Holistic Framework for the Implementation and Validation of PBF-LB/M with Risk Management for Individual Products through Predictive Process Stability

Abstract

1. Introduction

1.1. Motivation

1.2. Objective and Structure

2. State of the Art

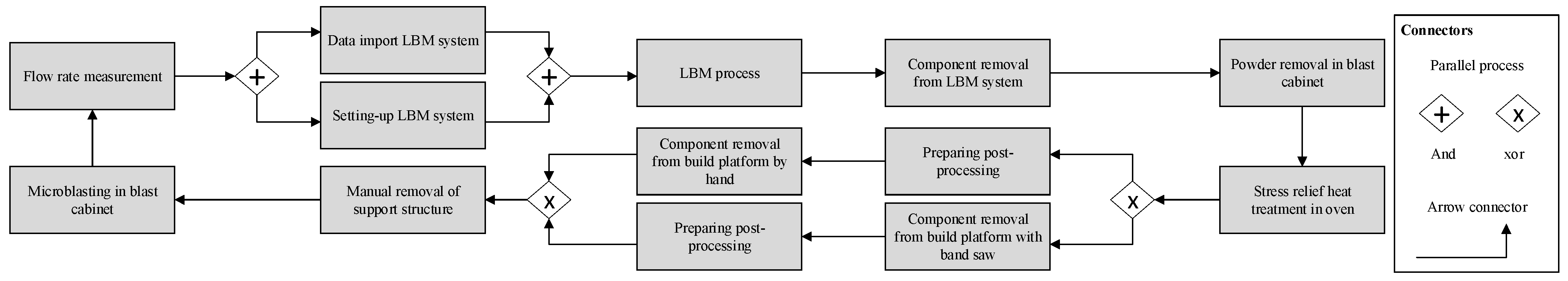

2.1. Additive Manufacturing Process Chain

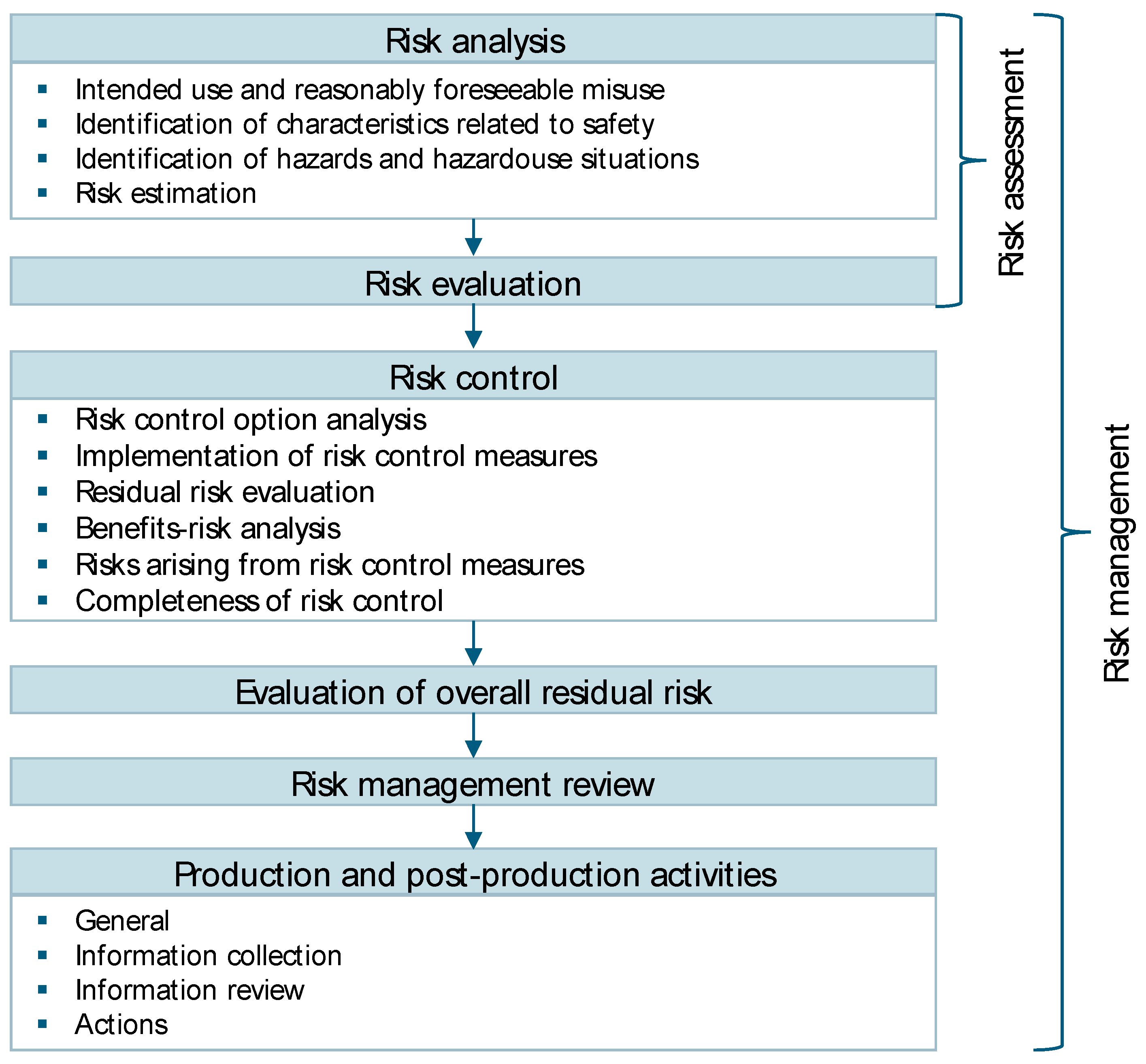

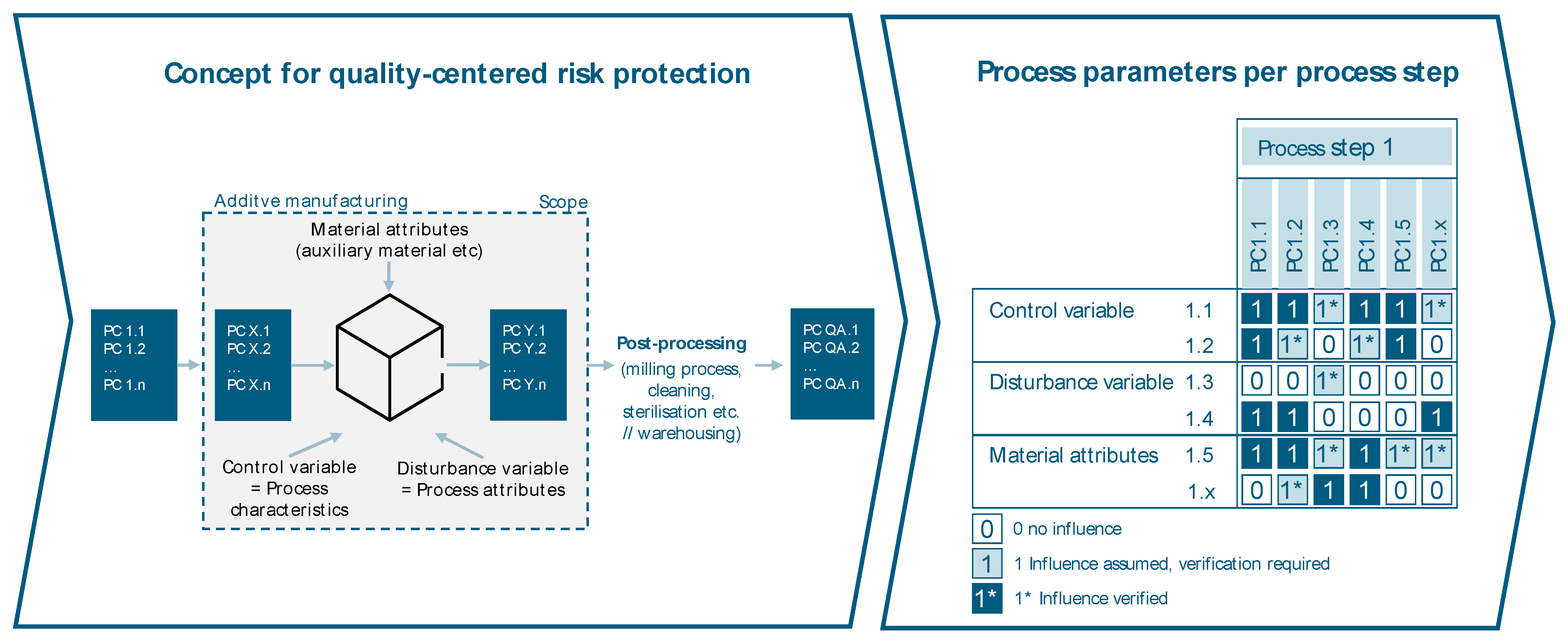

2.2. Technical Risk Management in AM Production Processes

- Preliminary Hazard Analysis (PHA);

- Fault Tree Analysis (FTA);

- Event Tree Analysis (ETA);

- Failure Mode and Effects Analysis (FMEA);

- Hazard and Operability Study (HAZOP);

- Hazard Analysis and Critical Control Point (HACCP).

2.3. Special Features with Individual Products and Mass Personalization

3. Approach and Methodology

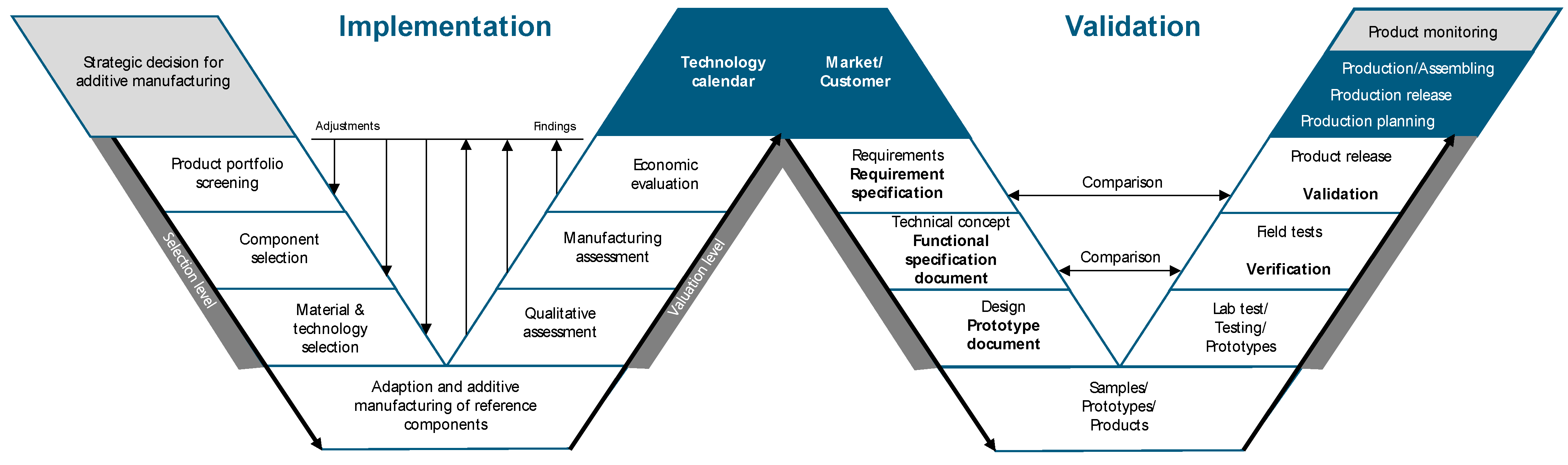

3.1. Framework Overview

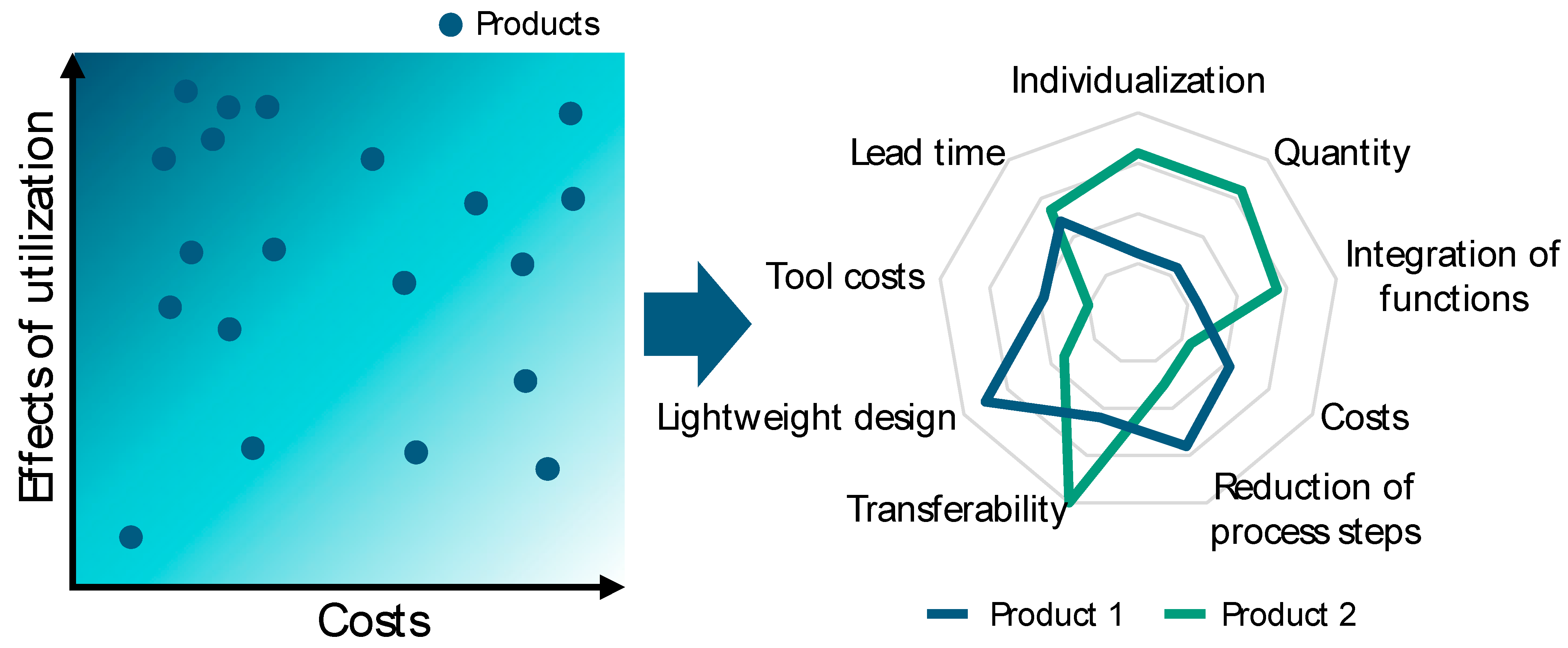

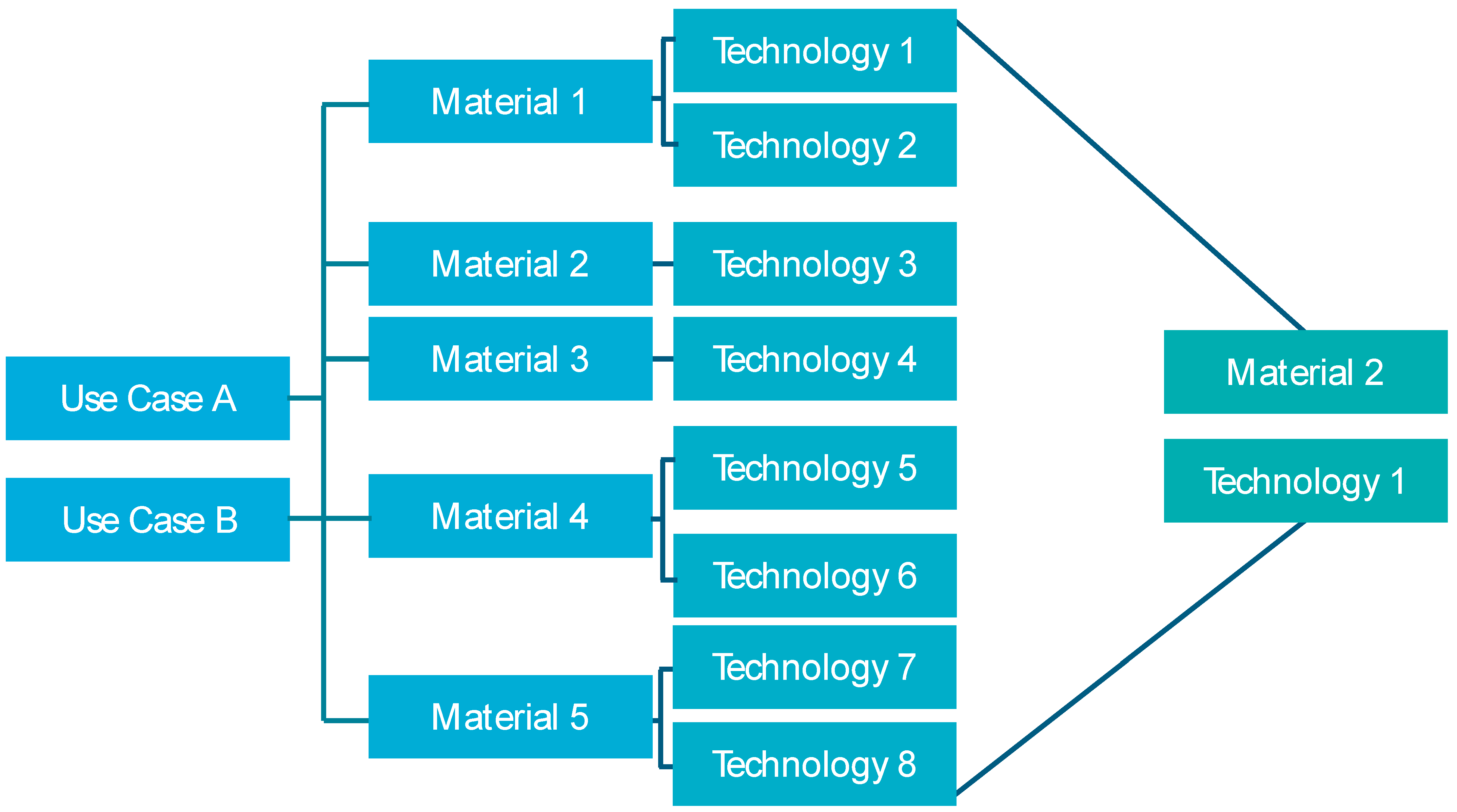

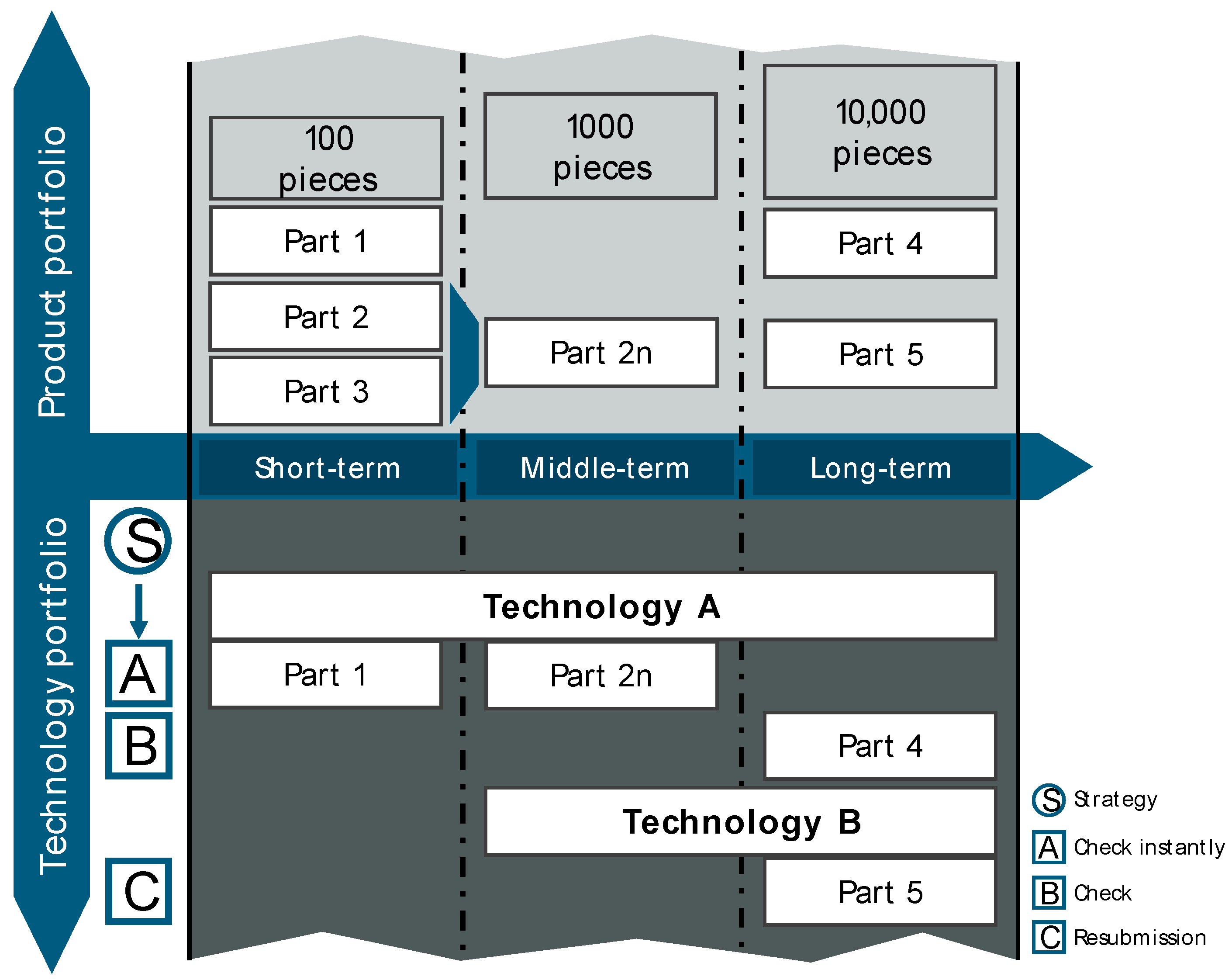

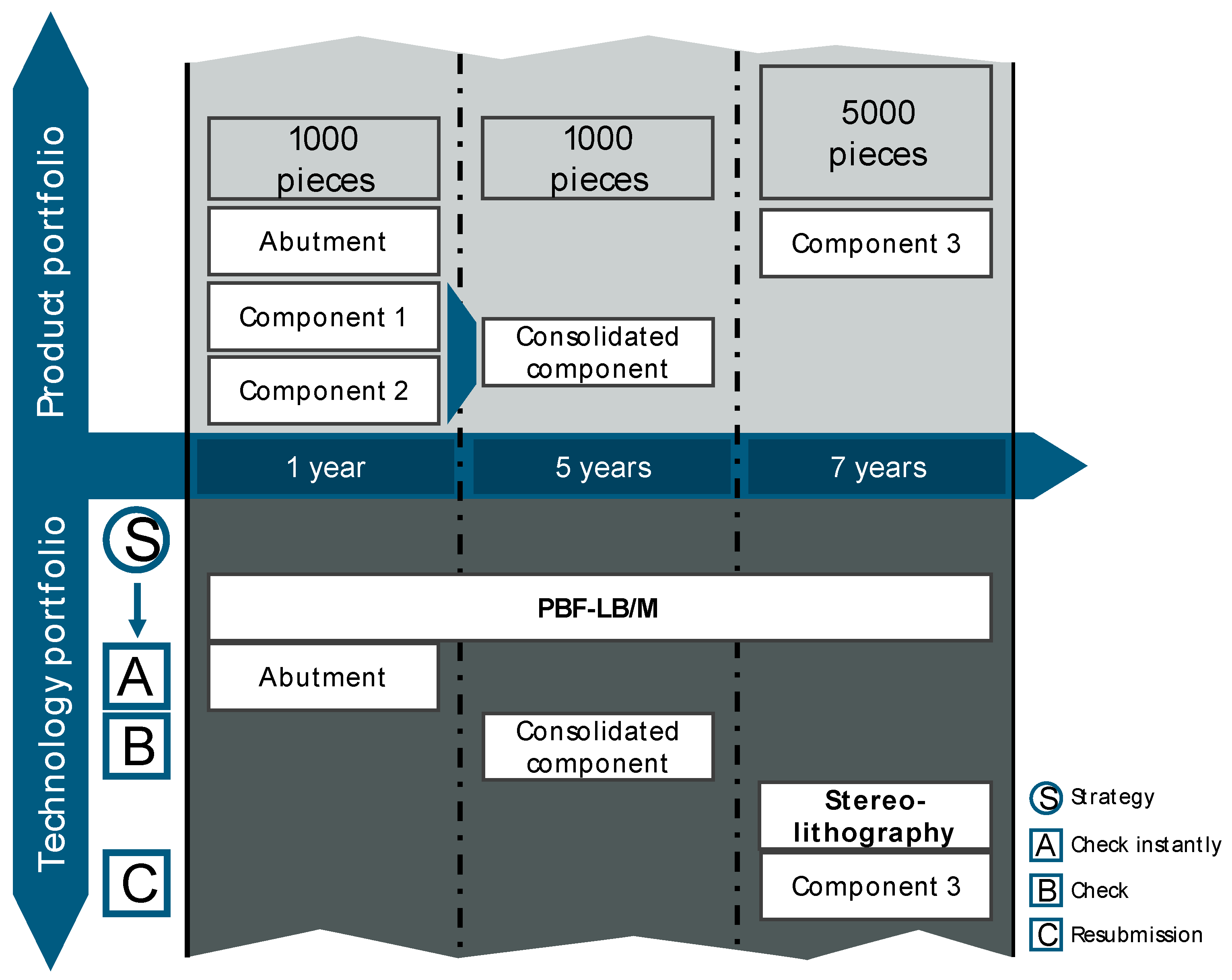

3.2. Phase 1: Implementation of AM in Production Process Chains

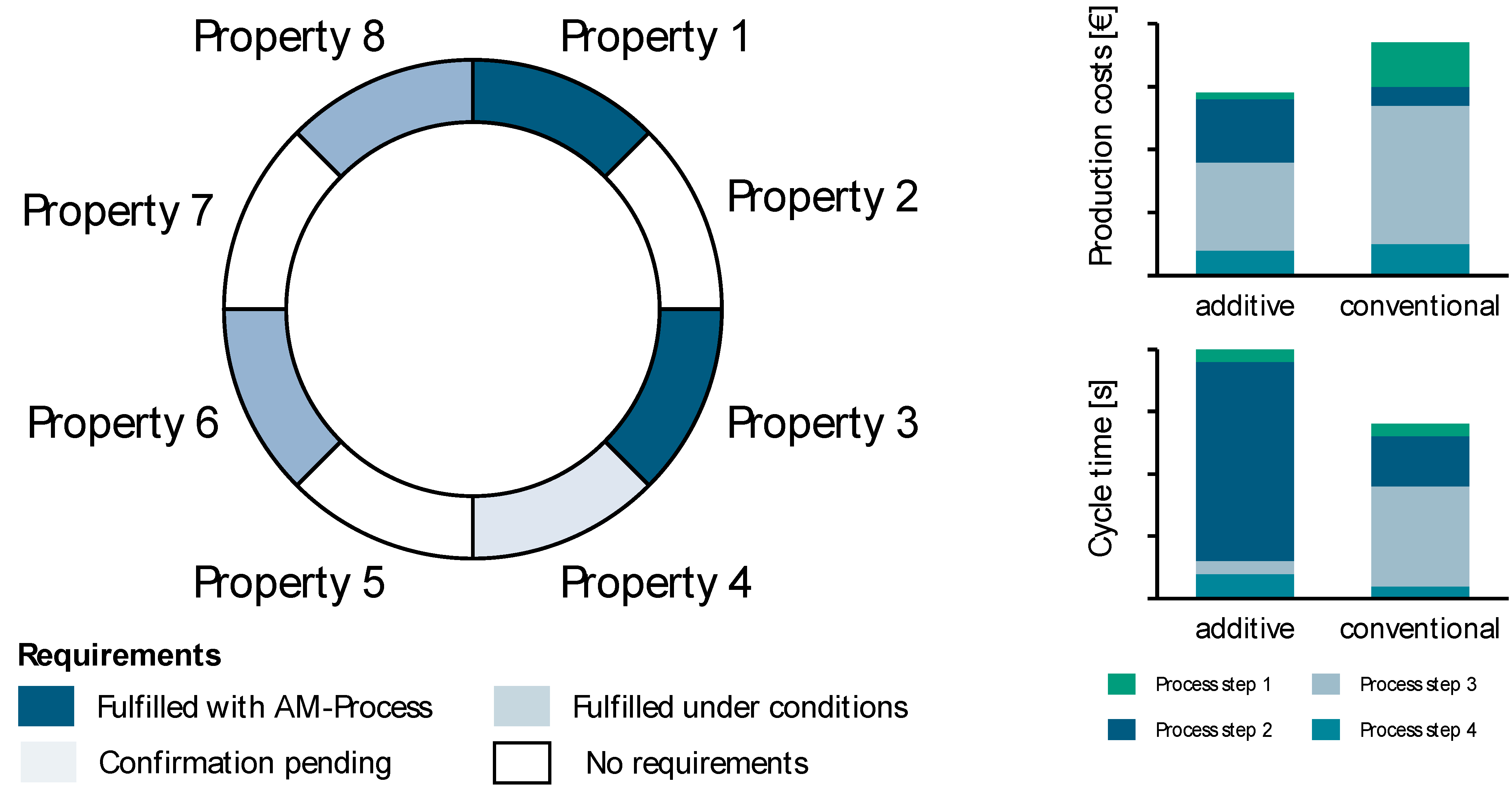

3.3. Phase 2: Validation of AM in Production Process Chains

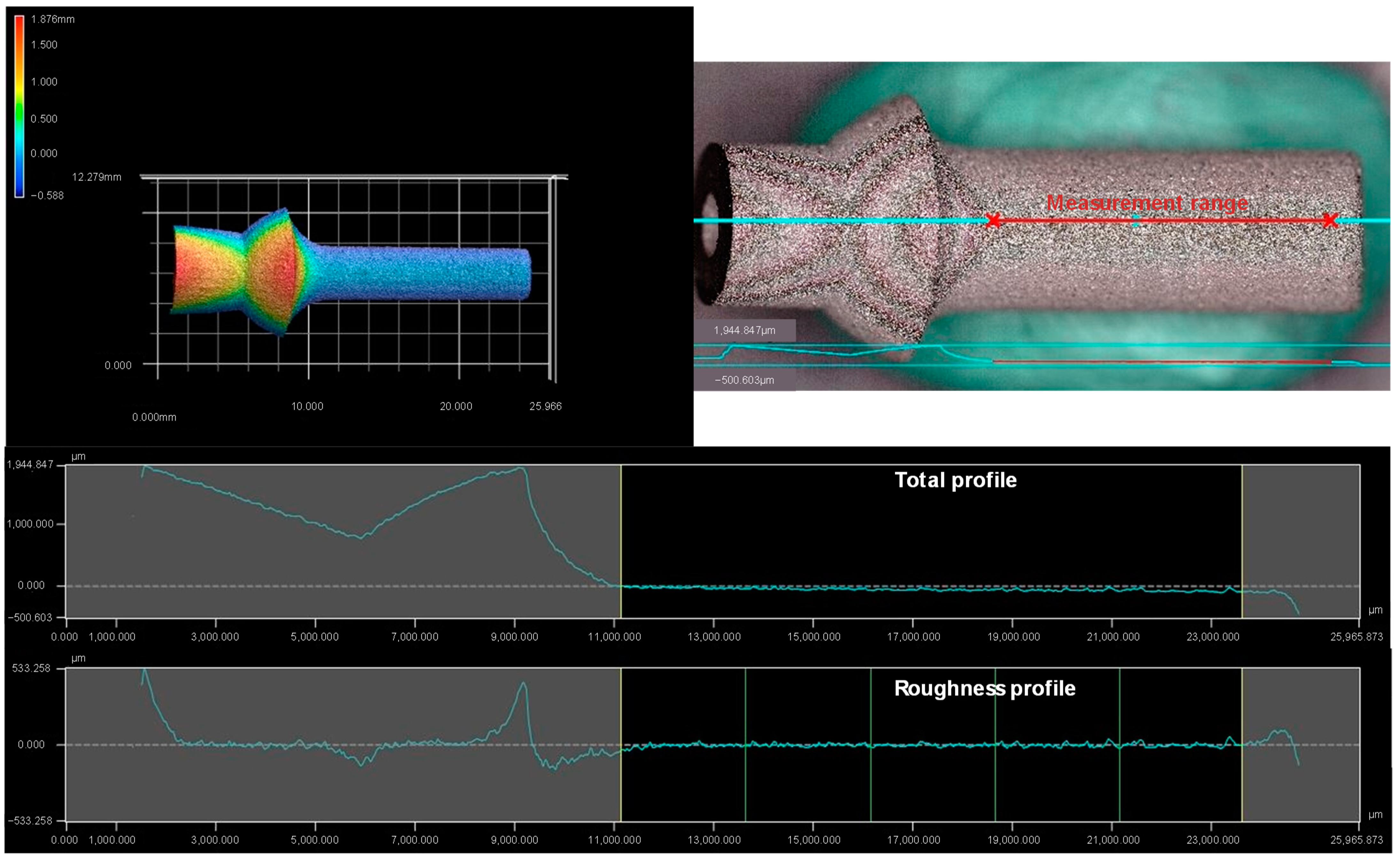

4. Verification

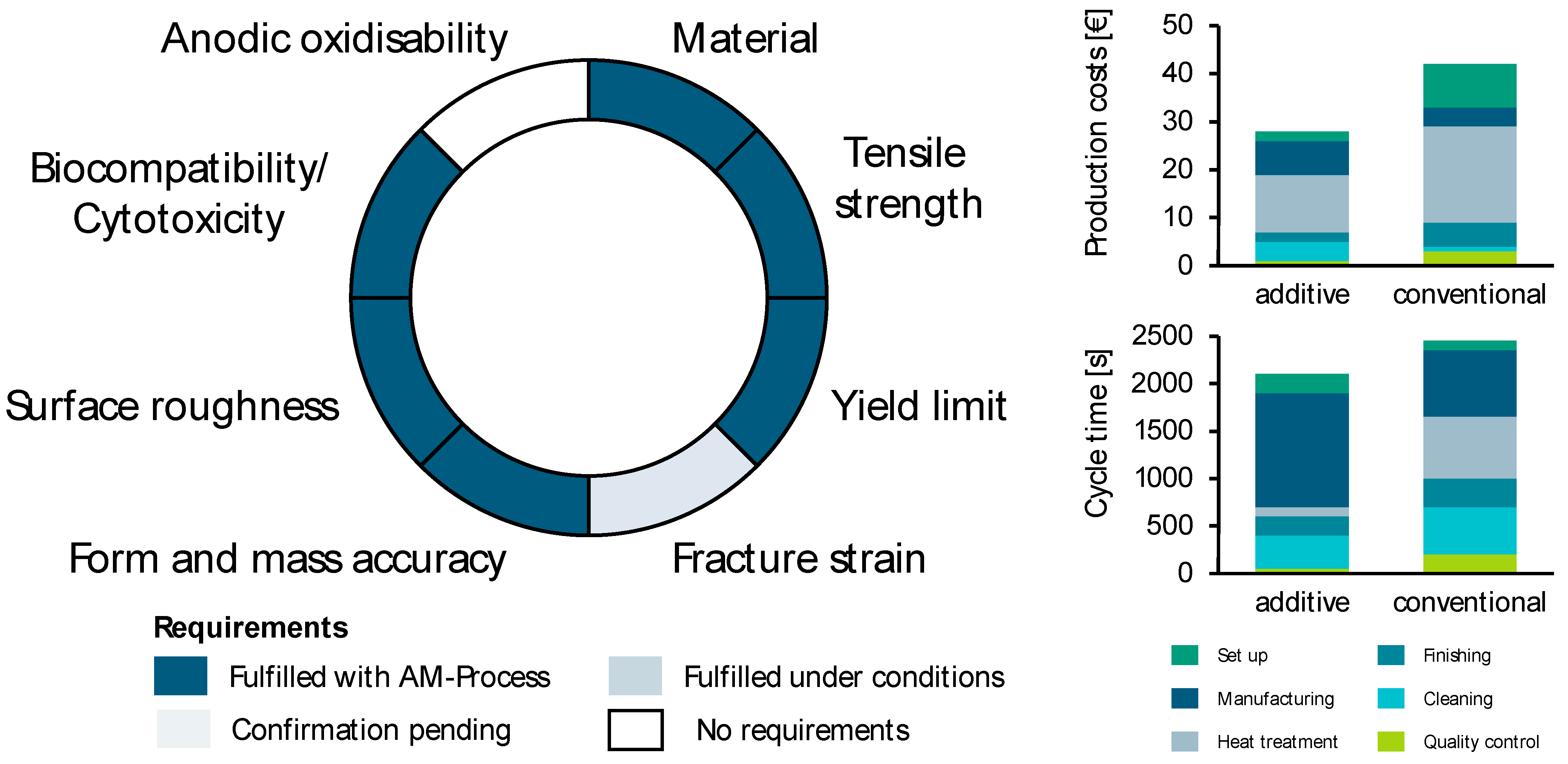

4.1. Phase 1: Implementation of AM in Production Process Chains

4.2. Phase 2: Validation of AM in Production Process Chains

5. Discussion of Results and Limitations

6. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

Appendix C

| Parameter | Value |

|---|---|

| Laser power | 119.25 W |

| Scan speed | 700 m/s |

| Laser spot diameter | 40.00 µm |

| Hatch distance | 50.00 µm |

| Layer thickness | 25.00 µm |

| Scan strategy | Bidirectional (ZigZag) |

| Shielding gas | Argon |

References

- Meboldt, M.; Klahn, C. Industrializing Additive Manufacturing—Proceedings of Additive Manufacturing in Products and Applications—AMPA2017, 1st ed.; Springer International Publishing: Cham, Switzerland, 2018; ISBN 9783319668666. [Google Scholar]

- Groneberg, H.; Bock, T.; Doepper, F. Resilience in value creation systems through additive manufacturing: A decision model. Procedia Comput. Sci. 2023, 217, 296–305. [Google Scholar] [CrossRef]

- Groneberg, H.; Koller, J.; Mahr, A.; Döpper, F. Development of a systematic approach to identify non-value-adding operations in the LBM process chain. Procedia CIRP 2021, 104, 1613–1618. [Google Scholar] [CrossRef]

- Starodubova, A.; Iskhakova, D.; Gareeva, N. Efficiency of Business Models Based on Innovations (Additive Technologies) in a Circular Economy. In Challenges and Solutions in the Digital Economy and Finance: Proceedings of the 5th International Scientific Conference on Digital Economy and Finances (DEFIN 2022), St. Petersburg, 2022; Rumyantseva, A., Plotnikov, V., Minin, A.S., Anyigba, H., Eds.; Springer International Publishing: Cham, Switzerland, 2022; ISBN 9783031144103. [Google Scholar]

- Erenstone, J. 3D Printed Prostheses: The Path from Hype to Reality. Can. Prosthet. Orthot. J. 2023, 6, 4. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Han, C.; Gao, M.; Kandukuri, S.Y.; Zhou, K. A review on qualification and certification for metal additive manufacturing. Virtual Phys. Prototyp. 2022, 17, 382–405. [Google Scholar] [CrossRef]

- Bello, K.A.; Kanakana-Katumba, M.G.; Maladzhi, R.W. A Review of Additive Manufacturing Post-Treatment Techniques for Surface Quality Enhancement. Procedia CIRP 2023, 120, 404–409. [Google Scholar] [CrossRef]

- Jensen, S.C.; Carroll, J.D.; Pathare, P.R.; Saiz, D.J.; Pegues, J.W.; Boyce, B.L.; Jared, B.H.; Heiden, M.J. Long-term process stability in additive manufacturing. Addit. Manuf. 2023, 61, 103284. [Google Scholar] [CrossRef]

- Elahi, B. Safety Risk Management for Medical Devices, 2nd ed.; Academic Press: Amsterdam, The Netherlands, 2022; ISBN 9780323918237. [Google Scholar]

- Castaño Reyes, C.E. Ein modelbasierter Ansatz zur Verwirklichung eines Umfassenden Risikomanagements für Medizingeräte; RWTH Aachen University: Aachen, Germany, 2021. [Google Scholar]

- Rajamani, P.K.; Ageyeva, T.; Kovács, J.G. Personalized Mass Production by Hybridization of Additive Manufacturing and Injection Molding. Polymers 2021, 13, 309. [Google Scholar] [CrossRef] [PubMed]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Fritzsche, R.; Winter, S.; Lohmer, J. Logistik in Wissenschaft und Praxis; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2021; ISBN 978-3-658-33479-6. [Google Scholar]

- Holmström, J.; Partanen, J.; Tuomi, J.; Walter, M. Rapid manufacturing in the spare parts supply chain. J. Manuf. Technol. Manag. 2010, 21, 687–697. [Google Scholar] [CrossRef]

- Mashhadi, A.R.; Esmaeilian, B.; Behdad, S. Impact of additive manufacturing adoption on future of supply chain. In Proceedings of the ASME 2015 International Manufacturing Science and Engineering, Charlotte, NC, USA, 8–12 June 2015. [Google Scholar] [CrossRef]

- Foith-Förster, P. Design of Matrix Production Systems for the Personalized Production of Mechatronic Machine Modules. Doctoral Dissertation, Universität Stuttgart, Stuttgart, Germany, 2023. [Google Scholar]

- Kleszczynski, S. Potenziale der Bildgestützten Prozessüberwachung zur Steigerung des Technologischen Reifegrades von Laser-Strahlschmelzverfahren. Doctoral Dissertation, Universität Duisburg-Essen, Duisburg, Germany, 2018. [Google Scholar]

- Martucci, A.; Aversa, A.; Lombardi, M. Ongoing Challenges of Laser-Based Powder Bed Fusion Processing of Al Alloys and Potential Solutions from the Literature—A Review. Materials 2023, 16, 1084. [Google Scholar] [CrossRef]

- Groneberg, H.; Schuh, C.; Steinhilper, R.; Doepper, F. Implementation of Methods for the Optimization of Processes and Production Systems: Catching the Mood of Small and Medium-sized German Enterprises. In Advances in Production Research; Schmitt, R., Schuh, G., Eds.; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-030-03450-4. [Google Scholar]

- Groneberg, H.; Horstkotte, R.; Pruemmer, M.; Bergs, T.; Döpper, F. Concept for the reduction of non-value-adding operations in Laser Powder Bed Fusion (L-PBF). Procedia CIRP 2022, 107, 344–349. [Google Scholar] [CrossRef]

- Gebhardt, A.; Kessler, J.; Thurn, L. 3D-Drucken: Grundlagen und Anwendungen des Additive Manufacturing (AM), 2., neu Bearbeitete und Erweiterte Auflage; Hanser: München, Germany, 2016; ISBN 9783446448452. [Google Scholar]

- Diniță, A.; Neacșa, A.; Portoacă, A.I.; Tănase, M.; Ilinca, C.N.; Ramadan, I.N. Additive Manufacturing Post-Processing Treatments, a Review with Emphasis on Mechanical Characteristics. Materials 2023, 16, 4610. [Google Scholar] [CrossRef] [PubMed]

- Dzemko, M.; Engelmann, B.; Hartmann, J.; Schmitt, J. Toward Shifted Production Strategies Through Additive Manufacturing: A Technology and Market Review for Changing Value Chains. Procedia CIRP 2019, 86, 228–233. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Bhatia, A.; Sehgal, A.K. Additive manufacturing materials, methods and applications: A review. Mater. Today Proc. 2023, 81, 1060–1067. [Google Scholar] [CrossRef]

- Ituarte, I.F.; Coatanea, E.; Salmi, M.; Tuomi, J.; Partanen, J. Additive Manufacturing in Production: A Study Case Applying Technical Requirements. Phys. Procedia 2015, 78, 357–366. [Google Scholar] [CrossRef]

- Pollard, M.; Tran, P.; Dickens, T. Porosity Reducing Processing Stages of Additive Manufactured Molding (AMM) for Closed-Mold Composite Fabrication. Materials 2020, 13, 5328. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Kumar, M.; Chohan, J.S. Material-specific properties and applications of additive manufacturing techniques: A comprehensive review. Bull. Mater. Sci. 2021, 44, 181. [Google Scholar] [CrossRef]

- Spears, T.G.; Gold, S.A. In-process sensing in selective laser melting (SLM) additive manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 16–40. [Google Scholar] [CrossRef]

- Ge, J.; Pillay, S.; Ning, H. Post-Process Treatments for Additive-Manufactured Metallic Structures: A Comprehensive Review. J. Mater. Eng. Perform. 2023, 32, 7073–7122. [Google Scholar] [CrossRef]

- Peng, X.; Kong, L.; Fuh, J.Y.H.; Wang, H. A Review of Post-Processing Technologies in Additive Manufacturing. JMMP 2021, 5, 38. [Google Scholar] [CrossRef]

- Breuninger, J.; Becker, R.; Wolf, A.; Rommel, S.; Verl, A. Generative Fertigung mit Kunststoffen; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-24324-0. [Google Scholar]

- Baldinger, M. Supply Chain Management für Additive Manufacturing: Konzepte, Werkzeuge und Prozesse für die Zusammenarbeit mit Dienstleistern zur Reduktion der Risiken beim Einstieg in Additive Manufacturing; ETH Library: Zürich, Germany, 2016. [Google Scholar]

- Feldmann, C.; Gorj, A. 3D-Druck und Lean Production, 1st ed.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2017; ISBN 978-3-658-18407-0. [Google Scholar]

- Molenda, P.; Groneberg, H.; Schötz, S.; Döpper, F. Resilience Balanced Scorecard: Measuring Resilience of Manufacturing Companies at Multiple Levels. Procedia CIRP 2023, 120, 189–194. [Google Scholar] [CrossRef]

- Park, M.; Venter, M.P.; Du Plessis, A. A lattice structure coupon sample for build quality control in metal additive manufacturing. Mater. Des. 2023, 235, 112436. [Google Scholar] [CrossRef]

- DIN EN ISO 14971; Medical Devices—Application of Risk Management to Medical Devices. Deutsches Institut für Normung e. V.: Berlin, Germany, 2022.

- DIN ISO 31000; Risk Management—Guidelines. Deutsches Institut für Normung e. V.: Berlin, Germany, 2018.

- ISO/TR 24971:2020; Medical Devices—Guidance on the Application of ISO 14971. Deutsches Institut für Normung e. V.: Berlin, Germany, 2020.

- Modarres, M. Risk Analysis in Engineering: Techniques, Tools, and Trends; Taylor & Francis: Boca Raton, FL, USA, 2006; ISBN 978-1-57444-794-1. [Google Scholar]

- IATF 16949:2016; Quality Management System Requirements for Automotive Production and Relevant Service Parts Organisations. AIAG: Southfield, MI, USA, 2016.

- ISO/ASTM 52920:2023; Additive Manufacturing—Qualification Principles—Requirements for Industrial Additive Manufacturing Processes and Production Sites. ISO: Geneva, Switzerland, 2023.

- Hunte, J.L.; Neil, M.; Fenton, N.E. A hybrid Bayesian network for medical device risk assessment and management. Reliab. Eng. Syst. Saf. 2024, 241, 109630. [Google Scholar] [CrossRef]

- DIN EN 60601-1; Medizinische elektrische Geräte—Teil 1: Allgemeine Festlegungen für die Sicherheit einschließlich der wesentlichen Leistungsmerkmale. Deutsches Institut für Normung e. V.: Berlin, Germany, 2022.

- Madrigal, J.; Jeong, S. Personalization Process of 3D Printed Products using Parametric Design. Arch. Des. Res. 2022, 35, 31–47. [Google Scholar] [CrossRef]

- Hu, S.J. Evolving Paradigms of Manufacturing: From Mass Production to Mass Customization and Personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef]

- Kumar, A. From mass customization to mass personalization: A strategic transformation. Int. J. Flex. Manuf. Syst. 2007, 19, 533–547. [Google Scholar] [CrossRef]

- Hu, S.J.; Ko, J.; Weyand, L.; ElMaraghy, H.A.; Lien, T.K.; Koren, Y.; Bley, H.; Chryssolouris, G.; Nasr, N.; Shpitalni, M. Assembly system design and operations for product variety. CIRP Ann. 2011, 60, 715–733. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.-S.; Yang, J.-H.; Wang, K.-S. Industry 4.0: A way from mass customization to mass personalization production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Aheleroff, S.; Mostashiri, N.; Xu, X.; Zhong, R.Y. Mass Personalisation as a Service in Industry 4.0: A Resilient Response Case Study. Adv. Eng. Inform. 2021, 50, 101438. [Google Scholar] [CrossRef]

- Zheng, P.; Yu, S.; Wang, Y.; Zhong, R.Y.; Xu, X. User-experience Based Product Development for Mass Personalization: A Case Study. Procedia CIRP 2017, 63, 2–7. [Google Scholar] [CrossRef]

- Lacroix, R.; Seifert, R.W.; Timonina-Farkas, A. Benefiting from additive manufacturing for mass customization across the product life cycle. Oper. Res. Perspect. 2021, 8, 100201. [Google Scholar] [CrossRef]

- Ilg, J. Systematische Eignungsanalyse Zum Einsatz Additiver Fertigungsverfahren: Anwendung Am Beispiel der Medizintechnik; Gabler: Wiesbaden, Germany, 2019; ISBN 978-3-658-24630-3. [Google Scholar]

- DIN EN ISO/ASTM 52910; Additive Fertigung—Konstruktion—Anforderungen, Richtlinien und Empfehlungen. Beuth Verlag GmbH: Berlin, Germany, 2022.

- VDI 3405; Additive Manufacturing Processes, Rapid Manufacturing: Basics, Definitions, Processes. Beuth Verlag GmbH: Düsseldorf, Germany, 2014.

- Bröhl, A.P.; Dröschel, W. (Eds.) Das V-Modell: Der Standard für die Softwareentwicklung mit Praxisleitfaden; 2. Auflage; Oldenbourg Wissenschaftsverlag: München, Germany, 1995; ISBN 3486234706. [Google Scholar]

- Su, G.; Deng, D. Regulatory requirements and optimization of multiple criteria decision analysis to quantify the benefit-risk assessment of medical devices. Expert. Rev. Med. Devices 2023, 20, 273–281. [Google Scholar] [CrossRef] [PubMed]

- Schlagintweit, S. Validating Additive Manufacturing Processes to Meet Medical Regulations: Ensure Safe and Reproducible Manufacturing Results; TÜV Rheinland Australia: Heidelberg West, VIC, Australia, 2021. [Google Scholar]

- ISO/ASTM TS 52930:2021; Additive Manufacturing—Qualification Principles—Installation, Operation and Performance (IQ/OQ/PQ) of PBF-LB Equipment. ISO: Geneva, Switzerland, 2021.

- Xie, Y.; Zhou, J.; Wei, Q.; Yu, Z.M.; Luo, H.; Zhou, B.; Tang, Z.G. Improving the long-term stability of Ti6Al4V abutment screw by coating micro/nano-crystalline diamond films. J. Mech. Behav. Biomed. Mater. 2016, 63, 174–182. [Google Scholar] [CrossRef] [PubMed]

- Tshephe, T.S.; Akinwamide, S.O.; Olevsky, E.; Olubambi, P.A. Additive manufacturing of titanium-based alloys- A review of methods, properties, challenges, and prospects. Heliyon 2022, 8, e09041. [Google Scholar] [CrossRef] [PubMed]

- Jang, T.-S.; Kim, D.; Han, G.; Yoon, C.-B.; Jung, H.-D. Powder based additive manufacturing for biomedical application of titanium and its alloys: A review. Biomed. Eng. Lett. 2020, 10, 505–516. [Google Scholar] [CrossRef] [PubMed]

- Huber, F.; Rasch, M.; Schmidt, M. Laser Powder Bed Fusion (PBF-LB/M) Process Strategies for In-Situ Alloy Formation with High-Melting Elements. Metals 2021, 11, 336. [Google Scholar] [CrossRef]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of Process Parameters on the Surface Roughness of Overhanging Structures in Laser Powder Bed Fusion Additive Manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef]

- Piscopo, G.; Salmi, A.; Atzeni, E. On the quality of unsupported overhangs produced by laser powder bed fusion. Int. J. Manuf. Res. 2019, 14, 198. [Google Scholar] [CrossRef]

- Shange, M.; Yadroitsava, I.; Du Plessis, A.; Yadroitsev, I. Roughness and Near-Surface Porosity of Unsupported Overhangs Produced by High-Speed Laser Powder Bed Fusion. 3D Print. Addit. Manuf. 2022, 9, 288–300. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; Wei, H.; Zhang, C.; Chen, X.; Zhang, K. Effect of processing parameters on overhanging surface roughness during laser powder bed fusion of AlSi10Mg. J. Manuf. Process. 2021, 61, 440–453. [Google Scholar] [CrossRef]

- Feng, S.; Kamat, A.M.; Sabooni, S.; Pei, Y. Experimental and numerical investigation of the origin of surface roughness in laser powder bed fused overhang regions. Virtual Phys. Prototyp. 2021, 16, S66–S84. [Google Scholar] [CrossRef]

- Gebhardt, A.; Kessler, J.; Schwarz, A. Produktgestaltung für die Additive Fertigung; Hanser: München, Germany, 2019; ISBN 978-3-446-46133-8. [Google Scholar]

- Charles, A.; Elkaseer, A.; Paggi, U.; Thijs, L.; Hagenmeyer, V.; Scholz, S. Down-facing surfaces in laser powder bed fusion of Ti6Al4V: Effect of dross formation on dimensional accuracy and surface texture. Addit. Manuf. 2021, 46, 102148. [Google Scholar] [CrossRef]

- Charles, A.; Elkaseer, A.; Thijs, L.; Hagenmeyer, V.; Scholz, S. Effect of Process Parameters on the Generated Surface Roughness of Down-Facing Surfaces in Selective Laser Melting. Appl. Sci. 2019, 9, 1256. [Google Scholar] [CrossRef]

- Pacurar, R.; Balc, N.; Prem, F. Research on how to improve the accuracy of the SLM metallic parts. AIP Conf. Proc. 2011, 1353, 1385–1390. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Surface Morphology in Selective Laser Melting of Metal Powders. Phys. Procedia 2011, 12, 264–270. [Google Scholar] [CrossRef]

- Nandwana, P.; Plotkowski, A.; Kannan, R.; Yoder, S.; Dehoff, R. Predicting geometric influences in metal additive manufacturing. Mater. Today Commun. 2020, 25, 101174. [Google Scholar] [CrossRef]

- Mugwagwa, L.; Dimitrov, D.; Matope, S.; Yadroitsev, I. Evaluation of the impact of scanning strategies on residual stresses in selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 102, 2441–2450. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.-P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, Z.; Aladawi, A.S.; Kindi, M.A.; Hatmi, I.A.; Chen, H.; Chen, L. Influence of Laser Processing Strategy and Remelting on Surface Structure and Porosity Development during Selective Laser Melting of a Metallic Material. Metall. Mater. Trans. A 2019, 50, 4423–4434. [Google Scholar] [CrossRef]

- Hofmann, A.; Grotz, T.; Köstler, N.; Mahr, A.; Döpper, F. Electrical Smoothing of the Powder Bed Surface in Laser-Based Powder Bed Fusion of Metals. J. Manuf. Mater. Process. 2024, 8, 112. [Google Scholar] [CrossRef]

- Krauss, H. Qualitätssicherung beim Laserstrahlschmelzen durch Schichtweise Thermografische In-Process-Überwachung; Utzverlag: München, Germany, 2017; ISBN 9783831672936. [Google Scholar]

- Yavari, R.; Smoqi, Z.; Riensche, A.; Bevans, B.; Kobir, H.; Mendoza, H.; Song, H.; Cole, K.; Rao, P. Part-scale thermal simulation of laser powder bed fusion using graph theory: Effect of thermal history on porosity, microstructure evolution, and recoater crash. Mater. Des. 2021, 204, 109685. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Deckers, J.; Yasa, E.; Wauthlé, R. Assessing and comparing influencing factors of residual stresses in selective laser melting using a novel analysis method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 980–991. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- DIN EN ISO 4287; Geometrische Produktspezifikation (GPS)—Oberflächenbeschaffenheit: Tastschnittverfahren—Benennungen, Definitionen und Kenngrößen der Oberflächenbeschaffenheit. Beuth Verlag GmbH: Berlin, Germany, 2010.

- DIN EN ISO 4288; Geometrische Produktspezifikation (GPS)—Oberflächenbeschaffenheit: Tastschnittverfahren—Regeln und Verfahren für die Beurteilung der Oberflächenbeschaffenheit. Beuth Verlag GmbH: Berlin, Germany, 1998.

| Product Strategy | ||||

|---|---|---|---|---|

| Mass Production | Mass Customization | Personalized Production | ||

| Comparison Attributes | Production Goal | Scale | Scale Scope | Scale Scope Value |

| Desired Product Characteristic | Quality Cost | Quality Cost Variety | Quality Cost Variety Efficacy | |

| Customer Role | Buy | Buy Choose | Buy Choose Design | |

| Production System | Dedicated Manufacturing Systems | Reconfigurable Manufacturing Systems | On-Demand Manufacturing Systems | |

| Critical Quality Attributes | |||||

|---|---|---|---|---|---|

| Angle between Base and Body | Source | Surface Roughness | Source | ||

| Control Variable | Angle between base and body | 2 | Expert Interviews | 2 | [64,65,66,67,68] |

| Layer thickness | 2 | Expert Interviews | 2 | [69,70,71] | |

| Laser power | 2 | [72] | 2 | [68,70,71] | |

| Scanning speed | 2 | [72] | 2 | [68,70,71] | |

| Hatching distance | 1 | Expert Interviews | 1 | [73] | |

| Scanning strategy | 2 | [74,75,76] | 2 | [77] | |

| Disturbance Variable | Condition of recoating blade during process time | 2 | Expert Interviews | 2 | [78] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Groneberg, H.; Oberdiek, S.; Schulz, C.; Hofmann, A.; Schloske, A.; Doepper, F. Holistic Framework for the Implementation and Validation of PBF-LB/M with Risk Management for Individual Products through Predictive Process Stability. J. Manuf. Mater. Process. 2024, 8, 158. https://doi.org/10.3390/jmmp8040158

Groneberg H, Oberdiek S, Schulz C, Hofmann A, Schloske A, Doepper F. Holistic Framework for the Implementation and Validation of PBF-LB/M with Risk Management for Individual Products through Predictive Process Stability. Journal of Manufacturing and Materials Processing. 2024; 8(4):158. https://doi.org/10.3390/jmmp8040158

Chicago/Turabian StyleGroneberg, Hajo, Sven Oberdiek, Carolin Schulz, Andreas Hofmann, Alexander Schloske, and Frank Doepper. 2024. "Holistic Framework for the Implementation and Validation of PBF-LB/M with Risk Management for Individual Products through Predictive Process Stability" Journal of Manufacturing and Materials Processing 8, no. 4: 158. https://doi.org/10.3390/jmmp8040158

APA StyleGroneberg, H., Oberdiek, S., Schulz, C., Hofmann, A., Schloske, A., & Doepper, F. (2024). Holistic Framework for the Implementation and Validation of PBF-LB/M with Risk Management for Individual Products through Predictive Process Stability. Journal of Manufacturing and Materials Processing, 8(4), 158. https://doi.org/10.3390/jmmp8040158