V.; Yeong, W.Y. 3D and 4D Printing of Polymer/CNTs-Based Conductive Composites. In 3D and 4D Printing of Polymer Nanocomposite Materials: Processes, Applications, and Challenges; Sadasivuni, K.K., Deshmukh, K., Almaadeed, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 297–324. [Google Scholar] [CrossRef]

- Seiti, M.; Degryse, O.; Ferraro, R.M.; Giliani, S.; Bloemen, V.; Ferraris, E. 3D Aerosol Jet® Printing for Microstructuring: Advantages and Limitations. Int. J. Bioprint. 2023, 9, 0257. [Google Scholar] [CrossRef]

- Peng, X. Multimaterial 3D/4D Printing by Integrating Digital Light Processing and Direct Ink Writing. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2022. [Google Scholar]

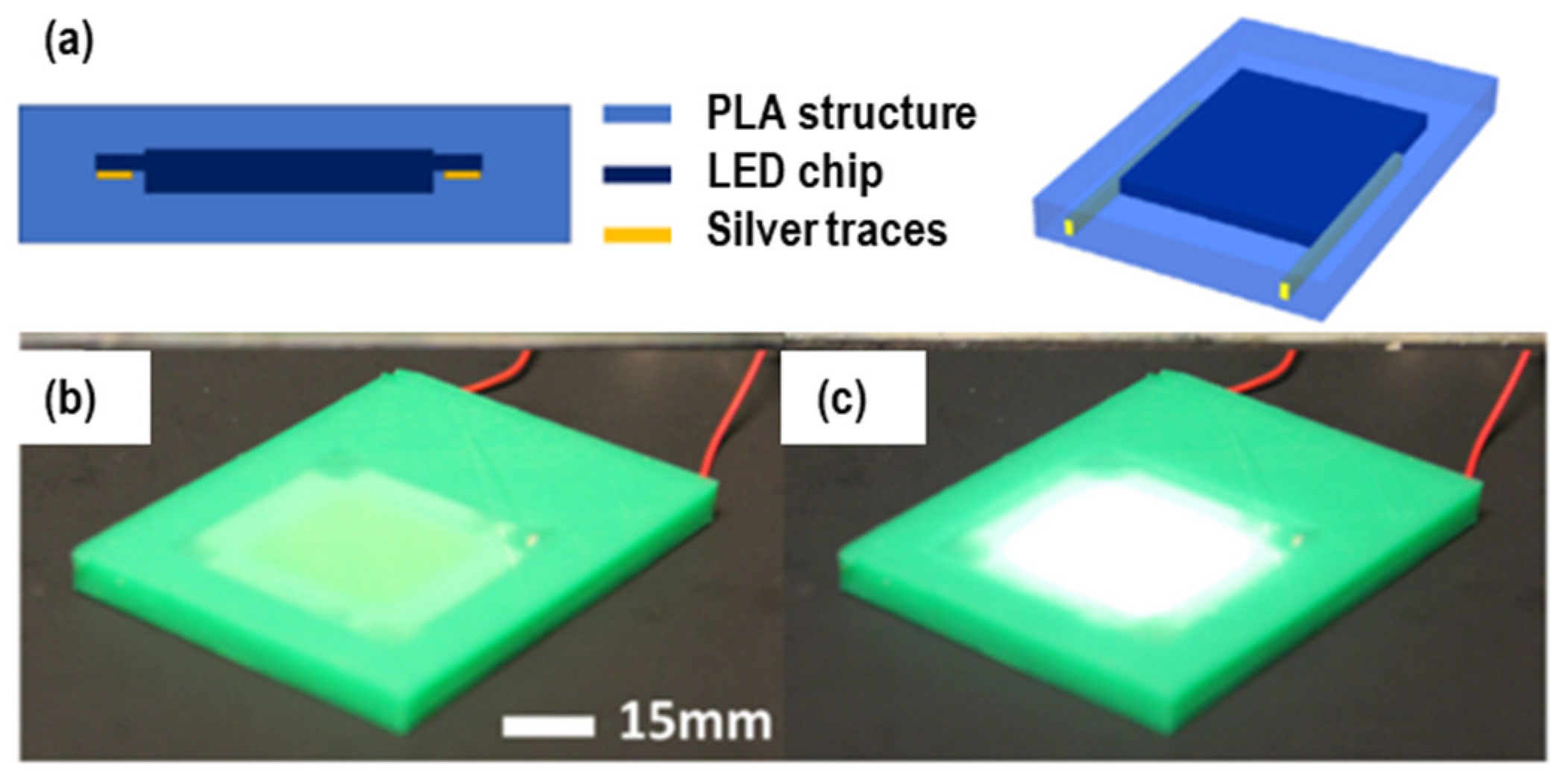

- Marasso, S.L.; Cocuzza, M.; Bertana, V.; Perrucci, F.; Tommasi, A.; Ferrero, S.; Scaltrito, L.; Pirri, C.F. PLA Conductive Filament for 3D Printed Smart Sensing Applications. Rapid Prototyp. J. 2018, 24, 739–743. [Google Scholar] [CrossRef]

- Udroiu, R.; Braga, I.C. Polyjet Technology Applications for Rapid Tooling. MATEC Web Conf. 2017, 112, 03011. [Google Scholar] [CrossRef]

- Venzac, B.; Deng, S.; Mahmoud, Z.; Lenferink, A.; Costa, A.; Bray, F.; Otto, C.; Rolando, C.; Le Gac, S. PDMS Curing Inhibition on 3D-Printed Molds: Why? Also, How to Avoid It? Anal. Chem. 2021, 93, 7180–7187. [Google Scholar] [CrossRef] [PubMed]

- Mossotti, G.; Piscitelli, A.; Catania, F.; Aronne, M.; Galfré, G.; Lamberti, A.; Ferrero, S.; Scaltrito, L.; Bertana, V. Advances in Water Resource Management: An In Situ Sensor Solution for Monitoring High Concentrations of Chromium in the Electroplating Industry. Water 2024, 16, 1167. [Google Scholar] [CrossRef]

- Donvito, L.; Galluccio, L.; Lombardo, A.; Morabito, G.; Nicolosi, A.; Reno, M. Experimental Validation of a Simple, Low-Cost, T-Junction Droplet Generator Fabricated through 3D Printing. J. Micromech. Microeng. 2015, 25, 035013. [Google Scholar] [CrossRef]

- Shahinpoor, M. (Ed.) General Introduction to Smart Materials—Knovel. In Fundamentals of Smart Materials; Royal Society of Chemistry (RSC): London, UK, 2020; pp. 1–13. [Google Scholar] [CrossRef]

- Vatanparast, S.; Boschetto, A.; Bottini, L.; Gaudenzi, P. New Trends in 4D Printing: A Critical Review. Appl. Sci. 2023, 13, 7744. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Song, Z.; Ren, L.; Liu, Q.; Ren, L. Biomimetic Shape-Color Double-Responsive 4D Printing. Adv. Mater. Technol. 2019, 4, 1900293. [Google Scholar] [CrossRef]

- Isapour, G.; Lattuada, M.; Isapour, G.; Lattuada, M. Bioinspired Stimuli-Responsive Color-Changing Systems. Adv. Mater. 2018, 30, 1707069. [Google Scholar] [CrossRef]

- Leith, G.A.; Martin, C.R.; Mathur, A.; Kittikhunnatham, P.; Park, K.C.; Shustova, N.B. Dynamically Controlled Electronic Behavior of Stimuli-Responsive Materials: Exploring Dimensionality and Connectivity. Adv. Energy Mater. 2022, 12, 2100441. [Google Scholar] [CrossRef]

- Gai, Y.; Li, H.; Li, Z.; Gai, Y.; Li, Z.; Li, H. Self-Healing Functional Electronic Devices. Small 2021, 17, 2101383. [Google Scholar] [CrossRef] [PubMed]

- Caltagirone, P.E.; Benafan, O. Shape Memory Materials Analysis and Research Tool (SM2ART): Finding Data Anomalies and Trends. Shape Mem. Superelast. 2023, 9, 558–584. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, W.M.; Kang, S.F.; Wu, X.L.; Lu, H.B.; Fu, J.; Cui, H. From 3D to 4D Printing: Approaches and Typical Applications. J. Mech. Sci. Technol. 2015, 29, 4281–4288. [Google Scholar] [CrossRef]

- Hu, J. (Ed.) Preparation of Shape Memory Polymers. In Shape Memory Polymers and Textile; Woodhead Publishing: Sawston, UK, 2007; pp. 28–62. [Google Scholar] [CrossRef]

- Dong, Y.; Chen, K.; Liu, H.; Li, J.; Liang, Z.; Kan, Q. Adjustable Mechanical Performances of 4D-Printed Shape Memory Lattice Structures. Compos. Struct. 2024, 334, 117971. [Google Scholar] [CrossRef]

- Ding, Z.; Yuan, C.; Peng, X.; Wang, T.; Qi, H.J.; Dunn, M.L. Direct 4D Printing via Active Composite Materials. Sci. Adv. 2017, 3, e1602890. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Cheng, J.; Li, Z.; Ye, H.; Wei, X.; Li, H.; Wang, R.; Zhang, Y.F.; Yang, H.Y.; Guo, C.; et al. Multimaterial Three-Dimensional Printing of Ultraviolet-Curable Ionic Conductive Elastomers with Diverse Polymers for Multifunctional Flexible Electronics. ACS Appl. Mater. Interfaces 2023, 15, 3455–3466. [Google Scholar] [CrossRef] [PubMed]

- Elahinia, M.H. Shape Memory Alloy Actuators: Design, Fabrication, and Experimental Evaluation; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015. [Google Scholar] [CrossRef]

- Sampath, S.; Alagappan, S.; Priyanga, G.S.; Gupta, R.K.; Behera, A.; Nguyen, T.A. Shape Memory Ceramics. In Advanced Flexible Ceramics: Design, Properties, Manufacturing, and Emerging Applications; Elsevier: Amsterdam, The Netherlands, 2023; pp. 13–24. [Google Scholar] [CrossRef]

- Uchino, K. Antiferroelectric Shape Memory Ceramics. Actuators 2016, 5, 11. [Google Scholar] [CrossRef]

- Słoma, M. 3D Printed Electronics with Nanomaterials. Nanoscale 2023, 15, 5623–5648. [Google Scholar] [CrossRef]

- Gopinath, S.; Adarsh, N.N.; Radhakrishnan Nair, P.; Mathew, S. Recent Trends in Thermo-Responsive Elastomeric Shape Memory Polymer Nanocomposites. Polym. Compos. 2023, 44, 4433–4458. [Google Scholar] [CrossRef]

- LinLin, W.; FengHua, Z.; ShanYi, D.; JinSong, L. Advances in 4D Printed Shape Memory Composites and Structures: Actuation and Application. Sci. China Technol. Sci. 2023, 66, 1271–1288. [Google Scholar] [CrossRef]

- Tang, Y.; Dai, B.; Su, B.; Shi, Y. Recent Advances of 4D Printing Technologies Toward Soft Tactile Sensors. Front. Mater. 2021, 8, 658046. [Google Scholar] [CrossRef]

- Bito, J.; Bahr, R.; Hester, J.; Kimionis, J.; Nauroze, A.; Su, W.; Tehrani, B.; Tentzeris, M.M. Inkjet-/3D-/4D-Printed Autonomous Wearable RF Modules for Biomonitoring, Positioning and Sensing Applications. In Proceedings of the Micro- and Nanotechnology Sensors, Systems, and Applications IX, Anaheim, CA, USA, 9–13 April 2017; SPIE: Bellingham, WA, USA, 2017; Volume 10194, p. 101940Z. [Google Scholar] [CrossRef]

- Deng, H.; Zhang, C.; Sattari, K.; Ling, Y.; Su, J.W.; Yan, Z.; Lin, J. 4D Printing Elastic Composites for Strain-Tailored Multistable Shape Morphing. ACS Appl. Mater. Interfaces 2021, 13, 12719–12725. [Google Scholar] [CrossRef] [PubMed]

- Moon, K.J.; Lee, H.; Kim, J.; Bianchi, A. ShrinkCells: Localized and Sequential Shape-Changing Actuation of 3D-Printed Objects via Selective Heating. In Proceedings of the UIST 2022—Proceedings of the 35th Annual ACM Symposium on User Interface Software and Technology, Bend, OR, USA, 29 October–November 2022; Association for Computing Machinery, Inc.: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Liu, H.; Liu, R.; Chen, K.; Liu, Y.; Zhao, Y.; Cui, X.; Tian, Y. Bioinspired Gradient Structured Soft Actuators: From Fabrication to Application. Chem. Eng. J. 2023, 461, 141966. [Google Scholar] [CrossRef]

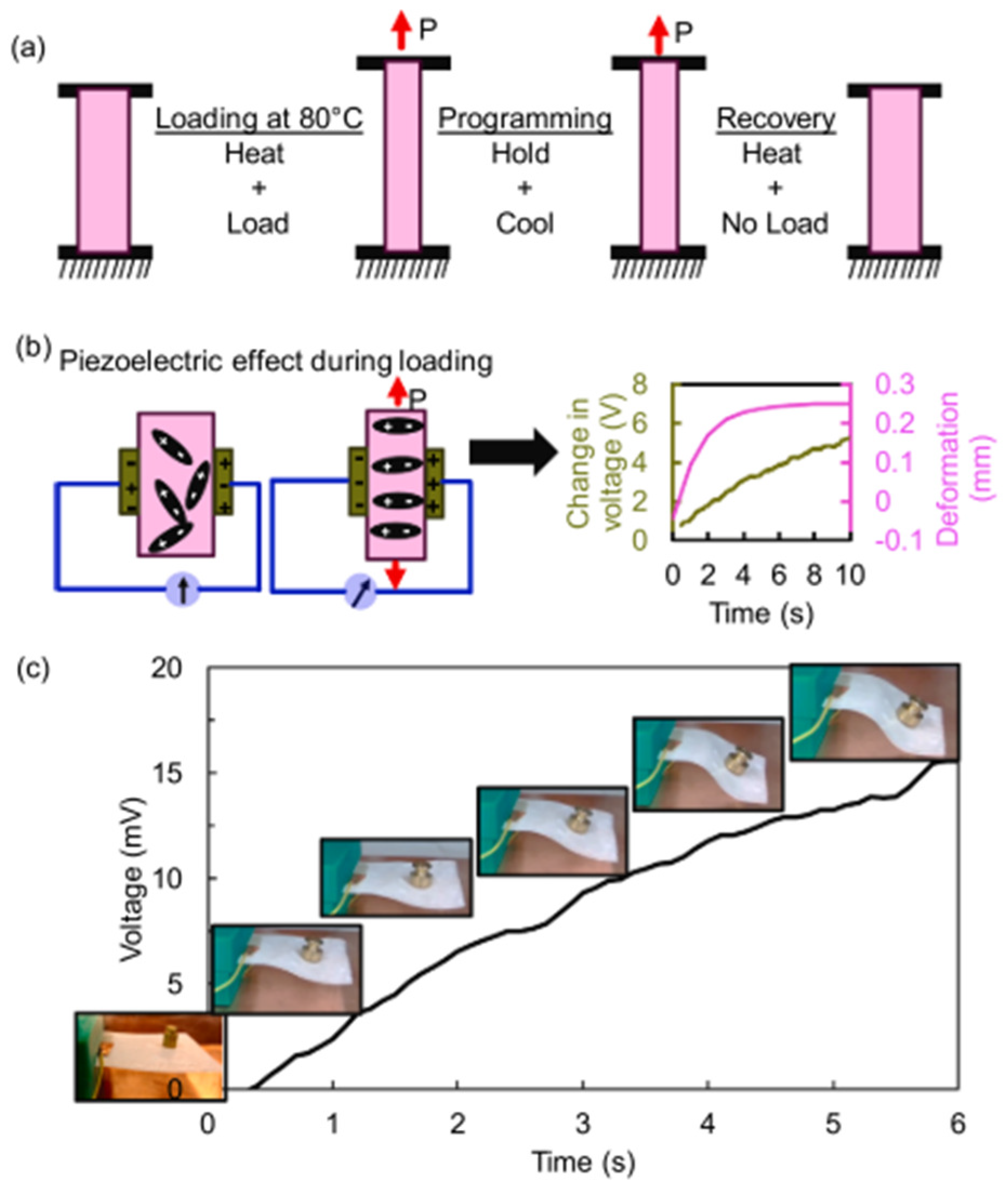

- Liu, R.; Kuang, X.; Deng, J.; Wang, Y.C.; Wang, A.C.; Ding, W.; Lai, Y.C.; Chen, J.; Wang, P.; Lin, Z.; et al. Shape Memory Polymers for Body Motion Energy Harvesting and Self-Powered Mechanosensing. Adv. Mater. 2018, 30, 1705195. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Huang, L.; Song, H.; Ni, C.; Wu, J.; Zhao, Q.; Xie, T. 4D Printing of a Digital Shape Memory Polymer with Tunable High Performance. ACS Appl. Mater. Interfaces 2019, 11, 32408–32413. [Google Scholar] [CrossRef] [PubMed]

- Baumgartner, M.; Hartmann, F.; Drack, M.; Preninger, D.; Wirthl, D.; Gerstmayr, R.; Lehner, L.; Mao, G.; Pruckner, R.; Demchyshyn, S.; et al. Resilient yet Entirely Degradable Gelatin-Based Biogels for Soft Robots and Electronics. Nat. Mater. 2020, 19, 1102–1109. [Google Scholar] [CrossRef] [PubMed]

- Patadiya, J.; Gawande, A.; Joshi, G.; Kandasubramanian, B. Additive Manufacturing of Shape Memory Polymer Composites for Futuristic Technology. Ind. Eng. Chem. Res. 2021, 60, 15885–15912. [Google Scholar] [CrossRef]

- Bodkhe, S.; Ermanni, P. 3D Printing of Multifunctional Materials for Sensing and Actuation: Merging Piezoelectricity with Shape Memory. Eur. Polym. J. 2020, 132, 109738. [Google Scholar] [CrossRef]

- Wu, L.; Huang, J.; Zhai, M.; Sun, B.; Chang, H.; Huang, S.; Liu, H. Deformable Bowtie Antenna Realized by 4D Printing. Electronics 2021, 10, 1792. [Google Scholar] [CrossRef]

- Chen, D.; Liu, Q.; Han, Z.; Zhang, J.; Song, H.L.; Wang, K.; Song, Z.; Wen, S.; Zhou, Y.; Yan, C.; et al. 4D Printing Strain Self-Sensing and Temperature Self-Sensing Integrated Sensor–Actuator with Bioinspired Gradient Gaps. Adv. Sci. 2020, 7, 2000584. [Google Scholar] [CrossRef]

- Vinciguerra, M.R.; Patel, D.K.; Zu, W.; Tavakoli, M.; Majidi, C.; Yao, L. Multimaterial Printing of Liquid Crystal Elastomers with Integrated Stretchable Electronics. ACS Appl. Mater. Interfaces 2023, 15, 24777–24787. [Google Scholar] [CrossRef] [PubMed]

- Van Moorleghem, W.; Chandrasekaran, M.; Reynaerts, D.; Peirs, J.; Van Brussel, H. Shape Memory and Superelastic Alloys: The New Medical Materials with Growing Demand. Biomed. Mater. Eng. 1998, 8, 55–60. [Google Scholar] [PubMed]

- Amadi, A.; Mohyaldinn, M.; Ridha, S.; Ola, V. Advancing Engineering Frontiers with NiTi Shape Memory Alloys: A Multifaceted Review of Properties, Fabrication, and Application Potentials. J. Alloys Compd. 2024, 976, 173227. [Google Scholar] [CrossRef]

- Kulkarni, G.K.; Gund, G.S. Copper-Based Shape-Memory Alloy. Shape Memory Composites Based on Polymers and Metals for 4D Printing: Processes, Applications and Challenges; Springer: Berlin/Heidelberg, Germany, 2022; pp. 93–114. [Google Scholar] [CrossRef]

- Milleret, A. 4D Printing of Ni–Mn–Ga Magnetic Shape Memory Alloys: A Review. Mater. Sci. Technol. 2022, 38, 593–606. [Google Scholar] [CrossRef]

- Cirillo, L.; Greco, A.; Masselli, C. CHECK TEMPERATURE: A Small-Scale Elastocaloric Device for the Cooling of the Electronic Circuits. Int. J. Heat Technol. 2022, 40, 665–670. [Google Scholar] [CrossRef]

- Masselli, C.; Cirillo, L.; Greco, A. Cooling of Electronic Circuits through Elastocaloric Solid-State Technology: A Numerical Analysis for the Development of the CHECK TEMPERATURE Prototype. Appl. Therm. Eng. 2023, 230, 120729. [Google Scholar] [CrossRef]

- Dong, X.; Jiang, X.; Li, P.; Mi, Y.; Liu, Q. Three-Dimensional Fluid-Thermal–Mechanical Coupling Numerical Modeling of Elastocaloric Cooler for Electronic Chip. Appl. Therm. Eng. 2024, 248, 123199. [Google Scholar] [CrossRef]

- Hussain Shah, S.I.; Lim, S. RF Advancements Enabled by Smart Shape Memory Materials in the Microwave Regime: A State-of-the-Art Review. Mater. Today Phys. 2024, 44, 101435. [Google Scholar] [CrossRef]

- Jose, S.; Chakraborty, G.; Bhattacharyya, R. Coupled Thermo-Mechanical Analysis of a Vibration Isolator Made of Shape Memory Alloy. Int. J. Solids Struct. 2017, 115–116, 87–103. [Google Scholar] [CrossRef]

- Hurd, E.W.; Flint, J.A.; Daniel, I.H. Shape-Memory Alloys in Reconfigurable Antennas. In Proceedings of the 2014 Loughborough Antennas and Propagation Conference, LAPC 2014, Loughborough, UK, 10–11 November 2014; pp. 363–367. [Google Scholar] [CrossRef]

- Baytore, C.; Palandoken, M.; Kaya, A. Shape Memory Alloy NiTi Antenna with WiFi Application: 2.4/5.8 GHz Dual Band, Shape Memory Alloy Equatomic NiTi (Nitinol) Planar Metal Plate Antenna with a WiFi Application in Built-in Oven with Metal Housing Effect. In Proceedings of the 2016 16th Mediterranean Microwave Symposium (MMS), Abu Dhabi, United Arab Emirates, 14–16 November 2016. [Google Scholar] [CrossRef]

- Ladakhan, S.H.; Sreesha, R.B.; Makireddypalli Adinarayanappa, S. A Study of the Functional Capabilities of Shape Memory Alloy-Based 4D Printed Analogous Bending Actuators. Prog. Addit. Manuf. 2024, 9, 85–105. [Google Scholar] [CrossRef]

- Kohl, M.; Skrobanek, K.D. Linear Microactuators Based on the Shape Memory Effect. Sens. Actuators A 1998, 70, 104–115. [Google Scholar] [CrossRef]

- Yao, T.; Wang, Y.; Zhu, B.; Wei, D.; Yang, Y.; Han, X. 4D Printing and Collaborative Design of Highly Flexible Shape Memory Alloy Structures: A Case Study for a Metallic Robot Prototype. Smart Mater. Struct. 2020, 30, 015018. [Google Scholar] [CrossRef]

- Singh, A.J.; Wala, S.; Ladakhan, S.H.; Sreesha, R.B.; Adinarayanappa, S.M. Design and Fabrication of Shape Memory Alloy Based 4D-Printed Actuator for FWMAV: A Performance Study. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Zeng, X.; Du, Z.; Schuh, C.A.; Gan, C.L. Enhanced Shape Memory and Superelasticity in Small-Volume Ceramics: A Perspective on the Controlling Factors. MRS Commun. 2017, 7, 747–754. [Google Scholar] [CrossRef]

- Huang, R.; Urban, A.; Jiao, D.; Zhe, J.; Choi, J.W. Inductive Proximity Sensors within a Ceramic Package Manufactured by Material Extrusion of Binder-Coated Zirconia. Sens. Actuators A Phys. 2022, 338, 113497. [Google Scholar] [CrossRef]

- Kong, D.; Guo, A.; Wu, H.; Li, X.; Wu, J.; Hu, Y.; Qu, P.; Wang, S.; Guo, S. Four-Dimensional Printing of Polymer-Derived Ceramics with High-Resolution, Reconfigurability, and Shape Memory Effects. Addit. Manuf. 2024, 83, 2214–8604. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Lu, X.; Zhao, Y.; Zhou, Z.; Xu, J.; Yin, J.; Tang, T.; Wang, P.; Yi, S.; et al. 4D Additive-Subtractive Manufacturing of Shape Memory Ceramics. Adv. Mater. 2023, 35, 2302108. [Google Scholar] [CrossRef]

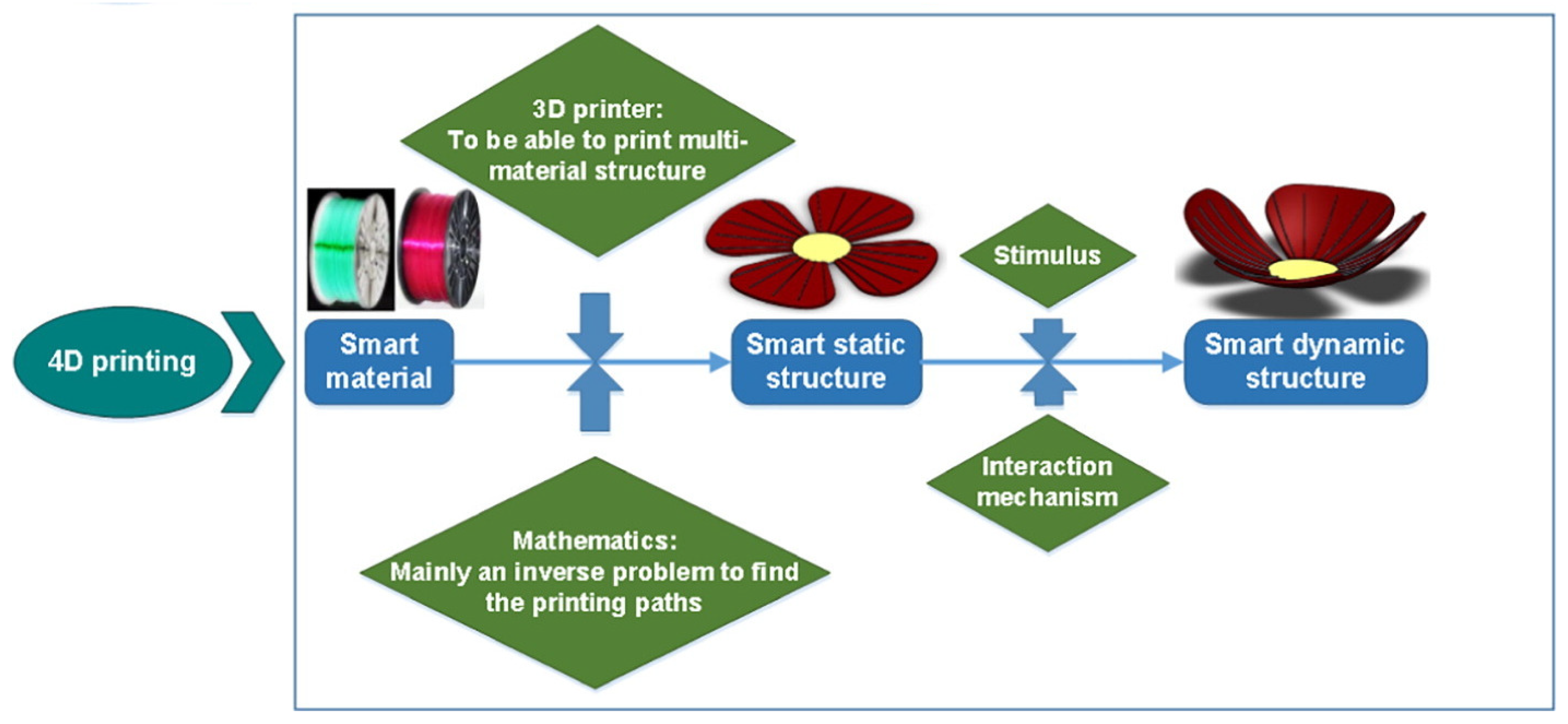

| Factors Responsible for 4D Printing | |

|---|---|

| AM processes | Fused filament fabrication, stereolithography, digital light projection, inkjet, selective laser sintering |

| Smart materials | Shape memory polymers (SMP), stimuli-responsive |

| Stimuli | Physical, chemical, biological |

| Interaction mechanisms | Mechanical, physical manipulation |

| Mathematical models | Forward and backward production |

| Application | Fabrication Technology | AM Category | Examples | Ref. |

|---|---|---|---|---|

| Actuators | Vat photopolymerization | DLP | O-EGaIn thermoresponsive electronics (functional electronics) | [14] |

| Multi-technology platform | IJP/DIW/FFF/AJ/PnP | Soft pneumatic actuator (soft robotic) Digital LED lamp LCE-based actuator (soft robotics) | [27,31] | |

| Antennas | FFF | FFF | 3D Hilbert dipole antenna Hemispherical DRA with a metallic cap Millimeter-wave dual-polarized DR reflectarray | [18,19,20] |

| Self-morphing circuit | FFF | FFF | Thermally activated self-folding electronics (origami structure) | [22] |

| Sensors | Extrusion-based | DIW | Shape-changing, electrical responsive liquid sensor Resistive strain and flexible sensors | [24,25] |

| DIW/EHD | Temperature and humidity sensor | [25] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aronne, M.; Polano, M.; Bertana, V.; Ferrero, S.; Frascella, F.; Scaltrito, L.; Marasso, S.L. Application of 3D and 4D Printing in Electronics. J. Manuf. Mater. Process. 2024, 8, 164. https://doi.org/10.3390/jmmp8040164

Aronne M, Polano M, Bertana V, Ferrero S, Frascella F, Scaltrito L, Marasso SL. Application of 3D and 4D Printing in Electronics. Journal of Manufacturing and Materials Processing. 2024; 8(4):164. https://doi.org/10.3390/jmmp8040164

Chicago/Turabian StyleAronne, Matilde, Miriam Polano, Valentina Bertana, Sergio Ferrero, Francesca Frascella, Luciano Scaltrito, and Simone Luigi Marasso. 2024. "Application of 3D and 4D Printing in Electronics" Journal of Manufacturing and Materials Processing 8, no. 4: 164. https://doi.org/10.3390/jmmp8040164

APA StyleAronne, M., Polano, M., Bertana, V., Ferrero, S., Frascella, F., Scaltrito, L., & Marasso, S. L. (2024). Application of 3D and 4D Printing in Electronics. Journal of Manufacturing and Materials Processing, 8(4), 164. https://doi.org/10.3390/jmmp8040164