Theoretical-Numerical Investigation of a New Approach to Reconstruct the Temperature Field in PBF-LB/M Using Multispectral Process Monitoring

Abstract

1. Introduction

1.1. Radiation Measurement Technology

1.2. Metrological Detection of Melt Pool Quantities—State of the Art

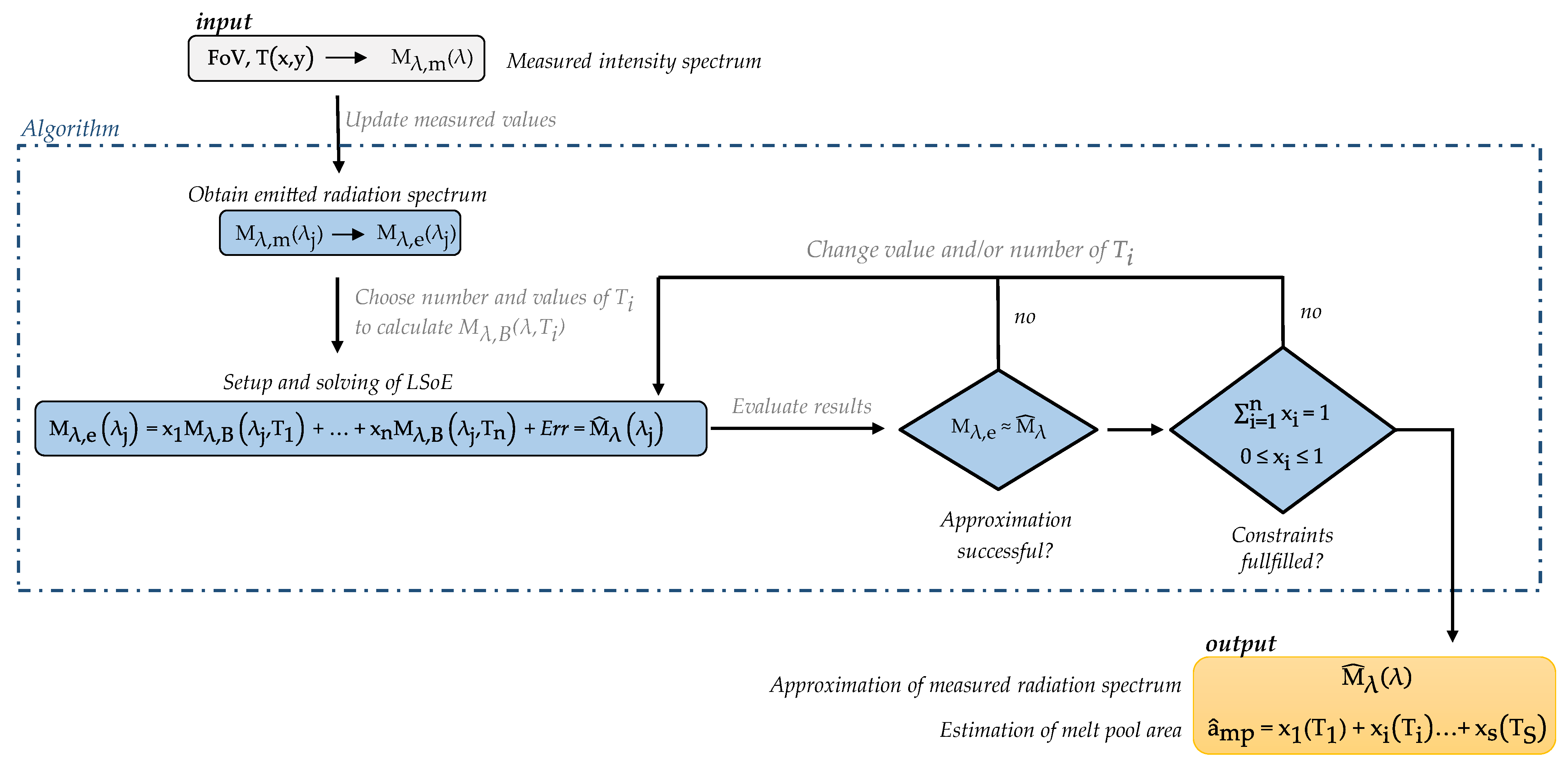

2. Derivation of Methodology

2.1. Measurement Approach

2.2. Theoretical Considerations

2.3. Methodology of Computational Studies

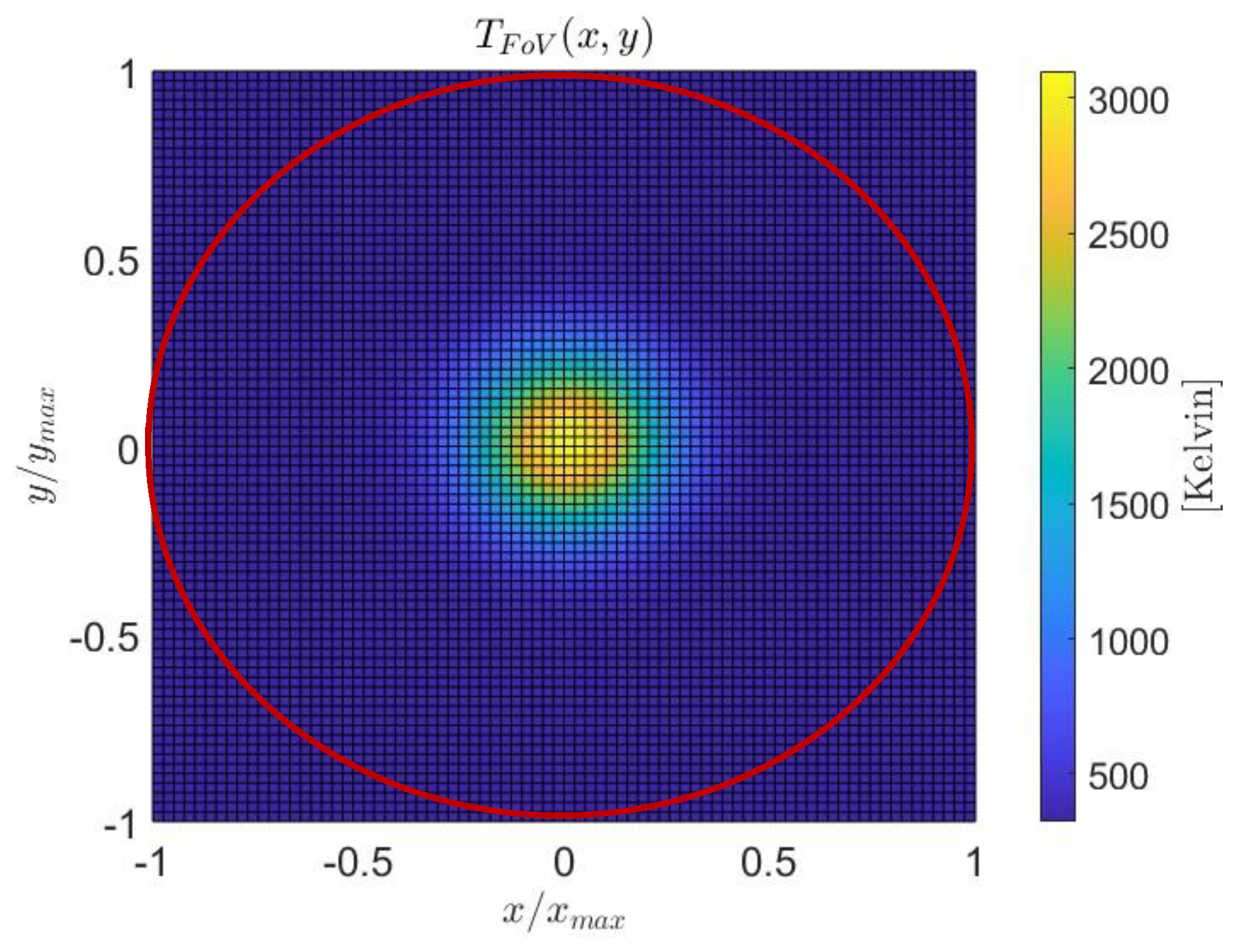

2.4. Surrogate Reference Data

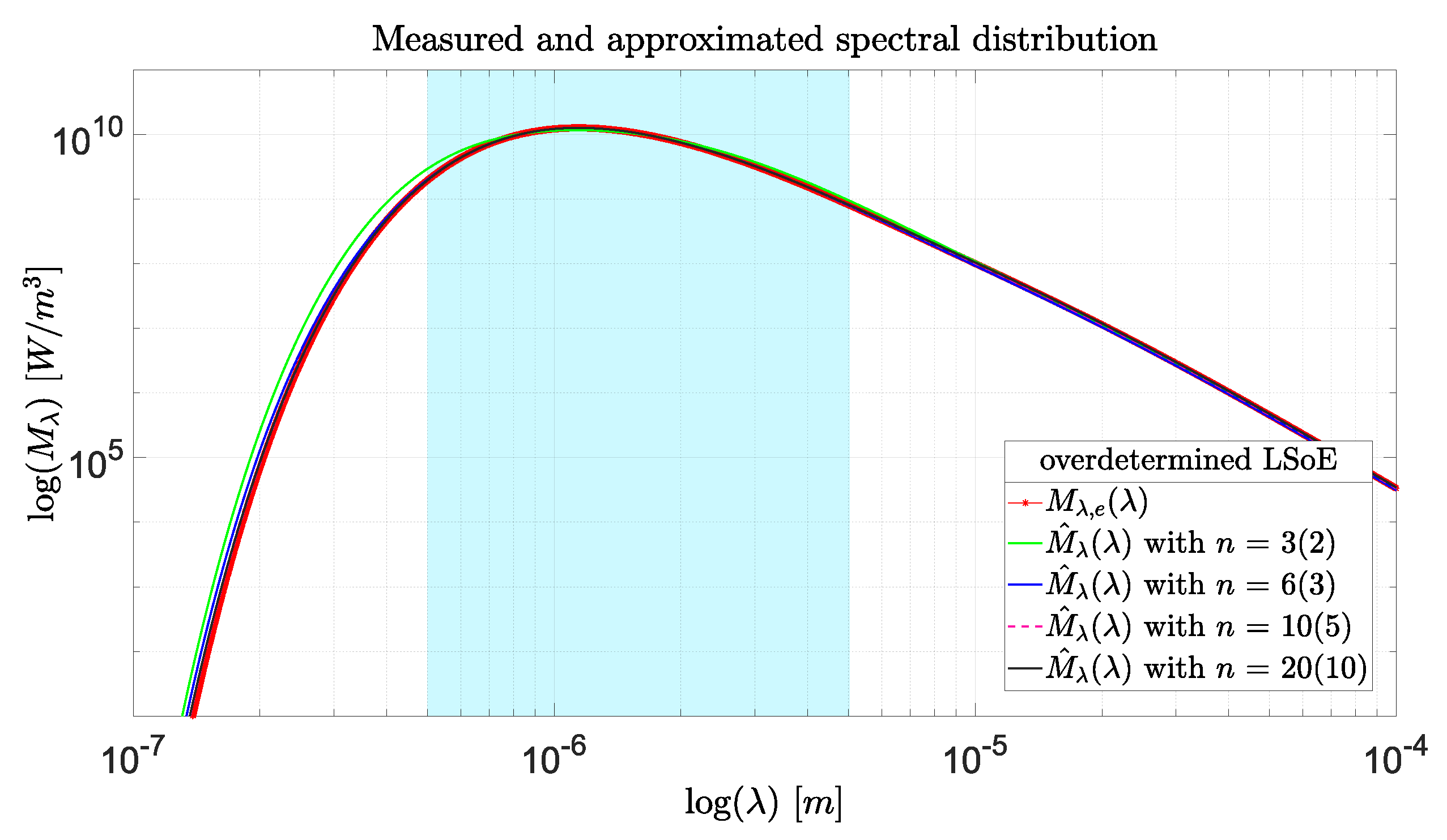

3. Computational Studies

3.1. Load Case of a Pulse Laser

3.2. Load Case of a Moving Laser

3.3. Numerical Modeling of Experimental Uncertainties

4. Discussion

5. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Grasso, M.; Colosimo, B.M. Process defects and in situ monitoring methods in metal powder bed fusion: A review. Meas. Sci. Technol. 2017, 28, 44005. [Google Scholar] [CrossRef]

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, É.; Egan, D.S.; Vijayaraghavan, R.K.; Joshi, A.M.; Acinas Garzon, V.; Dowling, D.P.; McNally, P.J.; et al. In-situ sensing, process monitoring and machine control in Laser Powder Bed Fusion: A review. Addit. Manuf. 2021, 45, 102058. [Google Scholar] [CrossRef]

- Mani, M.; Lane, B.; Donmez, A.; Feng, S.; Moylan, S.; Fesperman, R. Measurement Science Needs for Real-Time Control of Additive Manufacturing Powder Bed Fusion Processes; US Dept. of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Lough, C.S.; Escano, L.I.; Qu, M.; Smith, C.C.; Landers, R.G.; Bristow, D.A.; Chen, L.; Kinzel, E.C. In-situ optical emission spectroscopy of selective laser melting. J. Manuf. Process. 2020, 53, 336–341. [Google Scholar] [CrossRef]

- Doubenskaia, M.A.; Zhirnov, I.V.; Teleshevskiy, V.I.; Bertrand, P.; Smurov, I.Y. Determination of True Temperature in Selective Laser Melting of Metal Powder Using Infrared Camera. Mater. Sci. Forum 2015, 834, 93–102. [Google Scholar] [CrossRef]

- Chen, L.; Yao, X.; Ng, N.; Moon, S.K. In-situ Melt Pool Monitoring of Laser Aided Additive Manufacturing using Infrared Thermal Imaging. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Kuala Lumpur, Malaysia, 7–10 December 2022; pp. 1478–1482. [Google Scholar] [CrossRef]

- Ocylok, S.; Alexeev, E.; Mann, S.; Weisheit, A.; Wissenbach, K.; Kelbassa, I. Correlations of Melt Pool Geometry and Process Parameters During Laser Metal Deposition by Coaxial Process Monitoring. Phys. Procedia 2014, 56, 228–238. [Google Scholar] [CrossRef]

- Schmidt, M.; Gorny, S.; Rüssmeier, N.; Partes, K. Investigation of Direct Metal Deposition Processes Using High-Resolution In-line Atomic Emission Spectroscopy. J. Therm. Spray Technol. 2023, 32, 586–598. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Brandt, M. An accurate and real-time melt pool dimension measurement method for laser direct metal deposition. Int. J. Adv. Manuf. Technol. 2021, 114, 2421–2432. [Google Scholar] [CrossRef]

- Bernhard, F. Handbuch der Technischen Temperaturmessung; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Rahne, E. Thermografie: Theorie, Messtechnik, Praxis; 1. Auflage; Wiley-VCH GmbH: Weinheim, Germany, 2022; ISBN 352782071X. [Google Scholar]

- Grujić, K. A Review of Thermal Spectral Imaging Methods for Monitoring High-Temperature Molten Material Streams. Sensors 2023, 23, 1130. [Google Scholar] [CrossRef]

- Kulchin, Y.N.; Gribova, V.V.; Timchenko, V.A.; Basakin, A.A.; Nikiforov, P.A.; Yatsko, D.S.; Zhevtun, I.G.; Subbotin, E.P.; Nikitin, A.I. Melt Pool Temperature Control in Laser Additive Process. Bull. Russ. Acad. Sci. Phys. 2022, 86, S108–S113. [Google Scholar] [CrossRef]

- Kolb, T.; Gebhardt, P.; Schmidt, O.; Tremel, J.; Schmidt, M. Melt pool monitoring for laser beam melting of metals: Assistance for material qualification for the stainless steel 1.4057. Procedia CIRP 2018, 74, 116–121. [Google Scholar] [CrossRef]

- Krauss, H.; Zeugner, T.; Zaeh, M.F. Layerwise Monitoring of the Selective Laser Melting Process by Thermography. Phys. Procedia 2014, 56, 64–71. [Google Scholar] [CrossRef]

- Rodriguez, E.; Mireles, J.; Terrazas, C.A.; Espalin, D.; Perez, M.A.; Wicker, R.B. Approximation of absolute surface temperature measurements of powder bed fusion additive manufacturing technology using in situ infrared thermography. Addit. Manuf. 2015, 5, 31–39. [Google Scholar] [CrossRef]

- Scheuschner, N.; Altenburg, S.J.; Pignatelli, G.; Maierhofer, C.; Straße, A.; Gornushkin, I.B.; Gumenyuk, A. Vergleich der Messungen der Schmelzbadtemperatur bei der Additiven Fertigung von Metallen mittels IR-Spektroskopie und Thermografie. Tm Tech. Mess. 2021, 88, 626–632. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Smurov, I.; Grigoriev, S.; Pavlov, M.; Tikhonova, E. Optical Monitoring in Elaboration of Metal Matrix Composites by Direct Metal Deposition. Phys. Procedia 2012, 39, 767–775. [Google Scholar] [CrossRef]

- Clijsters, S.; Craeghs, T.; Buls, S.; Kempen, K.; Kruth, J.-P. In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. Int. J. Adv. Manuf. Technol. 2014, 75, 1089–1101. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Pavlov, M.; Grigoriev, S.; Smurov, I. Definition of brightness temperature and restoration of true temperature in laser cladding using infrared camera. Surf. Coat. Technol. 2013, 220, 244–247. [Google Scholar] [CrossRef]

- Altenburg, S.J.; Maierhofer, C.; Straße, A.; Gumenyuk, A. Comparison of MWIR thermography and high-speed NIR thermography in a laser metal deposition (LMD) process. In Proceedings of the 2018 International Conference on Quantitative InfraRed Thermography, Berlin, Germany, 25–29 June 2018. [Google Scholar]

- Altenburg, S.J.; Straße, A.; Gumenyuk, A.; Maierhofer, C. In-situ monitoring of a laser metal deposition (LMD) process: Comparison of MWIR, SWIR and high-speed NIR thermography. Quant. InfraRed Thermogr. J. 2022, 19, 97–114. [Google Scholar] [CrossRef]

- Lane, B.; Heigel, J.; Ricker, R.; Zhirnov, I.; Khromschenko, V.; Weaver, J.; Phan, T.; Stoudt, M.; Mekhontsev, S.; Levine, L. Measurements of melt pool geometry and cooling rates of individual laser traces on IN625 bare plates. Integr. Mater. Manuf. Innov. 2020, 9, 16–30. [Google Scholar] [CrossRef]

- Berumen, S.; Bechmann, F.; Lindner, S.; Kruth, J.-P.; Craeghs, T. Quality control of laser- and powder bed-based Additive Manufacturing (AM) technologies. Phys. Procedia 2010, 5, 617–622. [Google Scholar] [CrossRef]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Dörfert, R.; Tyralla, D. In-situ-Messung der Schmelzbadbreite beim pulverbettbasierten Laserstrahlschmelzen. In laf-Flashtalk Proceedings; BIAS—Bremer Institut für angewandte Strahltechnik GmbH: Bremen, Germany, 2020. [Google Scholar]

- Lane, B.; Moylan, S.; Whitenton, E.; Ma, L. Thermographic Measurements of the Commercial Laser Powder Bed Fusion Process at NIST. Rapid Prototyp. J. 2016, 22, 778–787. [Google Scholar] [CrossRef]

- Devesse, W.; de Baere, D.; Guillaume, P. High Resolution Temperature Measurement of Liquid Stainless Steel Using Hyperspectral Imaging. Sensors 2017, 17, 91. [Google Scholar] [CrossRef]

- Gerdes, N.; Hoff, C.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Hyperspectral imaging for prediction of surface roughness in laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2021, 115, 1249–1258. [Google Scholar] [CrossRef]

- Qu, D.-X.; Berry, J.; Calta, N.P.; Crumb, M.F.; Guss, G.; Matthews, M.J. Temperature Measurement of Laser-Irradiated Metals Using Hyperspectral Imaging. Phys. Rev. Appl. 2020, 14, 014031. [Google Scholar] [CrossRef]

- O’Byrne, R.P.; Sergeyev, S.V.; Flavin, D.A.; Slattery, S.A.; Nikogosyan, D.N.; Jones, J.D.C. Anisotropic Fiber Bragg Gratings Inscribed by High-Intensity Femtosecond-UV Pulses: Manufacturing Technology and Strain Characterization for Sensing Applications. IEEE Sens. J. 2008, 8, 1256–1263. [Google Scholar] [CrossRef]

- Shafer, A.B.; Megill, L.R.; Droppleman, L. Optimization of the Czerny–Turner Spectrometer. J. Opt. Soc. Am. 1964, 54, 879. [Google Scholar] [CrossRef]

- Feng, Z.; Xia, G.; Lu, R.; Cai, X.; Cui, H.; Hu, M. High-Performance Ultra-Thin Spectrometer Optical Design Based on Coddington’s Equations. Sensors 2021, 21, 323. [Google Scholar] [CrossRef]

- AVANTES. Optical Spectrometers Introduction—Must Read—Avantes. Available online: https://www.avantes.com/support/theoretical-background/introduction-to-spectrometers/ (accessed on 21 September 2023).

- Angelastro, A.; Campanelli, S.L. An integrated analytical model for the forecasting of the molten pool dimensions in Selective Laser Melting. Laser Phys. 2022, 32, 26001. [Google Scholar] [CrossRef]

- AVANTES. AvaSpec-NIR256/512-1.7-EVO—Avantes. Available online: https://www.avantes.com/products/spectrometers/nirline/avaspec-nir256-512-1-7-evo/ (accessed on 6 October 2023).

- Infiniti Electro-Optics. InSb (Indium Antimonide). Available online: https://www.infinitioptics.com/glossary/insb (accessed on 21 September 2023).

- Quantum Design, Inc. MWIR Spectral Camera Specim. Quantum Design. Available online: https://qd-europe.com/ro/en/product/mwir-spectral-camera/ (accessed on 6 October 2023).

| 323.15 | 1660 [23] | 3100 |

| n | w | |||

|---|---|---|---|---|

| 0.0689 | 6(3) | 26 | 0.0852 | −23.055 |

| 10(5) | 30 | 0.0804 | −15.3055 | |

| 20(10) | 40 | 0.0740 | −5.1974 |

| (a) | (b) | ||||

|---|---|---|---|---|---|

| n | w | n | w | ||

| 20(3) | 40 | 20.48 | 50(25) | 70 | 0.47 |

| 20(5) | −4.80 | 100(50) | 120 | 1.09 | |

| 20(8) | −1.73 | 200(100) | 220 | −2.88 | |

| 20(15) | −19.12 | 500(250) | 520 | −7.70 |

| n | w | Sensor Type | ||

|---|---|---|---|---|

| 20(10) | 40 | 1100–1750 | InGaAs | −3.58 |

| 170 | −5.31 | |||

| 40 | 3000–5000 | InSb | −5.19 | |

| 154 | −8.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

May, L.; Werz, M. Theoretical-Numerical Investigation of a New Approach to Reconstruct the Temperature Field in PBF-LB/M Using Multispectral Process Monitoring. J. Manuf. Mater. Process. 2024, 8, 73. https://doi.org/10.3390/jmmp8020073

May L, Werz M. Theoretical-Numerical Investigation of a New Approach to Reconstruct the Temperature Field in PBF-LB/M Using Multispectral Process Monitoring. Journal of Manufacturing and Materials Processing. 2024; 8(2):73. https://doi.org/10.3390/jmmp8020073

Chicago/Turabian StyleMay, Lisa, and Martin Werz. 2024. "Theoretical-Numerical Investigation of a New Approach to Reconstruct the Temperature Field in PBF-LB/M Using Multispectral Process Monitoring" Journal of Manufacturing and Materials Processing 8, no. 2: 73. https://doi.org/10.3390/jmmp8020073

APA StyleMay, L., & Werz, M. (2024). Theoretical-Numerical Investigation of a New Approach to Reconstruct the Temperature Field in PBF-LB/M Using Multispectral Process Monitoring. Journal of Manufacturing and Materials Processing, 8(2), 73. https://doi.org/10.3390/jmmp8020073