A Review on Wire-Laser Directed Energy Deposition: Parameter Control, Process Stability, and Future Research Paths

Abstract

1. Introduction

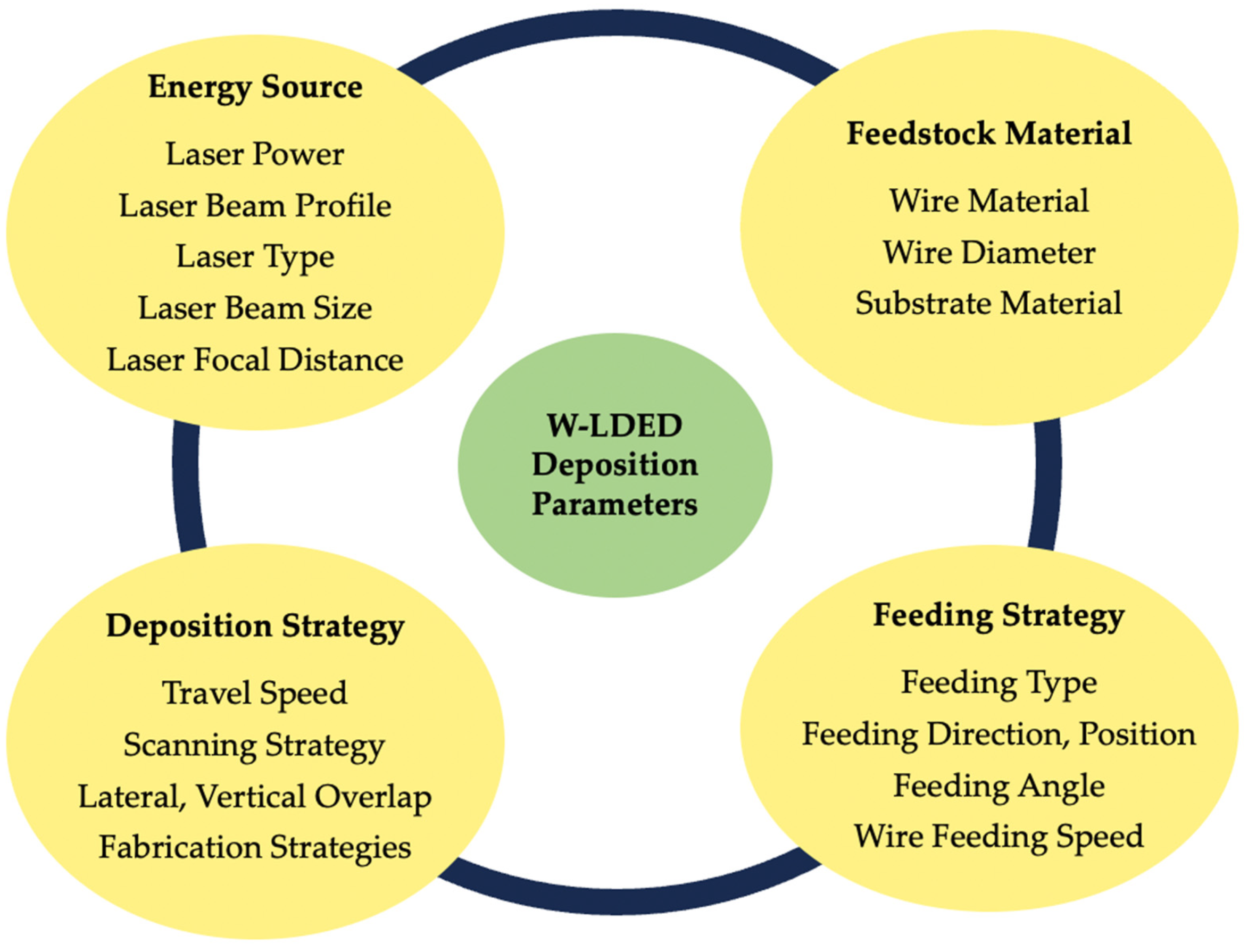

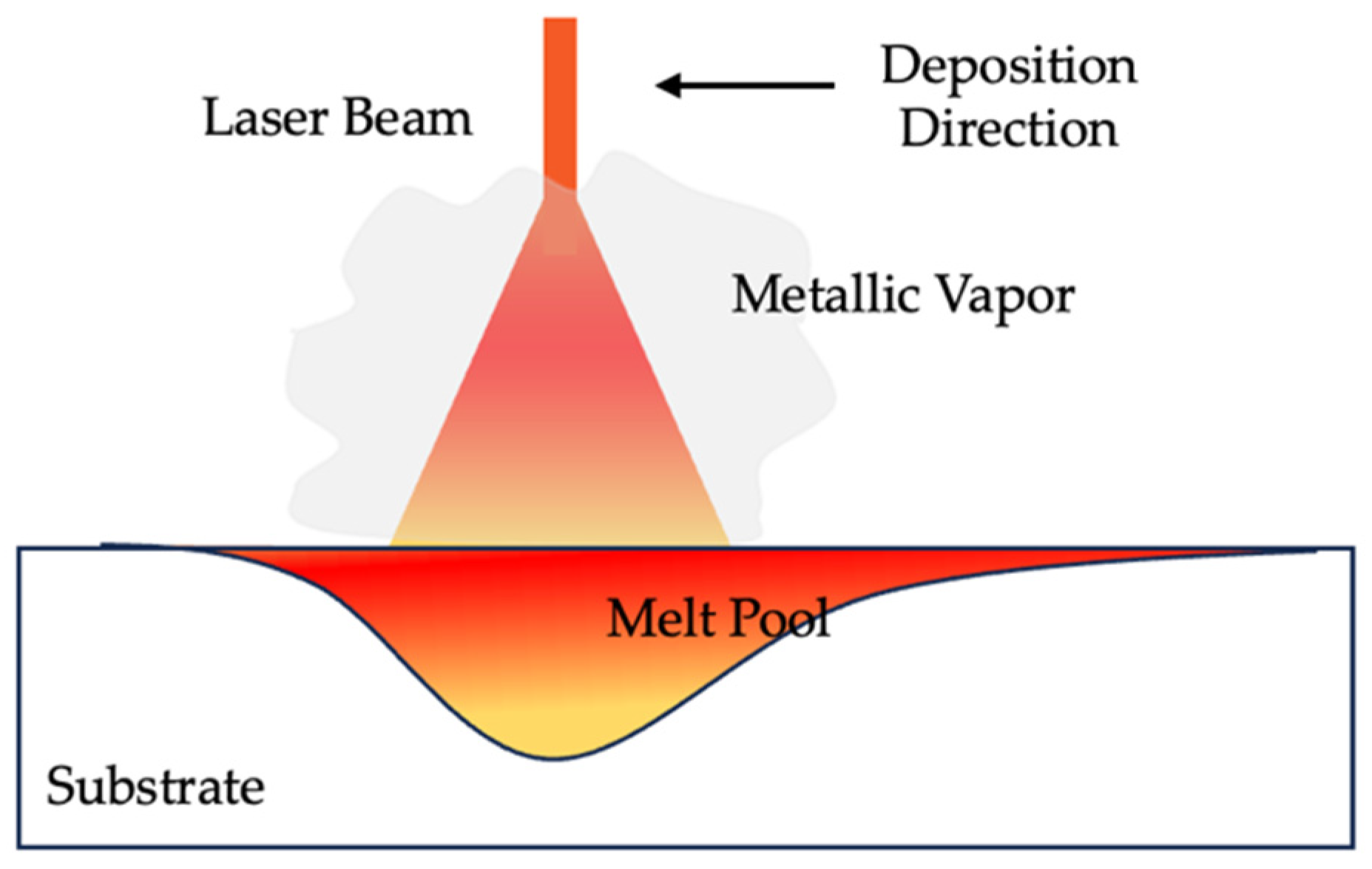

2. Energy Characteristics

2.1. Input Energy

2.2. Laser Characteristics

2.2.1. Laser Types

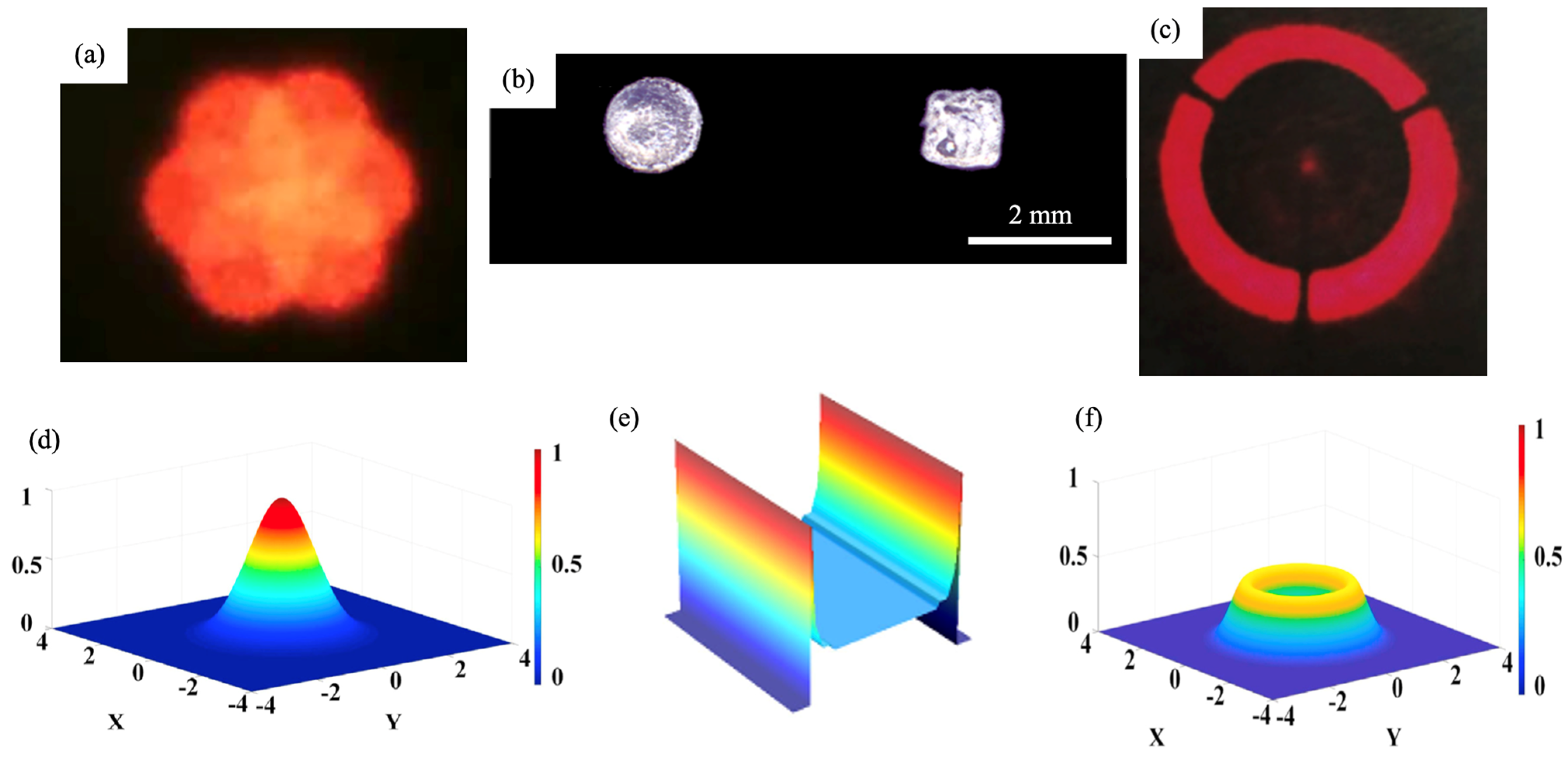

2.2.2. Laser Beam Profile

2.2.3. Beam Irradiance and Focal Spot Size

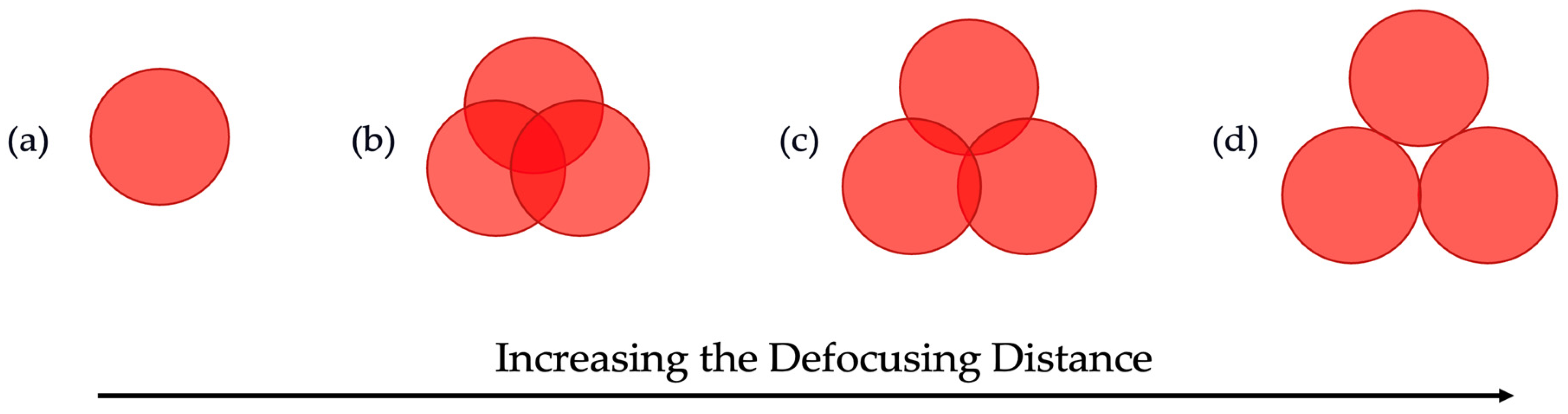

2.2.4. Focal Distance

3. Feed Wire Characteristics

3.1. Wire Size

3.2. Types of Wire Feeding

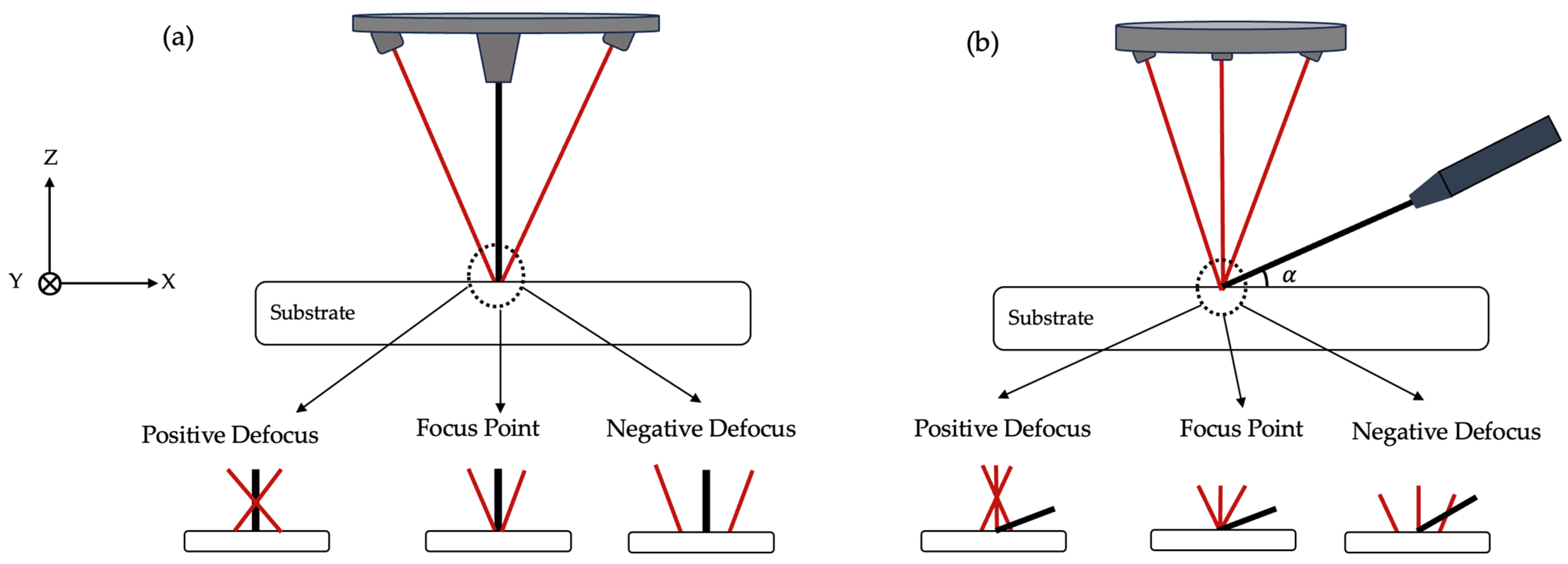

3.2.1. Lateral Wire Feeding

3.2.2. Coaxial Wire Feeding

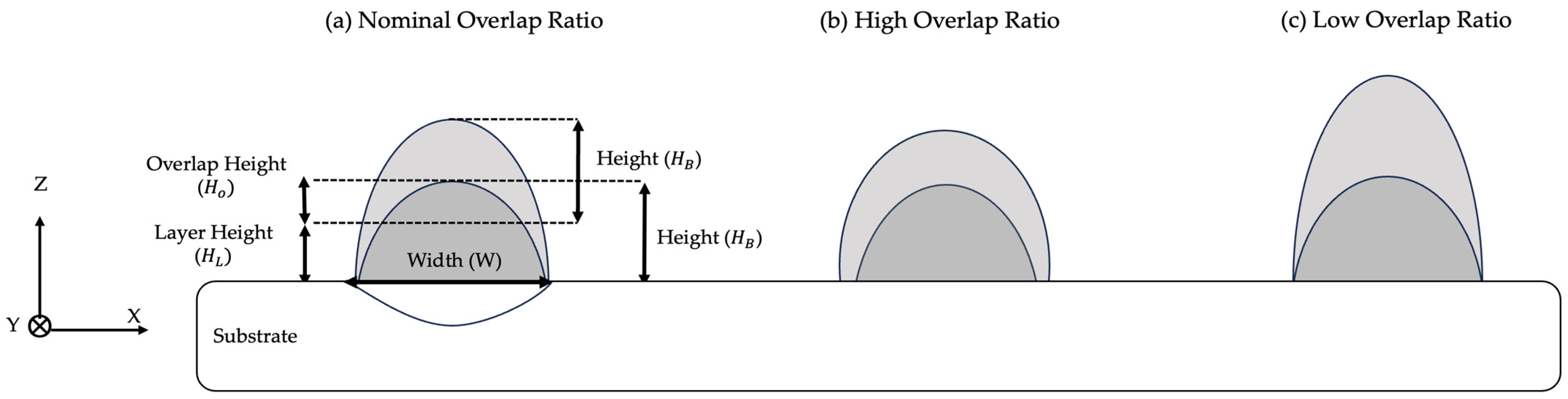

4. Bead Geometry

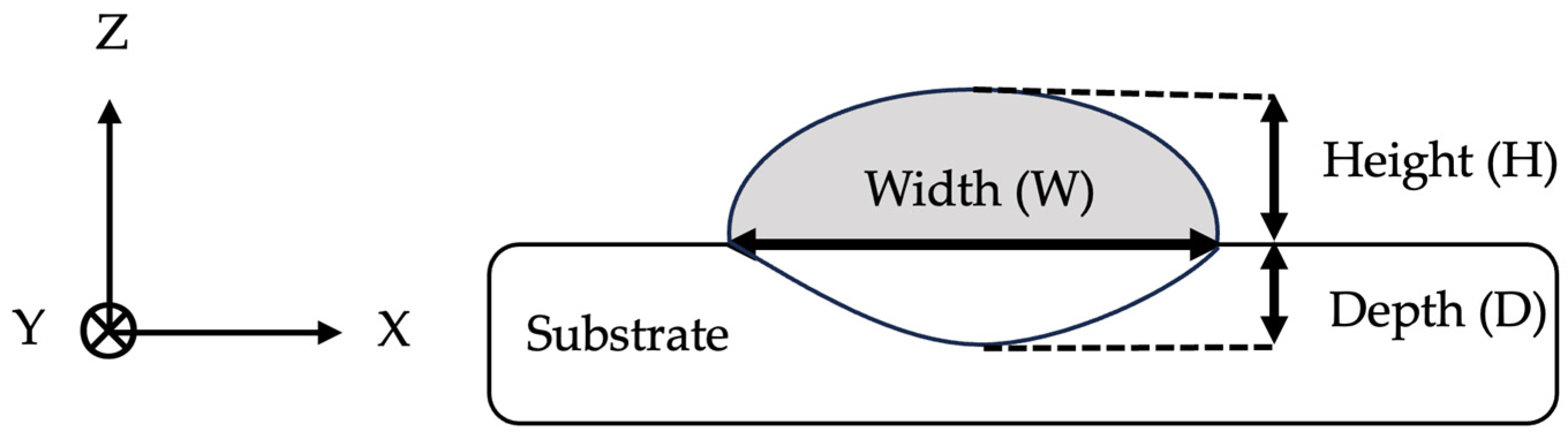

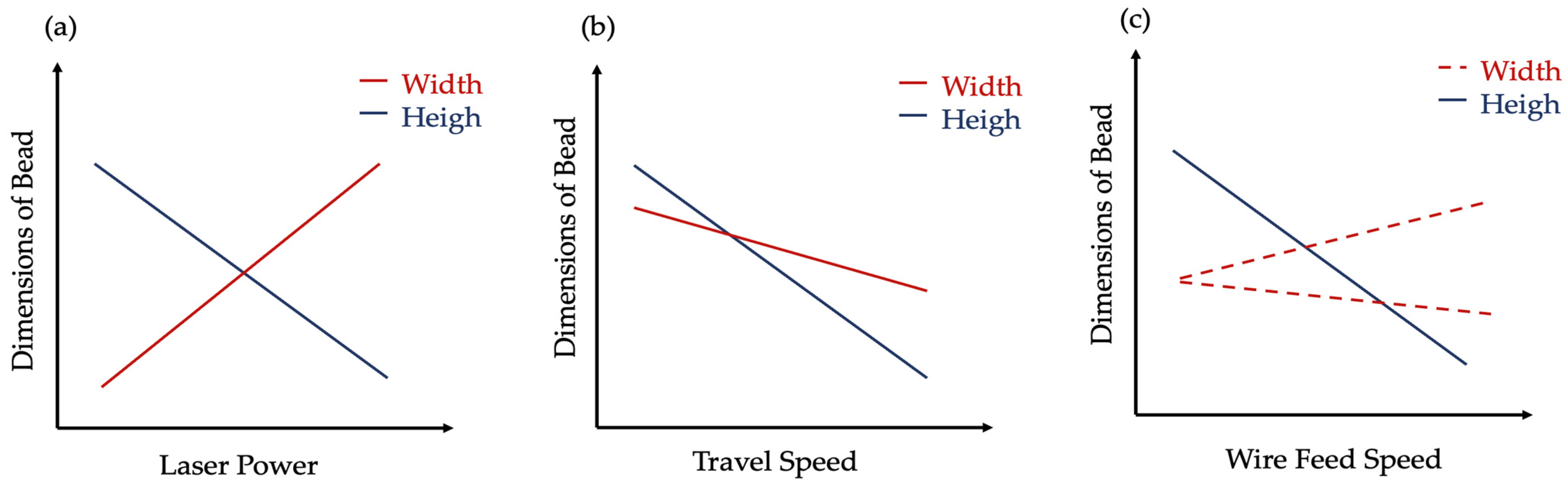

4.1. Beads Characteristics

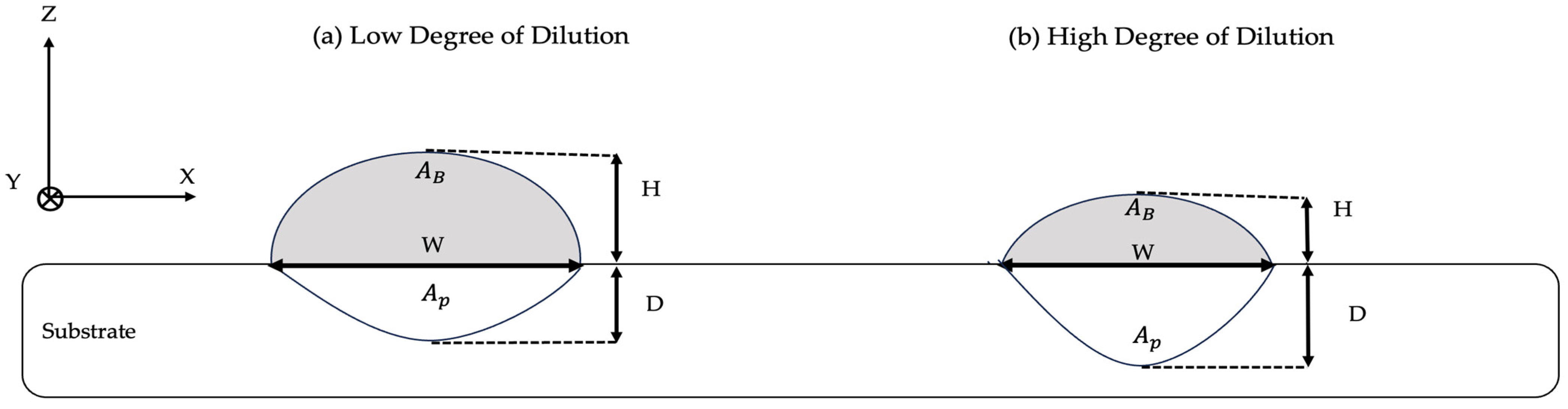

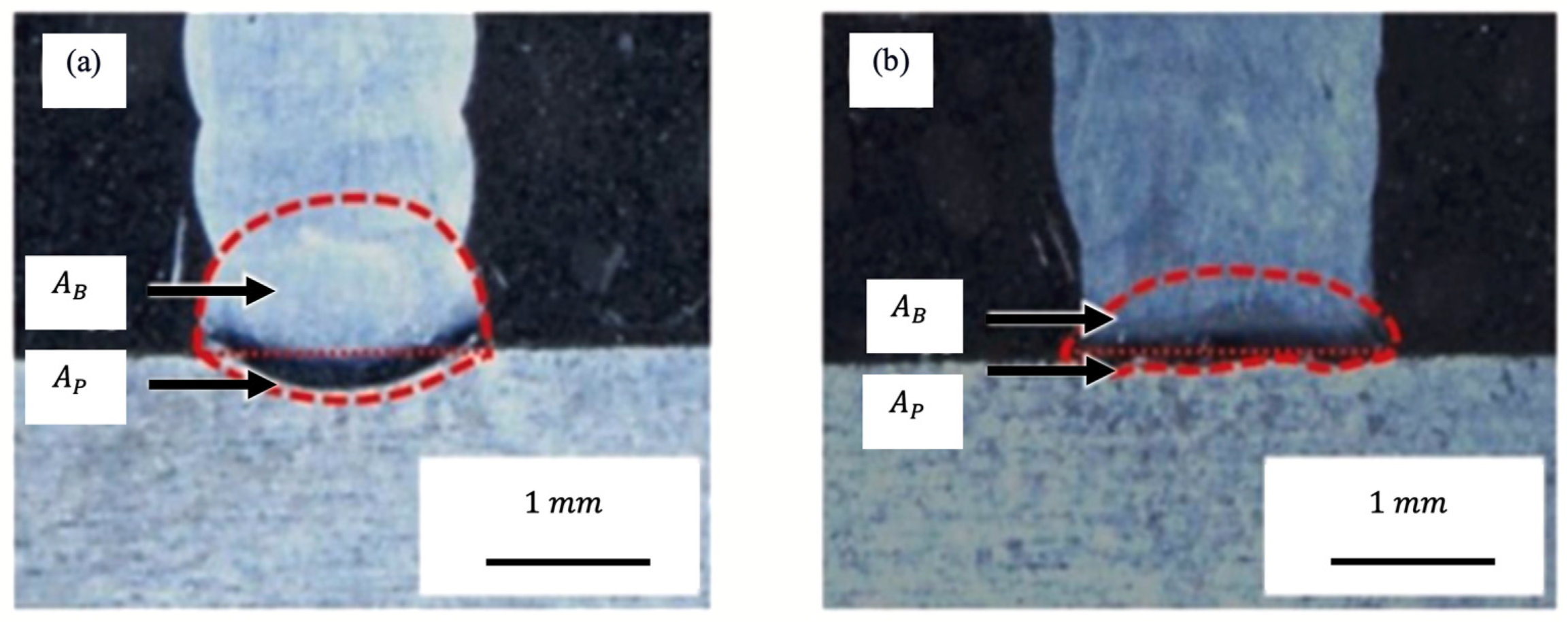

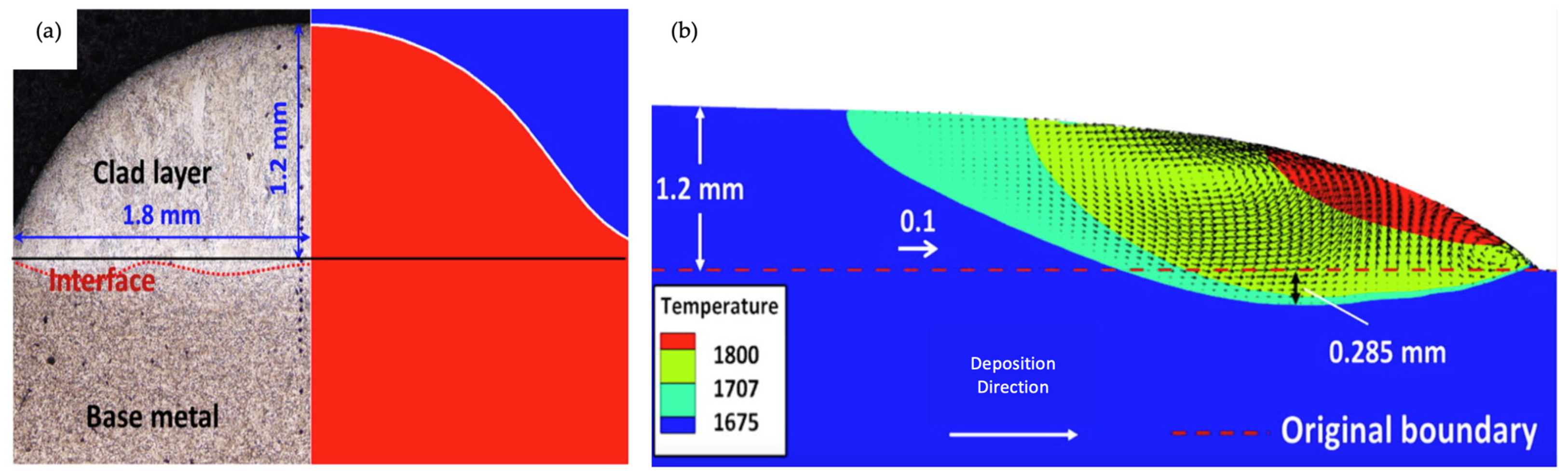

4.1.1. Dilution

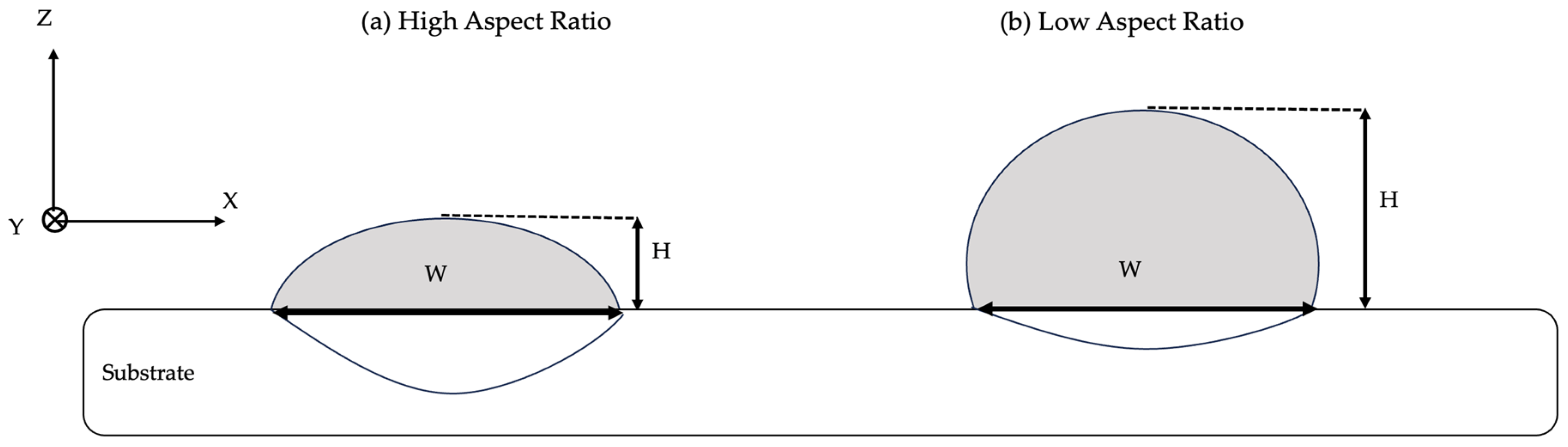

4.1.2. Aspect Ratio

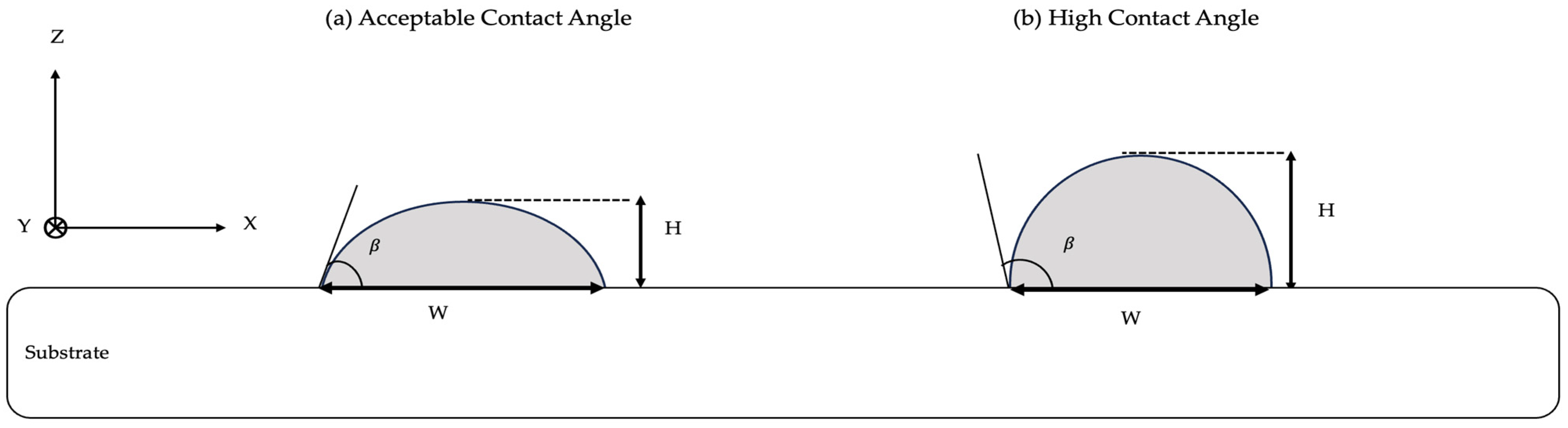

4.1.3. Contact Angle

5. Deposition Stability Analysis

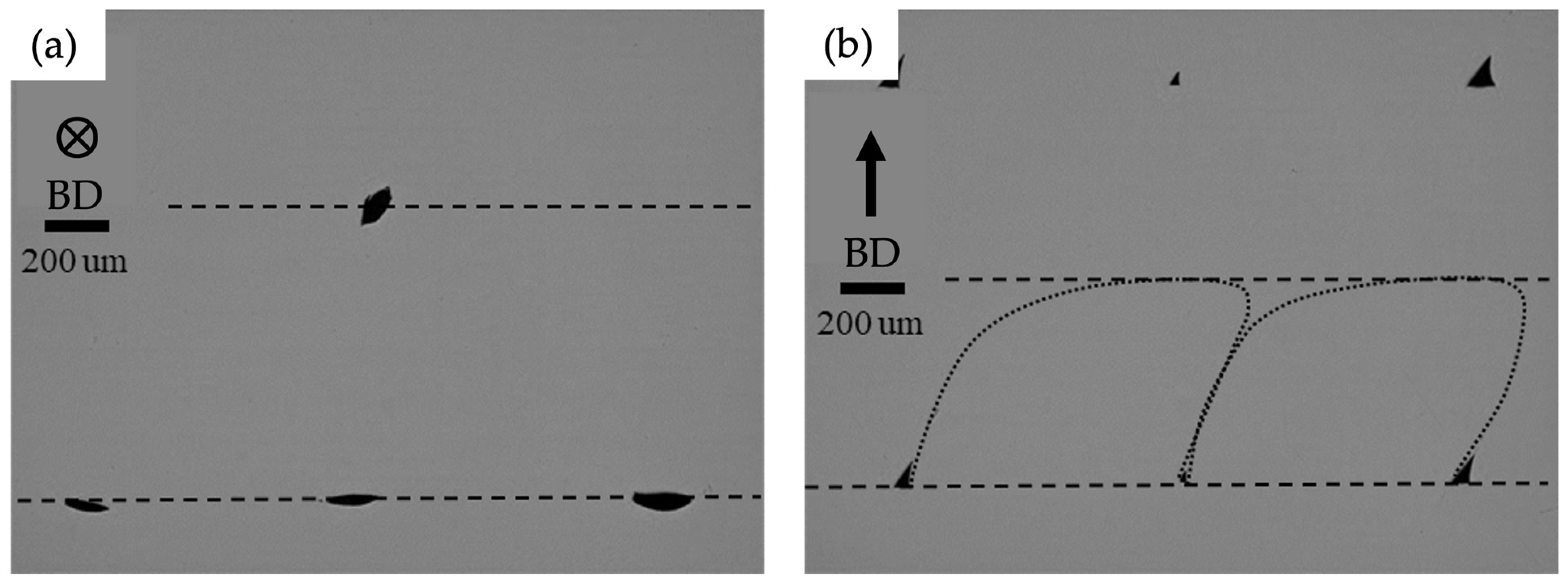

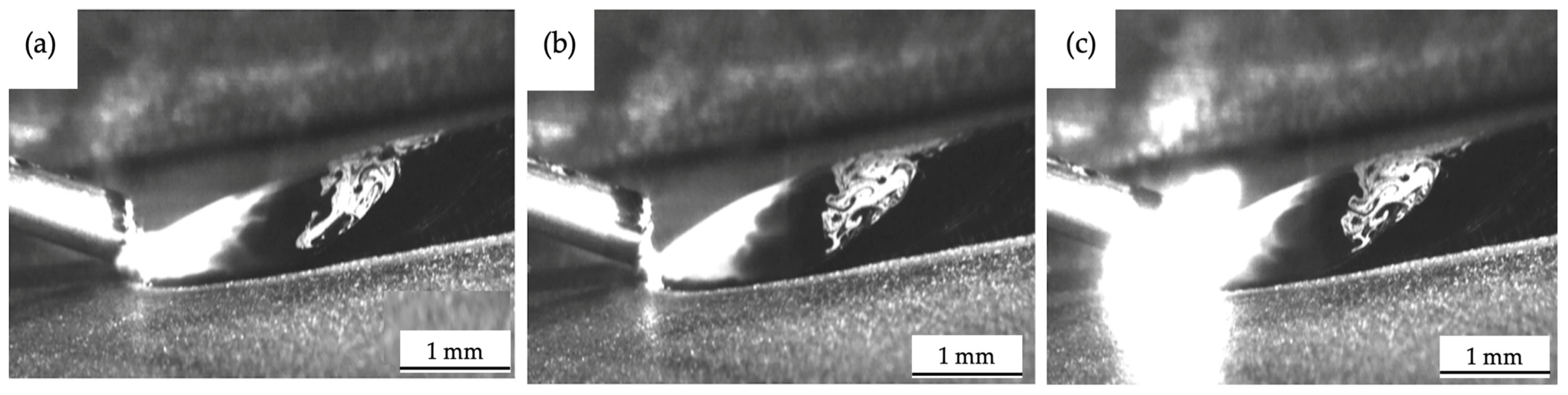

5.1. Single-Track Deposition

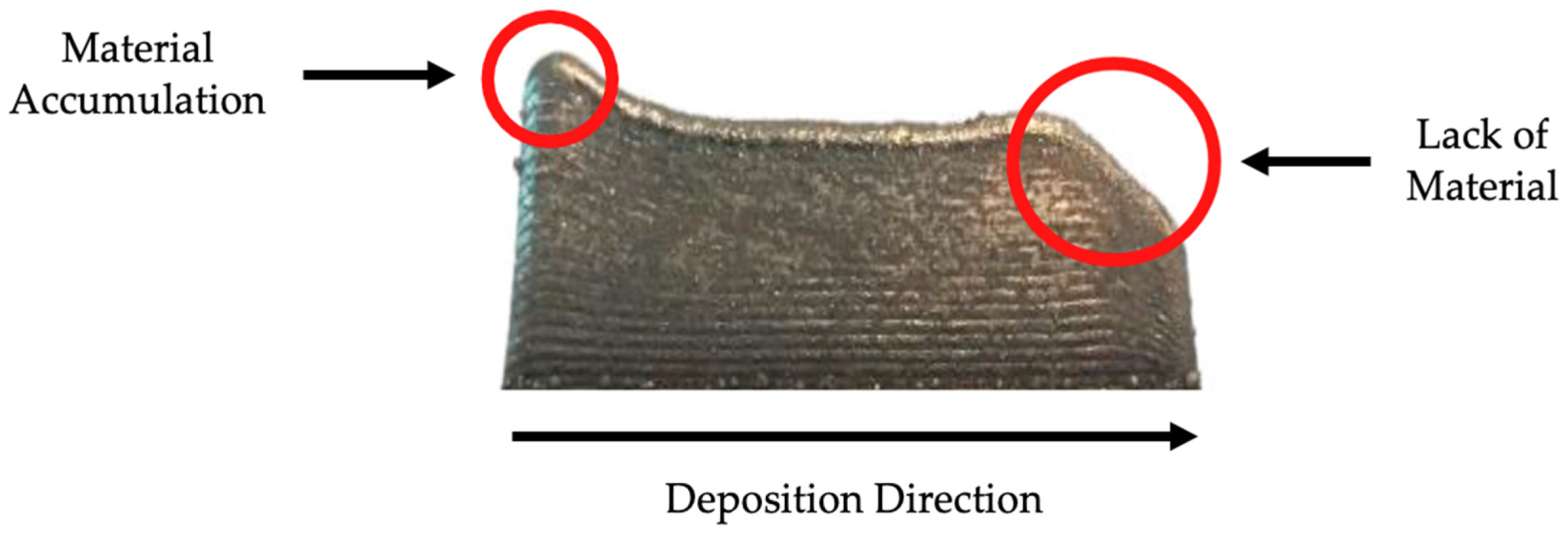

5.2. Multilayer Deposition

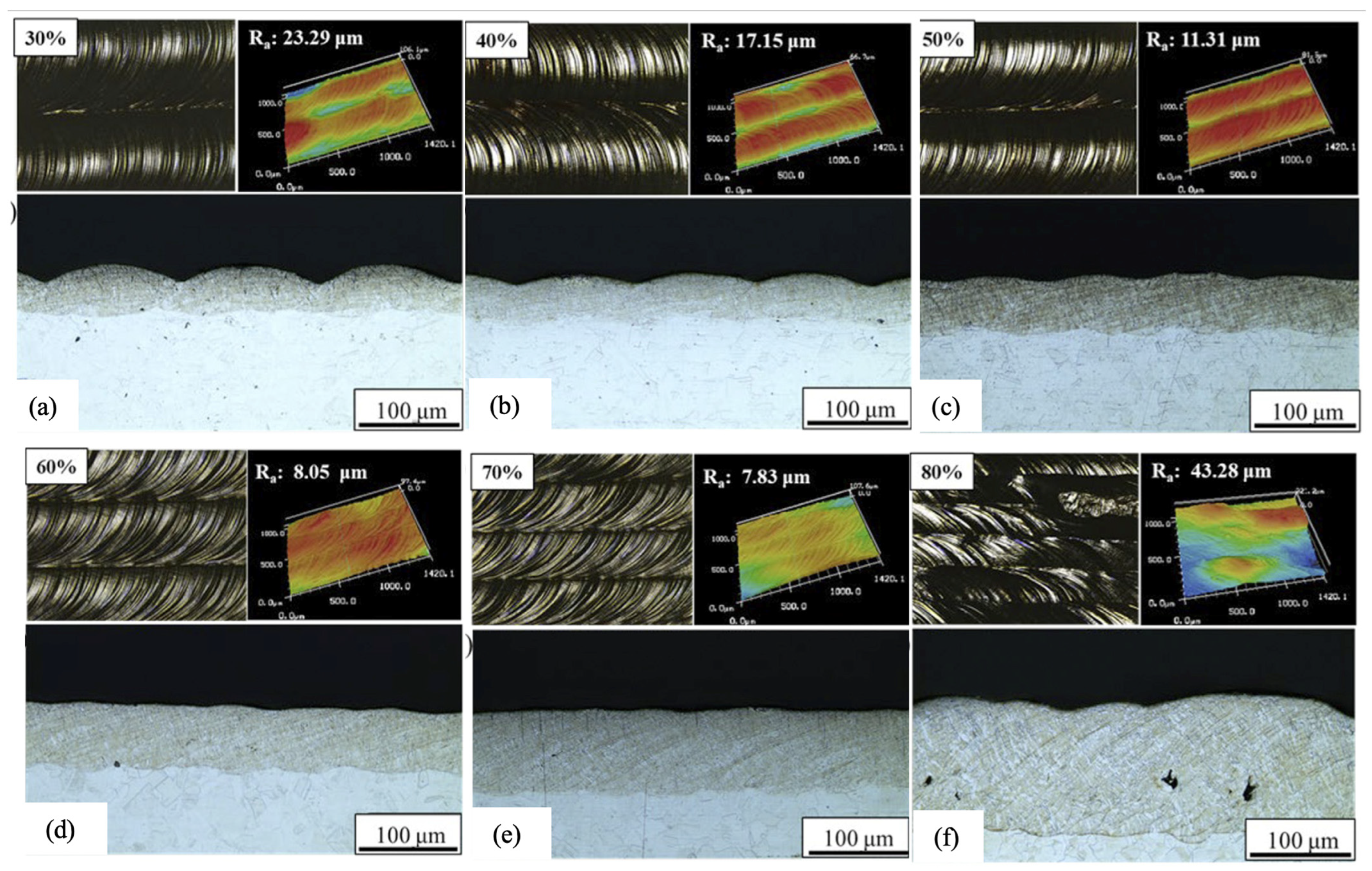

6. Deposition Quality

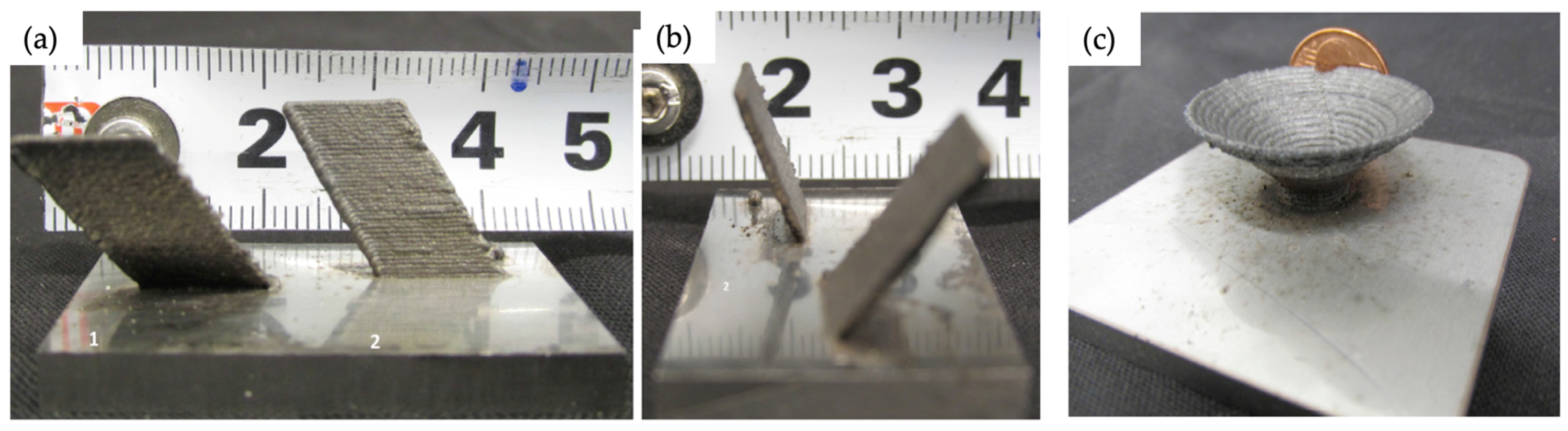

6.1. External Defects

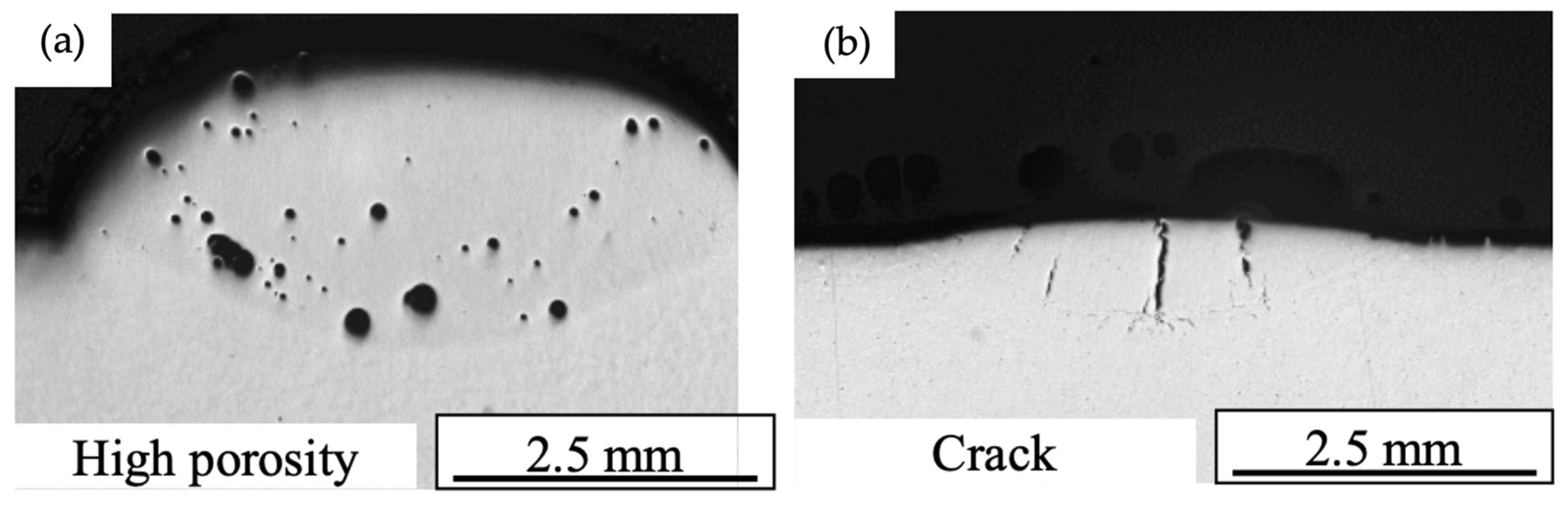

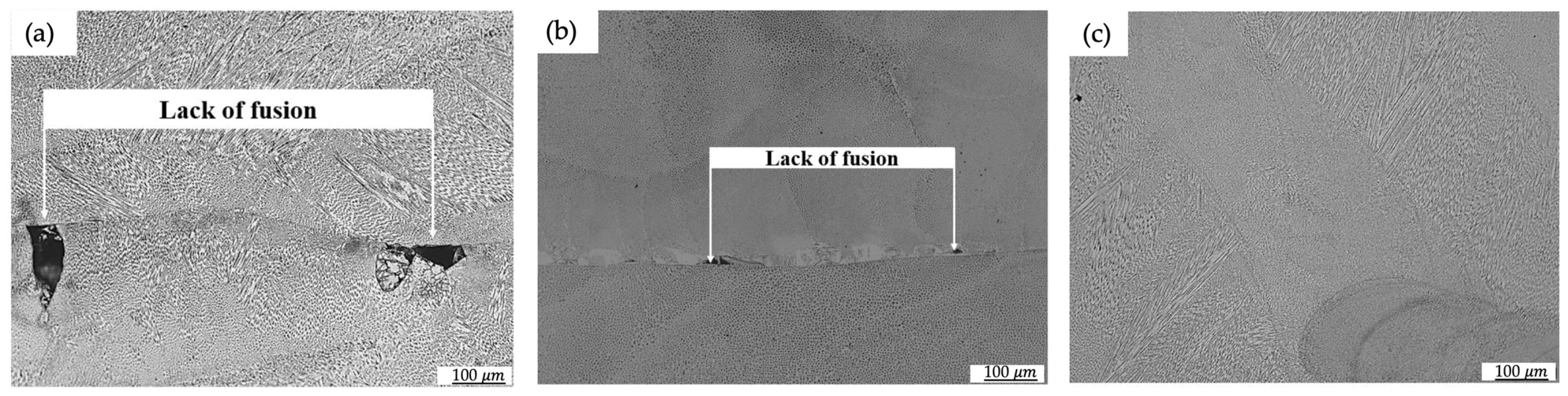

6.2. Internal Defects

7. Deposition Characteristics

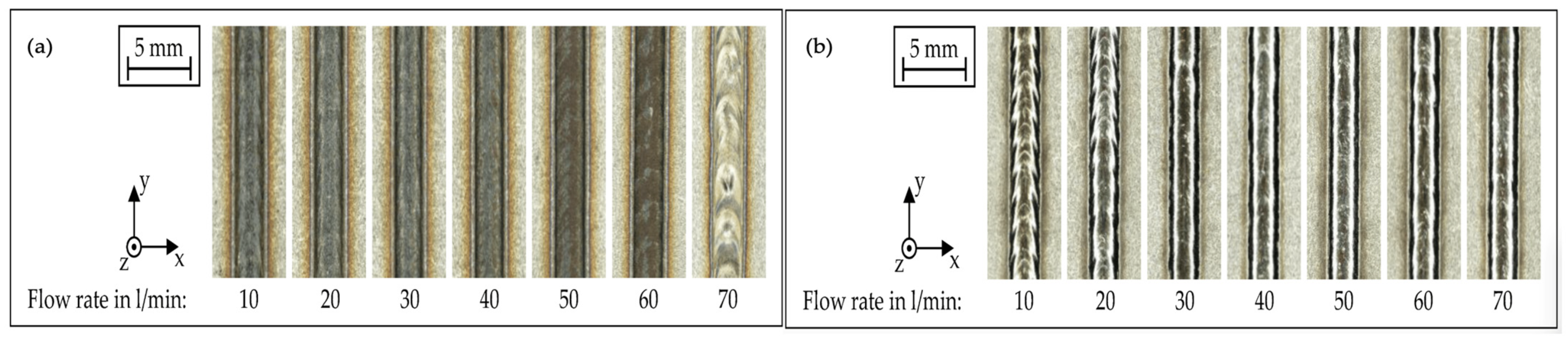

7.1. Shielding Gas

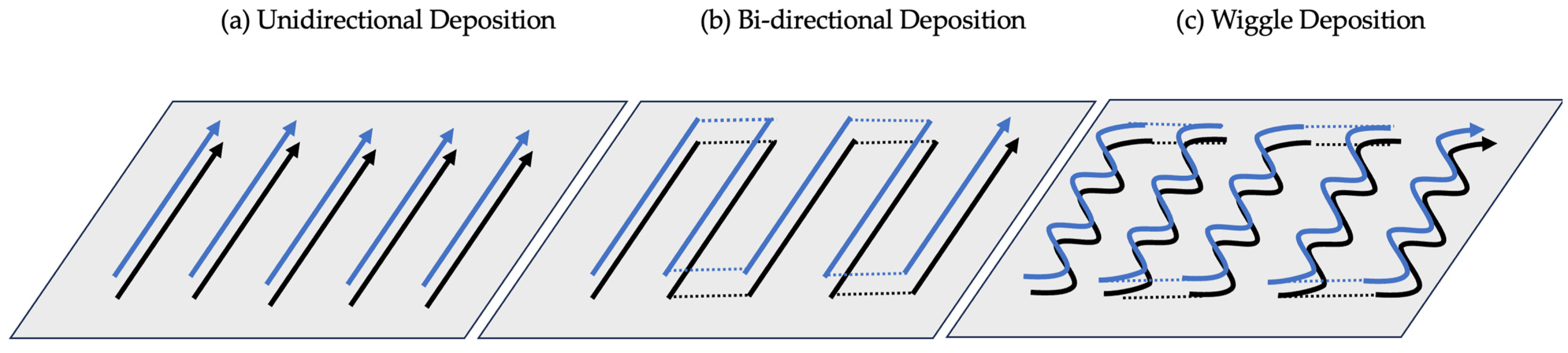

7.2. Scanning Strategy

7.3. Heating the Substrate

7.4. Wire Feeding Temperature

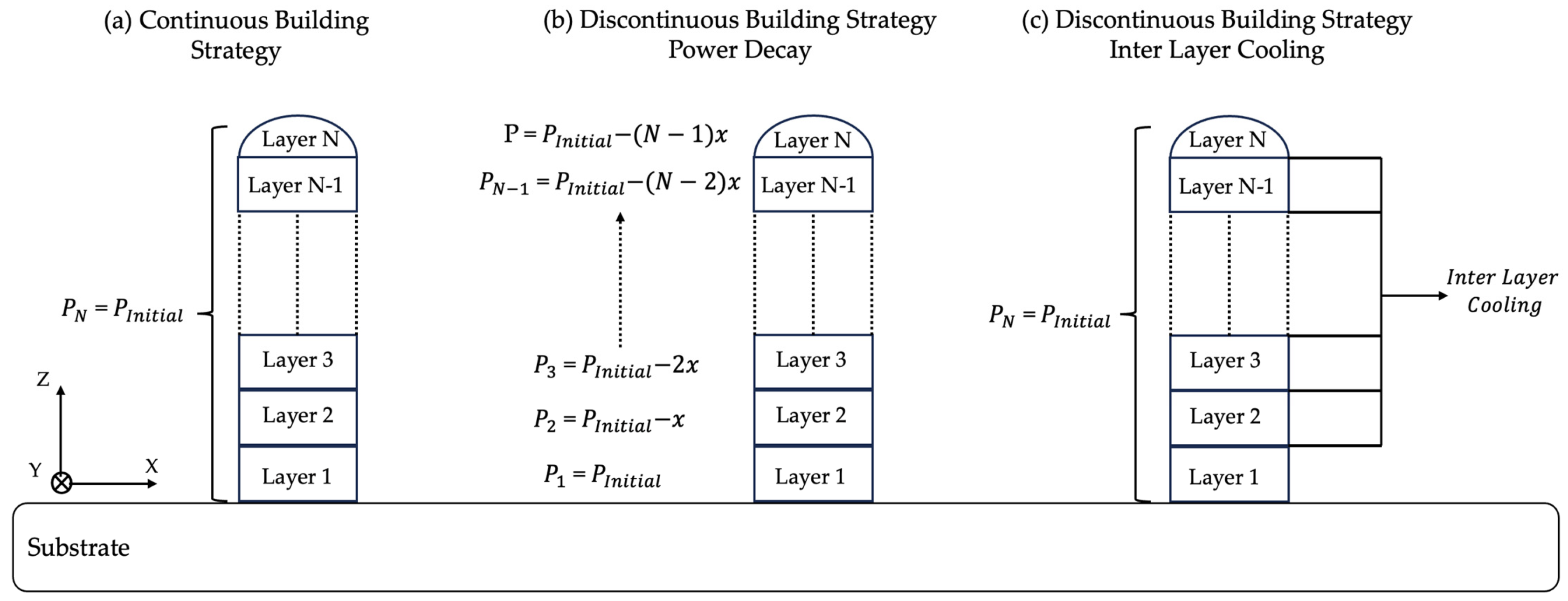

7.5. Building Strategy

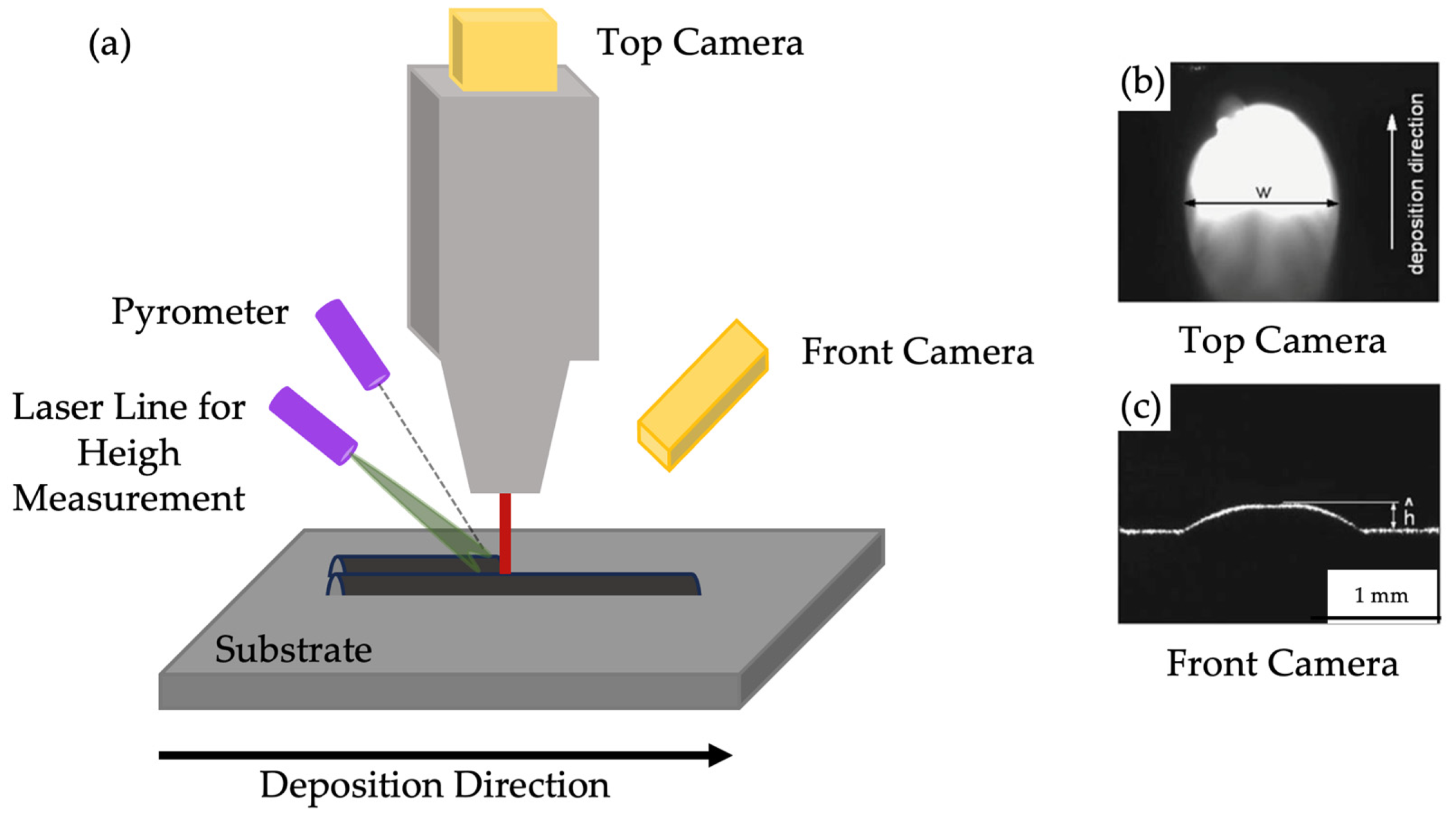

8. Monitoring and Control

9. Modeling and Predicting W-LDED Process

9.1. Numerical Modeling

9.2. Analytical Modeling

9.3. ML Modeling

10. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Taminger, K.M.; Domack, C.S. Challenges in Metal Additive Manufacturing for Large-Scale Aerospace Applications; Springer: Cham, Switzerland, 2020; pp. 105–124. [Google Scholar] [CrossRef]

- Kawalkar, R.; Dubey, H.K.; Lokhande, S.P. A Review for Advancements in Standardization for Additive Manufacturing. Mater. Today Proc. 2022, 50, 1983–1990. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Charalampous, P.; Kostavelis, I.; Tzetzis, D.; Tzovaras, D. Impact of Metal Additive Manufacturing Parameters on the Powder Bed Fusion and Direct Energy Deposition Processes: A Comprehensive Review. Prog. Addit. Manuf. 2021, 6, 349–365. [Google Scholar] [CrossRef]

- Wang, D.; Liu, L.; Deng, G.; Deng, C.; Bai, Y.; Yang, Y.; Wu, W.; Chen, J.; Liu, Y.; Wang, Y.; et al. Recent Progress on Additive Manufacturing of Multi-Material Structures with Laser Powder Bed Fusion. Virtual Phys. Prototyp. 2022, 17, 329–365. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Gibbons, G.; Das, A.; Howes, P.D. A Review of Laser Powder Bed Fusion Additive Manufacturing of Aluminium Alloys: Microstructure and Properties. Addit. Manuf. 2021, 46, 102155. [Google Scholar] [CrossRef]

- Nandy, J.; Sarangi, H.; Sahoo, S. A Review on Direct Metal Laser Sintering: Process Features and Microstructure Modeling. Lasers Manuf. Mater. Process. 2019, 6, 280–316. [Google Scholar] [CrossRef]

- Galati, M.; Iuliano, L. A Literature Review of Powder-Based Electron Beam Melting Focusing on Numerical Simulations. Addit. Manuf. 2018, 19, 1–20. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A Review of Selective Laser Melting of Aluminum Alloys: Processing, Microstructure, Property and Developing Trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning Strategy in Selective Laser Melting (SLM): A Review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar] [CrossRef]

- Ahn, D.G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.A.; Veldhuis, S.C. A Review of Metal Additive Manufacturing Technologies. Solid. State Phenom. 2018, 278, 1–14. [Google Scholar] [CrossRef]

- Fu, R.; Tang, S.; Lu, J.; Cui, Y.; Li, Z.; Zhang, H.; Xu, T.; Chen, Z.; Liu, C. Hot-Wire Arc Additive Manufacturing of Aluminum Alloy with Reduced Porosity and High Deposition Rate. Mater. Des. 2021, 199, 109370. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal Additive Manufacturing in Aerospace: A Review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Mehdiyev, Z.; Felho, C. Metal Additive Manufacturing in Automotive Industry: A Review of Applications, Advantages, and Limitations. Mater. Sci. Forum 2023, 1103, 49–62. [Google Scholar] [CrossRef]

- Tom, T.; Sreenilayam, S.P.; Brabazon, D.; Jose, J.P.; Joseph, B.; Madanan, K.; Thomas, S. Additive Manufacturing in the Biomedical Field-Recent Research Developments. Results Eng. 2022, 16, 100661. [Google Scholar] [CrossRef]

- Li, Z.; Sui, S.; Ma, X.; Tan, H.; Zhong, C.; Bi, G.; Clare, A.T.; Gasser, A.; Chen, J. High Deposition Rate Powder- and Wire-Based Laser Directed Energy Deposition of Metallic Materials: A Review. Int. J. Mach. Tools Manuf. 2022, 181, 103942. [Google Scholar] [CrossRef]

- Yang, S.; Xu, D.; Yan, D.; Albert, M.; Pasebani, S. Additive Manufacturing of ODS Steels Using Powder Feedstock Atomized with Elemental Yttrium. In Proceedings of the 34th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 14–16 August 2023; pp. 1478–1488. [Google Scholar]

- Yang, S.; Pasebani, S. Additive Manufacturing of Austenitic Oxide Dispersion Strengthened Alloy Using Powder Feedstock Gas-Atomized with Elemental Yttrium via Laser Directed Energy Deposition; Oregon State University: Corvallis, OR, USA, 2023. [Google Scholar]

- Liang, Z.; Liao, Z.; Zhang, H.; Li, Z.; Wang, L.; Chang, B.; Du, D. Improving Process Stability of Electron Beam Directed Energy Deposition by Closed-Loop Control of Molten Pool. Addit. Manuf. 2023, 72, 103638. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Vyatskikh, A.; Das, M.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Laser-Based Directed Energy Deposition (DED-LB) of Advanced Materials. Mater. Sci. Eng. A 2022, 840, 142967. [Google Scholar] [CrossRef]

- Rodríguez-González, P.; Neubauer, E.; Ariza, E.; Bolzoni, L.; Gordo, E.; Ruiz-Navas, E.M. Assessment of Plasma Deposition Parameters for DED Additive Manufacturing of AA2319. J. Manuf. Mater. Process. 2023, 7, 113. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A Review on Wire Arc Additive Manufacturing: Monitoring, Control and a Framework of Automated System. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-Feed Additive Manufacturing of Metal Components: Technologies, Developments and Future Interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The Metallurgy and Processing Science of Metal Additive Manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Serjouei, A.; Zolfagharian, A.; Fotouhi, M.; Moradi, M.; Ariffin, M.K.A.; Bodaghi, M. A Review on Additive/Subtractive Hybrid Manufacturing of Directed Energy Deposition (DED) Process. Adv. Powder Mater. 2022, 1, 100054. [Google Scholar] [CrossRef]

- Urhal, P.; Weightman, A.; Diver, C.; Bartolo, P. Robot Assisted Additive Manufacturing: A Review. Robot. Comput. Integr. Manuf. 2019, 59, 335–345. [Google Scholar] [CrossRef]

- Sibisi, P.N.; Popoola, A.P.I.; Arthur, N.K.K.; Pityana, S.L. Review on Direct Metal Laser Deposition Manufacturing Technology for the Ti-6Al-4V Alloy. Int. J. Adv. Manuf. Technol. 2020, 107, 1163–1178. [Google Scholar] [CrossRef]

- Brückner, F.; Nowotny, S.; Leyens, C. Innovations in Laser Cladding and Direct Metal Deposition; Beyer, E., Morris, T., Eds.; SPIE LASE: San Francisco, CA, USA, 2012; p. 823904. [Google Scholar] [CrossRef]

- He, W.; Shi, W.; Li, J.; Xie, H. In-Situ Monitoring and Deformation Characterization by Optical Techniques; Part I: Laser-Aided Direct Metal Deposition for Additive Manufacturing. Opt. Lasers Eng. 2019, 122, 74–88. [Google Scholar] [CrossRef]

- Brooks, H.; Molony, S. Design and Evaluation of Additively Manufactured Parts with Three Dimensional Continuous Fibre Reinforcement. Mater. Des. 2016, 90, 276–283. [Google Scholar] [CrossRef]

- Xu, X.; Mi, G.; Luo, Y.; Jiang, P.; Shao, X.; Wang, C. Morphologies, Microstructures, and Mechanical Properties of Samples Produced Using Laser Metal Deposition with 316 L Stainless Steel Wire. Opt. Lasers Eng. 2017, 94, 1–11. [Google Scholar] [CrossRef]

- Kisielewicz, A.; Thalavai Pandian, K.; Sthen, D.; Hagqvist, P.; Valiente Bermejo, M.A.; Sikström, F.; Ancona, A. Hot-Wire Laser-Directed Energy Deposition: Process Characteristics and Benefits of Resistive Pre-Heating of the Feedstock Wire. Metal 2021, 11, 634. [Google Scholar] [CrossRef]

- Becker, D.; Boley, S.; Eisseler, R.; Stehle, T.; Möhring, H.C.; Onuseit, V.; Hoßfeld, M.; Graf, T. Influence of a Closed-Loop Controlled Laser Metal Wire Deposition Process of S Al 5356 on the Quality of Manufactured Parts before and after Subsequent Machining. Prod. Eng. 2021, 15, 489–507. [Google Scholar] [CrossRef]

- Piscopo, G.; Iuliano, L. Current Research and Industrial Application of Laser Powder Directed Energy Deposition. Int. J. Adv. Manuf. Technol. 2022, 119, 6893–6917. [Google Scholar] [CrossRef]

- Özel, T.; Shokri, H.; Loizeau, R. A Review on Wire-Fed Directed Energy Deposition Based Metal Additive Manufacturing. J. Manuf. Mater. Process. 2023, 7, 45. [Google Scholar] [CrossRef]

- Wasmer, K.; Wüst, M.; Cui, D.; Masinelli, G.; Shevchik, S. Monitoring of Functionally Graded Material during Laser Directed Energy Deposition by Acoustic Emission and Optical Emission Spectroscopy Using Artificial Intelligence. Virtual Phys. Prototyp. 2023, 18, e2189599. [Google Scholar] [CrossRef]

- Nowotny, S.; Scharek, S.; Beyer, E.; Richter, K.-H. Laser Beam Build-Up Welding: Precision in Repair, Surface Cladding, and Direct 3D Metal Deposition. J. Therm. Spray. Technol. 2007, 16, 344–348. [Google Scholar] [CrossRef]

- Gu, H.; Li, L. Computational Fluid Dynamic Simulation of Gravity and Pressure Effects in Laser Metal Deposition for Potential Additive Manufacturing in Space. Int. J. Heat. Mass. Transf. 2019, 140, 51–65. [Google Scholar] [CrossRef]

- Navarro, M.; Matar, A.; Diltemiz, S.F.; Eshraghi, M. Development of a Low-Cost Wire Arc Additive Manufacturing System. J. Manuf. Mater. Process. 2021, 6, 3. [Google Scholar] [CrossRef]

- Xue, P.; Zhu, L.; Xu, P.; Lu, H.; Wang, S.; Yang, Z.; Ning, J.; Sing, S.L.; Ren, Y. Microstructure Evolution and Enhanced Mechanical Properties of Additively Manufactured CrCoNi Medium-Entropy Alloy Composites. J. Alloys Compd. 2022, 928, 167169. [Google Scholar] [CrossRef]

- Abdulrahman, K.O.; Akinlabi, E.T.; Mahamood, R.M.; Pityana, S.; Tlotleng, M. Laser Metal Deposition of Titanium Aluminide Composites: A Review. Mater. Today Proc. 2018, 5, 19738–19746. [Google Scholar] [CrossRef]

- Zhong, C.; Liu, J.; Zhao, T.; Schopphoven, T.; Fu, J.; Gasser, A.; Schleifenbaum, J.H. Laser Metal Deposition of Ti6Al4V—A Brief Review. Appl. Sci. 2020, 10, 764. [Google Scholar] [CrossRef]

- Savinov, R.; Wang, Y.; Shi, J. An Exploratory Study on Biocompatible Ti-6Mn-4Mo Alloy Manufactured by Directed Energy Deposition. Mater. Sci. Addit. Manuf. 2023, 2, 2180. [Google Scholar] [CrossRef]

- Abuabiah, M.; Mbodj, N.G.; Shaqour, B.; Herzallah, L.; Juaidi, A.; Abdallah, R.; Plapper, P. Advancements in Laser Wire-Feed Metal Additive Manufacturing: A Brief Review. Materials 2023, 16, 2030. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Chen, S.; Xiao, J.; Jiang, X.; Jia, Y. Laser Wire-Feed Metal Additive Manufacturing of the Al Alloy. Opt. Laser Technol. 2021, 134, 106627. [Google Scholar] [CrossRef]

- Suresh Kumar, K. Parameter Determination and Experimental Validation of a Wire Parameter Determination and Experimental Validation of a Wire Feed. Additive Manufacturing Model. Feed. Additive Manufacturing Model. 2015. Available online: https://scholarsmine.mst.edu/masters_theseshttps://scholarsmine.mst.edu/masters_theses/7989 (accessed on 20 March 2024).

- Sreekanth, S.; Ghassemali, E.; Hurtig, K.; Joshi, S.; Andersson, J. Effect of Direct Energy Deposition Process Parameters on Single-Track Deposits of Alloy 718. Metal 2020, 10, 96. [Google Scholar] [CrossRef]

- Pinkerton, A.J. Advances in the Modeling of Laser Direct Metal Deposition. J. Laser Appl. 2015, 27, S15001. [Google Scholar] [CrossRef]

- Akbari, M.; Kovacevic, R. Joining of Elements Fabricated by a Robotized Laser/Wire Directed Energy Deposition Process by Using an Autogenous Laser Welding. Int. J. Adv. Manuf. Technol. 2019, 100, 2971–2980. [Google Scholar] [CrossRef]

- Liu, M.; Kumar, A.; Bukkapatnam, S.; Kuttolamadom, M. A Review of the Anomalies in Directed Energy Deposition (DED) Processes & Potential Solutions—Part Quality & Defects. In Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2021; Volume 53, pp. 507–518. [Google Scholar] [CrossRef]

- Ishfaq, K.; Abdullah, M.; Mahmood, M.A. A State-of-the-Art Direct Metal Laser Sintering of Ti6Al4V and AlSi10Mg Alloys: Surface Roughness, Tensile Strength, Fatigue Strength and Microstructure. In Optics and Laser Technology; Elsevier Ltd.: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Kies, F.; Haase, C. Directed Energy Deposition of Inconel 718 Powder, Cold and Hot Wire Using a Six-Beam Direct Diode Laser Set-Up. Addit. Manuf. 2021, 47, 102269. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Gao, N. Influence of Energy Density on Metallurgy and Properties in Metal Additive Manufacturing. Mater. Sci. Technol. 2017, 33, 1269–1289. [Google Scholar] [CrossRef]

- Akbari, M.; Ding, Y.; Kovacevic, R. Process Development for A Robotized Laser Wire Additive Manufacturing. 2017. Available online: http://asmedigitalcollection.asme.org/MSEC/proceedings-pdf/MSEC2017/50732/V002T01A015/2519393/v002t01a015-msec2017-2951.pdf (accessed on 15 March 2024).

- Motta, M.; Demir, A.G.; Previtali, B. High-Speed Imaging and Process Characterization of Coaxial Laser Metal Wire Deposition. Addit. Manuf. 2018, 22, 497–507. [Google Scholar] [CrossRef]

- Abioye, T.E.; Folkes, J.; Clare, A.T. A Parametric Study of Inconel 625 Wire Laser Deposition. J. Mater. Process Technol. 2013, 213, 2145–2151. [Google Scholar] [CrossRef]

- Mamphekgo, T.C.; Maledi, N.; Tshabalala, L.C.; Hagedorn-Hansen, D. The Effects of Laser Wire Directed Energy Deposition Processing Parameters on the Properties of 309L Stainless Steel. MATEC Web Conf. 2023, 388, 05007. [Google Scholar] [CrossRef]

- Mazumder, J.; Schifferer, A.; Choi, J. Direct Materials Deposition: Designed Macro and Microstructure. Mater. Res. Innov. 1999, 3, 118–131. [Google Scholar] [CrossRef]

- Wang, M.; Ventzke, V.; Kashaev, N. Wire-Based Laser Directed Energy Deposition of AA7075: Effect of Process Parameters on Microstructure and Mechanical Properties. J. Mater. Res. Technol. 2022, 21, 388–403. [Google Scholar] [CrossRef]

- Froend, M.; Riekehr, S.; Kashaev, N.; Klusemann, B.; Enz, J. Process Development for Wire-Based Laser Metal Deposition of 5087 Aluminium Alloy by Using Fibre Laser. J. Manuf. Process 2018, 34, 721–732. [Google Scholar] [CrossRef]

- Wang, M.; Kashaev, N. Investigation of Process Window for AA7075 Considering Effects of Different Wire Feed Directions in Lateral Laser Metal Deposition. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2022; Volume 111, pp. 218–223. [Google Scholar] [CrossRef]

- da Silva, A.; Wang, S.; Volpp, J.; Kaplan, A.F.H. Vertical Laser Metal Wire Deposition of Al-Si Alloys. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2020; Volume 94, pp. 341–345. [Google Scholar] [CrossRef]

- Shaikh, M.O.; Chen, C.C.; Chiang, H.C.; Chen, J.R.; Chou, Y.C.; Kuo, T.Y.; Ameyama, K.; Chuang, C.H. Additive Manufacturing Using Fine Wire-Based Laser Metal Deposition. Rapid Prototyp. J. 2020, 26, 473–483. [Google Scholar] [CrossRef]

- Demir, A.G. Micro Laser Metal Wire Deposition for Additive Manufacturing of Thin-Walled Structures. Opt. Lasers Eng. 2018, 100, 9–17. [Google Scholar] [CrossRef]

- Demir, A.G.; Biffi, C.A. Micro Laser Metal Wire Deposition of Thin-Walled Al Alloy Components: Process and Material Characterization. J. Manuf. Process 2019, 37, 362–369. [Google Scholar] [CrossRef]

- Assuncao, E.; Williams, S. Comparison of Continuous Wave and Pulsed Wave Laser Welding Effects. Opt. Lasers Eng. 2013, 51, 674–680. [Google Scholar] [CrossRef]

- Fuerschbach, P.W.; Eisler, G.R. Effect of Laser Spot Weld Energy and Duration on Melting and Absorption. Sci. Technol. Weld. Join. 2002, 7, 241–246. [Google Scholar] [CrossRef]

- Ye, Z.P.; Zhang, Z.J.; Jin, X.; Xiao, M.Z.; Su, J.Z. Study of Hybrid Additive Manufacturing Based on Pulse Laser Wire Depositing and Milling. Int. J. Adv. Manuf. Technol. 2017, 88, 2237–2248. [Google Scholar] [CrossRef]

- Medrano, A.; Folkes, J.; Segal, J.; Pashby, I. Fibre Laser Metal Deposition with Wire: Parameters Study and Temperature Monitoring System; SPIE: Washington, DC, USA, 2008; p. 713122. [Google Scholar] [CrossRef]

- Shi, J.; Zhu, P.; Fu, G.; Shi, S. Geometry Characteristics Modeling and Process Optimization in Coaxial Laser inside Wire Cladding. Opt. Laser Technol. 2018, 101, 341–348. [Google Scholar] [CrossRef]

- Gao, L.; Chuang, A.C.; Kenesei, P.; Ren, Z.; Balderson, L.; Sun, T. An Operando Synchrotron Study on the Effect of Wire Melting State on Solidification Microstructures of Inconel 718 in Wire-Laser Directed Energy Deposition. Int. J. Mach. Tools Manuf. 2024, 194, 104089. [Google Scholar] [CrossRef]

- Valentin, M.; Arnaud, C.; Kling, R. Additive Manufacturing by Wire Based Laser Metal Deposition; SPIE LASE: San Francisco, CA, USA, 2019. [Google Scholar]

- Liu, X.; Wang, H.; Kaufmann, K.; Vecchio, K. Directed Energy Deposition of Pure Copper Using Blue Laser. J. Manuf. Process 2023, 85, 314–322. [Google Scholar] [CrossRef]

- Wang, A.; Wei, Q.; Tang, Z.; Ren, P.; Zhang, X.; Wu, Y.; Wang, H.; Du Plessis, A.; Huang, J.; Hu, K.; et al. Effects of Processing Parameters on Pore Defects in Blue Laser Directed Energy Deposition of Aluminum by in and Ex Situ Observation. J. Mater. Process Technol. 2023, 319, 118068. [Google Scholar] [CrossRef]

- Tang, Z.; Wei, Q.; Gao, Z.; Yang, H.; Wang, A.; Wan, L.; Luo, C.; Wu, Y.; Wang, H.; Wang, H. 2000W Blue Laser Directed Energy Deposition of AlSi7Mg: Process Parameters, Molten Pool Characteristics, and Appearance Defects. Virtual Phys. Prototyp. 2023, 18, e2120405. [Google Scholar] [CrossRef]

- Govekar, E.; Jeromen, A.; Kuznetsov, A.; Levy, G.; Fujishima, M. Study of an Annular Laser Beam Based Axially-Fed Powder Cladding Process. CIRP Ann. 2018, 67, 241–244. [Google Scholar] [CrossRef]

- Govekar, E.; Kuznetsov, A.; Jerič, A. Drop on Demand Generation from a Metal Wire by Means of an Annular Laser Beam. J. Mater. Process Technol. 2016, 227, 59–70. [Google Scholar] [CrossRef]

- Kotar, M.; Govekar, E. The Influence of the Workpiece Illumination Proportion in Annular Laser Beam Wire Deposition Process. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 74, pp. 228–232. [Google Scholar] [CrossRef]

- Kotar, M.; Fujishima, M.; Levy, G.; Govekar, E. Initial Transient Phase and Stability of Annular Laser Beam Direct Wire Deposition. CIRP Ann. 2019, 68, 233–236. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, Y.; Wang, H.; Shi, T.; Su, B.; Zhang, L. Effect of Annular Laser Metal Deposition (ALMD) Process Parameters on Track Geometry and Thermal History on Ti6Al4V Alloy Clad. Materials 2023, 16, 4062. [Google Scholar] [CrossRef] [PubMed]

- Froend, M.; Ventzke, V.; Kashaev, N.; Klusemann, B.; Enz, J. Thermal Analysis of Wire-Based Direct Energy Deposition of Al-Mg Using Different Laser Irradiances. Addit. Manuf. 2019, 29, 100800. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, X.; Jiang, M.; Lei, Z.; Wang, Z.; Liang, J.; Wu, S.; Ma, S.; Jiang, N.; Chen, Y. Coaxial Laser Metal Wire Deposition of Ti6Al4V Alloy: Process, Microstructure and Mechanical Properties. J. Mater. Res. Technol. 2022, 20, 2578–2590. [Google Scholar] [CrossRef]

- Kotar, M.; Fujishima, M.; Levy, G.N.; Govekar, E. Advances in the Understanding of the Annular Laser Beam Wire Cladding Process. J. Mater. Process Technol. 2021, 294, 117105. [Google Scholar] [CrossRef]

- Goffin, N.J.; Higginson, R.L.; Tyrer, J.R. The Use of Holographic Optical Elements (HOE’s) to Investigate the Use of a Flat Irradiance Profile in the Control of Heat Absorption in Wire-Fed Laser Cladding. J. Mater. Process. Technol. 2015, 220, 191–201. [Google Scholar] [CrossRef]

- Goffin, N.; Tyrer, J.R.; Jones, L.C.R.; Higginson, R.L. Simulated and Experimental Analysis of Laser Beam Energy Profiles to Improve Efficiency in Wire-Fed Laser Deposition. Int. J. Adv. Manuf. Technol. 2021, 114, 3021–3036. [Google Scholar] [CrossRef]

- Kell, J.; Tyrer, J.R.; Higginson, R.L.; Jones, J.C.; Noden, S. Laser Weld Pool Management through Diffractive Holographic Optics. Mater. Sci. Technol. 2012, 28, 354–363. [Google Scholar] [CrossRef]

- Madarieta-Churruca, M.; Pujana-Astarloa, J.; Garmendia-Saez-De-Heredia, I.; Leunda-Arrizabalaga, J. Additive Manufacturing of Metal Components Using Concentric-Wire Laser Metal Deposition. Dyna 2018, 93, 675–680. [Google Scholar] [CrossRef]

- Capello, E.; Previtali, B. The Influence of Operator Skills, Process Parameters and Materials on Clad Shape in Repair Using Laser Cladding by Wire. J. Mater. Process Technol. 2006, 174, 223–232. [Google Scholar] [CrossRef]

- Froend, M.; Ventzke, V.; Riekehr, S.; Kashaev, N.; Klusemann, B.; Enz, J. Microstructure and Microhardness of Wire-Based Laser Metal Deposited AA5087 Using an Ytterbium Fibre Laser. Mater. Charact. 2018, 143, 59–67. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An Overview of Direct Laser Deposition for Additive Manufacturing; Part I: Transport Phenomena, Modeling and Diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Hu, R.; Luo, M.; Liu, T.; Liang, L.; Huang, A.; Trushnikov, D.; Karunakaran, K.P.; Pang, S. Thermal Fluid Dynamics of Liquid Bridge Transfer in Laser Wire Deposition 3D Printing. Sci. Technol. Weld. Join. 2019, 24, 401–411. [Google Scholar] [CrossRef]

- Gonnabattula, A.; Thanumoorthy, R.S.; Bontha, S.; Balan, A.S.S.; Kumar, V.A.; Kanjarla, A.K. Process Parameter Optimization for Laser Directed Energy Deposition (LDED) of Ti6Al4V Using Single-Track Experiments with Small Laser Spot Size. Opt. Laser Technol. 2024, 175, 110861. [Google Scholar] [CrossRef]

- Odermatt, A.E.; Dorn, F.; Ventzke, V.; Kashaev, N. Coaxial Laser Directed Energy Deposition with Wire of Thin-Walled Duplex Stainless Steel Parts: Process Discontinuities and Their Impact on the Mechanical Properties. CIRP J. Manuf. Sci. Technol. 2022, 37, 443–453. [Google Scholar] [CrossRef]

- Fu, Y.; Demir, A.G.; Guo, N. Additive Manufacturing of Ti-6Al-4V Alloy by Micro-Laser Metal Wire Deposition with Pulsed Wave Emission: Processability and Microstructure Formation. Int. J. Adv. Manuf. Technol. 2023, 126, 2693–2711. [Google Scholar] [CrossRef]

- Hagqvist, P.; Heralić, A.; Christiansson, A.K.; Lennartson, B. Resistance Measurements for Control of Laser Metal Wire Deposition. Opt. Lasers Eng. 2014, 54, 62–67. [Google Scholar] [CrossRef]

- Takushima, S.; Morita, D.; Shinohara, N.; Kawano, H.; Mizutani, Y.; Takaya, Y. Optical In-Process Height Measurement System for Process Control of Laser Metal-Wire Deposition. Precis. Eng. 2020, 62, 23–29. [Google Scholar] [CrossRef]

- Liu, W.; Ma, J.; Liu, S.; Kovacevic, R. Experimental and Numerical Investigation of Laser Hot Wire Welding. Int. J. Adv. Manuf. Technol. 2015, 78, 1485–1499. [Google Scholar] [CrossRef]

- Ji, S.; Liu, F.; Shi, T.; Fu, G.; Shi, S. Effects of Defocus Distance on Three-Beam Laser Internal Coaxial Wire Cladding. Chin. J. Mech. Eng. 2021, 34, 45. [Google Scholar] [CrossRef]

- Valiente Bermejo, M.A.; Thalavai Pandian, K.; Axelsson, B.; Harati, E.; Kisielewicz, A.; Karlsson, L. Microstructure of Laser Metal Deposited Duplex Stainless Steel: Influence of Shielding Gas and Heat Treatment. Weld. World 2021, 65, 525–541. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Cao, X.; Wanjara, P. Microstructure and Hardness of Fiber Laser Deposited Inconel 718 Using Filler Wire. Int. J. Adv. Manuf. Technol. 2013, 69, 2569–2581. [Google Scholar] [CrossRef]

- Mathenia, R.; Flood, A.; McLain, B.; Sparks, T.; Liou, F. Effects of Laser Defocusing on Bead Geometry in Coaxial Titanium Wire-Based Laser Metal Deposition. Materials 2024, 17, 889. [Google Scholar] [CrossRef]

- Kim, J.-D.; Peng, Y. Melt Pool Shape and Dilution of Laser Cladding with Wire Feeding. J. Mater. Process. Technol. 2000, 104, 284–293. [Google Scholar] [CrossRef]

- Hussein, N.I.S.; Segal, J.; McCartney, D.G.; Pashby, I.R. Microstructure Formation in Waspaloy Multilayer Builds Following Direct Metal Deposition with Laser and Wire. Mater. Sci. Eng. A 2008, 497, 260–269. [Google Scholar] [CrossRef]

- Hu, Y.; Hua, Z.; Mi, G.; Zhang, M.; Liu, Z.; Zhang, X.; Yan, X.; Wang, C. Investigation on the Evolution of Deposition Layer Grain Structure and Its Effect on Mechanical Properties in Aluminum Alloy Fabricated by Laser Directed Energy Deposition. Mater. Sci. Eng. A 2024, 892, 145866. [Google Scholar] [CrossRef]

- Heralic, A.; Christiansson, A.K.; Hurtig, K.; Ottosson, M.; Lennartson, B. Control Design for Automation of Robotized Laser Metal-Wire Deposition. IFAC Proc. Vol. 2008, 41, 14785–14791. [Google Scholar] [CrossRef]

- Zhu, S.; Nakahara, Y.; Yamamoto, M. Optimization of Process Conditions for Additive Manufacturing Technology Combining High-Power Diode Laser and Hot Wire. Metal 2021, 11, 1583. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V. Directed Energy Deposition of Stainless Steel Wire with Laser Beam: Evaluation of Geometry and Affection Depth. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2021; Volume 99, pp. 348–351. [Google Scholar] [CrossRef]

- Zapata, A.; Bernauer, C.; Stadter, C.; Kolb, C.G.; Zaeh, M.F. Investigation on the Cause-Effect Relationships between the Process Parameters and the Resulting Geometric Properties for Wire-Based Coaxial Laser Metal Deposition. Metal 2022, 12, 455. [Google Scholar] [CrossRef]

- Heralić, A.; Christiansson, A.K.; Lennartson, B. Height Control of Laser Metal-Wire Deposition Based on Iterative Learning Control and 3D Scanning. Opt. Lasers Eng. 2012, 50, 1230–1241. [Google Scholar] [CrossRef]

- Abioye, T.E.; Medrano-Tellez, A.; Farayibi, P.K.; Oke, P.K. Laser Metal Deposition of Multi-Track Walls of 308LSi Stainless Steel. Mater. Manuf. Process. 2017, 32, 1660–1666. [Google Scholar] [CrossRef]

- Mok, S.H.; Bi, G.; Folkes, J.; Pashby, I. Deposition of Ti-6Al-4V Using a High Power Diode Laser and Wire, Part I: Investigation on the Process Characteristics. Surf. Coat. Technol. 2008, 202, 3933–3939. [Google Scholar] [CrossRef]

- Brandl, E.; Schoberth, A.; Leyens, C. Morphology, Microstructure, and Hardness of Titanium (Ti-6Al-4V) Blocks Deposited by Wire-Feed Additive Layer Manufacturing (ALM). Mater. Sci. Eng. A 2012, 532, 295–307. [Google Scholar] [CrossRef]

- Syed, W.U.H.; Li, L. Effects of Wire Feeding Direction and Location in Multiple Layer Diode Laser Direct Metal Deposition. In Applied Surface Science; Elsevier: Amsterdam, The Netherlands, 2005; Volume 248, pp. 518–524. [Google Scholar] [CrossRef]

- Xiao, R.; Chen, K.; Zuo, T.; Ambrosy, G.; Huegel, H. Influence of Wire Addition Direction in CO2 Laser Welding of Aluminum; Deng, S., Okada, T., Behler, K., Wang, X., Eds.; Photonics Asia: Shanghai, China, 2002; p. 128. [Google Scholar] [CrossRef]

- Li, J.; Li, H.N.; Liao, Z.; Axinte, D. Analytical Modelling of Full Single-Track Profile in Wire-Fed Laser Cladding. J. Mater. Process Technol. 2021, 290, 116978. [Google Scholar] [CrossRef]

- Gao, L.; Bhattacharyya, J.; Lin, W.; Ren, Z.; Chuang, A.C.; Shevchenko, P.D.; Nikitin, V.; Ma, J.; Agnew, S.R.; Sun, T. Tailoring Material Microstructure and Property in Wire-Laser Directed Energy Deposition through a Wiggle Deposition Strategy. Addit. Manuf. 2023, 77, 103801. [Google Scholar] [CrossRef]

- Zhou, Y.; Ning, F. Directed Energy Deposition With Coaxial Wire-Powder Feeding: Melt Pool Temperature and Microstructure. J. Manuf. Sci. Eng. 2023, 145, 081004. [Google Scholar] [CrossRef]

- Yuan, D.; Sun, X.; Sun, L.; Zhang, Z.; Guo, C.; Wang, J.; Jiang, F. Improvement of the Grain Structure and Mechanical Properties of Austenitic Stainless Steel Fabricated by Laser and Wire Additive Manufacturing Assisted with Ultrasonic Vibration. Mater. Sci. Eng. A 2021, 813, 141177. [Google Scholar] [CrossRef]

- Pütsch, O.; Gasser, A.; Biber, A.; Kelbassa, J.; Wissenbach, K.; Loosten, P.; Schleifenbaum, J.H. Influence of Focal Length on the Laser Metal Deposition Process with Coaxial Wire Feeding. In High-Power Laser Materials Processing: Applications, Diagnostics, and Systems VIII; Kaierle, S., Heinemann, S.W., Eds.; SPIE: Washington, DC, USA, 2019; p. 11. [Google Scholar] [CrossRef]

- Zapata, A.; Zhao, X.F.; Li, S.; Bernauer, C.; Zaeh, M.F. Three-Dimensional Annular Heat Source for the Thermal Simulation of Coaxial Laser Metal Deposition with Wire. J. Laser Appl. 2023, 35, 012020. [Google Scholar] [CrossRef]

- Bernauer, C.; Sigl, M.E.; Grabmann, S.; Merk, T.; Zapata, A.; Zaeh, M.F. Effects of the Thermal History on the Microstructural and the Mechanical Properties of Stainless Steel 316L Parts Produced by Wire-Based Laser Metal Deposition. Mater. Sci. Eng. A 2024, 889, 145862. [Google Scholar] [CrossRef]

- Steiner, M.F.; Speier, M.; Kelbassa, J.; Schopphoven, T.; Häfner, C.L. Influence of Tool Path Planning on Process Stability and Deposition Accuracy in Laser Material Deposition with Coaxial Wire Feed. J. Laser Appl. 2022, 34, 012026. [Google Scholar] [CrossRef]

- Bernauer, C.; Zapata, A.; Zaeh, M.F. Toward Defect-Free Components in Laser Metal Deposition with Coaxial Wire Feeding through Closed-Loop Control of the Melt Pool Temperature. J. Laser Appl. 2022, 34, 042044. [Google Scholar] [CrossRef]

- Bernauer, C.; Merk, T.; Zapata, A.; Zaeh, M.F. Laser Metal Deposition with Coaxial Wire Feeding for the Automated and Reliable Build-Up of Solid Metal Parts. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2022; Volume 926, pp. 65–79. [Google Scholar] [CrossRef]

- Garmendia, I.; Pujana, J.; Lamikiz, A.; Madarieta, M.; Leunda, J. Structured Light-Based Height Control for Laser Metal Deposition. J. Manuf. Process 2019, 42, 20–27. [Google Scholar] [CrossRef]

- Zapata, A.; Bernauer, C.; Hell, M.; Kriz, H.; Zaeh, M.F. Direction-Independent Temperature Monitoring for Laser Metal Deposition with Coaxial Wire Feeding. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2022; Volume 111, pp. 302–307. [Google Scholar] [CrossRef]

- Li, J.; Li, H.N.; Liao, Z.; Axinte, D. Overlapped Wire-Fed Laser Cladding on Inclined Surfaces: An Analytical Model Considering Gravity and a Model Application. J. Mater. Process Technol. 2022, 304, 117559. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Klocke, F.; Klingbeil, N.; Arntz, K.; Lamikiz, A.; Martinez, S. Evaluation of Efficiency and Mechanical Properties of Inconel 718 Components Built by Wire and Powder Laser Material Deposition. Rapid Prototyp. J. 2017, 23, 965–972. [Google Scholar] [CrossRef]

- Caiazzo, F. Additive Manufacturing by Means of Laser-Aided Directed Metal Deposition of Titanium Wire. Int. J. Adv. Manuf. Technol. 2018, 96, 2699–2707. [Google Scholar] [CrossRef]

- Brandl, E.; Michailov, V.; Viehweger, B.; Leyens, C. Deposition of Ti-6Al-4V Using Laser and Wire, Part II: Hardness and Dimensions of Single Beads. Surf. Coat. Technol. 2011, 206, 1130–1141. [Google Scholar] [CrossRef]

- Preis, J.; Xu, D.; Paul, B.K.; Eschbach, P.A.; Pasebani, S. Effect of Liquid Miscibility Gap on Defects in Inconel 625–GRCop42 Joints through Analysis of Gradient Composition Microstructure. J. Manuf. Mater. Process. 2024, 8, 42. [Google Scholar] [CrossRef]

- Su, L.; Xu, T.; Ma, X.; Mi, G.; Wang, L. Study on the Effect of ZrC and CNTs Particles on Inconel 625 Coatings Fabricated by Coaxial-Wire-Feed Laser Cladding. J. Mater. Res. Technol. 2024, 29, 3934–3945. [Google Scholar] [CrossRef]

- Bernauer, C.J.; Zapata, A.; Kick, L.; Weiss, T.; Sigl, M.E.; Zaeh, M.F. Pyrometry-Based Closed-Loop Control of the Melt Pool Temperature in Laser Metal Deposition with Coaxial Wire Feeding. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2022; Volume 111, pp. 296–301. [Google Scholar] [CrossRef]

- Liu, F.; Ji, S.S.; Shi, T.; Wan, L.; Shi, S.H.; Fu, G.Y. Parametric Study of the Three-Beam Laser inside Coaxial Wire Feeding Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2022, 123, 313–330. [Google Scholar] [CrossRef]

- Liu, S.; Brice, C.; Zhang, X. Interrelated Process-Geometry-Microstructure Relationships for Wire-Feed Laser Additive Manufacturing. Mater. Today Commun. 2022, 31, 103794. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar] [CrossRef]

- Benoit, M.J.; Sun, S.D.; Brandt, M.; Easton, M.A. Processing Window for Laser Metal Deposition of Al 7075 Powder with Minimized Defects. J. Manuf. Process 2021, 64, 1484–1492. [Google Scholar] [CrossRef]

- Ding, X.; Li, D.; Zhang, Q.; Ma, H.; Yang, J.; Fan, S. Effect of Ambient Pressure on Bead Shape, Microstructure and Corrosion Behavior of 4043 Al Alloy Fabricated by Laser Coaxial Wire Feeding Additive Manufacturing in Vacuum Environment. Opt. Laser Technol. 2022, 153, 108242. [Google Scholar] [CrossRef]

- Oliari, S.H.; Monteiro D’Oliveira, A.S.C.; Schulz, M. Manufatura Aditiva Do Aço Ferramenta H11 Por Deposição Metálica de Arame a Laser. Soldag. E Insp. 2017, 22, 466–479. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Gao, H.; Wu, L. Modeling of Bead Section Profile and Overlapping Beads with Experimental Validation for Robotic GMAW-Based Rapid Manufacturing. Robot. Comput. Integr. Manuf. 2013, 29, 417–423. [Google Scholar] [CrossRef]

- Cao, X.; Jahazi, M.; Fournier, J.; Alain, M. Optimization of Bead Spacing during Laser Cladding of ZE41A-T5 Magnesium Alloy Castings. J. Mater. Process Technol. 2008, 205, 322–331. [Google Scholar] [CrossRef]

- Garmendia, I.; Pujana, J.; Lamikiz, A.; Flores, J.; Madarieta, M. Development of an Intra-Layer Adaptive Toolpath Generation Control Procedure in the Laser Metal Wire Deposition Process. Materials 2019, 12, 352. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Wang, S.; Liu, W.; Shang, X. Characterization of Stainless Steel Parts by Laser Metal Deposition Shaping. Mater. Des. 2014, 55, 104–119. [Google Scholar] [CrossRef]

- Guo, C.; Long, J. Simulation on Geometric Morphology of Multi-Channel Deposition in Laser Wire Additive Manufacturing. J. Phys. Conf. Ser. 2022, 2252, 12049. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Ghanadi, N. Areal Analysis Investigation of Selective Laser Melting Parts. J. Manuf. Mater. Process. 2022, 6, 83. [Google Scholar] [CrossRef]

- Yan, F.; Luo, Y.; Wang, C. A Study of Multi-Layer Multi-Pass Laser Depositing with 316L Stainless Steel Wire. J. Mech. Sci. Technol. 2021, 35, 1681–1687. [Google Scholar] [CrossRef]

- Akbari, M. Development of a Robotized Laser Directed Energy Deposition Development of a Robotized Laser Directed Energy Deposition System and Process Challenges System and Process Challenges. Available online: http://digitalrepository.smu.edu (accessed on 20 March 2024).

- Ding, Y.; Akbari, M.; Kovacevic, R. Process Planning for Laser Wire-Feed Metal Additive Manufacturing System. Int. J. Adv. Manuf. Technol. 2018, 95, 355–365. [Google Scholar] [CrossRef]

- Baghdadchi, A.; Hosseini, V.A.; Bermejo, M.A.V.; Axelsson, B.; Harati, E.; Högström, M.; Karlsson, L. Wire Laser Metal Deposition Additive Manufacturing of Duplex Stainless Steel Components—Development of a Systematic Methodology. Materials 2021, 14, 7170. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Wei, S.; Wang, G.; Shin, Y.C.; Rong, Y. Comprehensive Modeling of Transport Phenomena in Laser Hot-Wire Deposition Process. Int. J. Heat. Mass. Transf. 2018, 125, 1356–1368. [Google Scholar] [CrossRef]

- Noori Rahim Abadi, S.M.A.; Mi, Y.; Kisielewicz, A.; Sikström, F.; Choquet, I. Influence of Laser-Wire Interaction on Heat and Metal Transfer in Directed Energy Deposition. Int. J. Heat. Mass. Transf. 2023, 205, 123894. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Jia, C.; Yang, L.; Yan, S. Laser-Directed Energy Deposition of In-Situ Titanium-Matrix Coatings with a Ti-B4C Cored Wire. Addit. Manuf. 2023, 73, 103682. [Google Scholar] [CrossRef]

- Ocylok, S.; Alexeev, E.; Mann, S.; Weisheit, A.; Wissenbach, K.; Kelbassa, I. Correlations of Melt Pool Geometry and Process Parameters during Laser Metal Deposition by Coaxial Process Monitoring. In Physics Procedia; Elsevier B.V.: Amsterdam, The Netherlands, 2014; Volume 56, pp. 228–238. [Google Scholar] [CrossRef]

- Da Silva, A.; Frostevarg, J.; Volpp, J.; Kaplan, A.F.H. Additive Manufacturing by Laser-Assisted Drop Deposition from a Metal Wire. Mater. Des. 2021, 209, 109987. [Google Scholar] [CrossRef]

- Bozeman, S.C.; Isgor, O.B.; Tucker, J.D. Effects of Processing Conditions on the Solidification and Heat-Affected Zone of 309L Stainless Steel Claddings on Carbon Steel Using Wire-Directed Energy Deposition. Surf. Coat. Technol. 2022, 444, 128698. [Google Scholar] [CrossRef]

- Wang, L.; Yuan, J.; Zhang, H.; Huang, Y.; Yang, L. Effect of the Laser-Wire Relative Position on the Wire-Based Laser-Directed Energy Deposition of In-Situ Synthesis Ti/TiB/TiC Composite Coatings. Mater. Charact. 2023, 206, 113408. [Google Scholar] [CrossRef]

- Abranovic, B.; Sarkar, S.; Chang-Davidson, E.; Beuth, J. Melt Pool Level Flaw Detection in Laser Hot Wire Directed Energy Deposition Using a Convolutional Long Short-Term Memory Autoencoder. Addit. Manuf. 2024, 79, 103843. [Google Scholar] [CrossRef]

- Semak, V.V.; Hopkins, J.A.; McCay, M.H.; McCay, T.D. Melt Pool Dynamics during Laser Welding. J. Phys. D Appl. Phys. 1995, 28, 2443–2450. [Google Scholar] [CrossRef]

- Ng, G.K.L.; Jarfors, A.E.W.; Bi, G.; Zheng, H.Y. Porosity Formation and Gas Bubble Retention in Laser Metal Deposition. Appl. Phys. A 2009, 97, 641–649. [Google Scholar] [CrossRef]

- Harvey, J.-P.; Chartrand, P. Modeling the Hydrogen Solubility in Liquid Aluminum Alloys. Metall. Mater. Trans. B 2010, 41, 908–924. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing Porosity in AlSi10Mg Parts Processed by Selective Laser Melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- du Plessis, A.; Macdonald, E. Hot Isostatic Pressing in Metal Additive Manufacturing: X-ray Tomography Reveals Details of Pore Closure. Addit. Manuf. 2020, 34, 101191. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing. J. Mater. Process Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Tweer, J.; Day, R.; Derra, T.; Dorow-Gerspach, D.; Loewenhoff, T.; Wirtz, M.; Linsmeier, C.; Bergs, T.; Natour, G. Initial Experiments to Regenerate the Surface of Plasma-Facing Components by Wire-Based Laser Metal Deposition. Nucl. Mater. Energy 2024, 38, 101577. [Google Scholar] [CrossRef]

- Cross, C.E. On the Origin of Weld Solidification Cracking. In Hot Cracking Phenomena in Welds; Springer: Berlin/Heidelberg, Germany; pp. 3–18. [CrossRef]

- Stopyra, W.; Gruber, K.; Smolina, I.; Kurzynowski, T.; Kuźnicka, B. Laser Powder Bed Fusion of AA7075 Alloy: Influence of Process Parameters on Porosity and Hot Cracking. Addit. Manuf. 2020, 35, 101270. [Google Scholar] [CrossRef]

- Liu, T.-S.; Chen, P.; Qiu, F.; Yang, H.-Y.; Jin, N.T.Y.; Chew, Y.; Wang, D.; Li, R.; Jiang, Q.-C.; Tan, C. Review on Laser Directed Energy Deposited Aluminum Alloys. Int. J. Extrem. Manuf. 2024, 6, 22004. [Google Scholar] [CrossRef]

- Yang, K.; Chen, M.; Zhao, K.; Jia, Z.; Wang, Z.; Qi, H.; Sun, G. Research on Gas Pore Formation and Inhibition Mechanism of High Nitrogen Steel during Laser Direct Metal Deposition. Opt. Laser Technol. 2024, 175, 110788. [Google Scholar] [CrossRef]

- Gomez-Omella, M.; Flores, J.; Sierra, B.; Ferreiro, S.; Hascoët, N.; Chinesta, F. Optimizing Porosity Detection in Wire Laser Metal Deposition Processes through Data-Driven AI Classification Techniques. Eng. Fail. Anal. 2023, 152, 107464. [Google Scholar] [CrossRef]

- Bernauer, C.; Meinzinger, L.; Zapata, A.; Zhao, X.F.; Baehr, S.; Zaeh, M.F. Design and Investigation of a Novel Local Shielding Gas Concept for Laser Metal Deposition with Coaxial Wire Feeding. Appl. Sci. 2023, 13, 5121. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Shi, T.; Shi, J.; Cheng, D.; Lu, L.; Shi, S. Experimental Investigation on Laser Metal Deposition of Ti-6Al-4V Alloy with Coaxial Local Shielding Gas Nozzle. J. Mater. Eng. Perform. 2020, 29, 7821–7829. [Google Scholar] [CrossRef]

- Arbo, S.M.; Tomovic-Petrovic, S.; Aunemo, J.; Dahle, N.; Jensrud, O. On Weldability of Aerospace Grade Al-Cu-Li Alloy AA2065 by Wire-Feed Laser Metal Deposition. J. Adv. Join. Process. 2022, 5, 100096. [Google Scholar] [CrossRef]

- Barroi, A.; Schwarz, N.; Herm, J.; Bielefeld, T.; Kaierle, S. A Small Volume, Local Shielding Gas Chamber with Low Gas Consumption for Laser Wire Additive Manufacturing of Bigger Titanium Parts; University of Texas at Austin: Austin, TX, USA, 2023. [Google Scholar]

- Kelbassa, J.; Gasser, A.; Bremer, J.; Pütsch, O.; Poprawe, R.; Henrich Schleifenbaum, J. Equipment and Process Windows for Laser Metal Deposition with Coaxial Wire Feeding. J. Laser Appl. 2019, 31, 022320. [Google Scholar] [CrossRef]

- Teichmann, E.W.; Kelbassa, J.; Gasser, A.; Tarner, S.; Schleifenbaum, J.H. Effect of Wire Feeder Force Control on Laser Metal Deposition Process Using Coaxial Laser Head. J. Laser Appl. 2021, 33, 012041. [Google Scholar] [CrossRef]

- Mbodj, N.G.; Abuabiah, M.; Plapper, P.; El Kandaoui, M.; Yaacoubi, S. Bead Geometry Prediction in Laser-Wire Additive Manufacturing Process Using Machine Learning: Case of Study. Appl. Sci. 2021, 11, 11949. [Google Scholar] [CrossRef]

- Misra, D.; Sundararajan, V.; Wright, P.K. Zig-Zag Tool Path Generation for Sculptured Surface Finishing. In Geometric and Algorithmic Aspects of Computer-Aided Design and Manufacturing; GE Global Research Center: Bangalore, India; Department of Mechanical Engineering, University of California: Berkeley, CA, USA, 2003. [Google Scholar]

- Bock, F.E.; Herrnring, J.; Froend, M.; Enz, J.; Kashaev, N.; Klusemann, B. Experimental and Numerical Thermo-Mechanical Analysis of Wire-Based Laser Metal Deposition of Al-Mg Alloys. J. Manuf. Process 2021, 64, 982–995. [Google Scholar] [CrossRef]

- Nickel, A.H.; Barnett, D.M.; Prinz, F.B. Thermal Stresses and Deposition Patterns in Layered Manufacturing. Mater. Sci. Eng. A 2001, 317, 59–64. [Google Scholar] [CrossRef]

- Singh, S.N.; Deoghare, A.B. Microstructure, Micro-Hardness and Tensile Properties of Ti6Al4V Manufactured by High Layer-Thickness Wire-Feed Multi-Laser Directed Energy Deposition. Mater. Lett. 2023, 340, 134207. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, Y.; Chen, H.; Xiong, J. Molten Pool Behaviors and Forming Characteristics in Wire-Laser Directed Energy Deposition with Beam Oscillation. J. Mater. Process Technol. 2024, 326, 118326. [Google Scholar] [CrossRef]

- Gräfe, S.; Dadgar, M.; Day, R.; Bergs, T. Laser Metal Deposition with Wire of Inconel 718 on Pre-Heated Substrates. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 26–29 June 2023. [Google Scholar]

- Maliutina, I.N.; Si-Mohand, H.; Piolet, R.; Missemer, F.; Popelyukh, A.I.; Belousova, N.S.; Bertrand, P. Laser Cladding of γ-TiAl Intermetallic Alloy on Titanium Alloy Substrates. Metall. Mater. Trans. A 2016, 47, 378–387. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Mehnen, J.; Williams, S.; Wang, F.; Almeida, P.S. A Computationally Efficient Finite Element Model of Wire and Arc Additive Manufacture. Int. J. Adv. Manuf. Technol. 2014, 70, 227–236. [Google Scholar] [CrossRef]

- Su, G.; Shi, Y.; Li, G.; Zhang, G.; Xu, Y. Improving the Deposition Efficiency and Mechanical Properties of Additive Manufactured Inconel 625 through Hot Wire Laser Metal Deposition. J. Mater. Process Technol. 2023, 322, 118175. [Google Scholar] [CrossRef]

- Baghdadchi, A.; Hosseini, V.A.; Valiente Bermejo, M.A.; Axelsson, B.; Harati, E.; Högström, M.; Karlsson, L. Wire Laser Metal Deposition of 22% Cr Duplex Stainless Steel: As-Deposited and Heat-Treated Microstructure and Mechanical Properties. J. Mater. Sci. 2022, 57, 9556–9575. [Google Scholar] [CrossRef]

- Liu, W.; Liu, S.; Ma, J.; Kovacevic, R. Real-Time Monitoring of the Laser Hot-Wire Welding Process. Opt. Laser Technol. 2014, 57, 66–76. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Harooni, M.; Ma, J.; Kovacevic, R. Real-Time Monitoring of Laser Hot-Wire Cladding of Inconel 625. Opt. Laser Technol. 2014, 62, 124–134. [Google Scholar] [CrossRef]

- Huang, W.; Xiao, J.; Chen, S.; Jiang, X. Control of Wire Melting Behavior during Laser Hot Wire Deposition of Aluminum Alloy. Opt. Laser Technol. 2022, 150, 107978. [Google Scholar] [CrossRef]

- Su, G.; Shi, Y.; Li, G.; Zhang, G.; Xu, Y. Highly-Efficient Additive Manufacturing of Inconel 625 Thin Wall Using Hot-Wire Laser Metal Deposition: Process Optimization, Microstructure, and Mechanical Properties. Opt. Laser Technol. 2024, 175, 110763. [Google Scholar] [CrossRef]

- Spencer, J.D.; Dickens, P.M.; Wykes, C. Rapid Prototyping of Metal Parts by Three-Dimensional Welding. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 1998, 212, 175–182. [Google Scholar] [CrossRef]

- Lee, Y.; Bandari, Y.; Nandwana, P.; Gibson Brian, T.; Richardson, B.; Simunovic, S. Effect of Interlayer Cooling Time, Constraint and Tool Path Strategy on Deformation of Large Components Made by Laser Metal Deposition with Wire. Appl. Sci. 2019, 9, 5115. [Google Scholar] [CrossRef]

- Hua, Z.; Xiong, L.; Zhang, M.; Wang, C.; Mi, G.; Jiang, P. Microstructure Evolution and Tribological Properties of (TiB+TiC)/Ti–6Al–4V Composites Fabricated via In Situ Laser-Directed Energy Deposition of Wire and Powders in an Underwater Environment. Compos. B Eng. 2023, 263, 110817. [Google Scholar] [CrossRef]

- Nakano, Y.; Morita, D.; Shinohara, N.; Ukai, Y.; Sumi, N.; Hashimoto, T. Fatigue Performance of Titanium–Aluminum–Vanadium Alloy Fabricated by Laser-Wire-Based Directed Energy Deposition Forming Dot-Shaped Beads. Mater. Trans. 2023, 64, 296–302. [Google Scholar] [CrossRef]

- Hatala, G.W.; Wang, Q.; Reutzel, E.W.; Fisher, C.R.; Semple, J.K. A Thermo-Mechanical Analysis of Laser Hot Wire Additive Manufacturing of Nab. Metal 2021, 11, 1023. [Google Scholar] [CrossRef]

- Menon, N.; Sawyer, B.A.; Jamieson, C.D.; Reutzel, E.W.; Basak, A. A Comparison of Microstructure and Microhardness Properties of IN718 Fabricated via Powder- and Wire-Fed Laser-Directed Energy Deposition. Materials 2023, 16, 1129. [Google Scholar] [CrossRef] [PubMed]

- Mani, M.; Lane, B.; Donmez, A.; Feng, S.; Moylan, S.; Fesperman, R. Measurement Science Needs for Real-Time Control of Additive Manufacturing Powder Bed Fusion Processes; NIST Interagency/Internal Report (NISTIR), National Institute of Standards and Technology: Gaithersburg, Maryland, 2015. [CrossRef]

- Schulz, M.; Klocke, F.; Riepe, J.; Klingbeil, N.; Arntz, K. Process Optimization of Wire-Based Laser Metal Deposition of Titanium. J. Eng. Gas. Turbine Power 2019, 141, 052102. [Google Scholar] [CrossRef]

- Gibson, B.T.; Bandari, Y.K.; Richardson, B.S.; Henry, W.C.; Vetland, E.J.; Sundermann, T.W.; Love, L.J. Melt Pool Size Control through Multiple Closed-Loop Modalities in Laser-Wire Directed Energy Deposition of Ti-6Al-4V. Addit. Manuf. 2020, 32, 100993. [Google Scholar] [CrossRef]

- Stehmar, C.; Gipperich, M.; Kogel-Hollacher, M.; Velazquez Iturbide, A.; Schmitt, R.H. Inline Optical Coherence Tomography for Multidirectional Process Monitoring in a Coaxial LMD-w Process. Appl. Sci. 2022, 12, 2701. [Google Scholar] [CrossRef]

- Iravani-Tabrizipour, M.; Toyserkani, E. An Image-Based Feature Tracking Algorithm for Real-Time Measurement of Clad Height. Mach. Vis. Appl. 2007, 18, 343–354. [Google Scholar] [CrossRef]

- Song, L.; Bagavath-Singh, V.; Dutta, B.; Mazumder, J. Control of Melt Pool Temperature and Deposition Height during Direct Metal Deposition Process. Int. J. Adv. Manuf. Technol. 2012, 58, 247–256. [Google Scholar] [CrossRef]

- Davis, T.A.; Shin, Y.C. Vision-Based Clad Height Measurement. Mach. Vis. Appl. 2011, 22, 129–136. [Google Scholar] [CrossRef]

- Fathi, A.; Khajepour, A.; Toyserkani, E.; Durali, M. Clad Height Control in Laser Solid Freeform Fabrication Using a Feedforward PID Controller. Int. J. Adv. Manuf. Technol. 2007, 35, 280–292. [Google Scholar] [CrossRef]

- Bi, G.; Gasser, A.; Wissenbach, K.; Drenker, A.; Poprawe, R. Identification and Qualification of Temperature Signal for Monitoring and Control in Laser Cladding. Opt. Lasers Eng. 2006, 44, 1348–1359. [Google Scholar] [CrossRef]

- Hofman, J.T.; Pathiraj, B.; van Dijk, J.; de Lange, D.F.; Meijer, J. A Camera Based Feedback Control Strategy for the Laser Cladding Process. J. Mater. Process Technol. 2012, 212, 2455–2462. [Google Scholar] [CrossRef]

- Hu, D.; Kovacevic, R. Sensing, Modeling and Control for Laser-Based Additive Manufacturing. Int. J. Mach. Tools Manuf. 2003, 43, 51–60. [Google Scholar] [CrossRef]

- Guerra, M.G.; Mazzarisi, M.; Latte, M.; Lavecchia, F.; Campanelli, S.; Galantucci, L.M. Off-Axis Monitoring of the Melt Pool Spatial Information in Laser Metal Deposition Process. Procedia CIRP 2024, 121, 144–149. [Google Scholar] [CrossRef]

- Heralić, A.; Christiansson, A.K.; Ottosson, M.; Lennartson, B. Increased Stability in Laser Metal Wire Deposition through Feedback from Optical Measurements. Opt. Lasers Eng. 2010, 48, 478–485. [Google Scholar] [CrossRef]

- Nie, Z.; Wang, G.; McGuffin-Cawley, J.D.; Narayanan, B.; Zhang, S.; Schwam, D.; Kottman, M.; Rong, Y. Experimental Study and Modeling of H13 Steel Deposition Using Laser Hot-Wire Additive Manufacturing. J. Mater. Process Technol. 2016, 235, 171–186. [Google Scholar] [CrossRef]

- Buhr, M.; Weber, J.; Wenzl, J.P.; Möller, M.; Emmelmann, C. Influences of Process Conditions on Stability of Sensor Controlled Robot-Based Laser Metal Deposition. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 74, pp. 149–153. [Google Scholar] [CrossRef]

- Flores-Prado, J.; Saéz-de-Heredia, I.G.; Cabanes-Axpe, E.I. Thermal Monitoring and Control by Infrared Camera in the Manufacture of Parts with Laser Metal Deposition. Dyna 2020, 95, 360–363. [Google Scholar] [CrossRef] [PubMed]

- Schmoeller, M.; Stadter, C.; Liebl, S.; Zaeh, M.F. Inline Weld Depth Measurement for High Brilliance Laser Beam Sources Using Optical Coherence Tomography. J. Laser Appl. 2019, 31, 022409. [Google Scholar] [CrossRef]

- Stadter, C.; Schmoeller, M.; Zeitler, M.; Tueretkan, V.; Munzert, U.; Zaeh, M.F. Process Control and Quality Assurance in Remote Laser Beam Welding by Optical Coherence Tomography. J. Laser Appl. 2019, 31, 022408. [Google Scholar] [CrossRef]

- Kogel-Hollacher, M.; Strebel, M.; Staudenmaier, C.; Schneider, H.-I.; Regulin, D. OCT Sensor for Layer Height Control in DED Using SINUMERIK® Controller. In Laser 3D Manufacturing VII; Helvajian, H., Gu, B., Chen, H., Eds.; SPIE: Washington, DC, USA, 2020; p. 23. [Google Scholar] [CrossRef]

- Tapia, G.; Elwany, A. A Review on Process Monitoring and Control in Metal-Based Additive Manufacturing. J. Manuf. Sci. Eng. 2014, 136, 060801. [Google Scholar] [CrossRef]

- Gibson, B.T.; Richardson, B.S.; Sundermann, T.W.; Love, L.J. Beyond the Toolpath: Site-Specific Melt Pool Size Control Enables Printing of Extra-Toolpath Geometry in Laser Wire-Based Directed Energy Deposition. Appl. Sci. 2019, 9, 4355. [Google Scholar] [CrossRef]

- Mbodj, N.G.; Abuabiah, M.; Plapper, P.; El Kandaoui, M.; Yaacoubi, S. Modeling and Control of Layer Height in Laser Wire Additive Manufacturing. Materials 2022, 15, 4479. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Yao, X.; Chew, Y.; Weng, F.; Moon, S.K.; Bi, G. Data-Driven Adaptive Control for Laser-Based Additive Manufacturing with Automatic Controller Tuning. Appl. Sci. 2020, 10, 7967. [Google Scholar] [CrossRef]

- Wang, Q.; Li, J.; Gouge, M.; Nassar, A.R.; (Pan) Michaleris, P.; Reutzel, E.W. Physics-Based Multivariable Modeling and Feedback Linearization Control of Melt-Pool Geometry and Temperature in Directed Energy Deposition. J. Manuf. Sci. Eng. 2017, 139, 021013. [Google Scholar] [CrossRef]

- Bernauer, C.; Leitner, P.; Zapata, A.; Garkusha, P.; Grabmann, S.; Schmoeller, M.; Zaeh, M.F. Segmentation-Based Closed-Loop Layer Height Control for Enhancing Stability and Dimensional Accuracy in Wire-Based Laser Metal Deposition. Robot. Comput. Integr. Manuf. 2024, 86, 102683. [Google Scholar] [CrossRef]

- Baghdadchi, A. Directed Energy Deposition Additive Manufacturing and Welding of Duplex Stainless Steel Using Laser Beam; University West, Division of Welding Technology: Trollhättan, Sweden, 2024. [Google Scholar]

- Pinkerton, A.J. Laser Direct Metal Deposition: Theory and Applications in Manufacturing and Maintenance. In Advances in Laser Materials Processing; Elsevier: Amsterdam, The Netherlands, 2010; pp. 461–491. [Google Scholar] [CrossRef]

- Yang, Z.; Verma, A.K.; Smith, L.; Guzel, A.; Chen, H.; Pistorius, P.C.; Rollett, A.D. Predicting Melt Pool Dimensions for Wire-Feed Directed Energy Deposition Process. Integr. Mater. Manuf. Innov. 2022, 11, 532–544. [Google Scholar] [CrossRef]

- Bayat, M.; Dong, W.; Thorborg, J.; To, A.C.; Hattel, J.H. A Review of Multi-Scale and Multi-Physics Simulations of Metal Additive Manufacturing Processes with Focus on Modeling Strategies. Addit. Manuf. 2021, 47, 102278. [Google Scholar] [CrossRef]

- Lalas, C.; Tsirbas, K.; Salonitis, K.; Chryssolouris, G. An Analytical Model of the Laser Clad Geometry. Int. J. Adv. Manuf. Technol. 2007, 32, 34–41. [Google Scholar] [CrossRef]

- Liu, J.; Li, L. Study on Cross-Section Clad Profile in Coaxial Single-Pass Cladding with a Low-Power Laser. Opt. Laser Technol. 2005, 37, 478–482. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Brandt, M. Model Predictive Control of Laser Metal Deposition. Int. J. Adv. Manuf. Technol. 2019, 105, 1055–1067. [Google Scholar] [CrossRef]

- Corbin, D.J.; Nassar, A.R.; Reutzel, E.W.; Beese, A.M.; Kistler, N.A. Effect of Directed Energy Deposition Processing Parameters on Laser Deposited Inconel® 718: External Morphology. J. Laser Appl. 2017, 29, 022001. [Google Scholar] [CrossRef]

- Guo, S.; Agarwal, M.; Cooper, C.; Tian, Q.; Gao, R.X.; Guo, W.G.; Guo, Y.B. Machine Learning for Metal Additive Manufacturing: Towards a Physics-Informed Data-Driven Paradigm. Journal of Manufacturing Systems; Elsevier B.V.: Amsterdam, The Netherlands, 2022; pp. 145–163. [Google Scholar] [CrossRef]

- Bonnín Roca, J.; Vaishnav, P.; Fuchs, E.R.H.; Morgan, M.G. Policy Needed for Additive Manufacturing. Nat. Mater. 2016, 15, 815–818. [Google Scholar] [CrossRef] [PubMed]

- Teng, C.; Gong, H.; Szabo, A.; Dilip, J.J.S.; Ashby, K.; Zhang, S.; Patil, N.; Pal, D.; Stucker, B. Simulating Melt Pool Shape and Lack of Fusion Porosity for Selective Laser Melting of Cobalt Chromium Components. J. Manuf. Sci. Eng. 2017, 139, 011009. [Google Scholar] [CrossRef]

- Lee, S.; Peng, J.; Shin, D.; Choi, Y.S. Data Analytics Approach for Melt-Pool Geometries in Metal Additive Manufacturing. Sci. Technol. Adv. Mater. 2019, 20, 972–978. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Zhang, G.; Hu, J.; Wu, L. Bead Geometry Prediction for Robotic GMAW-Based Rapid Manufacturing through a Neural Network and a Second-Order Regression Analysis. J. Intell. Manuf. 2014, 25, 157–163. [Google Scholar] [CrossRef]

- Ai, Y.; Yan, Y.; Yuan, P.; Wang, Y. The Numerical Investigation of Cladding Layer Forming Process in Laser Additive Manufacturing with Wire Feeding. Int. J. Therm. Sci. 2024, 196, 108669. [Google Scholar] [CrossRef]

- Chua, B.L.; Ahn, D.G.; Kim, J.G. Influences of Deposition Strategies on Thermo-Mechanical Characteristics of a Multilayer Part Deposited by a Wire Feeding Type DED Process. J. Mech. Sci. Technol. 2019, 33, 5615–5622. [Google Scholar] [CrossRef]

- Liu, S.; Brice, C.; Zhang, X. Hierarchical Bead Materials Multi-Property Design for Wire-Feed Laser Additive Manufacturing. J. Manuf. Process 2022, 80, 546–557. [Google Scholar] [CrossRef]

| Abbreviation | Full Name | Abbreviation | Full Name |

|---|---|---|---|

| AM | Additive manufacturing | HAZ | Heat effected zone |

| MAM | Metal additive manufacturing | LOF | Lack of fusion |

| PBF | Powder bed fusion | CCD | Charge-coupled device |

| LPBF | Laser powder bed fusion | CMOS | Complementary metal oxide semiconductor |

| DED | Directed energy deposition | OCT | Optical coherence tomography |

| EB-DED | Electron beam DED | PI | Proportional-Integral |

| LDED | Laser DED | PLC | Programmable Logic Controller |

| P-DED | Plasma DED | MPC | Model Predictive Control |

| WAAM | Wire arc DED | ILC | Iterative Learning Control |

| W-LDED | Wire-laser DED | FEA | Finite element analysis |

| TS | Travel speed | CFD | Computational fluid dynamics |

| WFS | Wire feed speed | ML | Machine learning |

| Wire | Powder | |

|---|---|---|

| Cost effectiveness | ✓ | |

| Deposition rate | ✓ | |

| Material efficiency | ✓ | |

| Material availability | ✓ | |

| Build volume | ✓ | |

| Dimensional resolution | ✓ | |

| Multi-material deposition capability | ✓ | |

| Health/Safety hazards | ✓ | |

| Ease of handling/storing | ✓ | |

| Contamination sensitivity | ✓ | |

| Oxygen/moisture pickup sensitivity | ✓ |

| Dilution | Aspect Ratio | Contact Angle | |

|---|---|---|---|

| ↑ Power | ↑ | ↑ | ↓ |

| ↑ TS | ↑ | ↑ | ↓ |

| ↑ WFR | ↓ | ↓ | ↑ |

| Wire Material | Diameter (mm) | Wire Feeding Type | Laser Type | Laser Classification | Substrate Material | Shielding Gas | Machine Type | Ref. |

|---|---|---|---|---|---|---|---|---|

| AA4043 | 1.2 | Lateral Front feeding 30 | Fiber laser Diode laser | Continuous | AA5083 | Argon | Custom Built | [74] |

| AA4043 | 0.4 | Coaxial | Fiber laser | Continuous | Ti6Al4V | Argon | Custom Built | [140] |

| AA4047 | 0.4 | Lateral Front feeding 30 | Nd:YAG laser | Pulsed | AA5754 | Argon | Custom Built | [67] |

| AA5A06 | 1.2 | Lateral Front, back feeding 45 | Fiber laser | Continuous | AA4043 | Argon | KUKA 6-axis Robot (Augsburg, Germany) | [47] |

| AA5A06 | 1.2 | Lateral 45 | Fiber laser | Continuous | AA5052 | Argon | Custom Built | [193] |

| AA5078 | 1 | Coaxial | Disc laser | Continuous | AA5078 | Argon | KUKA 6-axis Robot | [122] |

| AA5083 | 1 | Coaxial | Disc laser | Continuous | AlSi1MgMn | - * | KUKA 6-axis Robot | [110] |

| AA5087 | 1 | Lateral Front feeding 35 | Fiber laser | Continuous | AA 5754 | Argon | CNC-supported XYZ-machining center (IXION Corporation) | [62] |

| AA5087 | 1 | Lateral Front feeding 35 | Fiber laser | Continuous | AA5754 | Argon | CNC Controlled Machine | [83] |

| AA5356 | 1 | Coaxial | Fiber-guided disk laser | Continuous | AlSi1MgMn | Nitrogen | CoaxPrinter (Precitec GmbH & Co. KG, Gaggenau, Germany) | [35] |

| AA5356 | 1.2 | - | Fiber Laser | Continuous | AA5052 | - | KUKA 6-axis Robot | [106] |

| AA7075 | 1.2 | Lateral Front, back, side feeding 45 | Disk laser | Continuous | A7075 | Argon | CNC Controlled Machine | [63] |

| AA7075 | 1.2 | - | Disk laser | Continuous | AA7075 | Argon | CNC Controlled Machine | [61] |

| AlSi10Mg | 1.6 | Vertical wire feeding, Inclined laser 50 | Fiber laser | Continuous | AA6061 | Argon | Custom Built | [64] |

| Ti6Al4V | 1.2 | Lateral Front feeding 55 | Diode laser | Continuous | Ti6Al4V | Argon | KUKA 6-axis Robot | [114] |

| Ti6Al4V | 1.2 | Coaxial | Disk laser | Continuous | Ti6Al4V | Argon | KUKA 6-axis Robot | [84] |

| Ti6Al4V | 1 | Lateral Front feeding 50 | Fiber laser | Continuous | Ti6Al4V | Argon | Custom Built | [131] |

| Ti6Al4V | 1.2 | Lateral 30 | Fiber laser | Continuous | Ti6Al4V | Argon | KUKA 6-axis Robot | [197] |

| Ti6Al4V | 1 | Coaxial | Diode lasers | Continuous | - | Argon | Meltio M450 (Jaén, Spain) | [184] |

| Ti6Al4V | 1.2 | Lateral Front feeding 30 | Fiber laser Diode laser | Continuous | AA5083 | Argon | Custom Built | [74] |

| Ti6Al4V | 1.2 | Lateral Front feeding 45 | Customized Laser | Continuous | Ti6Al4V | Argon | CNC Controlled Machine | [198] |

| Ti6Al4V | 1.6 | Lateral 30 | Fiber laser | Continuous | Ti-6Al-4V | Argon | Custom Built | [48] |

| Ti6Al4V | 1.2 | Lateral Front, side, back feeding | Diode laser | Continuous | Ti6Al4V | Argon | CNC Controlled Machine | [113] |

| NAB | 1.14 | Lateral | Fiber laser | Continuous | NAB | - | ABB 6-axis Robot (ABB Robotics, Västerås, Sweden) | [199] |

| AWS ER 100S-G | 1.2 | Lateral Front Feeding | Fiber laser | Continuous | - | Argon | KUKA 6-axis Robot | [56] |

| Mild steel Lincoln ER 100S-G | 1.2 | Lateral Front feeding 40 | Fiber laser | Continuous | - | Argon | KUKA 6-axis Robot | [150] |

| H11 | 1.2 | Lateral 46.5 | Diode laser | Continuous | 42CrMo4 alloy steel | Argon | 5-axis CNC machine | [141] |

| SS 301 | 0.5 | Lateral Front feeding 30 | Nd:YAG laser | Pulsed | SS 316 | Argon | Custom Built | [66] |

| SS 304 | 1.2 | Lateral 35 | Fiber laser | Continuous | SS 304 | - | - | [93] |

| SS 304 | 0.5 | Coaxial | Co2 Laser | Continuous | SS 304 | - | - | [72] |

| SS 304 | 0.1 | Lateral 20 | Nd:YAG laser | Pulsed | SS316 | Argon | Custom Built | [65] |

| SS 308L | 1.2 | Lateral Front feeding 45 | Diode laser | Continuous | 590-MPa- class steel | Argon | Custom Built | [108] |

| SS 308 | 1 | Coaxial | Fiber laser | Pulsed | SS 316 | Argon | ABB 6-axis Robot | [57] |

| SS 308LSi | 1.2 | Lateral Front feeding 42 | Fiber laser | continuous | SS 304 | Argon | CNC Controlled Machine | [112] |

| SS 309 | 1 | Coaxial | Diode lasers | Contiguous | SS304 | Argon | Meltio M450 | [59] |

| SS 309 | 0.9 | Coaxial | Diode lasers | Continuous | AISI 1018 | Argon | Meltio M450 | [159] |

| SS 316L | 0.8 | Coaxial | Fiber laser | Continuous | C45 Carbon Steel | Argon | ABB 6-axis Robot | [89] |

| SS 316LSi | 1 | Coaxial | Disk laser | Continuous | SS 304 | Argon | KUKA 6-axis robot | [174] |

| SS 316LSi | 1.2 | Lateral Side feeding | Fiber laser | Continuous | SS 304 | Argon | KUKA 6-axis Robot | [51] |

| SS 316L | 0.8 | Lateral Front feeding 35–45 | Fiber laser | Continuous | SS 316L | Argon | ABB 6-axis Robot | [33] |

| SS 316 | 0.9 | Coaxial | Diode laser | Continuous | SS316 | Argon | Meltio M450 | [118] |

| SS 316 | 0.8 | Lateral Front feeding | Fiber laser | Continuous | SS 316 | Argon | ABB 6-axis Robot | [148] |

| SS 316 | 1 | Coaxial | Disk laser | Continuous | SS 304 | Argon | KUKA 6-axis Robot | [125,126] |

| SS 316L | 1 | Coaxial | Disc laser | Continuous | SS 304 | - | KUKA 6-axis Robot | [110] |

| SS 316 | 0.6 | Coaxial | Fiber laser | Pulsed | SS304 | Argon | Custom Built | [81] |

| DSS 2209 | 1.2 | - | Fiber laser | Continuous | DSS 2205 | - | ABB 6-axis Robot | [34] |

| DSS 2209 | 1.2 | Lateral | Fiber laser | continuous | DSS 2205 | Argon | ABB 6-axis Robot | [190] |

| DSS 2209 | 1.2 | - | Fiber laser | Continuous | DSS 2205 | Argon Nitrogen | ABB 6-axis Robot | [101] |

| DSS 2209 | 1.2 | Lateral | Fiber laser | Continuous | DSS 2205 | Argon | ABB 6-axis Robot | [151] |

| DSS 2209 | 0.8 | Coaxial | Fiber laser | Continuous | SS | Argon | KUKA 6-axis Robot | [95] |

| INC 718 | 1 | Coaxial | Diode laser | Continuous | SS 304 | Argon | Custom Built | [54] |

| INC 718 | 1 | Lateral Front feeding | Diode laser | Continuous | INC 718 | Argon | 5-axes CNC machine | [130] |

| INC 718 | 0.89 | Coaxial | Fiber laser | Continuous | INC 718 | Argon | ABB 6-axis Robot | [102] |

| INC 718 | 0.9 | Coaxial | Diode lasers | Continuous | INC 718 | Argon | μPrinter (Additec, USA) | [73] |

| INC 718 | 0.9 | - | Fiber laser | Continuous | INC 718 | Argon | Custom Built | [200] |

| INC 625 | 1.2 | Lateral Front feeding 42 | Fiber laser | Continuous | SS 304 | Argon | CNC controlled table | [58] |

| Input Variable | Controlled Variable | Monitoring | Sensor Position | Controller | Ref. |

|---|---|---|---|---|---|

| TS | Layer height | Structured light scanner | Off-axis | Closed loop | [127] |

| Deposition head Z position | Layer height | Structured light scanner | Off-axis | Closed loop | [144] |

| Deposition head Z position | Laser power | High speed camera, Laser line scanner | Off-axis | Closed loop | [57] |

| WFS | Layer height | OCT | In-axis | Closed Loop, PI Controller | [35] |

| Input temperature | Bead height | Laser profilometer | In-axis | MPC | [222] |

| WFS, Deposition head Z position | Layer height | 3D scanning system | In-axis | ILC, Step-height compensator | [111] |

| Laser power, WFS | Bead geometry | Cameras, Projected laser line | In-axis, Off-axis | PI-controller, Feed-forward compensator | [213] |

| Laser power, WFS | Bead geometry | Camera, Projected laser line | Off-axis | Closed loop | [107] |

| Laser power, Deposition rate, | Melt pool size, Laser power | Thermal camera | In-axis | Closed loop | [203] |

| Laser power | Melt pool size | Thermal camera | In-axis | Closed loop | [221] |

| WFS, Laser power | Bead height, Melt pool temperature | OCT, IR camera | In-axis | Closed loop | [125] |

| Laser power | Melt pool temperature | Pyrometer | In-axis | PI controller | [126] |

| Laser power | Melt pool temperature | Pyrometer | In-axis | PLC | [128] |

| WFS | Bead height | Camera, Laser line scanner | In-axis, Off-axis | Closed loop | [98] |

| Laser power, WFS | Melt pool temperature | Pyrometer | In-axis | Closed loop | [85] |

| Wire Preheating voltage and current | Liquid bridge transfer | Camera, Measurement circuit | In-axis Off-axis | PLC | [34] |

| Process Input | Predicted Output | Modelling Approach | Material | Ref. |

|---|---|---|---|---|

| Different deposition strategy | Temperature field | Numerical FEA | Ti6Al4V | [240] |

| Different ambient pressure | Bead geometry | Numerical CFD-ANSYS | SS 316 | [40] |

| Different beam shape and sizes | Bead geometry, Melt pool temperature | Numerical COMSOL | SS 316 | [87] |

| Increasing deposited layers | Melt pool temperature, Temperature profile | Numerical FEA | H13 | [214] |

| Different parameter set | Bead geometry, Melt pool geometry | Numerical ANSYS | SS 304 | [154] |

| Varying overlap ratio | Geometry of the multi-track deposition | Numerical Fluent | 5A06 aluminum | [146] |

| Different parameter set | Melt pool temperature, Melt pool geometry | Numerical FEA | AA5078 | [122] |

| Different deposition strategy | Temperature field | Numerical Flow 3D | 316L SS | [118] |

| Different scanning strategies | Temperature field | Numerical Flow 3D | INC 718 | [73] |

| Different focal position | Melt pool temperature | Numerical COMSOL | 304 SS | [100] |

| Different parameter set | Temperature field | Numerical FE-model | Al-mg | [182] |

| Different parameter set | Melt pool temperature | Python | Ti-6Al-4V | [48] |

| Wire tip temperature | Wire preheating temperature | Analytical | ER5A06 | [193] |

| Different parameter set | Bead geometry | Analytical | ER5A06 | [47] |

| Different parameter set | Bead geometry, Melt pool geometry | Analytical | SS 316 | [117] |

| Different parameter set | Bead geometry | ML Neural networking | INC 718 | [180] |

| Different parameter set | Bead geometry | Empirical model | INC 718 | [233] |

| Different parameter set | Melt pool geometry | ML | Ti6Al4V | [228] |

| Different parameter set | Bead geometry | ML | Ti6Al4V | [137] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghanadi, N.; Pasebani, S. A Review on Wire-Laser Directed Energy Deposition: Parameter Control, Process Stability, and Future Research Paths. J. Manuf. Mater. Process. 2024, 8, 84. https://doi.org/10.3390/jmmp8020084

Ghanadi N, Pasebani S. A Review on Wire-Laser Directed Energy Deposition: Parameter Control, Process Stability, and Future Research Paths. Journal of Manufacturing and Materials Processing. 2024; 8(2):84. https://doi.org/10.3390/jmmp8020084

Chicago/Turabian StyleGhanadi, Nahal, and Somayeh Pasebani. 2024. "A Review on Wire-Laser Directed Energy Deposition: Parameter Control, Process Stability, and Future Research Paths" Journal of Manufacturing and Materials Processing 8, no. 2: 84. https://doi.org/10.3390/jmmp8020084

APA StyleGhanadi, N., & Pasebani, S. (2024). A Review on Wire-Laser Directed Energy Deposition: Parameter Control, Process Stability, and Future Research Paths. Journal of Manufacturing and Materials Processing, 8(2), 84. https://doi.org/10.3390/jmmp8020084