Role of Li and Sc Additions and Machining Conditions on Cutting Forces on Milling Behavior of A7075-Based Alloys

Abstract

1. Introduction

- (1)

- To investigate how precipitation hardening, with variations in aging times and temperatures, and alloying with lithium affect the mechanical properties of A7075 alloys.

- (2)

- To investigate cutting forces during the machining of A7075 alloys and analyze how the specified inputs influence cutting forces in these specific alloys.

2. Experimental Procedure

3. Results and Discussion

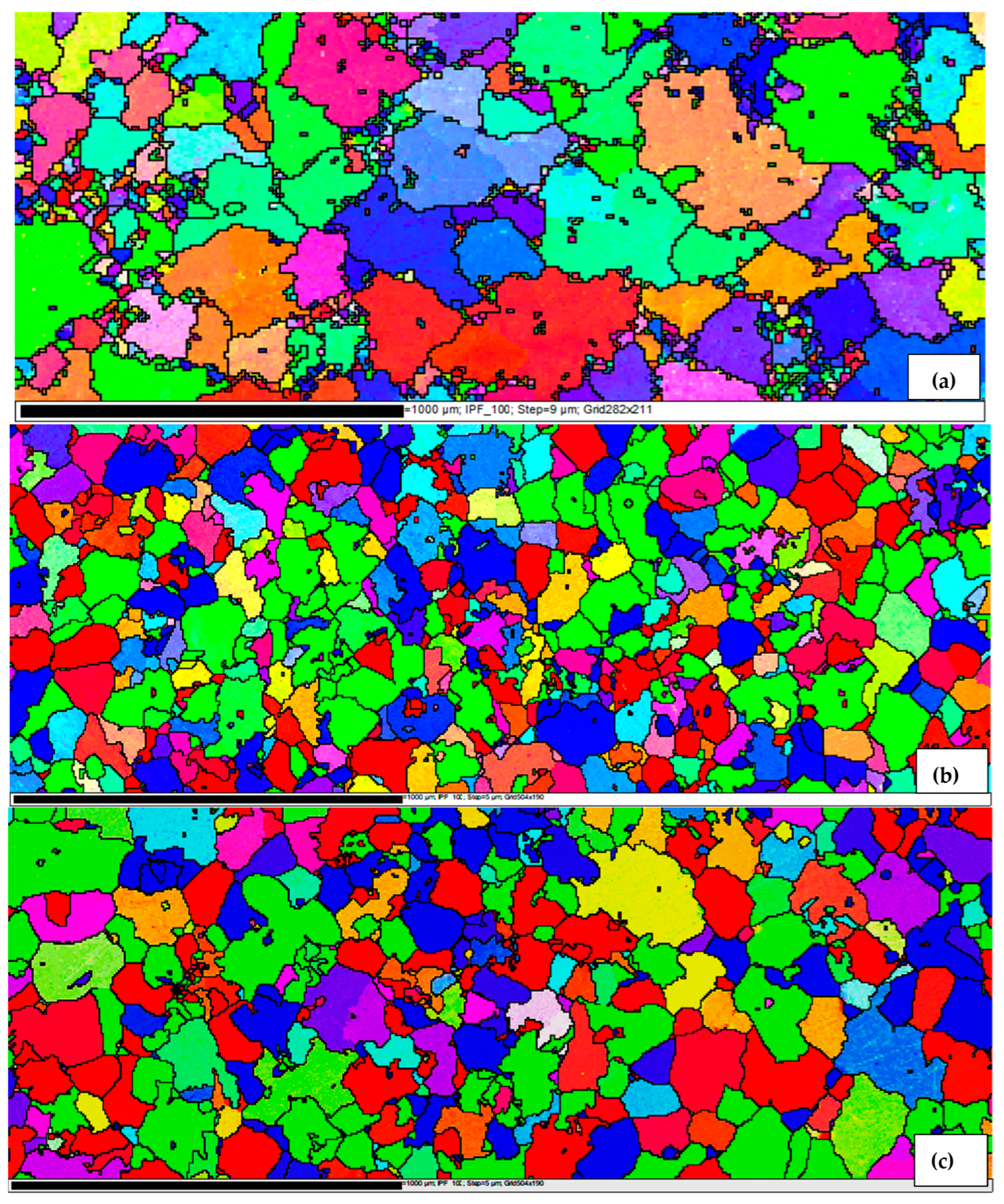

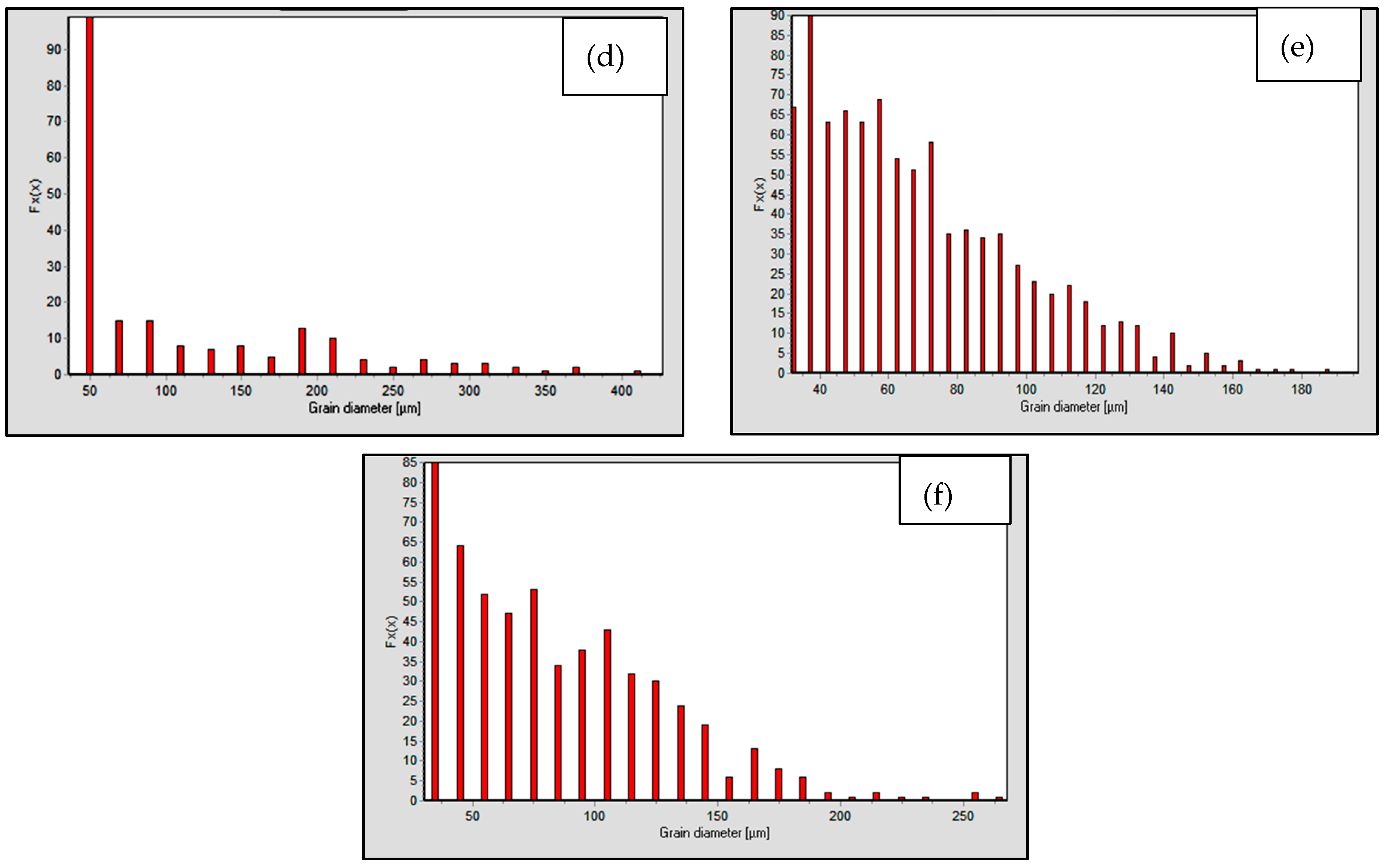

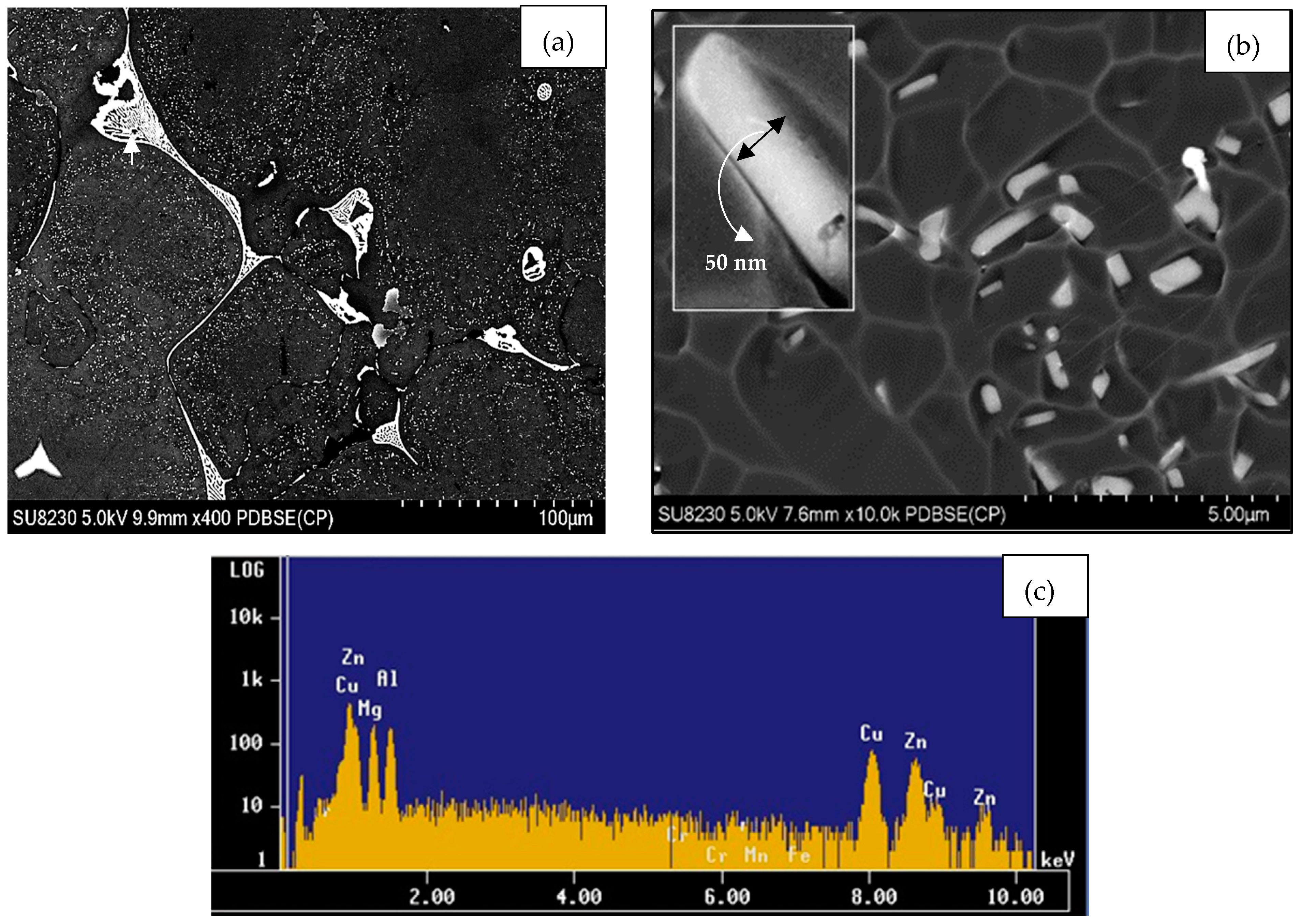

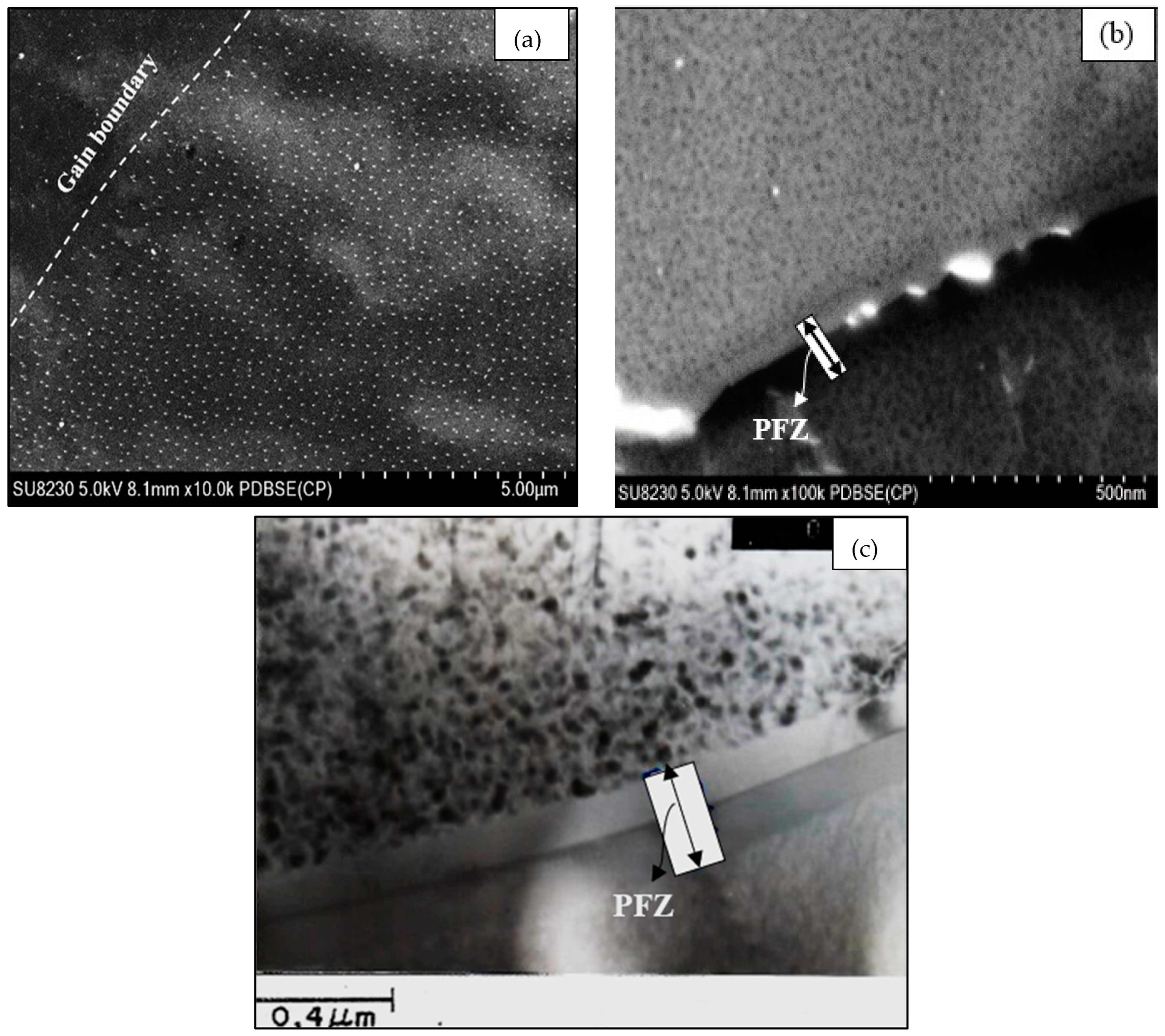

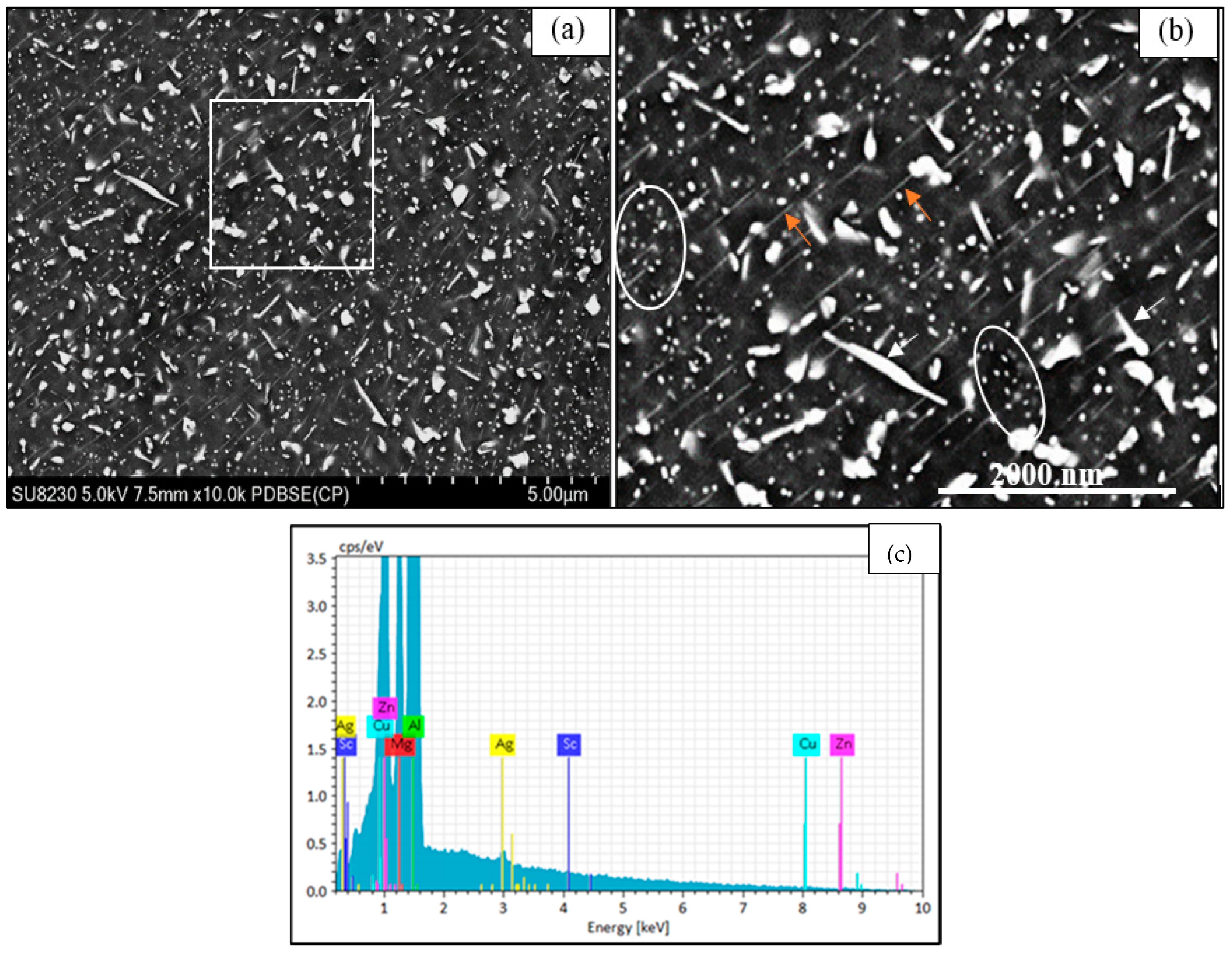

3.1. Microhardness and Microstructural Characterization

3.2. The Statistical Analysis of Cutting Force

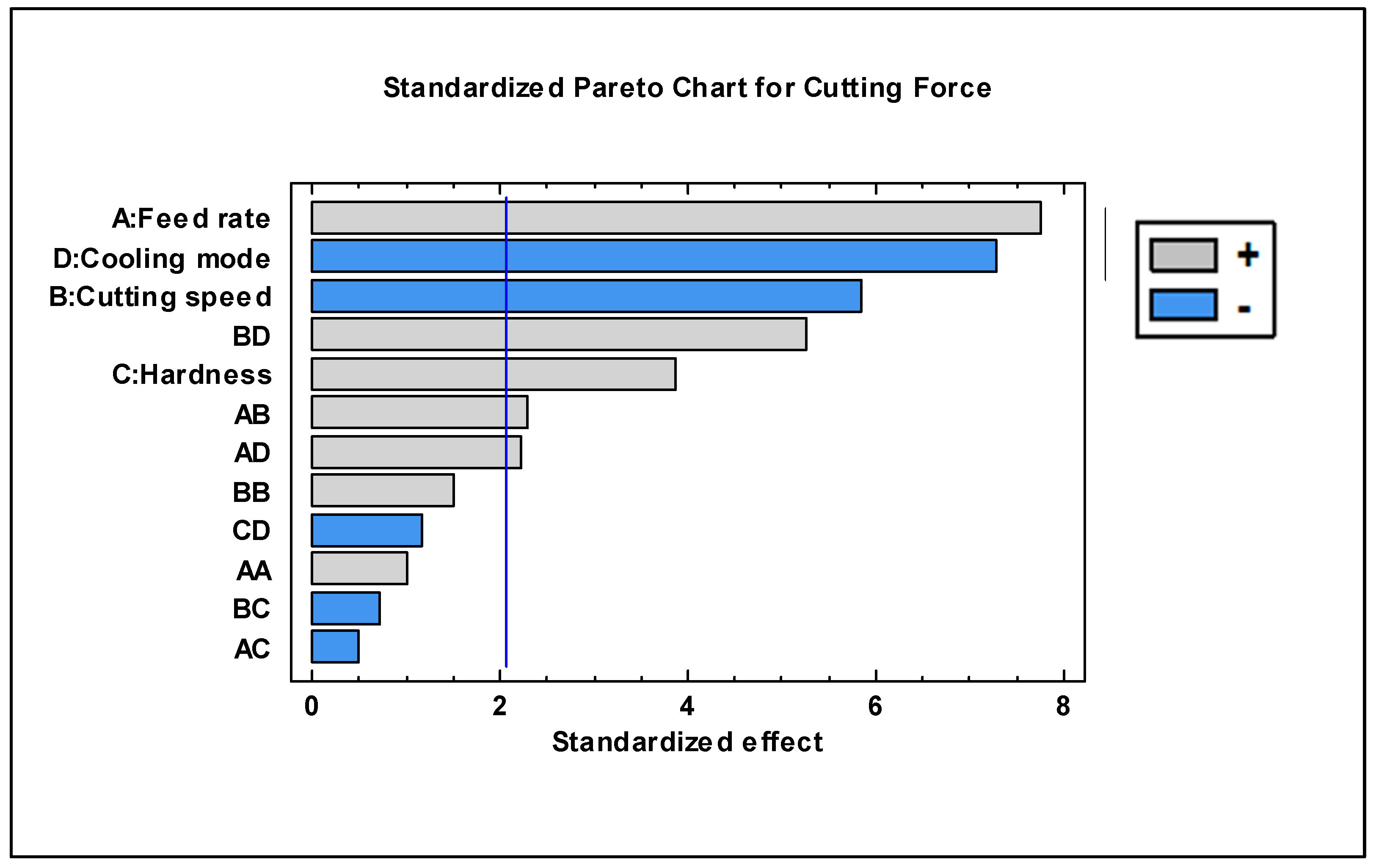

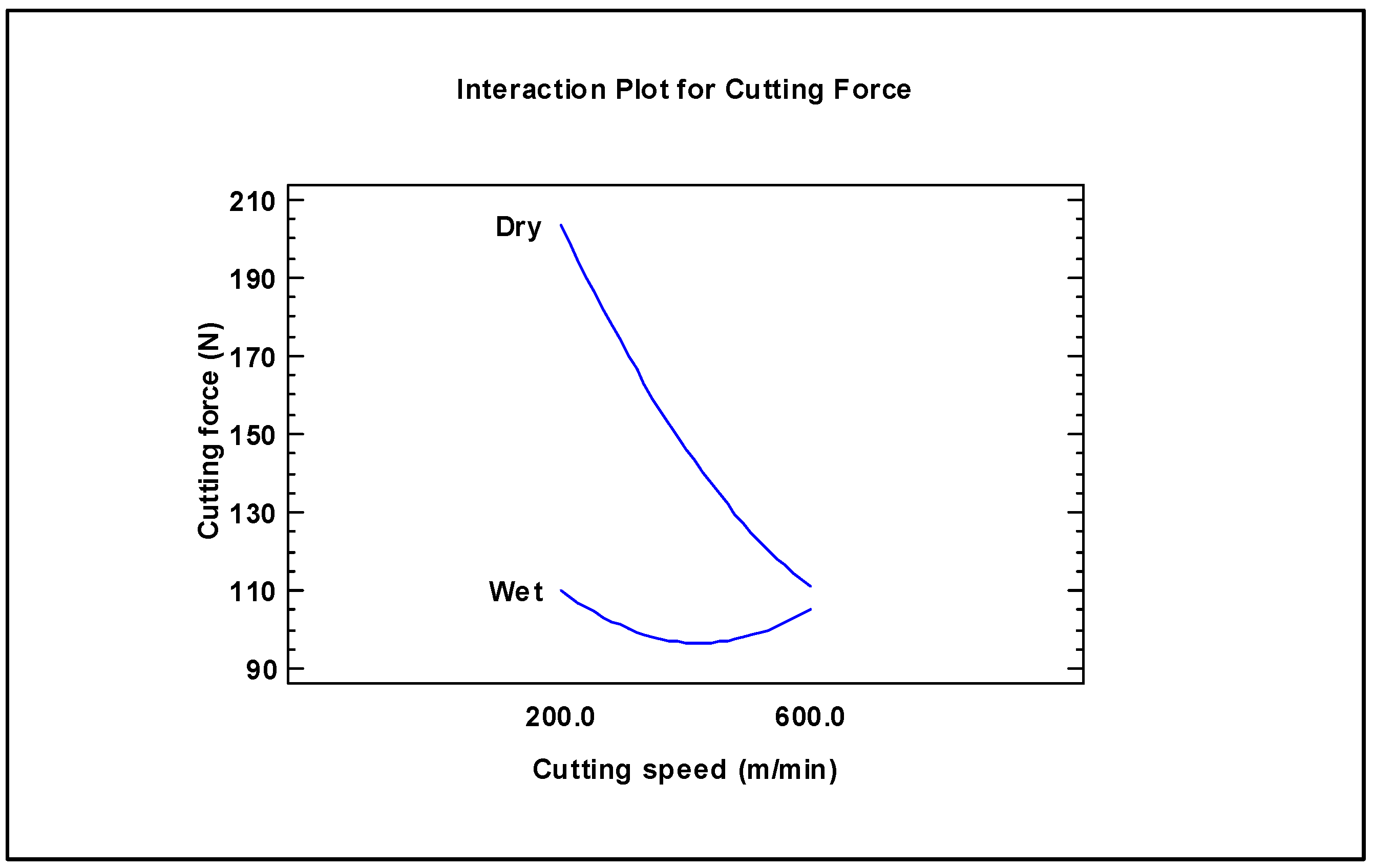

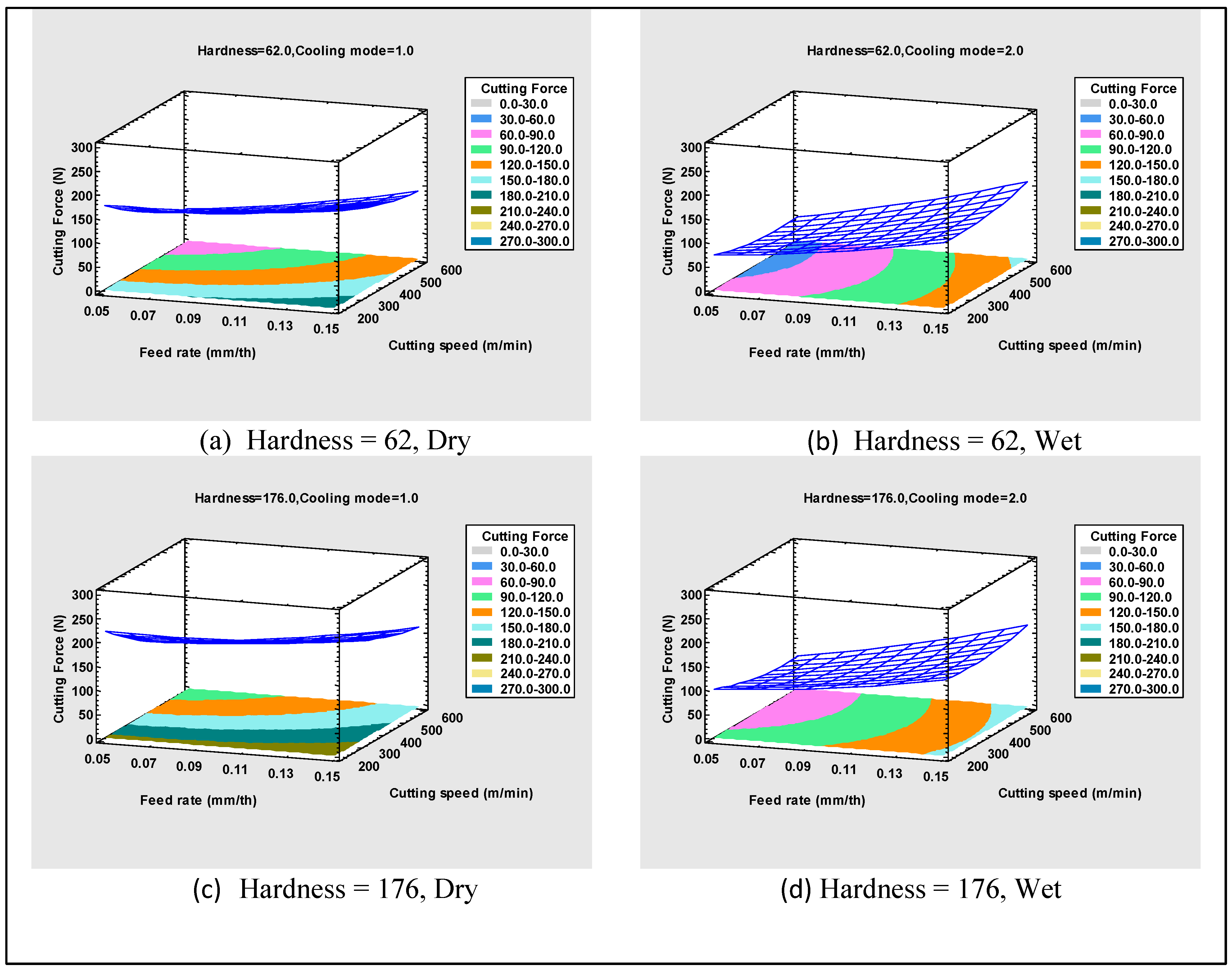

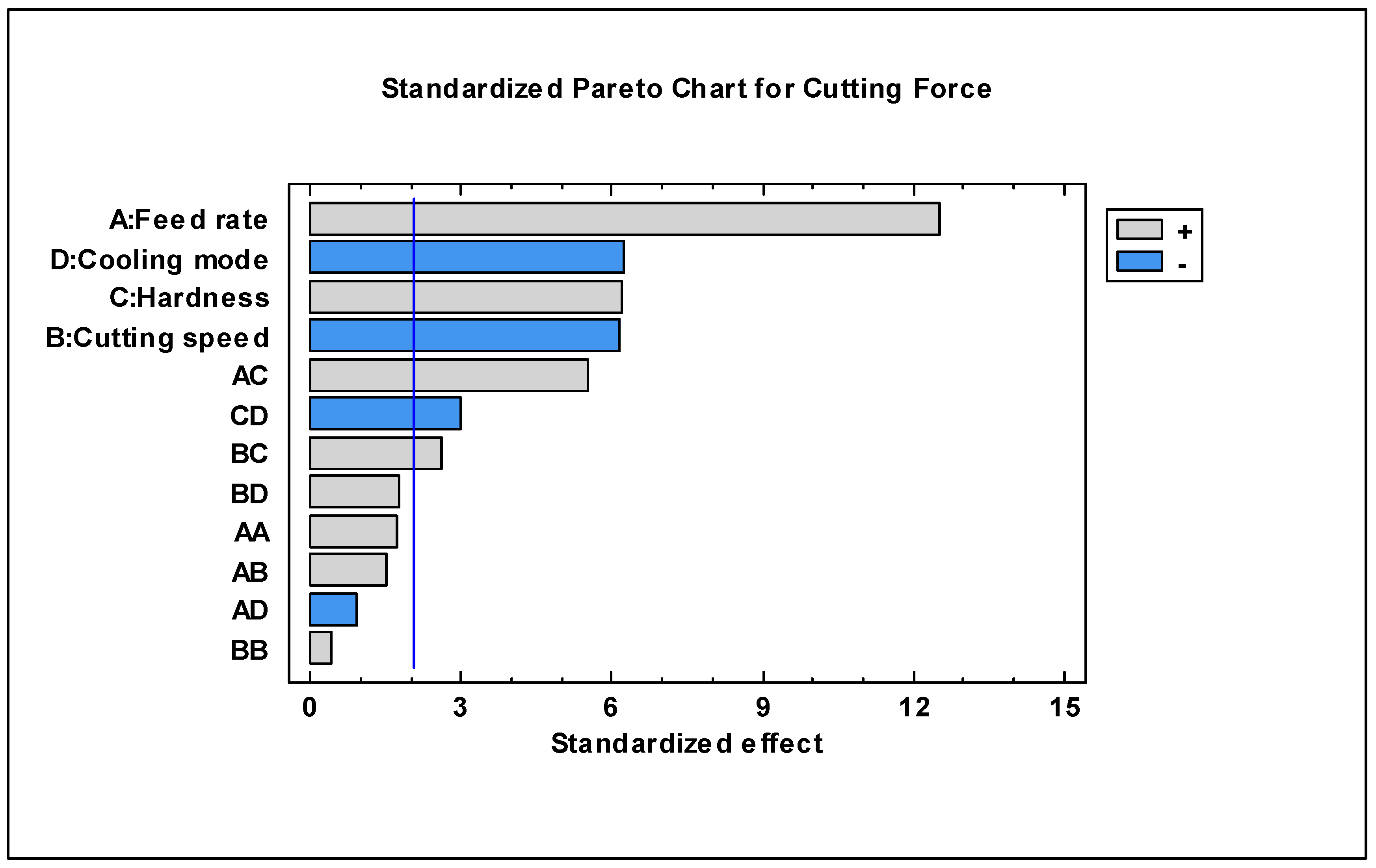

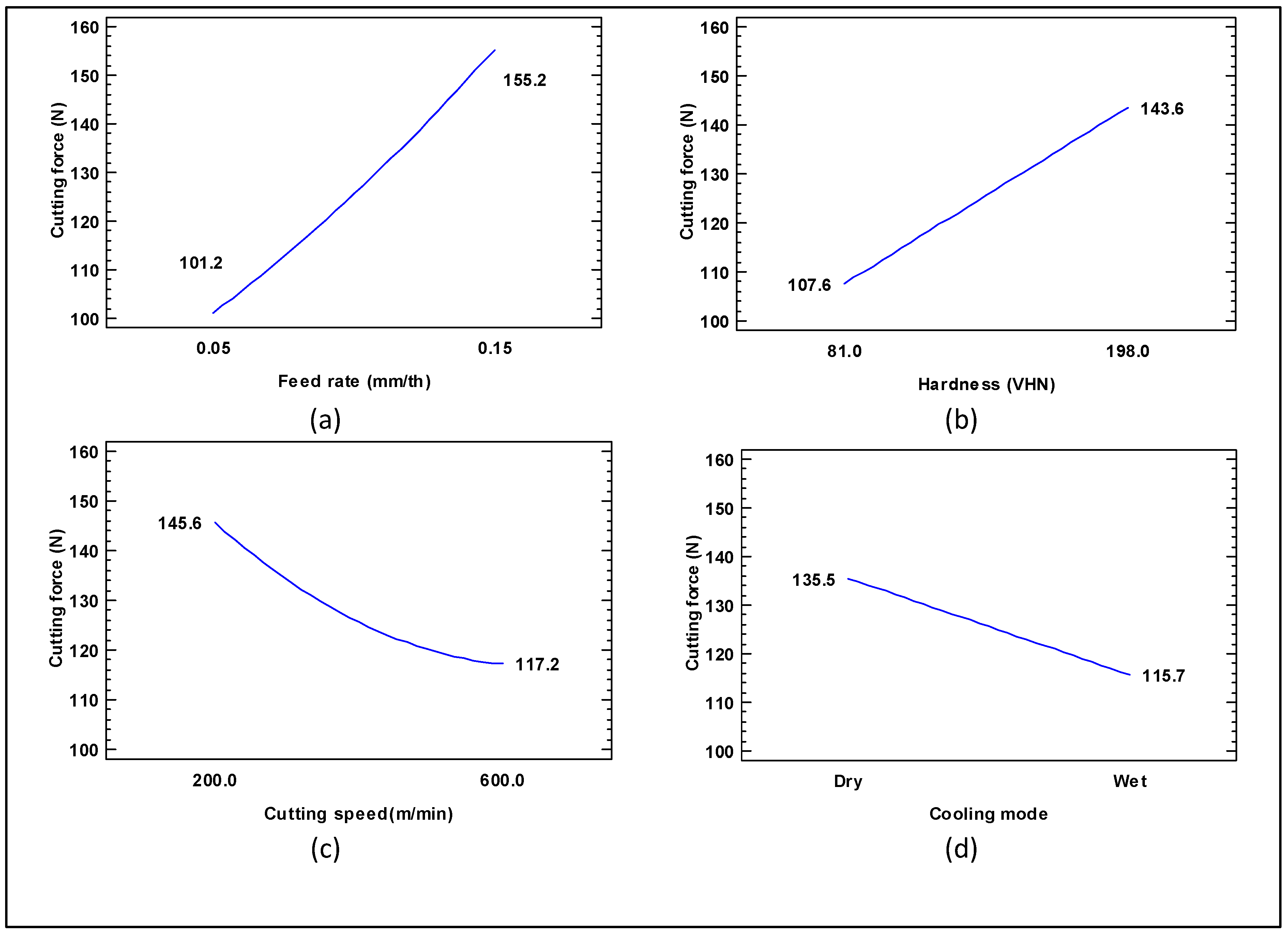

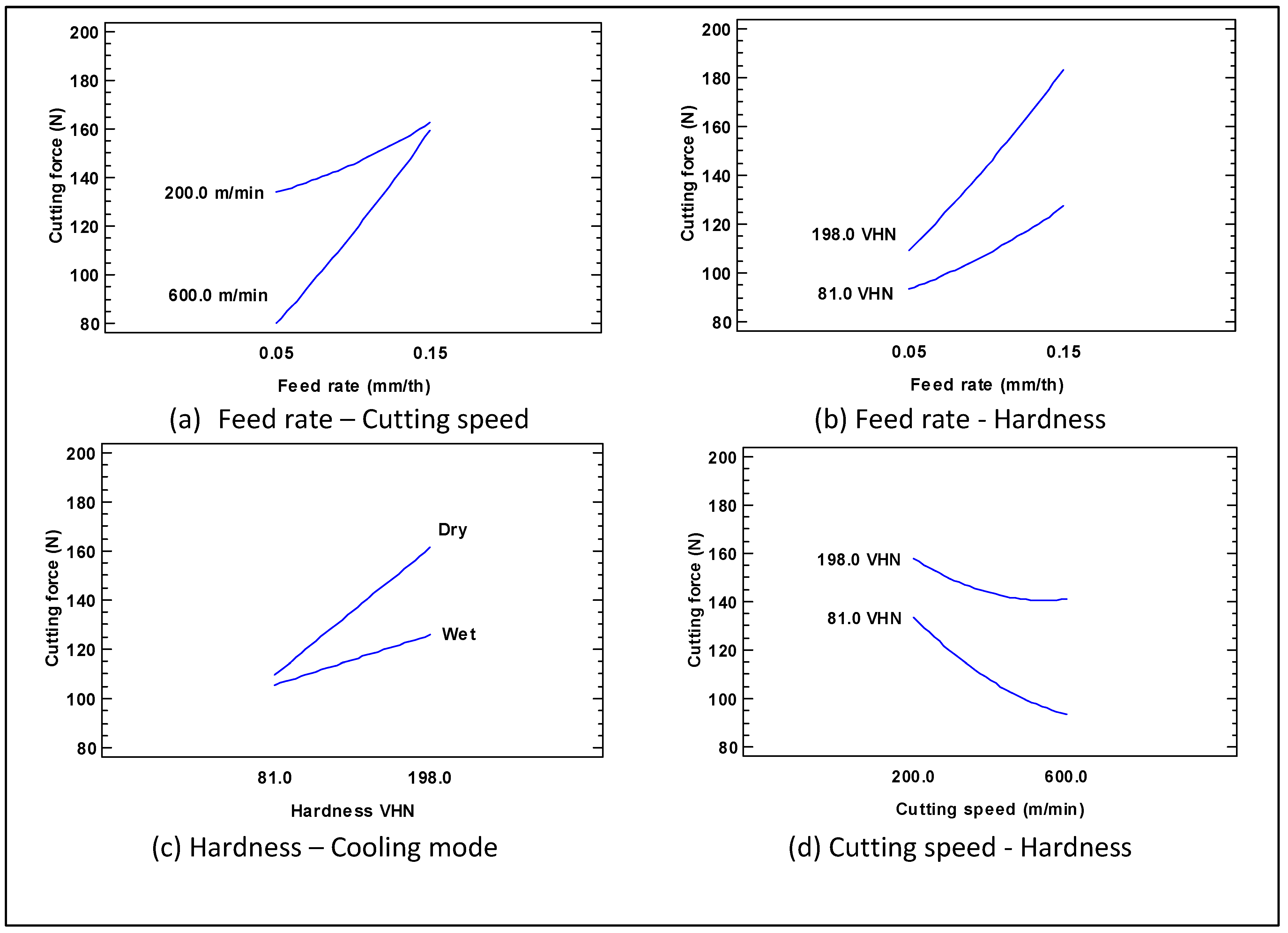

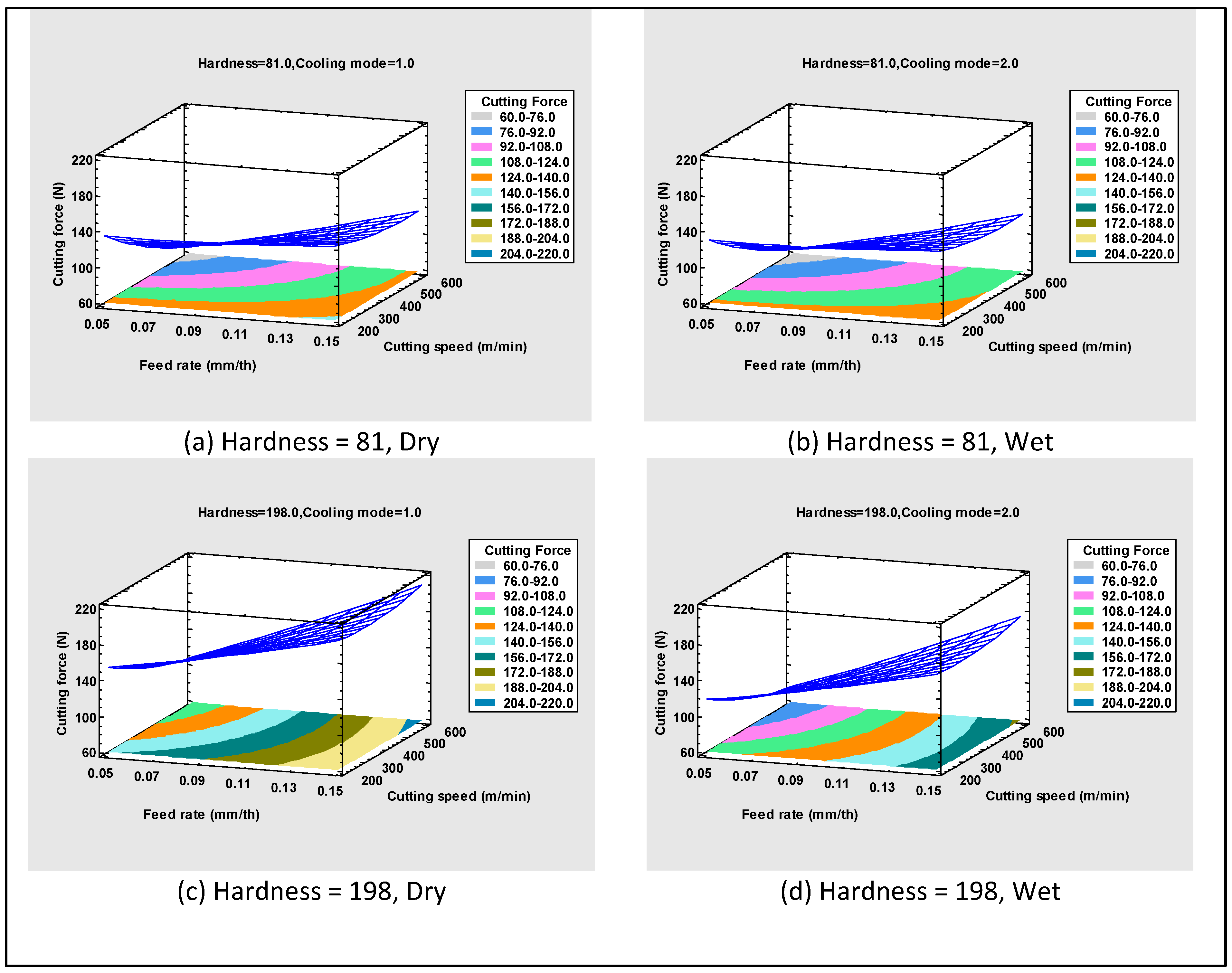

3.2.1. Statistical Analysis of Cutting Force in Machining of A7075

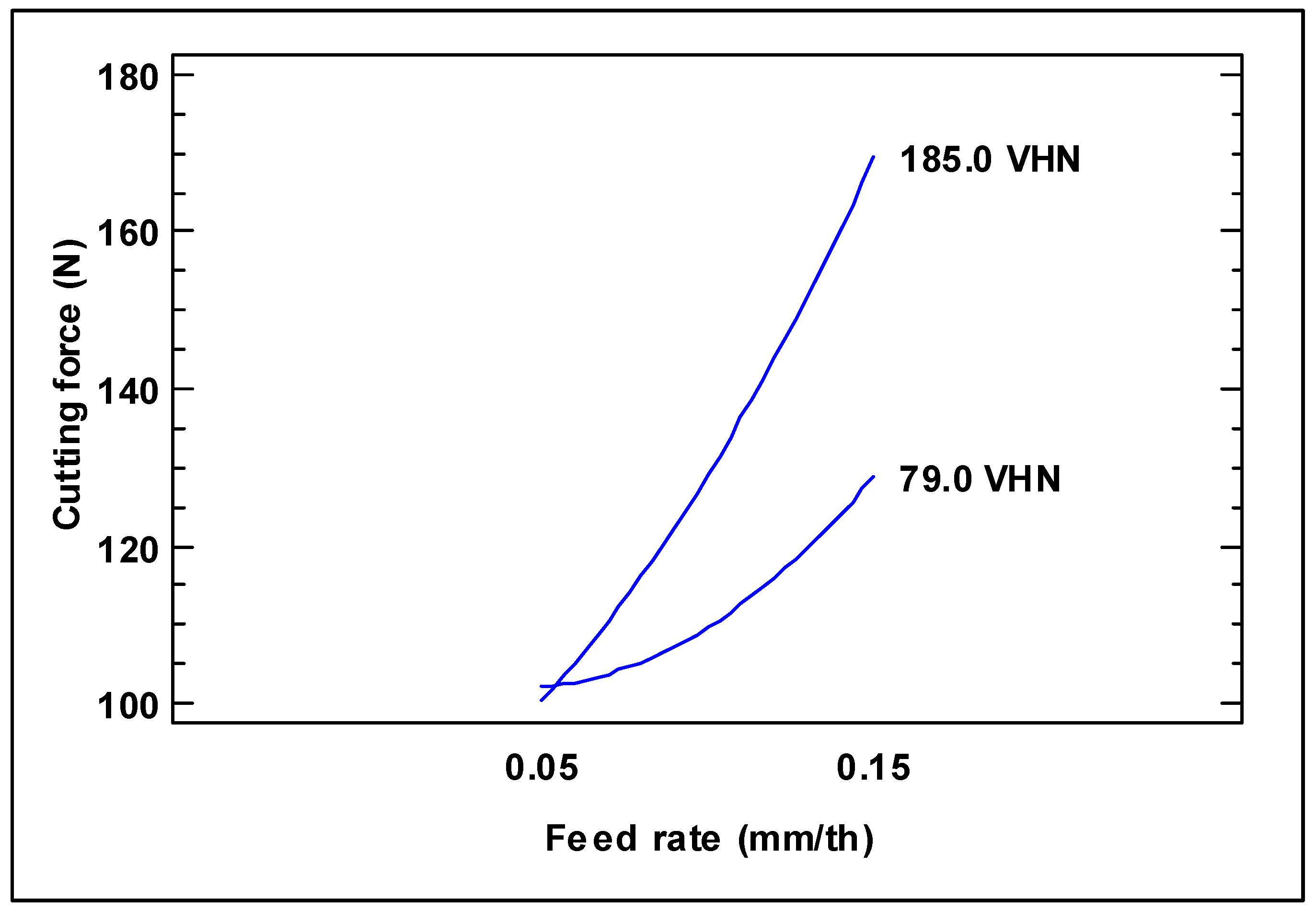

3.2.2. The Statistical Analysis of Cutting Force in Machining of A7075-Sc

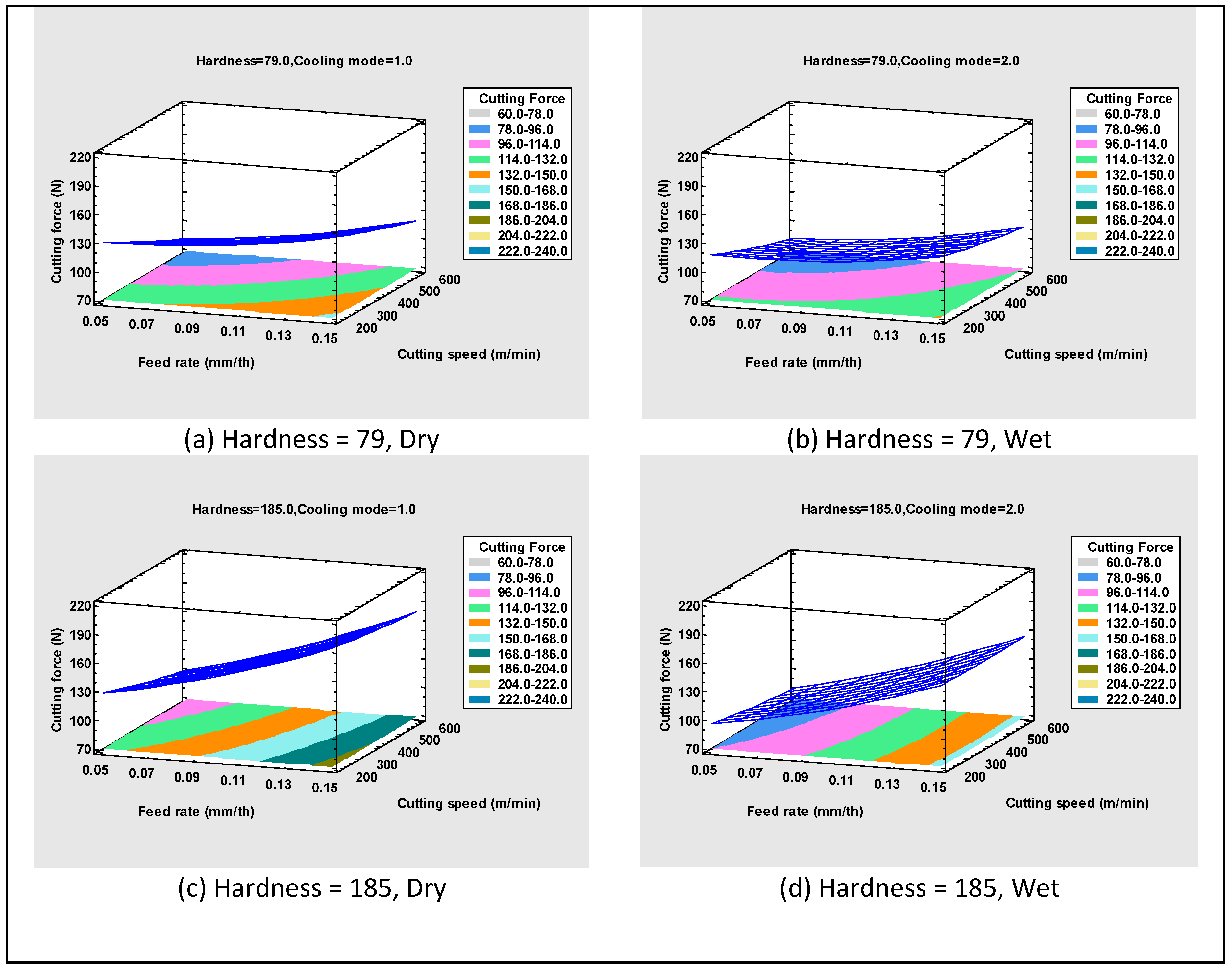

3.2.3. Statistical Analysis of Cutting Force in Machining of A7075-Li-Sc

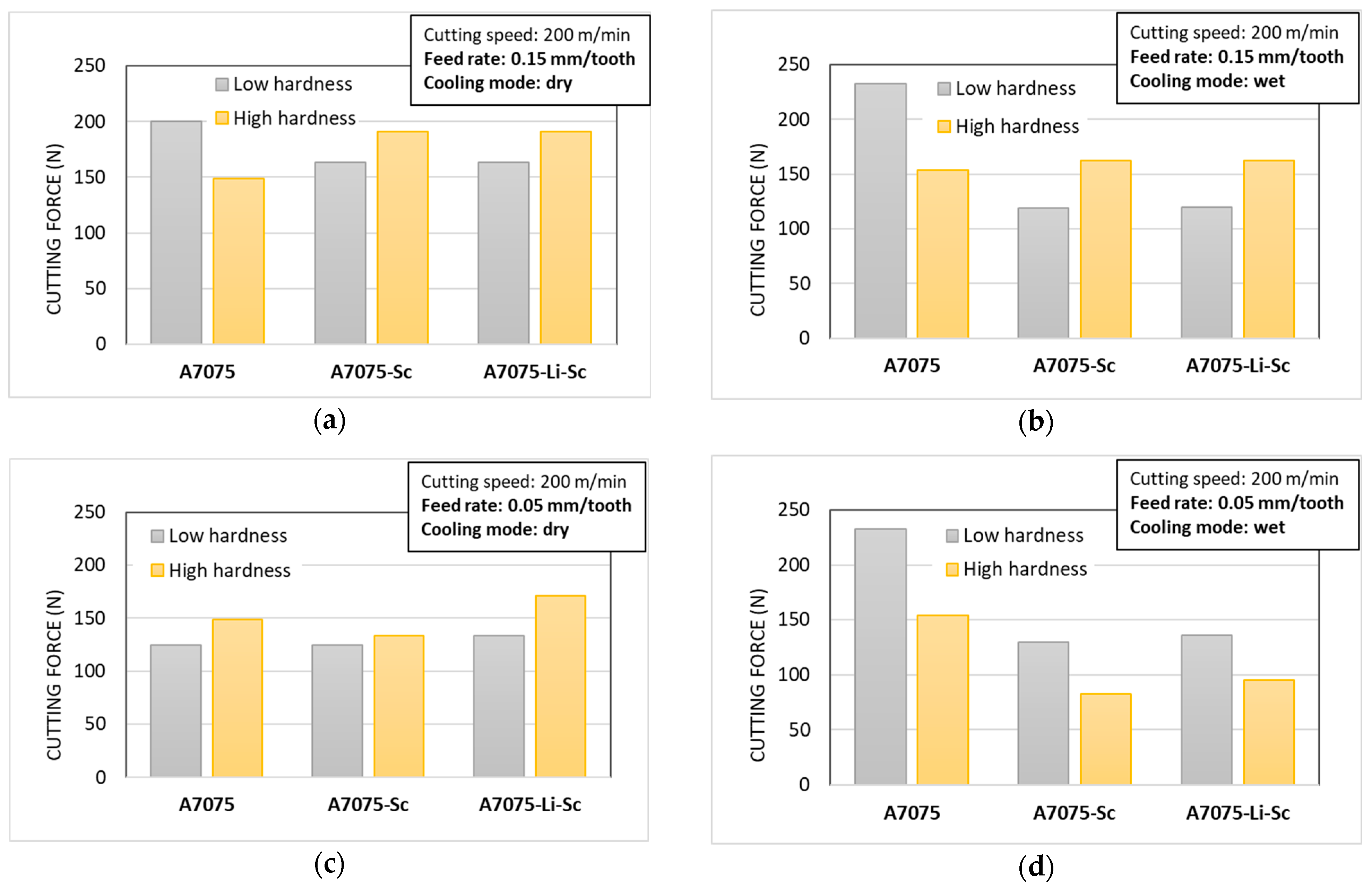

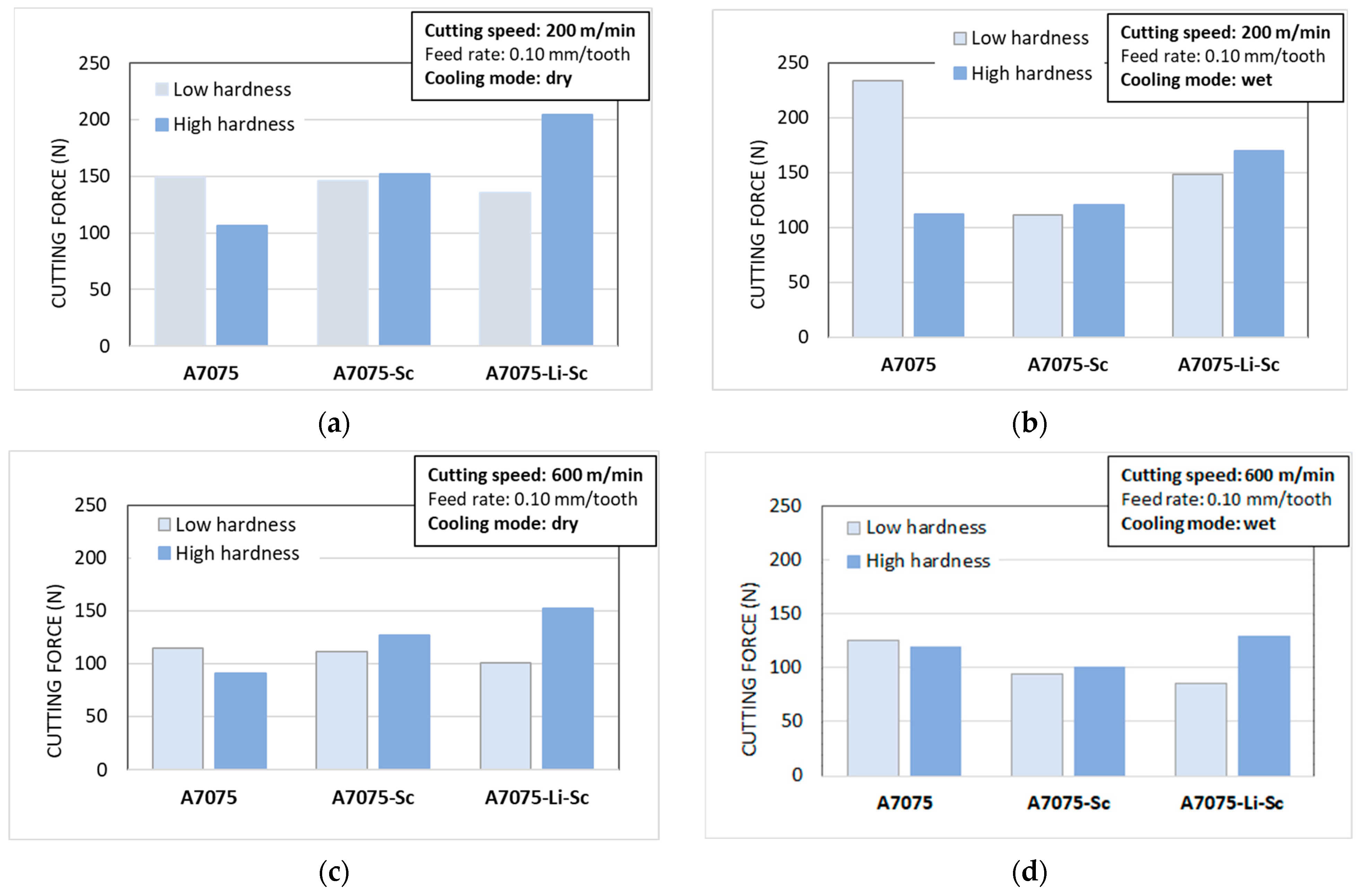

3.3. Comparative Analysis of the Effects of Added Elements

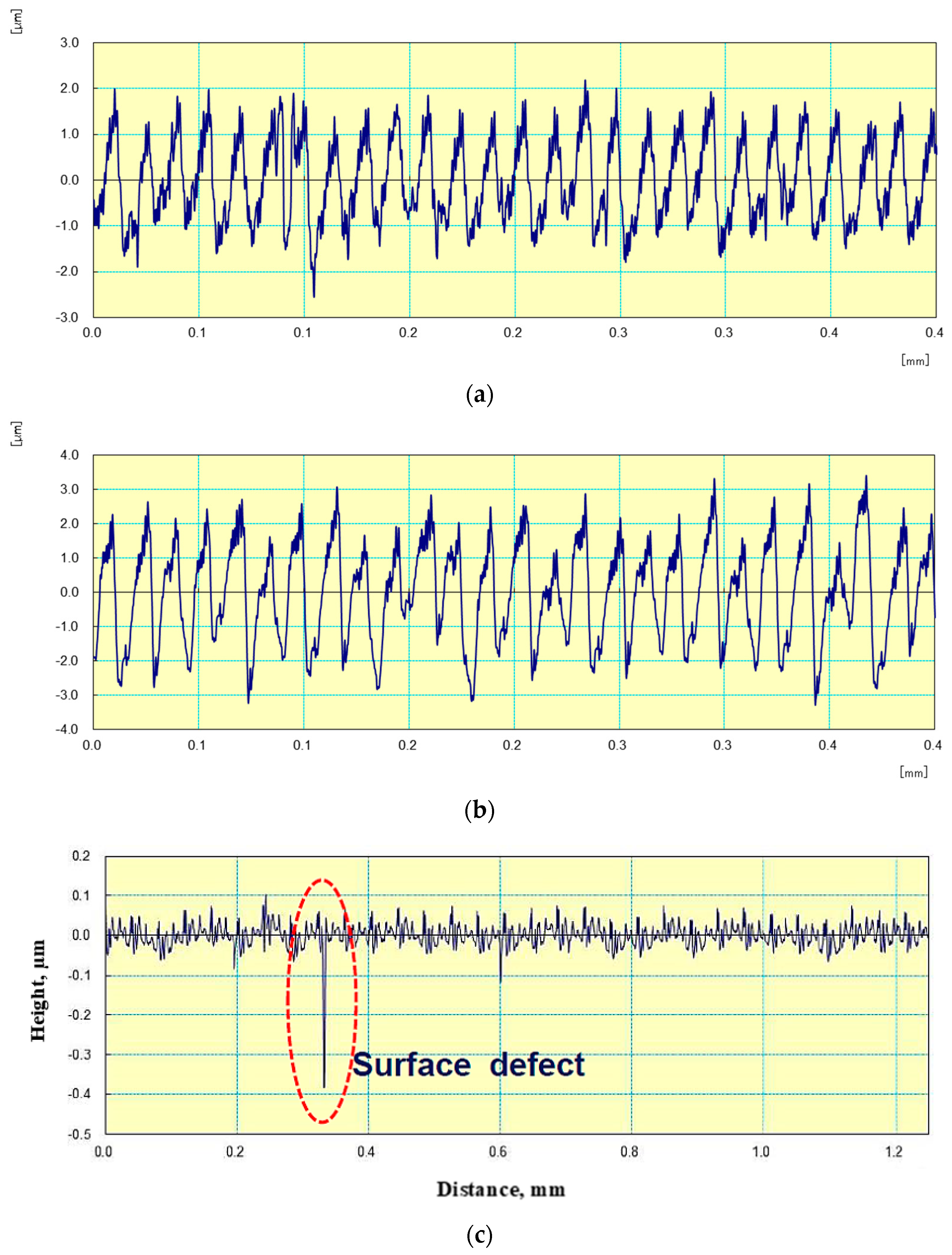

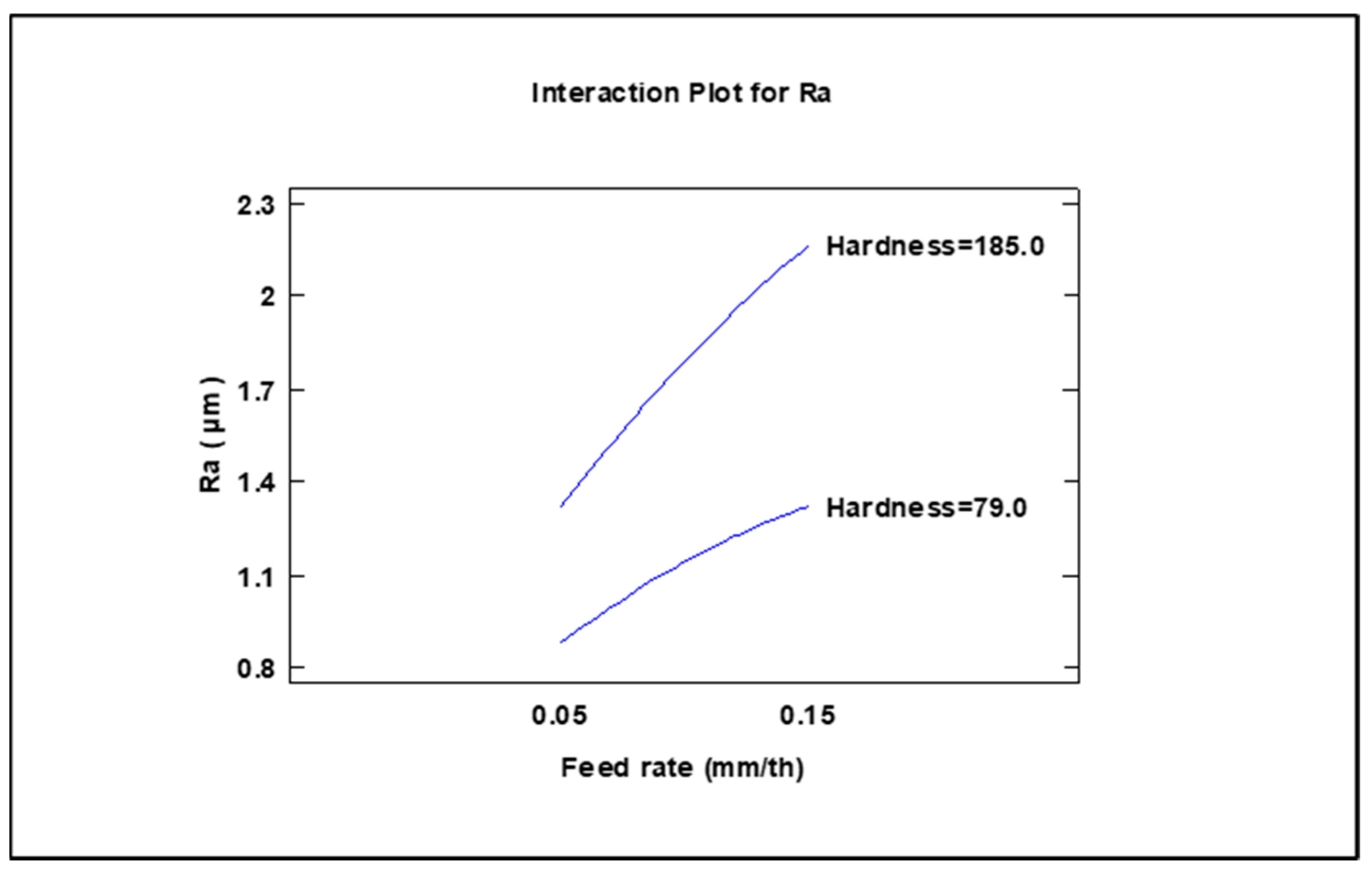

3.4. Surface Roughness

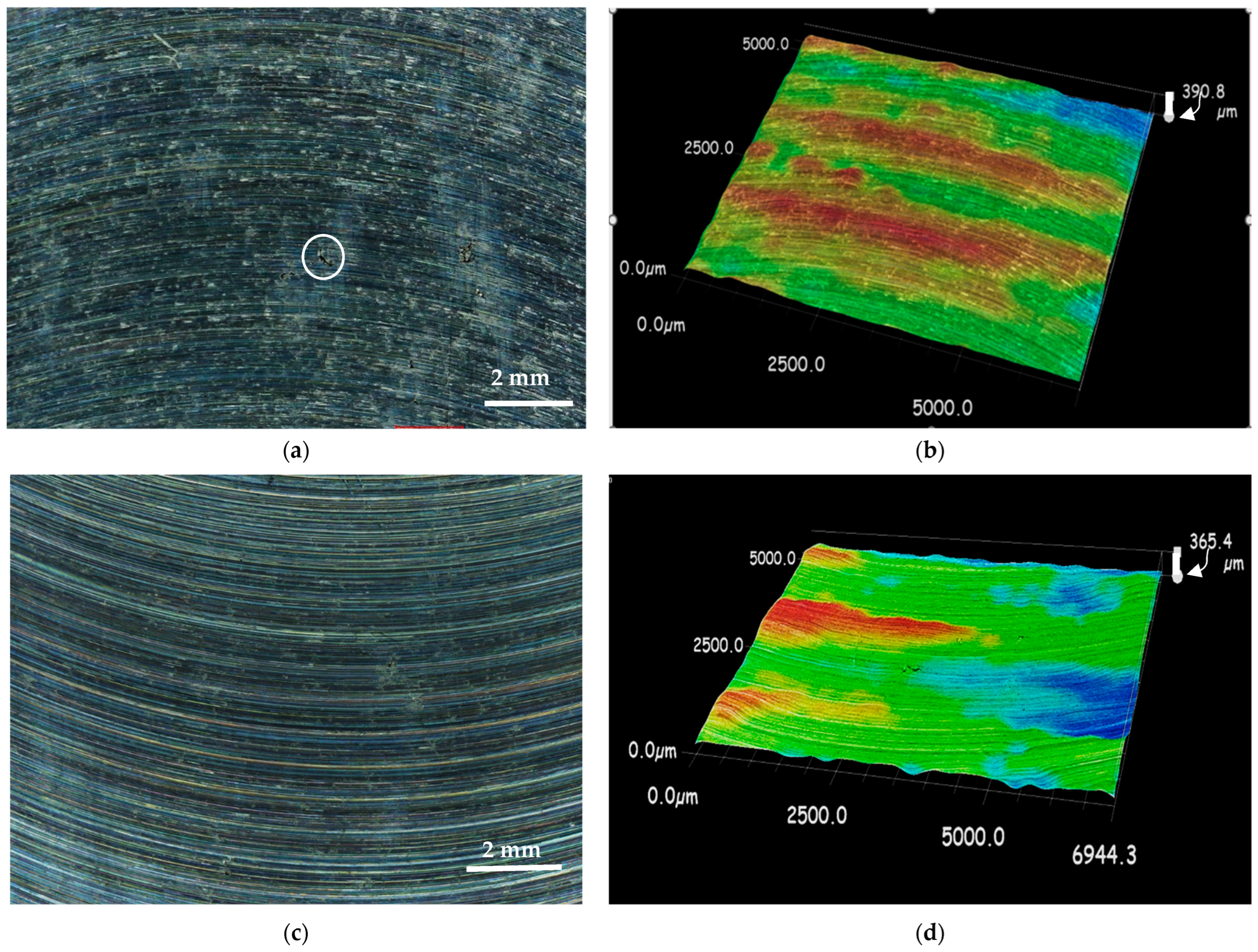

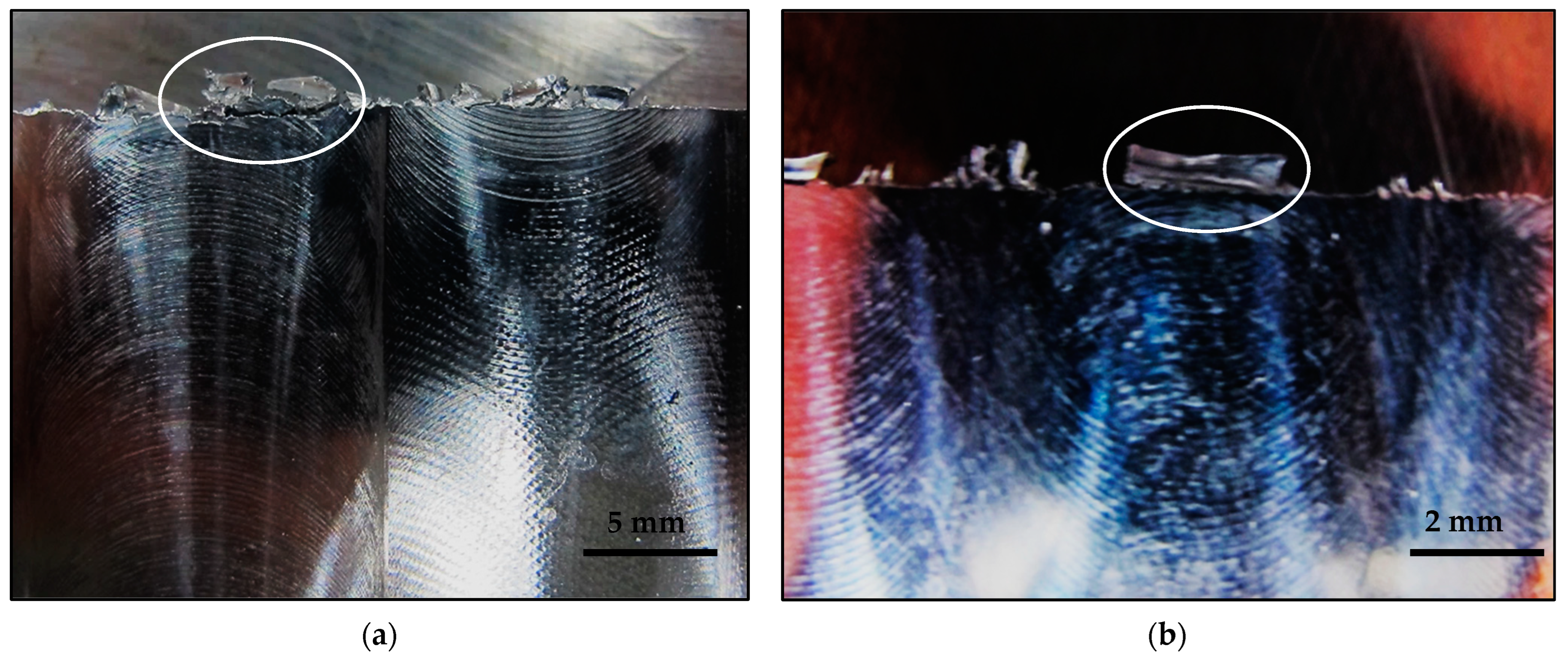

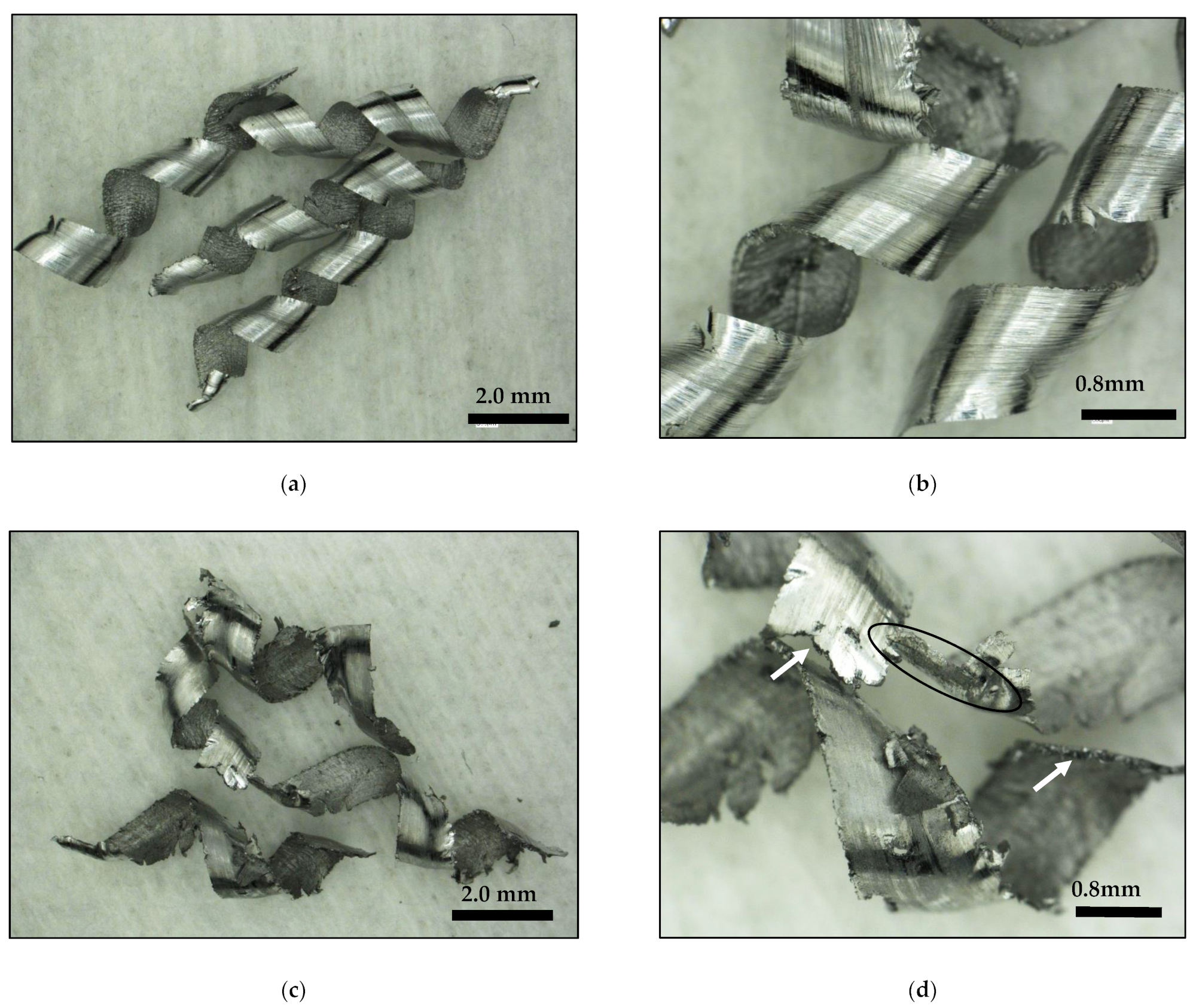

3.5. Burr and Chip Formation

4. Conclusions

- The feed rate has the most significant effect on the cutting force in all the studied alloys, with a more pronounced impact observed in the A7075 alloy under wet machining conditions.

- As for the A7075-Li and A7075-Li-Sc alloys, the impact of feed rate was more significant in workpieces with high hardness, i.e., aged at 120 °C/24 h.

- Wet machining significantly reduces the cutting force, with a more pronounced effect on harder materials, regardless of their composition.

- Dry machining yields satisfactory results when the alloys are in their soft conditions (i.e., aged at 280 °C/8 h, in particular for the A7075-Li-Sc alloy).

- It is recommended that the T6 heat treatment process (120 °C/24 h) be applied to the machined parts to enhance their hardness, which would significantly optimize their machinability characteristics.

- A practical conclusion drawn from the cutting force analysis is that, while increasing cutting speed generally reduces cutting force, this trend is more pronounced at lower feed rates for all alloys, at different levels.

- The implication of selecting lower feed rates and higher cutting speeds for the machining of these alloys not only reduces the cutting force but also maintains high material removal rates, making it an advantageous choice.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sunar, T.; Tuncay, T.; Özyürek, D.; Gürü, M. Investigation of Mechanical Properties of AA7075 Alloys Aged by Various Heat Treatments. Phys. Met. Met. 2020, 121, 1440–1446. [Google Scholar] [CrossRef]

- Altuntaş, G.; Altuntaş, O.; Bostan, B. Characterization of Al-7075/T651 Alloy by RRA Heat Treatment and Different Pre-deformation Effects. Trans. Indian Inst. Met. 2021, 74, 3025–3033. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Moeini, G.; Scharifi, E.; Lauhoff, C.; Böhm, S.; Niendorf, T. On the Effect of Quenching on Postweld Heat Treatment of Friction-Stir-Welded Aluminum 7075 Alloy. J. Mater. Eng. Perform. 2019, 28, 5255–5265. [Google Scholar] [CrossRef]

- Zou, X.L.; Hong, Y.A.N.; Chen, X.H. Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment. Trans. Nonferrous Met. Soc. China 2017, 27, 2146–2155. [Google Scholar] [CrossRef]

- Stojanovic, B.; Bukvic, M.; Epler, I. Application of aluminum and aluminum alloys in engineering. Appl. Eng. Lett. J. Eng. Appl. Sci. 2018, 3, 52–62. [Google Scholar] [CrossRef]

- Tajally, M.; Emadoddin, E. Mechanical and anisotropic behaviors of 7075 aluminum alloy sheets. Mater. Des. 2011, 32, 1594–1599. [Google Scholar] [CrossRef]

- Rana, R.S.; Purohit, R.; Das, S. Reviews on the influences of alloying elements on the microstructure and mechanical properties of aluminum alloys and aluminum alloy composites. Int. J. Sci. Res. Publ. 2012, 2, 1–7. [Google Scholar]

- Suresh, M.; Sharma, A.; More, A.; Nayan, N.; Suwas, S. Effect of Scandium addition on evolution of microstructure, texture and mechanical properties of thermo-mechanically processed Al-Li alloy AA2195. J. Alloys Compd. 2018, 740, 364–374. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Cao, L.; Tong, X.; Zou, Y.; Zhu, Q.; Tang, S.; Song, H.; Guo, M. Effect of Ag on aging precipitation behavior and mechanical properties of aluminum alloy 7075. Mater. Sci. Eng. A 2020, 804, 140515. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Chen, J.C.; Kirby, E.D. Surface roughness optimization in an end-milling operation using the Taguchi design method. J. Am. Acad. Dermatol. 2007, 184, 233–239. [Google Scholar] [CrossRef]

- Toenshoff, H.K.; Denkena, B. Basics of Cutting and Abrasive Processes; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Trent, E.M.; Wright, P.K. Metal Cutting; Butterworth-Heinemann: Boston, MA, USA, 2000. [Google Scholar]

- Lee, Y.J.; Wang, H. Sustainability of methods for augmented ultra-precision machining. Int. J. Precis. Eng. Manuf. Technol. 2023, 11, 585–624. [Google Scholar] [CrossRef]

- Astakhov, V.P. Improving sustainability of machining operation as a system endeavor. In Sustainable Machining; Davim, J., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–29. [Google Scholar]

- Mallick, R.; Kumar, R.; Panda, A.; Sahoo, A.K. Current Status of Hard Turning in Manufacturing: Aspects of Cooling Strategy and Sustainability. Lubricants 2023, 11, 108. [Google Scholar] [CrossRef]

- Chen, A.; Peng, Y.; Zhang, L.; Wu, G.; Li, Y. Microstructural evolution and mechanical properties of cast Al-3Li-1.5Cu-0.2Zr alloy during heat treatment. Mater. Charact. 2016, 114, 234–242. [Google Scholar] [CrossRef]

- Samuel, E.; Tahiri, H.; Samuel, A.M.; Songmene, V.; Samuel, F.H. A Review on Fundamentals of Grain Refining of Al-Si Cast Alloys. In Recent Advancements in Aluminum Alloys; IntechOpen Limited: London, UK, 2024; p. 83. [Google Scholar] [CrossRef]

- Tahiri, H.; Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Effect of Sr–Grain Refiner–Si interactions on the microstructure characteristics of Al–Si hypereutectic alloys. Int. J. Met. 2018, 12, 307–320. [Google Scholar] [CrossRef]

- Nafisi, S.; Ghomashchi, R. Grain refining of conventional and semi-solid A356 Al–Si alloy. J. Mater. Process. Technol. 2006, 174, 371–383. [Google Scholar] [CrossRef]

- Dong, X.; Ji, S. Si poisoning and promotion on the microstructure and mechanical properties of Al–Si–Mg cast alloys. J. Mater. Sci. 2018, 53, 7778–7792. [Google Scholar] [CrossRef]

- Easton, M.; St John, D. A model of grain refinement incorporating alloy constitution and potency of heterogeneous nucleant particles. Acta Mater. 2001, 49, 1867–1878. [Google Scholar] [CrossRef]

- Qian, M.; Cao, P.; Easton, M.; McDonald, S.; StJohn, D. An analytical model for constitutional supercooling-driven grain formation and grain size prediction. Acta Mater. 2010, 58, 3262–3270. [Google Scholar] [CrossRef]

- Men, H.; Fan, Z. Effects of solute content on grain refinement in an isothermal melt. Acta Mater. 2011, 59, 2704–2712. [Google Scholar] [CrossRef]

- StJohn, D.; Qian, M.; Easton, M.; Cao, P. The Interdependence Theory: The relationship between grain formation and nucleant selection. Acta Mater. 2011, 59, 4907–4921. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Armstrong, R.W. 60 years of Hall-Petch: Past to present nano-scale connections. Mater. Trans. 2014, 55, 2–12. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Knight, B.E.; Schuh, C.A. Six decades of the Hall–Petch effect—A survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 2016, 61, 495–512. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Marquis, E.A.; Seidman, D.N. Nanoscale structural evolution of Al3Sc precipitates in Al (Sc) alloys. Acta Mater. 2001, 49, 1909–1919. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Li, S.-S.; Li, L.; Han, J.; Wang, C.-T.; Xiao, Y.-Q.; Jian, X.-D.; Qian, P.; Su, Y.-J. First-Principles study on the nucleation of precipitates in ternary Al alloys doped with Sc, Li, Zr, and Ti elements. Appl. Surf. Sci. 2020, 526, 146455. [Google Scholar] [CrossRef]

- Prasad, N.E.; Ramachandran, T.R. Chapter 3—Phase diagrams and phase reactions in Al–Li alloys. In Aluminum-Lithium Alloys; Prasad, N.E., Gokhale, A.A., Wanhill, R.J.H., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2014; pp. 61–97. [Google Scholar]

- Khan, M.A.; Wang, Y.; Afifi, M.A.; Malik, A.; Nazeer, F.; Yasin, G.; Jiawei, B.; Zhang, H. Microstructure and mechanical properties of an Al-Zn-Cu-Mg alloy processed by hot forming processes followed by heat treatments. Mater. Charact. 2019, 157, 109901. [Google Scholar] [CrossRef]

- Milkereit, B.; Österreich, M.; Schuster, P.; Kirov, G.; Mukeli, E.; Kessler, O. Dissolution and Precipitation Behavior for Hot Forming of 7021 and 7075 Aluminum Alloys. Metals 2018, 8, 531. [Google Scholar] [CrossRef]

- Hu, T.; Ma, K.; Topping, T.; Schoenung, J.; Lavernia, E. Precipitation phenomena in an ultrafine-grained Al alloy. Acta Mater. 2013, 61, 2163–2178. [Google Scholar] [CrossRef]

- Viana, F.; Pinto, A.M.P.; Santos, H.M.C.; Lopes, A.B. Retrogression and re-ageing of 7075 aluminium alloy: Microstructural characterization. J. Mater. Process. Technol. 1999, 92–93, 54–59. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, W.; Xiao, D.; Ma, Y.; Huang, L.; Tang, Y. A critical review: Crystal structure, evolution and interaction mechanism with dislocations of nano precipitates in Al-Li alloys. Mater. Des. 2022, 217, 110629. [Google Scholar] [CrossRef]

- Samuel, F.H. Microstructural characterization of rapidly solidified Al-Li-Co powders. Met. Trans. A 1986, 17, 73–91. [Google Scholar] [CrossRef]

- Flores-Campos, R.; Estrada-Guel, I.; Miki-Yoshida, M.; Martínez-Sánchez, R.; Herrera-Ramírez, J.M. Microstructure and mechanical properties of 7075 aluminum alloy nanostructured composites processed by mechanical milling and indirect hot extrusion. Mater. Charact. 2012, 63, 39–46. [Google Scholar] [CrossRef]

- Rokni, M.R.; Zarei-Hanzaki, A.; Abedi, H.R.; Haghdadi, N. Microstructure evolution and mechanical properties of backward thixoextruded 7075 aluminum alloy. Mater. Des. (1980-2015) 2012, 36, 557–563. [Google Scholar] [CrossRef]

- Luo, J.; Luo, H.; Li, S.; Wang, R.; Ma, Y. Effect of pre-ageing treatment on second nucleating of GPII zones and precipitation kinetics in an ultrafine grained 7075 aluminum alloy. Mater. Des. 2019, 187, 108402. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, S.; Trimby, P.W.; Liao, X.; Murashkin, M.Y.; Valiev, R.Z.; Liu, J.; Cairney, J.M.; Ringer, S.P.; Sha, G. Dynamic precipitation, segregation and strengthening of an Al-Zn-Mg-Cu alloy (AA7075) processed by high-pressure torsion. Acta Mater. 2018, 162, 19–32. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Koh, D.-H.; Kim, H.-W.; Ahn, Y.-S. Improved bake-hardening response of Al-Zn-Mg-Cu alloy through pre-aging treatment. Scr. Mater. 2018, 147, 45–49. [Google Scholar] [CrossRef]

- Peng, X.; Li, Y.; Liang, X.; Guo, Q.; Xu, G.; Peng, Y.; Yin, Z. Precipitate behavior and mechanical properties of enhanced solution treated Al-Zn-Mg-Cu alloy during non-isothermal ageing. J. Alloys Compd. 2018, 735, 964–974. [Google Scholar] [CrossRef]

- dos Santos, J.; Staron, P.; Fischer, T.; Robson, J.; Kostka, A.; Colegrove, P.; Wang, H.; Hilgert, J.; Bergmann, L.; Hütsch, L.; et al. Understanding precipitate evolution during friction stir welding of Al-Zn-Mg-Cu alloy through in-situ measurement coupled with simulation. Acta Mater. 2018, 148, 163–172. [Google Scholar] [CrossRef]

- Reda, Y.; Yehia, H.; El-Shamy, A. Microstructural and mechanical properties of Al-Zn alloy 7075 during RRA and triple aging. Egypt. J. Pet. 2021, 31, 9–13. [Google Scholar] [CrossRef]

- Kilic, S.; Kacar, I.; Sahin, M.; Ozturk, F.; Erdem, O. Effects of Aging Temperature, Time, and Pre-Strain on Mechanical Properties of AA7075. Mater. Res. 2019, 22, e20190006. [Google Scholar] [CrossRef]

- Guner, A.T.; Dispinar, D.; Tan, E. Microstructural and Mechanical Evolution of Semisolid 7075 Al Alloy Produced by SIMA Process at Various Heat Treatment Parameters. Arab. J. Sci. Eng. 2019, 44, 1243–1253. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Krooß, P.; Fröck, H.; Milkereit, B.; Kessler, O.; Niendorf, T. Effects of Aging under Stress on Mechanical Properties and Microstructure of EN AW 7075 Alloy. Metals 2021, 11, 1142. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Scharifi, E.; Weidig, U.; Steinhoff, K.; Niendorf, T. Effect of Tool Temperature on Mechanical Properties and Microstructure of Thermo-Mechanically Processed AA6082 and AA7075 Aluminum Alloys. HTM J. Heat Treat. Mater. 2020, 75, 177–191. [Google Scholar] [CrossRef]

- Scharifi, E.; Savaci, U.; Kavaklioglu, Z.; Weidig, U.; Turan, S.; Steinhoff, K. Effect of thermo-mechanical processing on quench-induced precipitates morphology and mechanical properties in high strength AA7075 aluminum alloy. Mater. Charact. 2021, 174, 111026. [Google Scholar] [CrossRef]

- Liu, B.; Hu, X. Chapter 1—Hollow Micro- and Nanomaterials: Synthesis and Applications. In Micro and Nano Technologies, Advanced Nanomaterials for Pollutant Sensing and Environmental Catalysis; Zhao, Q., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–38. [Google Scholar]

- Marani, M.; Songmene, V.; Zeinali, M.; Kouam, J.; Zedan, Y. Neuro-fuzzy predictive model for surface roughness and cutting force of machined Al–20 Mg2Si–2Cu metal matrix composite using additives. Neural Comput. Appl. 2019, 32, 8115–8126. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, X.; Cao, X.; Yu, X.; Wang, Y. Analysis on the tool wear behavior of 7050-T7451 aluminum alloy under ultrasonic elliptical vibration cutting. Wear 2020, 466–467, 203538. [Google Scholar] [CrossRef]

- Zhang, P.; Yue, X.J.; Wang, P.H.; Yu, X. Surface integrity and tool wear mechanism of 7050-T7451 aluminum alloy under dry cutting. Vacuum 2020, 184, 31. [Google Scholar]

- Belhocine, A.; Ghazaly, N.M. Effects of material properties on generation of brake squeal noise using finite element method. Lat. Am. J. Solids Struct. 2015, 12, 1432–1447. [Google Scholar] [CrossRef]

- Junge, T.; Liborius, H.; Mehner, T.; Nestler, A.; Schubert, A.; Lampke, T. Measurement system based on the Seebeck effect for the determination of temperature and tool wear during turning of aluminum alloys. Procedia CIRP 2020, 93, 1435–1441. [Google Scholar] [CrossRef]

- Meng, X.; Lin, Y.; Mi, S. An Improved Johnson–Cook Constitutive Model and Its Experiment Validation on Cutting Force of ADC12 Aluminum Alloy During High-Speed Milling. Metals 2020, 10, 1038. [Google Scholar] [CrossRef]

- Cantero, J.L.; Díaz-Álvarez, J.; Miguélez, M.H.; Marín, N.C. Analysis of tool wear patterns in finishing turning of Inconel 718. Wear 2013, 297, 885–894. [Google Scholar] [CrossRef]

- Gupta, M.K.; Korkmaz, M.E.; Sarıkaya, M.; Krolczyk, G.M.; Günay, M.; Wojciechowski, S. Cutting forces and temperature measurements in cryogenic assisted turning of AA2024-T351 alloy: An experimentally validated simulation approach. Measurement 2021, 188, 110594. [Google Scholar] [CrossRef]

- Shankar, S.; Mohanraj, T. Tool condition monitoring in milling using sensor fusion technique. In Proceedings of the Malaysian International Tribology Conference, Penang, Malaysia, 16–17 November 2015; pp. 322–323. [Google Scholar]

- Shankar, S.; Mohanraj, T.; Thangarasu, S.K. Multi-response milling process optimization using the Taguchi method coupled to grey relational analysis. Mater. Test. 2016, 58, 462–470. [Google Scholar] [CrossRef]

- Pham, T.-H.; Nguyen, D.-T.; Banh, T.-L.; Tong, V.-C. Experimental study on the chip morphology, tool–chip contact length, workpiece vibration, and surface roughness during high-speed face milling of A6061 aluminum alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 234, 610–620. [Google Scholar] [CrossRef]

- Yuan, Y.; Jing, X.; Li, H.; Ehmann, K.F.; Zhang, D. Chatter detection based on wavelet coherence functions in micro-end-milling processes. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 233, 1934–1945. [Google Scholar] [CrossRef]

- Hamed, M.; Zedan, Y.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Effect of tool quality on the machinability characteristics of Al-Cu and Al-Si cast alloys. Int. J. Adv. Manuf. Technol. 2019, 106, 1317–1326. [Google Scholar] [CrossRef]

- Hamed, M.; Zedan, Y.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Milling parameters of Al-Cu and Al-Si cast alloys. Int. J. Adv. Manuf. Technol. 2019, 104, 3731–3743. [Google Scholar] [CrossRef]

- Songmene, V.; Khettabi, R.; Zaghbani, I.; Kouam, J.; Djebara, A. Machining and machinability of aluminum alloys. Alum. Alloys Theory Appl. 2011, 377, 400. [Google Scholar]

- Balout, B.; Songmene, V.; Masounave, J. An Experimental study of dust generation during dry drilling of pre-cooled and pre-heated workpiece materials. J. Manuf. Process. 2007, 9, 23–34. [Google Scholar] [CrossRef]

- Barry, J.; Byrne, G. The mechanisms of chip formation in machining hardened steels. J. Manuf. Sci. Eng. 2002, 124, 528–535. [Google Scholar] [CrossRef]

| Code | Si | Mg | Cr | Fe | Cu | Zn | Zr | Ti | Li | Sc | Ag |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A7075 | 0.20 | 2.1 | 0.18 | 0.16 | 1.5 | 5.6 | - | 0.03 | - | - | -- |

| A7075-Sc | 0.11 | 2.8 | 0.16 | 0.05 | 1.5 | 6.6 | 0.3 | 0.16 | 0.06 | 0.12 | 0.27 |

| A7075-Li-Sc | 0.16 | 2.2 | 0.14 | 0.10 | 1.3 | 6.5 | 0.3 | 0.15 | 2.2 | 0.18 | 0.27 |

| Number | Solution Heat Treatment | Quenching | Artificial Aging |

|---|---|---|---|

| 1 | (8 h @ 470 °C) | Quenched in warm water at 60 °C | None |

| 2 | Single aging (24 h @ 120 °C) | ||

| 3 | Single aging (8 h @ 280 °C) | ||

| 4 | Double aging (24 h @ 120 °C + 8 h @ 180 °C) | ||

| 5 | Double aging (8 h @ 180 °C + 24 h @ 120 °C) | ||

| 6 | Double aging (8 h @ 280 °C + 24 h @ 120 °C) |

| Experimental Variables | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Cutting speed (m/min) | 200 | 400 | 600 |

| Feed per tooth (mm/z) | 0.05 | 0.1 | 0.15 |

| Cooling mode | Dry | - | Wet |

| Material | A7075 | A7075-Sc | A7075-Li-Sc |

| Aging treatment | 8 h @ 280 °C | - | 24 h @ 120 °C |

| Test (Tool Path) | Cutting Speed (m/min) | Feed Rate (mm/tooth) | Cutting Time (s) |

|---|---|---|---|

| 1 | 200 | 0.05 | 4.71 |

| 2 | 400 | 0.05 | 2.36 |

| 3 | 600 | 0.05 | 1.57 |

| 4 | 200 | 0.1 | 2.36 |

| 5 | 400 | 0.1 | 1.18 |

| 6 | 600 | 0.1 | 0.79 |

| 7 | 200 | 0.15 | 1.57 |

| 8 | 400 | 0.15 | 0.79 |

| 9 | 600 | 0.15 | 0.52 |

| Heat Treatment | Solution Heat Treatment | Artificial Aging | Alloy Type | Micro-Hardness (HVN) |

|---|---|---|---|---|

| 1 | 8 h @ 470 °C | - | A7075 | 113.7 |

| A7075-Sc | 149.6 | |||

| A7075-Li-Sc | 155.4 | |||

| 2 | Single aging (24 h @ 120 °C) | A7075 | 176 | |

| A7075-Sc | 185 | |||

| A7075-Li-Sc | 198 | |||

| 3 | Single aging (8 h @ 280 °C) | A7075 | 62.6 | |

| A7075-Sc | 79.2 | |||

| A7075-Li-Sc | 80.8 | |||

| 4 | Double aging (24 h @ 120 °C + 8 h @ 180 °C) | A7075 | 142.7 | |

| A7075-Sc | 167.4 | |||

| A7075-Li-Sc | 174.8 | |||

| 5 | Double aging (8 h @ 180 °C + 24 h @ 120 °C) | A7075 | 144.8 | |

| A7075-Sc | 171.9 | |||

| A7075-Li-Sc | 174 | |||

| 6 | Double aging (8 h @ 280 °C + 24 h @ 120 °C) | A7075 | 65.9 | |

| A7075-Sc | 78.8 | |||

| A7075-Li-Sc | 78.7 |

| (a) | |||||||

| Material | Test Number | Cutting Speed (m/min) | Feed Rate (mm/tooth) | F (N) | |||

| Softest (62 VHN) | Hardest (176 VHN) | ||||||

| Dry | Wet | Dry | Wet | ||||

| A7075 | 1 | 200 | 0.05 | 61.0 | 73.0 | 203.8 | 261.1 |

| 2 | 0.10 | 106.4 | 112.5 | 149.4 | 233.6 | ||

| 3 | 0.15 | 149.0 | 154.8 | 200.4 | 233.8 | ||

| 4 | 400 | 0.05 | 62.3 | 81.6 | 80.3 | 132.7 | |

| 5 | 0.10 | 103.4 | 118.0 | 121.2 | 150.9 | ||

| 6 | 0.15 | 145.6 | 164.1 | 172.0 | 184.5 | ||

| 7 | 600 | 0.05 | 53.9 | 73.5 | 73.7 | 88.1 | |

| 8 | 0.1 | 90.8 | 119.2 | 114.8 | 125.0 | ||

| 9 | 0.15 | 124.4 | 165.7 | 155.7 | 170.2 | ||

| (b) | |||||||

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value | ||

| A: Feed rate | 4.56841 | 1 | 4.56841 | 216.82 | 0.0000 | ||

| B: Cutting speed | 0.219268 | 1 | 0.219268 | 10.41 | 0.0037 | ||

| C: Hardness | 1.13849 | 1 | 1.13849 | 54.03 | 0.0000 | ||

| D: Cooling mode | 1.88604 | 1 | 1.88604 | 89.51 | 0.0000 | ||

| AA | 0.0347161 | 1 | 0.0347161 | 1.65 | 0.2121 | ||

| AB | 0.007921 | 1 | 0.007921 | 0.38 | 0.5458 | ||

| AC | 0.360885 | 1 | 0.360885 | 17.13 | 0.0004 | ||

| AD | 0.000442042 | 1 | 0.000442042 | 0.02 | 0.8861 | ||

| BB | 0.0351125 | 1 | 0.0351125 | 1.67 | 0.2096 | ||

| BC | 0.0000601667 | 1 | 0.0000601667 | 0.00 | 0.9578 | ||

| BD | 0.000988167 | 1 | 0.000988167 | 0.05 | 0.8305 | ||

| CD | 0.464669 | 1 | 0.464669 | 22.05 | 0.0001 | ||

| Total error | 0.484606 | 23 | 0.0210698 | ||||

| Total (corr.) | 9.20161 | 35 | |||||

| Material | Test Number | Cutting Speed (m/min) | Feed Rate (mm/tooth) | F (N) | |||

|---|---|---|---|---|---|---|---|

| Softest (79 VHN) | Hardest (185 VHN) | ||||||

| Dry | Wet | Dry | Wet | ||||

| A7075-Sc | 1 | 200 | 0.05 | 124.3 | 129.9 | 133.3 | 82.3 |

| 2 | 0.1 | 146.0 | 111.6 | 151.8 | 120.9 | ||

| 3 | 0.15 | 163.0 | 119.9 | 191.1 | 162.1 | ||

| 4 | 400 | 0.05 | 96.0 | 101.3 | 117.8 | 91.4 | |

| 5 | 0.1 | 106.1 | 111.2 | 144.5 | 118.2 | ||

| 6 | 0.15 | 135.5 | 121.7 | 173.0 | 162.2 | ||

| 7 | 600 | 0.05 | 75.9 | 82.2 | 109.8 | 80.9 | |

| 8 | 0.1 | 111.4 | 93.7 | 127.3 | 100.9 | ||

| 9 | 0.15 | 117.9 | 112.6 | 185.8 | 155.9 | ||

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| A: Feed rate | 13,804.8 | 1 | 13,804.8 | 156.82 | 0.0000 |

| B: Cutting speed | 3311.15 | 1 | 3311.15 | 37.61 | 0.0000 |

| C: Hardness | 3383.36 | 1 | 3383.36 | 38.43 | 0.0000 |

| D: Cooling mode | 3433.96 | 1 | 3433.96 | 39.01 | 0.0000 |

| AA | 266.805 | 1 | 266.805 | 3.03 | 0.0951 |

| AB | 203.776 | 1 | 203.776 | 2.31 | 0.1418 |

| AC | 2679.71 | 1 | 2679.71 | 30.44 | 0.0000 |

| AD | 76.3267 | 1 | 76.3267 | 0.87 | 0.3614 |

| BB | 14.8512 | 1 | 14.8512 | 0.17 | 0.6851 |

| BC | 6048.37 | 1 | 6048.37 | 39.79 | 0.0000 |

| BD | 244.482 | 1 | 244.482 | 1.61 | 0.2174 |

| CD | 4578.78 | 1 | 4578.78 | 30.12 | 0.0000 |

| Total error | 3496.59 | 23 | 152.025 | ||

| Total (corr.) | 70,993.4 | 35 |

| Material | Test Number | Cutting Speed (m/min) | Feed Rate (mm/tooth) | F (N) | |||

|---|---|---|---|---|---|---|---|

| Softest (81 VHN) | Hardest (198 VHN) | ||||||

| Dry | Wet | Dry | Wet | ||||

| A7075-Li-Sc | 1 | 200 | 0.05 | 133.4 | 135.7 | 171.4 | 95.3 |

| 2 | 0.1 | 125.5 | 134.0 | 182.1 | 133.1 | ||

| 3 | 0.15 | 135.4 | 148.1 | 204.2 | 170.0 | ||

| 4 | 400 | 0.05 | 90.8 | 97.9 | 125.7 | 93.7 | |

| 5 | 0.1 | 109.3 | 113.4 | 158.1 | 131.2 | ||

| 6 | 0.15 | 133.4 | 109.4 | 195.6 | 169.8 | ||

| 7 | 600 | 0.05 | 61.1 | 64.1 | 109.5 | 82.6 | |

| 8 | 0.1 | 100.9 | 85.3 | 152.2 | 128.4 | ||

| 9 | 0.15 | 147.5 | 113.4 | 204.1 | 178.4 | ||

| Source | Sum of Squares | Df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| A: Feed rate | 17,501.4 | 1 | 17,501.4 | 161.48 | 0.0000 |

| B: Cutting speed | 4836.52 | 1 | 4836.52 | 44.62 | 0.0000 |

| C: Hardness | 11,620.8 | 1 | 11,620.8 | 107.22 | 0.0000 |

| D: Cooling mode | 3528.36 | 1 | 3528.36 | 32.55 | 0.0000 |

| AA | 56.0035 | 1 | 56.0035 | 0.52 | 0.4795 |

| AB | 2606.1 | 1 | 2606.1 | 24.05 | 0.0001 |

| AC | 2394.0 | 1 | 2394.0 | 22.09 | 0.0001 |

| AD | 3.01042 | 1 | 3.01042 | 0.03 | 0.8691 |

| BB | 268.733 | 1 | 268.733 | 2.48 | 0.1290 |

| BC | 803.884 | 1 | 803.884 | 7.42 | 0.0121 |

| BD | 6.72042 | 1 | 6.72042 | 0.06 | 0.8056 |

| CD | 2246.76 | 1 | 2246.76 | 20.73 | 0.0001 |

| Total error | 2492.82 | 23 | 108.384 | ||

| Total (corr.) | 48,365.2 | 35 |

| Parameters and Interactions | Material | ||

|---|---|---|---|

| A7075 | A7075-Sc | A7075-Li-Sc | |

| Feed rate: f | 1 | 1 | 1 |

| Cutting speed: V | 3 | 4 | 3 |

| Hardness: h | 5 | 3 | 2 |

| Cooling mode: c | 2 | 2 | 4 |

| Interaction: speed × cooling mode: V × c | 4 | 8 * | 9 * |

| Interaction: speed × hardness: V × h | 9 * | 7 | 8 |

| Interaction: feed rate × speed: f × V | 6 | 9 * | 5 |

| Interaction: feed rate × cooling mode: f × c | 7 | 10 * | 10 * |

| Interaction: hardness × cooling mode: h × c | 8 * | 6 | 7 |

| Interaction: feed rate × hardness: f × h | 10 * | 5 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahmasbi, A.; Moungomo, J.B.M.; Samuel, A.M.; Zedan, Y.; Songmene, V.; Samuel, F.H. Role of Li and Sc Additions and Machining Conditions on Cutting Forces on Milling Behavior of A7075-Based Alloys. J. Manuf. Mater. Process. 2024, 8, 83. https://doi.org/10.3390/jmmp8020083

Tahmasbi A, Moungomo JBM, Samuel AM, Zedan Y, Songmene V, Samuel FH. Role of Li and Sc Additions and Machining Conditions on Cutting Forces on Milling Behavior of A7075-Based Alloys. Journal of Manufacturing and Materials Processing. 2024; 8(2):83. https://doi.org/10.3390/jmmp8020083

Chicago/Turabian StyleTahmasbi, Ali, Jean Brice Mandatsy Moungomo, Agnes M. Samuel, Yasser Zedan, Victor Songmene, and Fawzy H. Samuel. 2024. "Role of Li and Sc Additions and Machining Conditions on Cutting Forces on Milling Behavior of A7075-Based Alloys" Journal of Manufacturing and Materials Processing 8, no. 2: 83. https://doi.org/10.3390/jmmp8020083

APA StyleTahmasbi, A., Moungomo, J. B. M., Samuel, A. M., Zedan, Y., Songmene, V., & Samuel, F. H. (2024). Role of Li and Sc Additions and Machining Conditions on Cutting Forces on Milling Behavior of A7075-Based Alloys. Journal of Manufacturing and Materials Processing, 8(2), 83. https://doi.org/10.3390/jmmp8020083