The Impact of PP-g-MAH on Mechanical Properties of Injection Molding of Long Glass Fiber/Polypropylene Pellets from Thermoplastic Pultrusion Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Characterization and Measurement

2.3.1. Mechanical Properties

2.3.2. Fiber Length Measurement

2.3.3. FTIR Spectroscopy

2.3.4. Morphology

3. Results

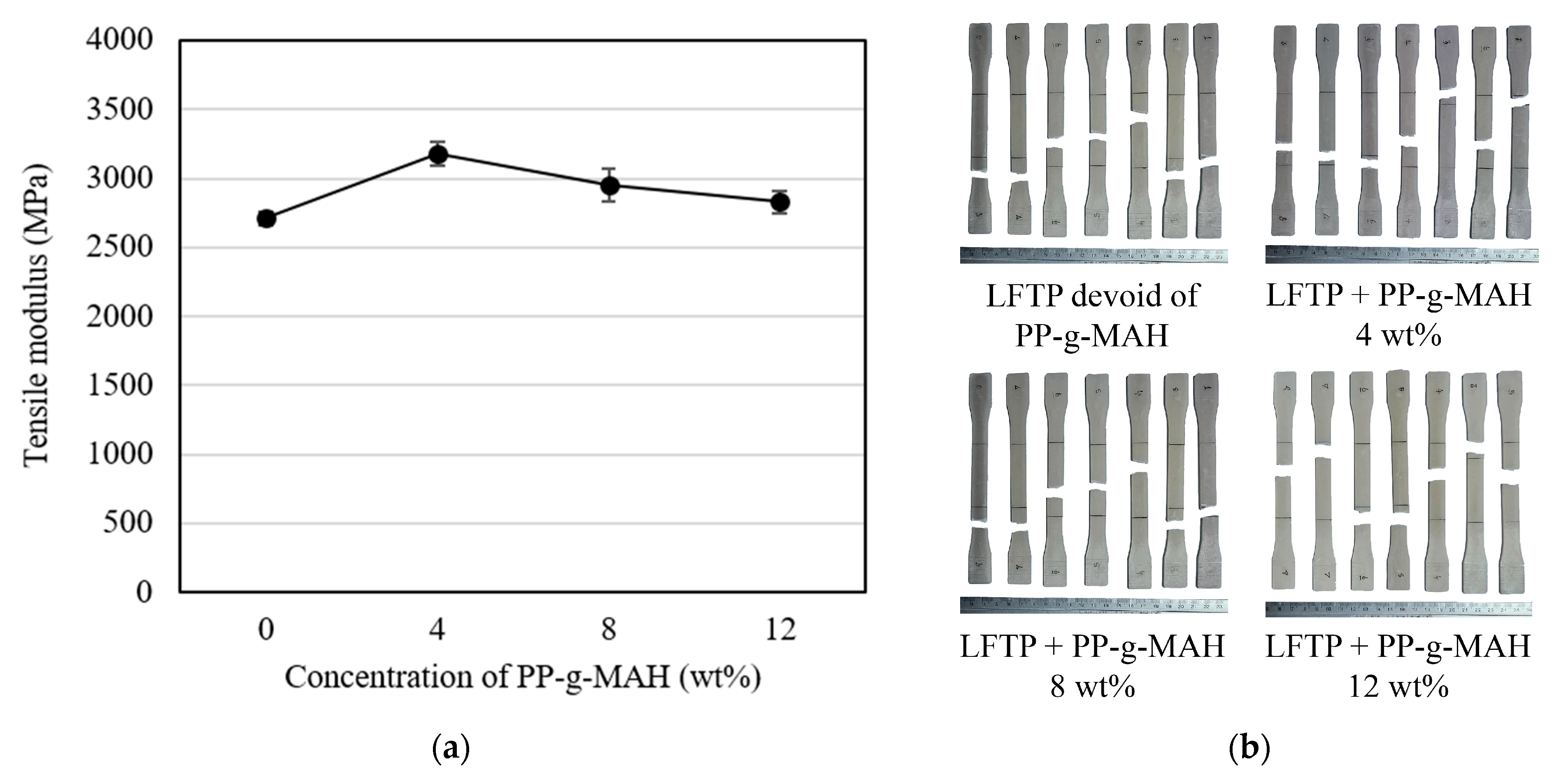

3.1. The Influence of the Coupling Agent on the Mechanical Properties of the LFTPc

3.2. Fiber Length of LFTPc

3.3. The Influence of the Coupling Agent on the Morphology of the LFTPc

3.4. FTIR Characterization

3.5. A Comparison of Properties between LFTPc and Commercial LFT

4. Conclusions

- Significant improvements were observed in the tensile modulus, flexural modulus, and impact strength of the LFTPc when an amount of 4 wt% PP-g-MAH was incorporated. Nevertheless, with the PP-g-MAH concentration exceeding 4 wt%, a decline in these properties was observed.

- The amount of PP-g-MAH added to LFTPc resulted in increases in both tensile and flexural strength. The enhanced interfacial bonding between GF and PP, along with the reduction in fiber pull-out, is the reason for this improvement. Therefore, the optimal concentration of PP-g-MAH for the LFTPc was found to be 4 wt%. This choice resulted in mechanical properties nearly equivalent to those of commercial products.

- The fiber length results indicate long fiber reinforcement, as there is a significant amount of fiber in the range of 3 to 6 mm of fiber length.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ning, H.; Lu, N.; Hassen, A.A.; Chawla, K.; Selim, M.; Pillay, S. A review of Long fibre-reinforced thermoplastic or long fibre thermoplastic (LFT) composites. Int. Mater. Rev. 2019, 65, 164–188. [Google Scholar] [CrossRef]

- Duncan, R.K.; Chen, X.G.; Bult, J.B.; Brinson, L.C.; Schadler, L.S. Measurement of the critical aspect ratio and interfacial shear strength in MWNT/polymer composites. Compos. Sci. Technol. 2010, 70, 599–605. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Application of micromechanical models to tensile properties of wood–plastic composites. Wood Sci. Technol. 2011, 45, 521–532. [Google Scholar] [CrossRef]

- Kim, S.-E.; Ahn, J.-G.; Ahn, S.; Park, D.-H.; Choi, D.-H.; Lee, J.-C.; Yang, H.-I.; Kim, K.-Y. Development of PA6/GF Long-Fiber-Reinforced Thermoplastic Composites Using Pultrusion and Direct Extrusion Manufacturing Processes. Appl. Sci. 2022, 12, 4838. [Google Scholar] [CrossRef]

- Alwekar, S.; Ogle, R.; Kim, S.; Vaidya, U. Manufacturing and characterization of continuous fiber-reinforced thermoplastic tape overmolded long fiber thermoplastic. Compos. Part B Eng. 2021, 207, 108597. [Google Scholar] [CrossRef]

- Markarian, J. Long fibre reinforced thermoplastics continue growth in automotive. Plast. Addit. Compd. 2007, 9, 20–24. [Google Scholar] [CrossRef]

- Balaji Thattaiparthasarathy, K.; Pillay, S.; Ning, H.; Vaidya, U.K. Process simulation, design and manufacturing of a long fiber thermoplastic composite for mass transit application. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1512–1521. [Google Scholar] [CrossRef]

- Xie, T.; Yang, G. Interface and mechanical properties of poly(methyl methacrylate)-fiber composites. J. Appl. Polym. Sci. 2004, 93, 2478–2483. [Google Scholar] [CrossRef]

- Krause, W.; Henning, F.; Tröster, S.; Geiger, O.; Eyerer, P. LFT-D—A Process Technology for Large Scale Production of Fiber Reinforced Thermoplastic Components. J. Thermoplast. Compos. Mater. 2003, 16, 289–302. [Google Scholar] [CrossRef]

- Sheikh, M.R.; Hassan, A.; Yahya, R.; Mohd Isa, M.R.; Hussin, A.; Hornsby, P.R. Interfacial shear strength and tensile properties of injection-molded, short- and long-glass fiber-reinforced polyamide 6,6 composites. J. Reinf. Plast. Compos. 2011, 30, 1233–1242. [Google Scholar] [CrossRef]

- Inoue, A.; Morita, K.; Tanaka, T.; Arao, Y.; Sawada, Y. Effect of screw design on fiber breakage and dispersion in injection-molded long glass-fiber-reinforced polypropylene. J. Compos. Mater. 2015, 49, 75–84. [Google Scholar] [CrossRef]

- Kunc, V.; Frame, B.; Nguyen, B.; Tucker, C.; Velez-Garcia, G. Fiber length distribution measurement for long glass and carbon fiber reinforced injection molded thermoplastics. In Proceedings of the Automotive Composite Conference & Exhibition, Society of Plastics Engineers, Troy, MI, USA, 11–13 September 2007. [Google Scholar]

- Van de Velde, K.; Kiekens, P. Thermoplastic pultrusion of natural fibre reinforced composites. Compos. Struct. 2001, 54, 355–360. [Google Scholar] [CrossRef]

- Yang, C.; Wang, G.; Zhao, J.; Zhao, G.; Zhang, A. Lightweight and strong glass fiber reinforced polypropylene composite foams achieved by mold-opening microcellular injection molding. J. Mater. Res. Technol. 2021, 14, 2920–2931. [Google Scholar] [CrossRef]

- Junaedi, H.; Baig, M.; Dawood, A.; Albahkali, E.; Almajid, A. Modeling analysis of the tensile strength of polypropylene base Short Carbon Fiber reinforced composites. J. Mater. Res. Technol. 2021, 11, 1611–1621. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef] [PubMed]

- El-Ghaoui, K.; Chatelain, J.-F.; Ouellet-Plamondon, C. Effect of Graphene on Machinability of Glass Fiber Reinforced Polymer (GFRP). J. Manuf. Mater. Process. 2019, 3, 78. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, X.; Wu, D. Preparation, microstructures, and properties of long-glass-fiber-reinforced thermoplastic composites based on polycarbonate/poly(butylene terephthalate) alloys. J. Reinf. Plast. Compos. 2015, 34, 1804–1820. [Google Scholar] [CrossRef]

- Hwang, D.; Cho, D. Fiber aspect ratio effect on mechanical and thermal properties of carbon fiber/ABS composites via extrusion and long fiber thermoplastic processes. J. Ind. Eng. Chem. 2019, 80, 335–344. [Google Scholar] [CrossRef]

- Tipboonsri, P.; Memon, A. Optimizing thermoplastic pultrusion parameters for quality long fiber thermoplastic pellets in glass fiber-reinforced polypropylene. Polym. Polym. Compos. 2023, 31, 1–11. [Google Scholar] [CrossRef]

- Tipboonsri, P.; Wattanahitsiri, V.; Memon, A. Long fiber thermoplastic pellets of glass fiber/polypropylene from pultrusion process. J. Phys. Conf. Ser. 2021, 1719, 012066. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef]

- Tipboonsri, P.; Pramoonmak, S.; Uawongsuwan, P.; Memon, A. Optimization of Thermoplastic Pultrusion Parameters of Jute and Glass Fiber-Reinforced Polypropylene Composite. Polymers 2024, 16, 83. [Google Scholar] [CrossRef]

- Memon, A.; Nakai, A. Mechanical Properties of Jute Spun Yarn/PLA Tubular Braided Composite by Pultrusion Molding. Energy Procedia 2013, 34, 818–829. [Google Scholar] [CrossRef]

- Nordin, N.A.; Yussof, F.M.; Kasolang, S.; Salleh, Z.; Ahmad, M.A. Wear Rate of Natural Fibre: Long Kenaf Composite. Procedia Eng. 2013, 68, 145–151. [Google Scholar] [CrossRef]

- Yadav, R.; Tirumali, M.; Wang, X.; Naebe, M.; Kandasubramanian, B. Polymer composite for antistatic application in aerospace. Def. Technol. 2020, 16, 107–118. [Google Scholar] [CrossRef]

- Lin, J.-H.; Huang, C.-L.; Liu, C.-F.; Chen, C.-K.; Lin, Z.-I.; Lou, c.-w. Polypropylene/Short Glass Fibers Composites: Effects of Coupling Agents on Mechanical Properties, Thermal Behaviors, and Morphology. Materials 2015, 8, 8279–8291. [Google Scholar] [CrossRef]

- Wenzhong, N. The effect of coupling agents on the mechanical properties of carbon fiber-reinforced polyimide composites. J. Thermoplast. Compos. Mater. 2015, 28, 1572–1582. [Google Scholar] [CrossRef]

- Denault, J.; Vu-Khanh, T. Fiber/Matrix Interaction in Carbon/PEEK Composites. J. Thermoplast. Compos. Mater. 1993, 6, 190–204. [Google Scholar] [CrossRef]

- Chen, M.; Wan, C.; Zhang, Y.; Zhang, Y. Fibre Orientation and Mechanical Properties of Short Glass Fibre Reinforced PP Composites. Polym. Polym. Compos. 2005, 13, 253–262. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mohanty, S. Sisal Glass Fiber Reinforced PP Hybrid Composites: Effect of MAPP on the Dynamic Mechanical and Thermal Properties. J. Reinf. Plast. Compos. 2010, 29, 1551–1568. [Google Scholar] [CrossRef]

- Abd Rahman, N.M.M.; Hassan, A.; Yahya, R. Extrusion and injection-molding of glass fiber/MAPP/polypropylene: Effect of coupling agent on DSC, DMA, and mechanical properties. J. Reinf. Plast. Compos. 2011, 30, 215–224. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, B.-H.; Choi, S.-W.; Kim, S.; Kim, H.-J. The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1473–1482. [Google Scholar] [CrossRef]

- Gümüş, B. Effect of MA-g-PP addition on mechanical properties of polypropylene/hollow glass spheres/nanoclay composites. Polym. Bull. 2022, 80, 3405–3422. [Google Scholar] [CrossRef]

- Kim, Y.; Park, O.O. Effect of Fiber Length on Mechanical Properties of Injection Molded Long-Fiber-Reinforced Thermoplastics. Macromol. Res. 2020, 28, 433–444. [Google Scholar] [CrossRef]

- Fu, X.; He, B.; Chen, X. Effects of Compatibilizers on Mechanical Properties of Long Glass Fiber-Reinforced Polypropylene. J. Reinf. Plast. Compos. 2009, 29, 936–949. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D790-10; Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D256-10; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2015.

- Wong, K.H.; Syed Mohammed, D.; Pickering, S.J.; Brooks, R. Effect of coupling agents on reinforcing potential of recycled carbon fibre for polypropylene composite. Compos. Sci. Technol. 2012, 72, 835–844. [Google Scholar] [CrossRef]

- Tharanikkarasu, K.; Kim, B. Modification of aqueous polyurethane dispersions via tetraphenylethane iniferters. J. Appl. Polym. Sci. 1999, 73, 2993–3000. [Google Scholar] [CrossRef]

- Abbasian, M.; Ghaeminia, H.; Jaymand, M. A facile and efficient strategy for the functionalization of multiple-walled carbon nanotubes using well-defined polypropylene-grafted polystyrene. Appl. Phys. A 2018, 124, 522. [Google Scholar] [CrossRef]

- Lian, Z.; Xu, Y.; Zuo, J.; Qian, H.; Luo, Z.; Wei, W. Preparation of PP-g-(AA-MAH) Fibers Using Suspension Grafting and Melt-Blown Spinning and its Adsorption for Aniline. Polymers 2020, 12, 2157. [Google Scholar] [CrossRef]

- Burgada, F.; Fages, E.; Quiles-Carrillo, L.; Lascano, D.; Ivorra-Martinez, J.; Arrieta, M.P.; Fenollar, O. Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber. Polymers 2021, 13, 1248. [Google Scholar] [CrossRef]

- Fan, M.; Zhang, Y.; Li, X.; Zeng, B.; Chen, S.; Zhu, W.; Wang, S.; Xu, J.; Feng, N. Facile synthesis and applications of polypropylene/polydimethylsiloxane graft copolymer. Polym. Adv. Technol. 2019, 30, 1226–1233. [Google Scholar] [CrossRef]

- Martinez, G.; Sanchez, S.; Ramos, L.; Perez, O.; Ramírez, E.; Benavides-Cantú, R.; Avila-Orta, C.; Cruz, V.; Mata, J.; Lozano-Ramirez, T.; et al. Aniline-Modified Polypropylene as a Compatibilizer in Polypropylene Carbon Nanotube Composites. Polym.-Plast. Technol. Eng. 2017, 57, 1360–1366. [Google Scholar] [CrossRef]

- Tselios, C.; Bikiaris, D.; Savidis, P.; Panayiotou, C.; Larena, A. Glass-fiber reinforcement of in situ compatibilized polypropylene/polyethylene blends. J. Mater. Sci. 1999, 34, 385–394. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tipboonsri, P.; Memon, A. The Impact of PP-g-MAH on Mechanical Properties of Injection Molding of Long Glass Fiber/Polypropylene Pellets from Thermoplastic Pultrusion Process. J. Manuf. Mater. Process. 2024, 8, 53. https://doi.org/10.3390/jmmp8020053

Tipboonsri P, Memon A. The Impact of PP-g-MAH on Mechanical Properties of Injection Molding of Long Glass Fiber/Polypropylene Pellets from Thermoplastic Pultrusion Process. Journal of Manufacturing and Materials Processing. 2024; 8(2):53. https://doi.org/10.3390/jmmp8020053

Chicago/Turabian StyleTipboonsri, Ponlapath, and Anin Memon. 2024. "The Impact of PP-g-MAH on Mechanical Properties of Injection Molding of Long Glass Fiber/Polypropylene Pellets from Thermoplastic Pultrusion Process" Journal of Manufacturing and Materials Processing 8, no. 2: 53. https://doi.org/10.3390/jmmp8020053

APA StyleTipboonsri, P., & Memon, A. (2024). The Impact of PP-g-MAH on Mechanical Properties of Injection Molding of Long Glass Fiber/Polypropylene Pellets from Thermoplastic Pultrusion Process. Journal of Manufacturing and Materials Processing, 8(2), 53. https://doi.org/10.3390/jmmp8020053